Preparation method for regularly electrostatic spinning hollow fibre

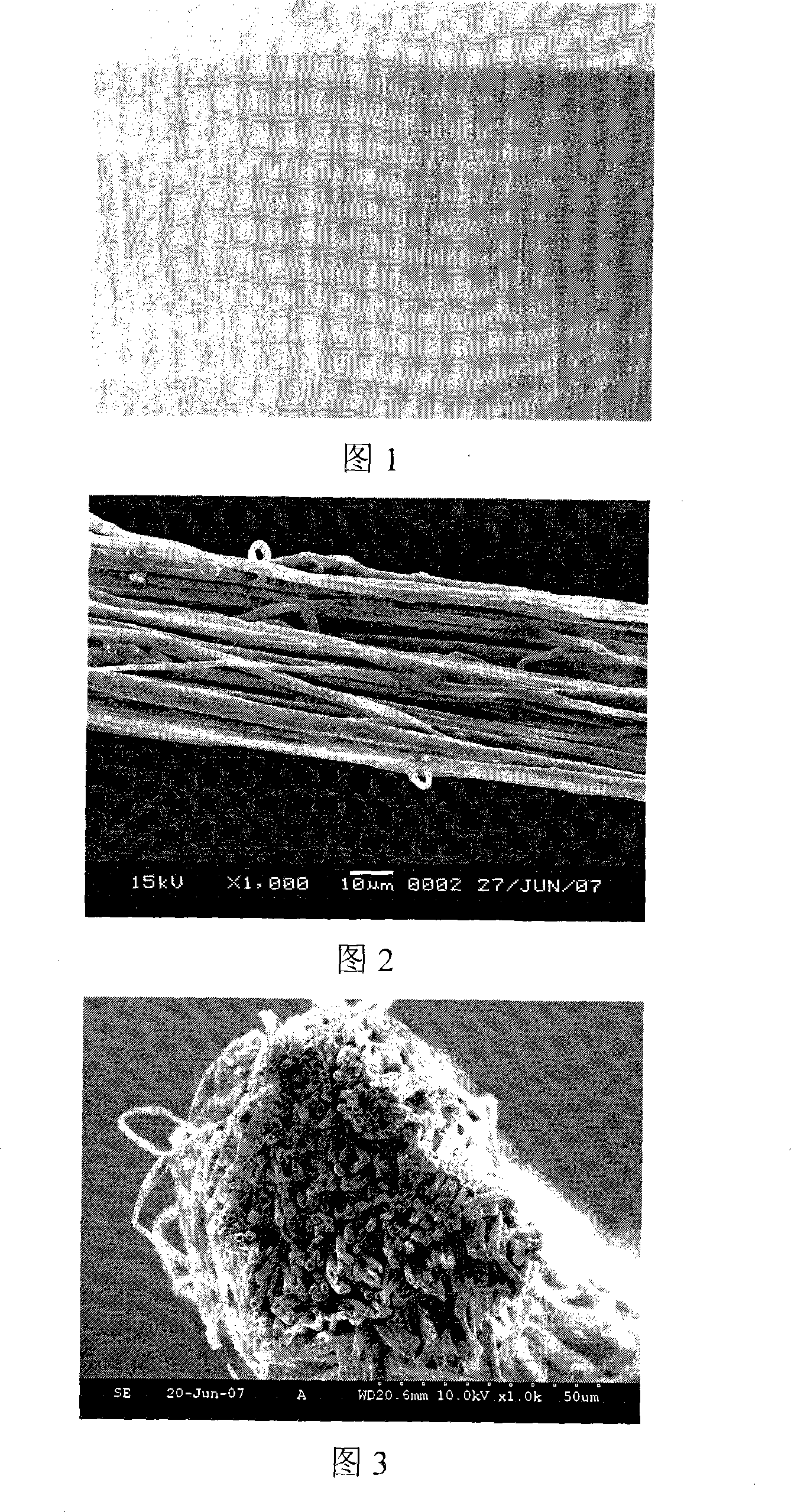

An electrospinning and electrospinning technology is applied in the field of preparation of regular electrospinning hollow fibers, and can solve the problems of difficulty in obtaining hollow fibers stably, complicated methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Dissolve 5.0 g of purified 3-hydroxybutyric acid and 3-hydroxyvaleric acid copolyester (PHBV) in 75 g (65 / 10) of dichloromethane / alcohol mixed solvent to obtain a transparent and uniform solution;

[0030] (2) add 20gN again, N-dimethylformamide (DMF) is mixed with spinning dope;

[0031] (3) Spinning stock solution is added into the container, extruded by micro-injection pump control, the nozzle is connected to high-voltage positive electrode, and the movable area is less than 100mm 2 The grounded microelectrode is used as the negative electrode, the electrospinning parameters are controlled at a voltage of 10kv, the nozzle aperture is 0.4mm, the solution flow rate is 2ml / h, the ambient temperature is 30°C, and the relative air humidity is 45%, and the electrospinning is carried out;

[0032] (4) The grounded microelectrode moves backwards continuously to obtain continuous regularized electrospun hollow fiber bundles;

[0033] (5) Collect the continuous hollow fib...

Embodiment 2

[0036] (1) Dissolving 12 g of purified polylactic acid (PLLA) in 68 g of dichloromethane solvent to obtain a transparent and uniform solution;

[0037] (2) add 20gN again, N-dimethylformamide (DMF) is mixed with spinning dope;

[0038] (3) Spinning stock solution is added into the container, extruded by micro-injection pump control, the nozzle is connected to high-voltage positive electrode, and the movable area is less than 100mm 2 The grounded microelectrode is used as the negative electrode, the electrospinning parameters are controlled at a voltage of 17kv, the nozzle aperture is 0.8mm, the solution flow rate is 60μl / min, the ambient temperature is 25°C, and the relative air humidity is 70%, and the electrospinning is carried out;

[0039] (4) The grounded microelectrode moves backwards continuously to obtain continuous regularized electrospun hollow fiber bundles;

[0040] (5) Collect the continuous hollow fiber bundles by winding them on the bobbin tube at a winding spe...

Embodiment 3

[0043] (1) 10 g of purified polymethyl methacrylate (PMMA) was dissolved in 60 g of acetone to obtain a transparent and uniform solution;

[0044] (2) add 30gN again, N-dimethylformamide (DMF) is mixed with spinning dope;

[0045] (3) Spinning stock solution is added into the container, extruded by micro-injection pump control, the nozzle is connected to high-voltage positive electrode, and the movable area is less than 100mm 2 The grounded microelectrode is used as the negative electrode, the electrospinning parameters are controlled at a voltage of 14kv, the nozzle aperture is 0.2mm, the solution flow rate is 10μl / min, the ambient temperature is 50°C, and the relative air humidity is 60%, and the electrospinning is carried out;

[0046](4) The grounded microelectrode moves backwards continuously to obtain continuous regularized electrospun hollow fiber bundles;

[0047] (5) Collect the continuous hollow fiber bundles by winding them on a bobbin at a winding speed of 120 r / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com