Photopolymer thin film photosensitive material used for holographic record, and preparation method therefor

A photopolymer and holographic recording technology, which is applied in the direction of photomechanical equipment, pattern surface photolithography, optics, etc., can solve the problems of low diffraction efficiency, short storage time, poor mechanical properties, etc., and achieve the source of raw materials Wide range, simple synthesis process, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] In addition, the present application also provides a method for preparing a photopolymer film photosensitive material that can be used for holographic recording, including:

[0065] (1) Preparation of photopolymer coating: under dark conditions or under safe lights, base resin, active fluororesin, silane-coupled nanoparticles, active monomer, plasticizer, photoinitiator, photosensitive additives, chain transfer agents, nonionic surfactants, heat stabilizers, optical brighteners, etc. are added to the solvent, stirred and mixed evenly to obtain photopolymer coatings;

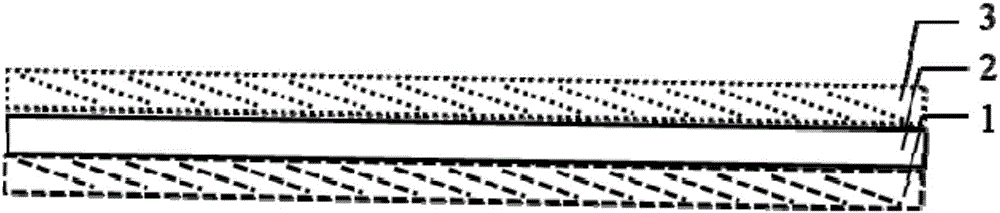

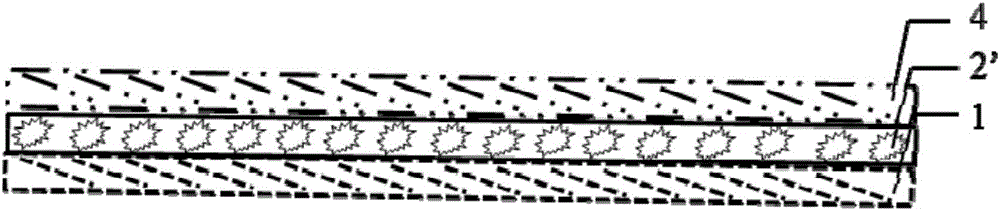

[0066] (2) Preparation of photopolymer film: in dark conditions or under safe lights, apply photopolymer coating on the base film layer, and cover the photopolymer surface after leveling and drying The protective layer;

[0067] The base film layer is one of PET film, PS film, cellulose acetate film or PVC film, and the protective layer is one of silicone oil PET film, cellulose acetate film or PVC film. ...

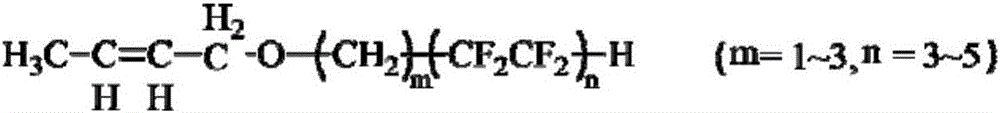

Embodiment 1

[0073] Under dark light or safe light, add in 500ml glass beaker: matrix resin polyvinyl butyral and cellulose acetate copolymer 30g (44.28wt%), active fluororesin BY-F500 (provided by Beijing Baiyuan chemical industry, has Structural formula 1) 8g (11.8wt%), self-made coupling nano-alumina particles 2g (2.95wt%), active liquid monomer 2-phenoxyethyl acrylate 3.4g (5.02wt%), ethylene glycol di Methacrylate 9.6g (14.17wt%), active solid monomer N-vinyl carbazole etc. 5.4g (7.97wt%), photoinitiator 2-(o-chlorophenyl)-4,5-bis(m- Methoxyphenyl) imidazole 1.8g (2.66wt%), photosensitizer 2,5-bis{[4-(diethylamino)-2-methylphenyl]-methylene}cyclopentanone 0.01g (0.015wt%), chain transfer agent: 4-methyl-4H-3-mercapto-1,2,4-triazole 4g (5.9wt%), plasticizer triethylene glycol diacrylate 3g (4.43 wt%) nonionic surfactant FC-4430 0.24g (0.35wt%), thermal stabilizer β-naphthol 0.2g (0.295wt%), optical brightener 7-(4'-chloro-6'-di Ethylamino-1',3',5'-triazine-4'-amino)-3-phenylcoumari...

Embodiment 2

[0077] Under dark or safe light, add in 500ml glass beaker: matrix resin polyvinyl acetate 50g (48.20wt%), active fluororesin BY-F400 (provided by Beijing Baiyuan chemical industry, have structural formula 2) 10g (9.64wt%) ), self-made coupling nano-alumina particles 3g (2.89wt%), active liquid monomer 2-(p-chlorophenoxyethyl methacrylate) 6g (5.78wt%), ethylene glycol dimethyl Acrylate 14g (13.50wt%), active solid monomer N-vinylcarbazole etc. 10g (9.64wt%), photoinitiator 2,2'-bis(o-chlorophenyl)-4,4',5, 5'-tetraphenyl 1,1'-diimidazole 2.4g (2.31wt%), photosensitizer 2,5-bis{[4-(diethylamino)phenyl]methylene}cyclopentanone 0.02g (0.019wt%), chain transfer agent: 2-mercaptobenzoxazole 3g (2.89wt%), plasticizer diethyl adipate 5g (4.82wt%) nonionic surfactant FC-4430 0.12g (0.12wt%), thermal stabilizer p-methoxyphenol 0.15g (0.14wt%), optical brightener 7-(4'-chloro-6'-diethylamino-1',3',5'- Triazine-4'-amino)-3-phenylcoumarin 0.05g (0.05wt%), mixed solvent 150ml, wherein bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com