Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

615results about "Artificial filaments from cellulose derivatives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

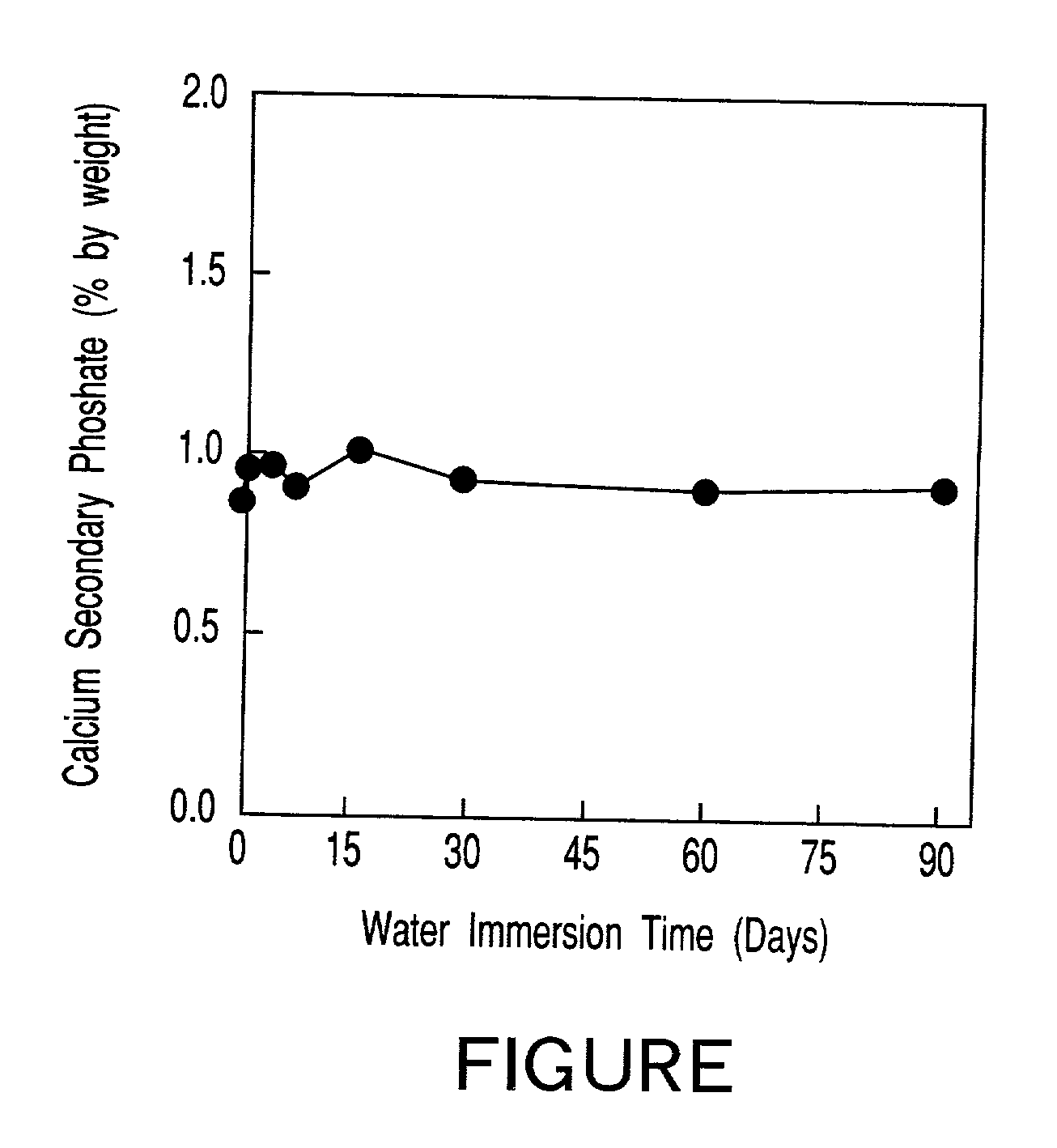

Melt-blown nonwoven fabric, process for producing same and the uses thereof

InactiveUS6207601B1Avoid undesirable oxidative processEliminate useLayered productsTobacco smoke filtersMean diameterPolymer science

The disclosure relates to a melt-blown non-woven fabric based on cellulose esters, with fibers of mean diameter less than about 10 microns. The fabric contains 0-10 wt. % extractable softener, has a reflection factor determined according to DIN 53 145 Part I (1992) of more than 60% and the cellulose ester has a degree of substitution DS of about 1.5-3.0. The softener is preferably water-extractable. A melt-blown non-woven fabric is produced with the cellulose ester as follows: a cellulose ester, cellulose acetate, with a DS of about 1.5-3.0, in particular 1.7-2.7, is mixed with softener in a weight ratio of about 2:1 to 1:4 and simultaneously heated and melted. The mixture of softener and cellulose ester has a melting index MFI (210 / 2.16) according to DIN 53 735 of about 400 to 5 g / 10 min., in particular 300 to 50 g / 10 min. The melt is worked in a melt-blown spinning device into a melt-blown non-woven fabric and the softener is then extracted with a softener solvent to leave a proportion of 0-10 wt. %. The melt-blown non-woven fabric is especially suitable as a filter material.

Owner:RHODIA ACETOW AG

Copolyesters and fibrous materials formed therefrom

InactiveUS20020132960A1Deep dyeabilityGood printabilityMonocomponent copolyesters artificial filamentArtificial filaments from cellulose derivativesCelluloseFiber

This invention relates to binary blends of cellulose esters and aliphatic-aromatic copolyesters, cellulose esters and aliphatic polyesters as well as ternary blends of cellulose esters and / or aliphatic polyesters and / or aliphatic-aromatic copolyesters and / or polymeric compounds as well as fibers, nonwovens, molded objects, and films prepared therefrom.

Owner:EASTMAN CHEM CO

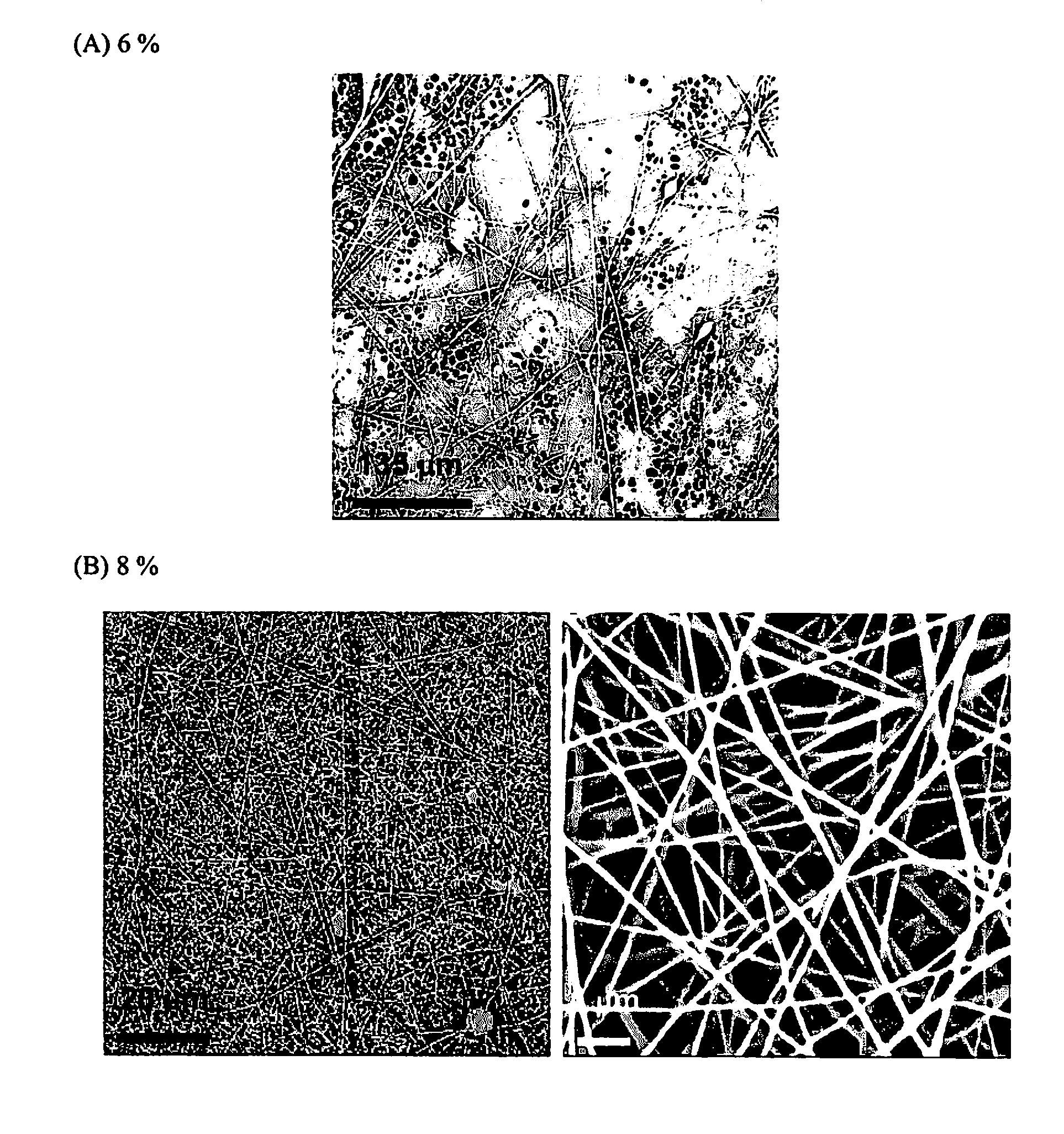

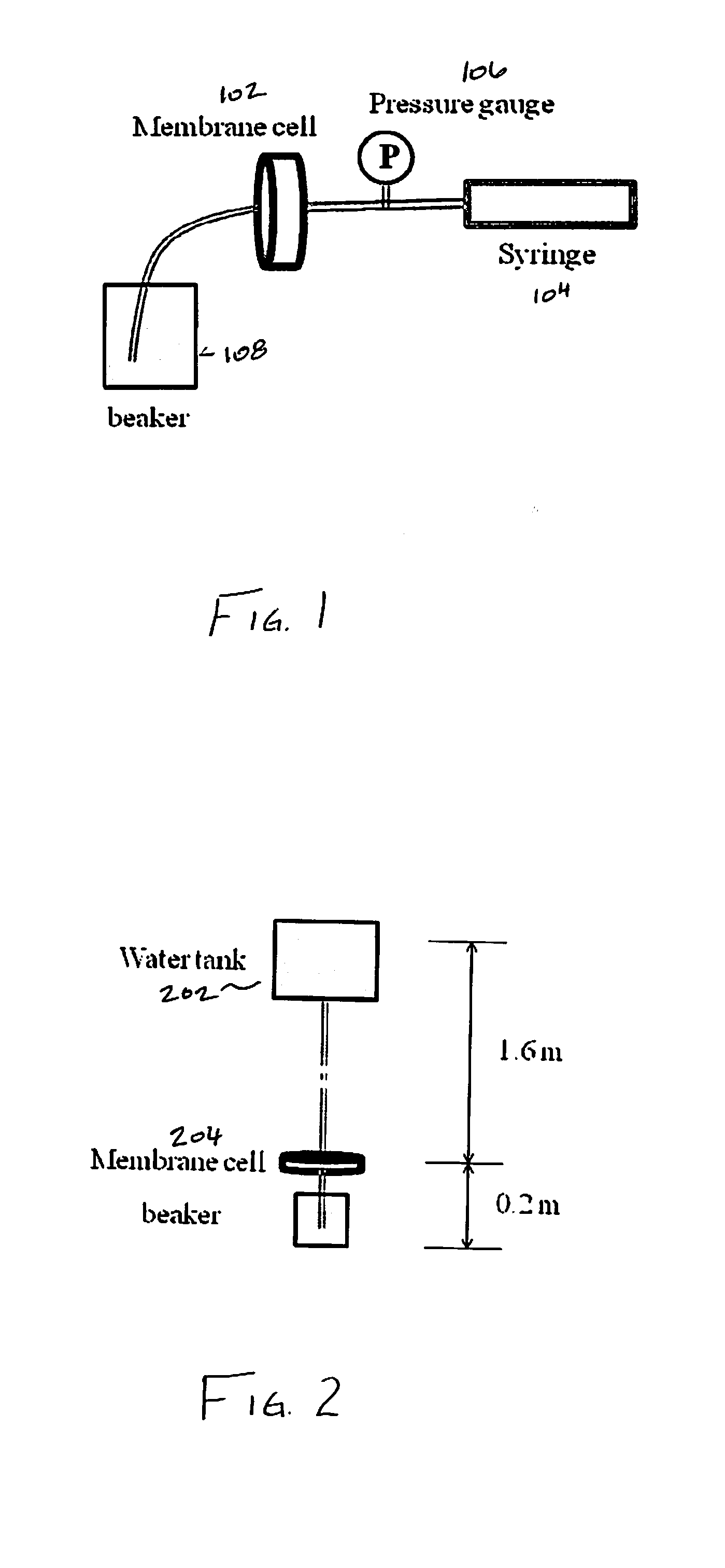

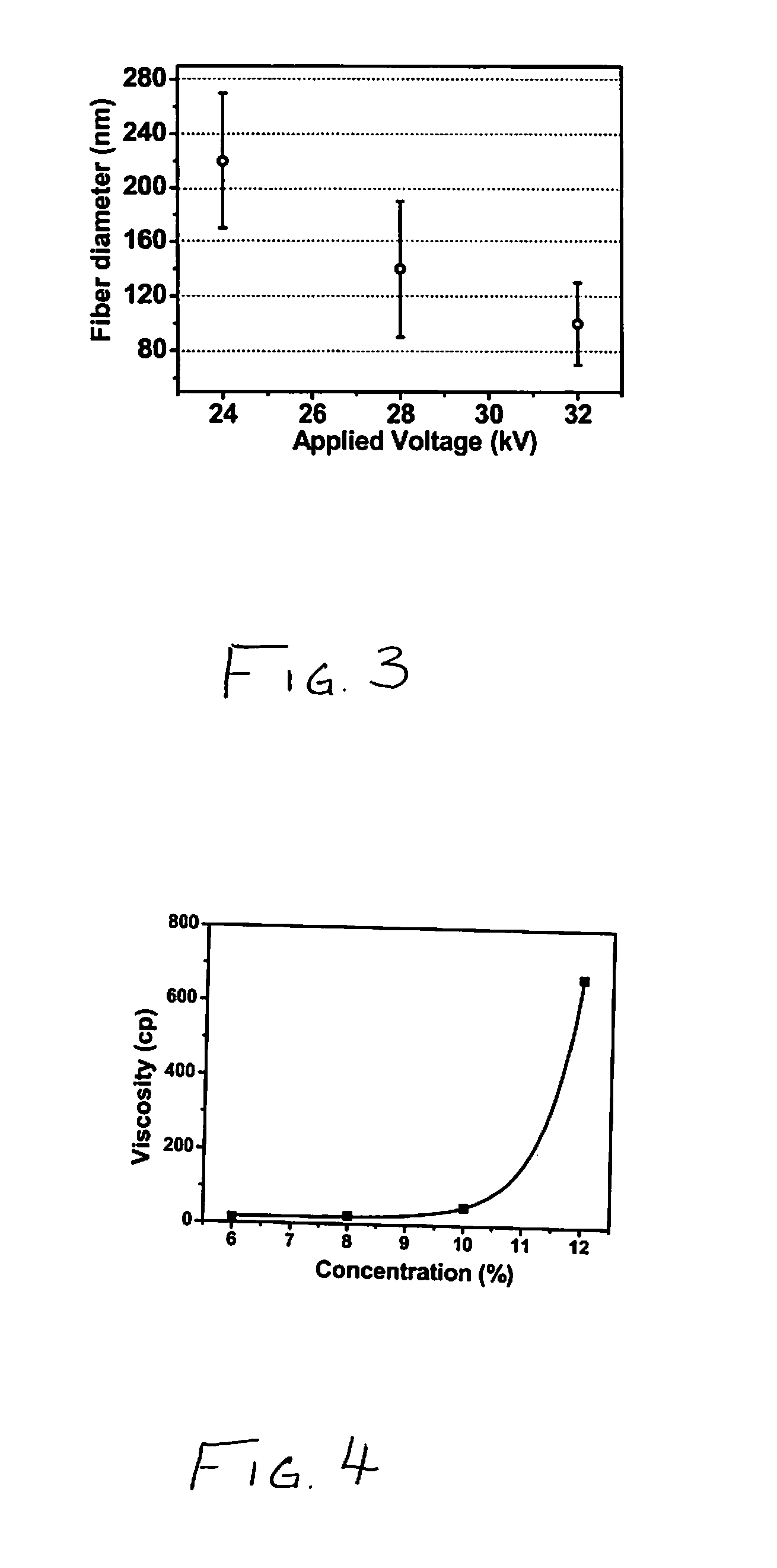

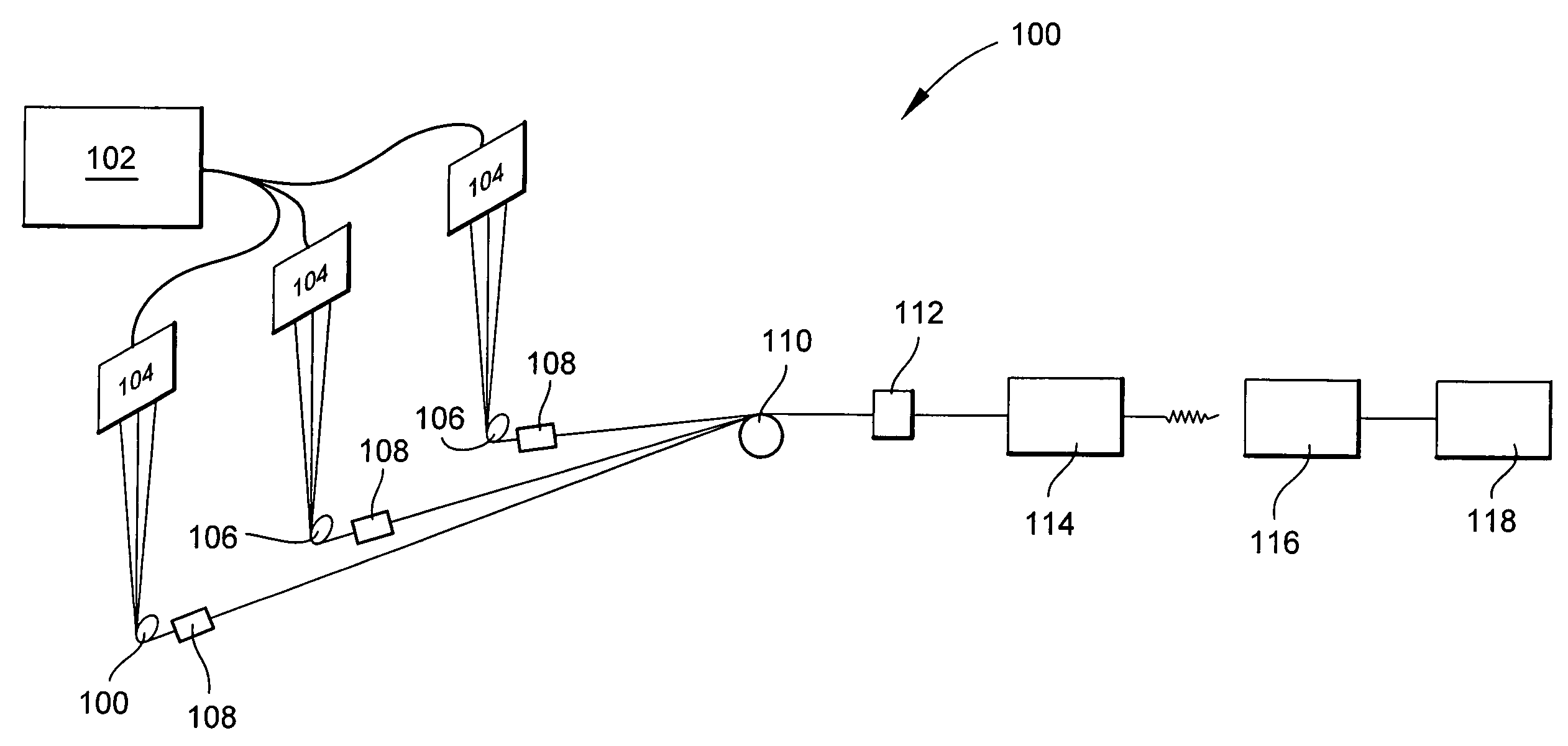

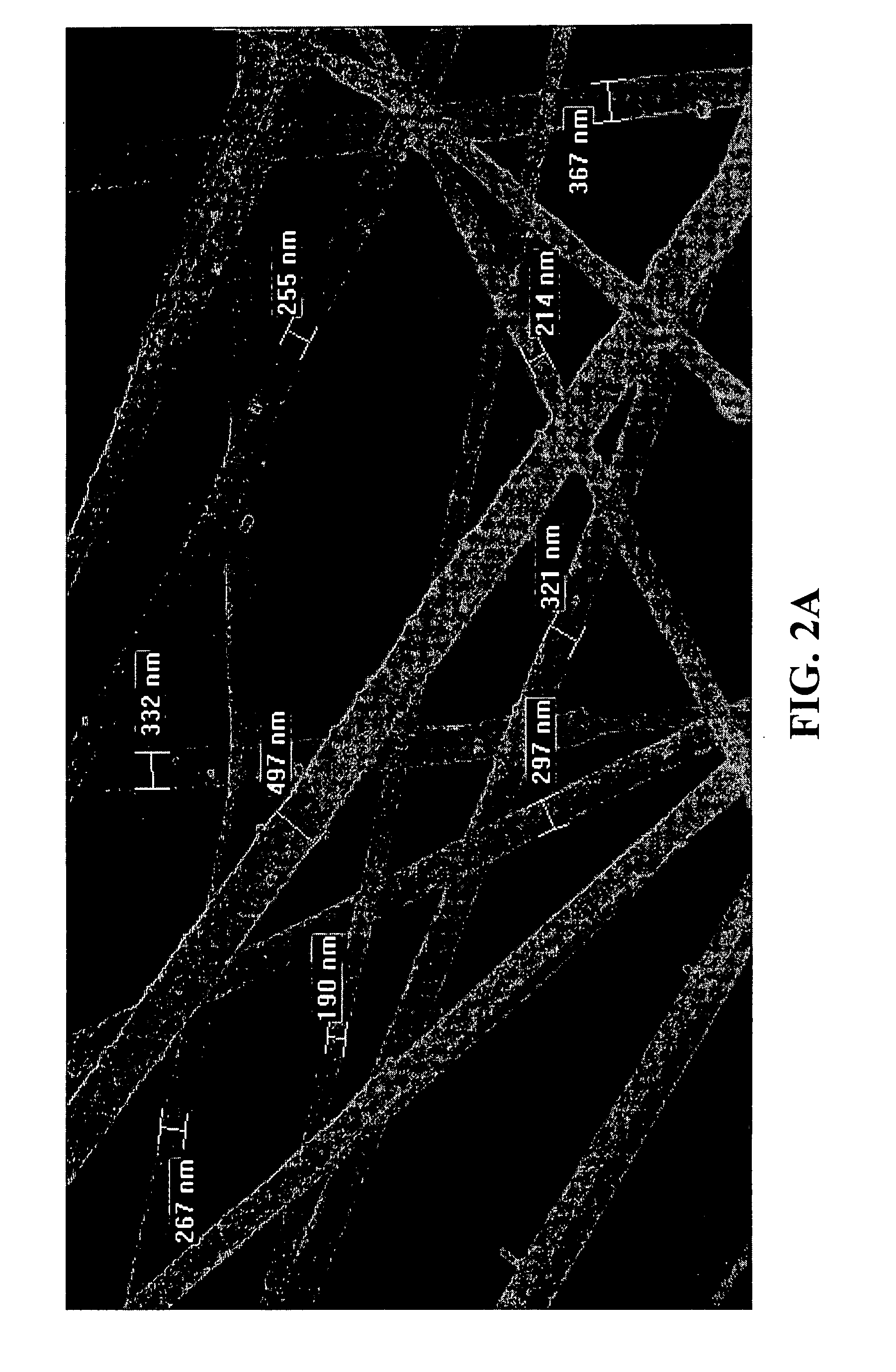

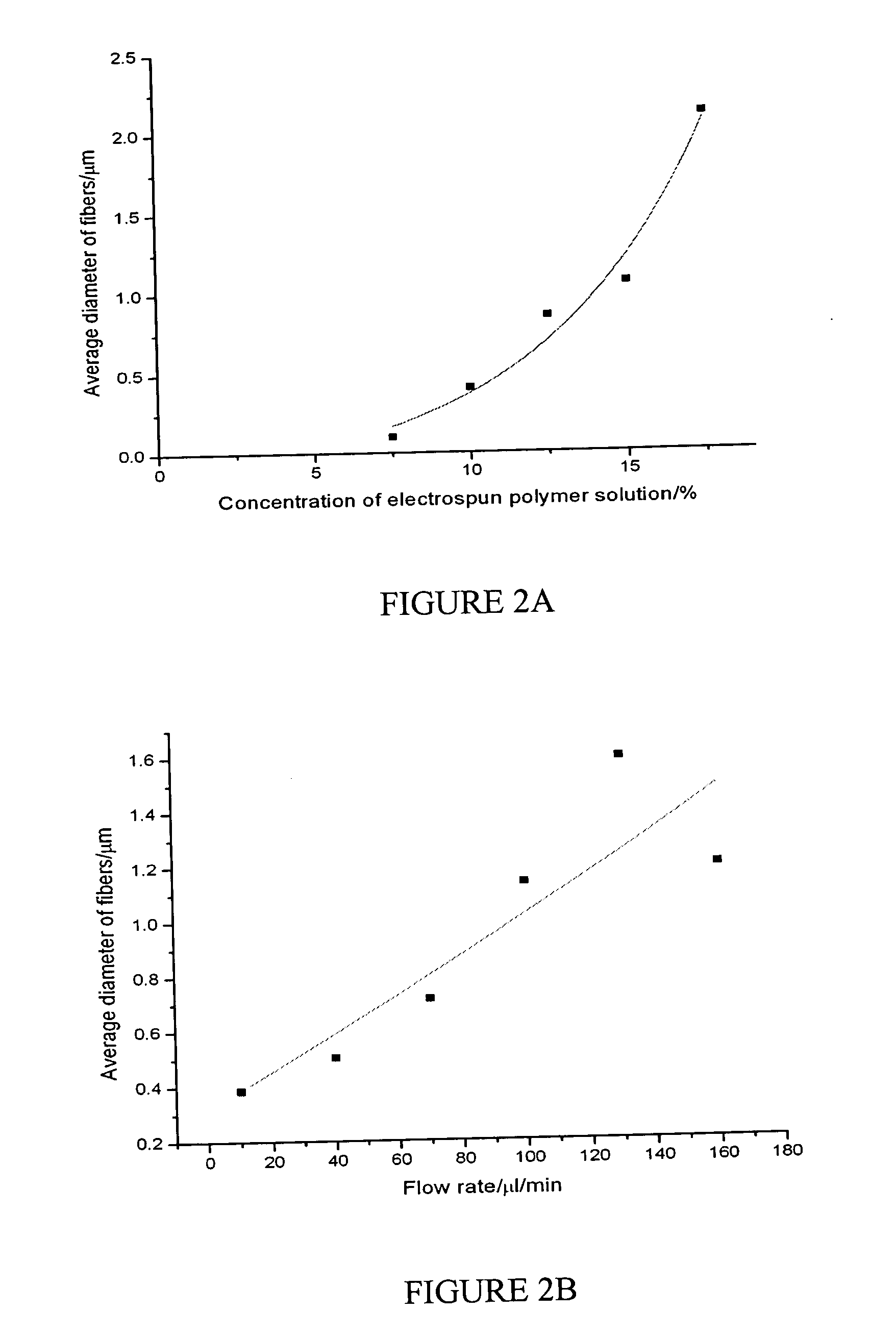

High flux high efficiency nanofiber membranes and methods of production thereof

A membrane is provided including a coating layer having cellulose nanofibers produced from oxidized cellulose microfibers and an electrospun substrate upon which the coating layer is applied. The nanofibers of the electrospun substrate have a diameter greater than that of the cellulose nanofibers. The membrane also has non-woven support upon which the electrospun substrate is disposed. Microfibers of the non-woven support have a diameter greater than that of the nanofibers of the electrospun substrate. Application of electrospun membrane is in microfiltration area, while the cellulose nanofiber membrane serves in ultra-filtration, nanofiltration, and reverse osmosis after chemical modification.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

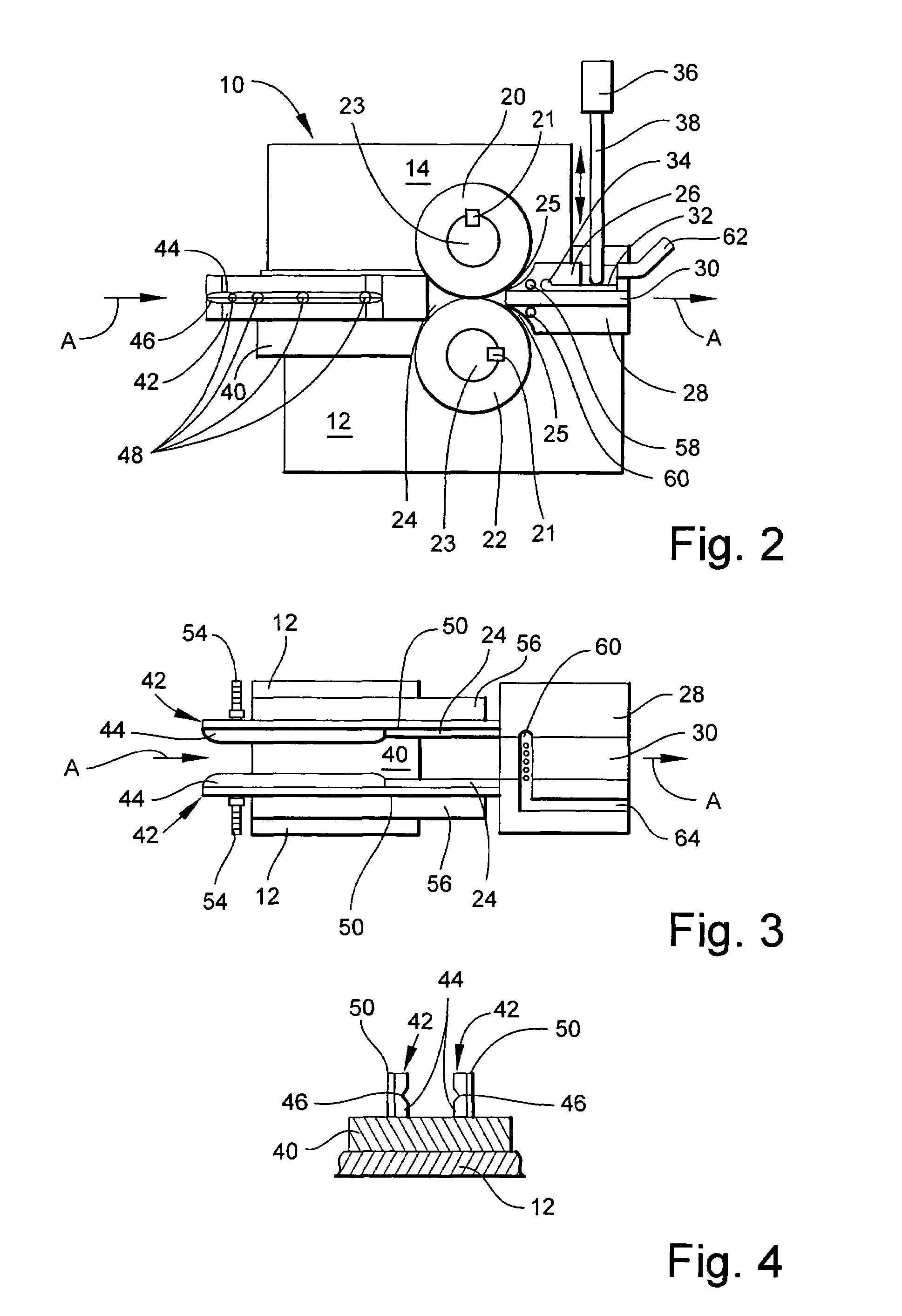

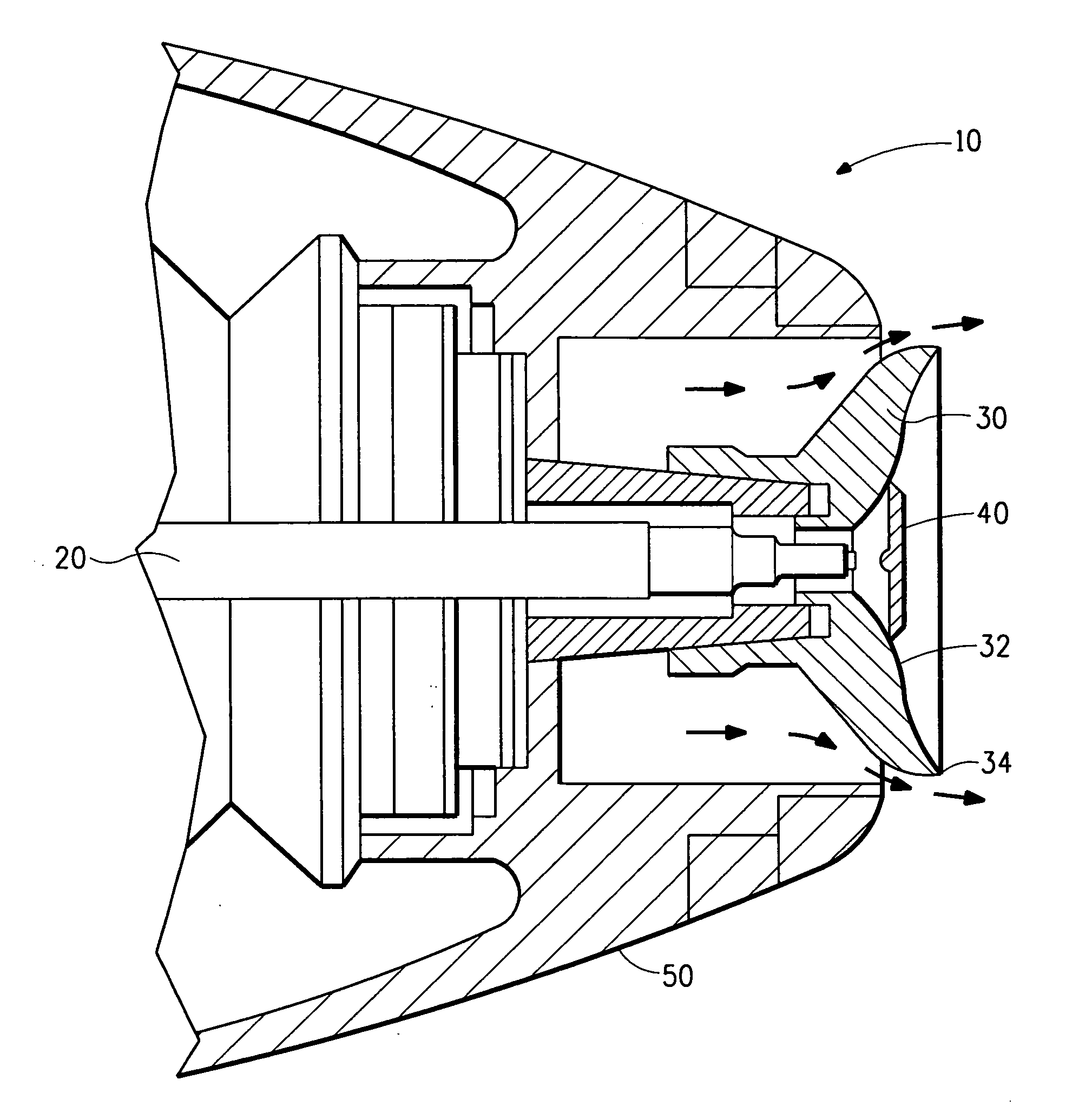

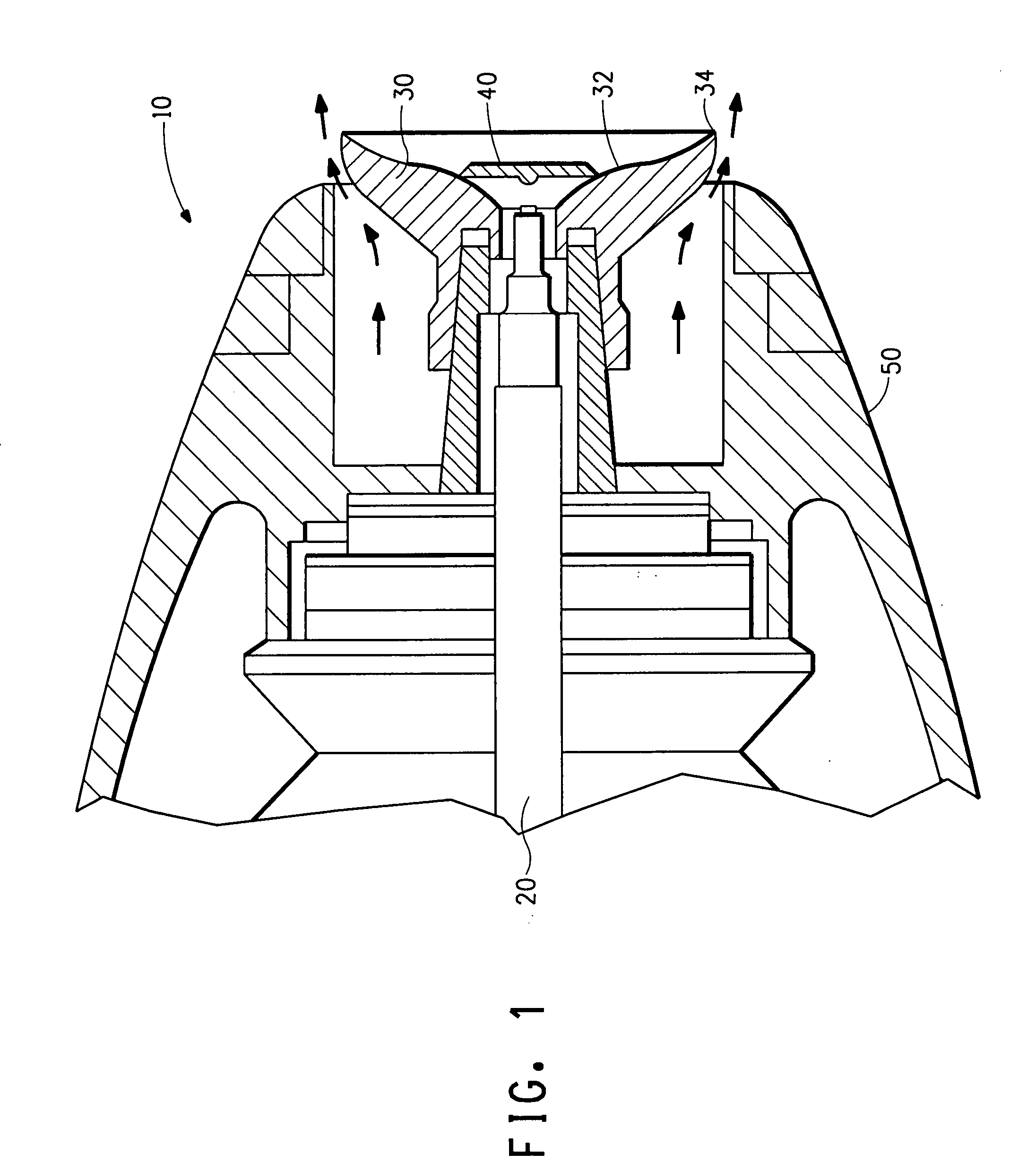

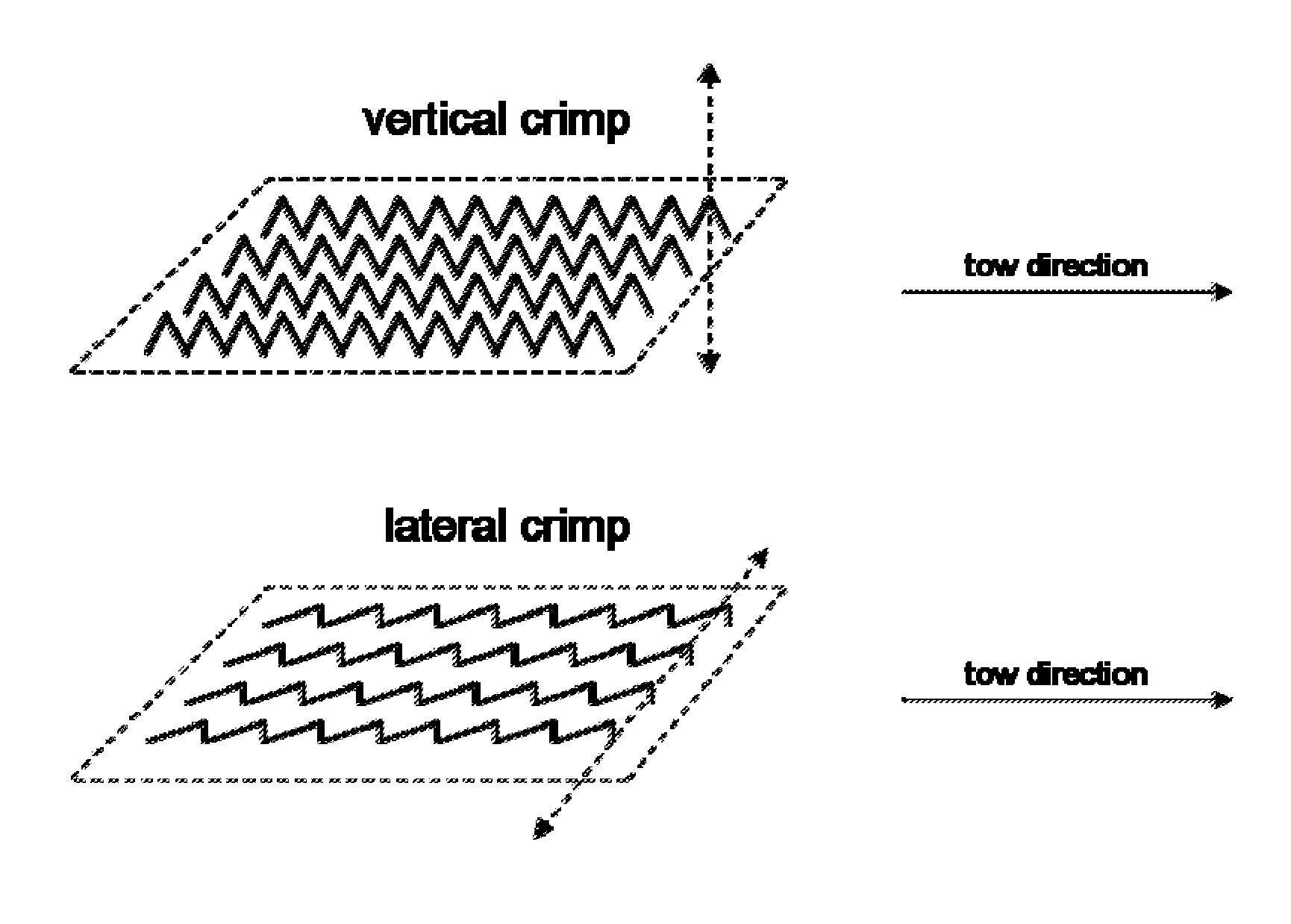

Process for making cellulose acetate tow

A process for making a cigarette tow comprising: spinning a dope; taking-up the as-spun cellulose acetate filaments; lubricating the filaments; forming a tow from the filaments; crimping the tow with a stuffer box crimper; drying the crimped tow; and baling the dried crimped tow. The process further comprises at least two of the following:A. crimping further comprising one roller of the pair of nip rollers being adapted to induce crimp into the tow;B. crimping further comprising one roller of the pair of nip rollers being made of a solid ceramic material;C. crimping further comprising a pair of tow edge lubricators;D. crimping further comprising a steam injector;E. further comprising plasticizing the tow;F. lubricating the filaments further comprises a finish consisting of a water emulsion.

Owner:DEUT BANK AG NEW YORK BRANCH AS COLLATERAL AGENT +1

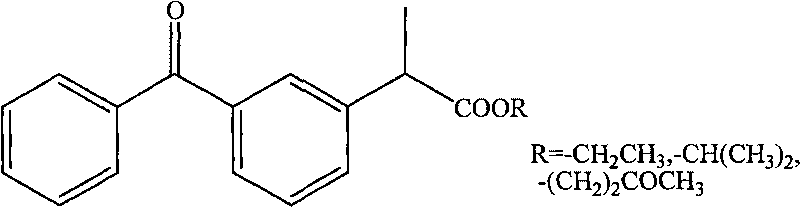

Medicinal fibre used for treating cutaneous inflammation and pain, preparation and application thereof

InactiveCN101724934AEasy to prepareLow costOrganic active ingredientsAntipyreticFiberOrganic solvent

The invention relates to medicinal fibre used for treating cutaneous inflammation and pain, which comprises the components of cellulose acetate nano fibre, a ketoprofen ester precursor medicine and a medicinal percutaneous sorbefacient, wherein the ketoprofen ester precursor medicine accounts for 0.1-30% of the total weight of the fibre, the medicinal percutaneous sorbefacient accounts for 0.1-10% of the total weight of the fibre, and the cellulose acetate nano fibre accounts for 1-99% of the total weight of the fibre; the preparation of the medicinal fibre comprises the following steps: dissolving the ketoprofen ester precursor medicine, the medicinal percutaneous sorbefacient and the cellulose acetate into an organic solvent to prepare spinning liquid and then spinning to prepare the required medicinal fibre. The medicinal fibre has the effect of treating cutaneous inflammation and pain, has simple preparation method, convenient source of the raw materials and low cost, is friendly to the environment and is suitable for industrialized production; the fibre can be prepared into medicine-carrying clothings or other fabrics which directly contact with the skin of a human body, and the percutaneous administration is safe and comfortable.

Owner:DONGHUA UNIV +1

Thermoplastic cellulose derivative composition and fiber comprising the same

InactiveUS6984631B2Good fluidityIncrease resistanceOrganic active ingredientsBiocidePolyesterSide chain

A thermoplastic cellulose derivative composition of the present invention contains, as a main component, a cellulose ester having an aliphatic polyester side chain having a repeat unit having 2 to 5 carbon atoms, wherein a rate of heating loss at 200° C. is 5 wt % or less, a melt viscosity at 200° C. and 1000 sec−1 is 50 to 300 Pa·sec, and a melt tension at the time of take-up at 200° C. and 100 m / min is 0.1 to 40 mN. The present invention can provide excellent fiber products by melt spinning of the composition.

Owner:TORAY IND INC

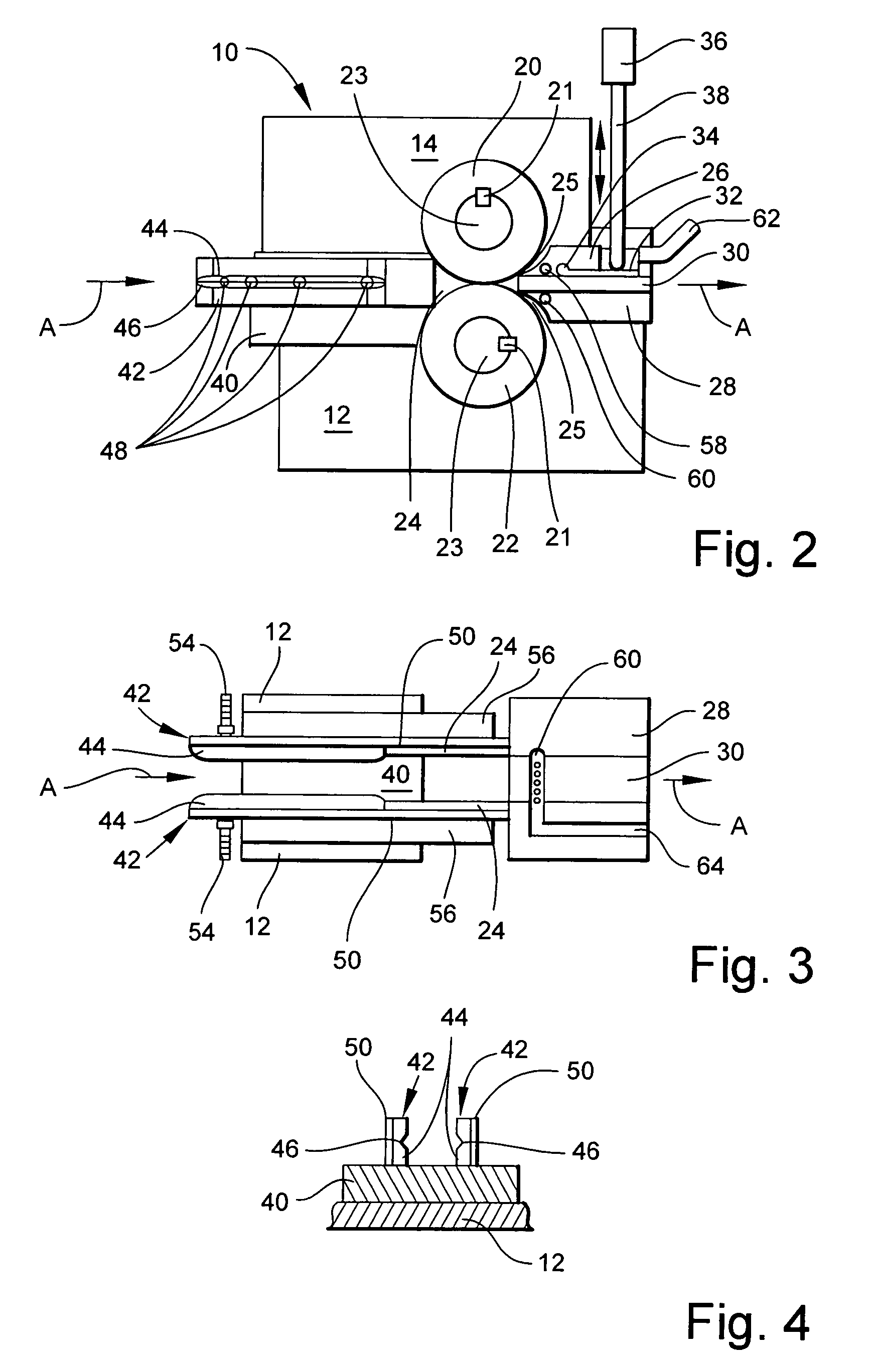

Process of making cellulose acetate tow

ActiveUS7585441B2Artificial filament physical treatmentArtificial filaments from cellulose derivativesFiberPlasticizer

In the manufacture of a fiber tow, particularly cellulose acetate tow, the tow is plasticized prior to entry into the crimper. The preferred plasticizer is water.

Owner:DEUT BANK AG NEW YORK BRANCH AS COLLATERAL AGENT +1

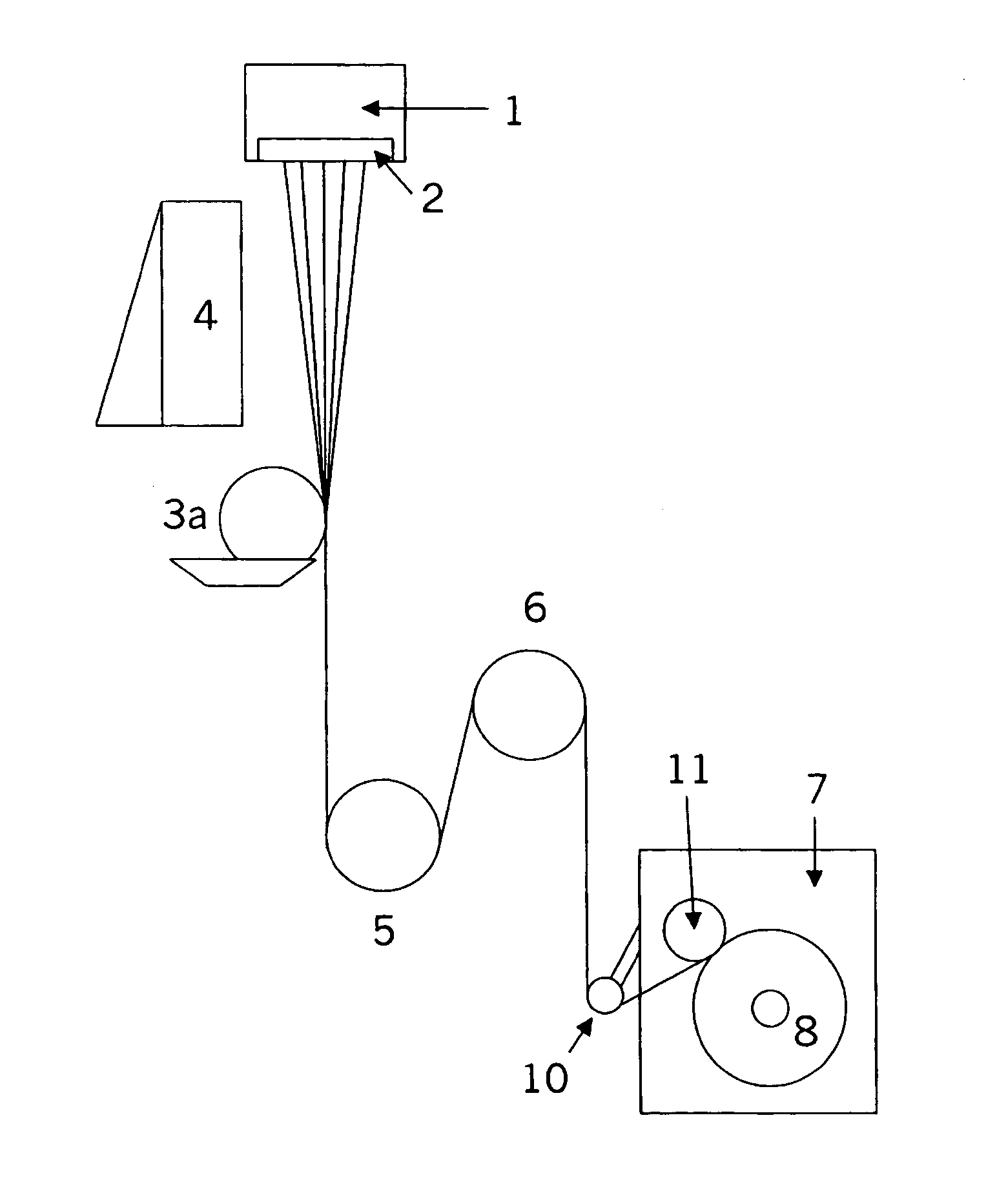

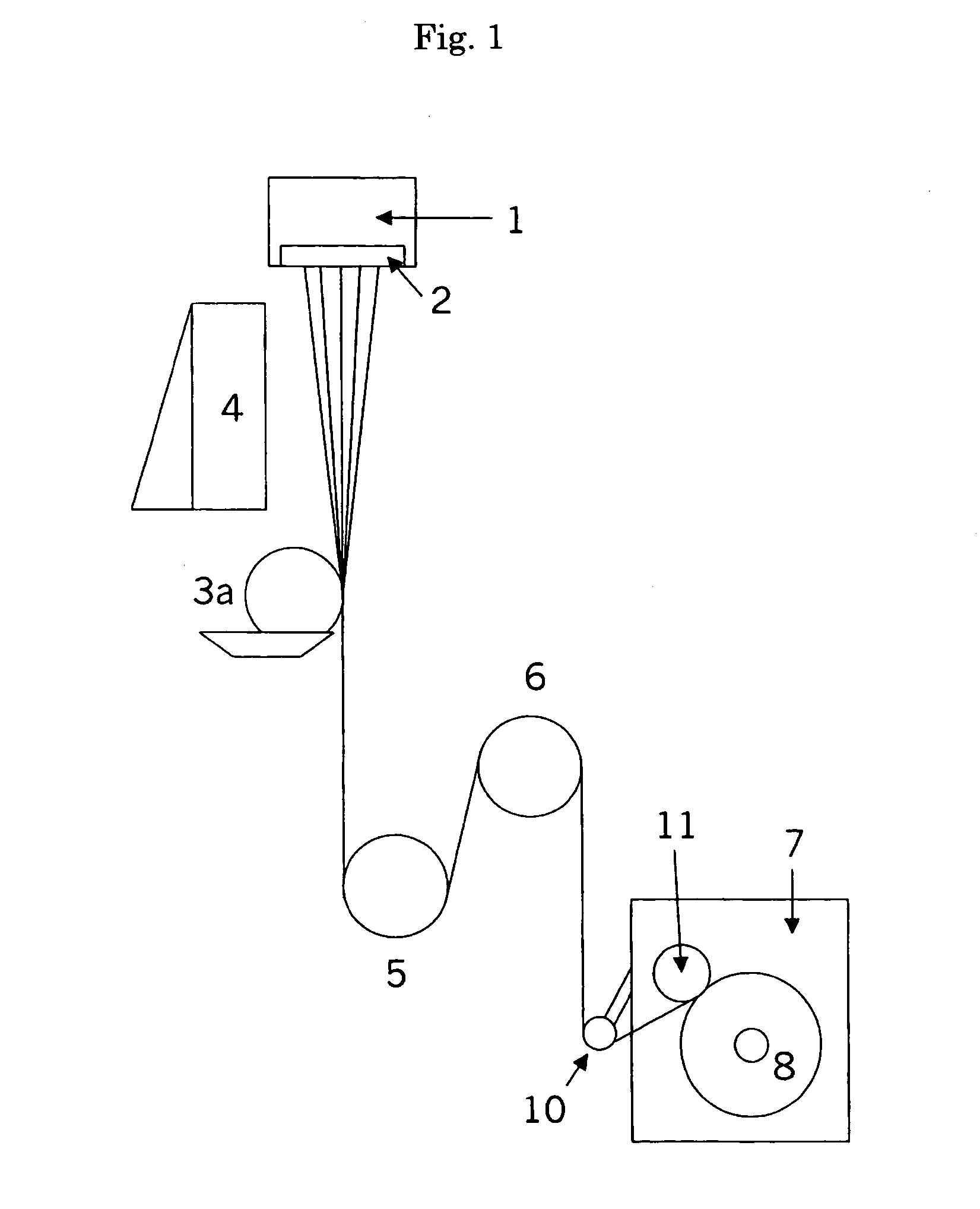

Method of producing an absorbent material, an absorbent material and absorbent articles including the material in question

InactiveUS6846924B1Facilitates uniform meteringSugar derivativesArtificial filaments from cellulose derivativesFiberOrganic solvent

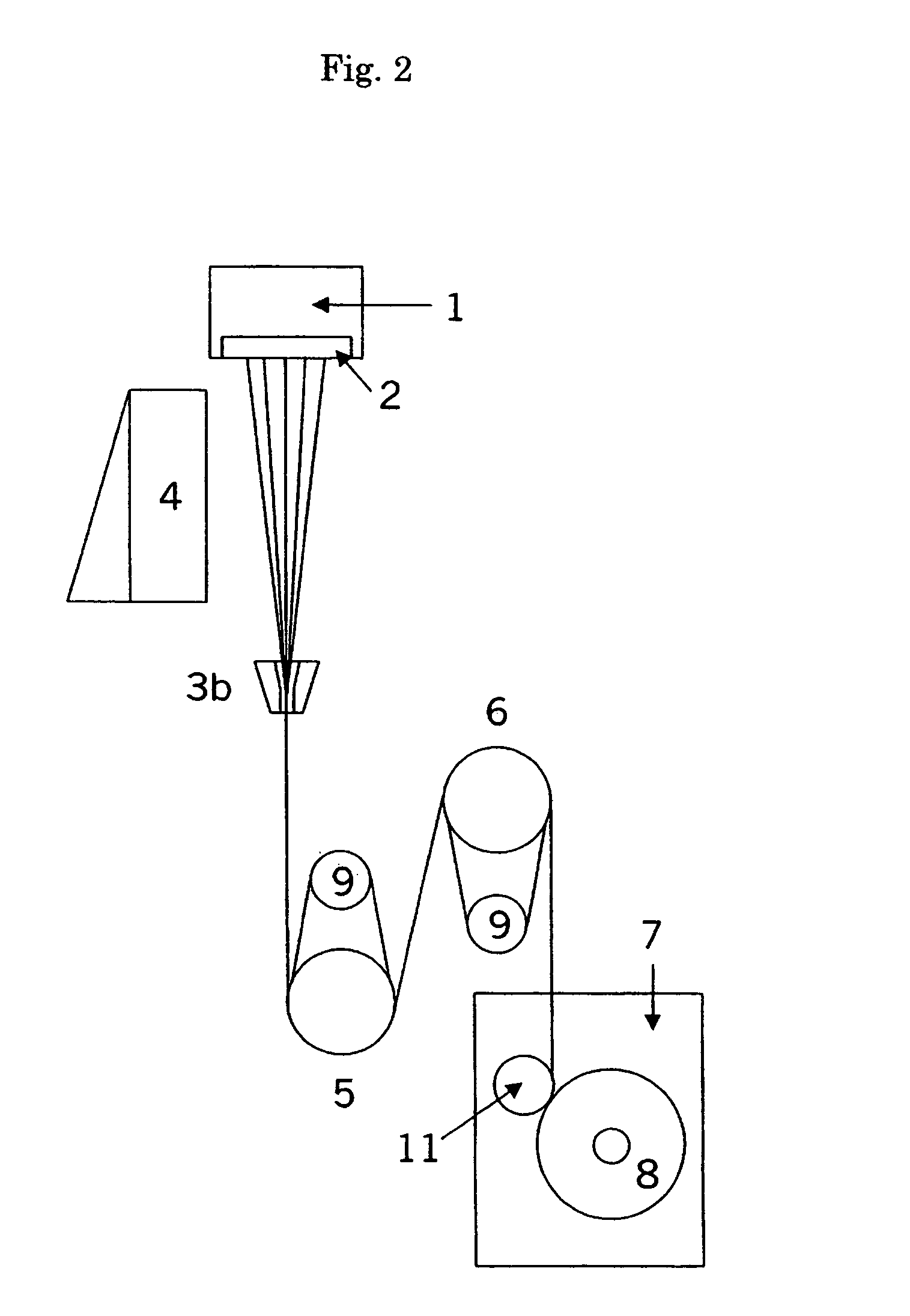

The present invention relates to a method of producing polysaccharide fibres (8), wherein the polysaccharide is dissolved and the solution is sprayed into a bath (7) which contains a water-miscible organic solvent and a cross-linker. The invention also relates to a polysaccharide fibre (8) produced by the method, and to an absorbent article which includes the polysaccharide fibre (8).

Owner:SCA HYGIENE PROD AB

Cellulose acetate and dope containing the same

InactiveUS7122660B1Good release effectSatisfactory optical propertyArtificial filaments from cellulose derivativesCarboxyl radicalCellulose diacetate

Using the dope containing the following cellulose acetate (1), (2), or (3), a film is prepared by the casting process:(1) a cellulose acetate having carboxyl groups binding to at least one member selected from the group consisting of a cellulose acetate and a hemicellulose acetate, wherein at least a part of said carboxyl groups are in an acidic form;(2) a cellulose acetate containing at least one member selected from the group consisting of an acid having an acid dissociation exponent pKa of 1.93 to 4.50 in water, an alkali metal salt of said acid and an alkaline earth metal of said acid; or(3) a cellulose acetate containing an alkali metal or an alkaline earth metal wherein the total content of an alkaline metal and an alkaline earth metal in 1 gram of the cellulose acetate is from an effective amount to 5.5×10−6 equivalent (in terms of ion equivalent). The above cellulose acetate is also useful for spinning process. The cellulose acetate includes a cellulose diacetate and a cellulose triacetate. The cellulose acetate of the present invention has high film-releasability from a support and excellent optical characteristics.

Owner:DAICEL CHEM IND LTD

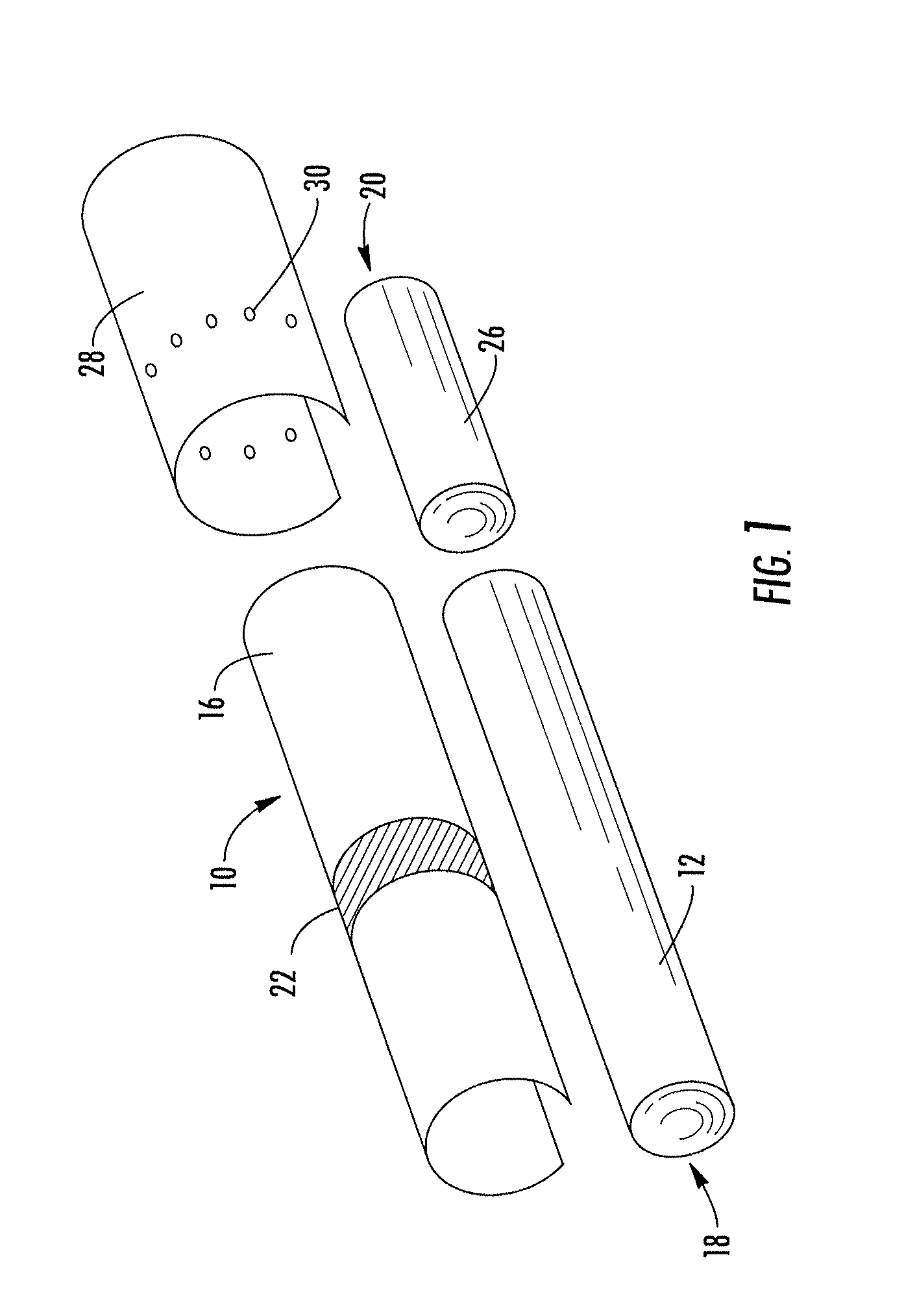

Degradable filter element

ActiveUS20110036366A1Improve degradation ratePromote degradationTobacco treatmentTobacco smoke filtersFiberPolymer science

A filter material adapted for use as a filter element of a smoking article is provided, the filter material including at least one segment of fibrous tow having a plurality of degradable particles dispersed therein, the degradable particles comprising a starch material. Exemplary starch materials include naturally-occurring starch, hydroxyalkylated starch, starch esters, ionically modified starch, oxidized starch, hydrolyzed starch, plasticized starch, gelatinized starch, grafted starch, crosslinked starch, transglycosylated starch, starch ethers, and mixtures thereof, as well as blends of starch with other polymers. Filter elements and smoking articles, such as cigarettes, that contain the filter material are also provided. A method of preparing polymer fibers for use in filter elements is also provided, the method including adding the starch material to a fiber precursor solution prior to fiber extrusion or dry-blending the starch material with the polymer material to be formed into fibers.

Owner:R J REYNOLDS TOBACCO COMPANY

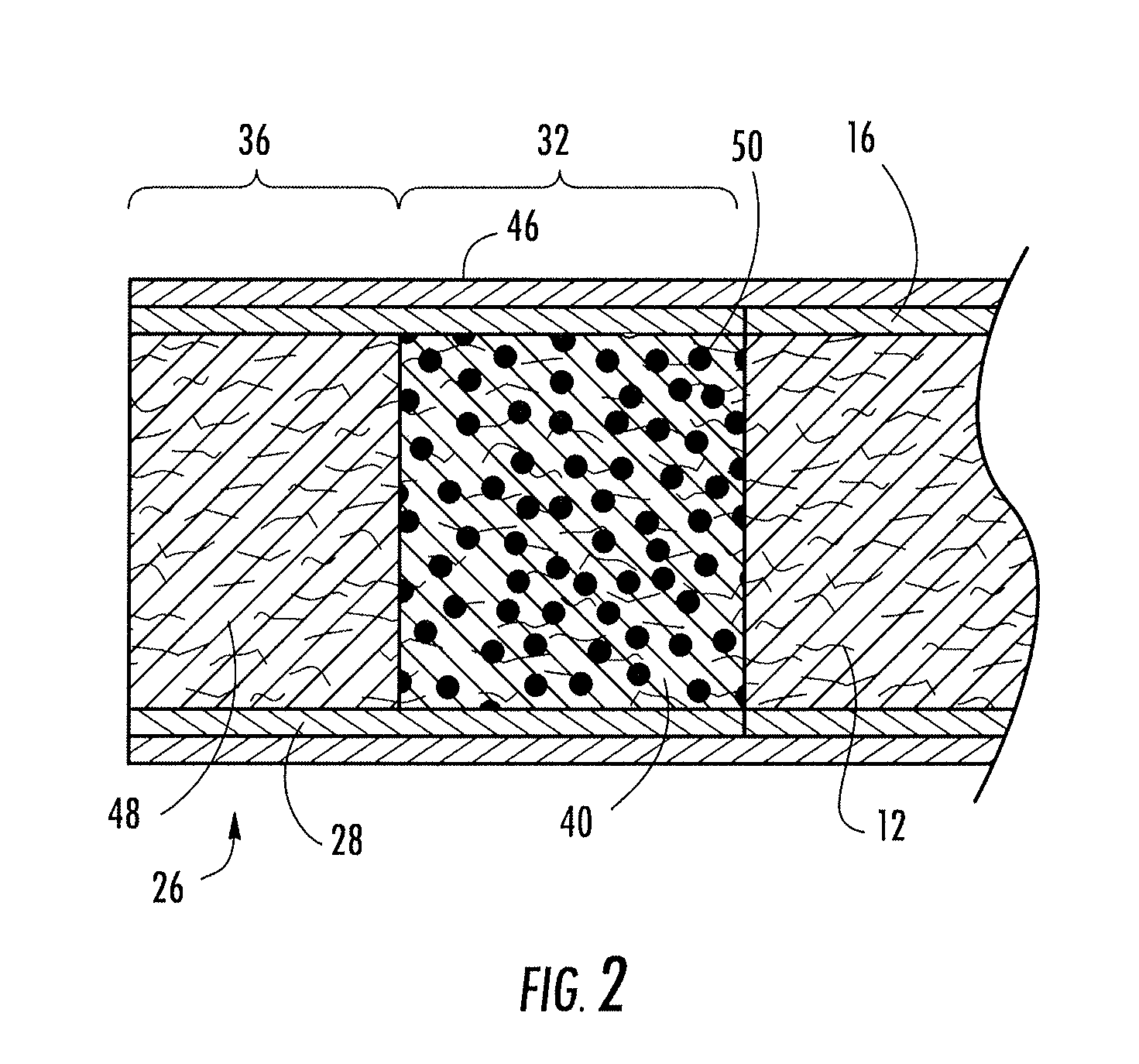

Biodegradable cellulose acetate structure and tobacco filter

A cellulose acetate structure excellent in its biodegradability. At least a surface region of the structure includes a biodegradable cellulose acetate composition containing a biodegradation promoting agent contained in cellulose acetate. The agent includes at least one compound selected from the group consisting of a salt of an oxygen acid of phosphorus, an ester of an oxygen acid of phosphorus or a salt thereof, carbonic acid and a salt thereof.

Owner:JAPAN TOBACCO INC

Cellulose ester composition

InactiveUS6139785AReduce preparation timeAvoid pollutionArtificial filaments from cellulose derivativesFlat articlesDegree of substitutionAcylal

The present invention provides a cellulose ester composition, containing 1 to 99% by weight of cellulose triacetate prepared by substituting hydroxyl groups of cellulose with acetyl and having a degree of substitution with acetyl, DSace, which satisfies the relationship: 2.7< / =DSace< / =3.0, and 99 to 1% by weight of a mixed fatty acid ester of cellulose prepared by substituting hydroxyl groups of cellulose with acetyl and acyl groups having three or more carbon atoms and having degrees of substitution with acetyl and acyl groups having three or more carbon atoms, DSace and DSacyl, respectively, which satisfy the relationships: (I) 2.20< / =DSace< / =2.95, (II) 0.05< / =DSacyl< / =0.80 and (III) 2.60< / =DSace+DSacyl< / =3.00.

Owner:DAICEL CHEM IND LTD

Optical film, polarizing plate and display

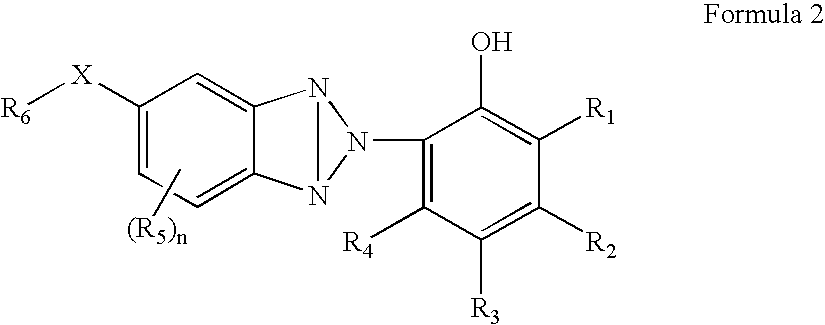

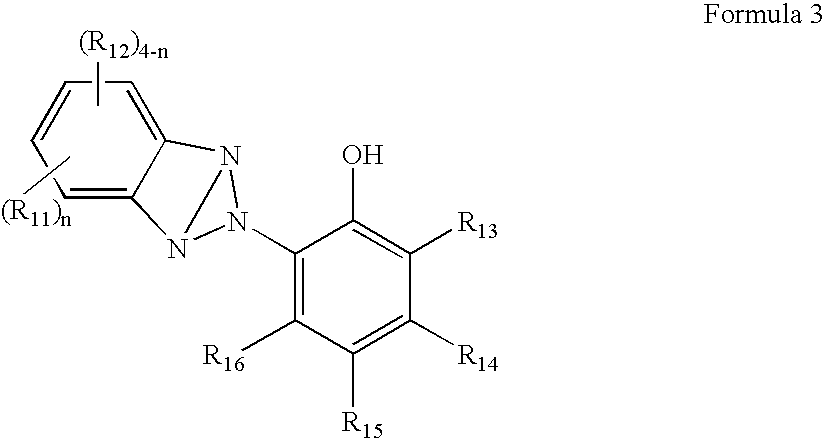

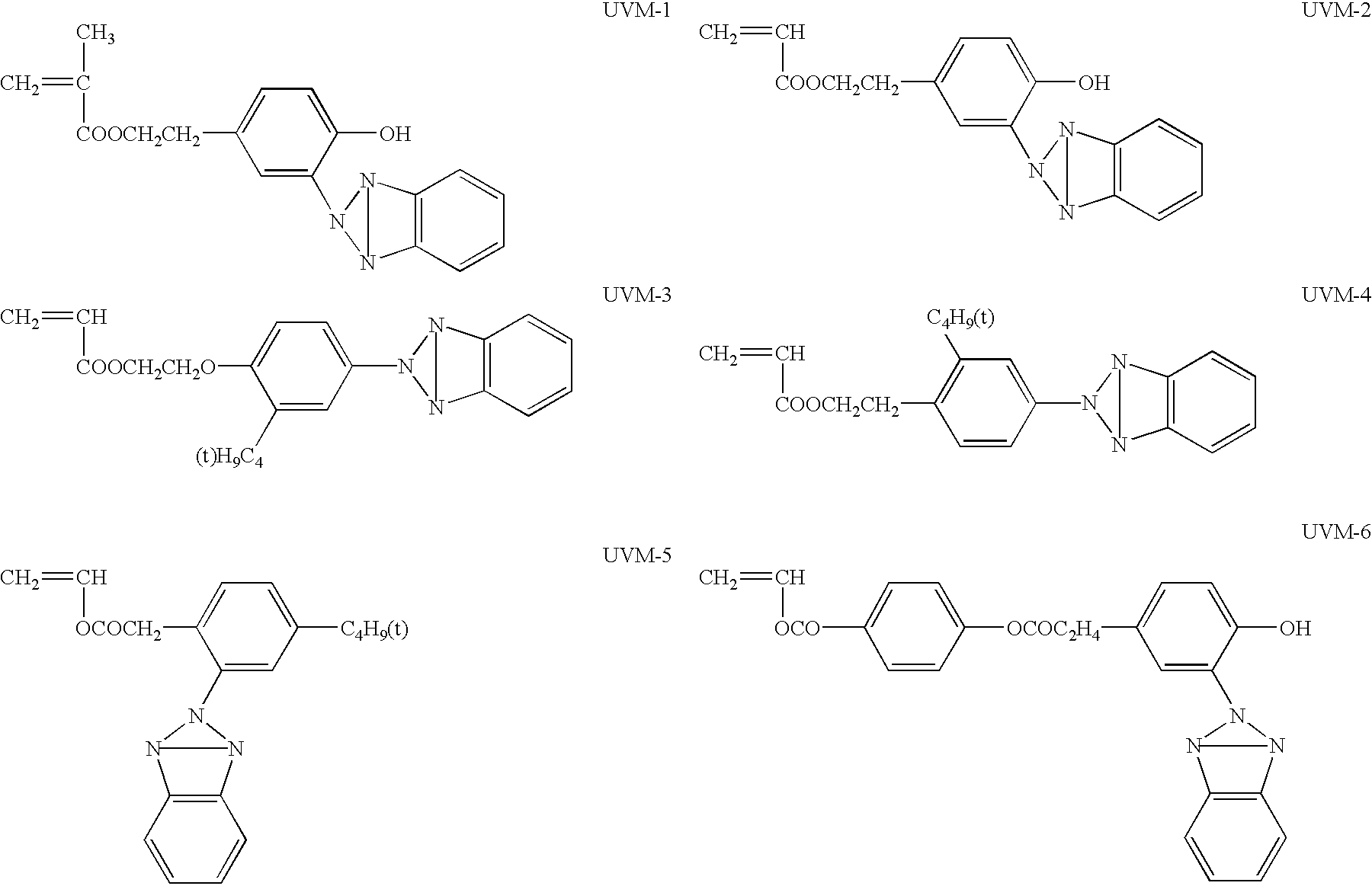

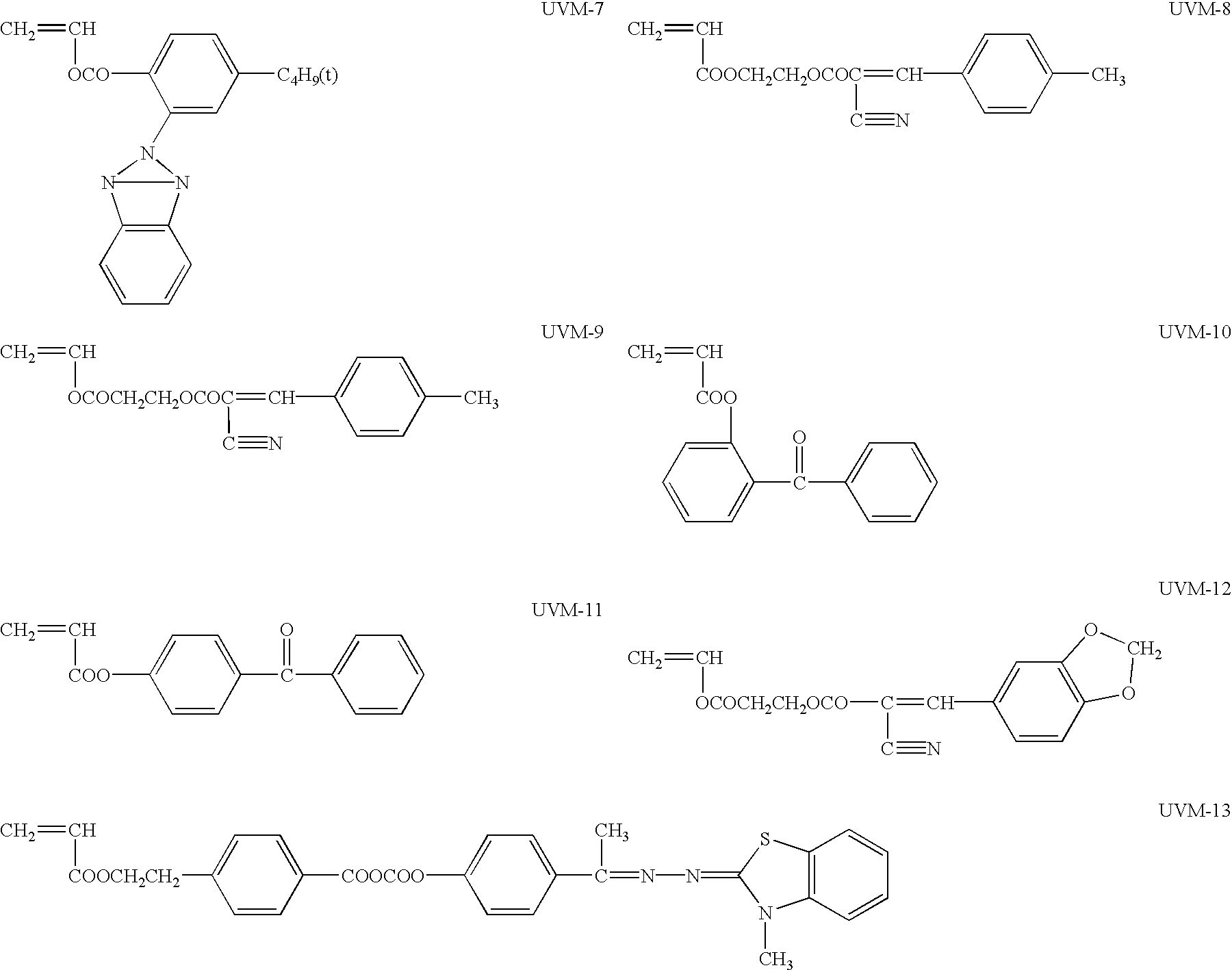

InactiveUS20060078754A1Easy to produceImprove production efficiencyElectric discharge tubesSynthetic resin layered productsCelluloseBenzene

A method for producing an optical film comprising steps of mixing a heated and molten cellulose ester having an acylated degree for from 2.5 to 2.9 and at least one of a UV absorbent having at least two benzotriazole skeletons and a UV absorbent having a weight average molecular weight of from 2,000 to 50,000 to form a mixture, and extruding the mixture to form a film.

Owner:KONICA MINOLTA OPTO

Cellulose ester film, cellulose ester dope, protective film of polarizing plate and polarizing plate

InactiveUS6974608B2Reduce penetrationImprove retentionLiquid crystal compositionsOptical filtersTectorial membraneCellulose ester membrane

Disclosed is a cellulose ester film comprising a polymer prepared by polymerizing at least one ethylenically unsaturated monomer selected from vinyl esters, vinyl esters having a functional group, acrylic esters, and acrylic esters having a functional group, wherein the polymer has a weight average molecular weight of not more than 5,000.

Owner:KONICA CORP

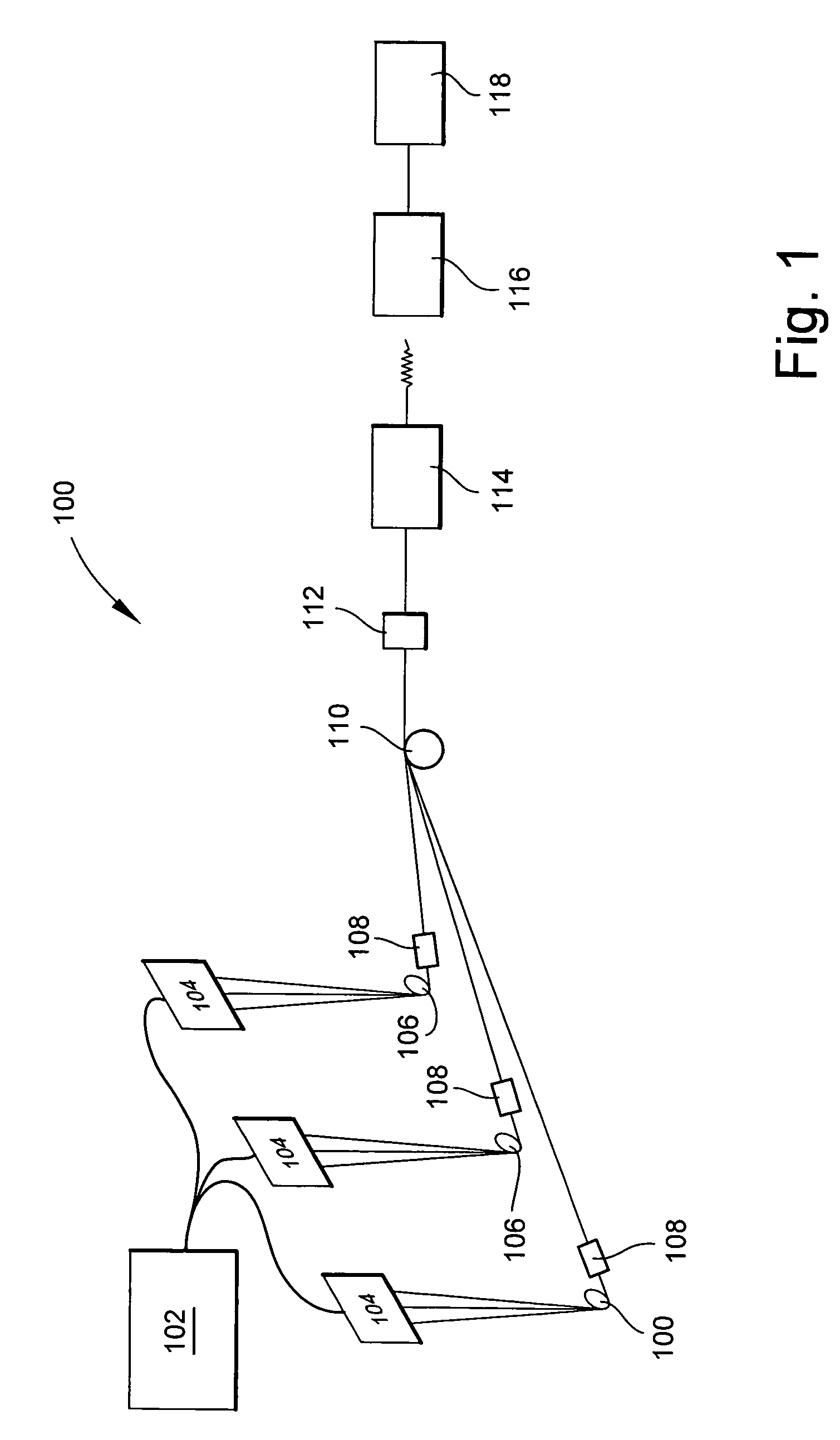

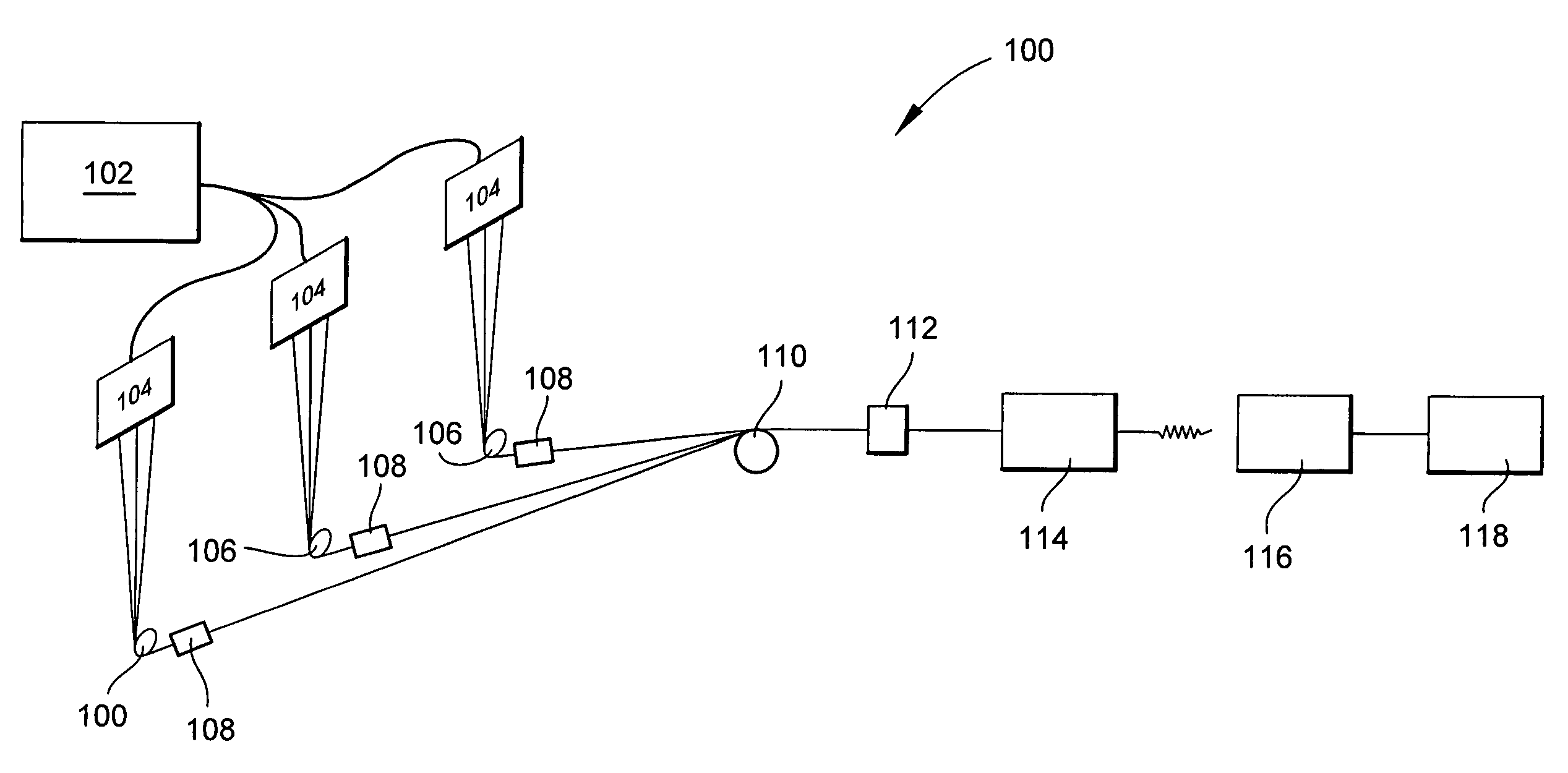

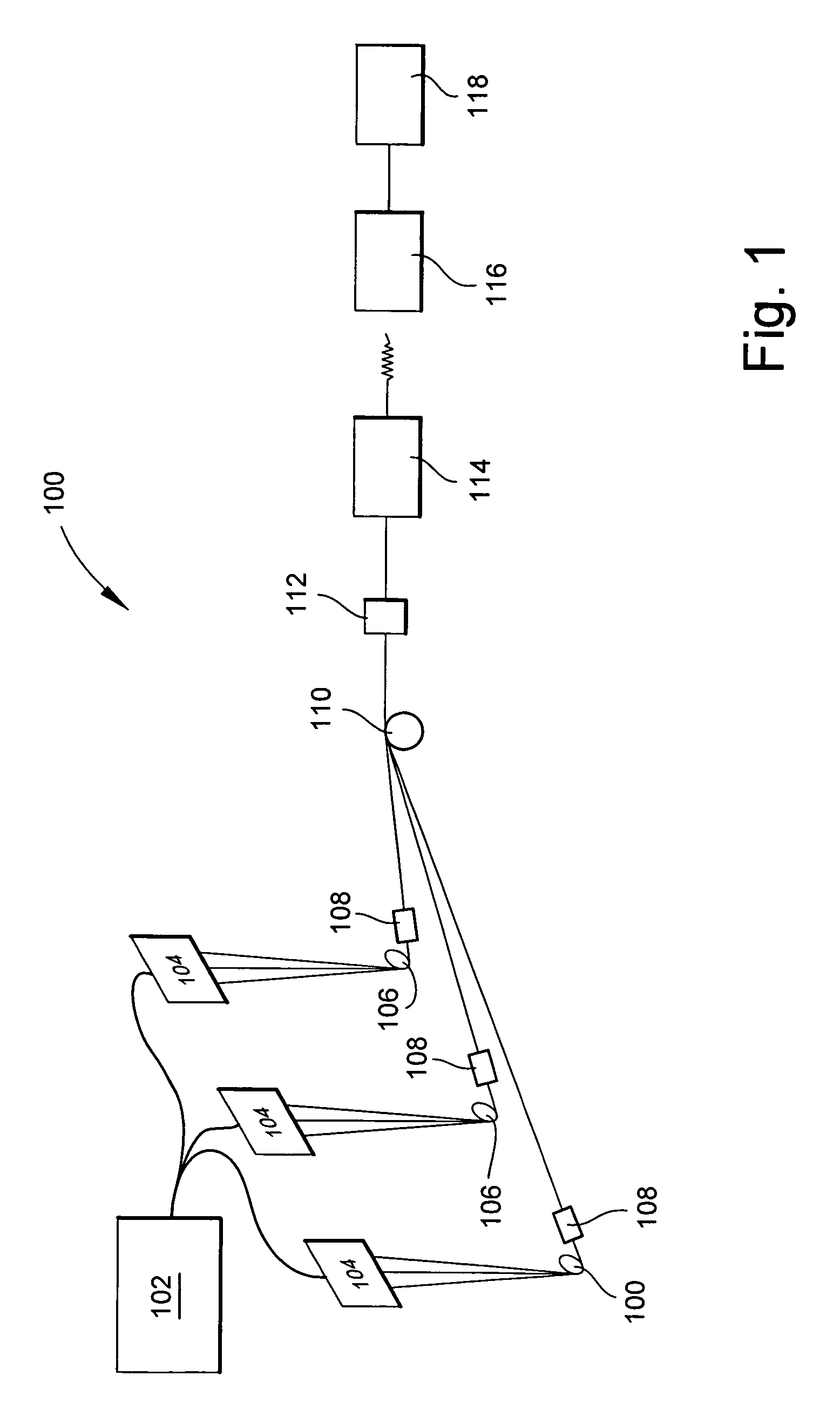

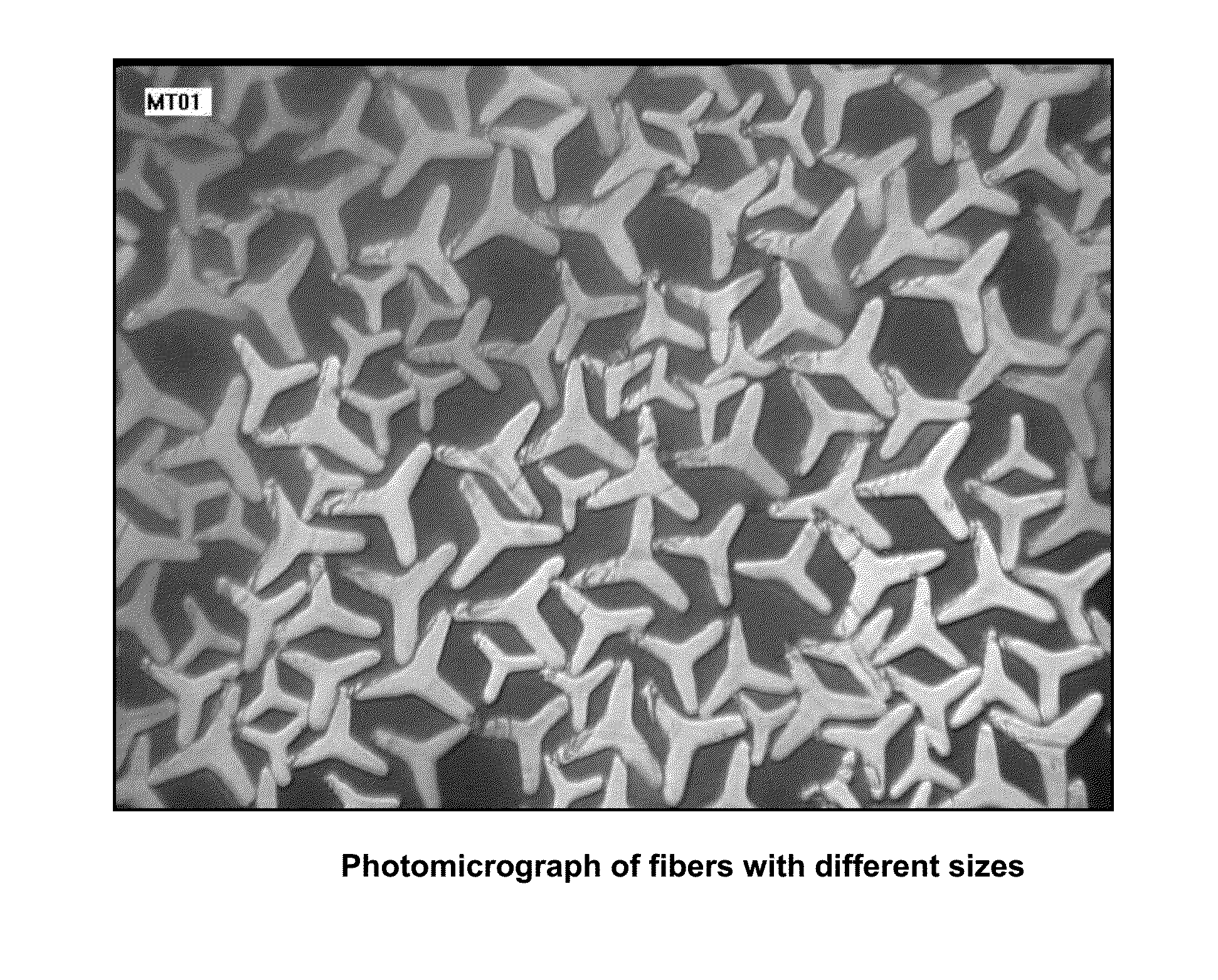

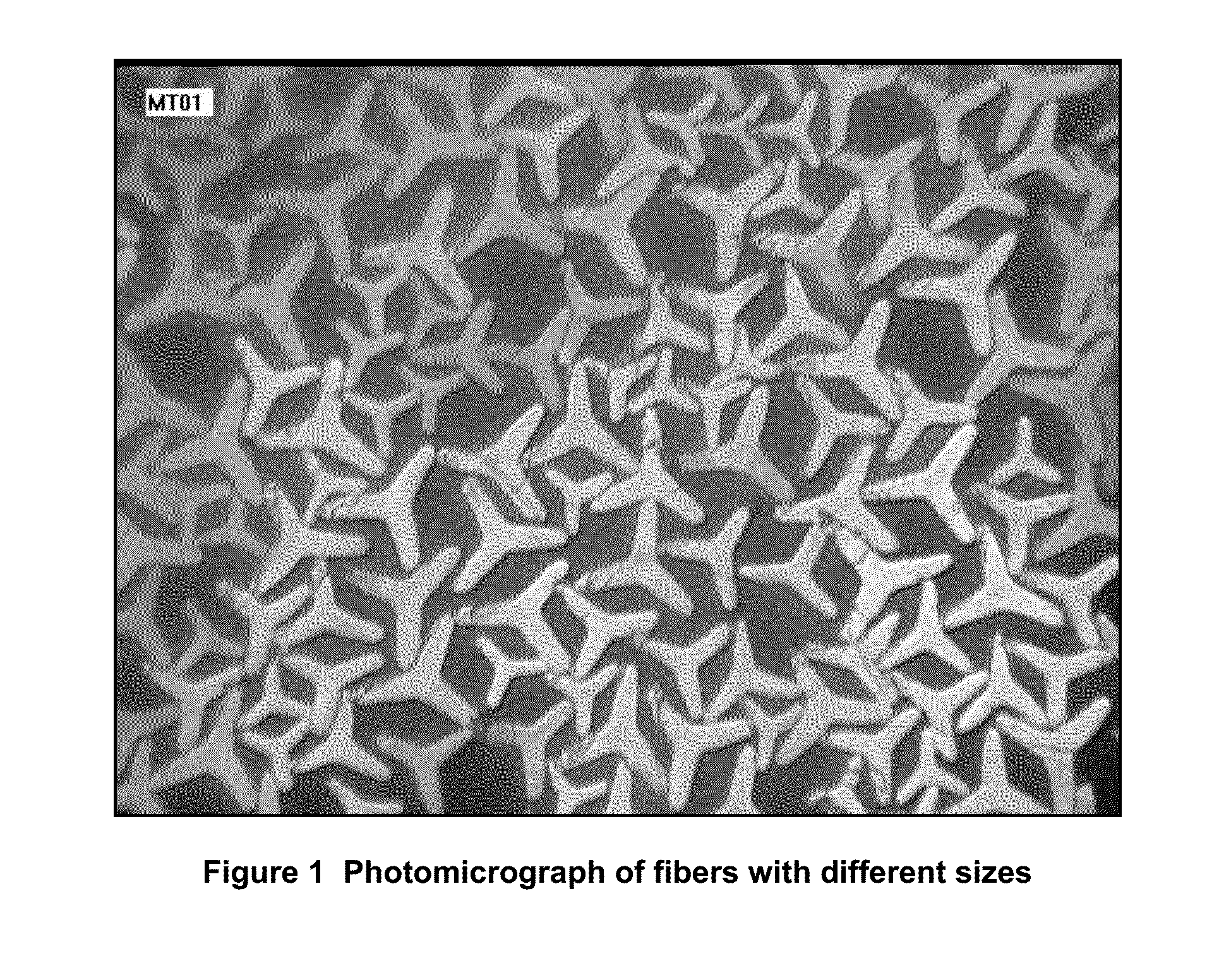

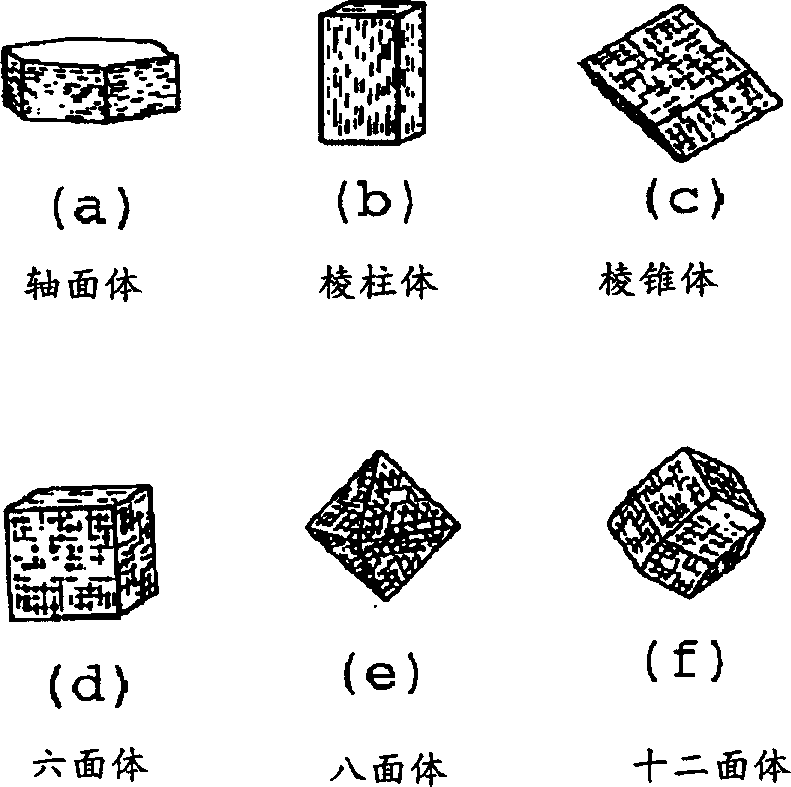

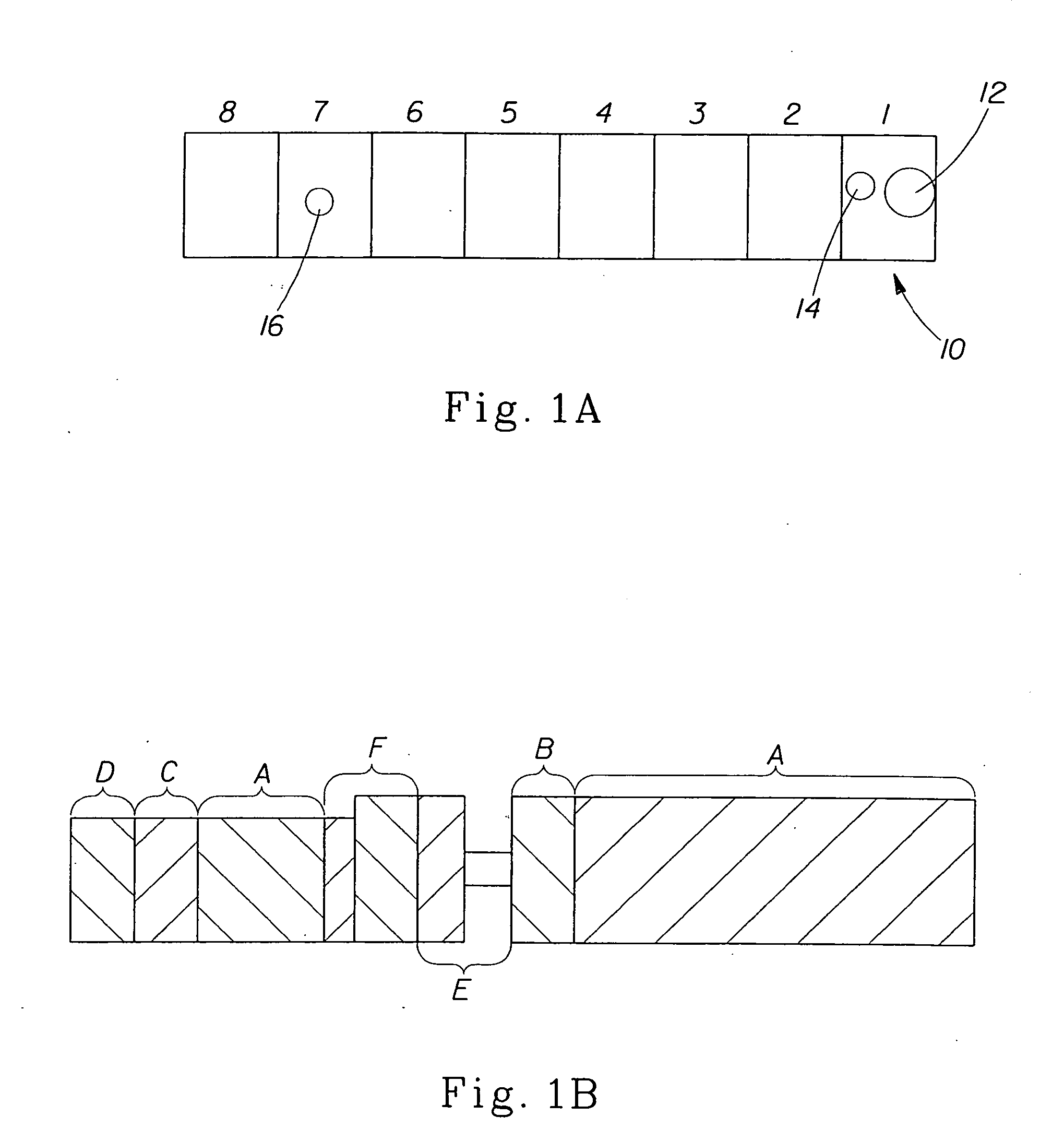

Fibers with chemical markers and physical features used for coding

Disclosed are fibers which contain identification fibers. The identification fibers can contain a one or more of chemical markers and one or more distinct features, or taggants, which may vary among the fibers or be incorporated throughout all of the fibers. The chemical markers and distinct features can be representative of specific supply chain information. The supply chain information can be used to track the fibers from manufacturing through intermediaries, conversion to final product, and / or the consumer. The disclosed embodiments also relate to the method for making and characterizing the fibers. Characterization of the fibers can include identifying chemical markers and distinct features and correlating the chemical markers and distinct features to manufacturer-specific taggants to determine supply chain information.

Owner:EASTMAN CHEM CO

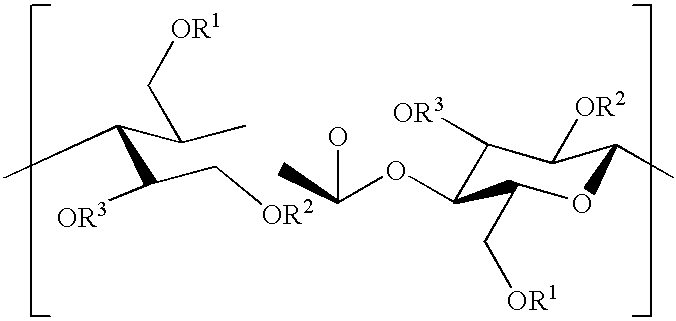

Carbohydrate esters and polyol esters as plasticizers for polymers, compositions and articles including such plasticizers and methods of using the same

The invention relates to methods of making carbohydrate and polyol esters suitable for use as plasticizers for polymer compositions. The invention also relates to plasticized polymer compositions comprising such carbohydrate and polyol esters. The invention also relates to articles prepared from such plasticized polymer compositions. The invention further relates to methods of using these compositions.

Owner:EASTMAN CHEM CO

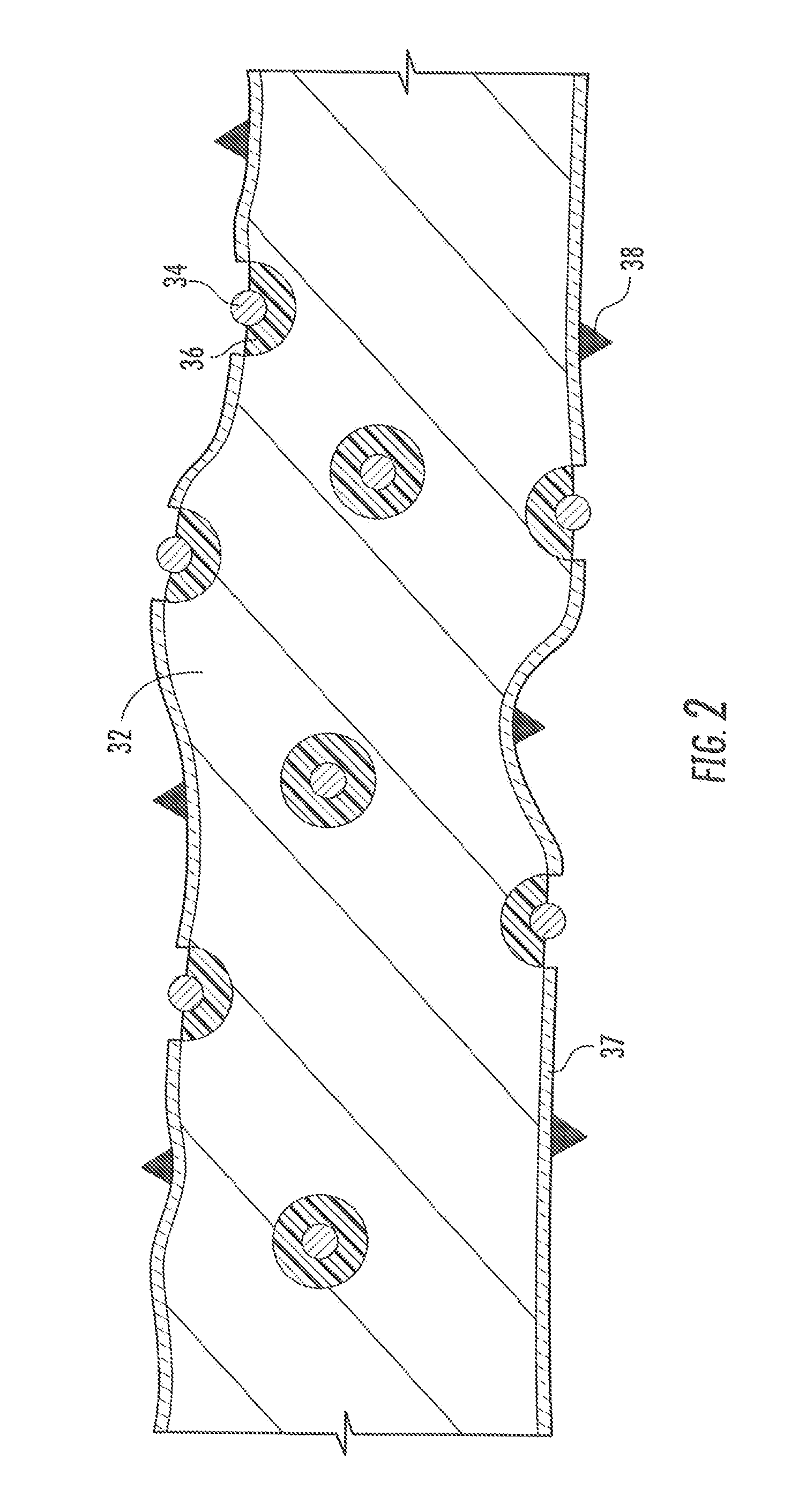

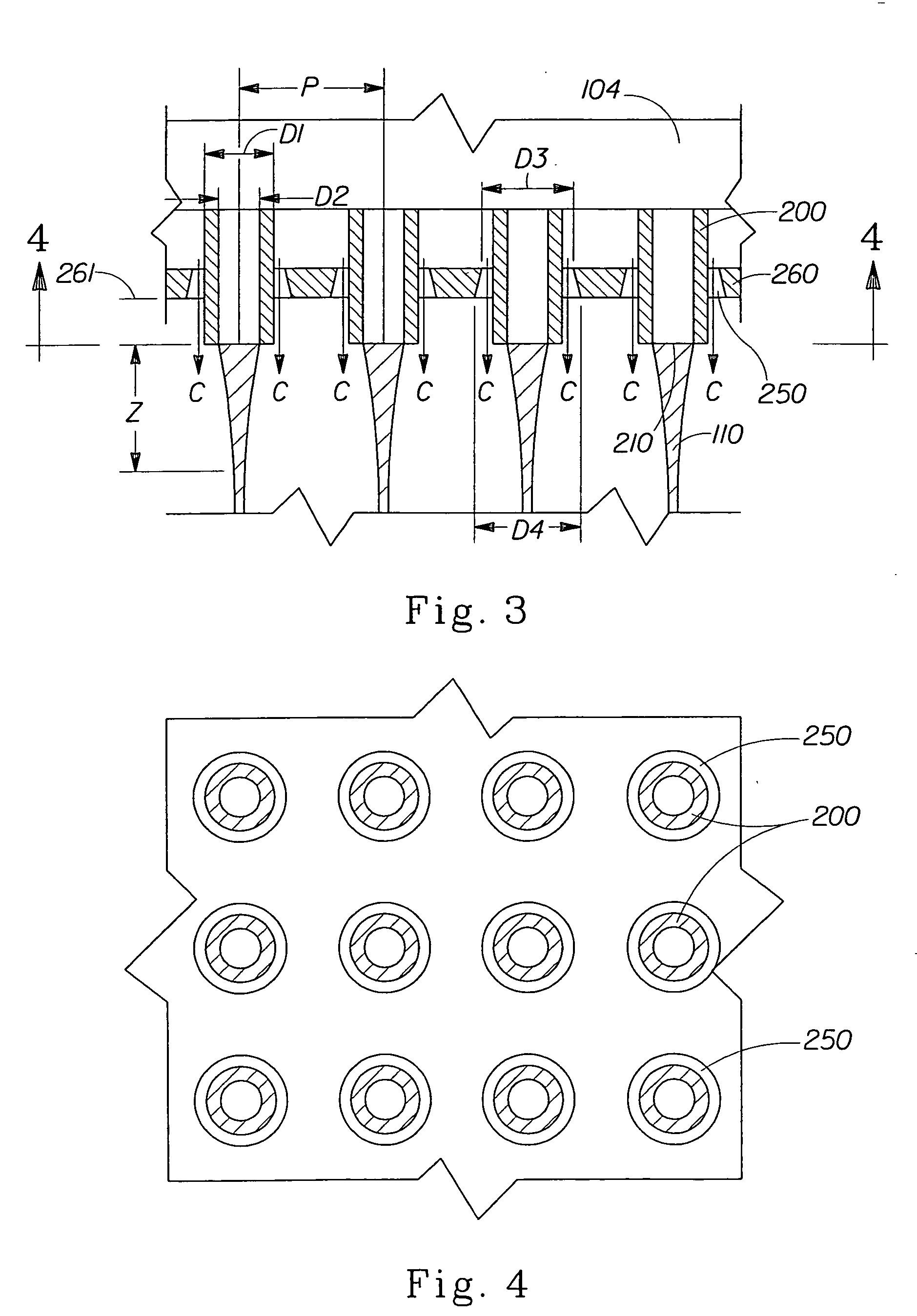

Method for making an acetate tow band with shape and size used for coding

Disclosed is a method of making an acetate tow bands comprising identification fibers which can be used for tracking and tracing the acetate tow band through at least part of the supply chain. Each identification fiber exhibits at least one distinct feature. Each group of distinguishable identification fibers can exhibit a taggant cross-section shape, a taggant cross-section size, or combination of the same taggant cross-section shape and same taggant cross-section size. The distinct features and the number of fibers in each group of distinguishable identification fibers can represent at least one supply chain component of the acetate tow band, including the manufacturer of the acetate tow band and the customer of the acetate tow band. The identification fibers can be produced on a cellulose acetate tow line using one or more spinnerets with spinneret holes to produce the taggant cross-section shapes and / or taggant cross-section sizes.

Owner:EASTMAN CHEM CO

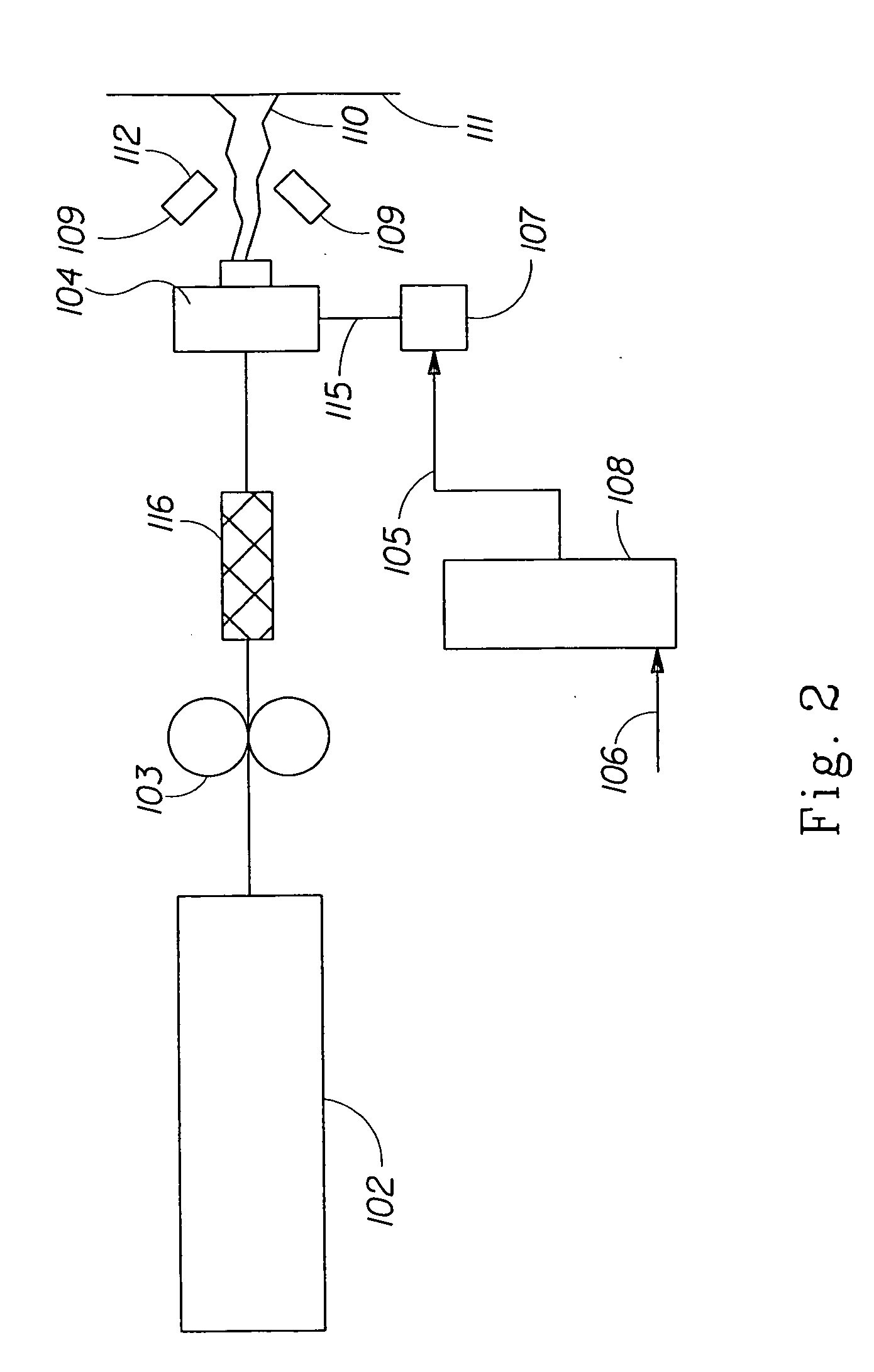

Preparation method for regularly electrostatic spinning hollow fibre

InactiveCN101144196ASimple manufacturing methodHollow filament manufactureArtificial filaments from cellulose derivativesHollow fibreFiber bundle

The present invention relates to a preparation method for regularized static electricity spinning hollow fiber, and the method comprises the procedures that: firstly, high molecular compound is dissolved in good solvent to be made into uniform solution; secondly, poor solvent is added to be dispensed into spinning raw liquid, and the volume ratio of the good solvent and the poor solvent is 10 / 1 to 1 / 3; thirdly, the spinning raw liquid is added into a container, is controlled and extruded by a micro-syringe pump, a jet opening is connected with a high voltage positive pole, a grounding microelectrode with the removable area of 0 to 100 mm 2 is taken as a negative pole, various parameters of static electricity spinning are adjusted, and the spinning raw liquid carries on the static electricity spinning; fourthly, the grounding microelectrode backwards and continuously moves, and a continuous regularized static electricity spinning hollow fiber bundle is obtained; fifthly, the continuous hollow fiber bundle obtains the regularized static electricity spinning hollow fiber through winding and collecting. The preparation method provided by the present invention is simple and feasible, and the obtained static electricity spinning hollow fiber has the potential application and the prospect in the fields such as nanowire devices, filtering materials, and composite reinforcing materials, etc.

Owner:DONGHUA UNIV

Acetate tow and filters with shape and size used for coding

Disclosed are acetate tow bands comprising identification fibers which can be used for tracking and tracing the acetate tow band through at least part of the supply chain. Each identification fiber exhibits at least one distinct feature. Each group of distinguishable identification fibers can exhibit a taggant cross-section shape, a taggant cross-section size, or combination of the same taggant cross-section shape and same taggant cross-section size. The distinct features and the number of fibers in each group of distinguishable identification fibers can represent at least one supply chain component of the acetate tow band, including the manufacturer of the acetate tow band and the customer of the acetate tow band. The distinct features are detectable in a filter comprising the acetate tow band.

Owner:EASTMAN CHEM CO

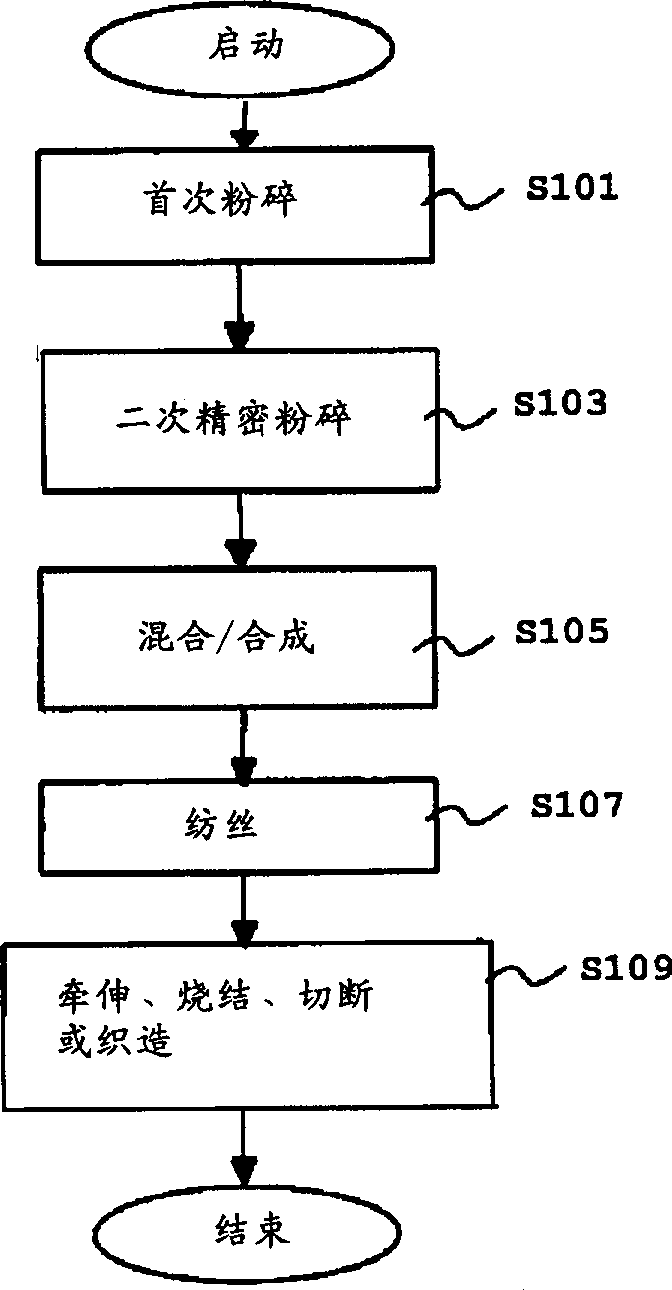

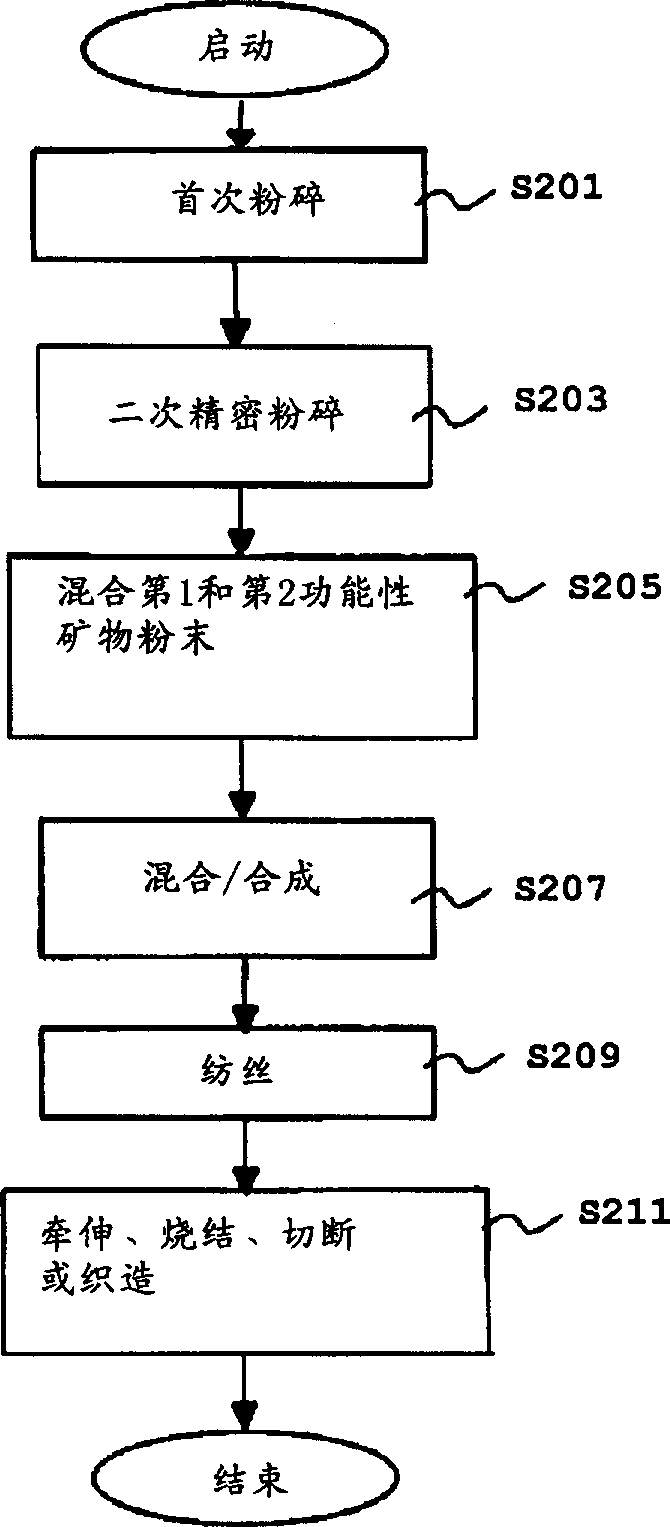

Manufacture of fibre containing functional mineral powder and fibre prepared by the same

InactiveCN1318657ABlood pressure controlRelief the painArtificial filaments from viscoseArtificial filaments from cellulose derivativesGranularityPolyresin

A method of producing fiber having functional mineral powders includes the steps of a first pulverizing functional mineral which crystal form of is pinacoid, a second closely pulverizing the first pulverized functional mineral powders to be less than 1 / 3 granularity of desired fineness, mixing and synthesizing 0.1-10 weight % of the second pulverized functional mineral powders and 90-99.9 weight % of a chemical resin, and spinning the mixture of functional mineral powders and the chemical resin.

Owner:石美秀

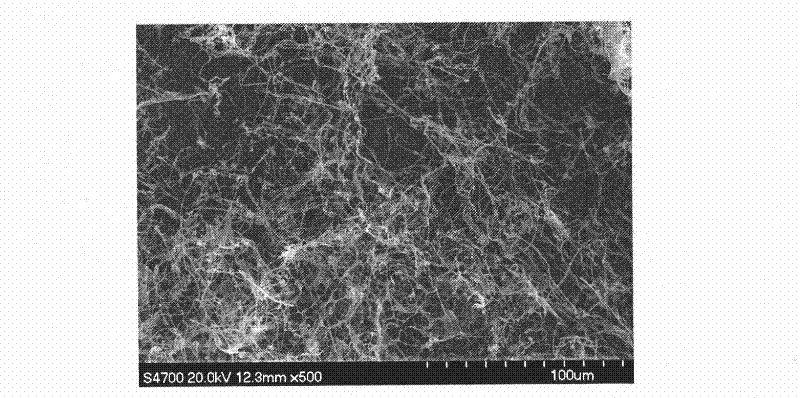

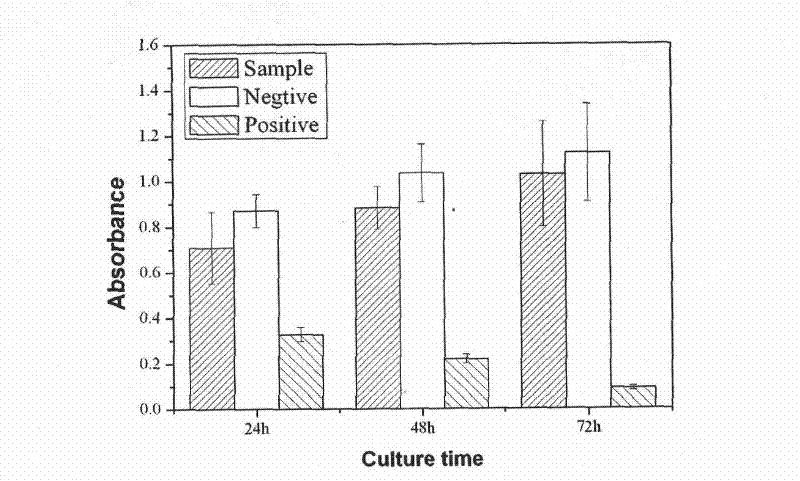

Natural polymer-based nano-fibrous membrane prepared by freeze-drying method

The invention relates a biodegradable and absorbable natural polymer-based nano-fibrous membrane prepared by a freeze-drying method, and the application thereof. The natural polymer-based nano-fibrous membrane is prepared through the following steps of: dissolving natural polymer powder into a corresponding solvent so as to prepare an extremely-dilute solution with the concentration of 0.001-0.1wt %; after the natural polymer powder is completely dissolved in the solvent, transferring the obtained natural polymer solution into a liquid nitrogen refrigerating device, so that the natural polymer solution is rapidly frozen in a liquid nitrogen environment; then, carrying out freeze-drying treatment on the obtained product in a freeze drier for 12-48 hours to obtain natural polymer-based nano fibers; and carrying out cross-linking on the obtained natural polymer-based nano fibers by a corresponding cross-linking agent to obtain a natural polymer-based nano-fibrous membrane, and then carrying out MTT (methyl thiazolyl tetrazolium) cytotoxicity test and cell vaccination experiments on the natural polymer-based nano-fibrous membrane, with the obtained results showing that the obtained fibrous membrane has no toxicity but has excellent cell adhesion and proliferation properties. The natural polymer-based nano-fibrous membrane disclosed by the invention is simple in the operation process, easy to control and low in cost; and by using the nano-fibrous membrane disclosed by the invention, ultra-fine natural polymer-based nano fibers can be prepared continuously on a large scale.

Owner:BEIJING UNIV OF CHEM TECH

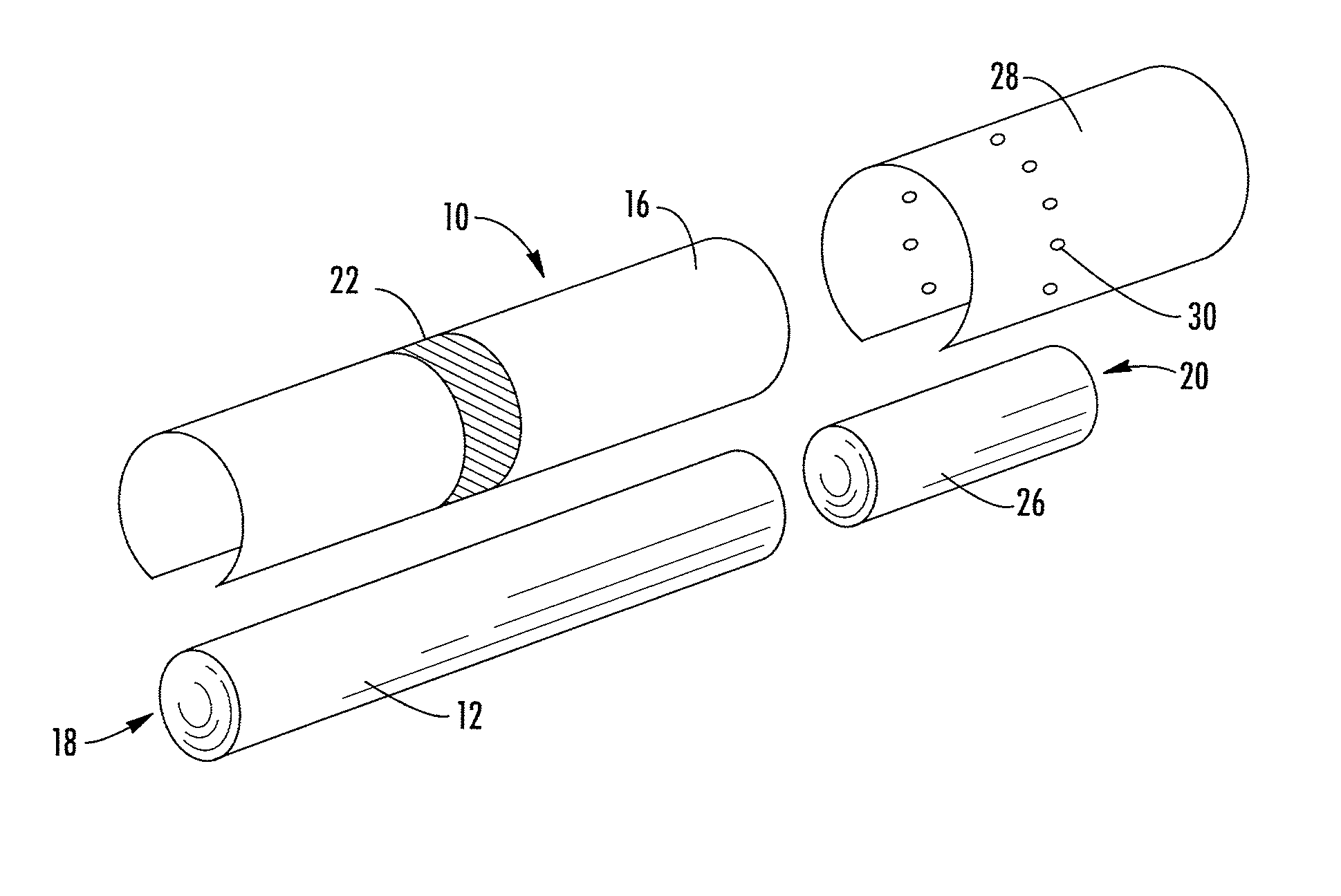

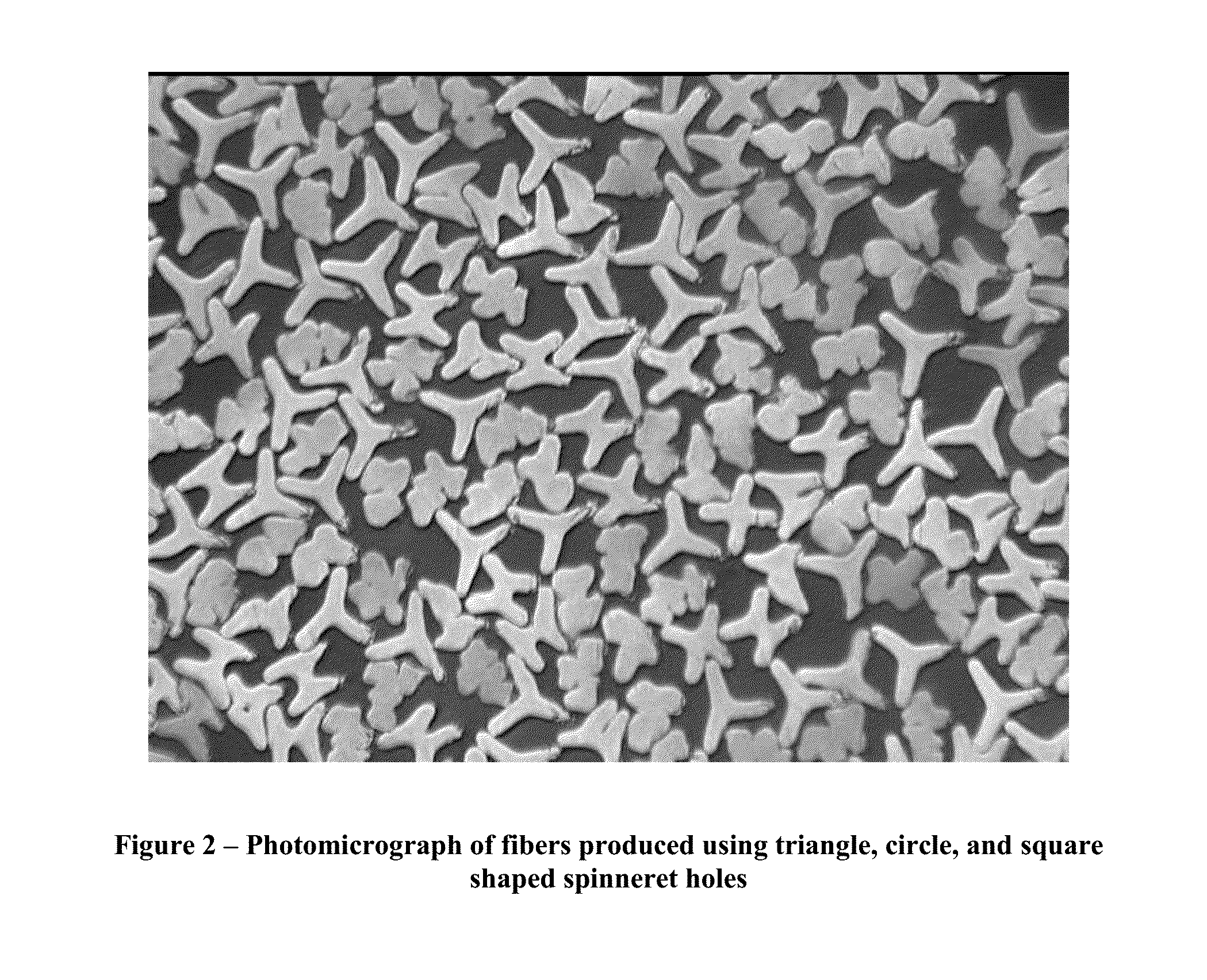

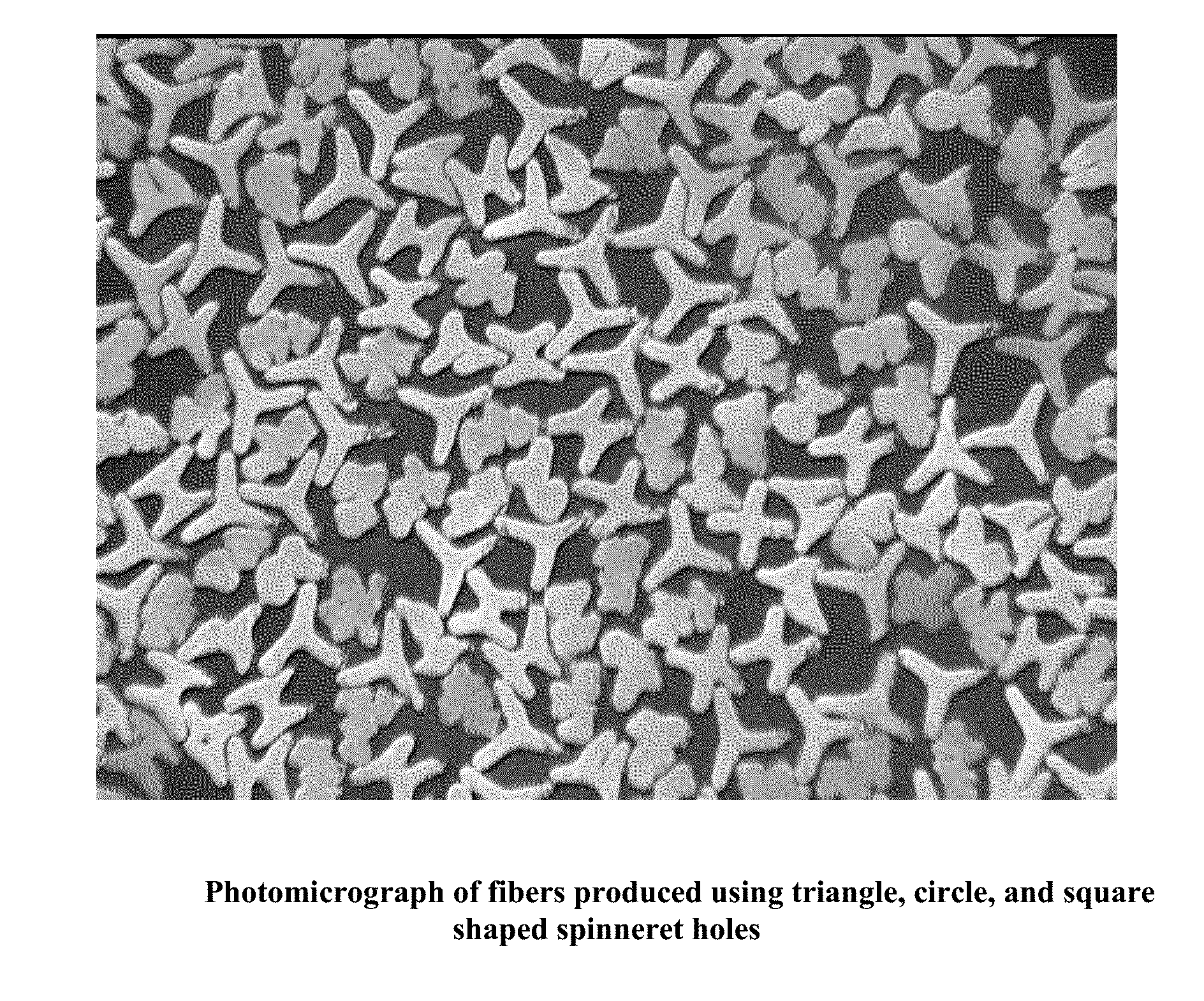

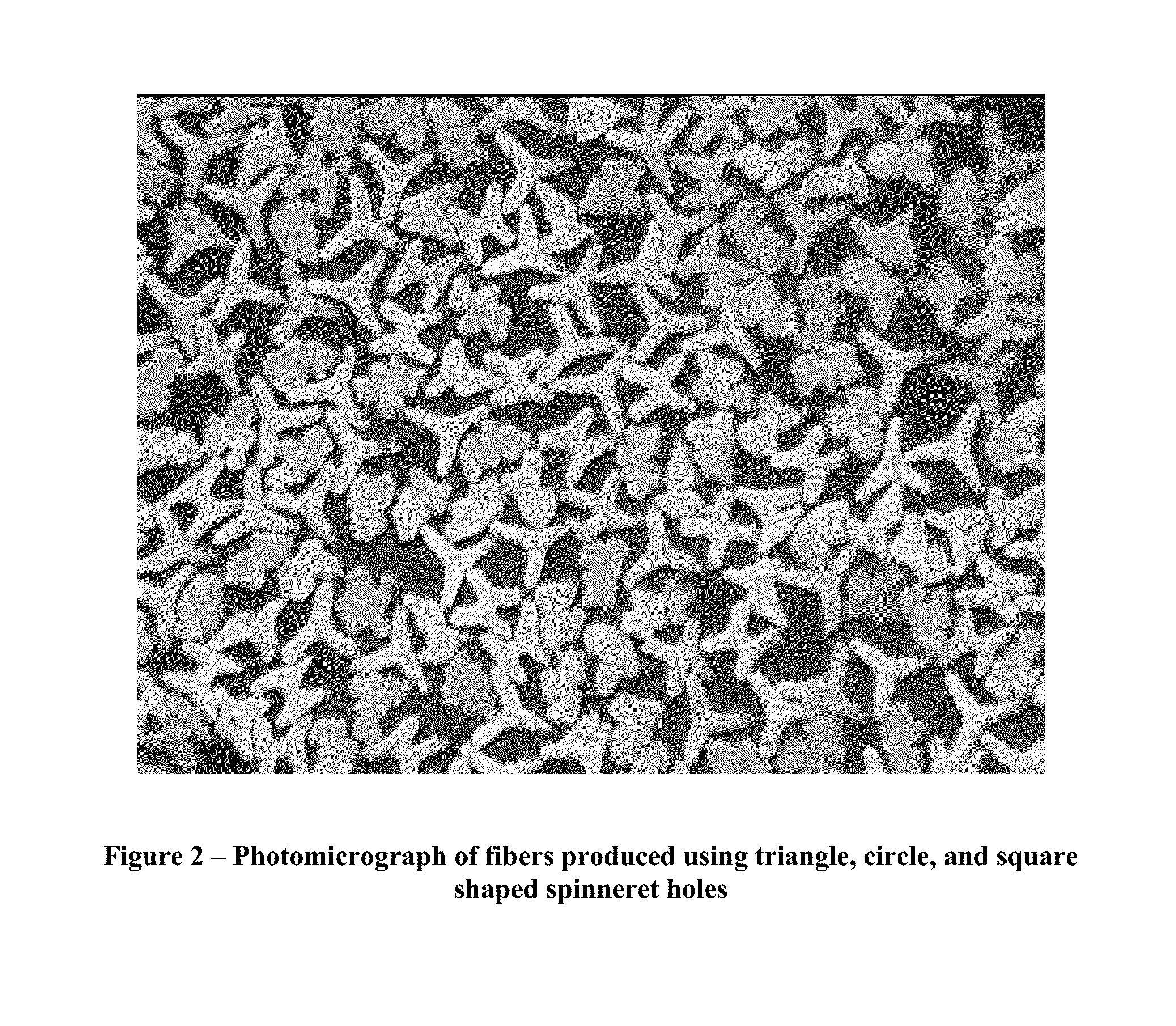

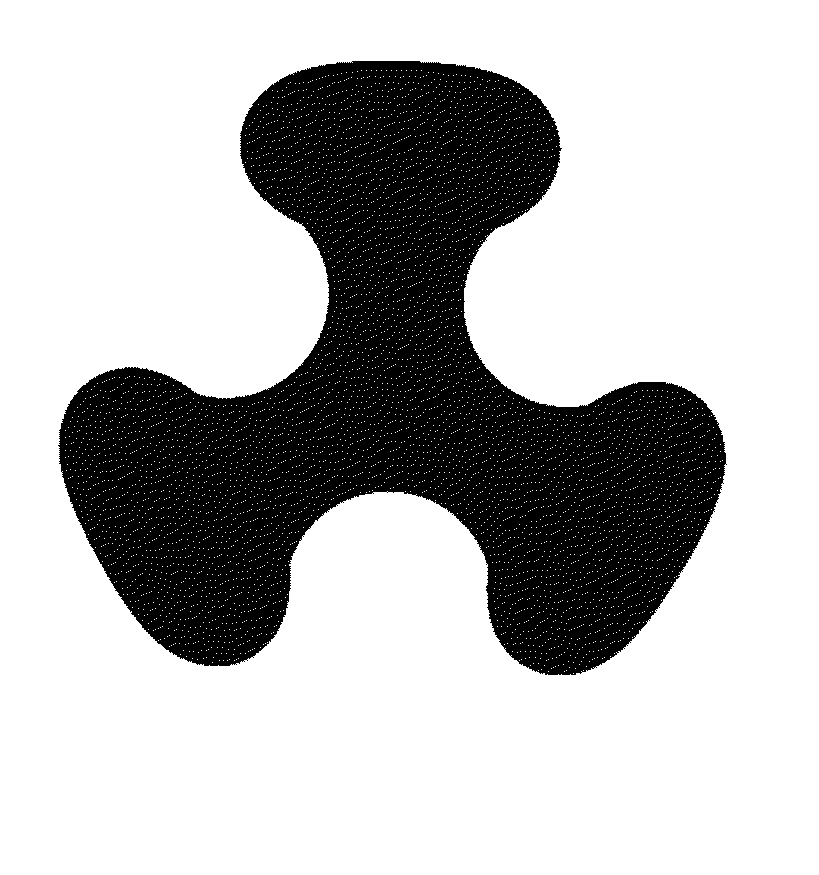

Process of making tri-arc filaments

InactiveUS8790556B2Readily apparentTobacco smoke filtersArtificial filaments from cellulose derivativesParticulatesEngineering

A spinneret having tri-arc holes may be used to produce tri-arc filaments. In some instances, tri-arc holes have a Y-shape with three prongs and each prong having an arc at the end of the prong that tapers from the end of the arc to a connection point of an adjacent arc, and tri-arc filaments have a generally-Y shape cross-section with bulbous or arcing tips. Further, tri-arc filaments may be useful in a plurality of applications including, but not limited to, filters, filters comprising particulate additives, and smoking device filters.

Owner:ACETATE INT LLC

Filter Element Comprising Multifunctional Fibrous Smoke-Altering Material

A filter element for use in a smoking article and providing filtration of particulate material and gaseous components of mainstream smoke is provided. The filter element includes a segment of fibrous tow comprising a plurality of individual filaments, wherein each individual filament includes a plurality of adsorbent material particles at least partially encapsulated with a removable encapsulant imbedded therein. The individual filaments may further include an outer coating that provides a plurality of reactive groups adapted for reaction with one or more components of mainstream smoke. Alternatively, the multifunctional filter element combines different fibrous filter materials, such as cellulose acetate or polyolefin filaments combined with activated carbon filaments and at least one of ion exchange filaments and catalytic filaments. A method of providing a cellulose acetate fibrous tow containing an imbedded adsorbent material is provided, wherein a plurality of encapsulated adsorbent particles are mixed with a cellulose acetate dope.

Owner:R J REYNOLDS TOBACCO COMPANY

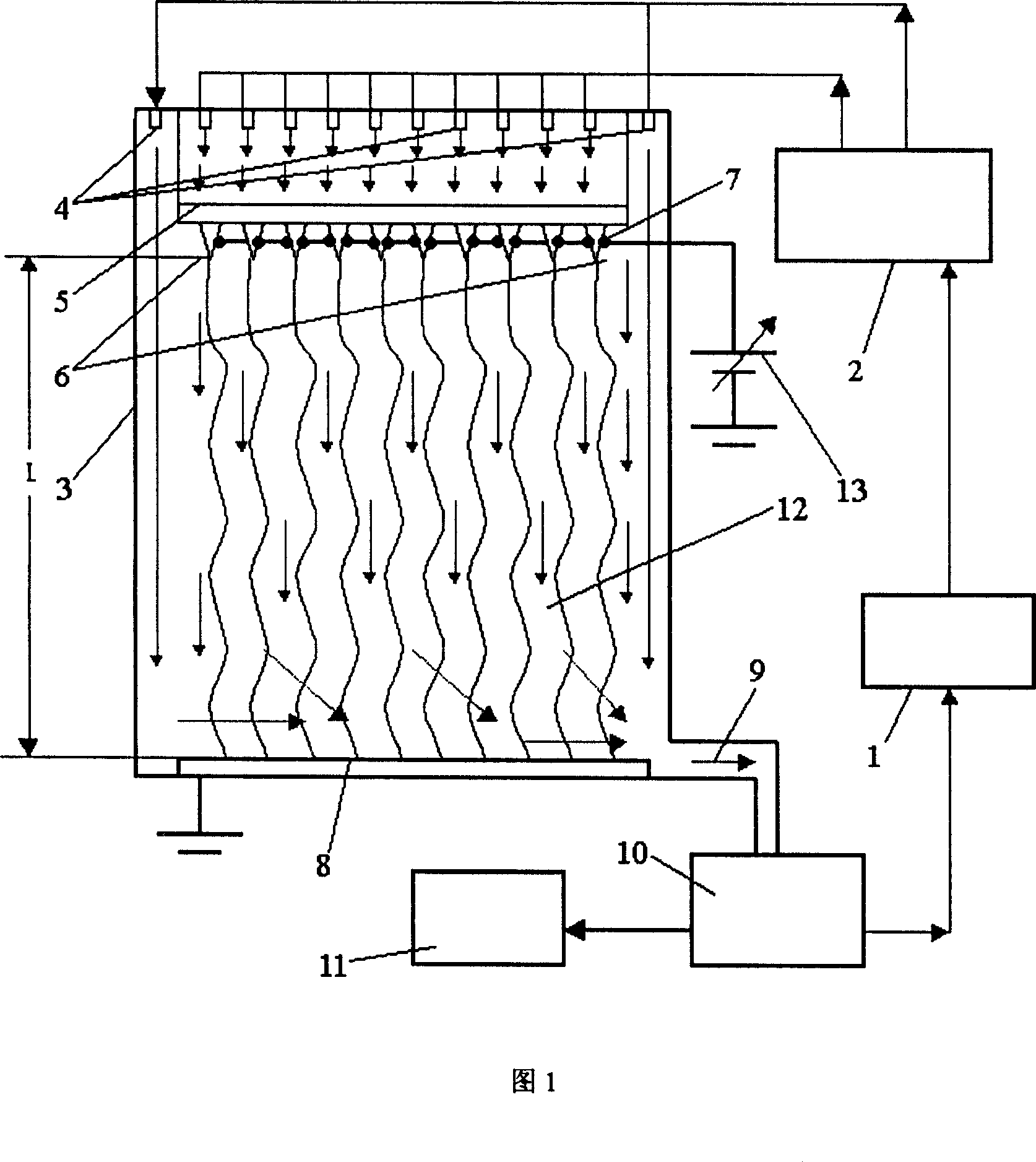

Gas layer propulsion electrostatic spinning apparatus and industrial application thereof

InactiveCN101033559AIncrease temperatureLow viscosityArtificial filaments from cellulose derivativesDry spinning methodsElectrospinningAirflow

This invention relates to a static filature device pushed by a gas layer and its industrial application, in which, the device includes: a gas circulation push device, a gas drying and heating device, a sealed filaturing room, and air inlet at the top of the sealed room, a material room at the upper part of the sealed room, a spinneret at the lower part of the material room, electrode connected on the spinneret, a material receiving device at the lower part of the sealed room, an air outlet at the lower-right part of the room, a cooling device cooling gas flow with solvent and a solvent recovering device, which can make static filature to molding to polymers, increases spinning efficiency greatly by applying multiple sprayers, controls the temperature and humid of the entry flows to alter the temperature and humid of filature raw liquid, and further more, the pushed gas flow can drive the volatiled solvent in the process to flow out to be recovered.

Owner:DONGHUA UNIV

Method for preparing Nano SiO2 fire retardant viscose fiber, and film

ActiveCN101050559ASimple processEasy to operateFlame-proof filament manufactureArtificial filaments from viscoseFire retardantSodium sulfate

The present invention relates to a preparation method of nano SiO2 fire-retardant viscose fiber and film, specially, it relates to a preparation method of fire-retardant viscose fiber formed from cellulose and SiO2 and organic-inorganic polymer nano composite membrane made of cellulose and SiO2. Said method includes the following steps: adding silicone sol with a certain mass into a viscose solution whose composition contains alpha-cellulose whose mass percentage content is 6-9% and sodium hydroxide whose mass percentage content is 5-6%; fully stirring and mixing them at 10-50 deg.C, deforming so as to obtain viscose-silicone sol solution, then adding said viscose-silicone sol into a coagulation acid bath prepared by using sulfuric acid, sodium sulfate, zinc sulfate and water, coagulating at 10-100 deg.C, spinning so as to obtain nano SiO2 fiber-retardant viscose fiber, utilizing coating process so as to obtain organic-inorganic polymer nano composite membrane of cellulose / SiO2.

Owner:QINGDAO UNIV

High Denier Per Filament and Low Total Denier Tow Bands

InactiveUS20130115452A1Readily apparentFilament/thread formingPretreated surfacesCellulose acetateEngineering

A method for producing a bale of crimped tow band may include providing a tow band having about 10 denier per filament or greater and about 20,000 total denier or less, the tow band comprising a plurality of cellulose acetate filaments; crimping the tow band thereby yielding a crimped tow band; conditioning the crimped tow band; and baling the crimped tow band to form a bale.

Owner:ACETATE INT LLC

Polymeric structures comprising a hydrophile/lipophile system

InactiveUS20050137330A1Good dispersionMonocomponent protein artificial filamentNon-fibrous pulp additionCrystallographyFiber

Owner:THE PROCTER & GAMBLE COMPANY

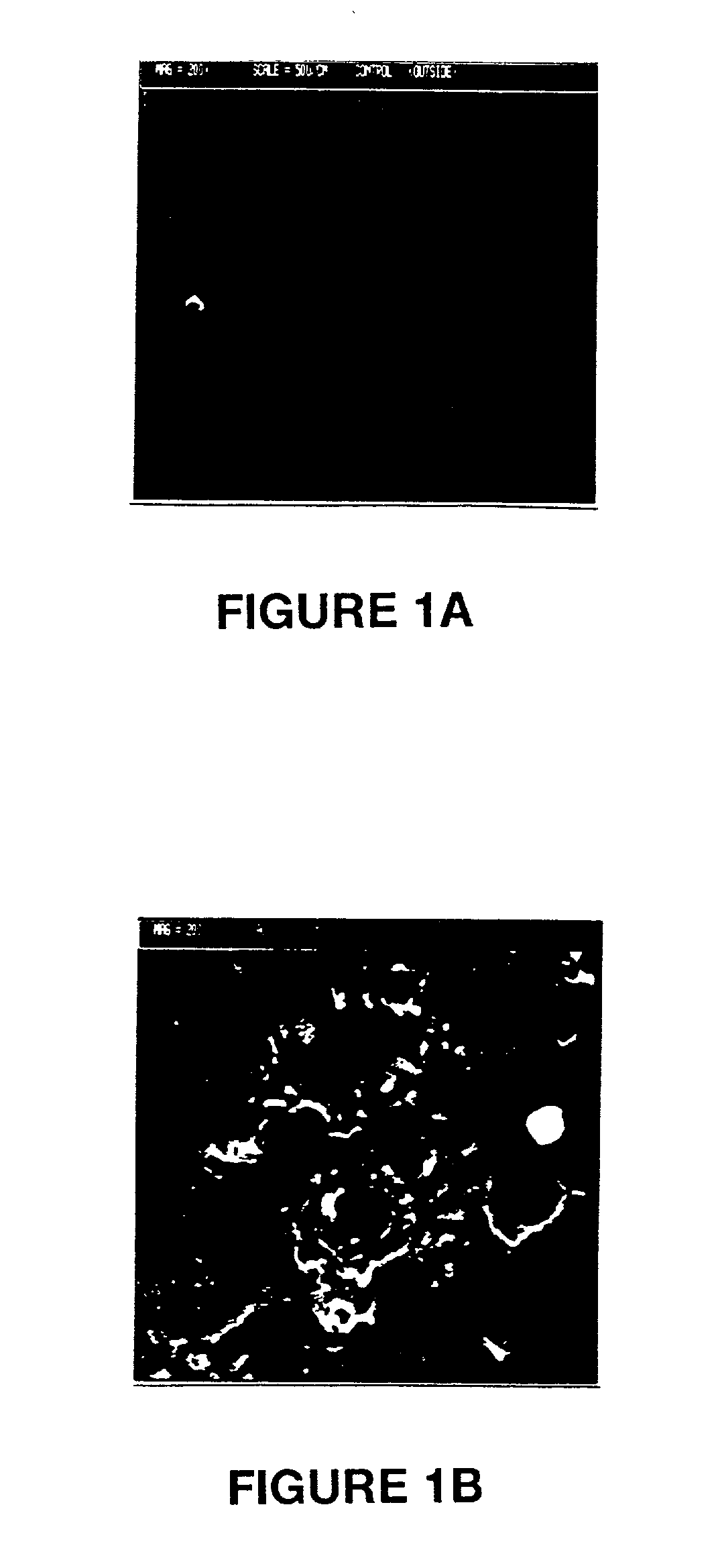

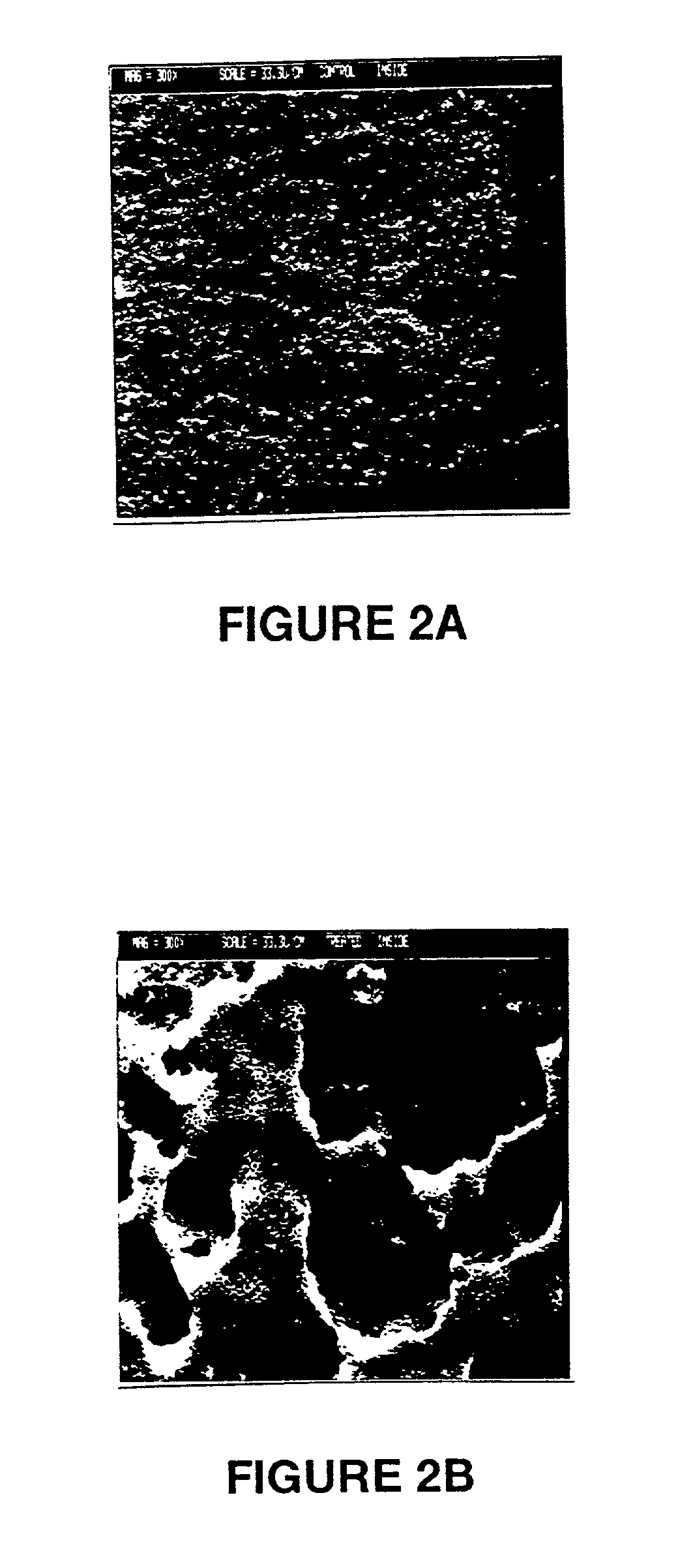

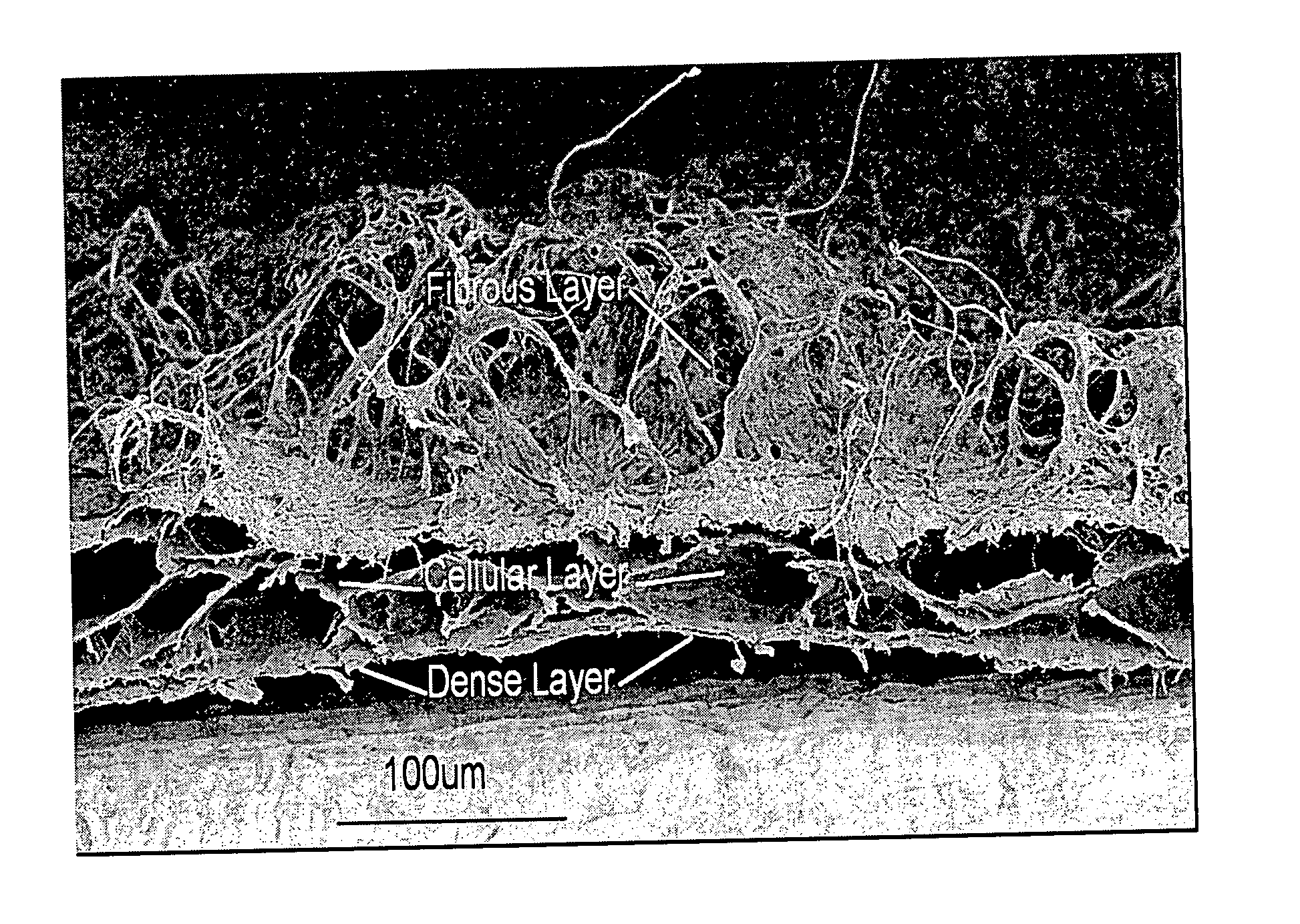

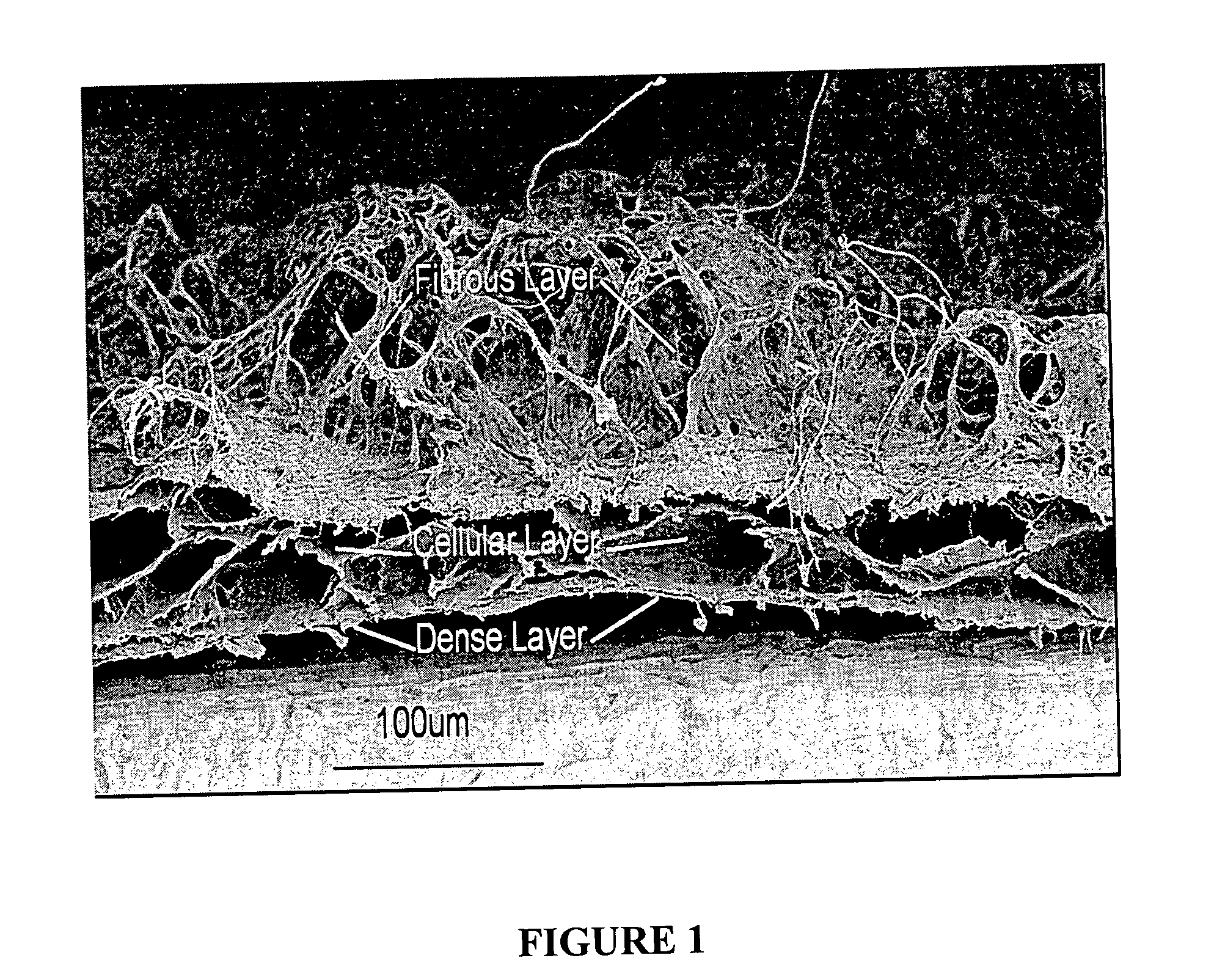

Three dimensional-BIO-mimicking active scaffolds

InactiveUS20070275458A1Easy to useLow costBioreactor/fermenter combinationsBiological substance pretreatmentsNano structuringCell-Extracellular Matrix

The invention provides a Cellulose acetate (CA) thin, porous membranes produced by electrospinning precursor polymer solutions in acetone at room temperature and a process for manufacturing the same. The invention also provides a Cellulose acetate (CA) thin, porous membranes produced by electrospinning precursor polymer solutions in acetone at room temperature further comprising ceramic nano-structured component (carbon nanotubes) in the polymer membranes to provide additional strength and porosity and a process for manufacturing the same. The fabricated CA-CT membranes specifically mimic the topography and porosity of natural Extracellular Matrix (ECM) and can be used as scaffolding for cell growth.

Owner:GOUMA PELAGIA IRENE

Process for making high efficiency synthetic filter media

ActiveUS20180280847A1Improve efficiencyLarge capacityArtificial filaments from cellulose derivativesMembrane filtersIndustrial gasGlass fiber

The present invention is generally related to a high capacity, high efficiency nonwoven filtration media comprising a gradient pore structure. In particular, the filtration media can comprise thermoplastic synthetic microfibers, fibrillated fibers, staple fibers, and a binder. Furthermore, the filtration media may be produced without the use of glass fibers or microglass fibers. A process for making the filtration media is also provided. Consequently, the filtration media of the present invention does not cause the same issues as conventional filtration media that comprises glass fibers and / or microglass fibers. Moreover, the filtration media can be used to treat fuel, lubrication fluids, hydraulic fluids, and various other industrial gases.

Owner:KNOWLTON TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com