Acylation cellophane and producing method thereof

A cellulose acylate and film technology, applied in the field of cellulose acylate film and its preparation, can solve the problems of low film quality and achieve the effect of excellent adhesion performance and optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

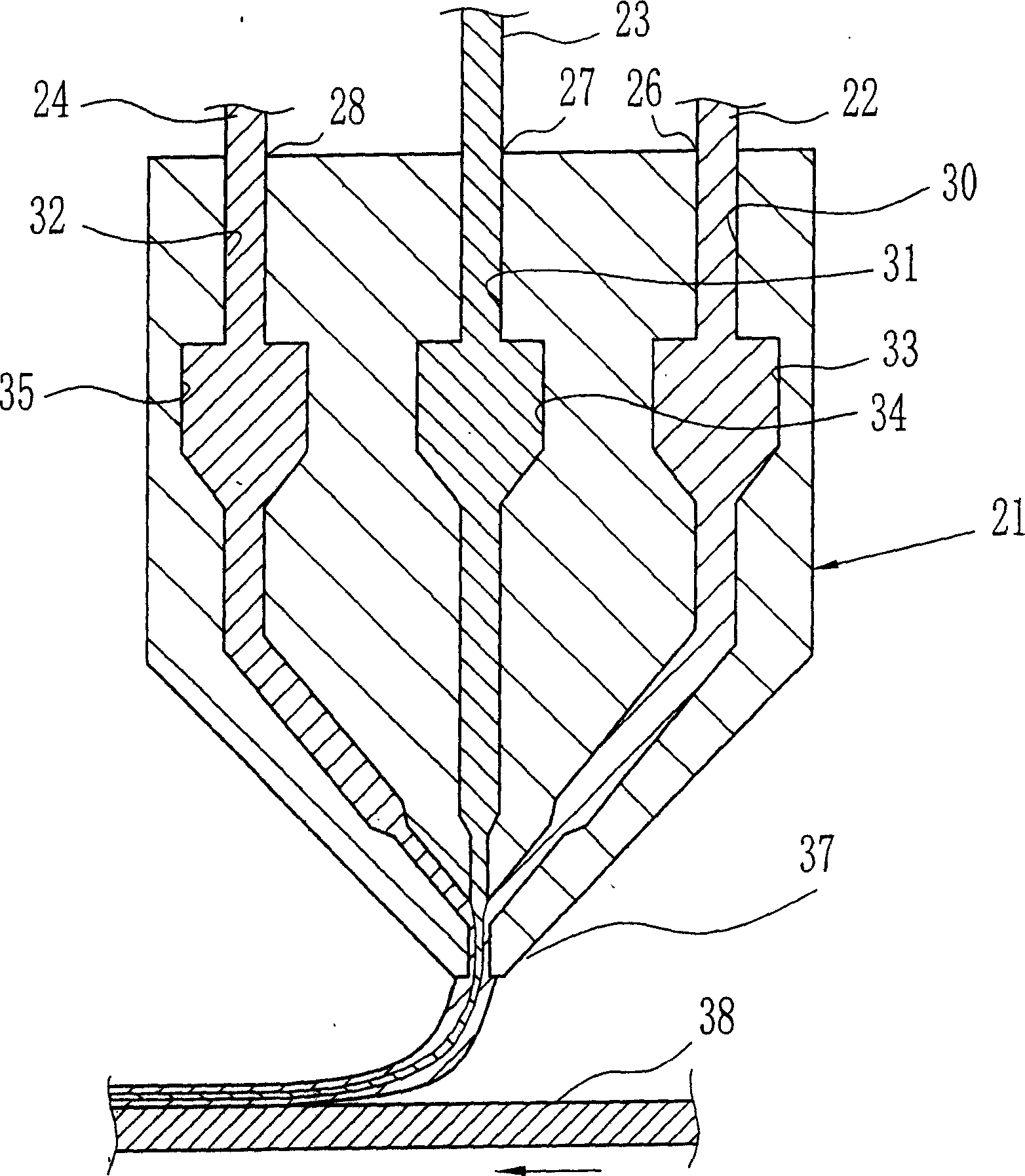

[0078] In Example 1, a cellulose acetate film 10 having a three-layer structure was prepared, and the adhesion property with polyvinyl alcohol was evaluated. The thin film 10 was formed in the feed sleeve type co-casting method so that the thickness of the first outer layer 11 was 18 μm, the thickness of the inner layer 12 was 4 μm, the thickness of the second outer layer 13 was 18 μm, and the total thickness T10 was 40 μm . A tape 38 is used as a substrate. The cellulose acetate of the outer layers 11 , 13 is made of wood pulp and has an average degree of acetylation of 2.8, and the cellulose acetate of the inner layer 12 is made of wood pulp and has an average degree of acetylation of 1.8. The outer and inner layers 11-13 are formed from paints 22-24. Mixed solvents for Coatings 22-24 were prepared by mixing dichloromethane, methanol, and n-butanol at a volume ratio of 85:12:3. The solid substances (including additives) added to the mixed solvent and their contents are sh...

Embodiment 2

[0093] In Example 2, the preparation Figure 4 A cellulose acetate film 50 having a 5-layer structure was used, and the adhesion performance with polyvinyl alcohol was evaluated. The thickness of the outer layers 51 , 55 of the film 50 is 3 μm, the thickness of the first and third inner layers 52 , 54 is 15 μm, and the thickness of the second inner layer 53 is 4 μm. The cellulose acetate of the first-third inner layers 52-54 and the second outer layer 55 are made of wood pulp, and only the cellulose acetate of the first outer layer 51 is made of cotton linter. The degree of acetylation of the outer layers 51, 55 was 1.8, the degree of acetylation of the first and third inner layers 52, 54 was 2.8, and the degree of acetylation of the second inner layer 53 was 2.75. The mixing ratios of solid matter and additives added to the paint for each layer were as follows. The cellulose acylate film was adhered to polyvinyl alcohol under the condition that the surface of the first oute...

Embodiment 3

[0129] In Example 3, a polyvinyl alcohol film (manufactured by Kuraray Co. Ltd) having a thickness of 75 μm was dipped in an aqueous solution at 25° C. with an iodine content of 0.3 g / liter and a potassium iodide content of 18.0 g / liter. Then, the film was stretched in an aqueous solution at 50°C in which the content of boric acid was 80 g / liter and the content of potassium iodide was 30 g / liter. Therefore, the film becomes 5 times larger and becomes a polarizing film. The cellulose acetate film obtained in Example 2 was adhered to the polarizing film with an adhesive, and then, they were dried for 30 minutes in a constant temperature room where the air temperature was kept at 80°C. Note that the binder is a 4% aqueous solution of polyvinyl alcohol (trade name: PVA-117H, manufactured by Kuraray Co. Ltd).

[0130] According to the obtained polarizing filter, use a spectrophotometer to obtain the parallel light transmittance Yp and cross light transmittance Yc in the visible ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com