Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

109 results about "Cellulose acetate film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellulose acetate film, or safety film, is used in photography as a base material for photographic emulsions. It was introduced in the early 20th century by film manufacturers and intended as a safe film base replacement for unstable and highly flammable nitrate film.

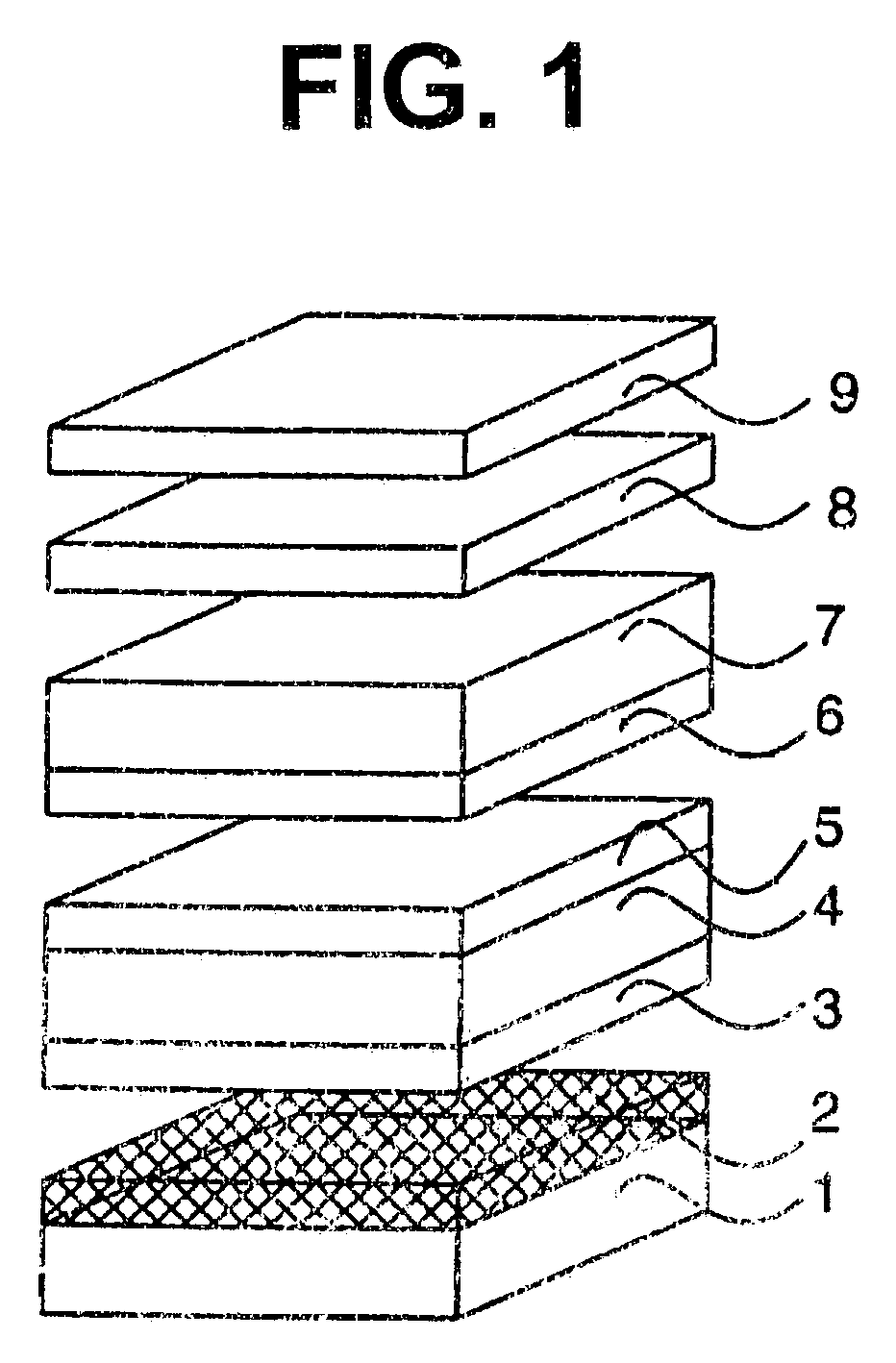

Optical compensating sheet, polarizing plate, and liquid-crystal display

InactiveUS20030218709A1Increased durabilityHigh light transmittanceLiquid crystal compositionsPolarising elementsAcetic acidLiquid-crystal display

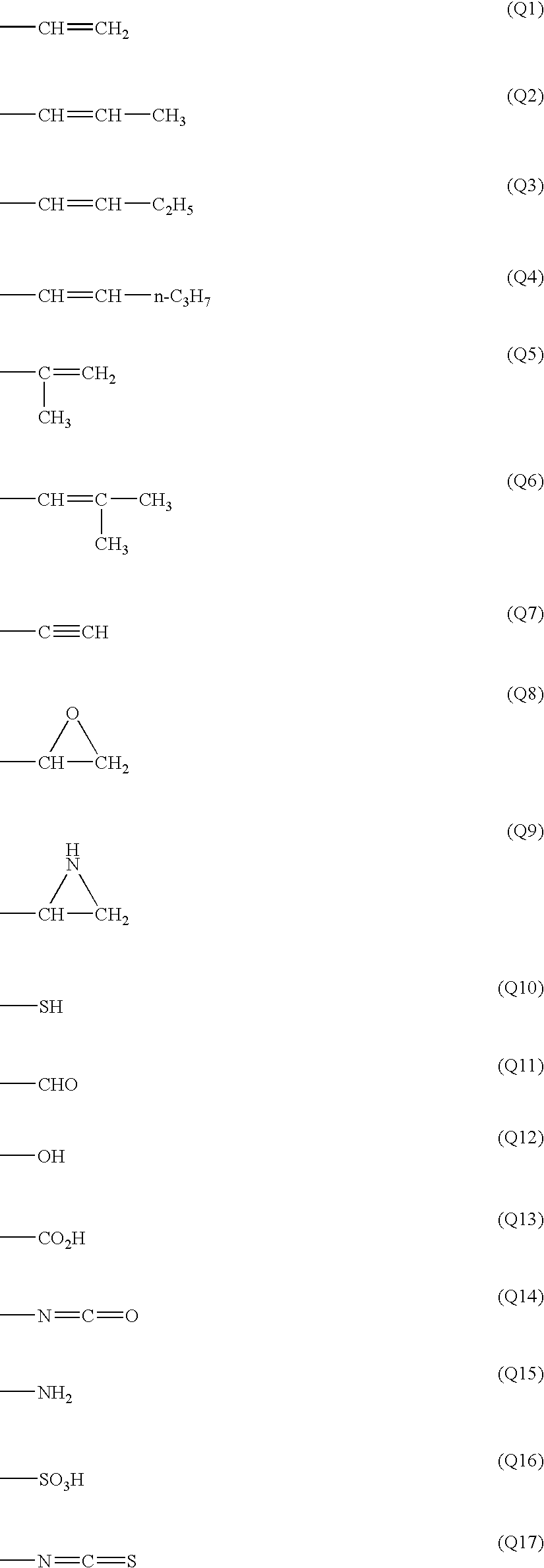

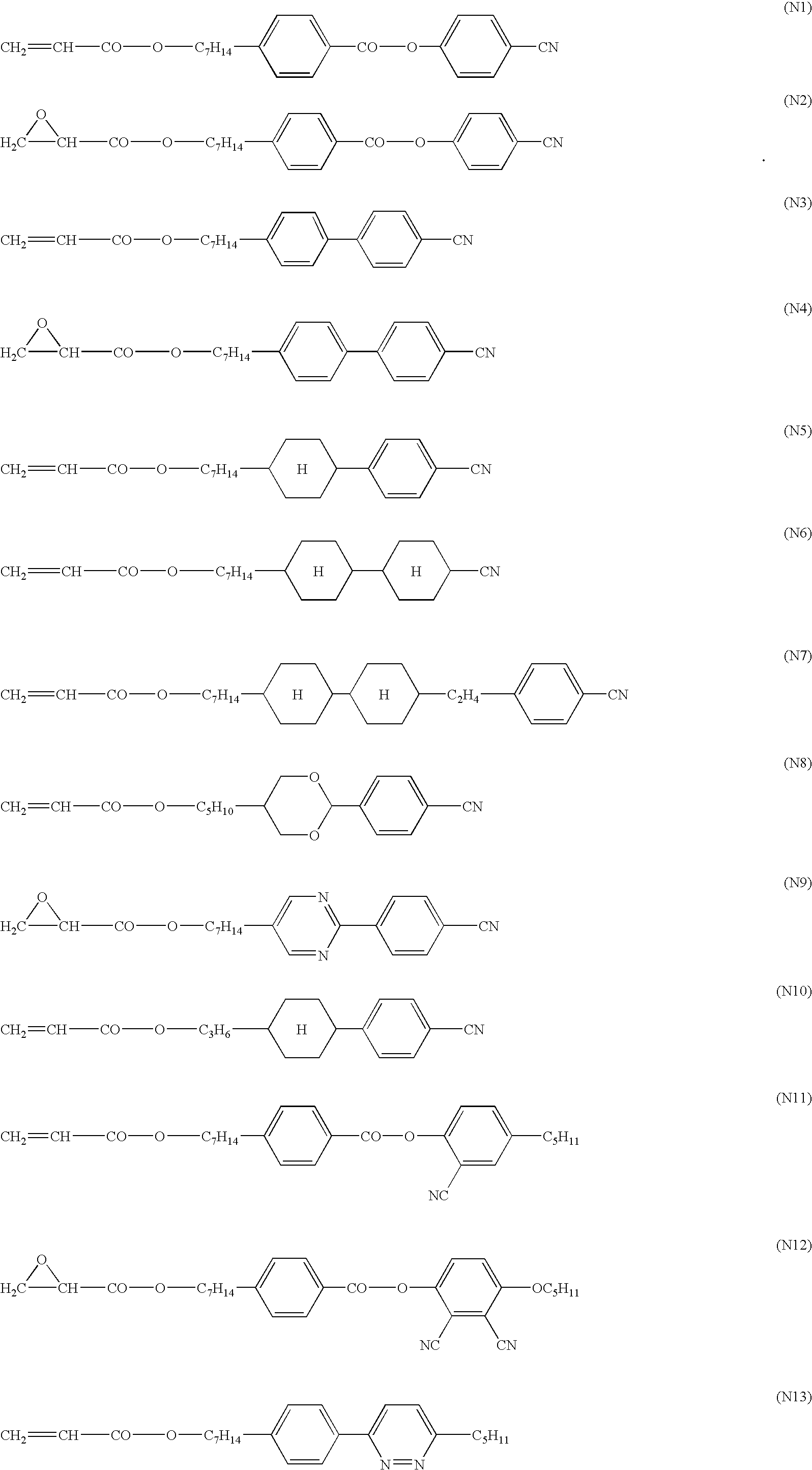

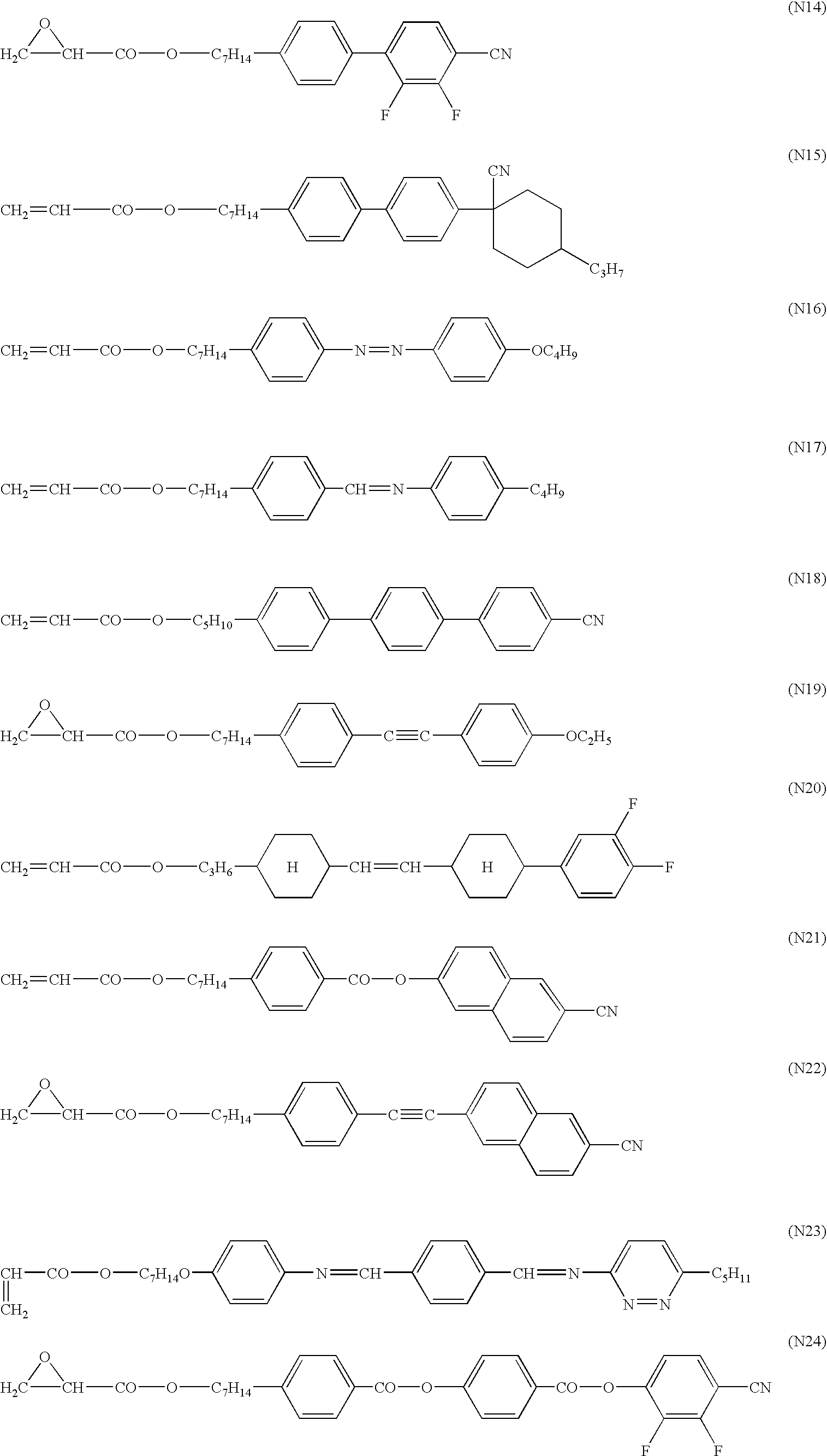

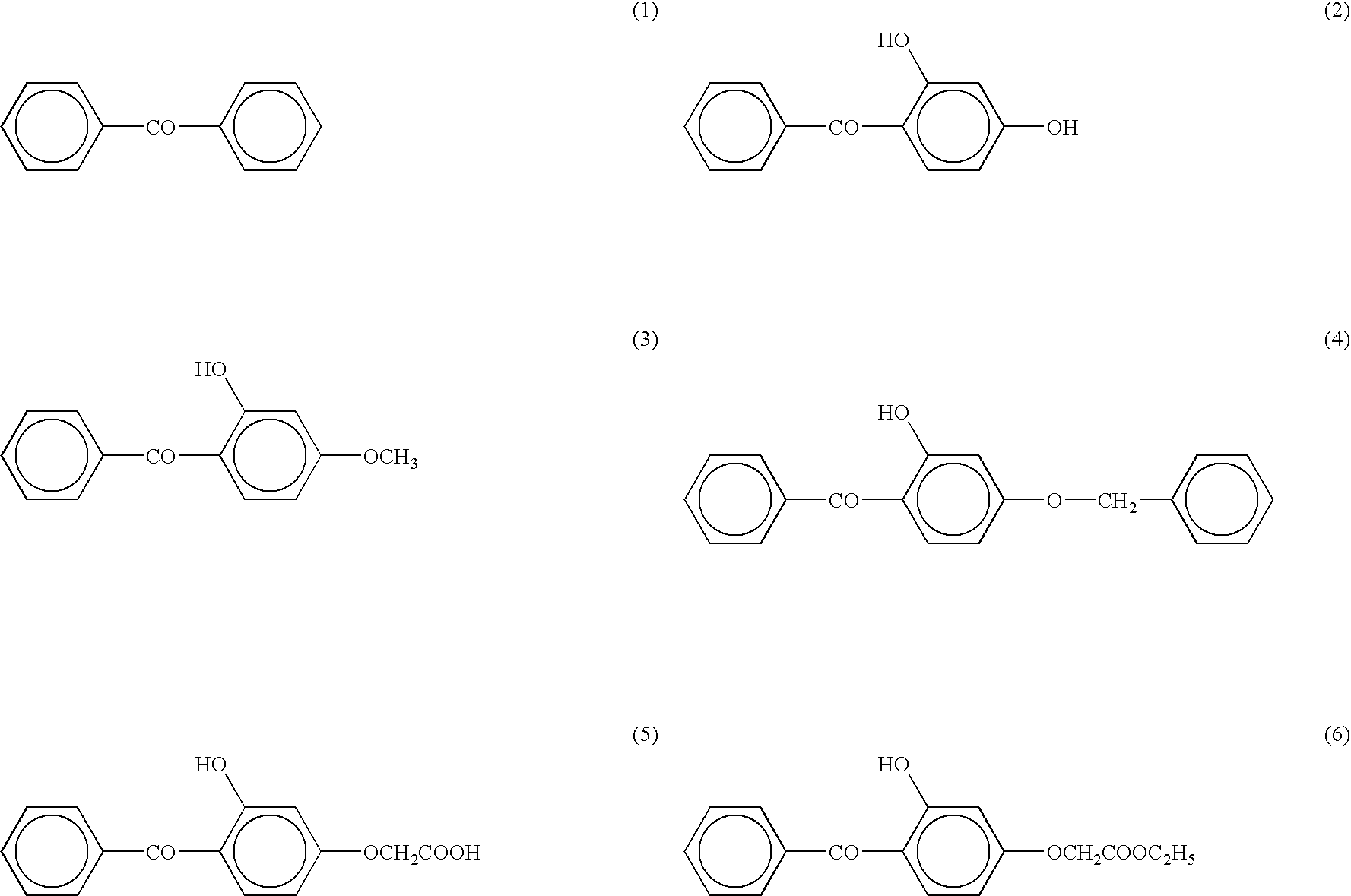

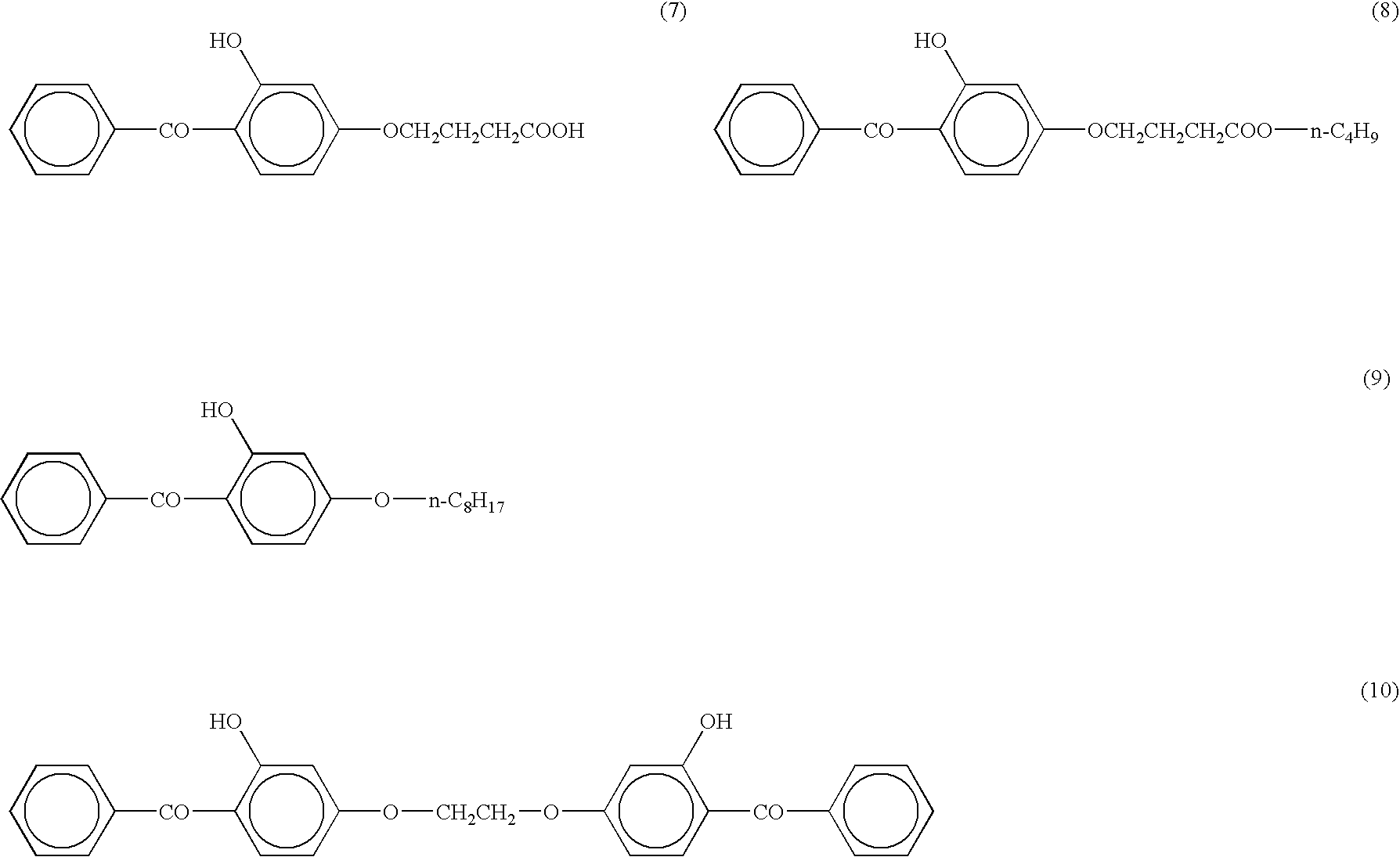

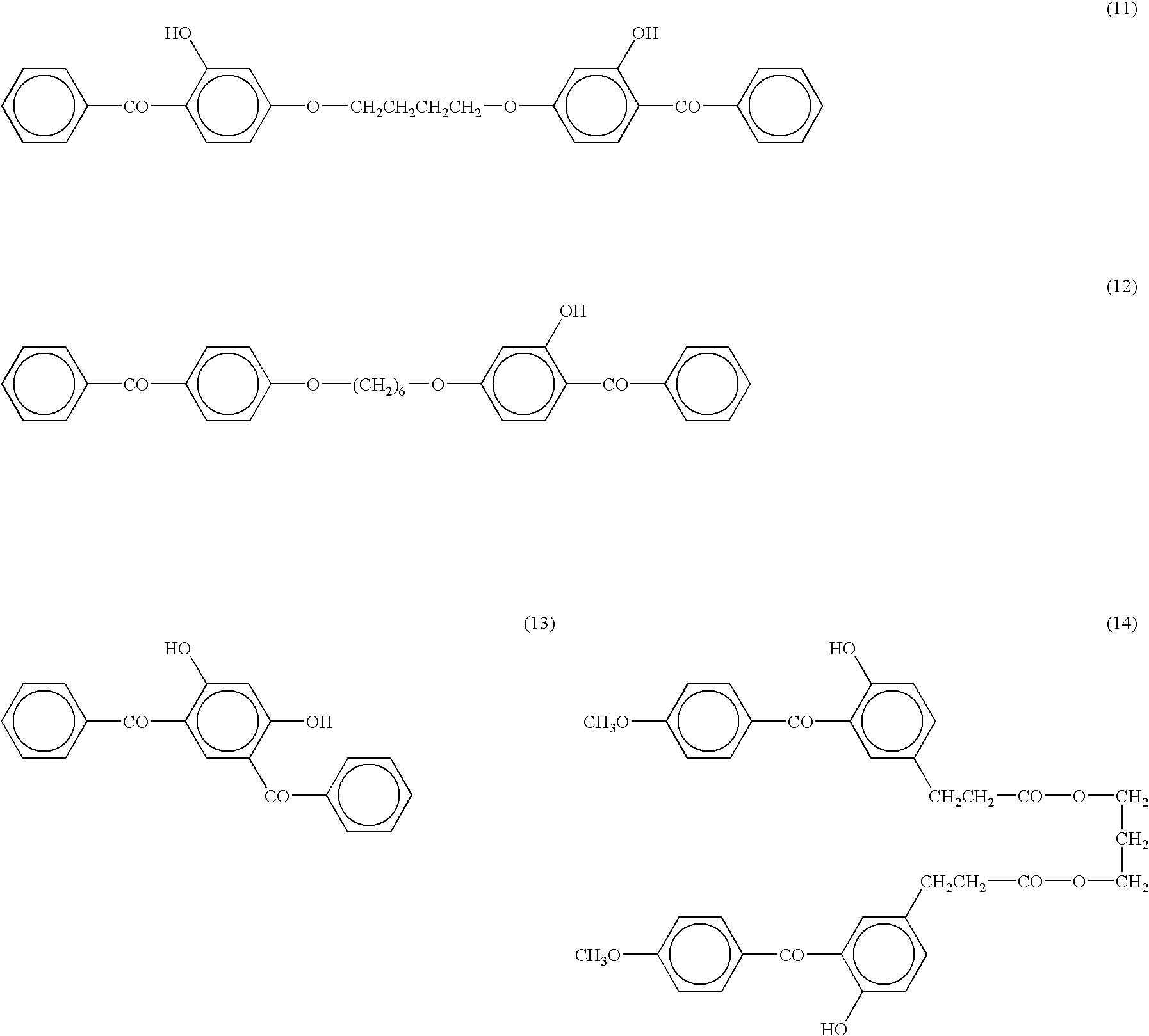

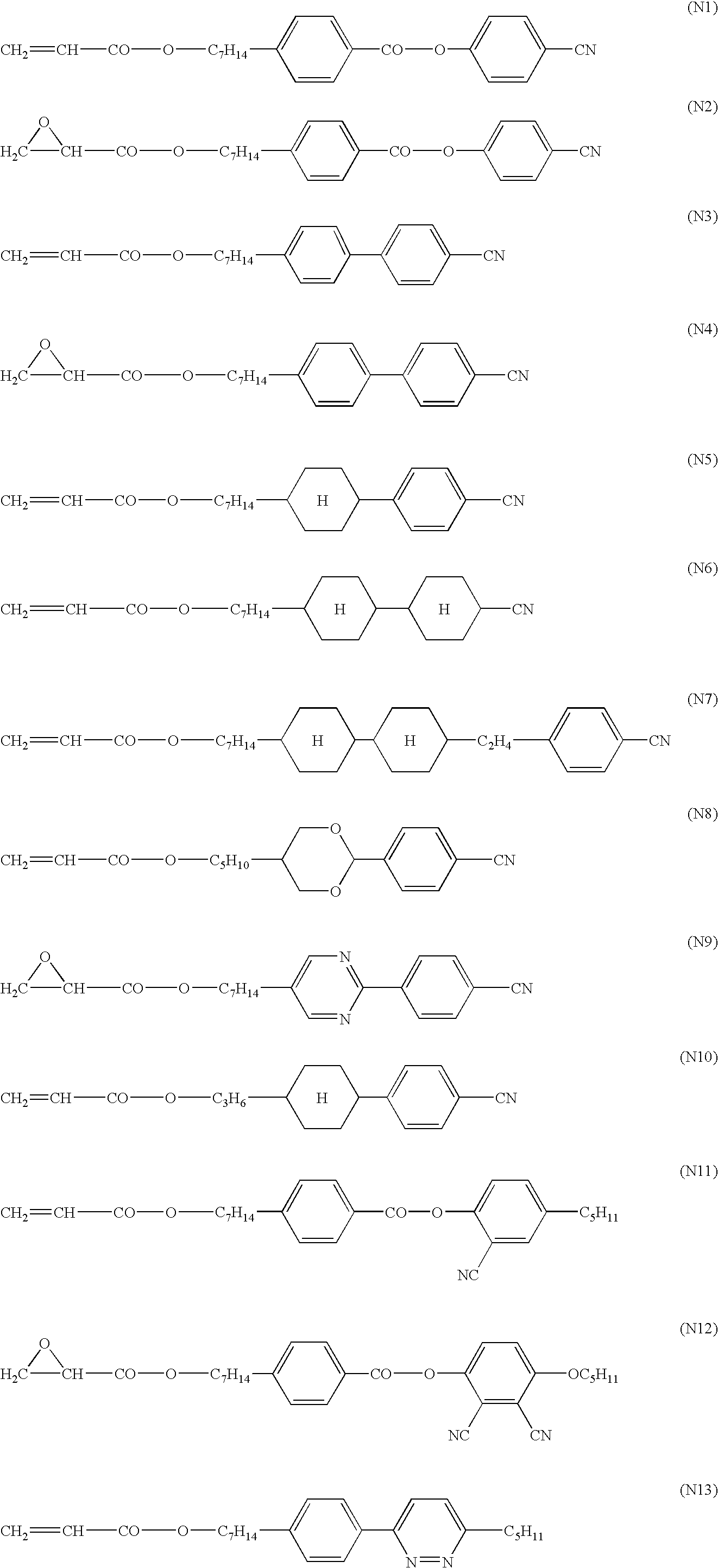

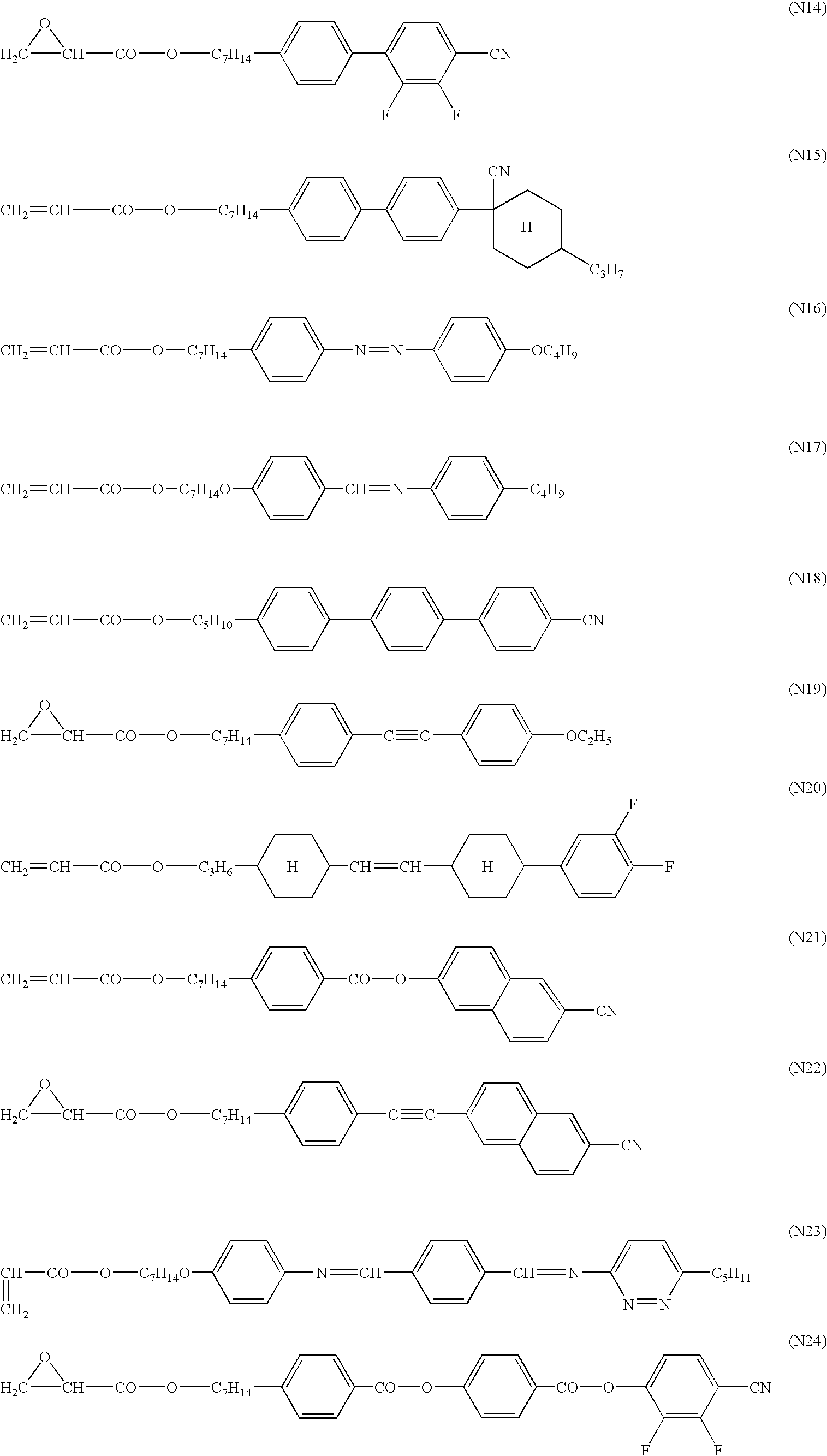

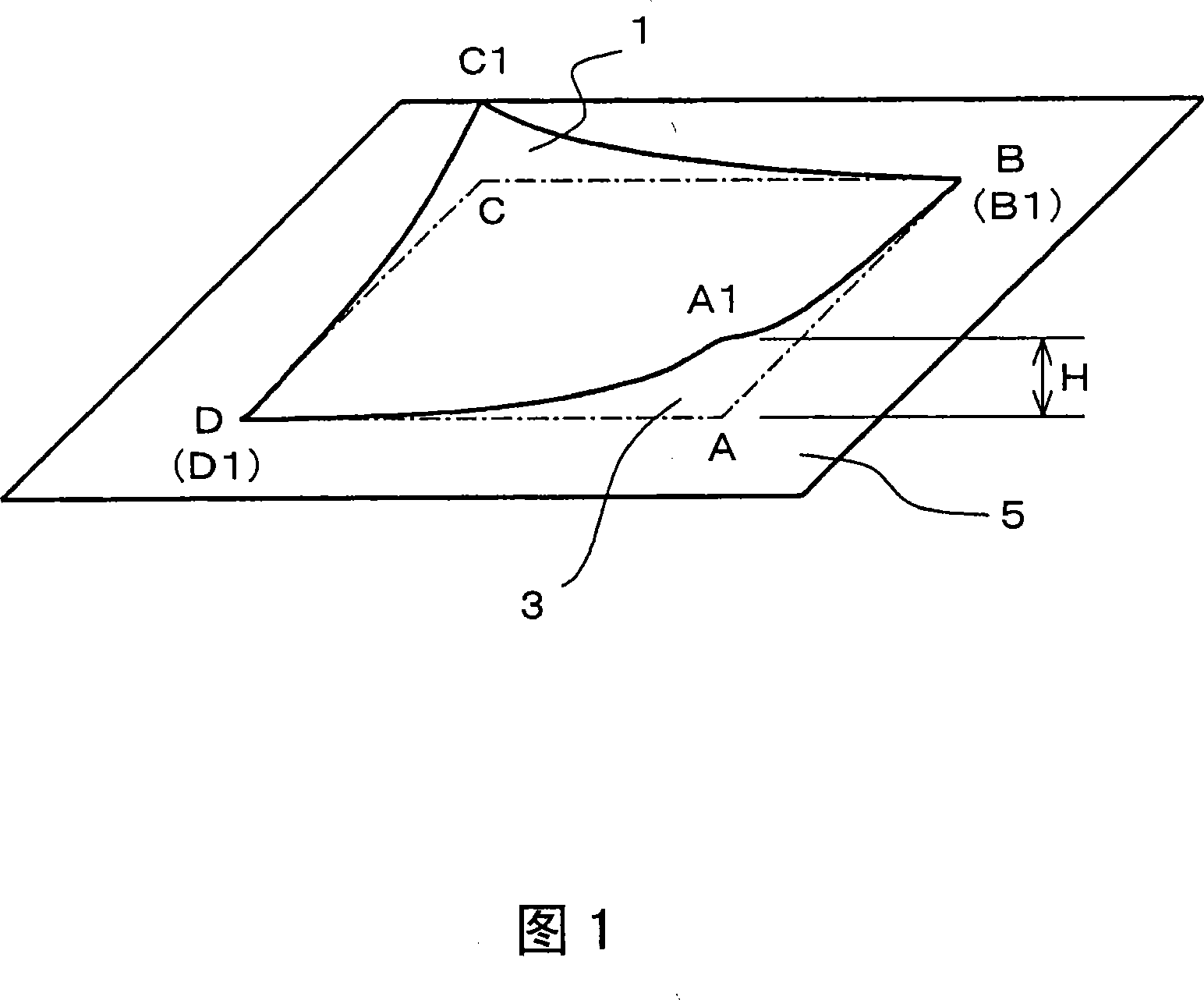

An optical compensatory sheet comprises a cellulose acetate film. The film contains 100 weight parts of cellulose acetate having an acetic acid content of 59.0 to 61.5% and 0.01 to 20 weight parts of an aromatic compound having at least two aromatic rings. The cellulose acetate film has an Re retardation value measured at 550 nm (Re550) in the range of 0 to 200 nm and an Rth retardation value measured at 550 nm (Rth550) in the range of 70 to 400 nm. The cellulose acetate film further has a thickness in the range of 10 to 70 mum. The optical compensatory sheet is used in a liquid crystal display.

Owner:FUJIFILM CORP

Ultraviolet light filter element

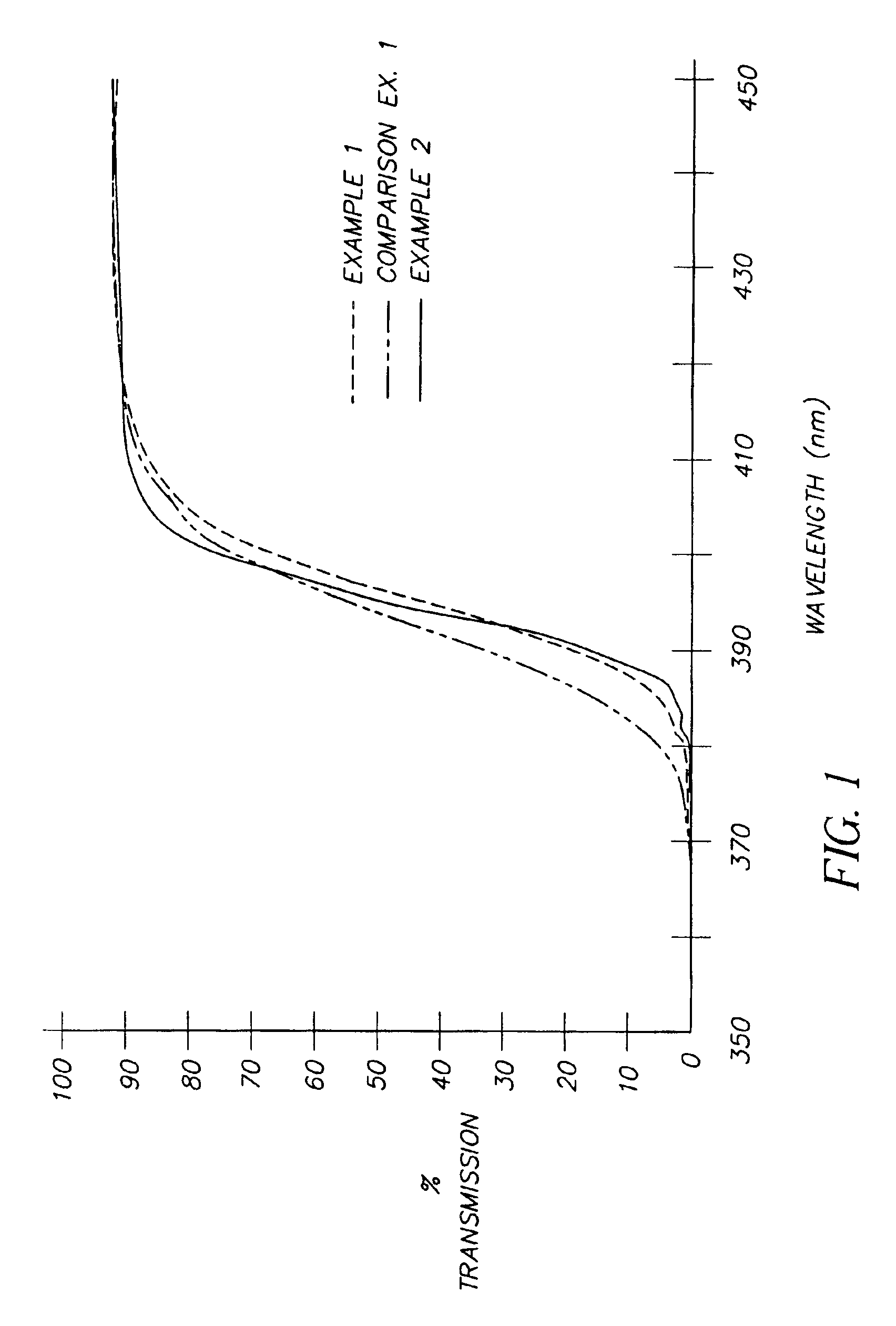

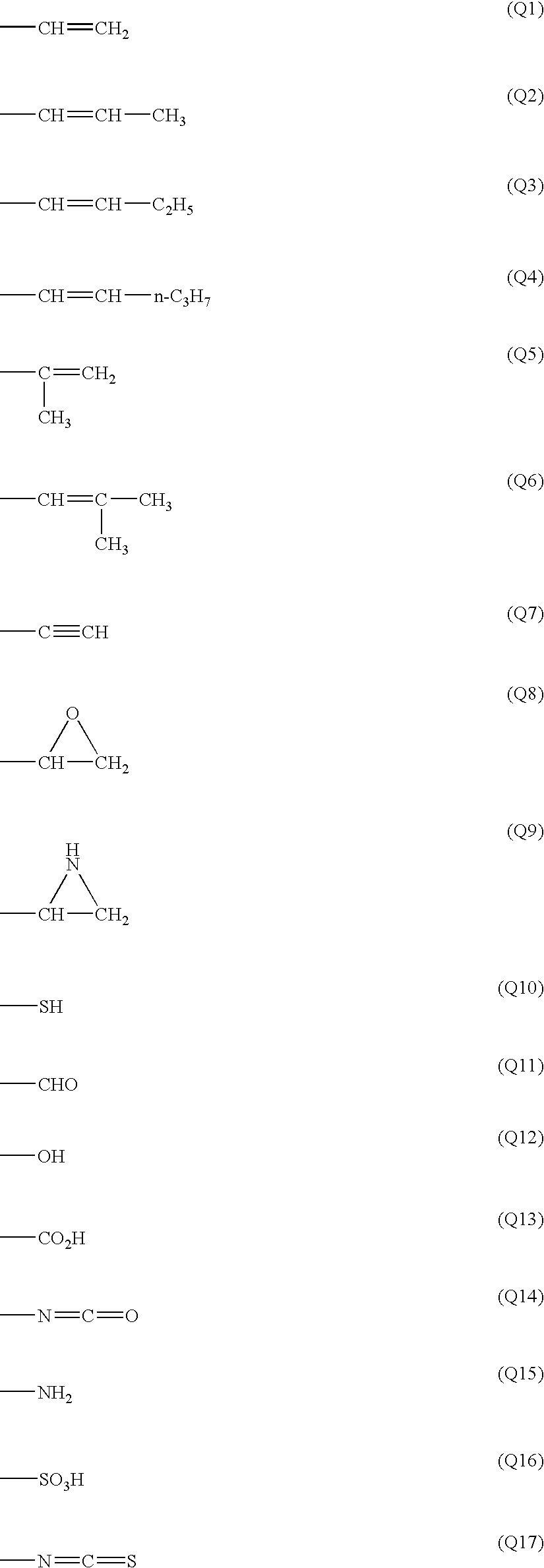

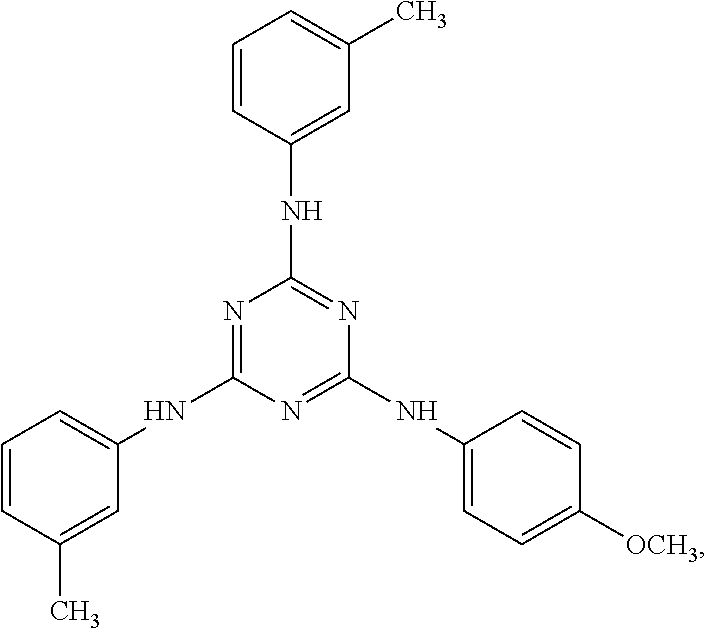

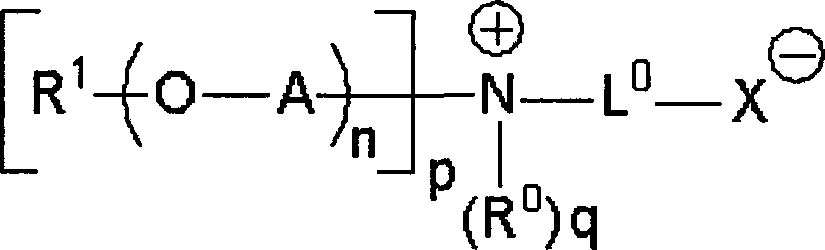

InactiveUS6872766B2Increased durabilityAvoid lightLiquid crystal compositionsOther chemical processesThio-Display device

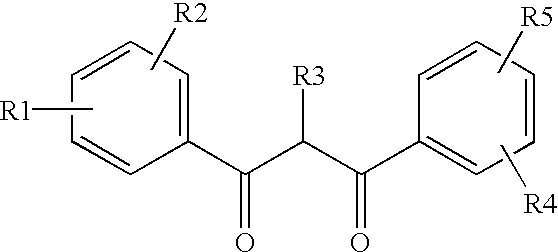

Ultraviolet light absorbing polymer film, coating, or molded article UV filter elements are described which comprise a polymer phase having molecularly dispersed therein a) a first ultraviolet absorbing dibenzoylmethane compound of formula (I) where R1 through R5 are each independently hydrogen, halogen, nitro, or hydroyxl, or further substituted or unsubstituted alkyl, alkenyl, aryl, alkoxy, acyloxy, ester, carboxyl, alkyl thio, aryl thio, alkyl amine, aryl amine, alkyl nitrile, aryl nitrile, arylsulfonyl, or 5-6 member heterocylce ring groups, and b) a second ultraviolet light absorbing compound which absorbs ultraviolet light at a wavelength for which the first compound is deficient at absorbing. In particular embodiments, the second ultraviolet light absorbing compound may comprise a hydroxyphenyl-s-triazine, hydroxyphenylbenzotriazole, formamidine, benzoxazinone, or benzophenone compound. In a specific embodiment of the invention, the above UV absorbing compounds are employed in cellulose acetate film for the fabrication of a protective film for polarizers for use in display applications.

Owner:EASTMAN KODAK CO

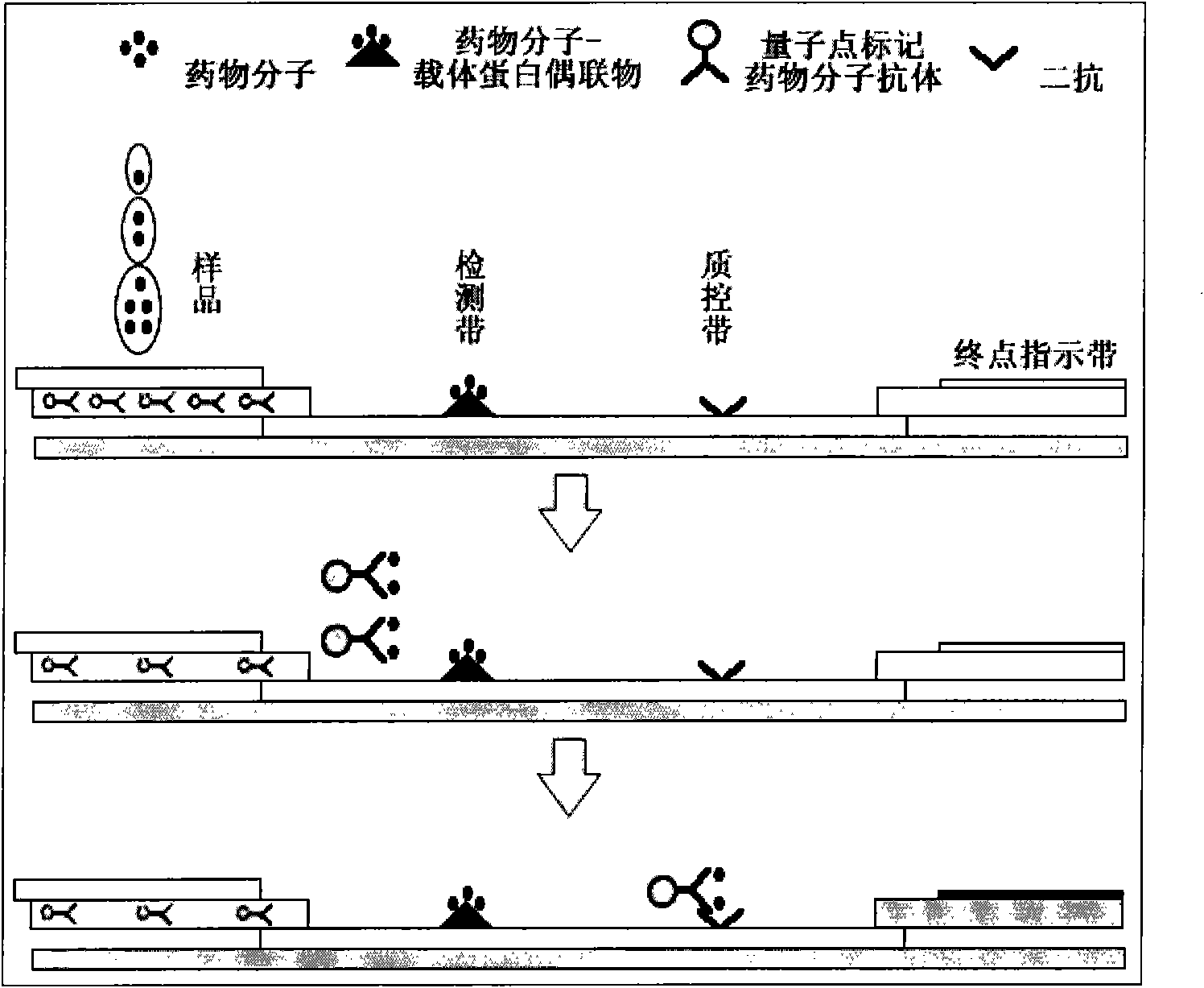

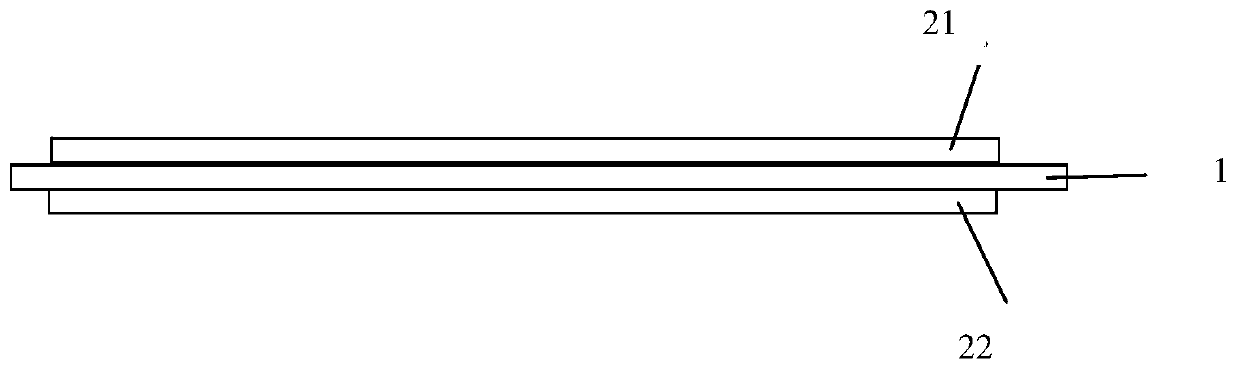

Drug residue competition-type quantum dot-labeled immunochromatography assay test-strip and observation device thereof

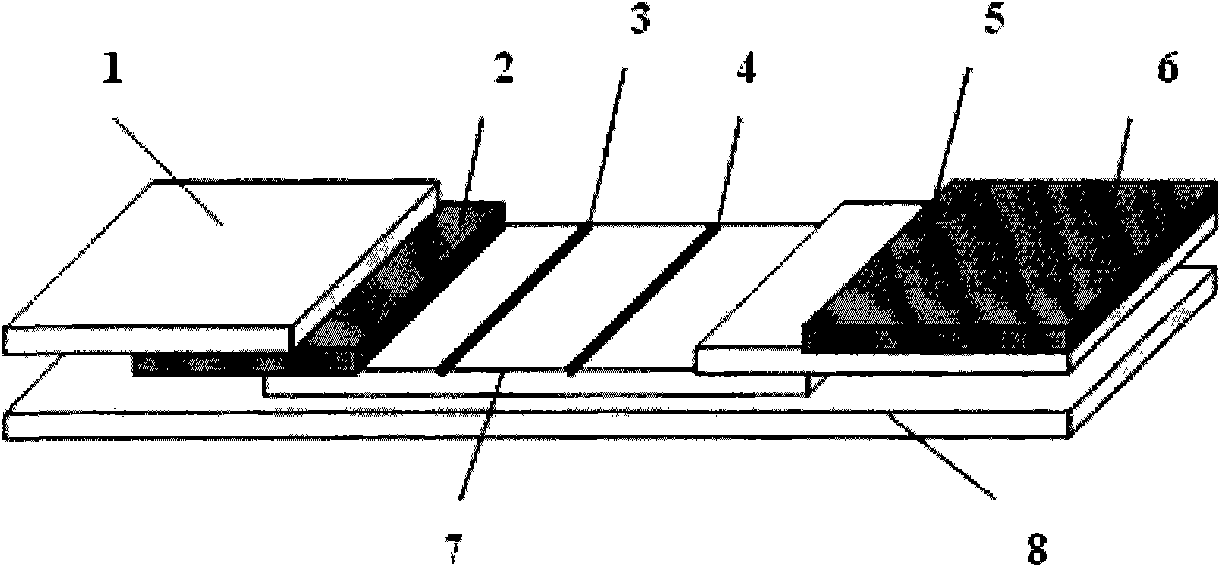

The invention provides a drug residue competition-type quantum dot-labeled immunochromatography assay test-strip / detection card and an observation device thereof, comprising the following preparation steps of coating the antibody of quantum dot-labeled drug molecule on a fiberglass film, coating the drug-molecular-carrier protein coupler and second antibody on a pyroxylin film or a cellulose acetate film respectively to form a detection belt and a quality control belt; preparing the immunochromatography assay test-strip from the fiberglass film and the pyroxylin film or the cellulose acetate film on a polyester or plastic plate, and assembling a shell. The quantum dots of the detection belt and the quality control belt on the test-strip is triggered by the ultraviolet LED source of the observation device, and the change of the fluorescent intensity of the observation belt and the quality control belt is observed, thus being capable of quantitatively analyzing the content of the drug molecule in the sample. The invention has simple operation, high sensitiveness and quick quantification, is suitable for detecting the drug residue in the food and can be widely applied to the customhouse, airport, health supervising department, household and the like.

Owner:CHINA JILIANG UNIV

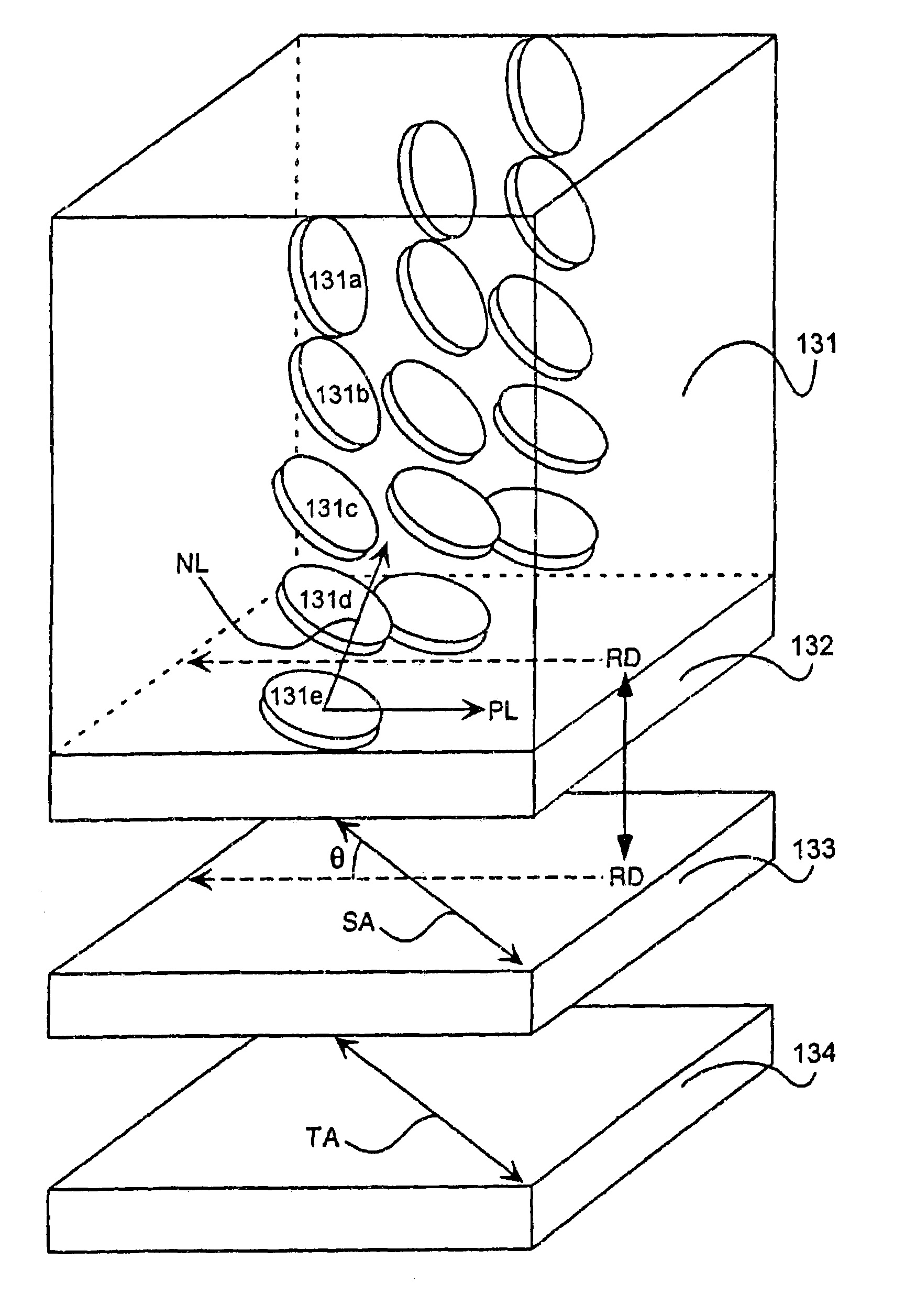

Optical compensatory sheet comprising a biaxially stretched cellulose acetate film, polarizing plate and liquid crystal display

InactiveUS7084944B2Increased durabilityHigh light transmittanceLiquid crystal compositionsPolarising elementsAcetic acidLiquid-crystal display

An optical compensatory sheet comprises a cellulose acetate film. The film contains 100 weight parts of cellulose acetate having an acetic acid content of 59.0 to 61.5% and 0.01 to 20 weight parts of an aromatic compound having at least two aromatic rings. The cellulose acetate film has an Re retardation value measured at 550 nm (Re550) in the range of 0 to 200 nm and an Rth retardation value measured at 550 nm (Rth550) in the range of 70 to 400 nm. The cellulose acetate film further has a thickness in the range of 10 to 70 μm. The optical compensatory sheet is used in a liquid crystal display.

Owner:FUJIFILM CORP

Cellulose acetate film with regulated retardation and thickness

InactiveUS20040001175A1Easily enlargedExcellent in preventing framewise light leakageLiquid crystal compositionsPolarising elementsAcetic acidCellulose acetate film

A cellulose acetate film is made of a cellulose acetate having an acetic acid content of 59.0 to 61.5%. The film is controlled to have a Re retardation value in the range of 0 to 20 nm, a Rth retardation value in the range of 30 to 70 nm, and a thickness in the range of 10 to 70 nm.

Owner:FUJIFILM CORP

Cellulose acetate film for use in liquid crystal displays

A liquid crystal device having a plurality of pixel electrodes for transmitting light, a first panel having an activation portion for selectively activating the plurality of pixel electrodes, an orientation layer formed on the activation portion, a light shielding pattern formed on the orientation layer, a second panel having a second orientation layer, a liquid crystal formed between the first and second panels, a polarizing plate or a color filter and a protective film on at least one of the aforementioned surfaces wherein the protective layer includes a cellulose ester selected from the group consisting of cellulose acetate, cellulose formate, cellulose propionate, cellulose butyrate, ethyl cellulose, methyl cellulose and benzyl cellulose having an inherent viscosity of from about 1.0 to less than 2.0 dl / g.

Owner:EASTMAN CHEM CO

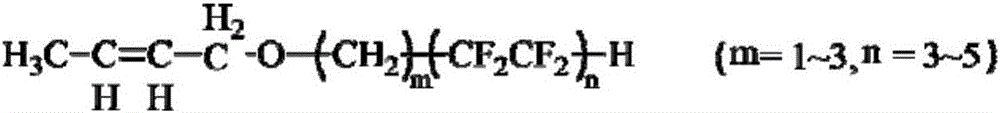

Fluorizated cellulose acetate film and preparation method

ActiveCN101716471AEasy to synthesizeEasy to makeSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisCeriumSulfanilamide

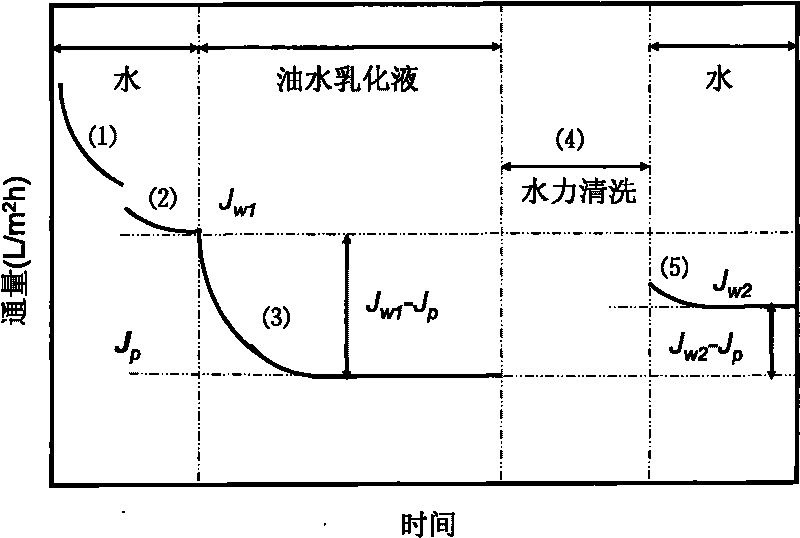

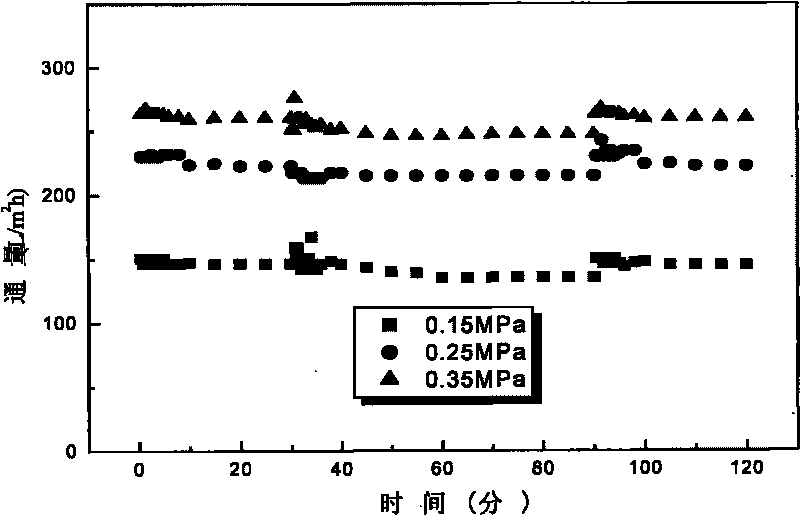

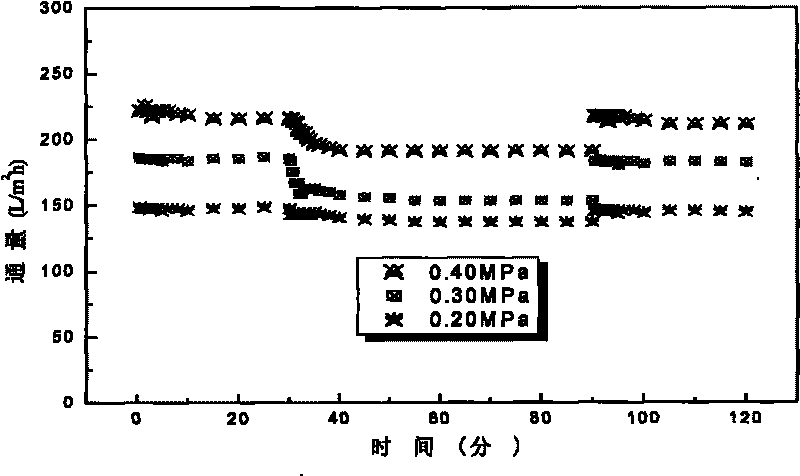

The invention relates to a fluorizated cellulose acetate film and a preparation method. The fluorizated cellulose acetate film is prepared by taking cerium salt as an initiator and grafting hydrophobic and oleophobic fluoroester methacrylic acid (FMA, such as methacrylic acid-12-fluorine heptyl ester G04, methacrylic acid hexafluoro-butyl ester G02 and the like) and hydrophilic polyglycol ester methacrylic acid (PEGMA) or methacrylic acid MAA and sulfanilamide MPDSAH sequentially onto cellulose acetate by a water-phase free-radical interfacial polymerization method; and then, taking the synthesized fluorizated cellulose acetate as a film material and preparing an asymmetrical oil-water separation film with pollution resistance and ultra-low flux depression by a non-solvent initiating phase conversion method. When the fluorizated cellulose acetate film is used for processing oil-water emulsion, the detention rate is as high as 99.8%, the rate of flux depression can be lowered to 3.4%, the water flux can be kept at 247.1L / m2h, and the rate of flux recovery is as high as 100%. The fluorizated cellulose acetate oil-water separation film has superior anti-pollution performance and strong recycle property.

Owner:南通诚恩机械有限公司

Process for producing cellulose acylate film

InactiveUS6897303B2High temporal stabilityHigh mechanical strengthSugar derivativesWood working apparatusSolubilityAlcohol

A cellulose acetate film is produced from a solution of a cellulose acylate in a mixed solvent. The mixed solvent comprises a main solvent and an alcohol. The mixed solvent essentially does not contain chlorine atom. The main solvent comprises an ester and a ketone. The ester has a solubility parameter of 16 to 23. The ketone has a solubility parameter of 16 to 23. The alcohol has a solubility parameter of 20 to 30. The mixed solvent comprises the ester in an amount of 58 to 96 wt. %, the ketone in an amount of 2 to 15 wt. %, and the alcohol in an amount of 2 to 40 wt. %.

Owner:FUJIFILM CORP

Cellulose acetate film

InactiveUS20040233363A1Retardation valueReduce contrastLiquid crystal compositionsPolarising elementsCrystallographyRefractive index

An optical compensatory sheet comprises a cellulose acetate support and an optically anisotropic layer. The optically anisotropic layer contains a discotic liquid crystal molecule. The cellulose acetate support has a Bth<550 >birefringence in the range of 0.0007 to 0.004.

Owner:FUJIFILM CORP

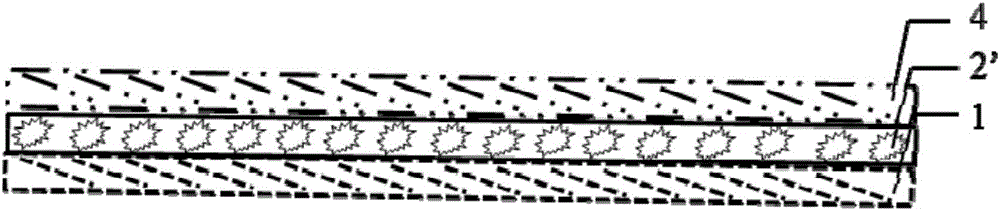

Photopolymer thin film photosensitive material used for holographic record, and preparation method therefor

InactiveCN106094435ASimple structureLow pricePhotomechanical apparatusPolymer thin filmsProtection layer

The invention provides a photopolymer thin film photosensitive material used for holographic record. The photopolymer thin film photosensitive material comprises a base film layer, a photopolymer photosensitive layer and a protection layer which are arranged in a laminated manner in sequence, wherein the base film layer is one of a PET film, a PS film, a cellulose acetate film or a PVC film; the photopolymer photosensitive layer is obtained from a photopolymer coating in a coating manner; the protection layer is one of a silicone oil PET film, cellulose acetate film or a PVC film; the photopolymer thin film photosensitive material is simple in structure, relatively wide in the raw material source, relatively low in cost, and low in environmental pollution; and the prepared photopolymer material has high diffraction efficiency and sensitivity, excellent mechanical performance, high heat resistance and high weather resistance. In addition, the invention also provides a preparation method for the photopolymer thin film photosensitive material used for holographic record.

Owner:SHENZHEN SHENDA AURORA TECH

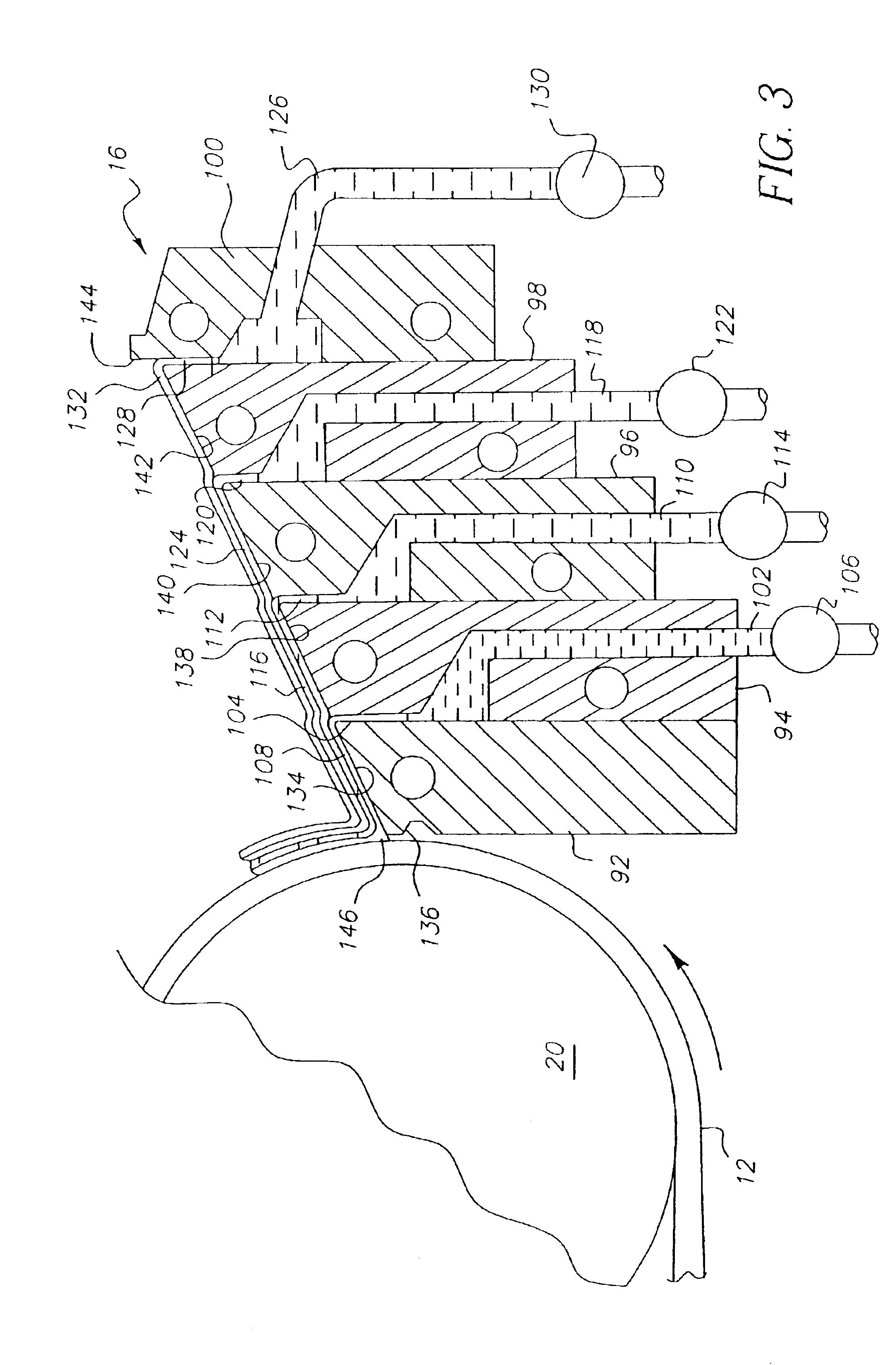

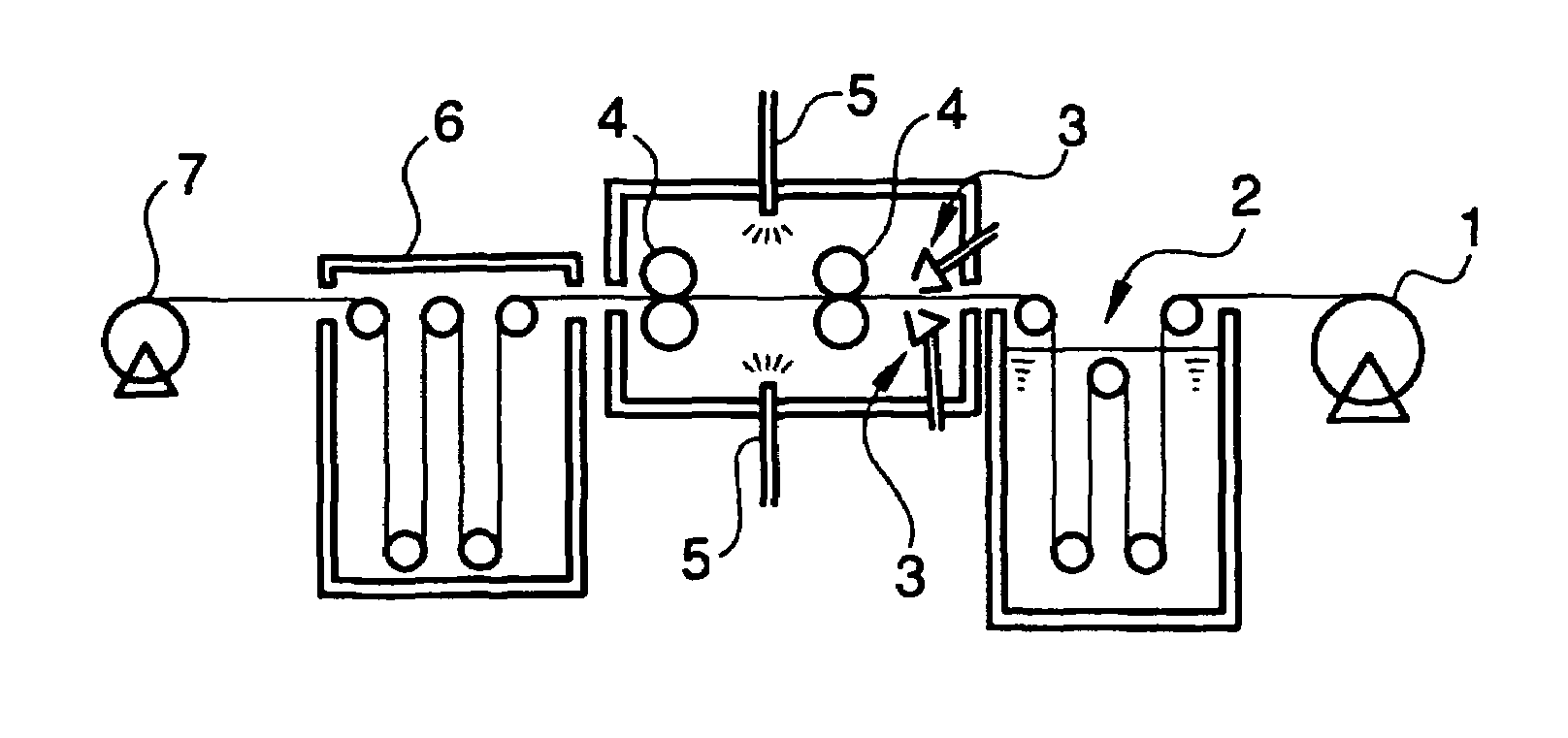

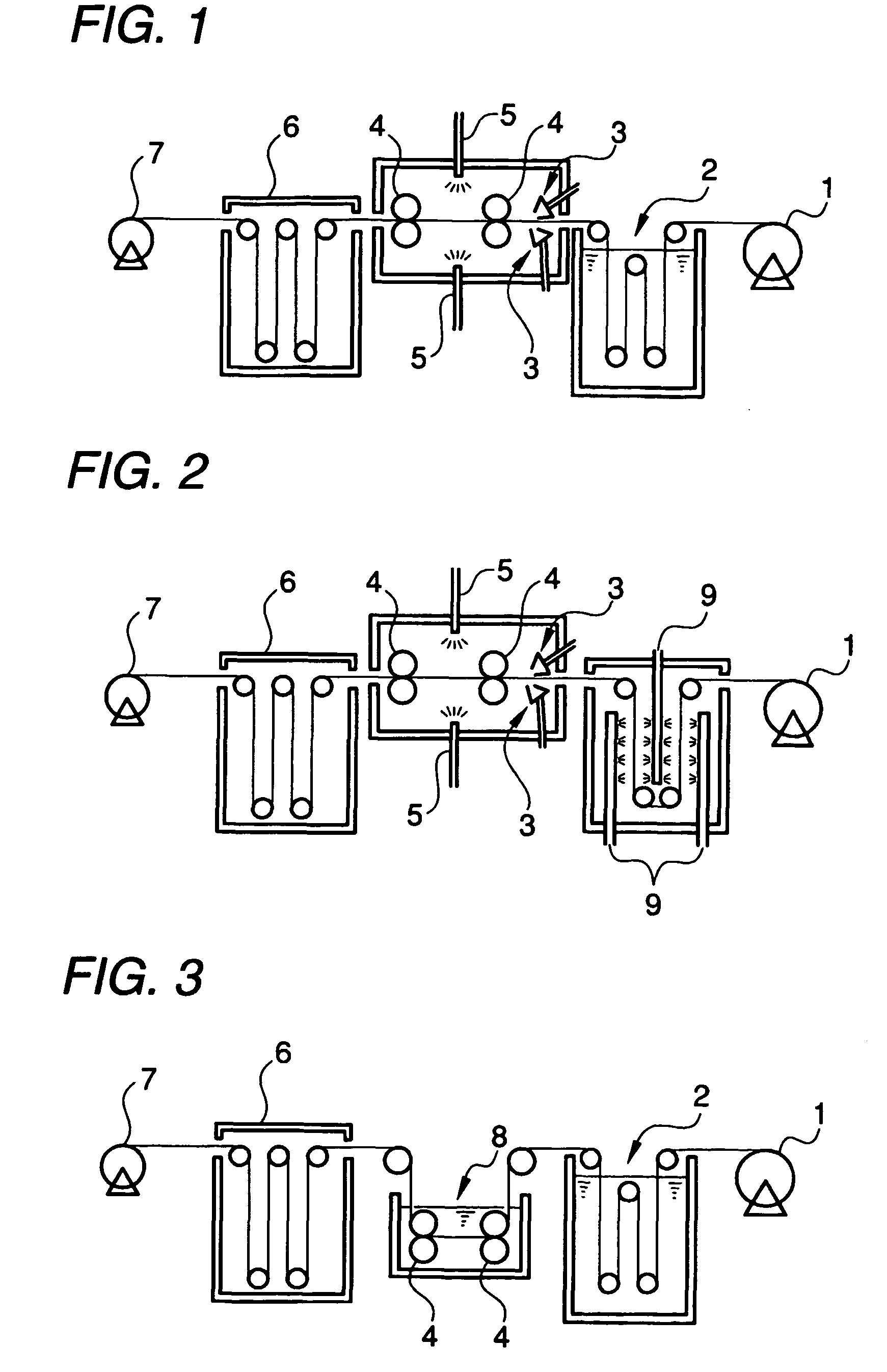

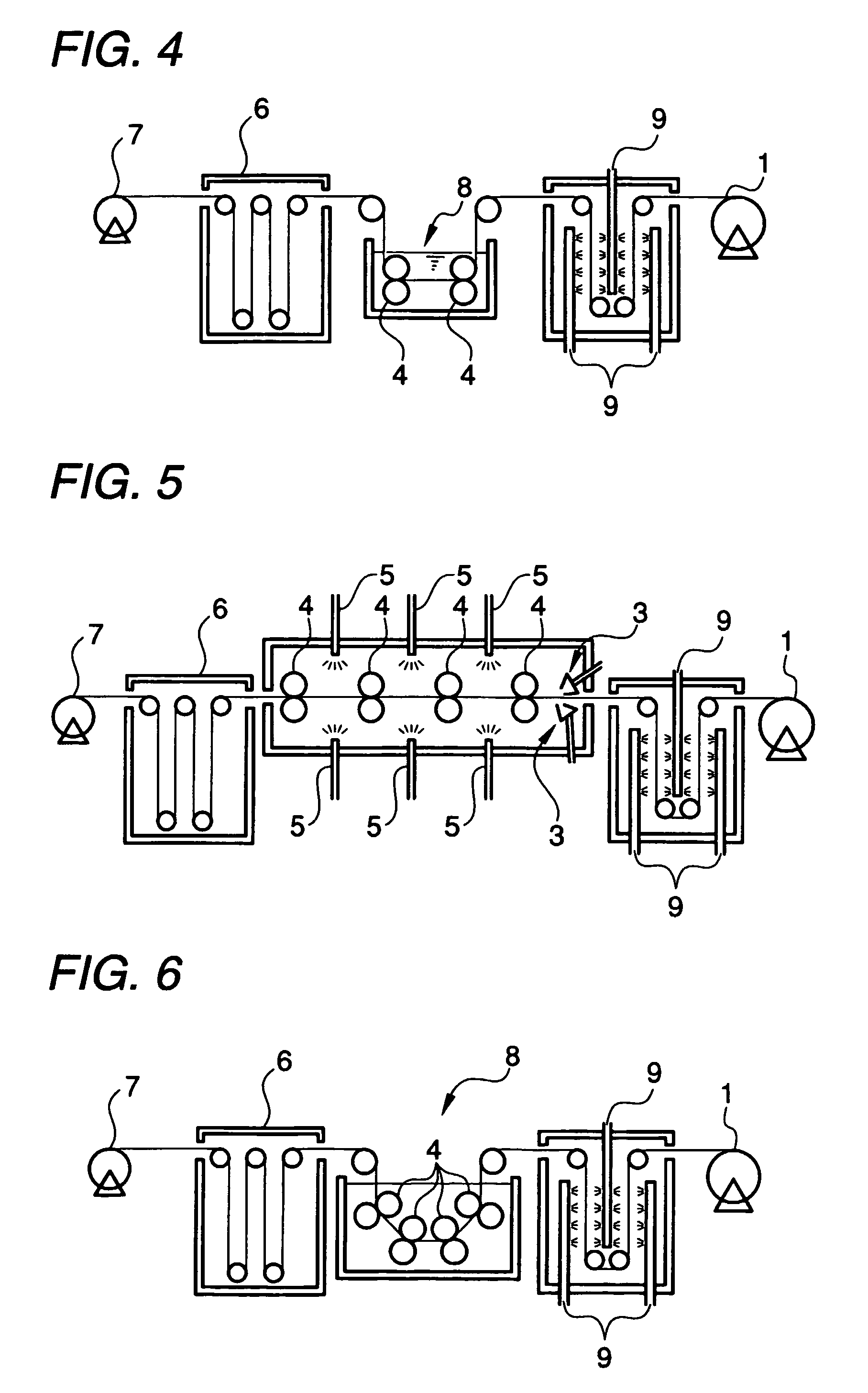

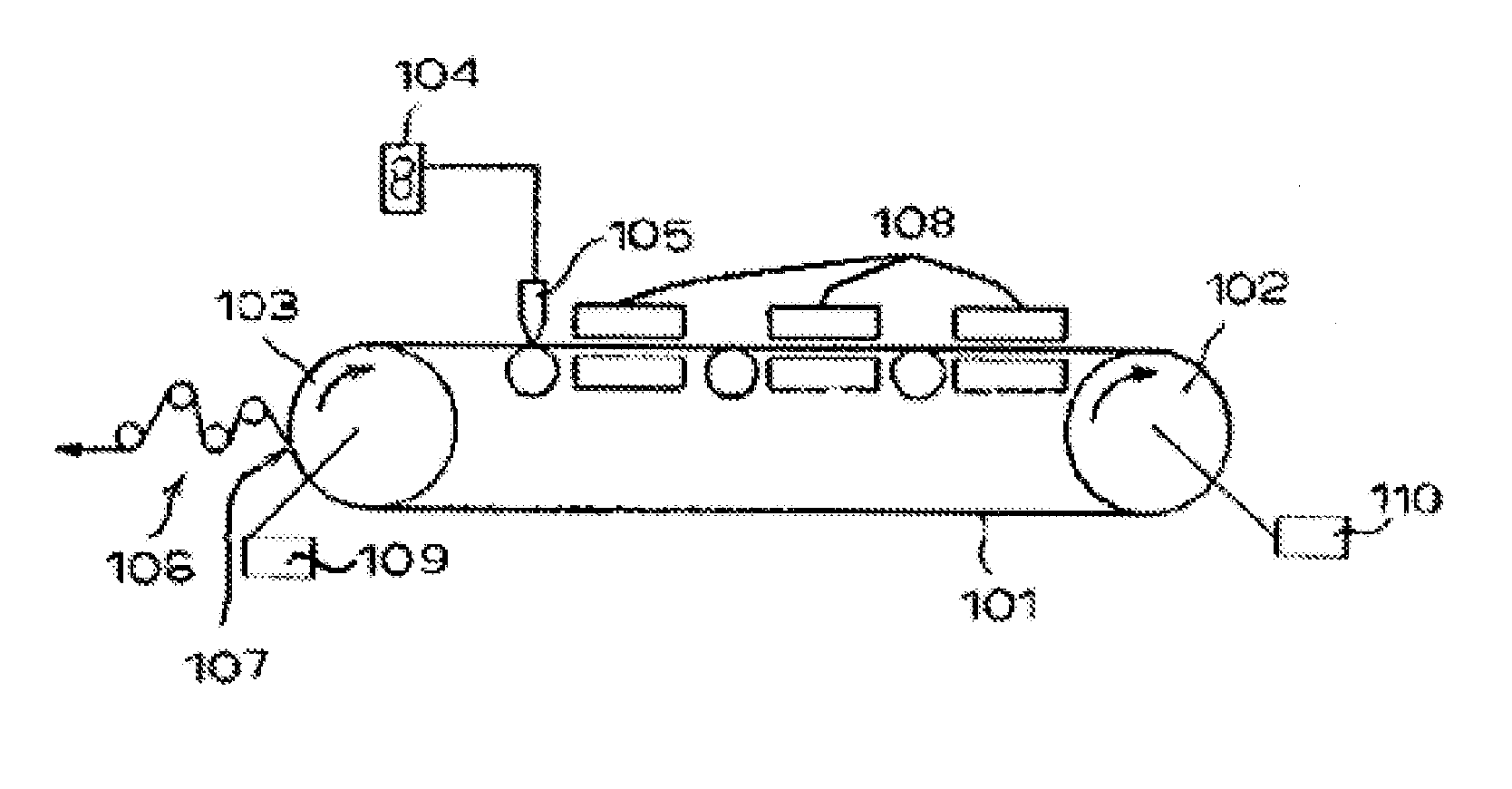

Cellulose acetate films prepared by coating methods

InactiveUS20060188708A1Improve handlingImprove stabilityDecorative surface effectsPolarising elementsLiquid layerCellulose acetate film

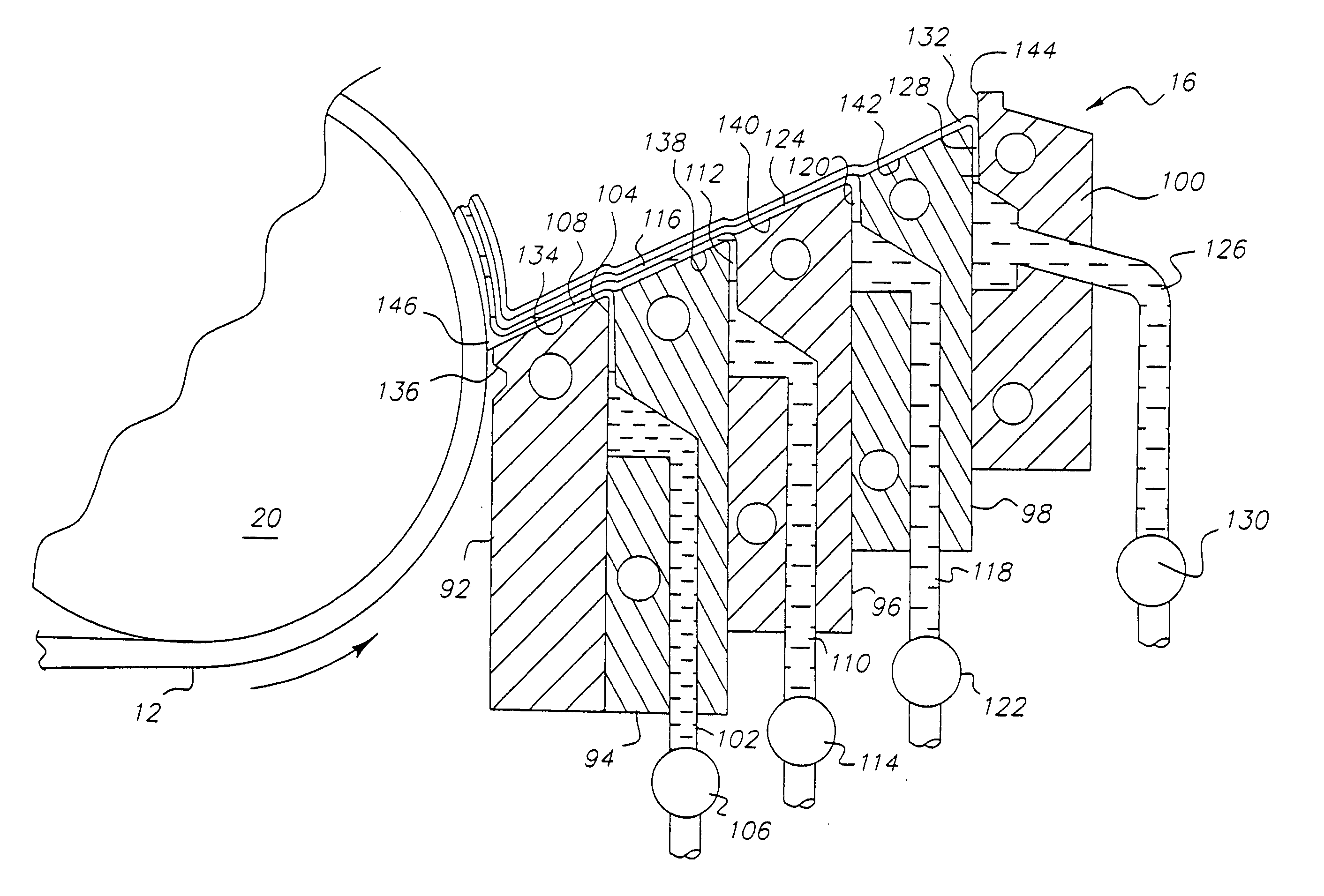

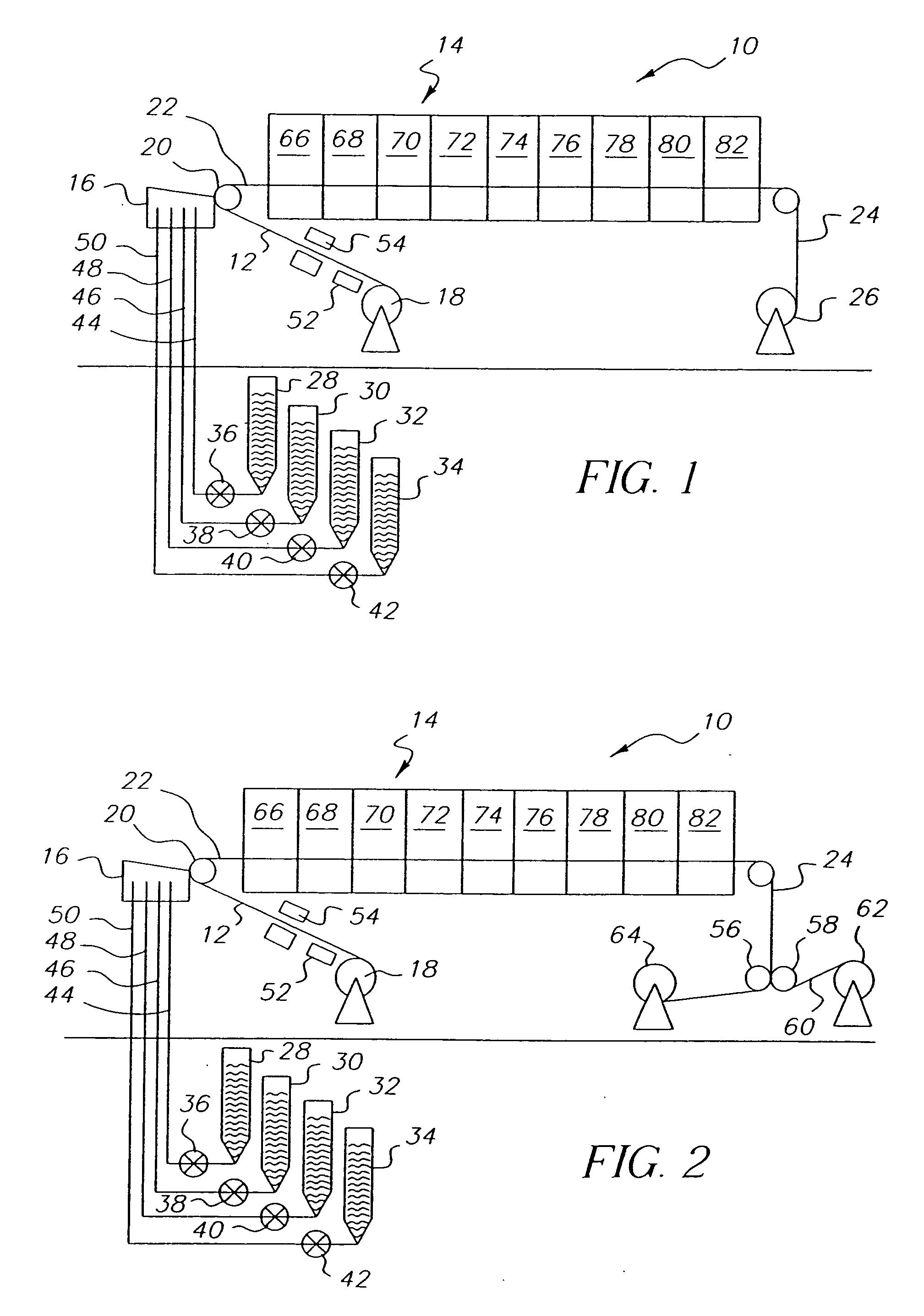

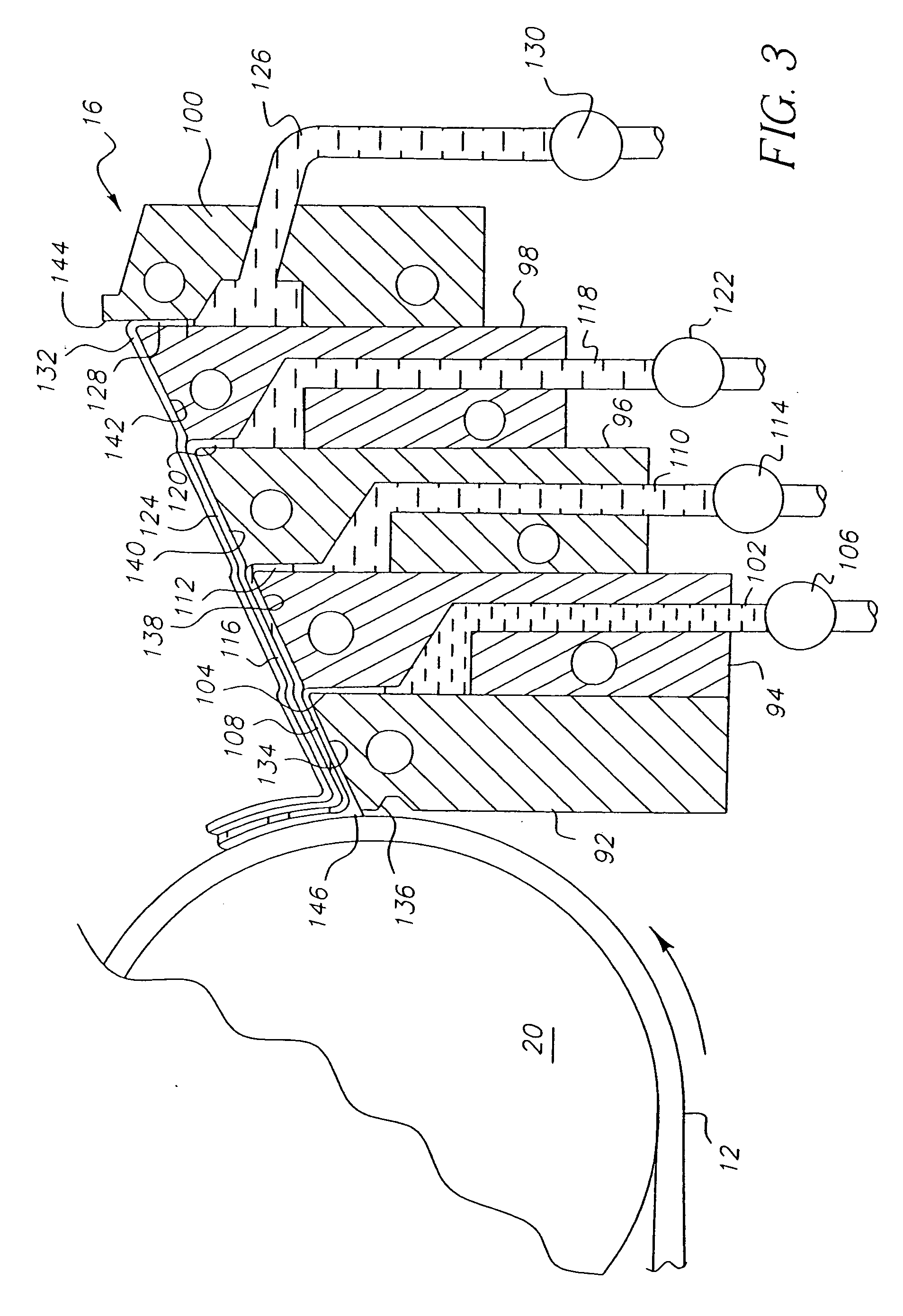

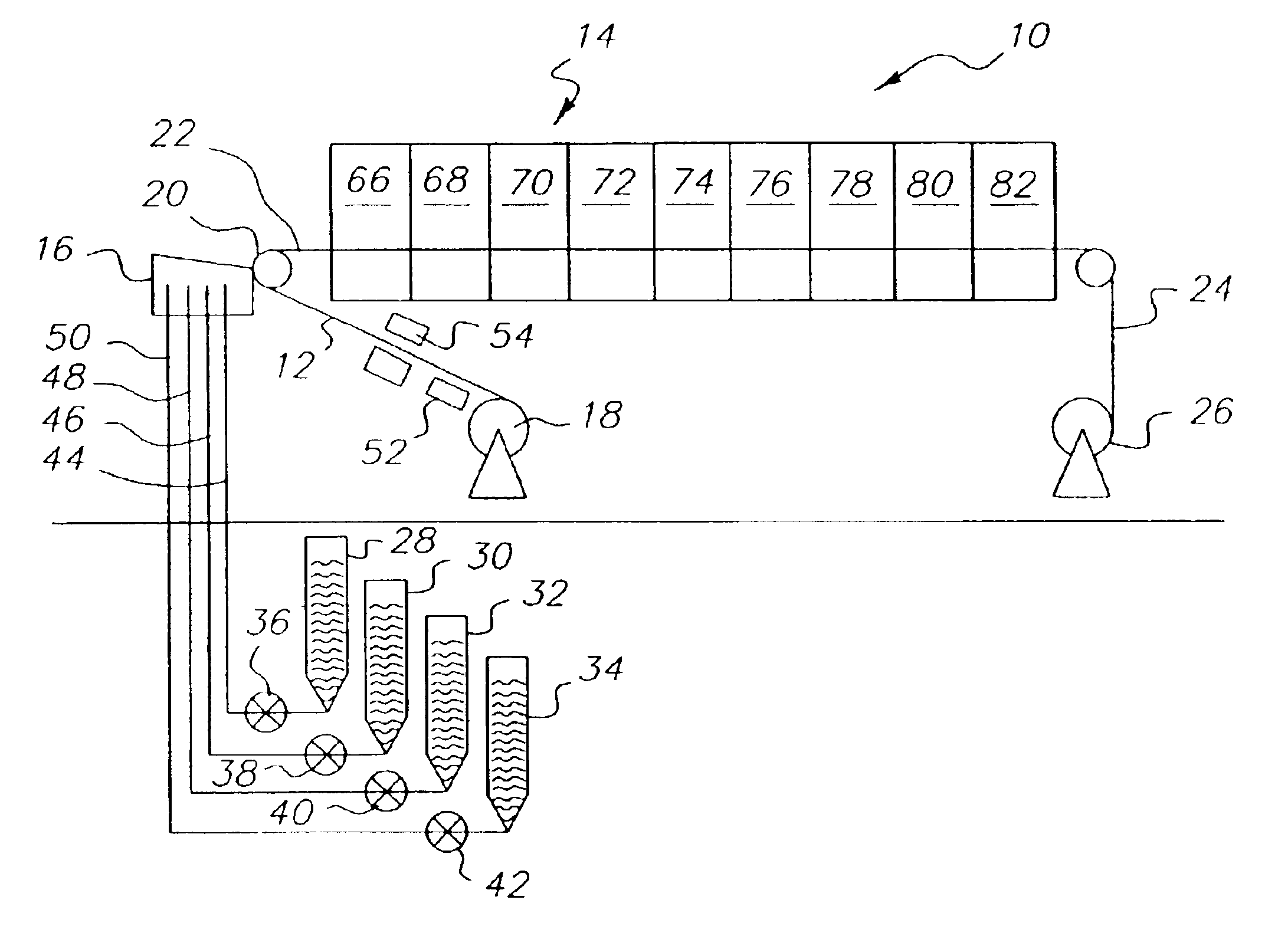

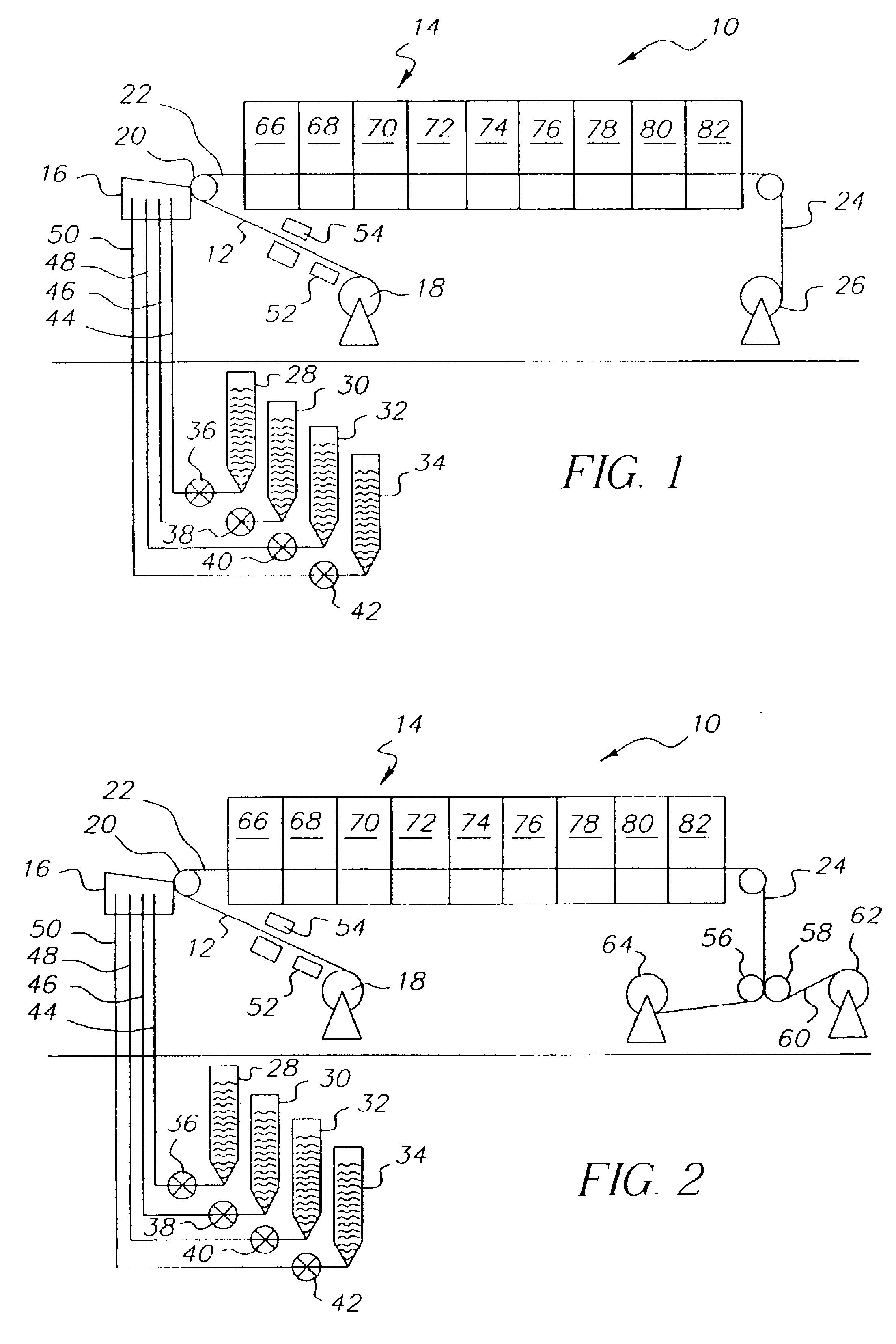

A method of film fabrication is taught that uses a coating and drying apparatus to fabricate resin films suitable for optical applications. In particular, cellulose acetate films are prepared by simultaneous application of multiple liquid layers to a moving carrier substrate. After solvent removal, the cellulose acetate films are peeled from the sacrificial carrier substrate. Cellulose acetate films prepared by the current invention exhibit good dimensional stability and low birefringence.

Owner:EASTMAN KODAK CO

Cellulose acetate film having controlled retardation and thickness

InactiveUS7019130B2Excellent in preventing framewise light leakageEasily enlargedLiquid crystal compositionsPolarising elementsAcetic acidCellulose acetate film

Owner:FUJIFILM CORP

Cellulose acetate films prepared by coating methods

InactiveUS7083752B2Reduce decreaseImprove handlingPretreated surfacesOptical articlesLiquid layerCellulose acetate film

A method of film fabrication is taught that uses a coating and drying apparatus to fabricate resin films suitable for optical applications. In particular, cellulose acetate films are prepared by simultaneous application of multiple liquid layers to a moving carrier substrate. After solvent removal, the cellulose acetate films are peeled from the sacrificial carrier substrate. Cellulose acetate films prepared by the current invention exhibit good dimensional stability and low birefringence.

Owner:EASTMAN KODAK CO

Method for producing optical compensating film, optical compensating film, circularly polarizing plate, and liquid crystal display

InactiveUS7099082B2Improve viewing angle characteristicsLiquid crystal compositionsPolarising elementsCrystallographyAcetic acid

Provided is a method for producing an optical compensating film, which comprises stretching a cellulose acetate film, the cellulose acetate film having a water content of 2.0 to 20.0% by weight, wherein the cellulose acetate for the film has an acetyl value of from 57.0% to 62.5%.

Owner:FUJIFILM CORP

Cellulose acetate forward osmosis film material and preparation method thereof

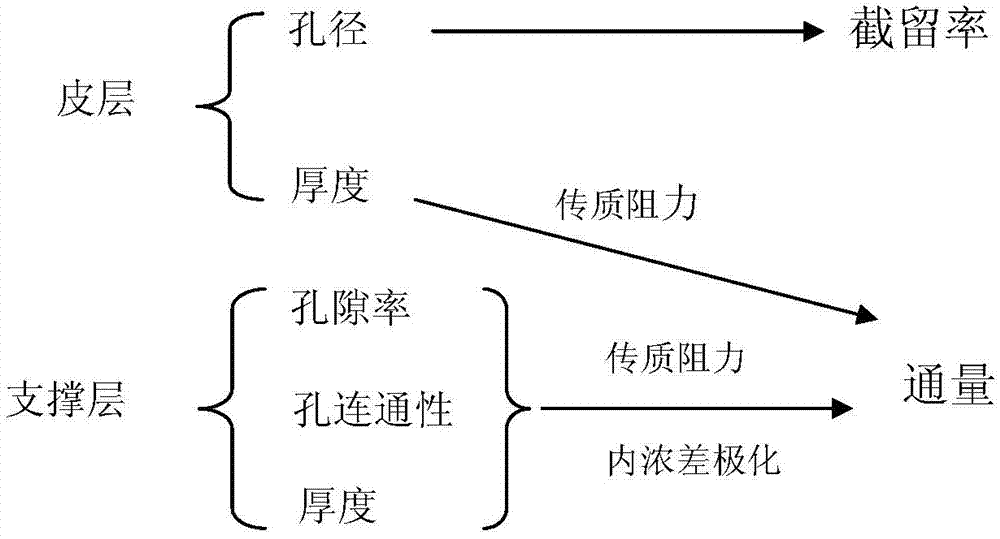

InactiveCN103785301AImprove hydrophilicityHas an ultra-thin structureSemi-permeable membranesPorosityConcentration polarization

The invention discloses a cellulose acetate forward osmosis film material. The cellulose acetate forward osmosis film material is a dissymmetric film, and is 20-150 micrometers in thickness and 55 to 90 percent in porosity. The cellulose acetate forward osmosis film material is made of cellulose acetate casting film liquid in a film scraping manner by adopting a film scraping machine; the content of cellulose acetate in the cellulose acetate casting film liquid is 5-40wt%, and the balance refers to macromolecule solvents. The cellulose acetate forward osmosis film material disclosed by the invention is suitable for being used in the forward osmosis process, is good in hydrophilcity and has a superthin structure; the porosity of a supporting layer is large; the connectivity of a hole structure is good; the internal concentration polarization can be effectively reduced; the compactness of a surface layer is good; the reject rate of univalency salt is high; small molecules such as trace suspended solids, bacteria and viruses in a water body can be effectively removed; the treatment efficiency is high and the operation cost is low.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Cellulose acetate film and method for producing it, polarizer and liquid crystal display device

InactiveUS20110193260A1Low degree of total acyl substitutionLow degreeFlat articlesCoatingsLiquid-crystal displayPolarizer

Owner:FUJIFILM CORP

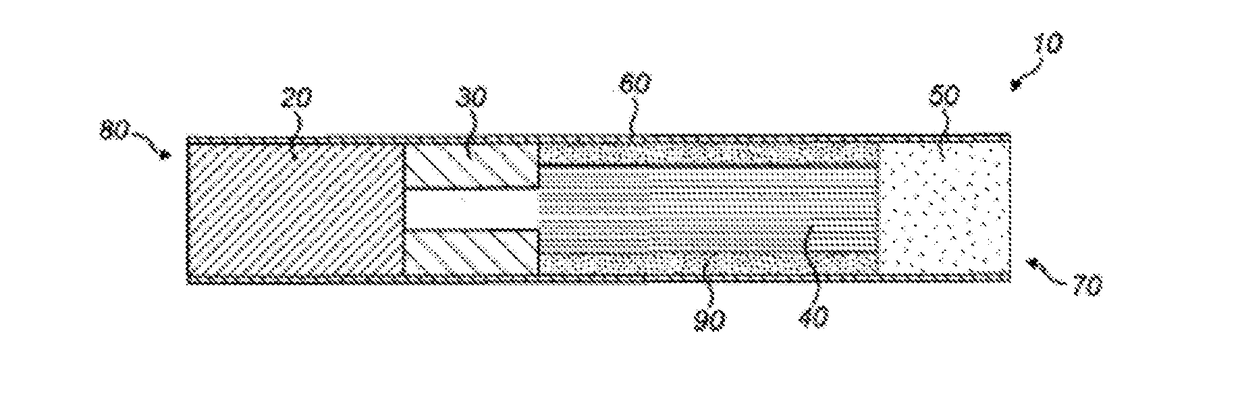

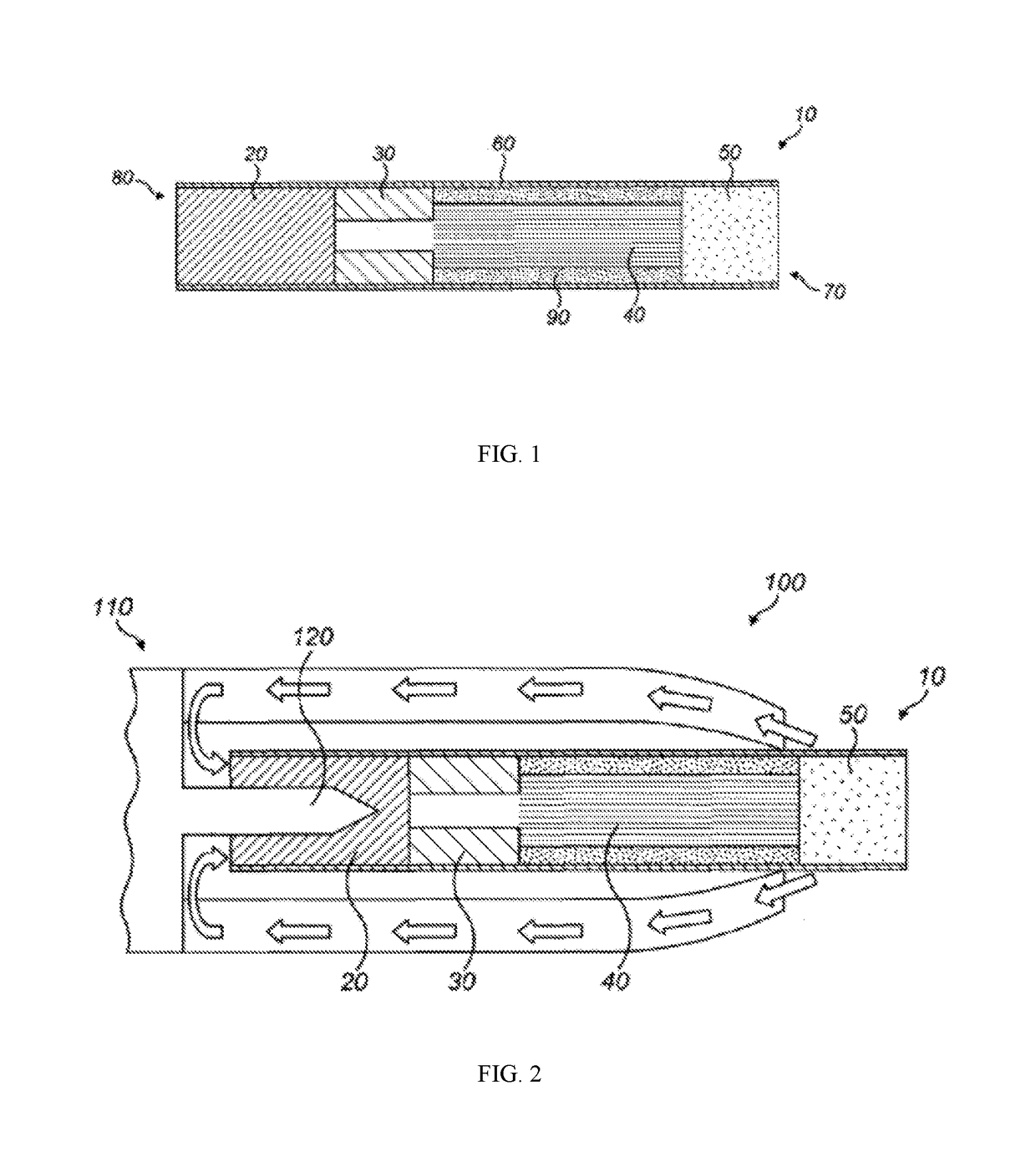

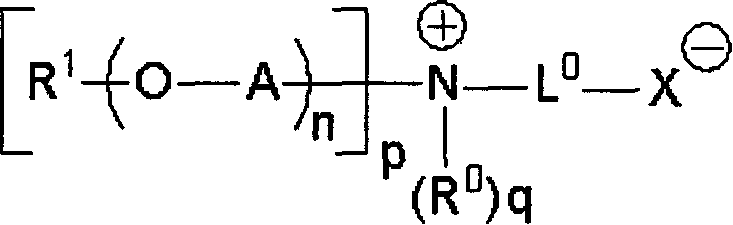

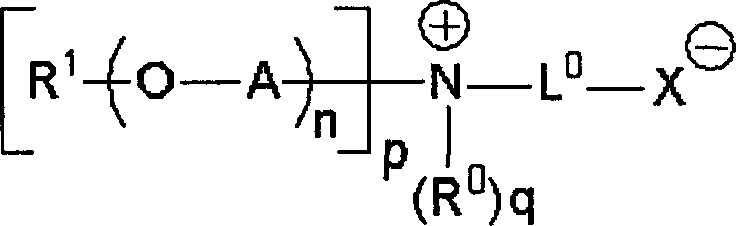

Cellulose acetate film for aerosol-generating device

Disclosed are cellulose acetate films for use in an aerosol-generating device, such as an electrically heated cigarette. The cellulose acetate films comprise cellulose acetate and a plasticizer.

Owner:CELANESE INT CORP

Alkali saponification method for cellulose acylate film, a surface saponified cellulose acylate film and an optical film utilizing the same

ActiveCN1720284AEffectively used asAdhesion defects do not occurPolarising elementsNon-linear opticsCelluloseLiquid-crystal display

The invention is to provide an alkali saponification method for uniformly and stably saponifying a cellulose acylate film, to provide a surface saponified cellulose acylate film adapted for an optical compensation sheet for a large-sized liquid crystal display apparatus without a display defect, and to provide a alkali saponified cellulose acylate film adapted for an optical compensation sheet with an appropriate adhesion between a transparent substrate and an orienting film. There is provided an alkali saponification method for cellulose acylate film characterized by alkali saponification of a cellulose acylate film with an alkali solution, particularly an alkali saponification method for achieving selective saponification by coating the alkali solution on one surface only of the film, and a cellulose acylate film processed by such alkali saponification method.

Owner:FUJIFILM CORP

Detection test paper for detecting benzoyl peroxide in flour and preparation method of detection test paper

InactiveCN102323258AJudgment content rangePrevent precipitationMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsBenzoyl peroxidePolyvinyl chloride

The invention discloses detection test paper for detecting benzoyl peroxide in flour and preparation method of the detection test paper. The test paper comprises a test strip and a standard colourimetric card, wherein the standard colourimetric card comprises 10 color lumps with corresponding concentration gradients of benzoyl peroxide from shallow to deep respectively 0mg / L, 12 mg / L, 36 mg / L, 60mg / L, 84 mg / L, 108 mg / L, 132 mg / L, 156 mg / L, 180 mg / L and 228 mg / L. The test strip comprises a substrate and a color-developing layer adhered on the front end of the substrate, the color-developing layer has a test function, the substrate is made of a PVC (polyvinyl chloride) sheet, and the color-developing layer is prepared by immersing a cellulose acetate film in a color-developing mixed solution consisting of 5-10 percent of potassium iodide, 0.2-0.8 percent of soluble starch and 2-8 percent of sodium carbonate and then drying in vacuum at a temperature of 40-80 DEG C for 20-50min. According to the comparison of the color-developing degree of a sample to be detected and the standard colourimetric card, the content range of the benzoyl peroxide can be rapidly judged. The detection test paper disclosed by the invention is simple, rapid and visual in operation when being used for detecting the benzoyl peroxide remained in the flour, and has high detection sensitivity and accuracy.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Method for preparing hydrophobic cellulosic organic nano clay composite heavy-metal ion adsorbing ceramsites

InactiveCN105561955AImprove hydrophobicityImprove adsorption capacityOther chemical processesWater contaminantsCelluloseSilanes

The invention discloses a method for preparing hydrophobic cellulosic organic nano clay composite heavy-metal ion adsorbing ceramsites and belongs to the field of composite materials. The method comprises the steps of firstly carrying out organizing treatment on sodium-based montmorillonite so as to obtain organic montmorillonite and change hydrophilic montmorillonite into hydrophobic montmorillonite, then, depositing a titanium dioxide film on the surface of a cellulose acetate film by a surface sol-gel method, carrying out pulping, then, preparing hydrophobic composite cellulose acetate film pulp by using an octadecyl trimethoxy silane toluene solution, loading the hydrophobic composite cellulose acetate film pulp and the organic montmorillonite to a high-speed emulsifying homogenizer together for intercalation, and finally, carrying out granulating and calcining, thereby obtaining the ceramsites. The material prepared by the method has a superficial hydrophobic effect and has good adsorption to heavy-metal ions, the heavy-metal ions can be recovered by a calcining method, no waste gas and waste liquid is discharged during preparation, and the product is biodegradable and environment-friendly.

Owner:梅庆波

Preparation method of biodegradable cellulose acetate film

The present invention relates to preparation process of biodegradable cellulose acetate film. Ramie cellulose is swelled first with water and then with glacial acetic acid, and reacted with acetic anhydride under catalysis of sulfuric acid to obtain yellow cellulose acetate gel. The obtained cellulose acetate gel is dissolved in acetone, and the solution is filtered and added with different kinds of plasticizer to compound film casting liquid. The film casting liquid is cast in mold to form cellulose acetate film of certain thickness, and after volatilizing the solvent, the cellulose acetate film is separated from the mold in a water bath. The biodegradable cellulose acetate film may be used in preserving soil moisture and may be biodegraded without destroying soil structure and polluting environment.

Owner:SHAANXI NORMAL UNIV

Preparation and application method of filter paper collecting biological sample

InactiveCN102182116AImprove accuracyImprove stabilityInorganic fibres/flakesFiltration separationEthylene diamineCellulose

The invention provides a preparation and application method of filter paper collecting a biological sample. An absorbing material with high accuracy, high stability and good repeatability is prepared by adding a specific stabilizer to the filter paper so that the sample is convenient to convey and store at normal temperature and easy to elute after drying, and the storage time of the biological sample is prolonged. According to the invention, a high-performance cellulose acetate film and a cellulose nitrate film are used as the filter paper materials; the filter paper material is completely soaked in 3.8 mM or 7.7 mM of aqueous solution of ethylene diamine tetraacetic acid; the completely soaked filter paper material is taken out and dried at 45 DEG C; and the finished product is taken out and stored in a sealed manner. The method provided by the invention is convenient for the detection process, and can lower the clinical examination cost and reduce economical burden on patients.

Owner:东莞南方医大代谢医学研发有限公司

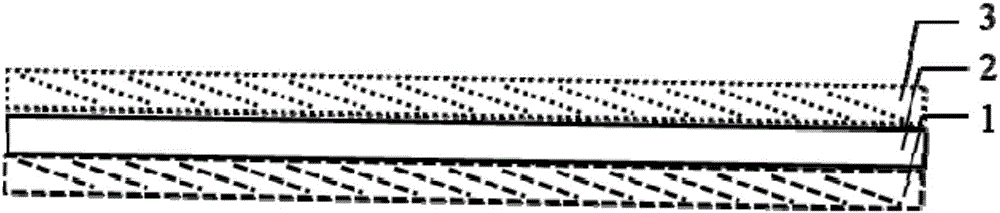

Biologically degradable pre-coating film

The invention relates to a biologically degradable pre-coating film, which comprises a substrate, an intermediate layer and a hot melt adhesive layer. The intermediate layer is arranged between the substrate and the hot melt adhesive layer, the substrate is a cellulose acetate film, the intermediate layer is made of polyethylenimine, and the hot melt adhesive layer is made of ethylene-vinyl acetate hot melt adhesive. The thickness of the substrate is 12-25 microns, the thickness of the intermediate layer is 0.01-0.03 micron, and the thickness of the hot melt adhesive layer is 12-40 microns. Since the cellulose acetate film is biologically degradable, the biologically degradable pre-coating film can be completely decomposed into CO2 and H2O under effects of microorganisms in the nature, such as bacteria, fungi and algae, and can also be used with waste paper into a pulp forming procedure to produce recycled paper. Therefore, the film is an environmentally friendly green plastic packaging material.

Owner:KANGDE XIN COMPOSITE MATERIAL CO LTD

Polarizer and manufacturing method thereof

ActiveCN101042446ALess frizzSynthetic resin layered productsPolarising elementsAdhesivePolyvinyl alcohol

A polarizing plate is prepared by laminating cycloolefin resin films by adhesives on one side of the polarizing film made of polyvinyl alcohol resin and laminating cellulose acetate films by adhesives on the other side, and the water fraction of the cellulose acetate films before lamination is adjusted over 0.5%. Adjustment of the water fraction can be carried out by soaking the cellulose acetate films in water and then drying. According to the invention, crimp is inhibited in the polarizing plate prepared by laminating cycloolefin resin films by adhesives on one side of the polarizing film made of polyvinyl alcohol resin and laminating cellulose acetate films by adhesives on the other side.

Owner:SUMITOMO CHEM CO LTD

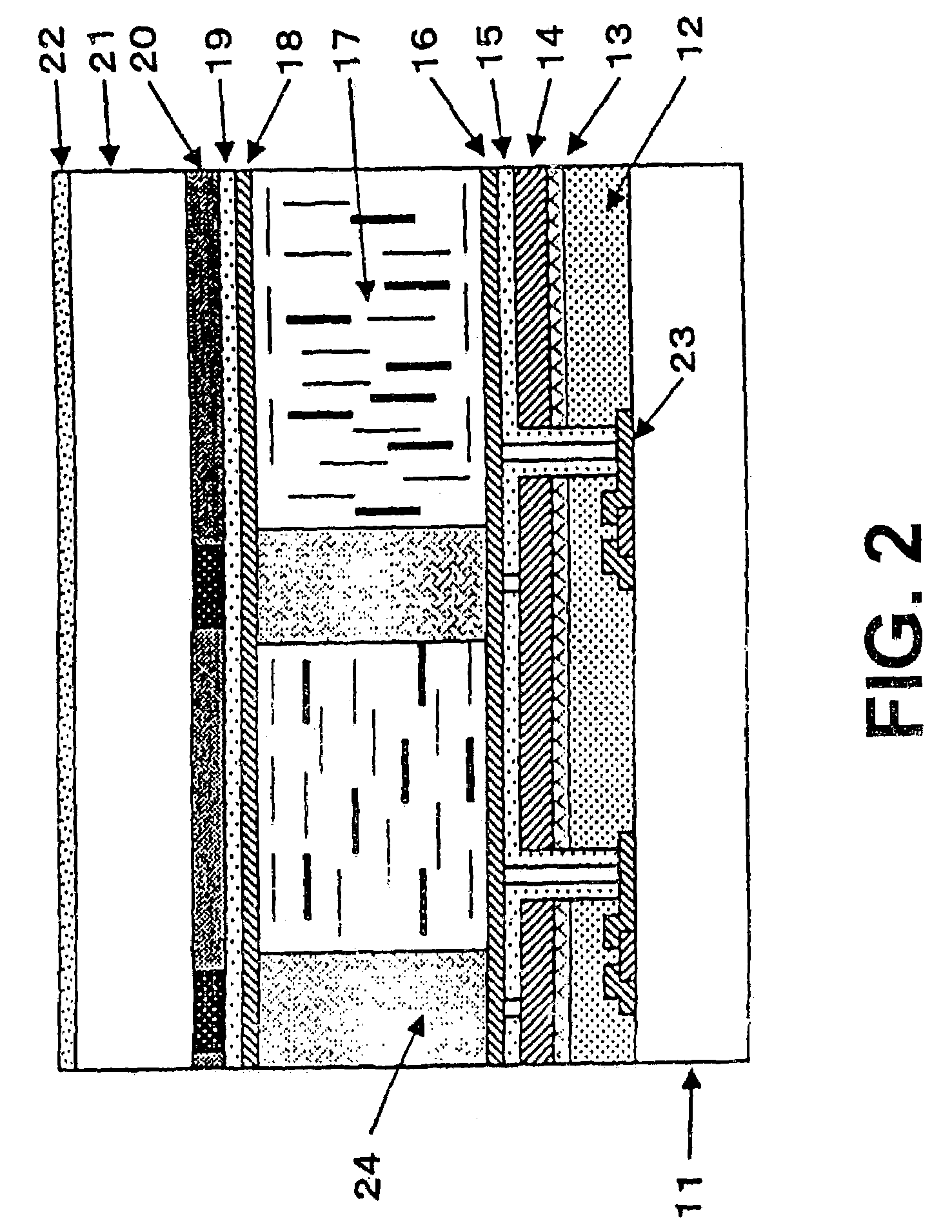

Liquid crystal display of OCB or VA mode

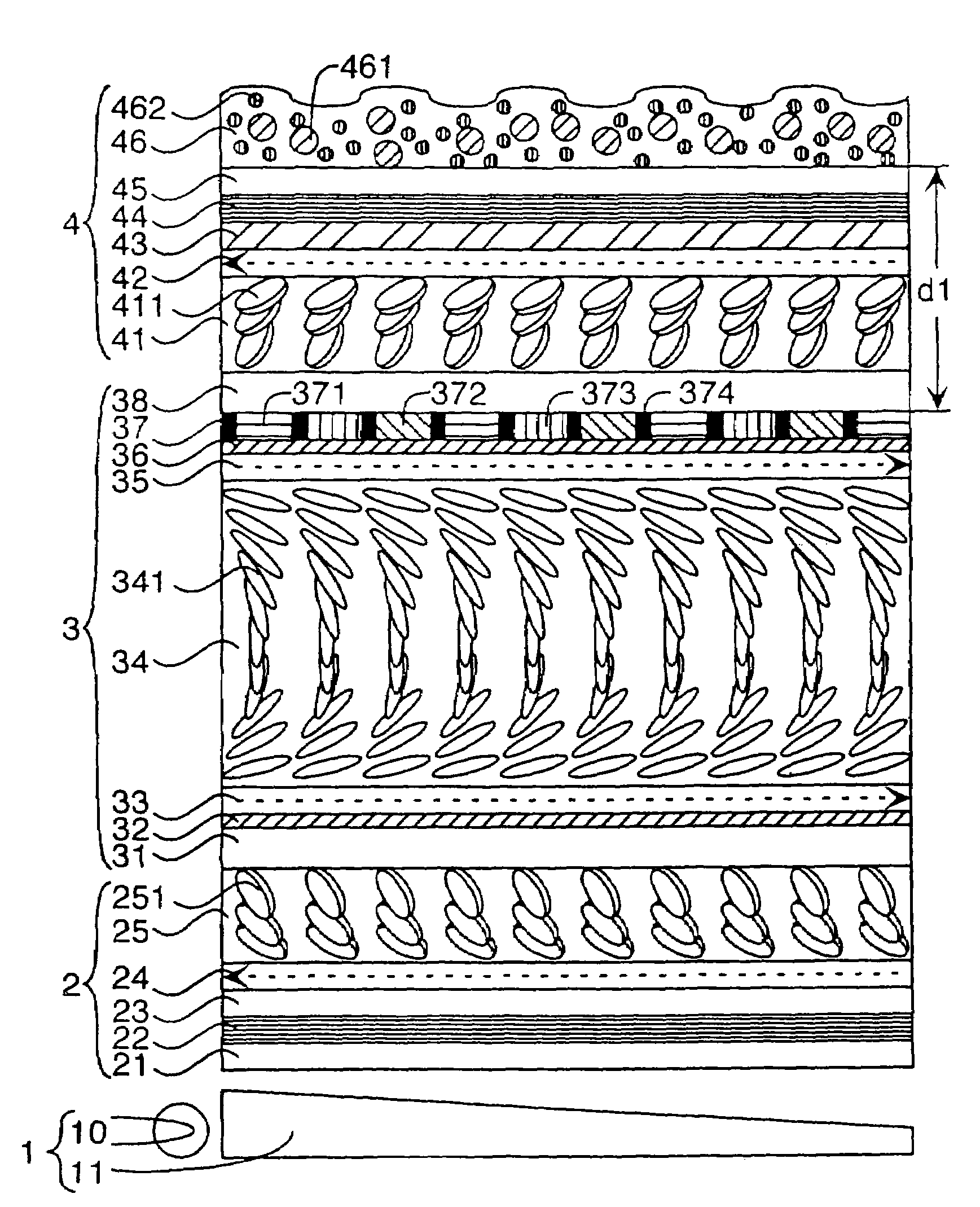

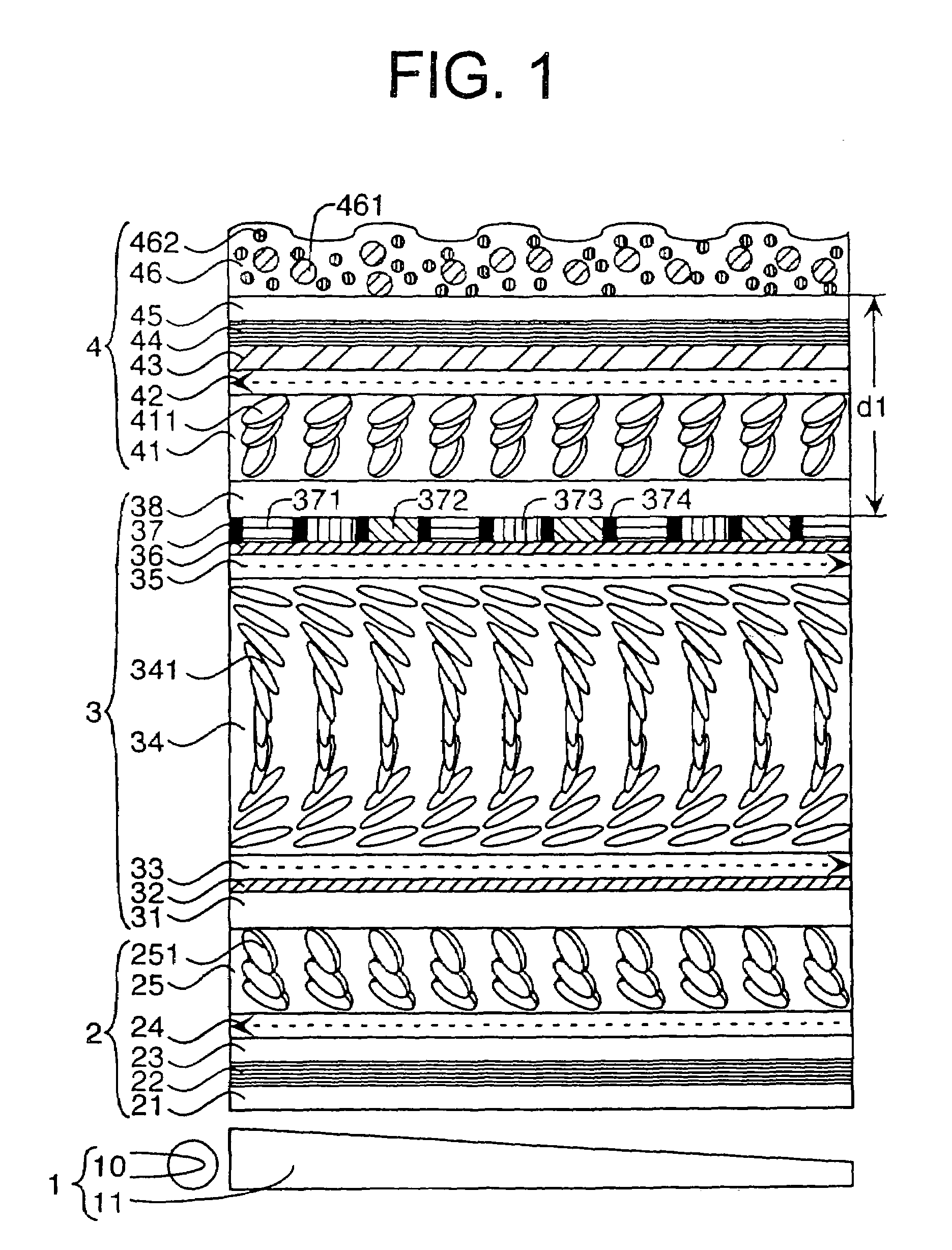

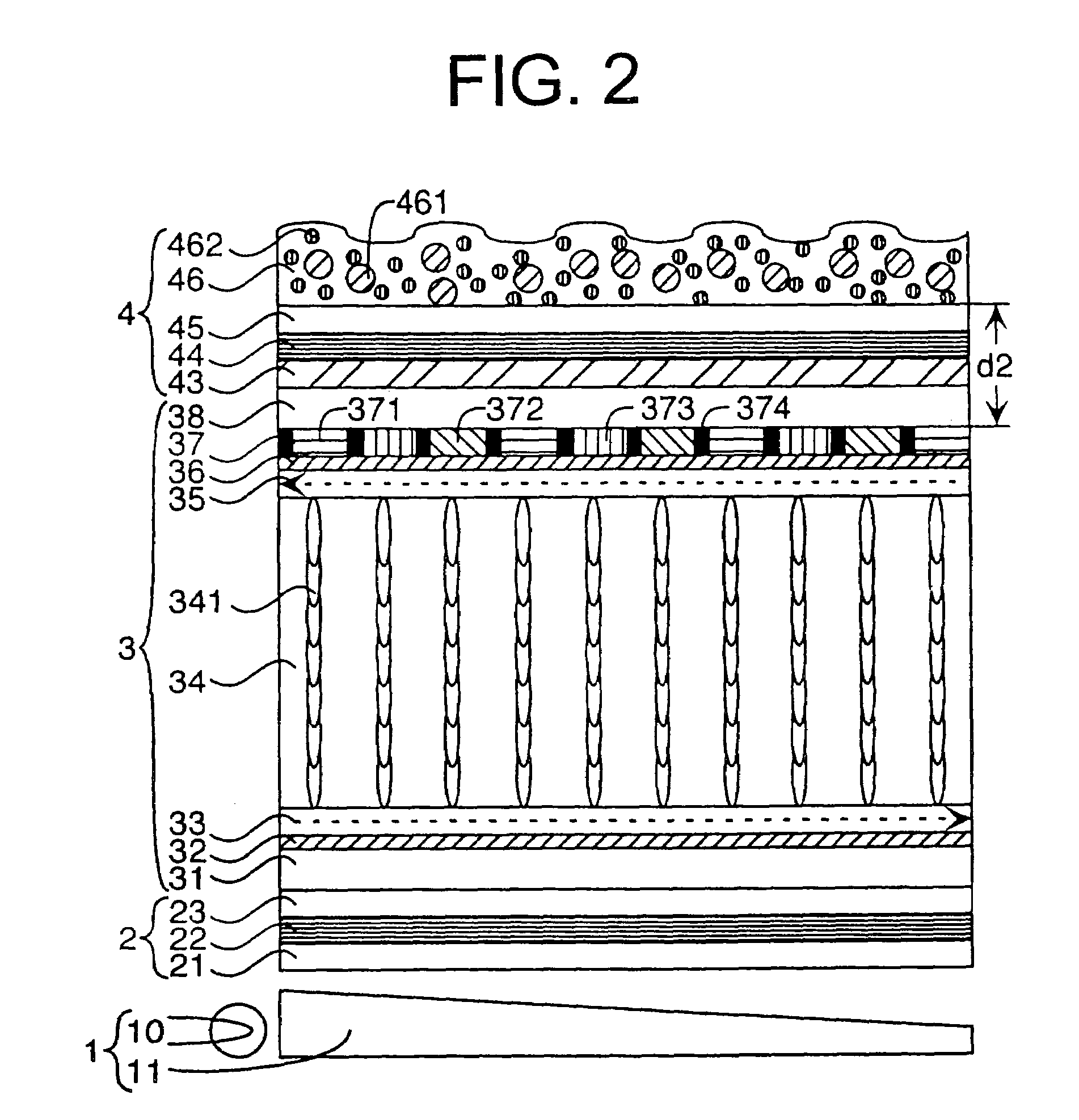

InactiveUS7586562B2Avoid changeImprove image qualityMechanical apparatusPoint-like light sourceTectorial membraneRefractive index

A liquid crystal display of OCB mode or VA mode comprises a backlight unit, a backlight-side polarizing plate, a liquid crystal cell of OCB mode or VA mode, and a viewer-side polarizing plate in order. The viewer-side polarizing plate comprises a first transparent protective film, a polarizing membrane, a second transparent protective film and a light-diffusing layer in order. In the liquid crystal display of OCB mode, an optically anisotropic layer is formed from liquid crystal compound on the first transparent protective film. The first transparent protective film is a cellulose acetate film having a Re retardation value of 20 to 70 nm and a Rth retardation value of 100 to 500 nm. The light-diffusing layer comprises transparent resin and transparent fine particles dispersed therein. The transparent resin and the transparent fine particles have refractive indices that are different from each other.

Owner:FUJIFILM CORP

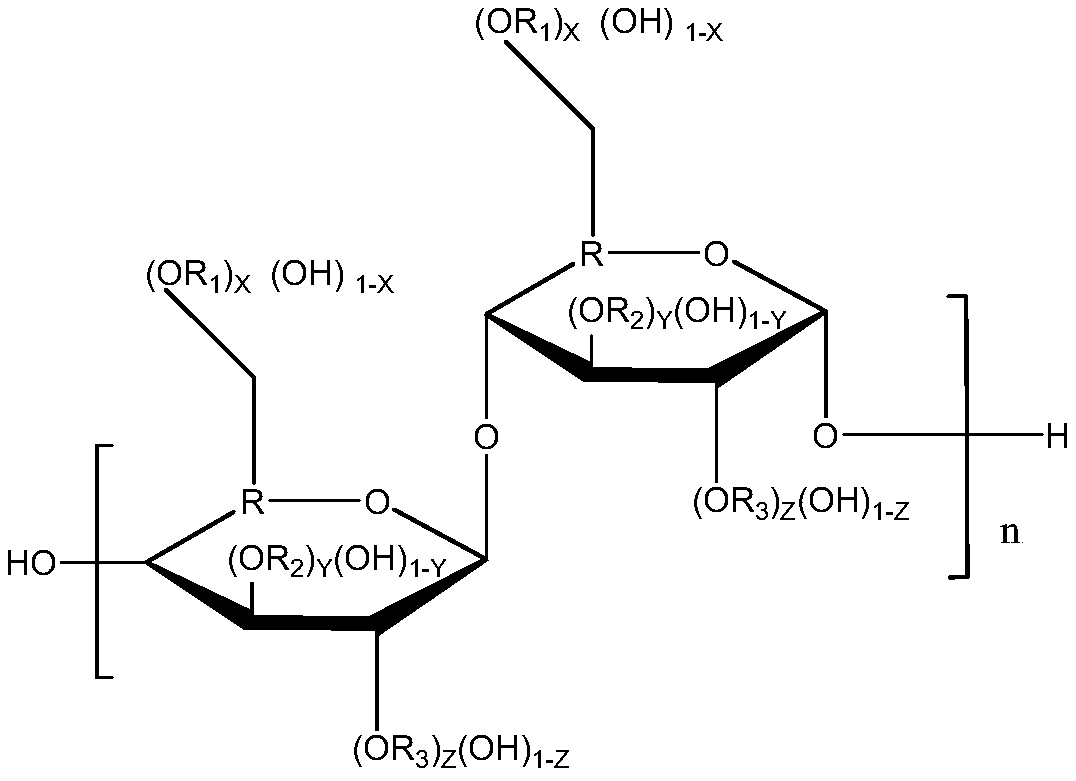

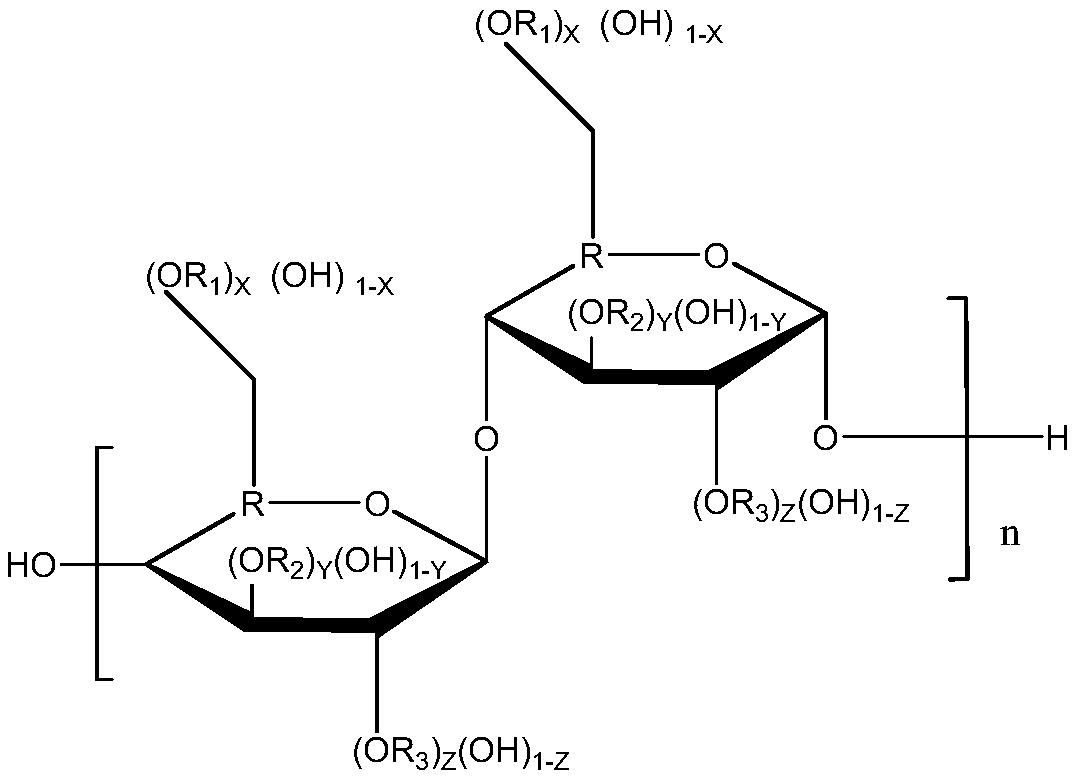

Biodegradable paper-plastic composite structure and preparation method thereof

A biodegradable paper-plastic composite structure comprises: at least one cellulose acetate or derivative film thereof; the invention discloses a paper base material. The cellulose acetate or cellulose acetate derivative film is combined with a paper base material to form a paper-plastic composite structure. The cellulosic material included in the formulation includes cellulose acetate having a degree of substitution of 1.5 to 2.8 or a derivative thereof; and a plasticizer capable of reducing the softening temperature of cellulose is also included. The basic paper material is paper obtained after cellulose pulp is physically processed, such as kraft paper and parchment. The preparation method of the biodegradable paper-plastic composite structure comprises the following steps: compoundinga cellulose acetate film through a heating and pressurizing method, or compounding through a solution coating method, namely coating the surface of paper with a cellulose acetate solution; and evaporating a solvent to prepare a cellulose acetate-containing paper composite material. The product disclosed by the invention can be applied to the field of food or packaging, and can be naturally degraded to eliminate or reduce the problem of environmental pollution caused by packaging materials.

Owner:NANTONG CELLULOSE FIBERS CO LTD +2

Preparation method of alveolate multilayer pore structure activated carbon film

ActiveCN102824901ALarge specific surface areaHigh porosityOther chemical processesAlkali metal oxides/hydroxidesCarbon filmPorosity

The invention relates to a preparation method of an alveolate multilayer pore structure activated carbon film. The technical scheme comprises the following steps of: taking cellulose acetate as film material, and taking low-boiling point organic solvent as solvent, so that film casting liquid can be prepared; preparing an alveolate multilayer pore structure cellulose acetate film by a water vapor assisting method, hydrolyzing in 0.1mol / L NaOH / ethanol solution for 10-24 hours, soaking in 1-5% of inorganic salt solution to be activated, stabilizing, carbonizing, washing, and drying, so that the alveolate multilayer pore structure activated carbon film can be prepared. The preparation method combines the water vapor assisting method with the carbonization, and is simple in technology, and suitable for the large-scale industrial preparation. The prepared alveolate multilayer pore structure activated carbon film has the characteristics of being multilayer in alveolate pore structure, large in specific surface area, and high in porosity. The prepared alveolate multilayer pore structure activated carbon film has a very high absorption function to organic dyestuff, and is easy to recycle.

Owner:FUJIAN NORMAL UNIV

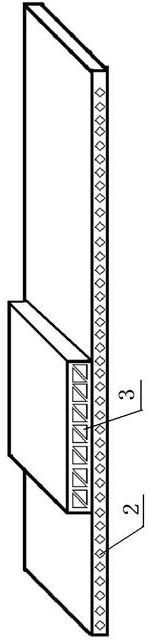

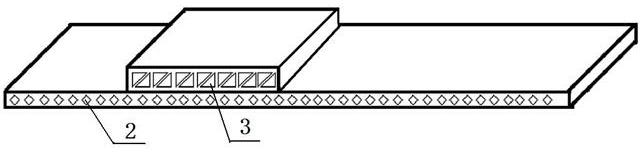

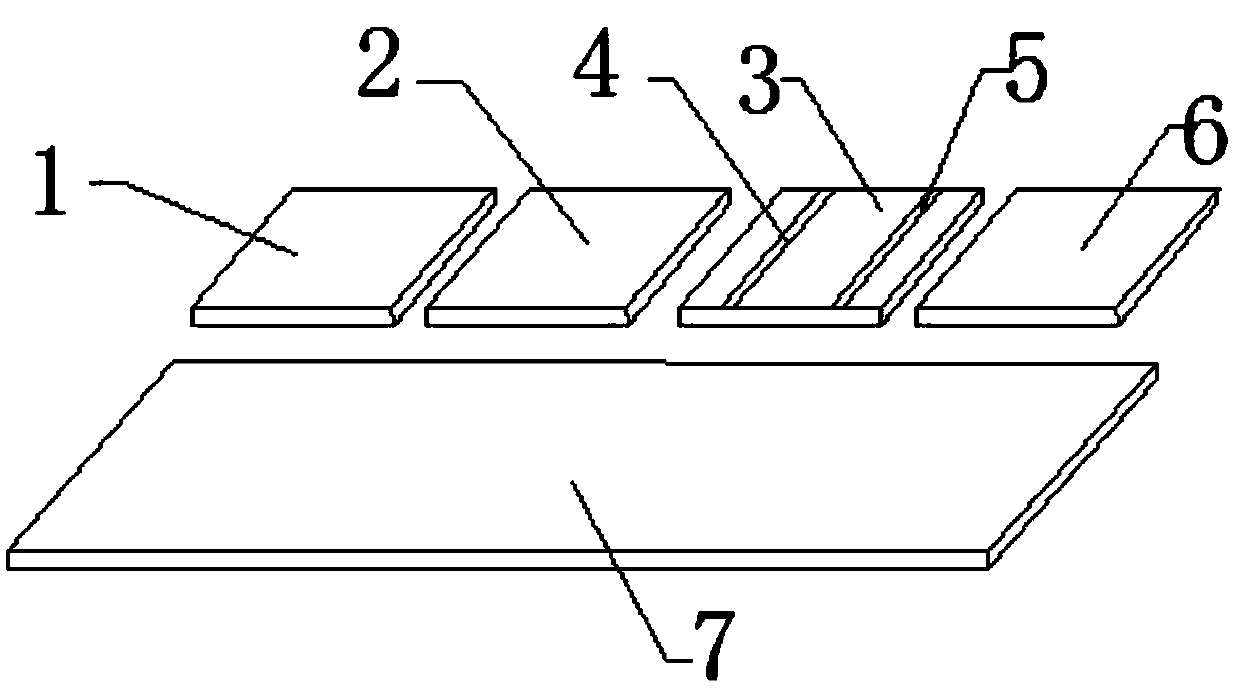

Test strip for detecting concentration of TG (thyroglobulin) and preparation method of test strip

InactiveCN107870234AEasy to getImprove water absorptionBiological testingControl lineTg thyroglobulin

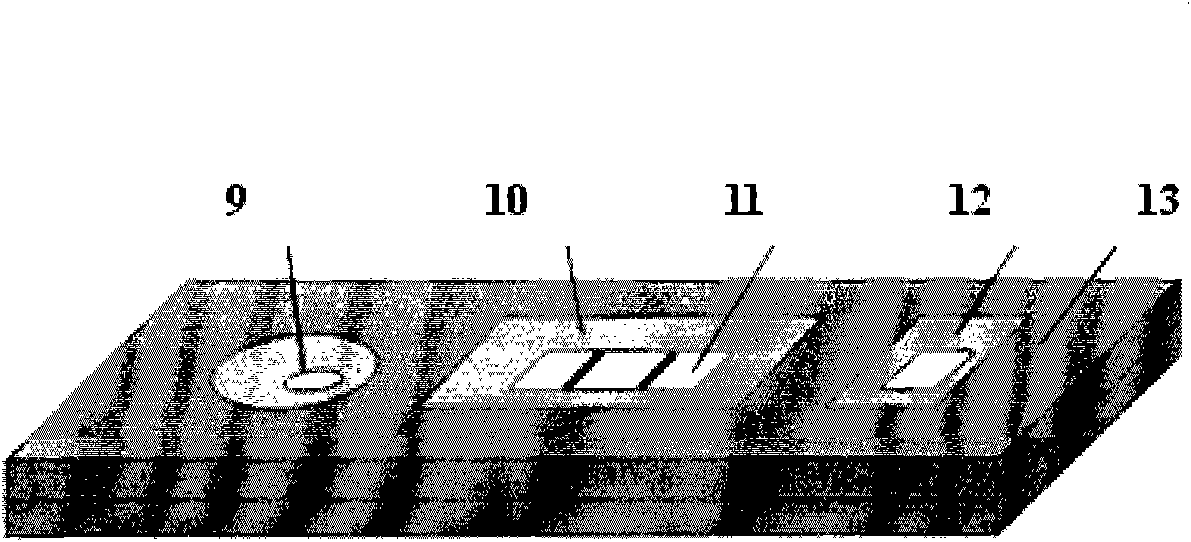

The invention discloses a test paper strip for detecting the concentration of thyroglobulin and a preparation method thereof. The test paper strip comprises strip-shaped nitrocellulose membranes arranged transversely and horizontally, and longitudinally spaced and parallel to each other on the cellulose acetate membrane. A strip-shaped detection line and a quality control line are respectively provided, wherein the end of the nitrocellulose membrane close to the quality control line is abutted against a horizontally arranged strip-shaped water-absorbing pad, and the end of the nitrocellulose membrane close to the detection line Butt against a horizontal strip-shaped colloidal gold pad, and the end of the colloidal gold pad away from the nitrocellulose membrane abuts against a horizontally horizontal strip-shaped sample pad; the colloidal gold pad contains a colloidal gold label pair anti-human thyroglobulin antibody, the detection line is coated with a detection antibody that can specifically bind to the anti-human thyroglobulin antibody, and the quality control line is coated with a detection antibody that can specifically bind to the free anti-human thyroglobulin antibody Quality control antibodies.

Owner:SHIKANGPEI MEDICAL TECH WUHAN CO LTD +1

Preparation method of ordered nano fiber-based flexible graphene film by induction of capillary action

The invention discloses a preparation method of an ordered nano fiber-based flexible graphene film by the induction of capillary action. The preparation method comprises the following steps of dissolving cellulose acetate in acetic acid, uniformly mixing and agitating, so as to obtain a spinning solution, carrying out electrostatic spinning, and drying, so as to obtain a cellulose acetate film; preparing graphene oxide, and purifying and separating through a microporous filtering film to obtain a graphene oxide lamella which is uniform in size and soluble in water; uniformly dispersing the graphene oxide in a substrate of the cellulose acetate film by utilizing a vacuum suction filtration method, and drying to subsequently prepare and obtain a graphene oxide film; thermally reducing a sample of the graphene oxide film through hot compression, so that the flexible graphene film using the cellulose acetate film as the substrate, which is prepared by the induction of the capillary action,can be obtained. A tiny capillary is formed in a micron-nano dimension by utilizing the substrate; the graphene oxide infiltrates to enter the surface of the substrate by utilizing the principle of the capillary action; the physical interaction and the adhesive force, with the substrate, of the graphene oxide film are greatly improved and thus, the flexible graphene film can adapt to the abuttingand the application on the surface of a complicated curved surface.

Owner:SOUTHEAST UNIV

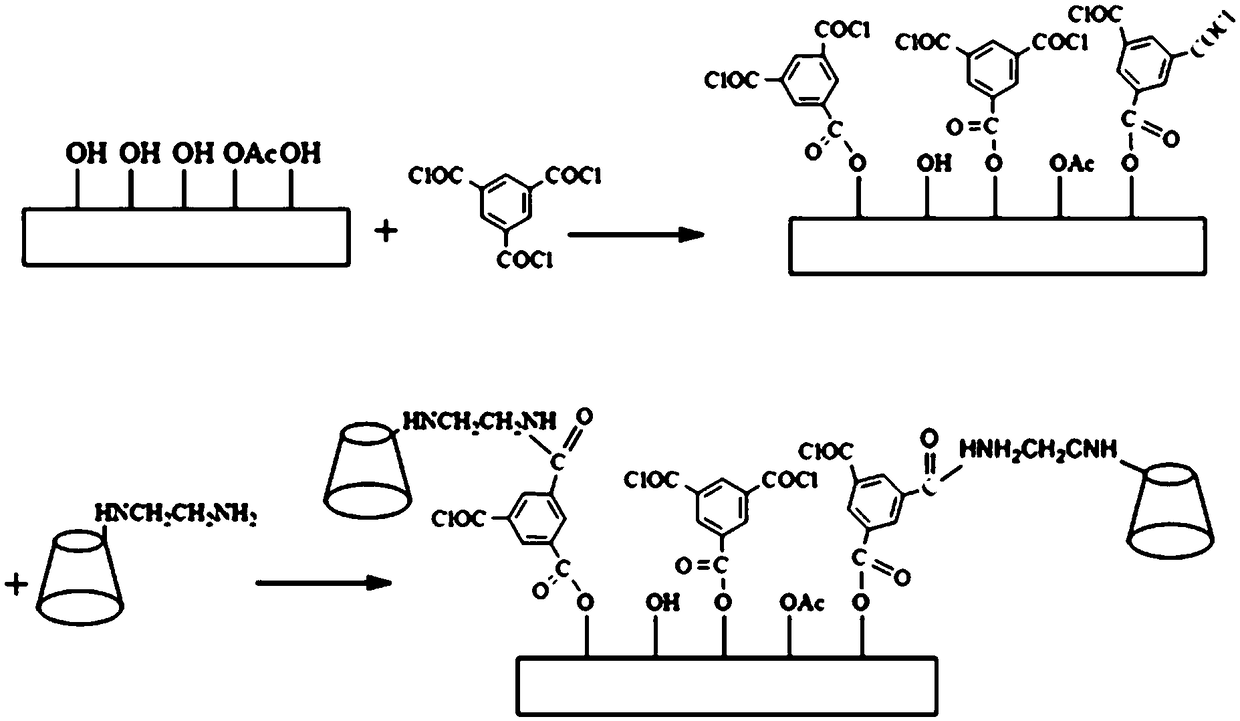

Chiral polyamide film and preparation method and application thereof

ActiveCN109485628AOvercome time-consuming disadvantagesLow costSolid sorbent liquid separationOptically-active compound separationEthylenediamineSulfonyl chloride

The invention discloses chiral polyamide film and a preparation method and application thereof. The chiral polyamide film as an interfacial polyamide cellulose acetate film with a chiral resolving capacity is prepared by: supporting the chiral resolving agent ethanediamine-beta-dextrin to the surface of acetate cellulose film, as a base film, through the bonding agent trimesoyl chloride, to be specific, performing two-step synthesis on beta-dextrin respectively with p-toluene sulfonyl chloride and anhydrous ethylenediamine to obtain ethanediamine modified-beta-dextrin, and performing interfacial polymerizing with the ethanediamine modified-beta-dextrin acting as a chiral resolving agent, trimesoyl chloride as a bonding agent and commercial acetate cellulose material, which has high mechanical strength, high compressive compaction resistance, good chemical stability and low price, as a base film material. The chiral polyamide film herein has low cost, is simple to prepare and is suitable for a wide range of resolving objects.

Owner:CHINA PHARM UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com