Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

622 results about "Degree of substitution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Degree of Substitution Explained: The degree of substitution (DS) of a polymer is the average number of substituent groups attached per base unit (in most cases of condensation of polymers) or per monomeric unit (in the case of addition polymers). The term has been mainly used in cellulose chemistry.

Cellulose Esters with High Hyrdoxyl Content and Their Use in Liquid Crystal Displays

InactiveUS20090096962A1Simple processEliminating layerLiquid crystal compositionsSynthetic resin layered productsLiquid-crystal displayDegree of substitution

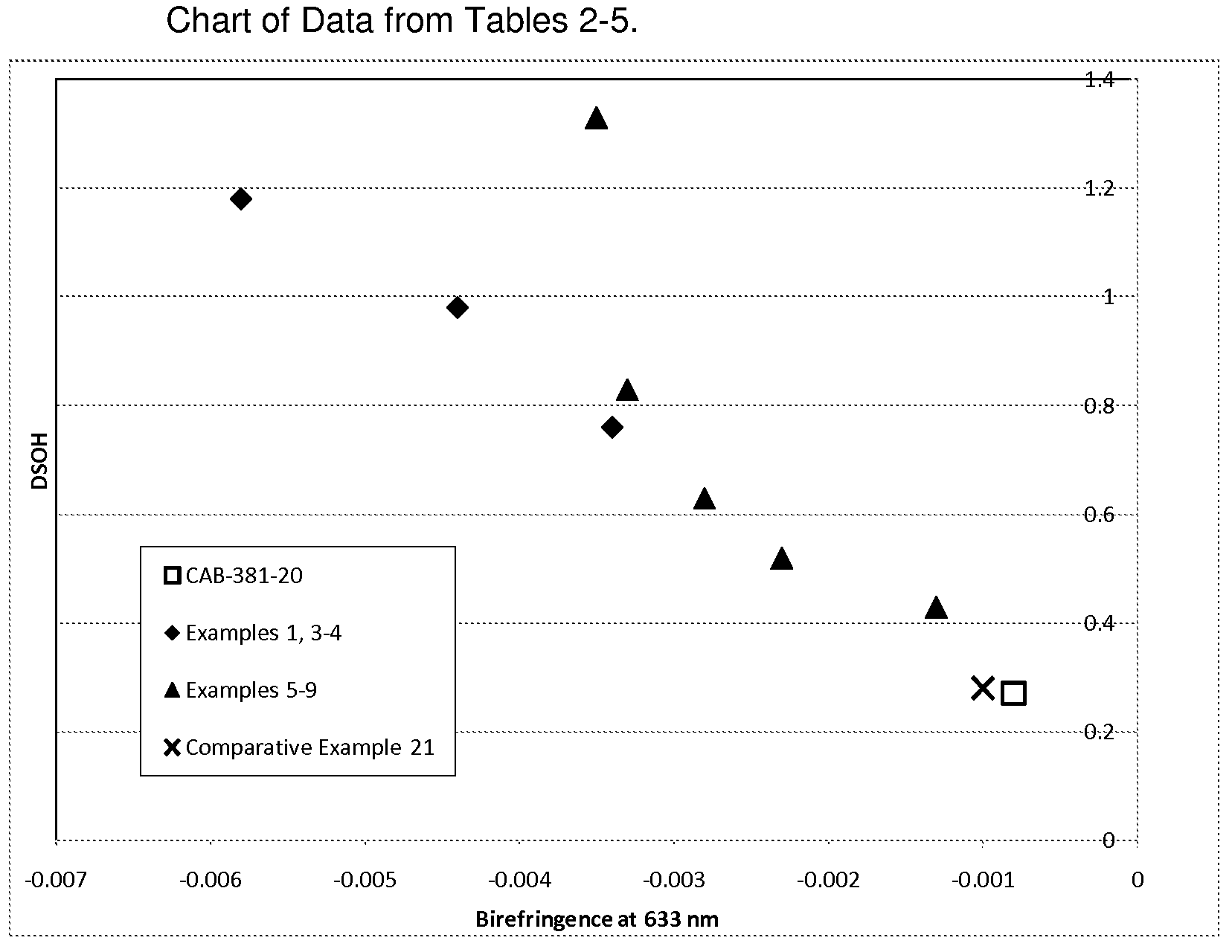

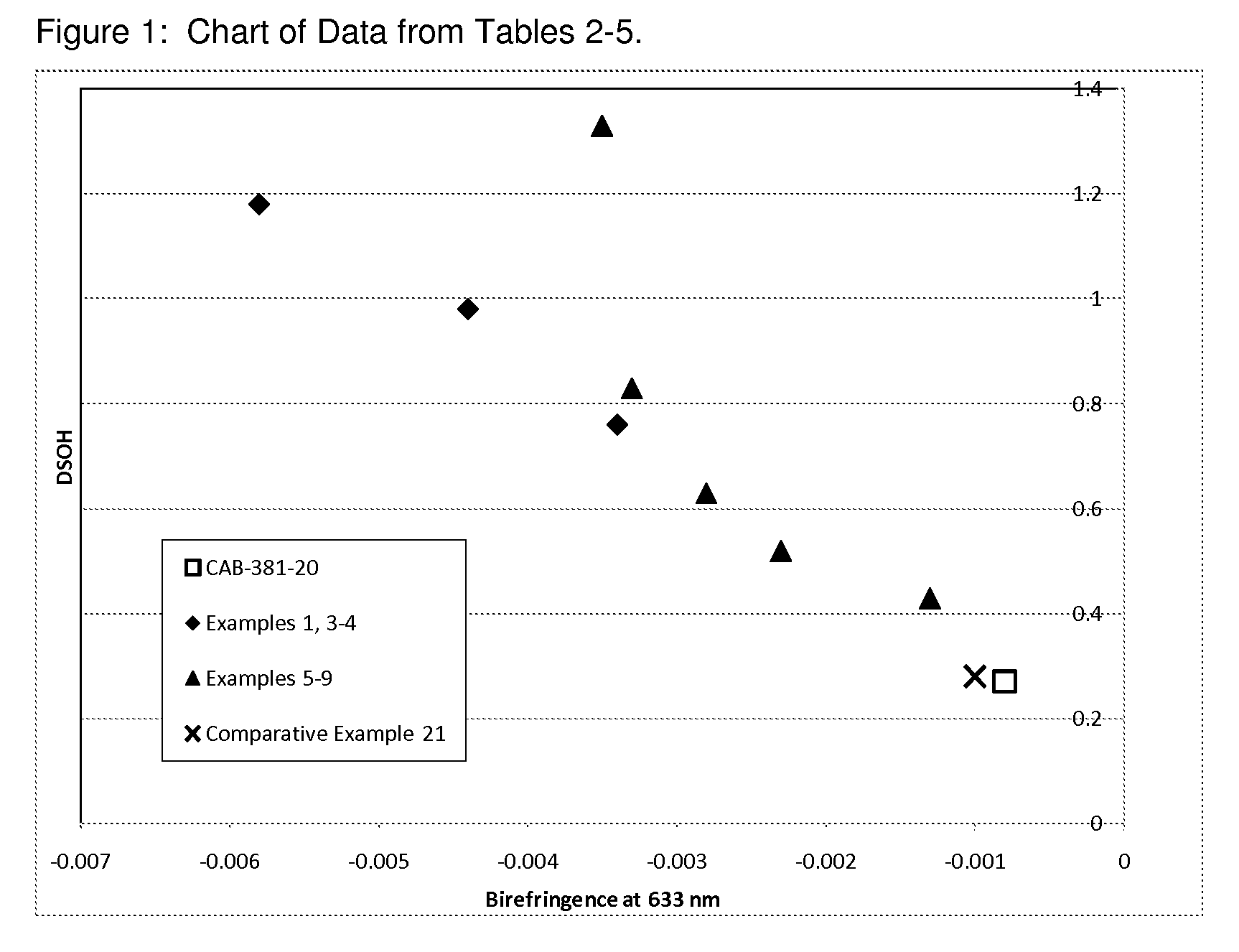

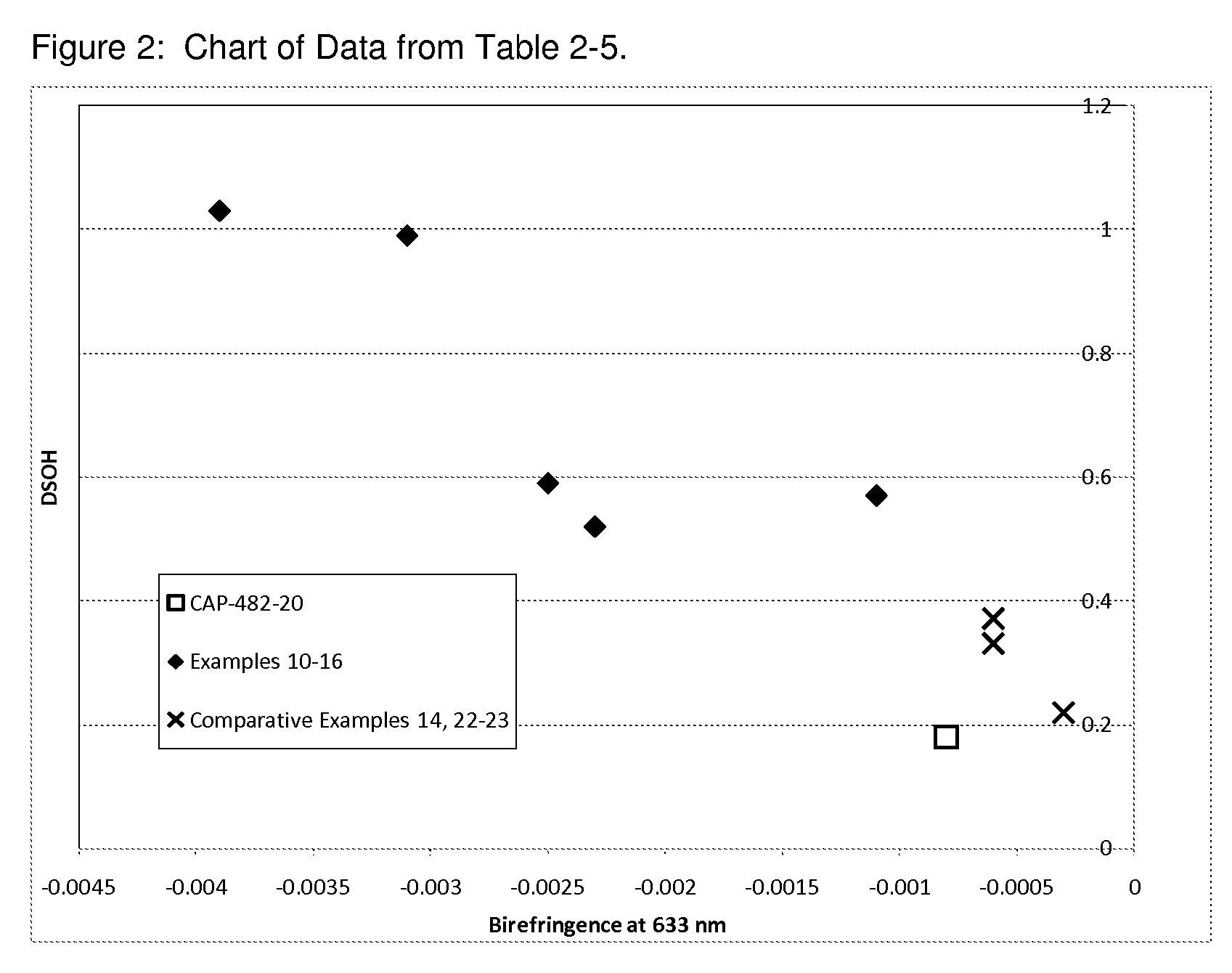

The invention relates to the preparations and uses of cellulose esters with a high degree of substitution of hydroxyl groups (also called high DSOH cellulose esters) as substrates and / or negative C-plate optical compensation films in LCD applications.

Owner:EASTMAN CHEM CO

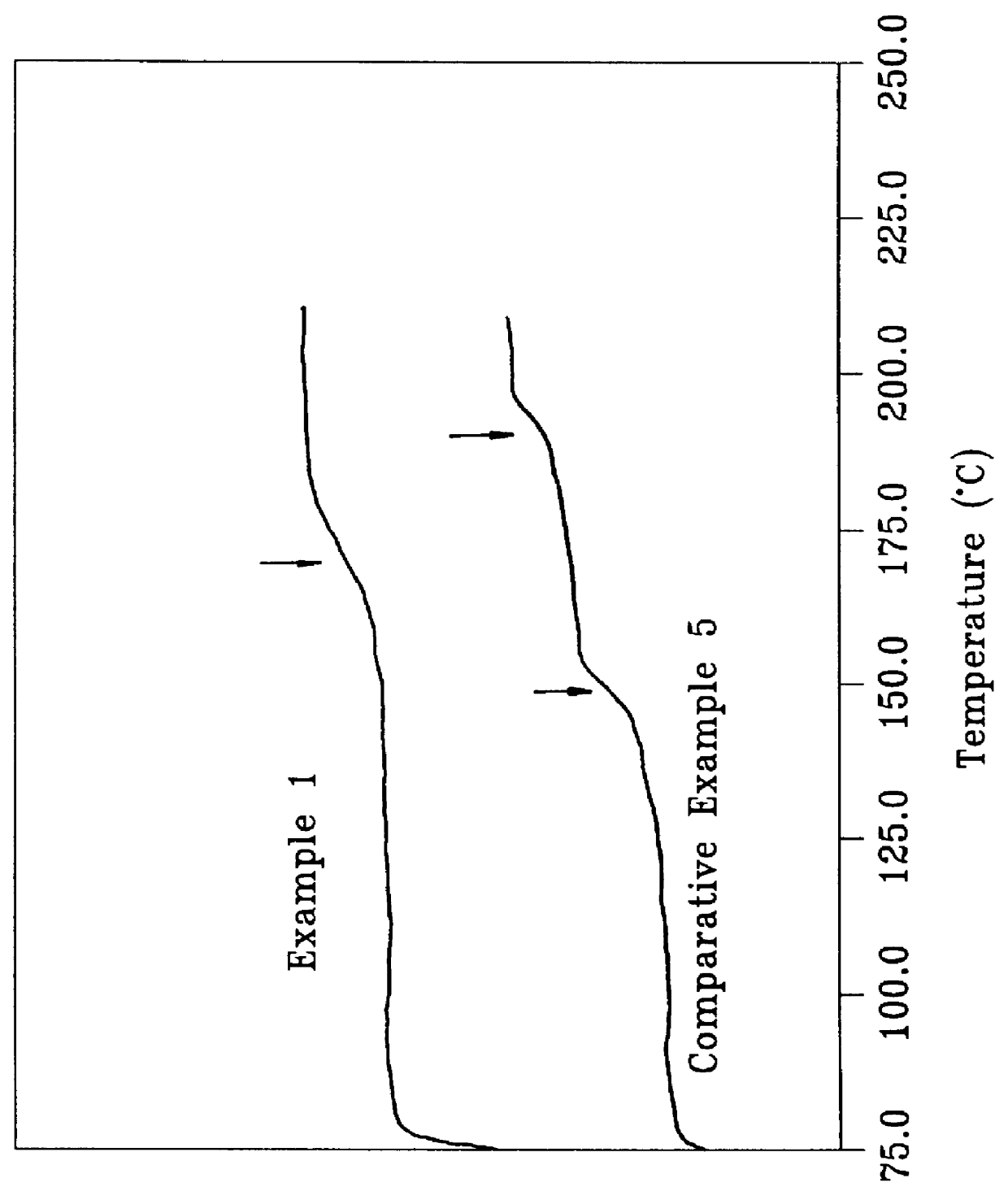

Melt-blown nonwoven fabric, process for producing same and the uses thereof

InactiveUS6207601B1Avoid undesirable oxidative processEliminate useLayered productsTobacco smoke filtersMean diameterPolymer science

The disclosure relates to a melt-blown non-woven fabric based on cellulose esters, with fibers of mean diameter less than about 10 microns. The fabric contains 0-10 wt. % extractable softener, has a reflection factor determined according to DIN 53 145 Part I (1992) of more than 60% and the cellulose ester has a degree of substitution DS of about 1.5-3.0. The softener is preferably water-extractable. A melt-blown non-woven fabric is produced with the cellulose ester as follows: a cellulose ester, cellulose acetate, with a DS of about 1.5-3.0, in particular 1.7-2.7, is mixed with softener in a weight ratio of about 2:1 to 1:4 and simultaneously heated and melted. The mixture of softener and cellulose ester has a melting index MFI (210 / 2.16) according to DIN 53 735 of about 400 to 5 g / 10 min., in particular 300 to 50 g / 10 min. The melt is worked in a melt-blown spinning device into a melt-blown non-woven fabric and the softener is then extracted with a softener solvent to leave a proportion of 0-10 wt. %. The melt-blown non-woven fabric is especially suitable as a filter material.

Owner:RHODIA ACETOW AG

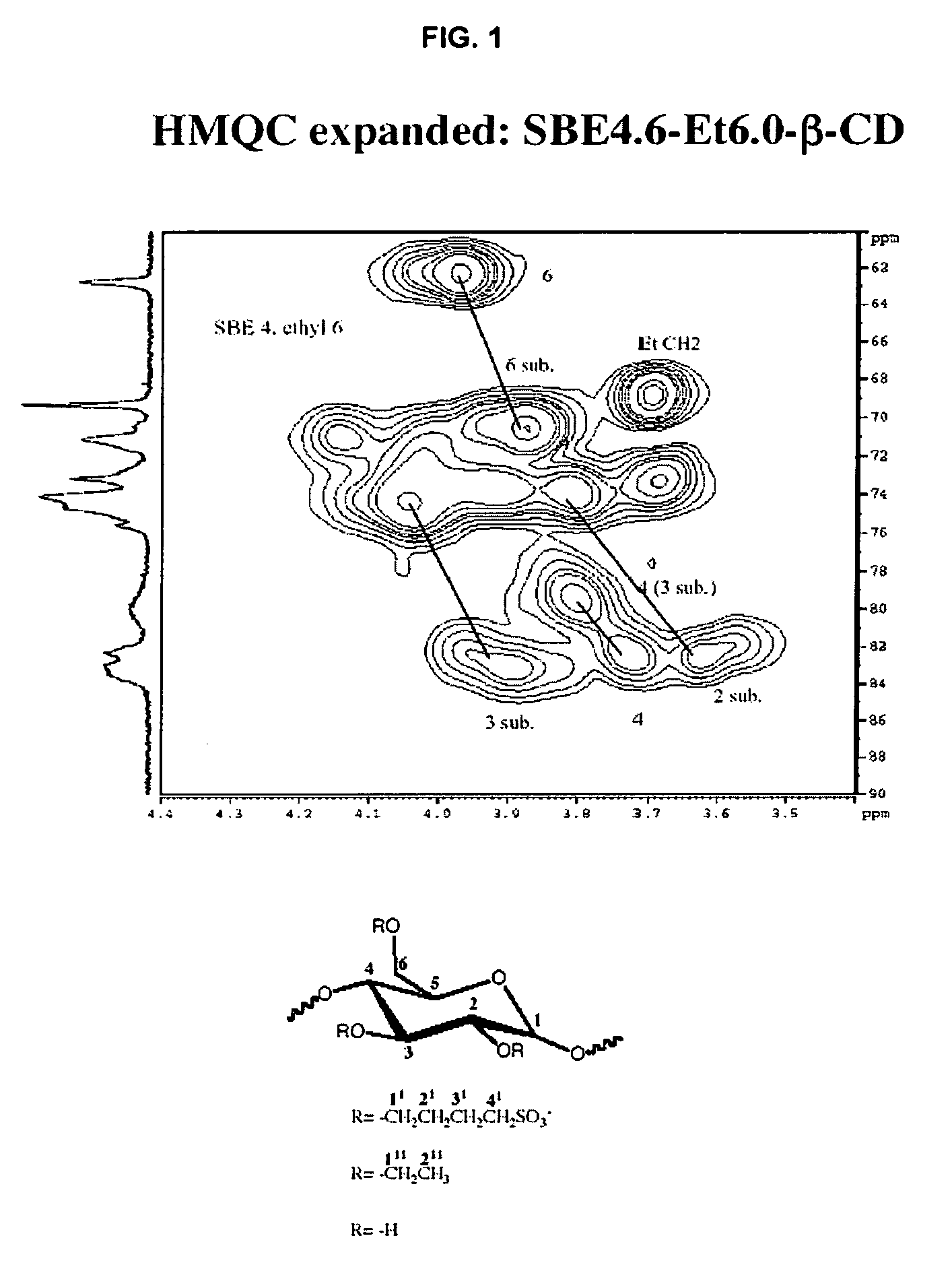

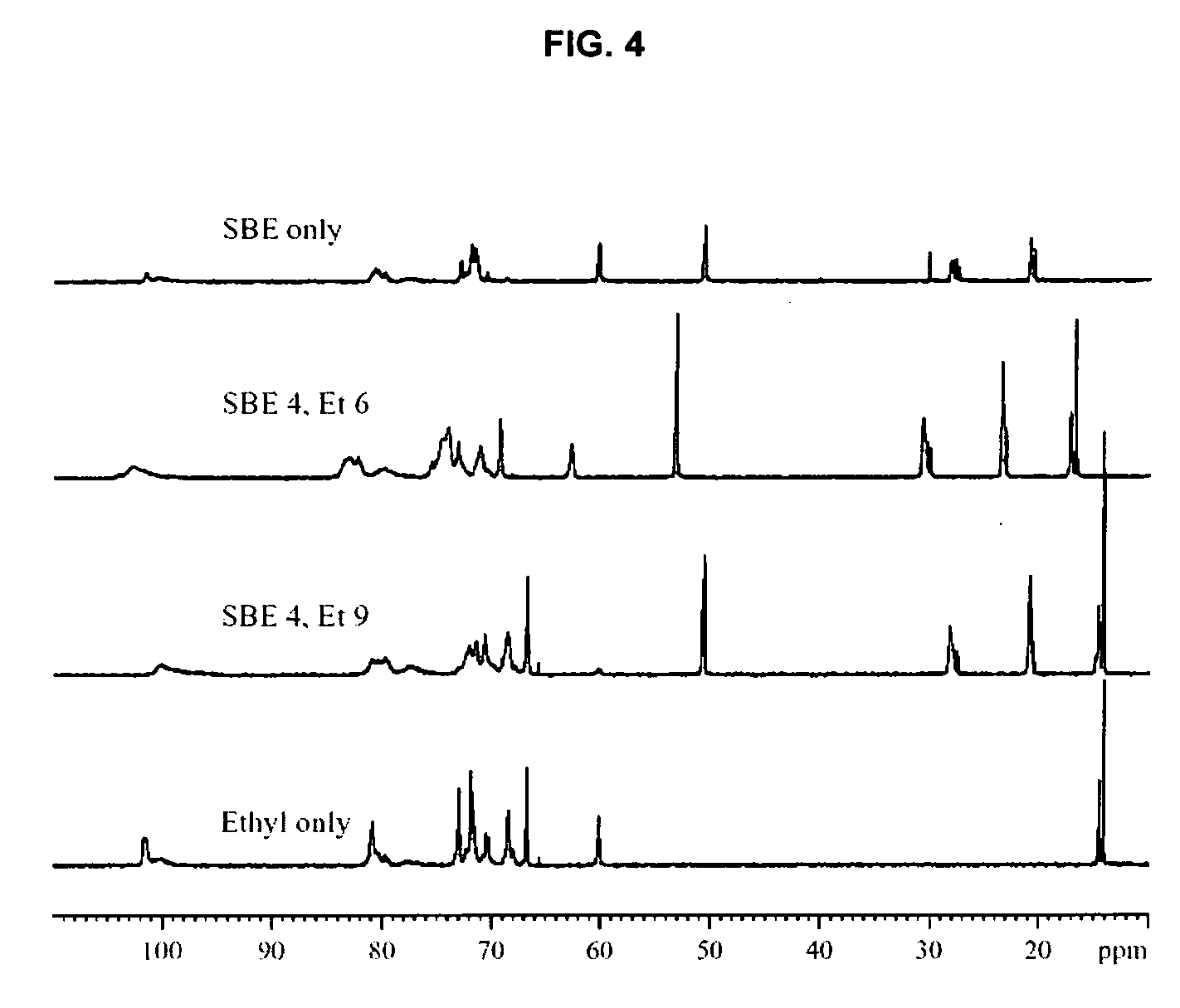

Sulfoalkyl ether-alkyl ether cyclodextrin derivatives

ActiveUS7625878B2Improve propertiesHigh degree of substitutionBiocideOrganic active ingredientsSolubilityCyclodextrin derivative

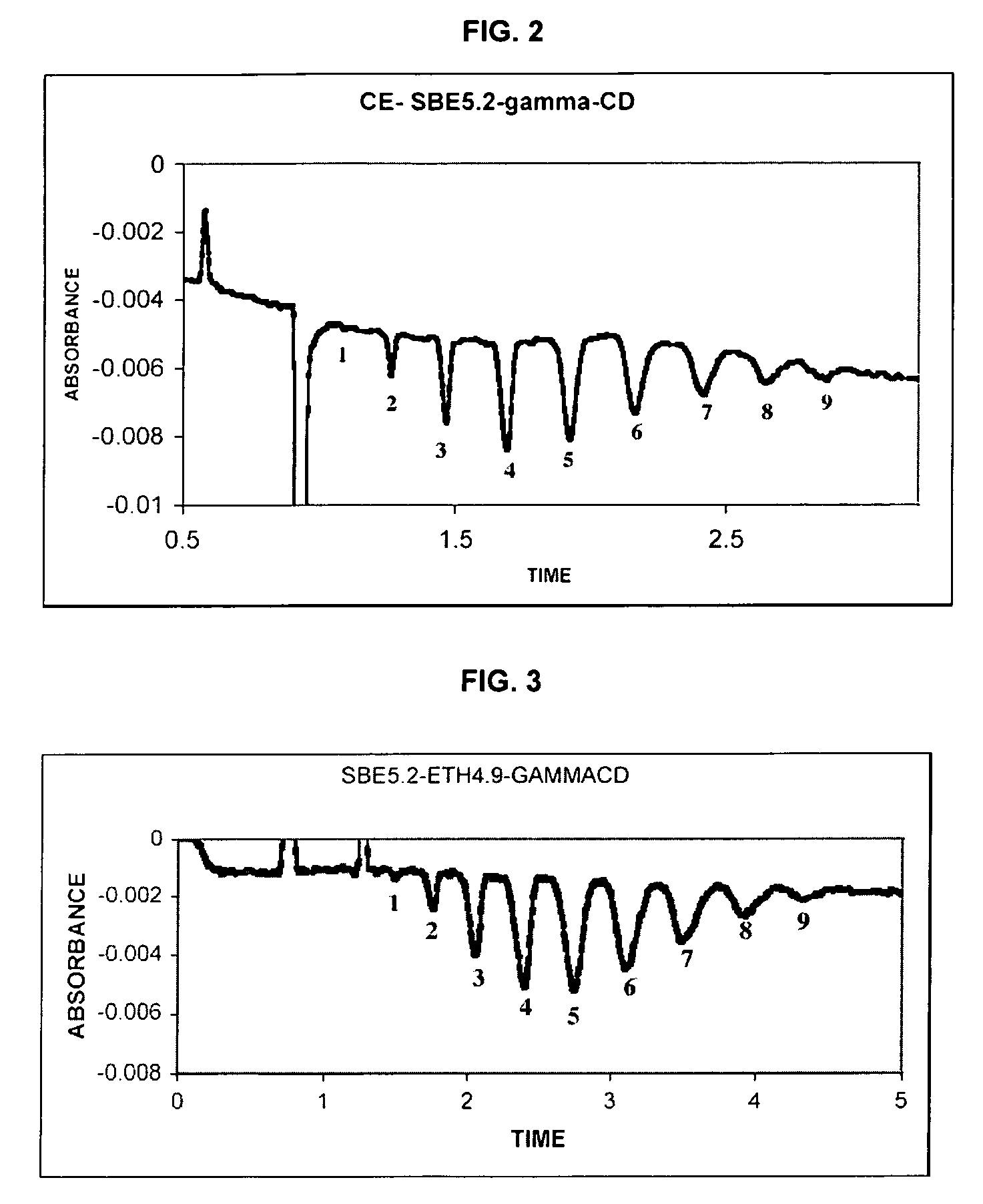

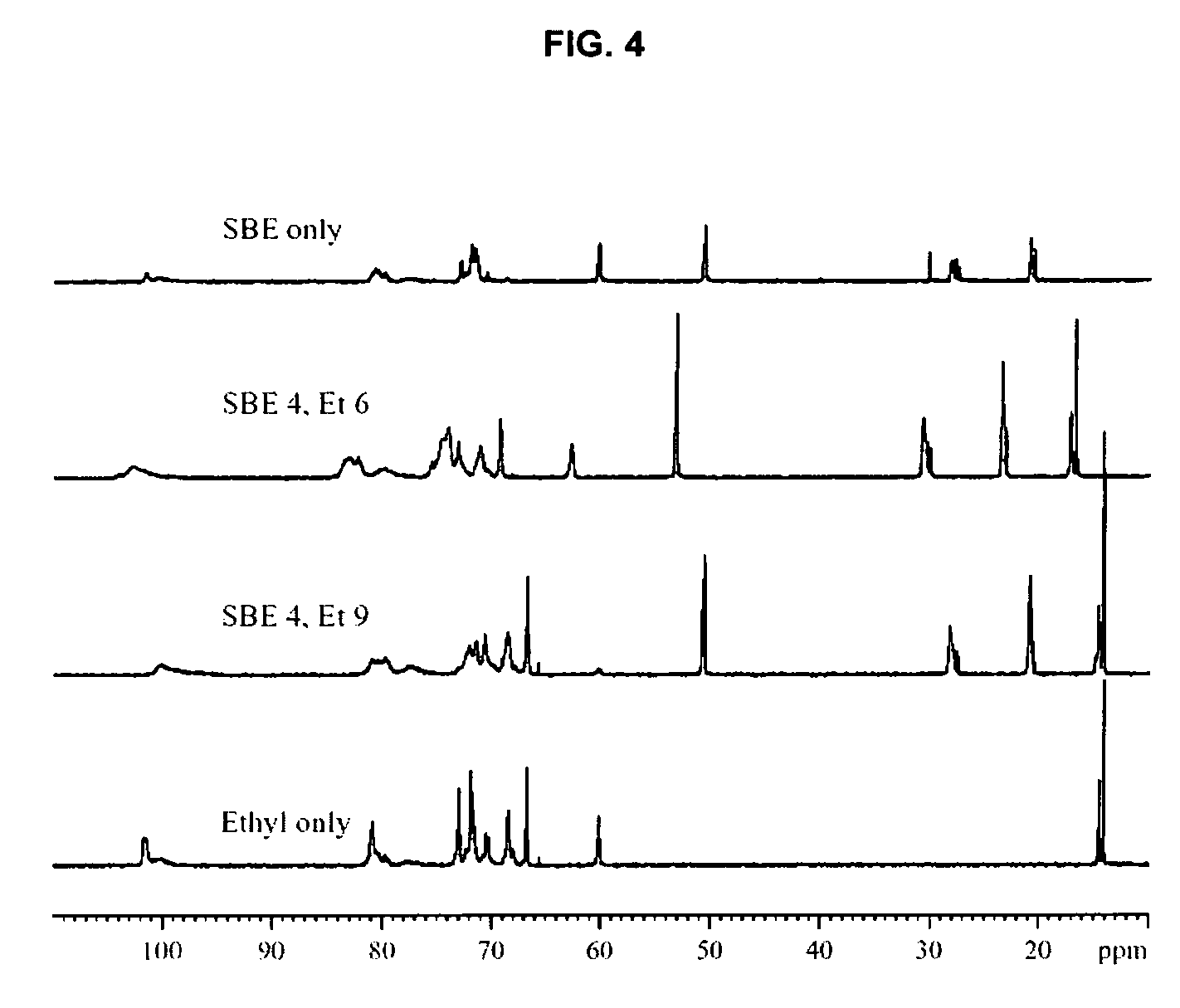

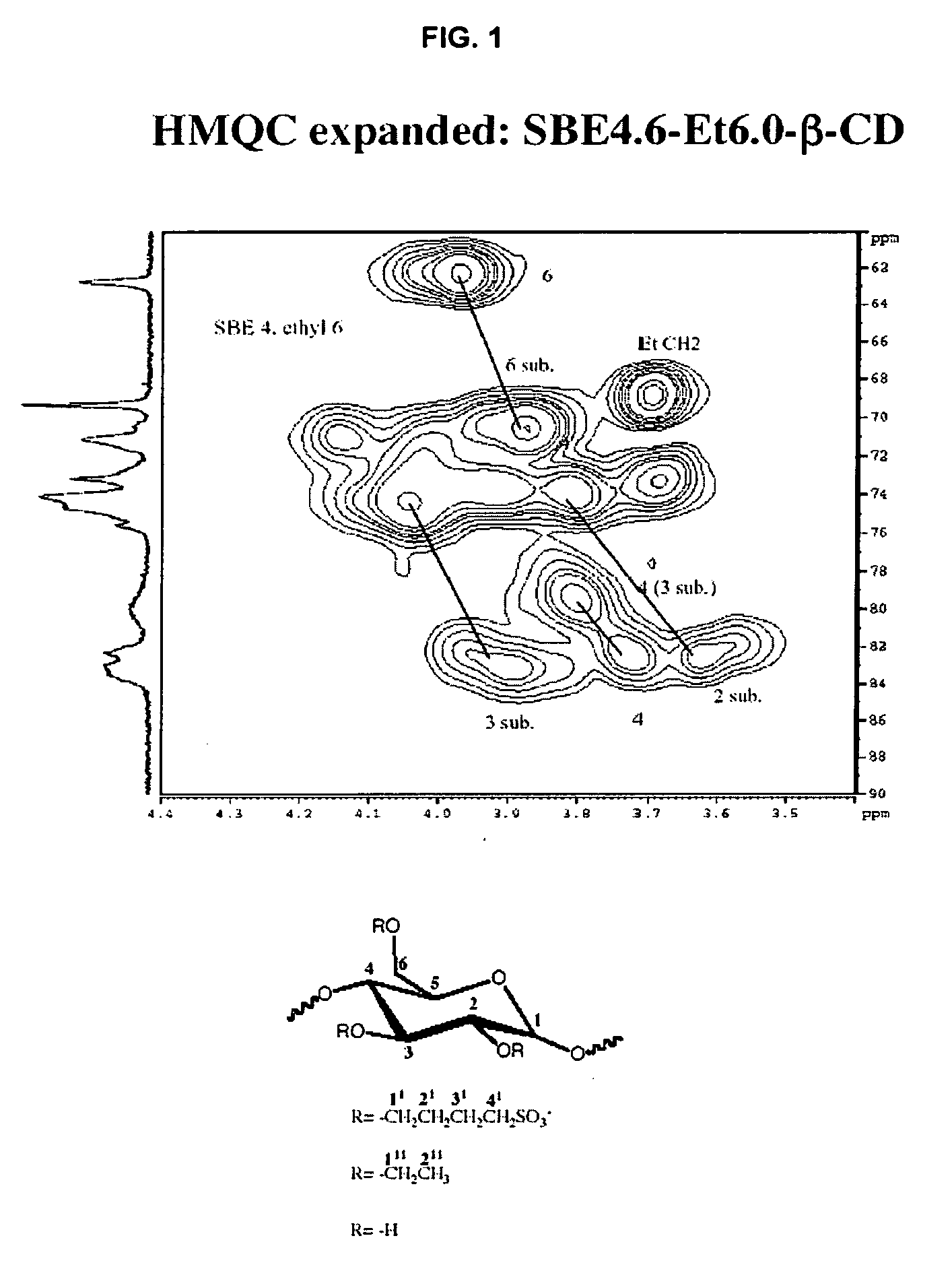

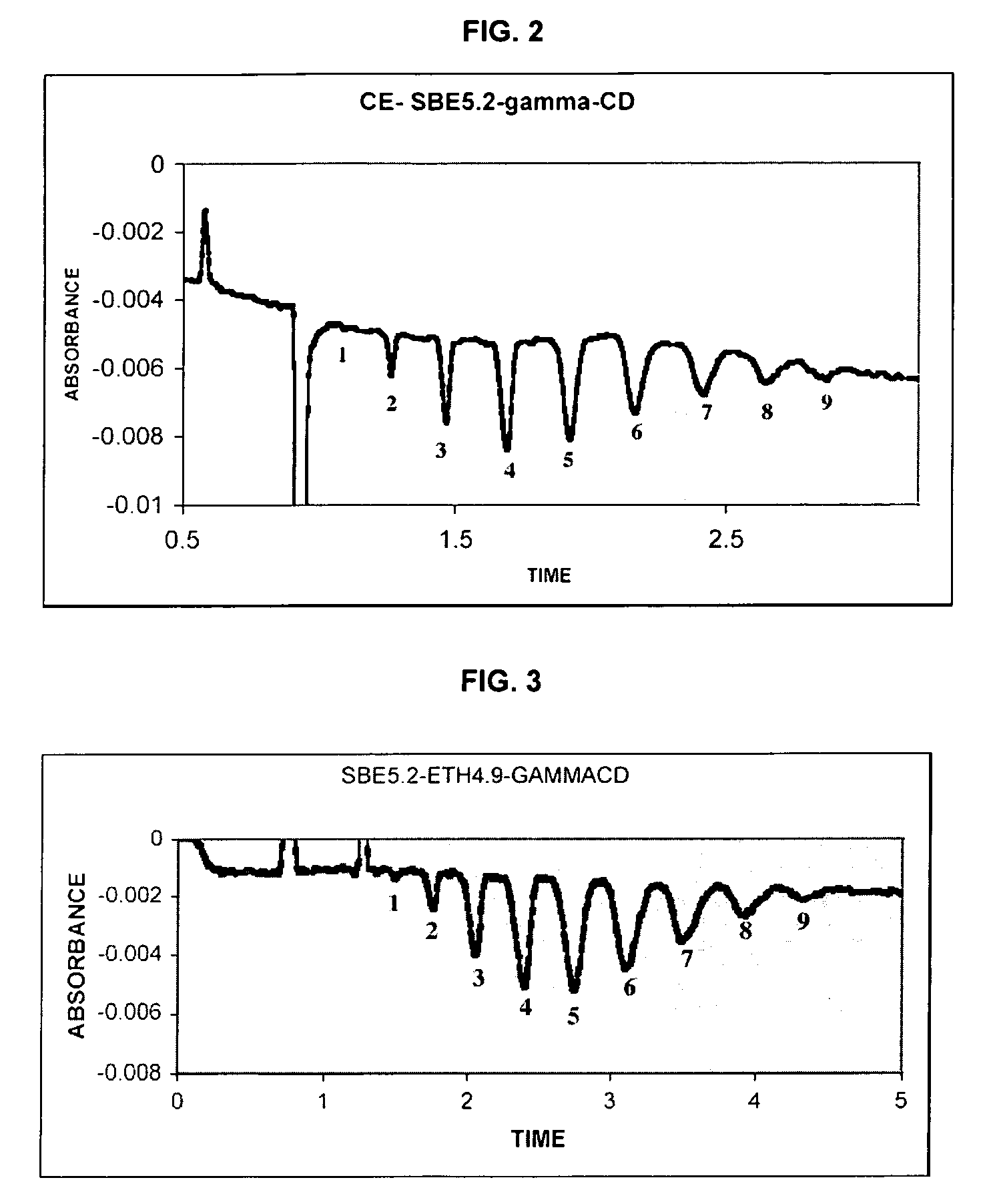

A sulfoalkyl ether-alkyl ether cyclodextrin (SAE-AE-CD) derivative is provided. The SAE-AE-CD possesses advantages over known SAE-CD and AE-CD derivatives as well as over the parent cyclodextrin by being more water soluble and less membrane disturbing. The SAE-AE-CD includes at least one sulfoalkyl ether group and at least one alkyl ether group even though the degree of substitution for the functional groups can be different. The SAE functional group can be present in molar excess over the AE functional group and vice versa. The total degree of substitution of the cyclodextrin, with respect to both functional groups, can be varied such that a minority or a majority of the hydroxyl moieties of the CD are derivatized. The SAE-AE-CD derivative can be used to solubilize compounds with insufficient water solubility. In some cases, they also stabilize compounds in solution against degradation or to solubilize degradation products formed during degradation. In addition, SAE-AE-CD can also be used for other purposes such as osmotic agents, agents used to mask the taste of problematic drugs. Surprisingly, while AE-CDs are known to be toxic by being membrane disturbing, SAE-AE-CDs are less membrane disturbing and therefore have greater safety.

Owner:UNIVERSITY OF KANSAS

Fracturing fluids and methods of making and using same

InactiveUS6844296B2High viscosityImprove conductivityCosmetic preparationsOther chemical processesPolymer scienceFracturing fluid

Fracturing fluid compositions and methods for their preparation and use are disclosed. The compositions are useful in the oil and gas drilling operations, as well as in gravel packing operations, water blocking, temporary plugging for purposes of wellbore isolation and / or fluid loss control, and other uses. The compositions comprise a liquid, a polymer soluble in the liquid, having a degree of substitution of ionic groups of about 0.01 to about 0.1; and a crosslinking agent capable of increasing the viscosity of the fracturing fluid by crosslinking the polymer in liquid.

Owner:BJ ENERGY SOLUTIONS LLC +1

Sulfoalkyl ether-alkyl ether cyclodextrin derivatives

ActiveUS20060258537A1Improve propertiesHigh degree of substitutionOrganic active ingredientsBiocideSolubilityCyclodextrin Derivatives

A sulfoalkyl ether-alkyl ether cyclodextrin (SAE-AE-CD) derivative is provided. The SAE-AE-CD possesses advantages over known SAE-CD and AE-CD derivatives as well as over the parent cyclodextrin by being more water soluble and less membrane disturbing. The SAE-AE-CD includes at least one sulfoalkyl ether group and at least one alkyl ether group even though the degree of substitution for the functional groups can be different. The SAE functional group can be present in molar excess over the AE functional group and vice versa. The total degree of substitution of the cyclodextrin, with respect to both functional groups, can be varied such that a minority or a majority of the hydroxyl moieties of the CD are derivatized. The SAE-AE-CD derivative can be used to solubilize compounds with insufficient water solubility. In some cases, they also stabilize compounds in solution against degradation or to solubilize degradation products formed during degradation. In addition, SAE-AE-CD can also be used for other purposes such as osmotic agents, agents used to mask the taste of problematic drugs. Surprisingly, while AE-CDs are known to be toxic by being membrane disturbing, SAE-AE-CDs are less membrane disturbing and therefore have greater safety.

Owner:UNIVERSITY OF KANSAS

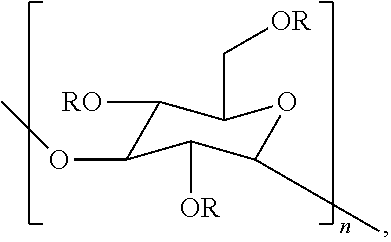

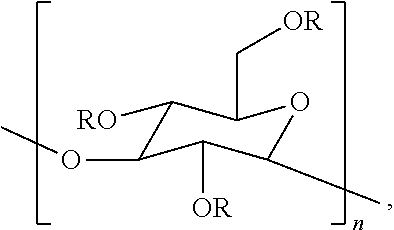

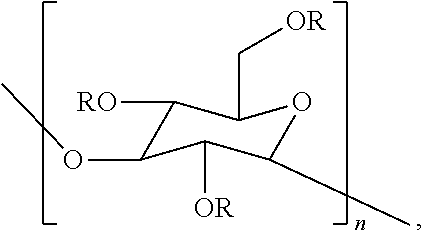

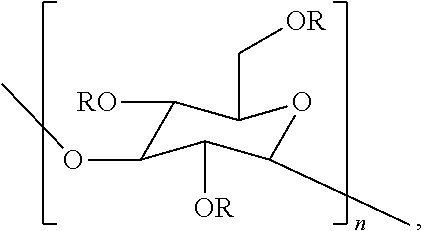

Compositions containing one or more poly alpha-1,3-glucan ether compounds

Compositions comprising cellulase and at least one poly alpha-1,3-glucan ether compound having a degree of substitution with an organic group of about 0.05-3.0 are disclosed. Such compositions can be dry or aqueous, the latter of which can have a viscosity of at least about 10 cPs. The disclosed composition can be in the form of a personal care product, household product, or industrial product, for example. Also disclosed are a method for preparing an aqueous composition comprising cellulase and a poly alpha-1,3-glucan ether compound, and a method of treating a material such as fabric by contacting it with this aqueous composition.

Owner:NUTRITION & BIOSCIENCES USA 4 INC

Liquid laundry detergents containing cationic hydroxyethyl cellulose polymer

InactiveUS7576048B2Organic detergent compounding agentsNon-ionic surface-active compoundsLiquid laundry detergentDegree of substitution

Aqueous liquid laundry detergent compositions useful for cleaning fabrics wherein the compositions contain from about 0.05% to about 0.4%, by weight of the composition, of a cationic hydroxyethyl cellulose polymer having a degree of substitution of the cationic charge of from about 0.01 to about 0.20; from about 5% to about 30%, by weight of the composition, of a surfactant comprising at least one anionic surfactant and at least one nonionic surfactant; and from about 2% to about 15%, by weight of the composition, of fatty acid. Use of such aqueous liquid laundry detergent compositions for handwashing delicate fabrics. Use of such aqueous liquid laundry detergent compositions for machine washing of delicate fabrics, wherein the machine washing occurs at a delicate machine setting.

Owner:THE PROCTER & GAMBLE COMPANY

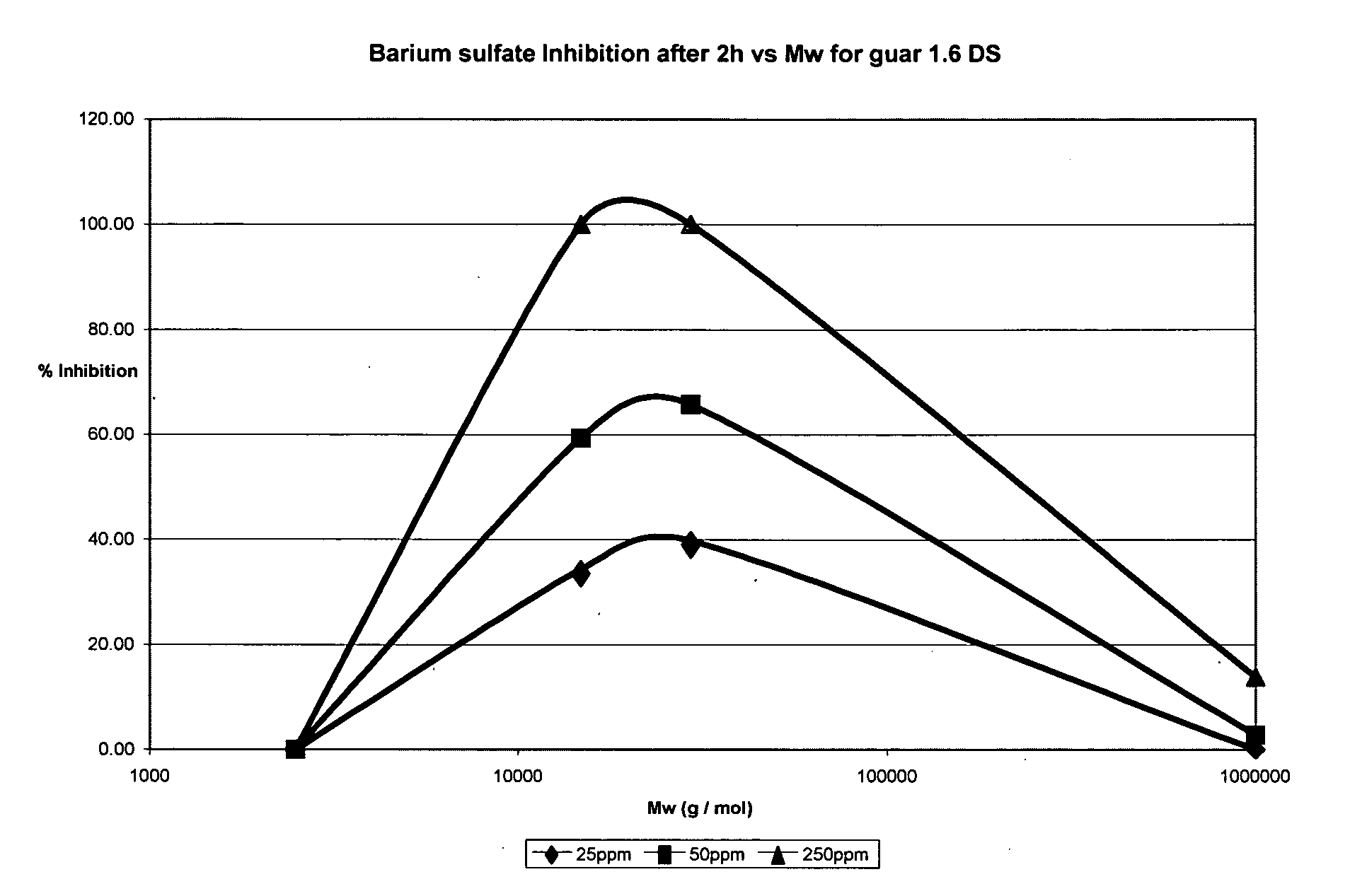

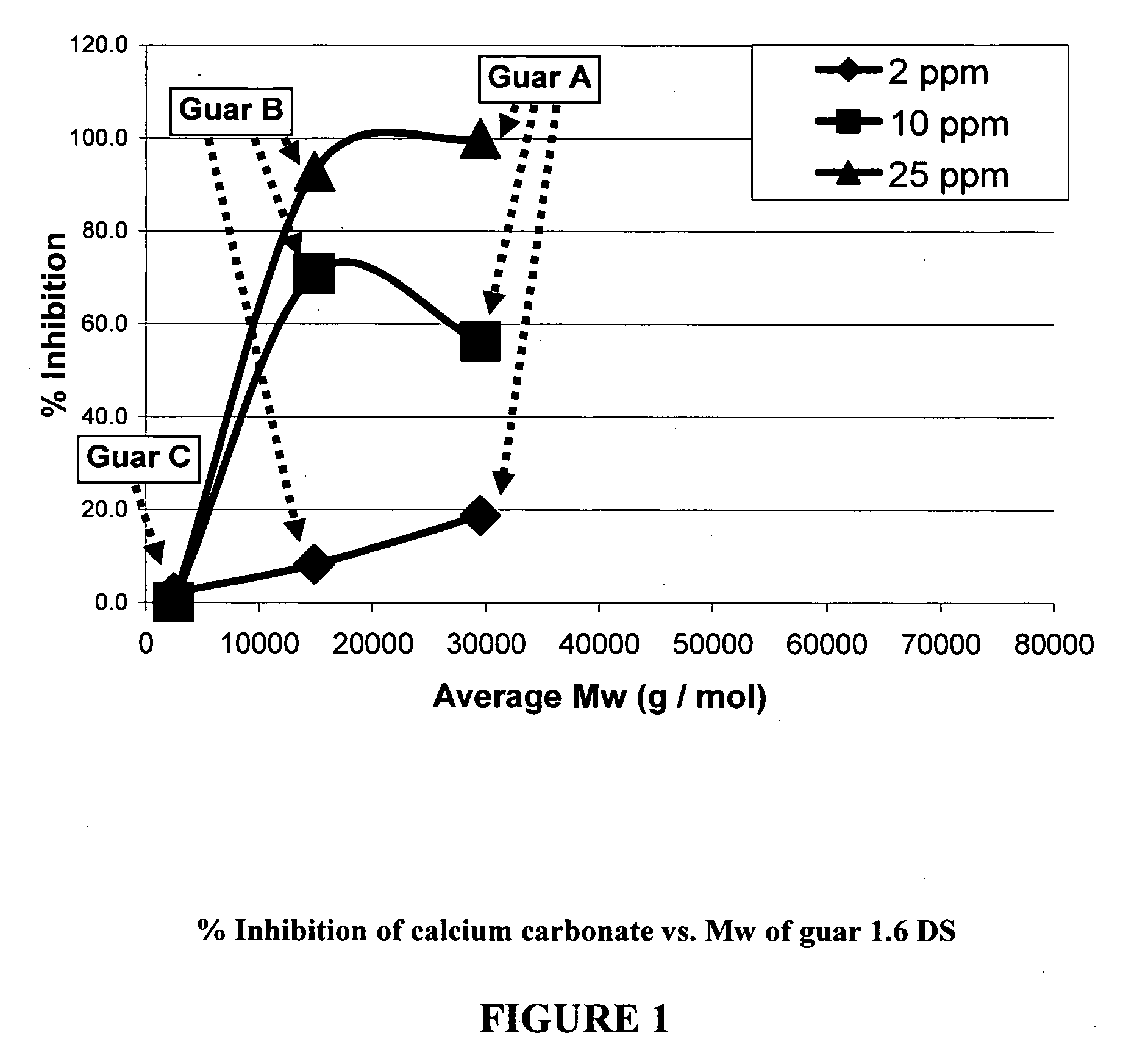

Polysaccharide based scale inhibitor

ActiveUS20080277620A1Reduce and prevent productionPrevent scalingWaste water treatment from quariesInorganic/elemental detergent compounding agentsSulfateDegree of substitution

A depolymerized-carboxyalkyl polysaccharide formed by de polymerizing a polysaccharide having from 0.5 to 3.0 degrees of substitution and reducing the molecular weight of said polysaccharide before or after said depolymerizing provides a biodegradable scale inhibitor useful to prevent deposition of scale comprising, for example, calcium, barium, sulfate and salts thereof. The depolymerized carboxyalkyl polysaccharide is particularly useful in off shore oil production squeeze treatments and in the treatment of scale formed in industrial water treatment.

Owner:RHODIA OPERATIONS SAS

Cellulose ester composition

InactiveUS6139785AReduce preparation timeAvoid pollutionArtificial filaments from cellulose derivativesFlat articlesDegree of substitutionAcylal

The present invention provides a cellulose ester composition, containing 1 to 99% by weight of cellulose triacetate prepared by substituting hydroxyl groups of cellulose with acetyl and having a degree of substitution with acetyl, DSace, which satisfies the relationship: 2.7< / =DSace< / =3.0, and 99 to 1% by weight of a mixed fatty acid ester of cellulose prepared by substituting hydroxyl groups of cellulose with acetyl and acyl groups having three or more carbon atoms and having degrees of substitution with acetyl and acyl groups having three or more carbon atoms, DSace and DSacyl, respectively, which satisfy the relationships: (I) 2.20< / =DSace< / =2.95, (II) 0.05< / =DSacyl< / =0.80 and (III) 2.60< / =DSace+DSacyl< / =3.00.

Owner:DAICEL CHEM IND LTD

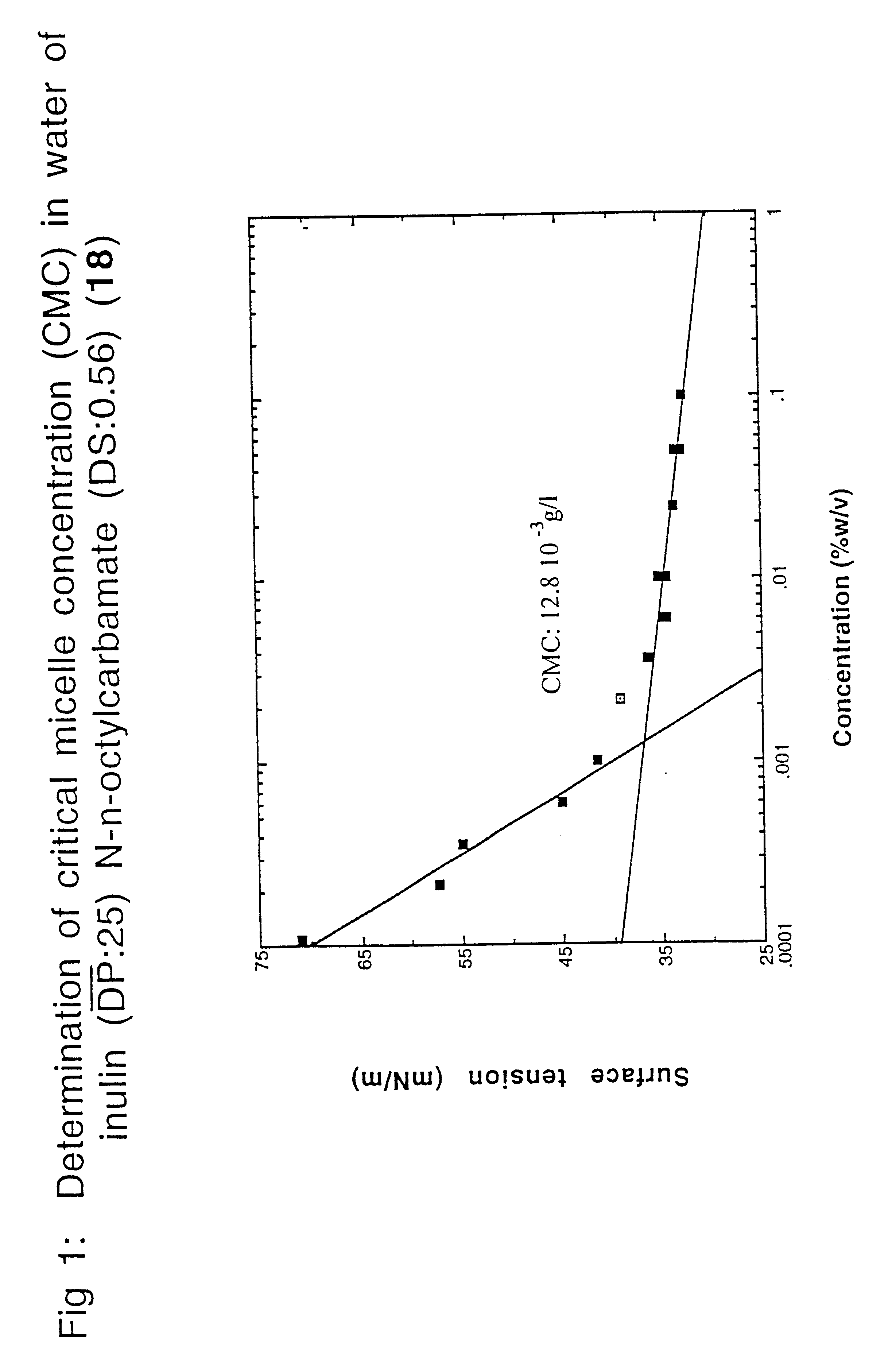

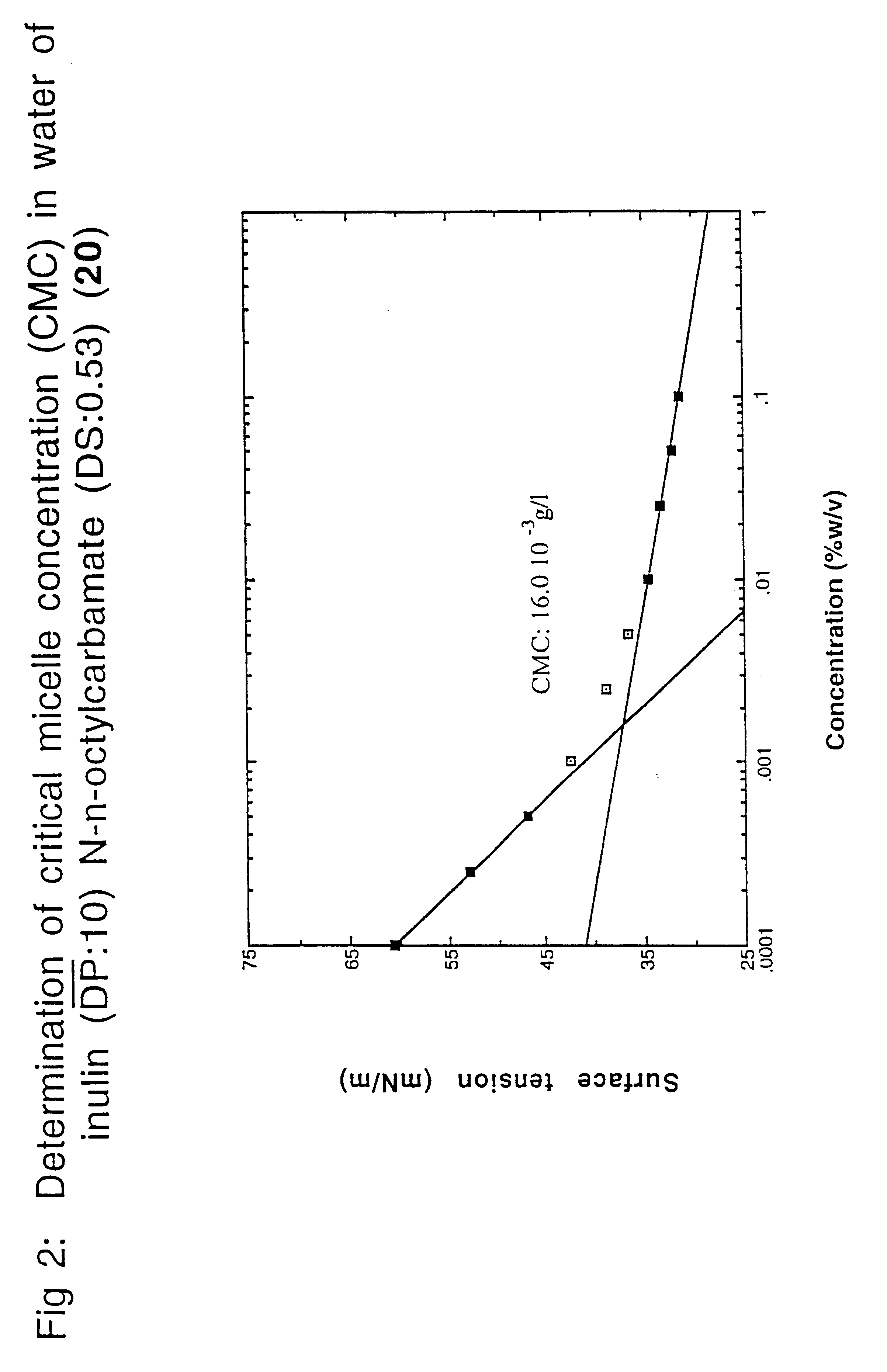

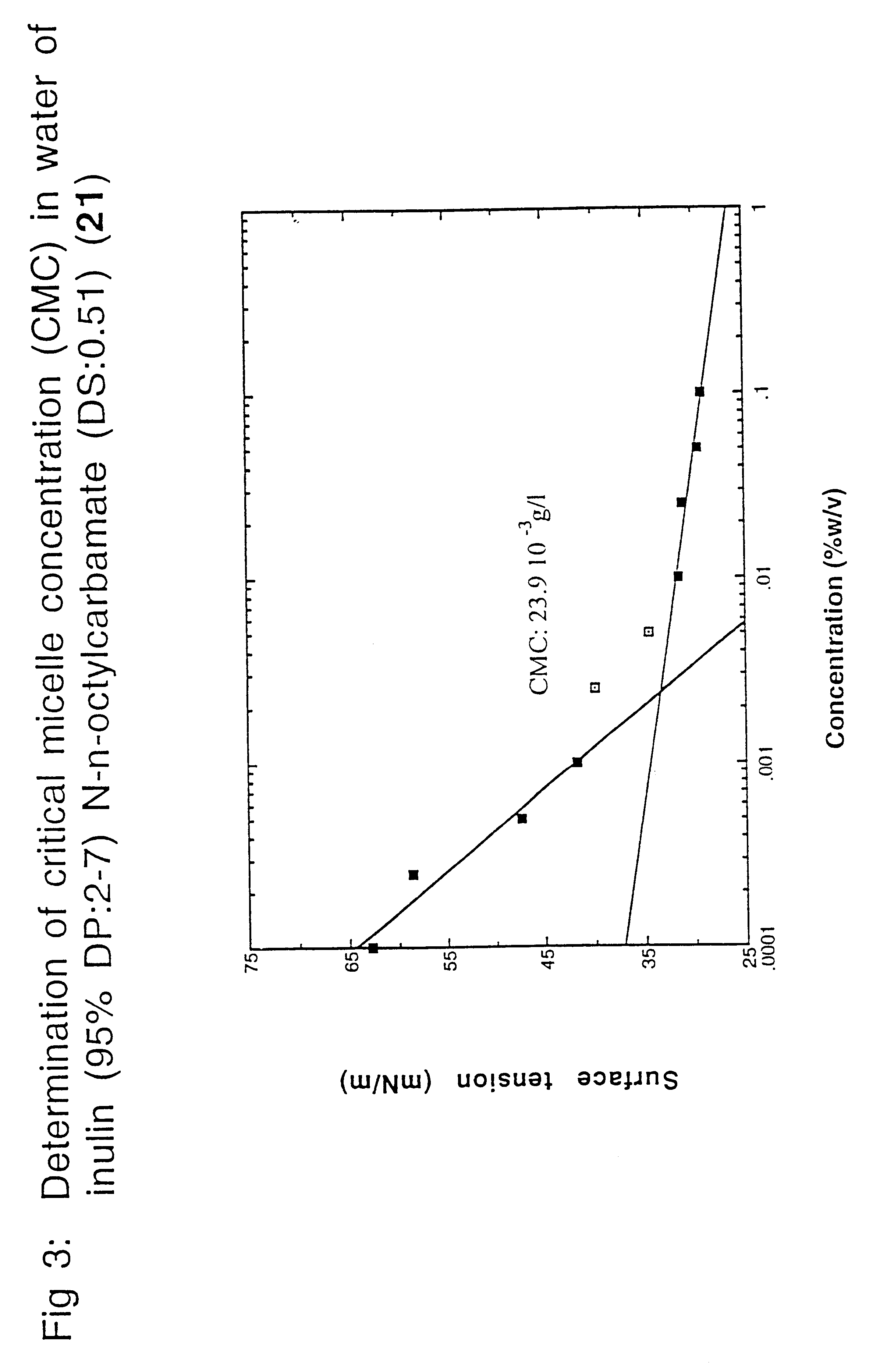

Surface-active alkylurethanes of fructans

InactiveUS6534647B1Readily solubleMaintain good propertiesEsterified saccharide compoundsNon-ionic surface-active compoundsEmulsionFoaming agent

The invention concerns the use as surface-active agent of a fructan N-alkylurethane (I) which is composed of saccharide units of general formula (II)whereinA represents a fructosyl unit (F) or a terminal glucosyl unit (G) of said fructan, being a levan or an inulin, with a degree of polymerisation (DP) of minimum 3,(O-CO-NH-R) represents an N-alkylaminocarbonyloxy group replacing a hydroxyl group of the saccharide unit A, wherein R represents a linear or branched, saturated or unsaturated alkyl group containing from 3 to 22 carbon atoms and any mixture thereof, and s represents the number of N-alkylaminocarbonyloxy groups per saccharide unit which is expressed as degree of substitution (DS), and said DS has a value ranging from 0.10 to 2.0. The invention further relates to novel fructan N-alkylurethanes (I), in particular inulin N-alkylurethanes (I), and a method for their manufacture. The fructan N-alkylurethanes (I) have good to excellent surface-active properties in combination with good biodegradability and are suitable as surfactants for use in household and industrial applications, e.g. as detergents, emulsifiers, emulsion stabilizers, foaming agents, foam stabilisers, dispersants and wetting agents.

Owner:TIENSE SUIKERRAFINADERIJ

Preparation method of lithium carboxymethyl cellulose for lithium battery

InactiveCN102206286AEnhanced mass transferImprove heat transfer performanceCell electrodesSolubilitySlurry

The invention relates to a preparation method of lithium carboxymethyl cellulose for a lithium battery, belonging to the field of natural high-polymer chemical modification. The preparation method provided by the invention comprises the following steps: dispersing sodium carboxymethyl cellulose prepared by a slurry process into an organic solvent, adding a hydrochloric acid water solution, mixing, reacting at 20-50 DEG C, removing the liquid, washing with an 80-95 vol% organic solvent, removing the liquid, baking, and pulverizing to obtain carboxymethyl cellulose acid; and dispersing the carboxymethyl cellulose acid in an organic solvent, adding an LiOH.H2O water solution, reacting at 40-60 DEG C, neutralizing with glacial acetic acid until the pH value is 6-8, washing with a 75-85% organic solvent, removing the liquid, baking, and pulverizing to obtain the lithium carboxymethyl cellulose. The preparation method can be used for obtaining lithium carboxymethyl cellulose with different degrees of substitution, different viscosities and excellent water solubility, and provides a novel water-soluble binder with low price and excellent properties, thereby enhancing the cyclical stability and discharge capacity of the lithium battery.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Personal care products incorporating cellulosic fatty acid esters

A personal care product composition containing a long chain fatty acid cellulose ester (LCCE) having a degree of substitution greater than about 1.0 of an ester substituent or residue from fatty acids having from 6 to 18 carbon atoms wherein the LCCE is soluble in at least one cosmetically acceptable solvent selected from the group consisting of hydrocarbons, alkyl esters, fats and oils, fatty acids, fatty alcohols, and silicone oils.

Owner:EASTMAN CHEM CO

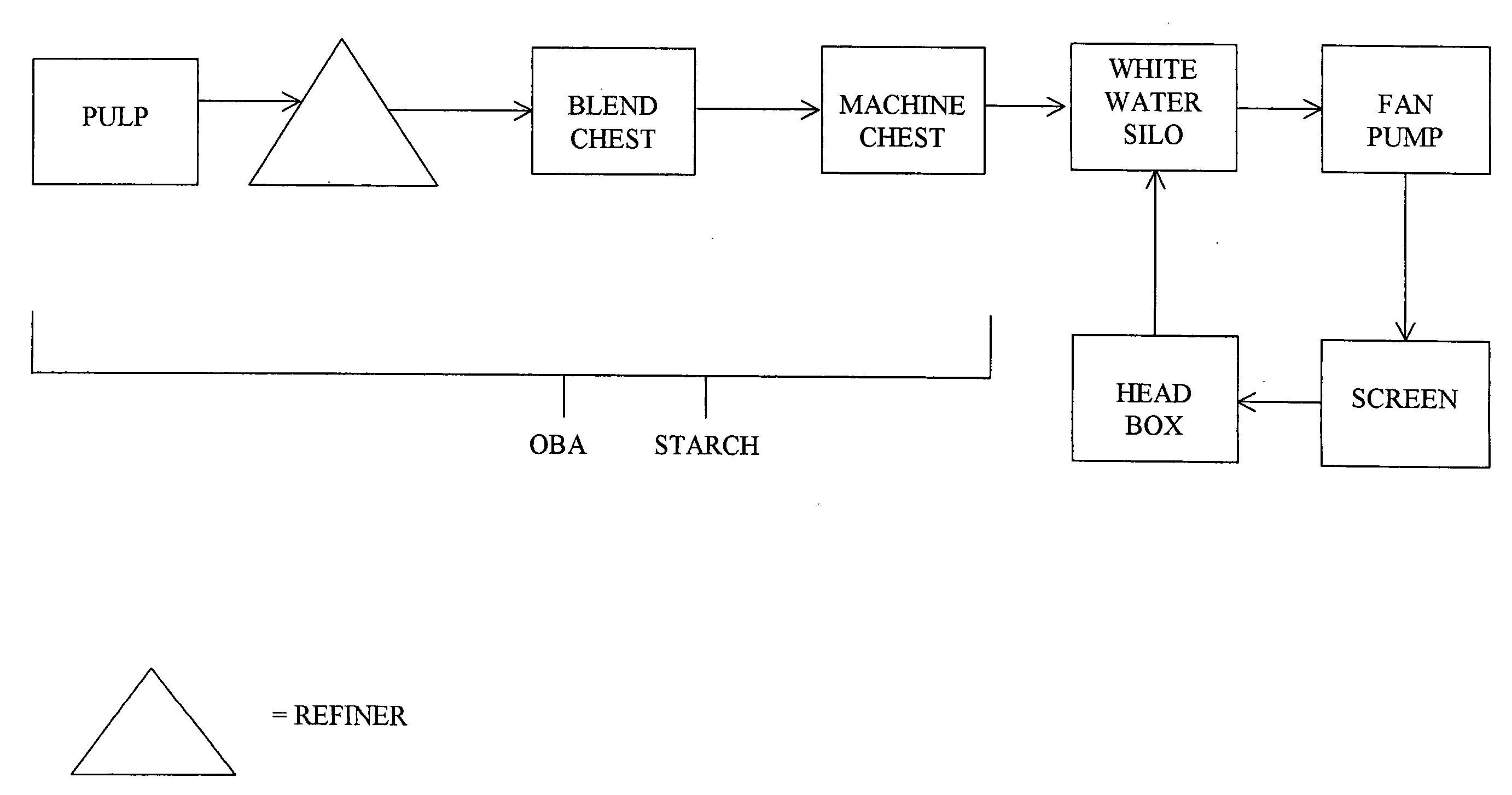

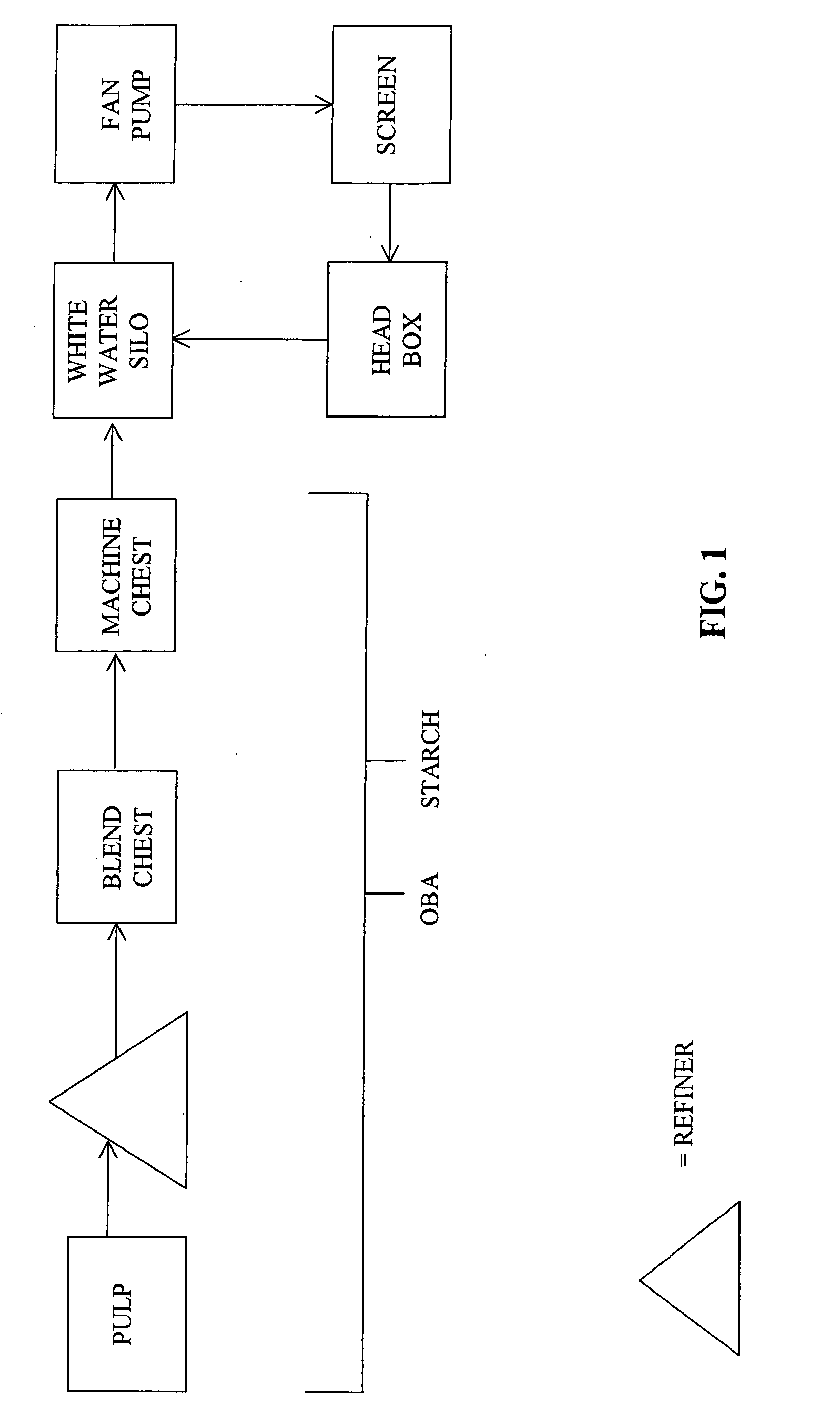

Papermaking processes using coagulants and optical brighteners

InactiveUS20070169903A1Reduce the amount requiredSatisfactory brightnessNatural cellulose pulp/paperSpecial paperPaperboardEngineering

A method of making paper or paperboard is described, which includes introducing at least one charged starch, preferably having a degree of substitution greater than 0.045, and at least one optical brightening agent to a papermaking pulp and then forming the pulp into paper or paperboard. The present invention further describes methods of improving optical brightener performance.

Owner:BUCKMAN LAB INT INC

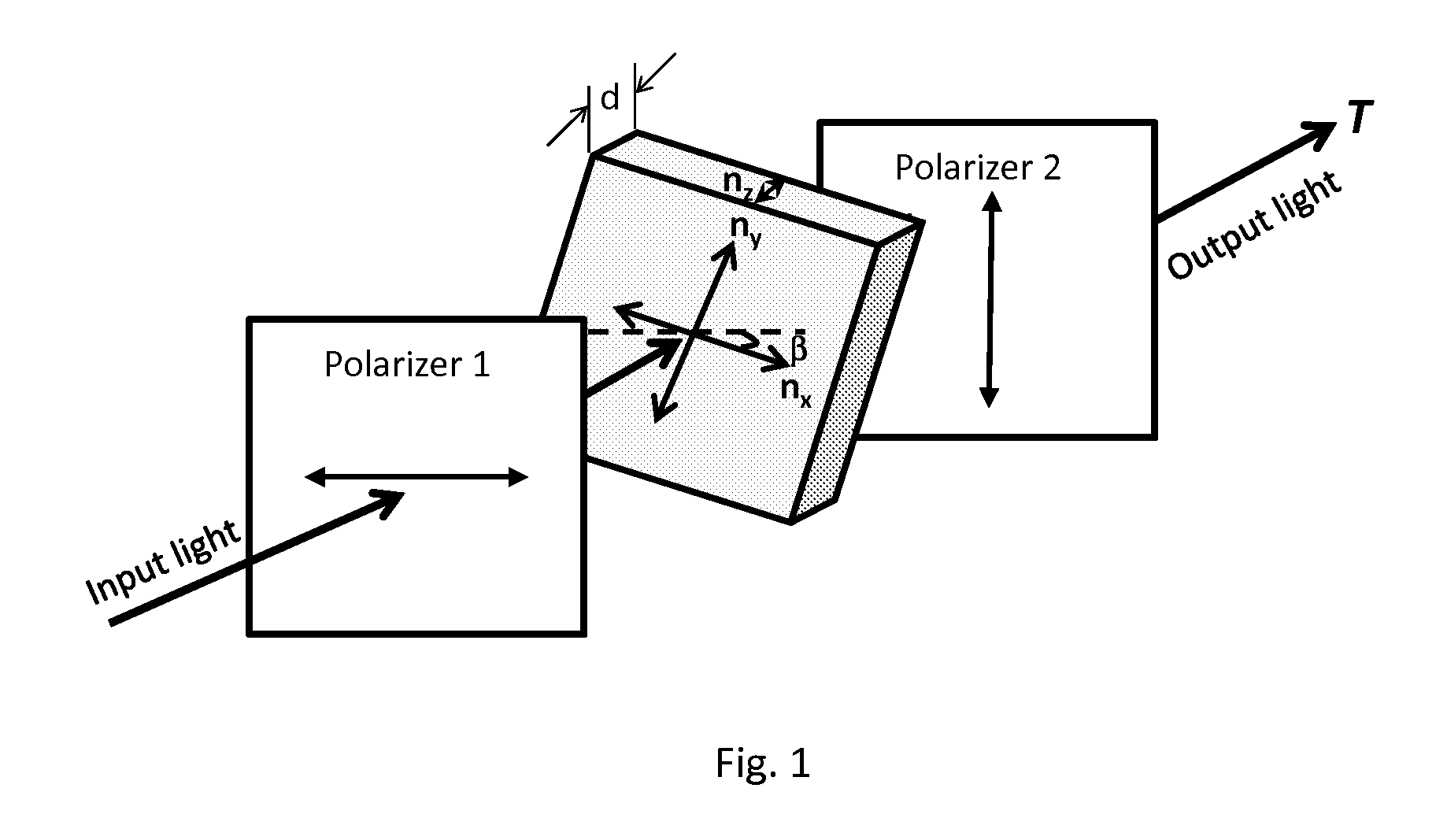

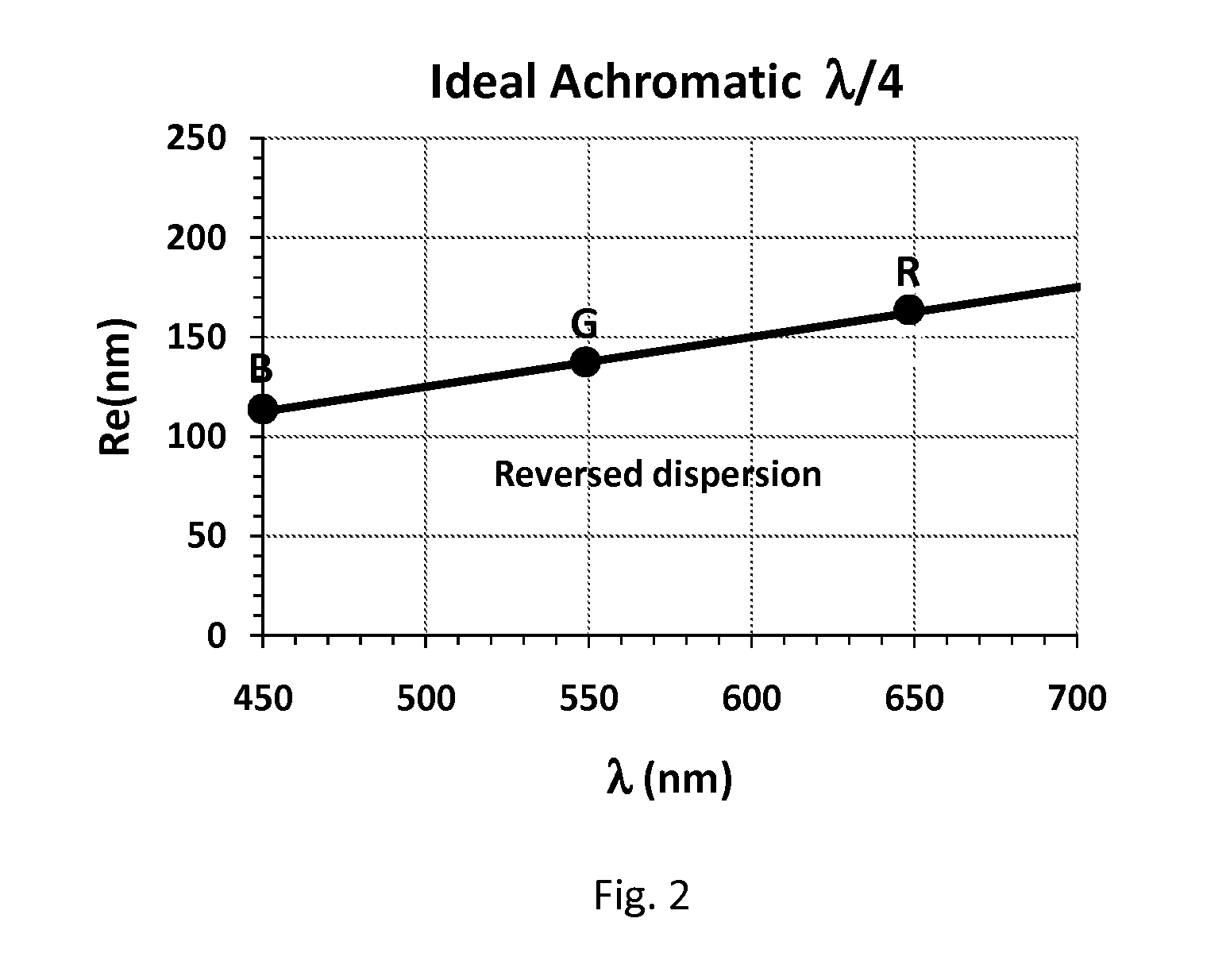

Multilayer cellulose ester film having reversed optical dispersion

InactiveUS20120003403A1High optical retardationReversed dispersionLiquid crystal compositionsSynthetic resin layered productsLiquid-crystal displayColor shift

The present invention relates to a multilayer cellulose ester film having a reversed optical dispersion. The film can have an A-B bi-layer or an A-B-A tri-layer configuration. The cellulose ester material for layer A has a hydroxyl degree of substitution (DSOH) from 0 to 0.5, while the cellulose ester material for layer B has a DSOH from 0.5 to 1.3. By manipulating the thickness of layers A and B, and the film stretching conditions, desirable optical retardation and optical dispersion properties can be obtained. The film can be used as an optical waveplate in liquid crystal displays to improve viewing angle, contrast ratio, and color shift.

Owner:EASTMAN CHEM CO

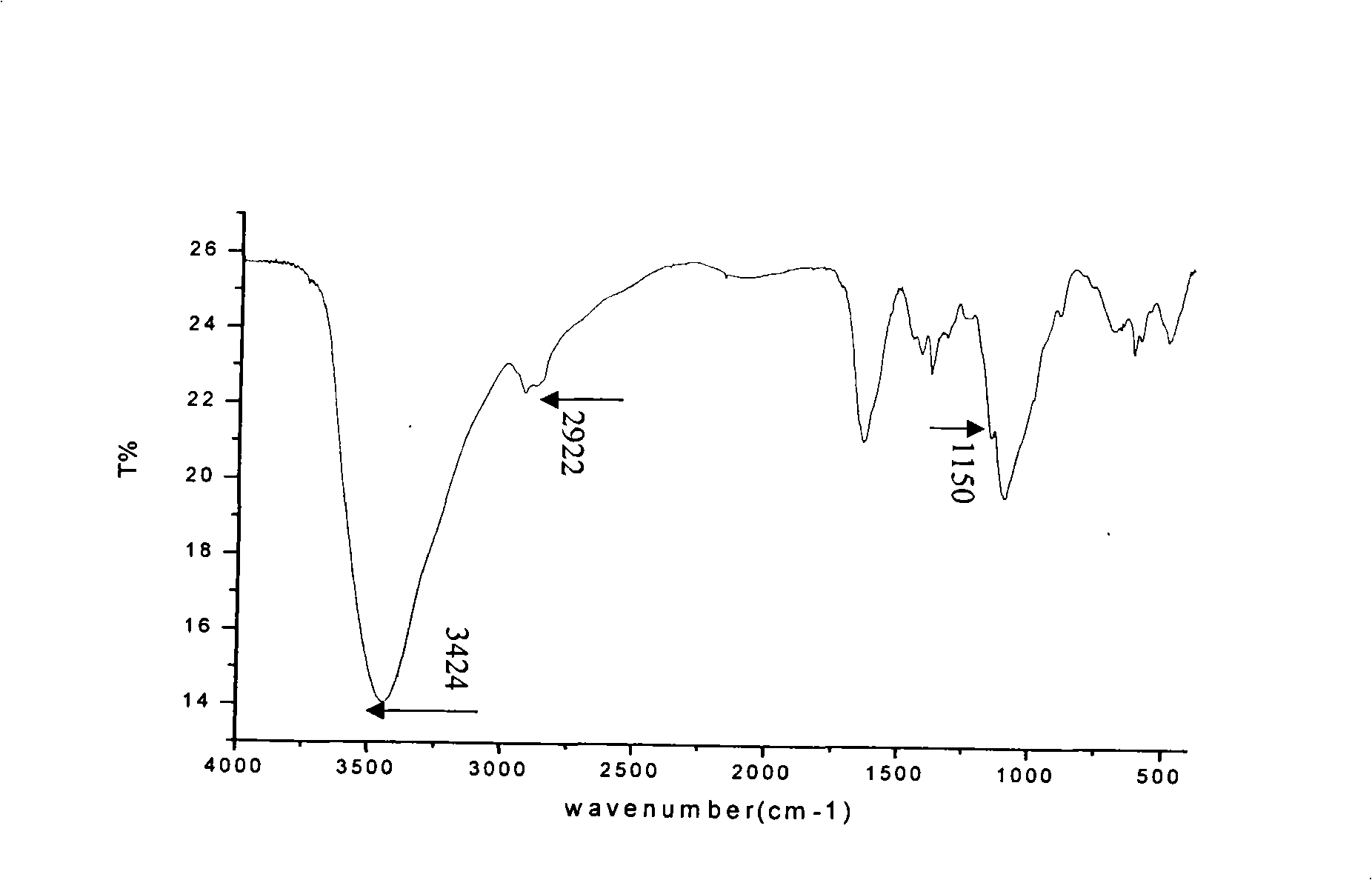

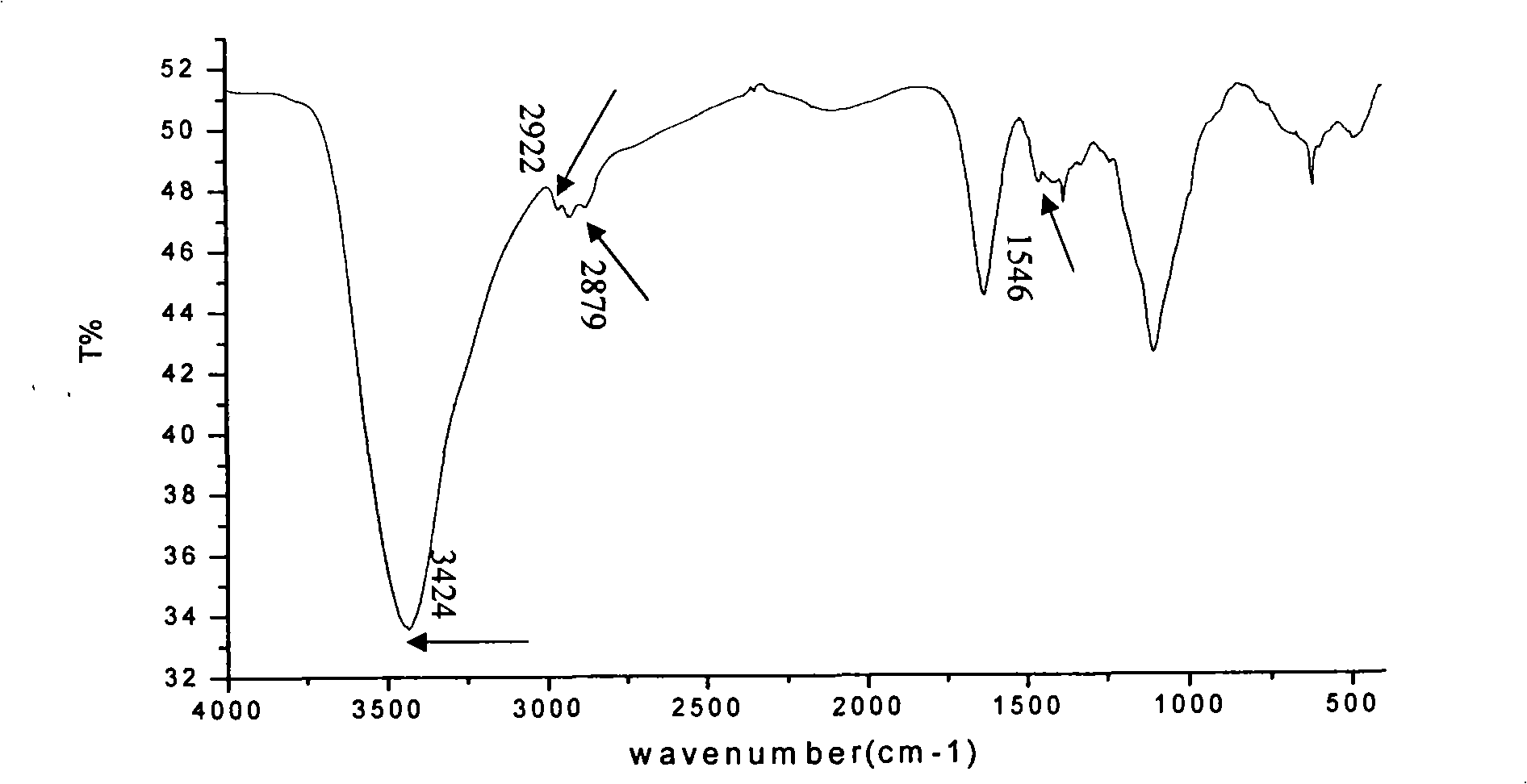

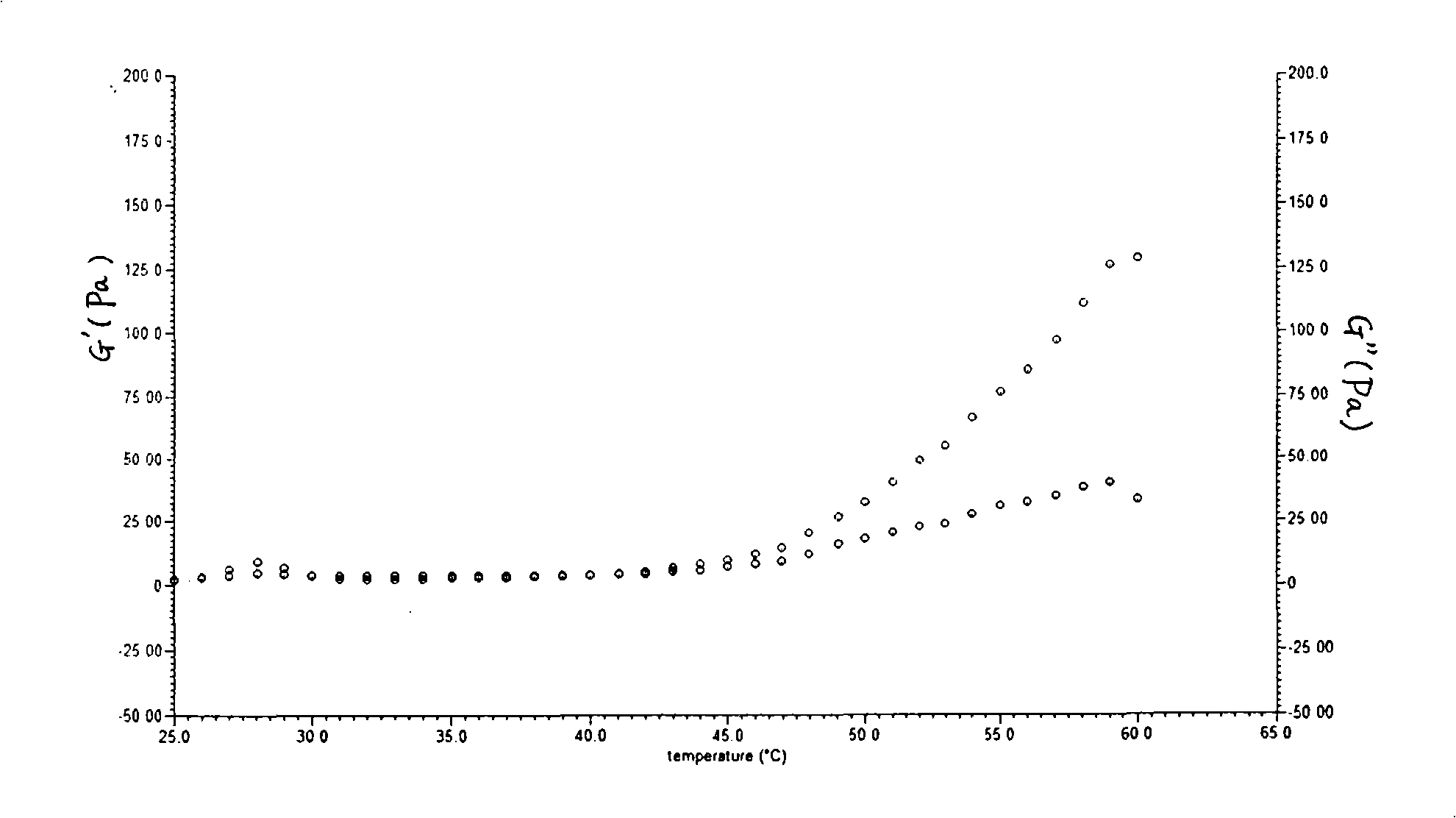

Preparation method of temperature sensitivity chitosan derivate-hydroxybutyl chitosan

The invention relates to a method for making a chitosan derivative. The method is characterized in that: firstly, the purified chitosan is activated by a strong base to form a hydroxyl-K type chitosan; secondly, a 1, 2-butyl oxide linkage is taken as an etherifying agent, an isopropanol is taken as a disperse phase, the reaction lasts 2 to 4 days moderately at room temperature; after the reaction is finished, 8 to 10 times volume of acetone is precipitated and washed to be neutral as well as is dried in vacuum at a temperature of 50 DEG C to obtain the white powder. The hydroxybutyl chitosan with different degrees of substitution is obtained by controlling the proportion of the chitosan and the 1, 2-butyl oxide linkage and the reaction time. The method has the advantages of good water-solubility and the existence of the temperature sensitivity at a physiological temperature.

Owner:SHANGHAI QISHENG BIOLOGICAL PREPARATION CO LTD

Hydrophobically midified saccharide surfactants

InactiveUS20040248761A1Cosmetic preparationsNon-ionic surface-active compoundsHigh concentrationFructan

The invention relates to the use as surfactant, for the preparation of dispersions of multiphase systems that comprise a continuous aqueous phase containing a high concentration of electrolytes, of hydrophobically modified saccharides of general formula (I) and (II) [A]n(-M)s (I) [B]m(-M)s'(II) wherein [A]n represents a fructan-type saccharide [B]m represents a starch-type saccharide (-M) represents a hydrophobic moiety that substitutes a hydrogen atom of a hydroxyl group of the fructosyl and / or glucosyl units of the fructan-type and starch-type saccharides, which is selected from the group consisting of an alkylcarbamoyl radical of formula R-NH-CO- and an alkylcarbonyl radical of formula R-CO-, wherein R represents a linear or branched, saturated or unsaturated alkyl group with from 4 to 32 carbon atoms, and s and s', which can have the same value or not, represent the number of said hydrophobic moieties that substitute the fructosyl or glucosyl unit, expressed as average degree of substitution (av. DS) which ranges from 0.01 to 0.5. The invention also relates to a method for the preparation and / or stabilisation of dispersions of multiphase systems that comprise a continuous aqueous phase containing a high concentration of electrolytes, by using as surfactant one or more hydrophobically modified saccharides of general formula (I) and / or (II) defined above. Also dispersions of multiphase systems are disclosed that comprise a continuous aqueous phase containing a high concentration of electrolytes and that comprise as surfactant one or more hydrophobically modified saccharides of general formula (I) and / or (II) defined above.

Owner:TIENSE SUIKERRAFINADERIJ

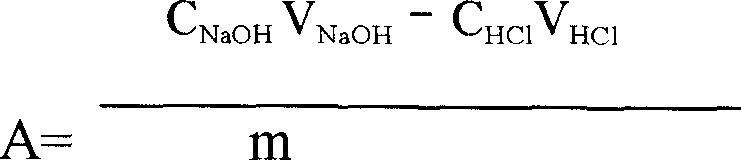

High substitution degree carboxymethyl indianbread polysaccharide and its preparation method and uses

ActiveCN1970579AIncrease the reaction concentrationIncreased degree of carboxymethyl substitutionAntibacterial agentsOrganic active ingredientsSolubilityAlcohol

The invention discloses a carboxymethyl pachyman (CMP) with high-degree of substitution and making method and application, which is characterized by the following: adopting water or water alcohol solution as dielectric; proceeding substitution reaction for pachyman, chloroacetic acid and fitful excessive sodium hydroxide to obtain CMP without vibrating technique and equipment; improving CMP D / S and solubility to reach injection need.

Owner:HUNAN BUTIAN PHARMA

Acylated chitosan wound dressing, and preparation method and application thereof

ActiveCN102727925AAvoid infectionGood hygroscopicityPackage sterilisationPharmaceutical delivery mechanismFiberWound dressing

The present invention relates to an acylated chitosan wound dressing, and a preparation method and application thereof. The wound dressing has high moisture absorption and high wet strength, forms into transparent gel after water absorption and swelling, does not adhere to a wound during contact with the wound, and can be conveniently and integrally removed. The wound dressing of the invention is prepared from acylated chitosan fibers containing carboxyl; and the acylated chitosan fiber is an acylated modified chitosan with an acylation degree of substitution of 0.10-0.50 in chitosan structure unit. As the wound treatment dressing, the acylated chitosan has effects of hemostasis and antibiosis and is especially suitable for the treatment of chronic wounds; and the high moisture absorption provides a moist environment for wound healing, and the wound dressing can rapidly absorb exudate and blood on wound surface to promote wound healing.

Owner:FOSHAN UNITED MEDICAL TECH

Compositions containing one or more poly alpha-1,3-glucan ether compounds

ActiveUS20150368595A1High viscosityCosmetic preparationsNon-ionic surface-active compoundsOrganic groupEther

Compositions comprising cellulase and at least one poly alpha-1,3-glucan ether compound having a degree of substitution with a positively charged organic group of about 0.05-3.0 are disclosed. Such compositions can be dry or aqueous, the latter of which can have a viscosity of at least about 10 cPs. The disclosed composition can be in the form of a personal care product, household product, or industrial product, for example. Also disclosed are a method for preparing an aqueous composition comprising cellulase and a poly alpha-1,3-glucan ether compound, and a method of treating a material such as fabric by contacting it with this aqueous composition.

Owner:NUTRITION & BIOSCIENCES USA 4 INC

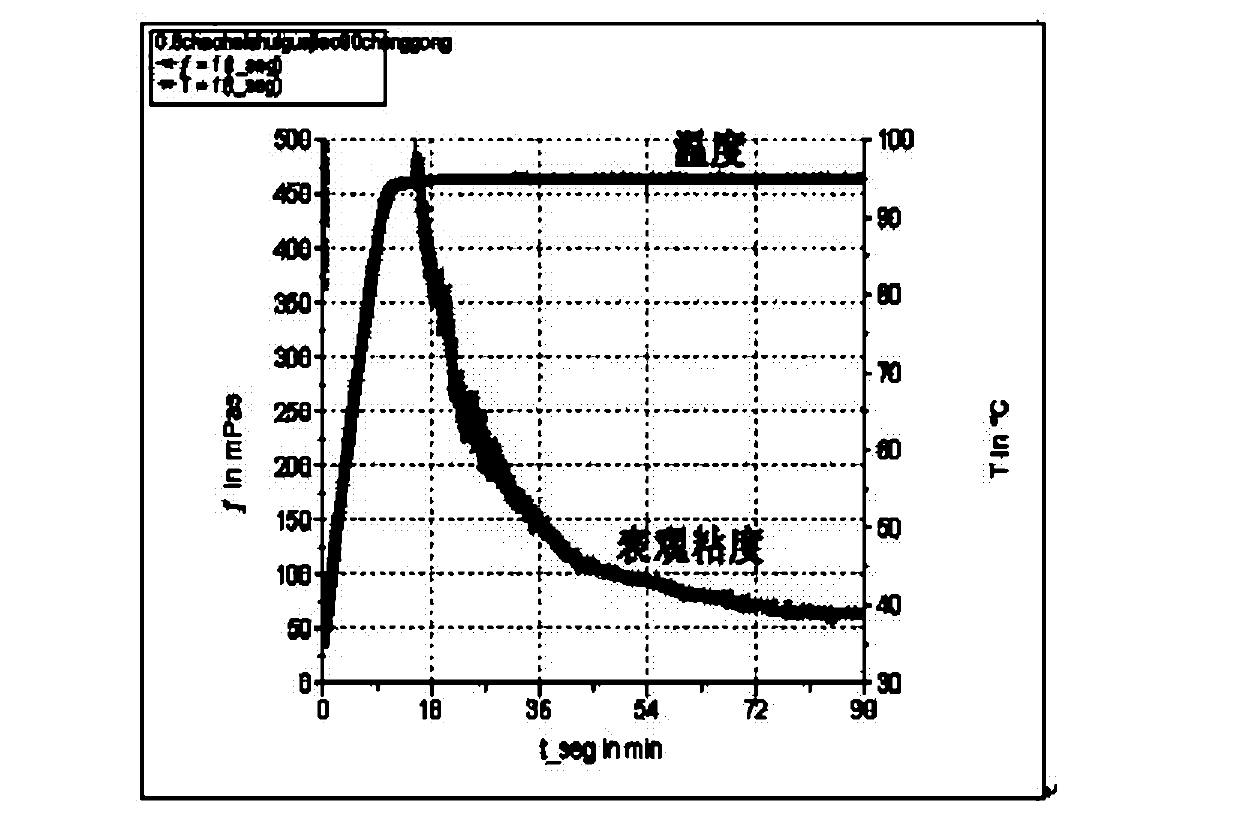

Method of preparing high viscosity carboxymethyl cellulose by slurry method

This invention relates to a preparation method of carboxymethyl cellulose with special high viscosity, in particular belonging to polymer chemistry technology, which technical program includes four steps namely cellulose activating reaction, etherification, neutralization reaction and cleaning. The key points of this invention are that slurry method can prepare the carboxymethyl cellulose with high degree of substitution and high viscosity, without the addition of cross-linker or hydrophobic reagent. The practical significance of this invention is that it can improve product performance, namely viscosity and substitution, so that it can be better used in oil drilling, textile, sewage treatment, food processing and other fields.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

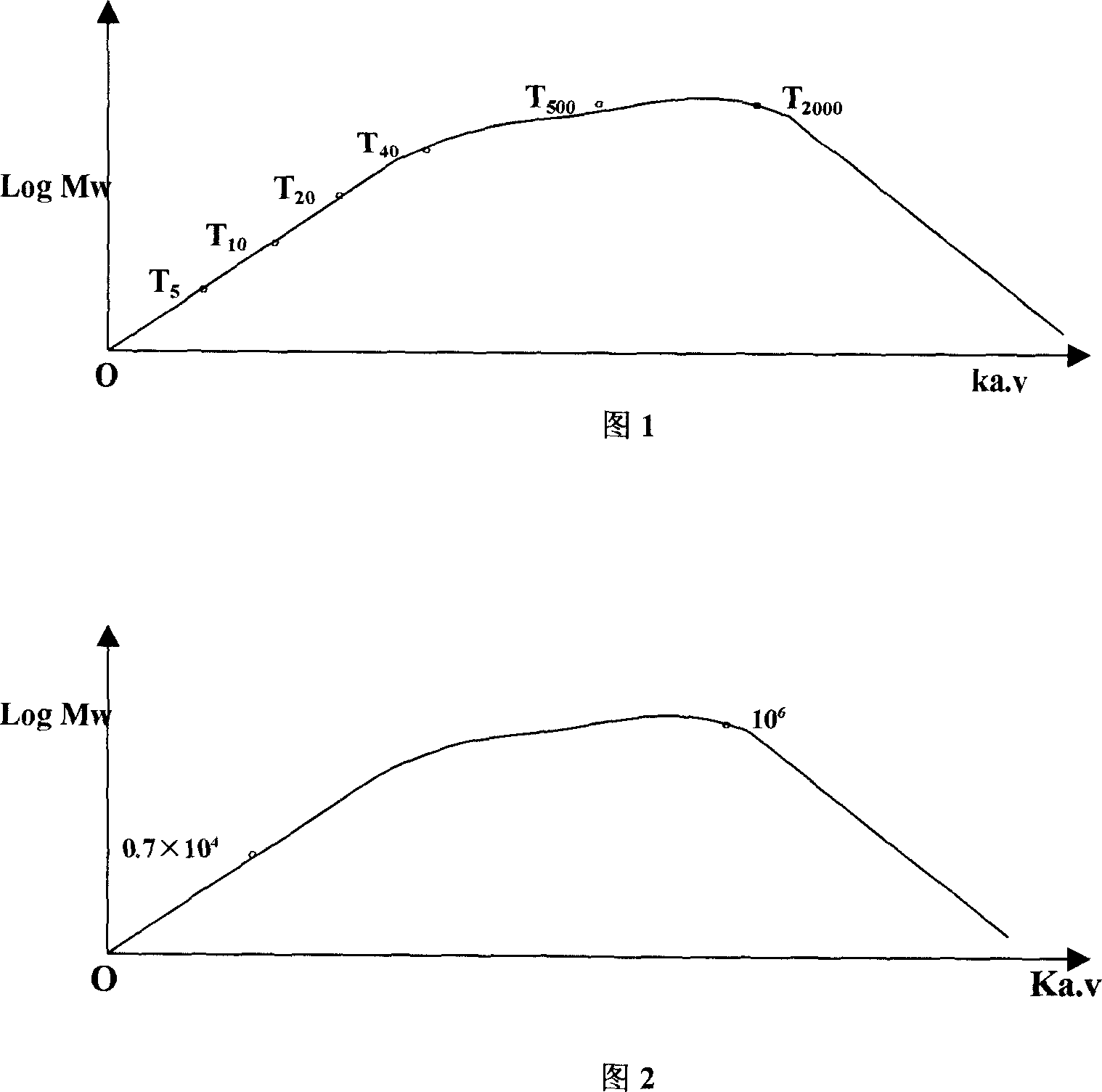

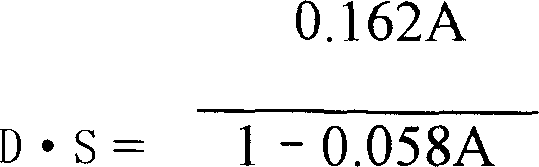

Functional systems with reduced odor cationic polygalactomannan

InactiveUS20060046943A1Reduce body malodorCosmetic preparationsHair cosmeticsPersonal careLower limit

A reduced odor composition is composed of a functional system such as household care, personal care or pet care products and at least one cationic polygalactomannan or a derivative of cationic polygalactomannan having a cationic degree of substitution (DS) lower limit of about 0.01 and an upper limit of about 3.0 and weight average molecular weight (Mw) having a lower limit of 200,000 and an upper limit of 2,000,000 a concentration with a lower limit of 0.005 wt % and an upper limit of 10 wt %, and a trimethylamine content of less than 25 ppm, wherein the composition, at an alkaline pH, has no discernible amine odor.

Owner:HERCULES INC

Curable coating compositions with carbamate compounds

InactiveUS6900270B2Good reaction selectivityHigh reactivitySynthetic resin layered productsPolyurea/polyurethane coatingsCarbamateMedicinal chemistry

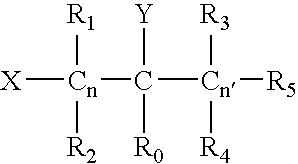

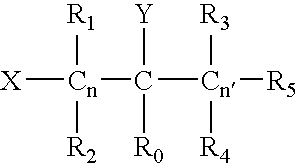

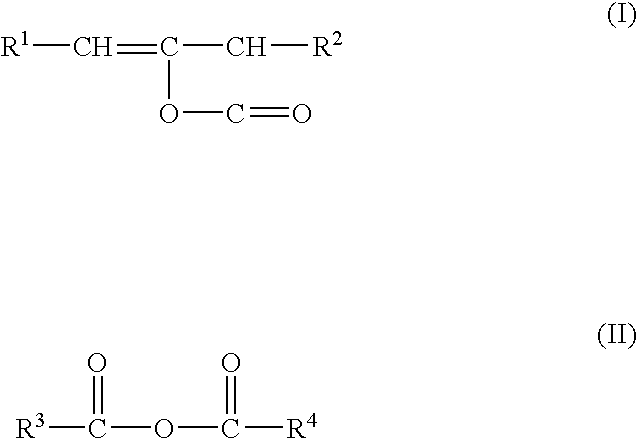

Provided is a curable coating composition comprising a reactive compound having one or more structures of the formula: wherein X is a primary carbamate group, Y is a hydroxy or halide group, n is an integer of 2 or more, n′ is an integer of 1 or more, and R0, R1, R2, R3, R4 and R5 may be H or a group selected from alkyl groups, aliphatic groups, cycloaliphatic groups, aromatic groups and mixtures thereof, with the provisos that at least one R1 or R2 group is selected from the group consisting of aliphatic groups, cycloaliphatic groups, aromatic groups, and mixtures thereof, and in substantially all structures primary carbamate group X is attached to a carbon atom having a lower degree of substitution than a carbon atom to which functional group Y is attached.

Owner:BASF CORP

Filler for papermaking process

The present invention relates to a filler comprising calcium salt and cellulose derivative having a degree of substitution of net ionic groups up to about 0.65, wherein the filler is substantially free from fibres or fibrils of cellulose or lignocellulose. The invention also relates to a filler comprising calcium salt and a cellulose derivative having a degree of substitution of net ionic groups up to about 0.65, wherein the cellulose derivative contains cationic groups.

Owner:AKZO NOBEL PULP & PERFORMANCE CHEM

Solid-phase preparation method for buserelin

InactiveCN101935339AHigh yieldLow costLuteinising hormone-releasing hormonePeptide preparation methodsPeptide sequenceCombinatorial chemistry

The invention provides a solid-phase preparation method for buserelin. The method comprises the following steps of: 1) preparing a Fmoc-Pro-HMPB-MBHA resin with degree of substitution of between 0.15 and 0.80mmol / g from Fmoc-Pro-OH and a HMPB-MBHA resin with degree of substitution of between 0.2 and 0.9mmol / g by a solid-phase synthesis method; 2) gradually coupling remaining protected amino acid of the Fmoc-Pro-HMPB-MBHA resin according to a peptide sequence to obtain buserelin-HMPB-MBHA resin; 3) cracking the buserelin-HMPB-MBHA resin to obtain fully-protected peptide; and 4) performing ethyl amination, deprotection and purification on the obtained fully-protected peptide to obtain buserelin. The invention aims to provide a buserelin solid-phase synthesis method which has the advantages of high yield, low cost, mild reaction conditions, small environmental pollution and contribution to realizing industrialization.

Owner:HYBIO PHARMA

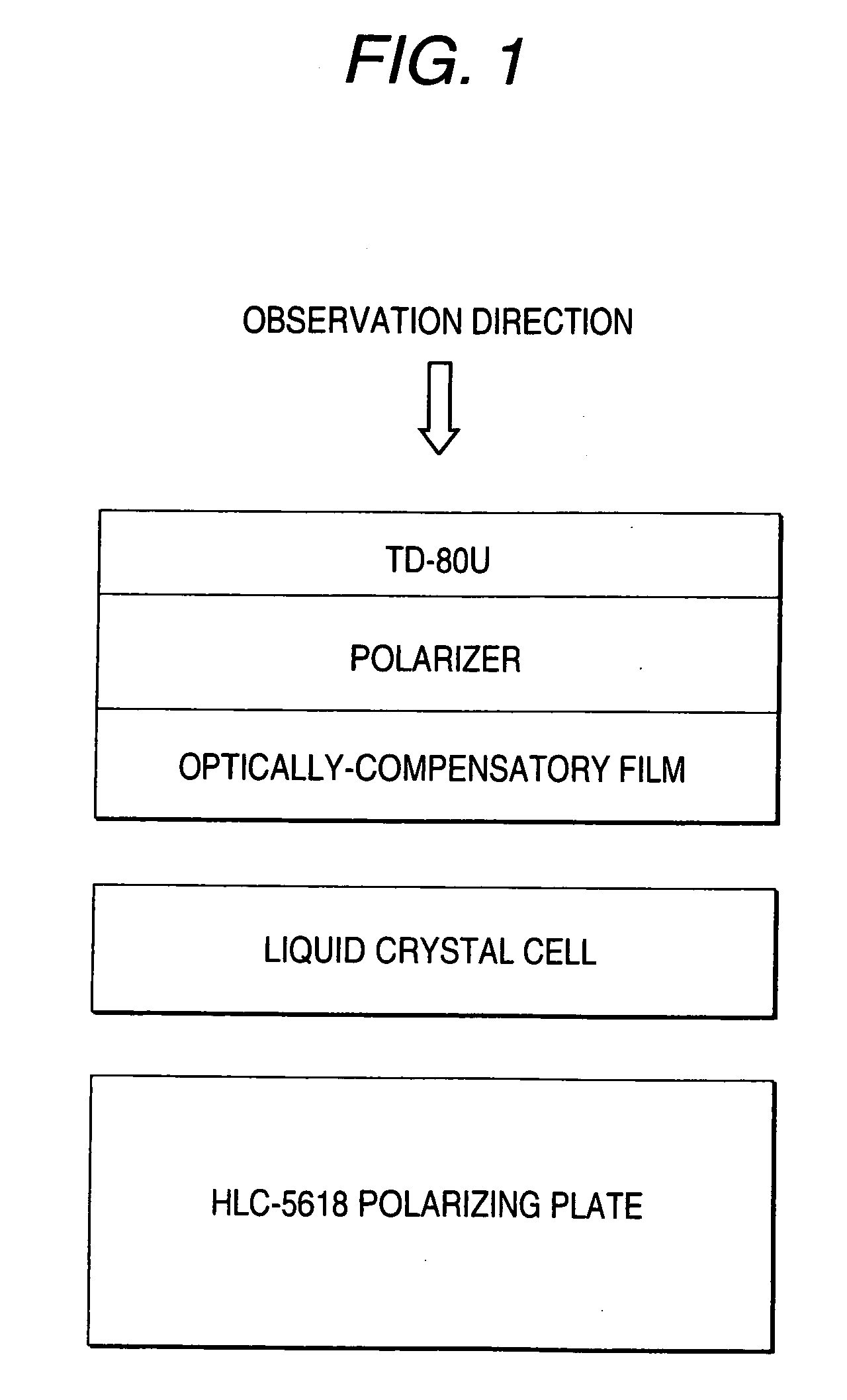

Cellulose Acylate Film, Method of Producing the Same, Cellulose Derivative Film, Optically Compensatory Film Using the Same, Optically-Compensatory Film Incorporating Polarizing Plate, Polarizing Plate and Liquid Crystal Display Device

InactiveUS20090290100A1Increase contrastImprove visibilityLiquid crystal compositionsCellulosic plastic layered productsPolymer scienceLiquid-crystal display

A method of producing a cellulose derivative film, the method comprising: forming a film with a solvent cast method from a dope including a cellulose derivative satisfying following conditions (a) and (b): (a) at least one among three hydroxyl groups included in a glucose unit of cellulose is substituted by a substituent of which a polarizability anisotropy Δα represented as following Expression (1) is 2.5×10−24 cm3 or higher: Expression (1): Δα=αx−(αy+αz) / 2, wherein αx, αy and αz is as defined in the specification; and (b) when a substitution degree by a substituent of which Δα is 2.5×10−24 cm3 or higher is PA, and a substitution degree by a substituent of which Δα is lower than 2.5×10−24 cm3 is PB, the PA and PB satisfy following Expressions (3) and (4): Expression (3): 2PA+PB>3.0; and Expression (4): PA>0.2.

Owner:FUJIFILM CORP

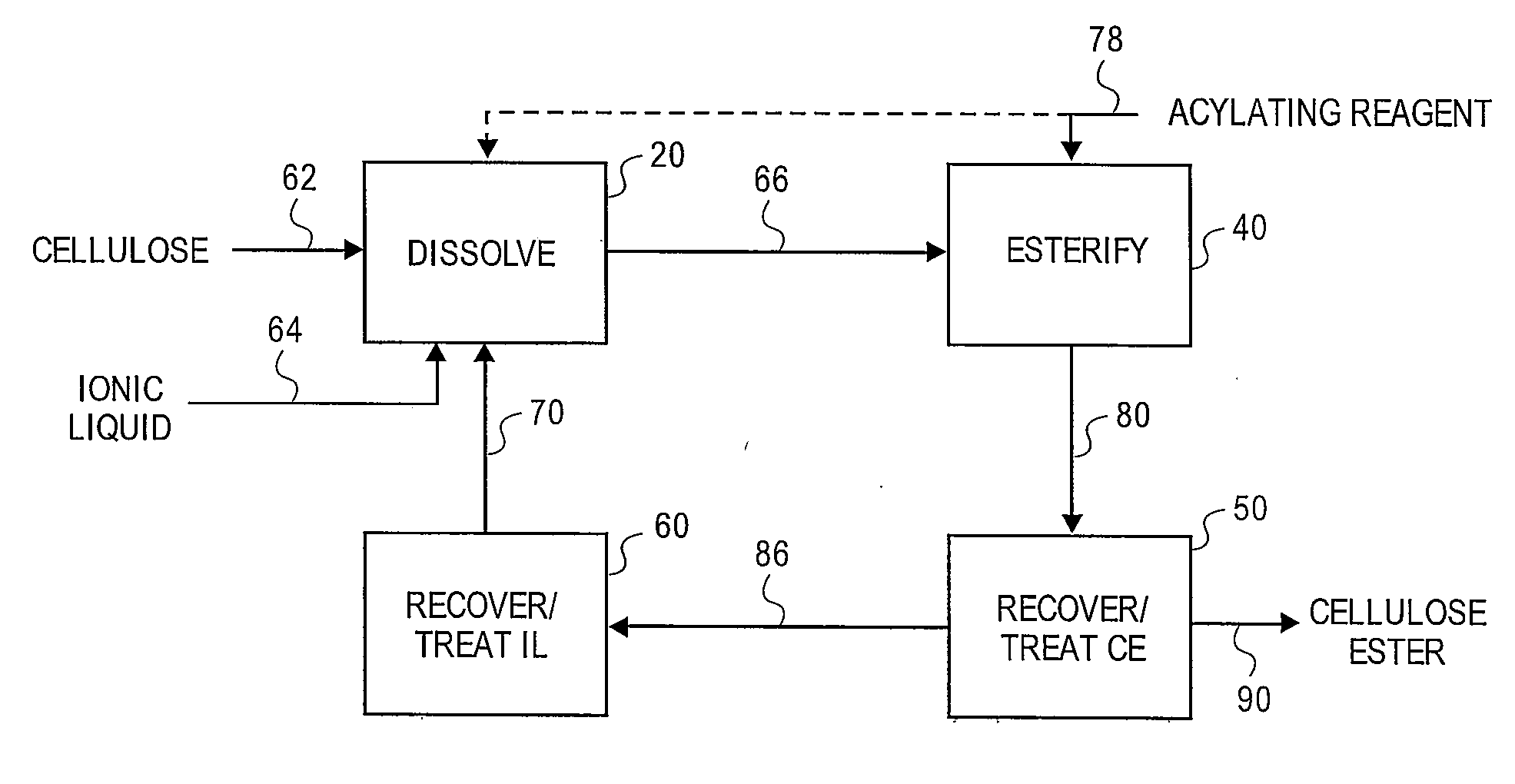

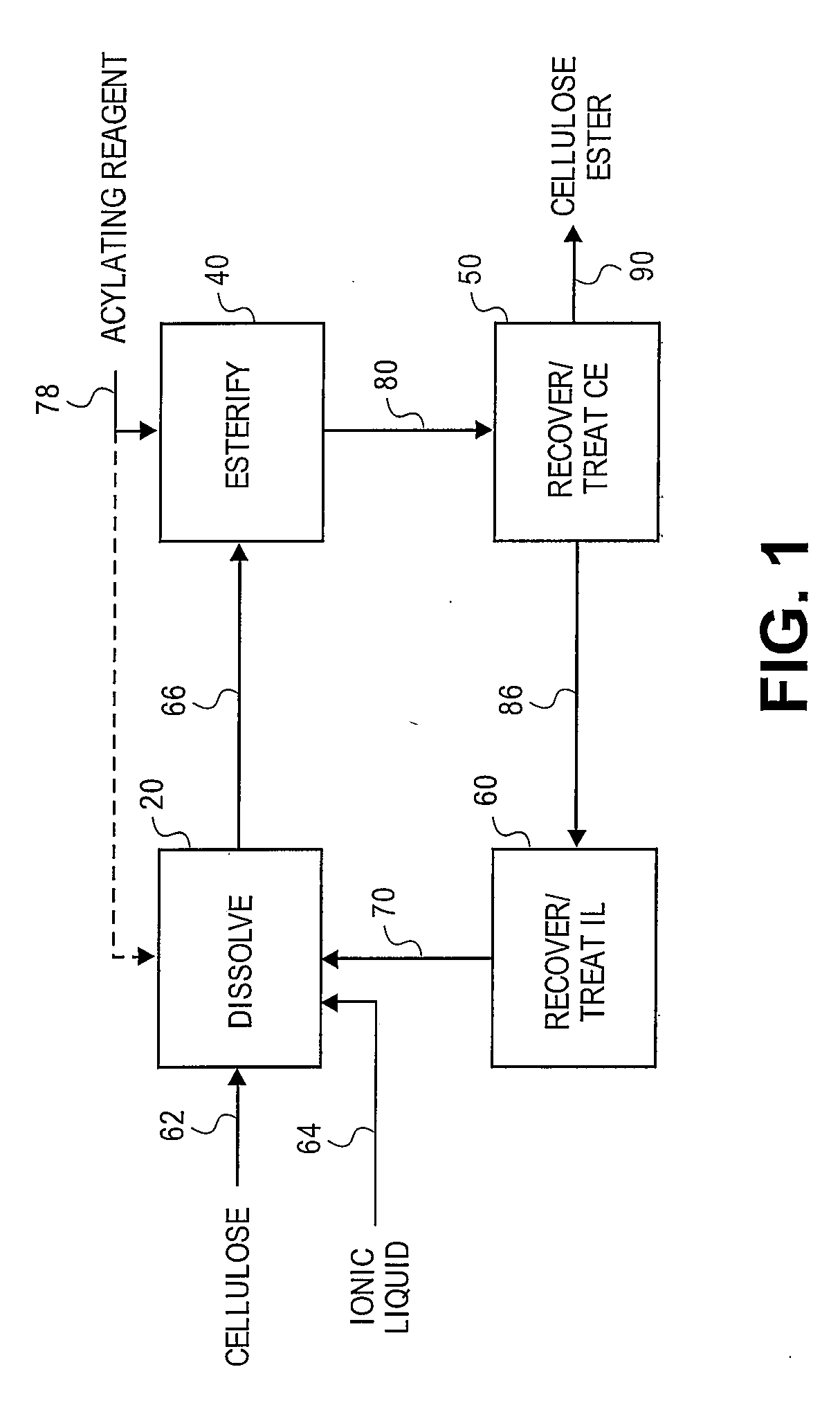

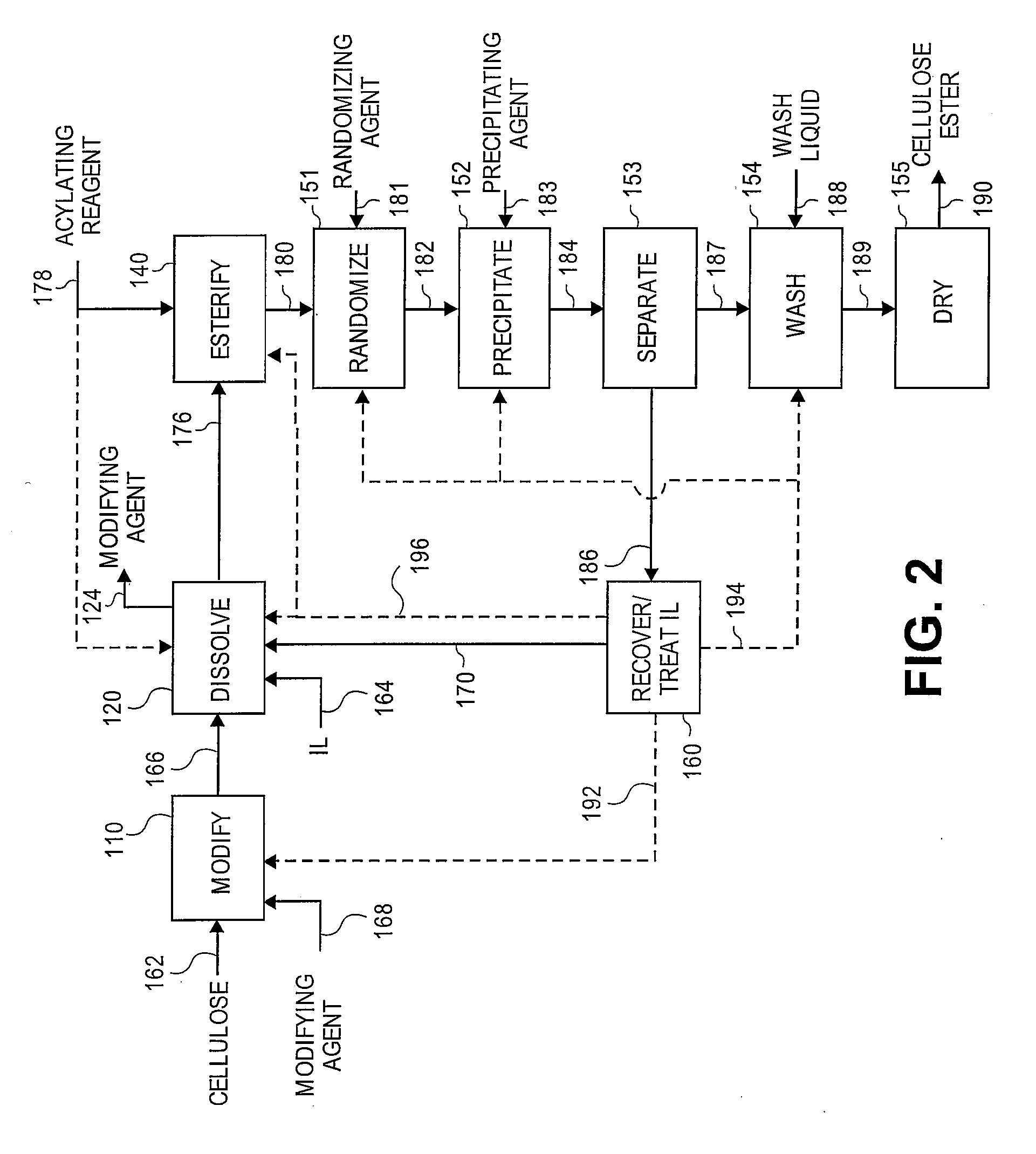

Cellulose esters and their production in halogenated ionic liquids

InactiveUS20090203898A1Esterified saccharide compoundsSugar derivativesCarbon chainDegree of substitution

Ionic liquids and cellulose ester compositions and processes for producing ionic liquids and cellulose esters. Cellulose esters can be produced by esterifying cellulose in a reaction medium comprising one or more halide ionic liquids and at least one binary component. Cellulose esters prepared via the methods of the present invention can have a degree of substitution (“DS”) of at least 1.5 and can comprise a plurality of ester substituents, where at least 50 percent of the ester substituents comprise alkyl esters having a carbon chain length of at least 6 carbons.

Owner:EASTMAN CHEM CO

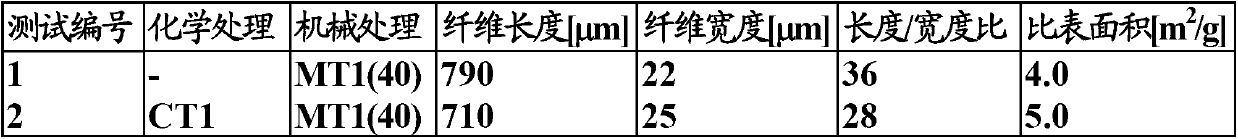

Cellulosic fibre composition

InactiveCN102971462AEasy to prepareWithout significant loss of qualityWood working apparatusPaper/cardboardChemical treatmentNitroxyl radicals

The invention relates to a composition comprising cellulosic fibres having an average degree of substitution of anionic groups of from 0.001 to 0.25, and DEG a length weighted mean fibre length up to 1,100 [mu]m and a length weighted mean fibre width over 10 [mu]m, or DEG a length weighted mean fibre length up to 1,100 [mu]m, and wherein at least 50 % by weight of the cellulosic material is insoluble in water, or DEG a length weighted mean fibre length / width ratio up to 30, or DEG a length weighted mean fibre width over 35 [mu]m. The invention also relates to a composition comprising cellulosic fibres having a specific surface area of at least 1.5 m2 / g, a length weighted mean fibre length / width ratio up to 30, and a dry solids content of at least 5 % by weight, based on the weight of the composition, or up to 30 % by weight, based on the total weight of the cellulosic fibres, of cellulosic fibres with a length weighted mean fibre length up to 100 [mu]m. Method of producing a composition comprising cellulosic fibres which comprises subjecting cellulosic fibres to chemical treatment and mechanical treatment, wherein the chemical treatment comprises treating cellulosic fibres with (i) at least one agent containing a carboxyl group, optionally substituted, (ii) at least one oxidant and at least one transition metal, or (iii) at least one nitroxyl radical, and the mechanical treatment comprises subjecting cellulosic fibres to extrusion with a twin-screw extruder or a planetary roller extruder. The invention also relates to a method of producing a composition comprising cellulosic fibres which comprises subjecting cellulosic fibres having an average degree of substitution of anionic groups of from 0.001 to 0.25 to extrusion. The invention also relates to a composition comprising cellulosic fibres obtainable by the methods, a process for producing a cellulosic pulp mixture which comprises mixing the composition with cellulosic pulp, a cellulosic pulp mixture obtainable by the process, and the use of the composition and cellulosic pulp mixture as an additive in the production of paper and board, processes for producing paper and board in which the composition or cellulosic pulp mixture is used, paper and board obtainable by the processes, and various uses of the paper and board.

Owner:AKZO NOBEL CHEM INT BV

High DS cationic polygalactomannan for skincare products

InactiveUS20060073110A1Provide protectionCosmetic preparationsHair cosmeticsDegree of substitutionBULK ACTIVE INGREDIENT

A skin care composition is provided with a) from about 1 to about 90 wt % of a surfactant, b) at least about 0.05 wt % of a cationic polymer wherein the cationic polymer has a mean average molecular weight (Mw) from about 2,000 to about 10,000,000 Dalton, and the cationic polymer has a cationic degree of substitution (DS) greater than 0.25 to about 3.0, and c) at least one skin care active ingredient, wherein the skin care composition provides at least one of the functions of cleansing, protection, moisturizing, firming, conditioning, occlusive barrier, emolliency, depositing, and anti-wrinkling to the skin.

Owner:HERCULES INC

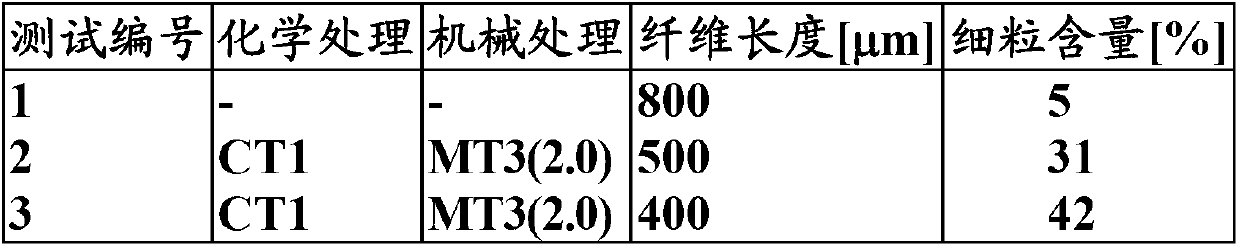

Pharmaceutical Compositions With Enhanced Performance

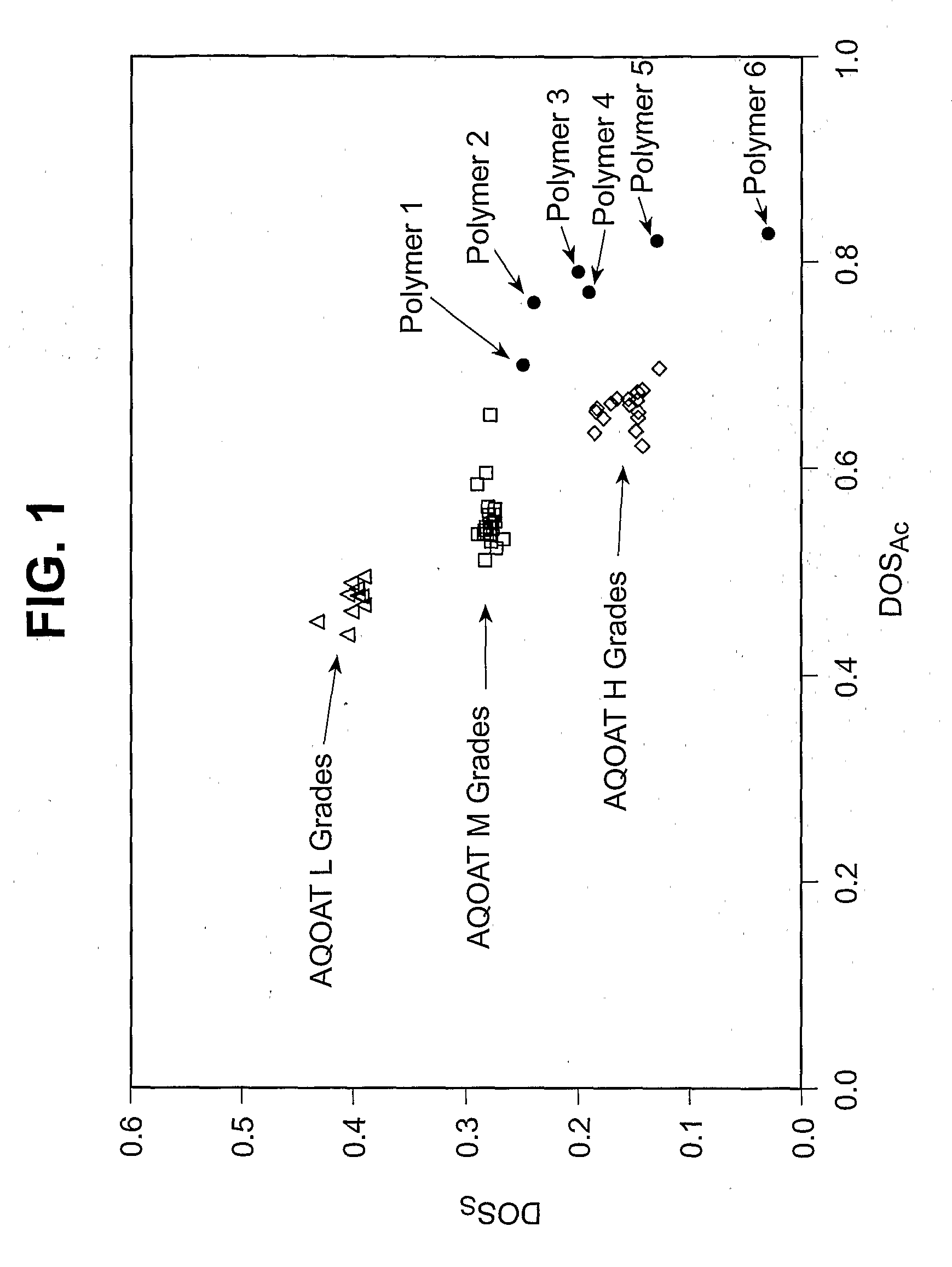

ActiveUS20080262107A1Improve concentrationIncrease drug concentrationPowder deliveryBiocideAcetic acidSolubility

Disclosed are polymers of hydroxypropyl methyl cellulose acetate succinate (HPMCAS) and hydroxypropyl methyl cellulose acetate (HPMCA) with unique degrees of substitution of hydroxypropoxy, methoxy, acetyl, and succinoyl groups. When used in making compositions comprising a low-solubility drug and such polymers, the polymers provide enhanced aqueous concentrations and / or improved physical stability.

Owner:LONZA BEND INC

Breakdown fluid and preparation method thereof

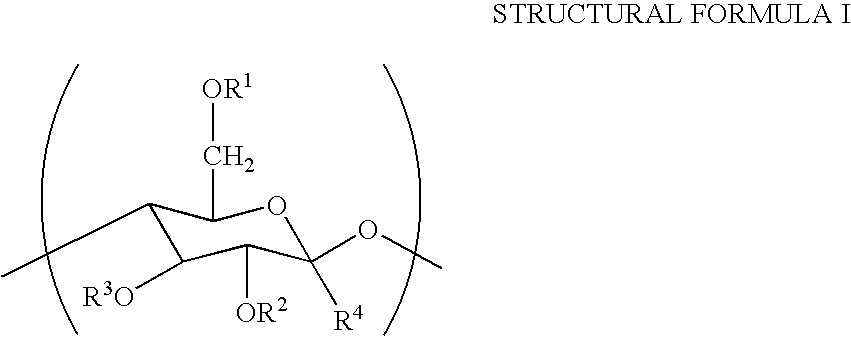

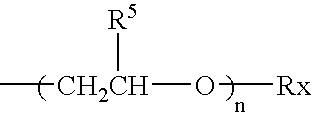

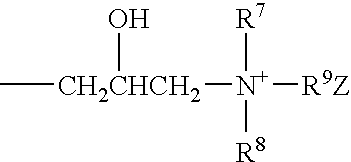

The invention relates to a breakdown fluid and a preparation method thereof. The breakdown fluid comprises the following components: thickener 0.3-1.2%, clay stabilizer 0.5-2%, bactericide 0.01-0.2%, cleanup additive 0.2-1%, and the balance of water-borne working fluid, wherein the thickener is a betaine-type amphoteric thickener based on guar gum derivatives and has a structural formula (I): wherein R is selected from hydroxylpropyl group, hydroxyethyl group, carboxymethyl group and 2-hydroxylpropyl-N,N,N-trimethyl group; R1 and R2 independently represent C1-C4 alkyl group, R3 represents carboxylate radical COO<-> or sulfonate radical SO3<->; and the degree of substitution of R is 0.02-0.6, and the degree of substitution of the betaine type amphoteric ions is 0.02-0.6.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com