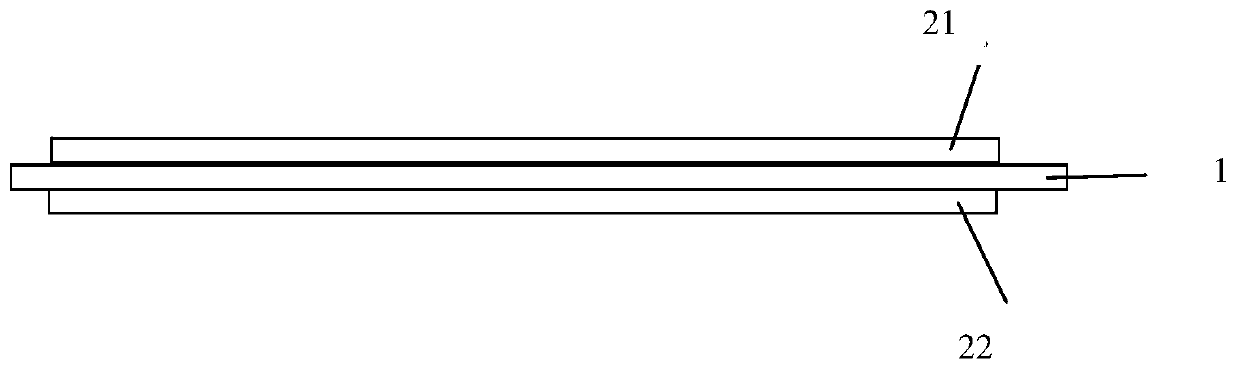

Biodegradable paper-plastic composite structure and preparation method thereof

A paper-plastic composite and biodegradable technology, applied in chemical instruments and methods, paper/cardboard layered products, cellulose plastic layered products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

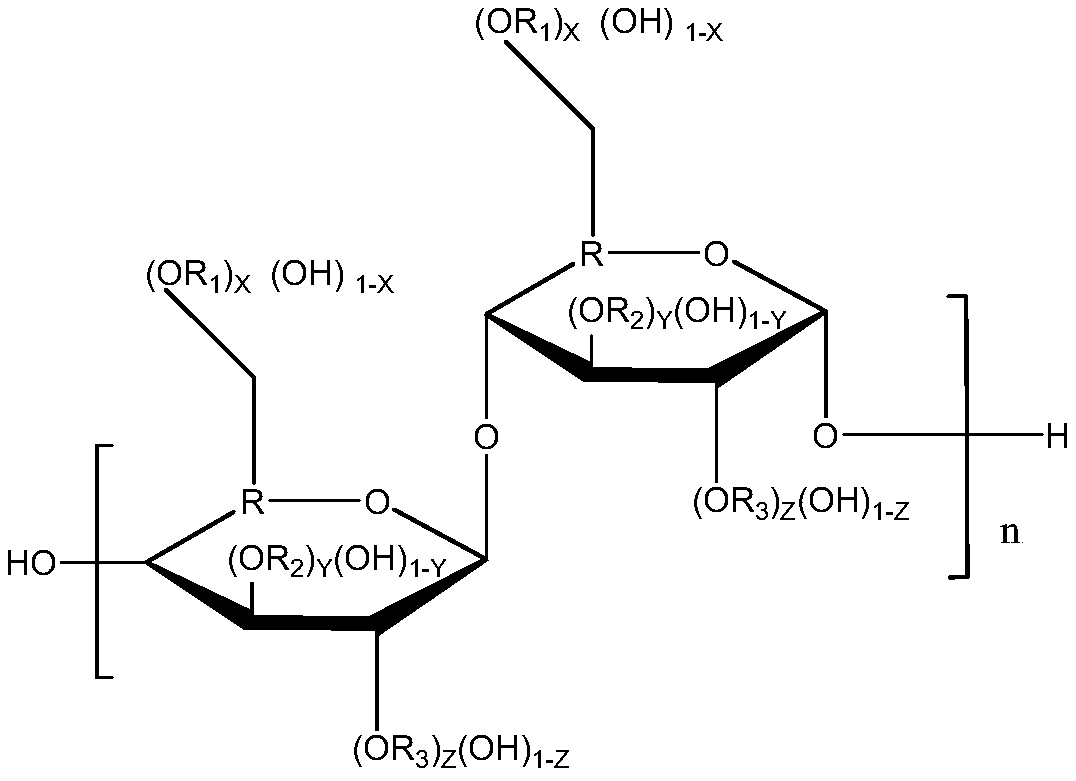

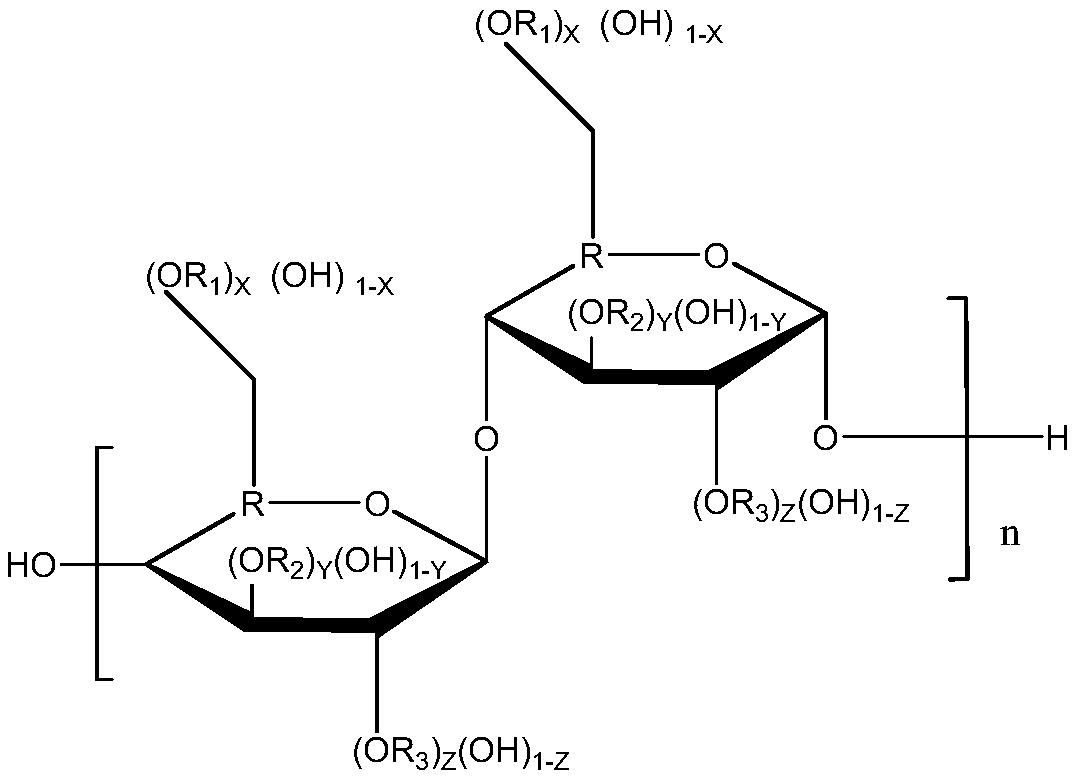

Method used

Image

Examples

Embodiment 1

[0085] 1) The cellulose acetate was crushed into a powder with a particle size of 200 μm in a grinder (the degree of acetyl substitution was 2.45, the intrinsic viscosity was 1.54 dL / g, the number average molecular weight was 37000, the weight average molecular weight was 63000, and the Mw / Mn was 1.7).

[0086] 2) Dry 70 parts of cellulose acetate powder at 120° C. for 2 hours, mix with 30 parts of glyceryl triacetate and 1 part of antioxidant 1010, and mix them uniformly on a mixer.

[0087] 3) Add the above-mentioned powder into the twin-screw extruder for plasticization and extrusion. The temperatures of the six heating zones of the twin-screw machine are 130 / 150 / 165 / 180 / 190 / 190 respectively, and the temperature of the head is 190°C. The head pressure is 0.2-0.4Mpa, and the screw speed is 50-90 rpm.

[0088] 4) The extruded filaments are stretched, cooled, and pelletized to make cellulose acetate plastic particles. The melt index is 100g / 10min.

Embodiment 2

[0090] 1) The cellulose acetate was crushed into a powder with a particle size of 200 μm in a grinder (the degree of acetyl substitution was 2.45, the intrinsic viscosity was 1.54 dL / g, the number average molecular weight was 37000, the weight average molecular weight was 63000, and the Mw / Mn was 1.7).

[0091] 2) After drying 70 parts of cellulose acetate powder at 120° C. for 2 hours, mix with 30 parts of triethylene glycol dimethyl ether and 1 part of antioxidant 1010 on a mixer.

[0092] 3) Add the above-mentioned powder into the twin-screw extruder for plasticization and extrusion. The temperatures of the six heating zones of the twin-screw machine are 130 / 150 / 165 / 180 / 190 / 190 respectively, and the temperature of the head is 190°C. The head pressure is 0.2-0.4Mpa, and the screw speed is 50-90 rpm.

[0093] 4) The extruded filaments are stretched, cooled, and pelletized to make cellulose acetate plastic particles. The melt index was 310 g / 10 min.

Embodiment 3

[0095] 1) Put the particles in Example 1 into a twin-screw extruder, heat at 200° C., and extrude through a die with a thickness of 1 mm to form a film.

[0096] 2) Stretching by stretching rollers 5 times to obtain a film with a thickness of 100 μm.

[0097] The contact angle of the prepared film was 76 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com