Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about "Monocomponent polycarbonates artificial filament" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

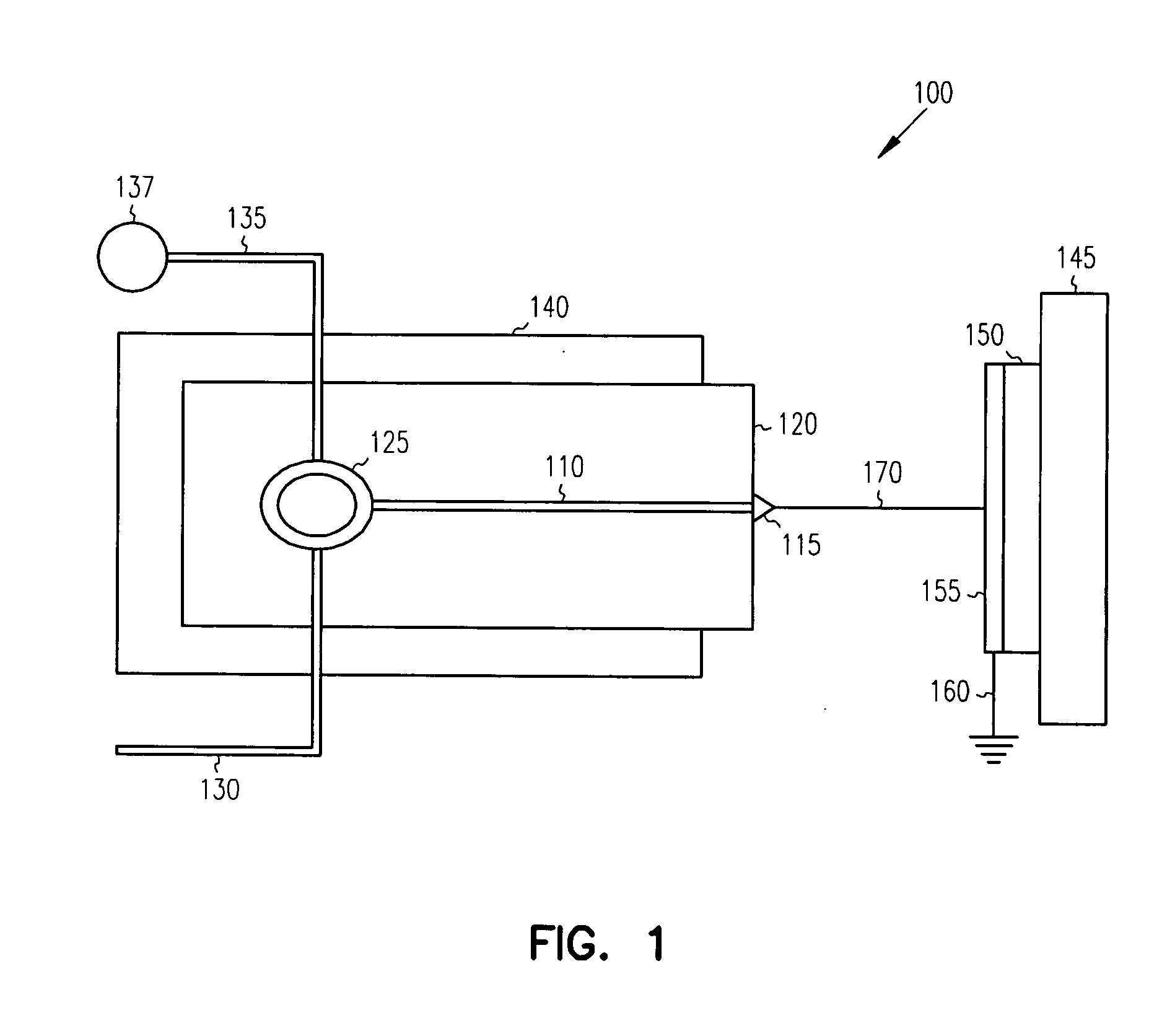

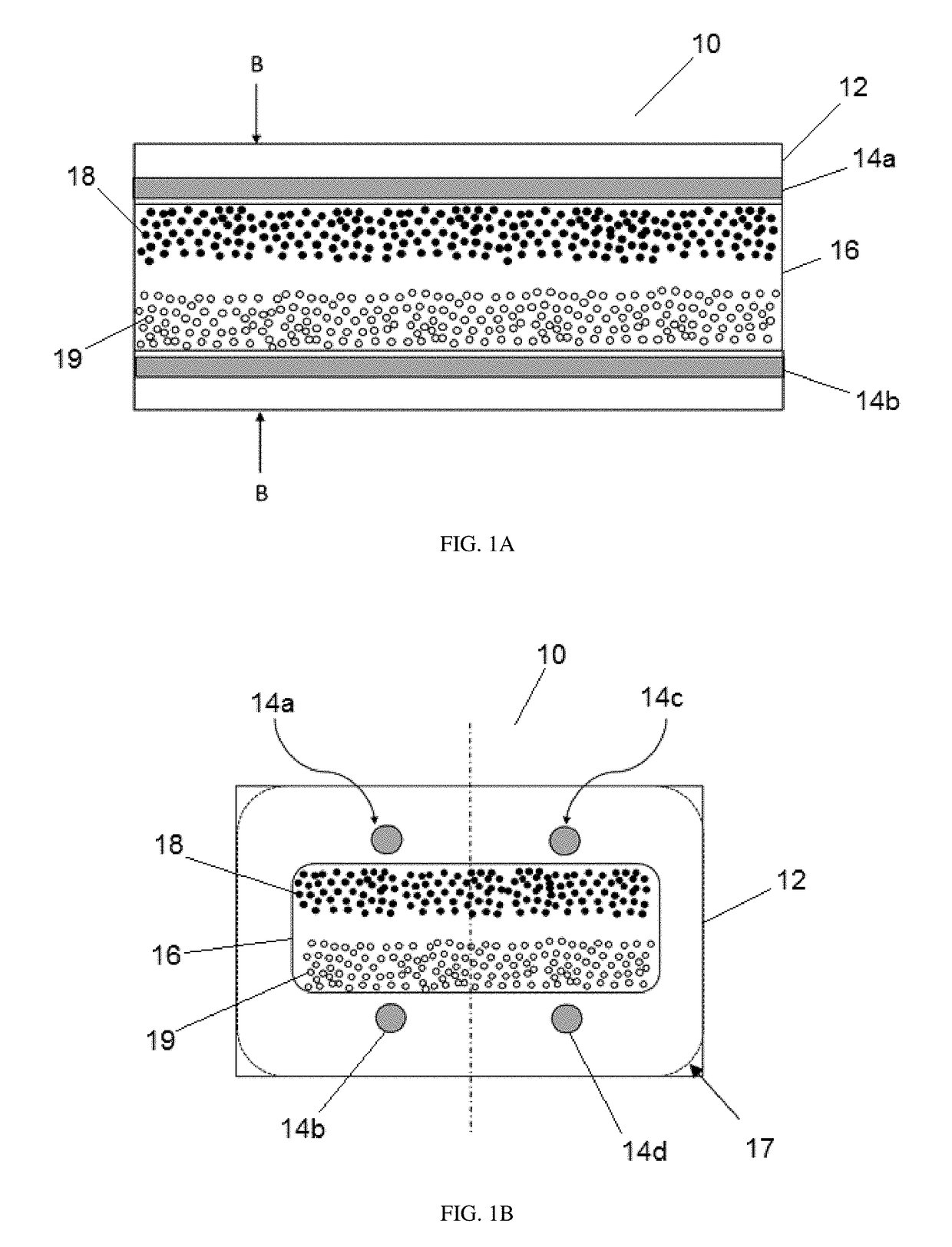

Reduced density article

InactiveUS10087556B2Additive manufacturing apparatusIncreasing energy efficiencyMicro structurePolymer science

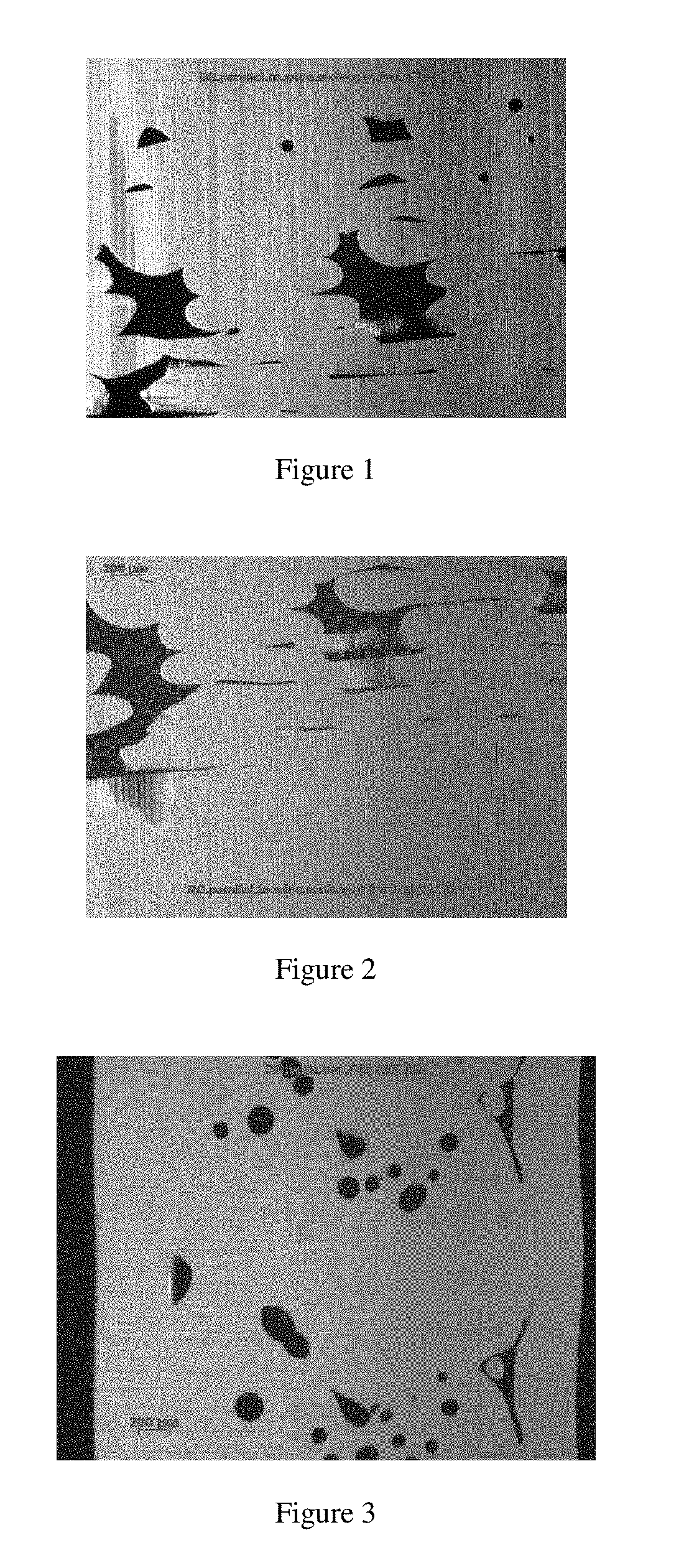

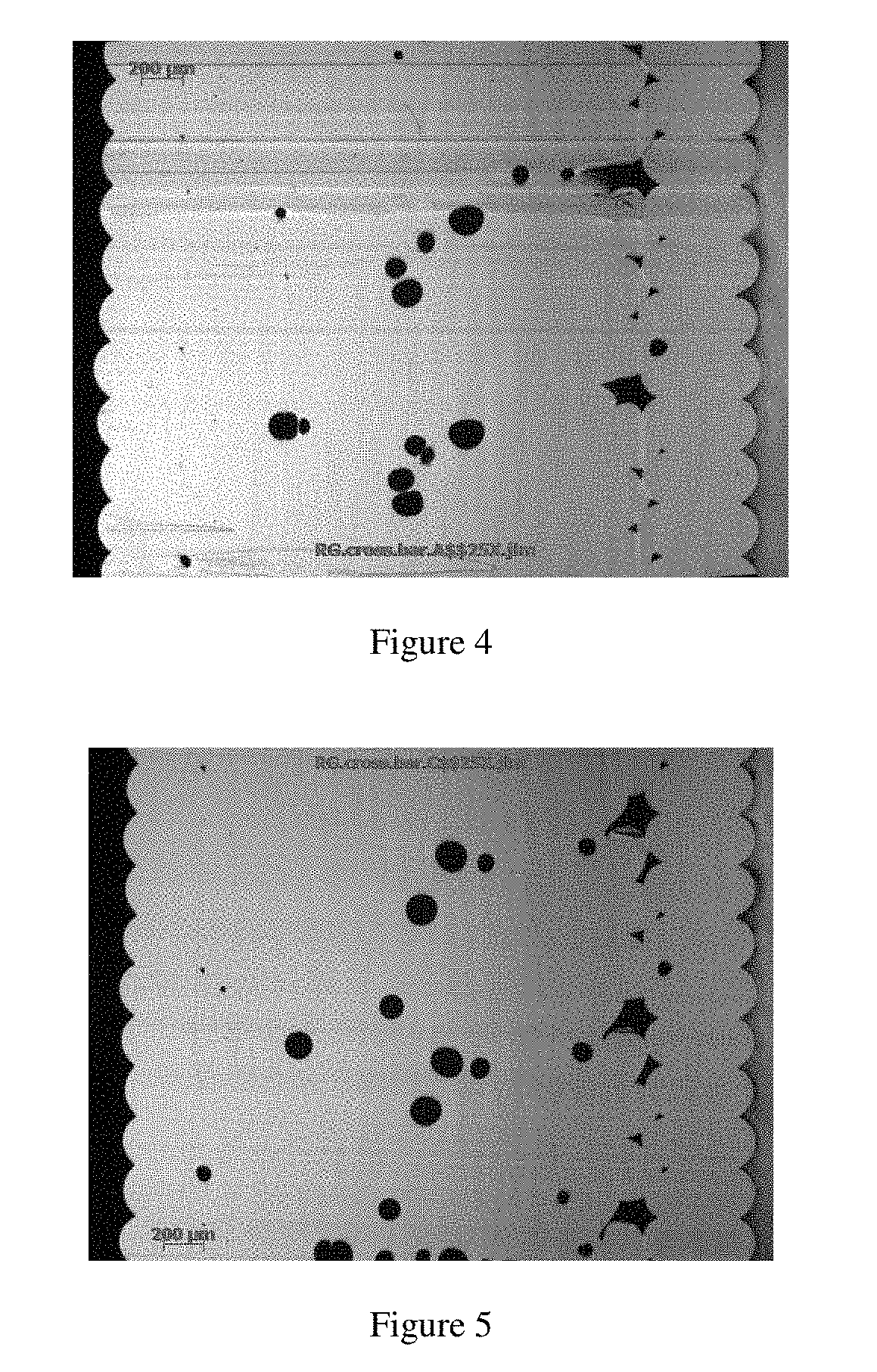

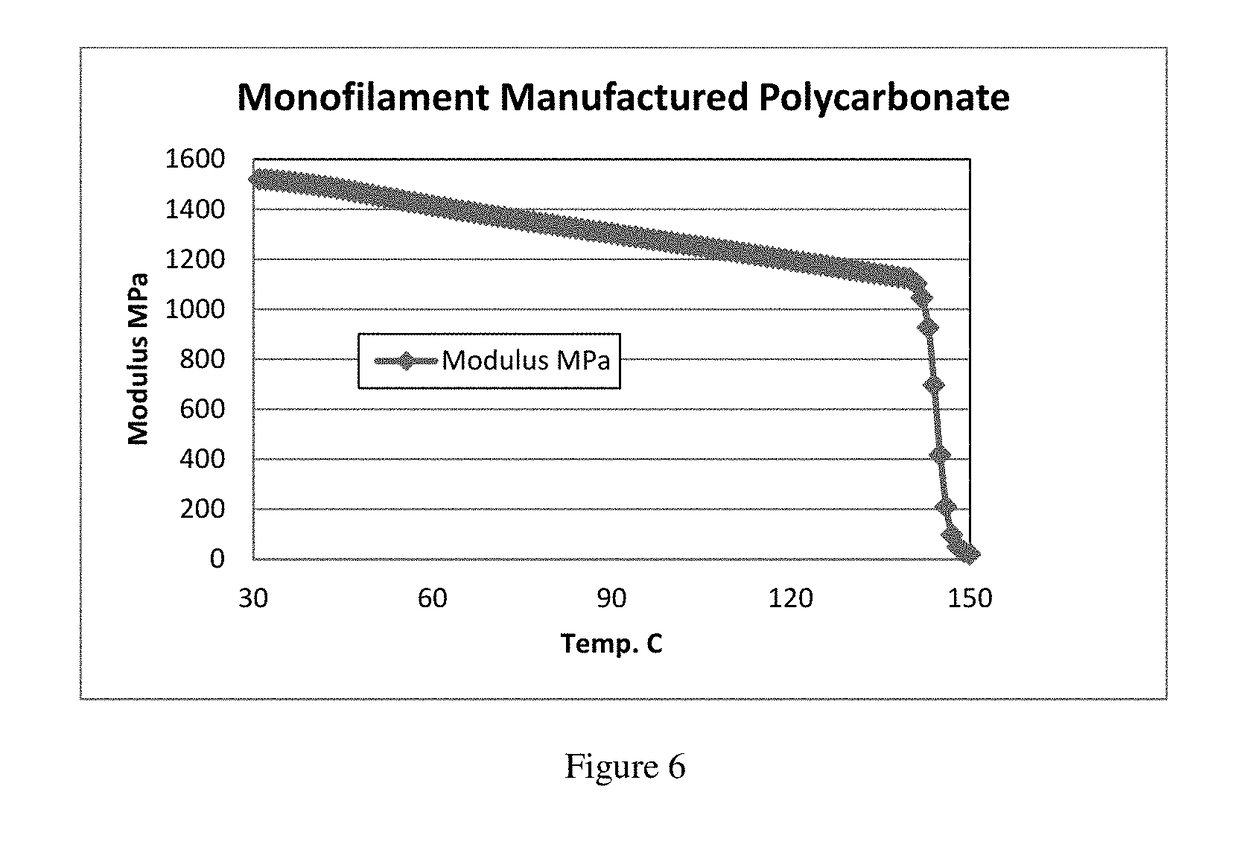

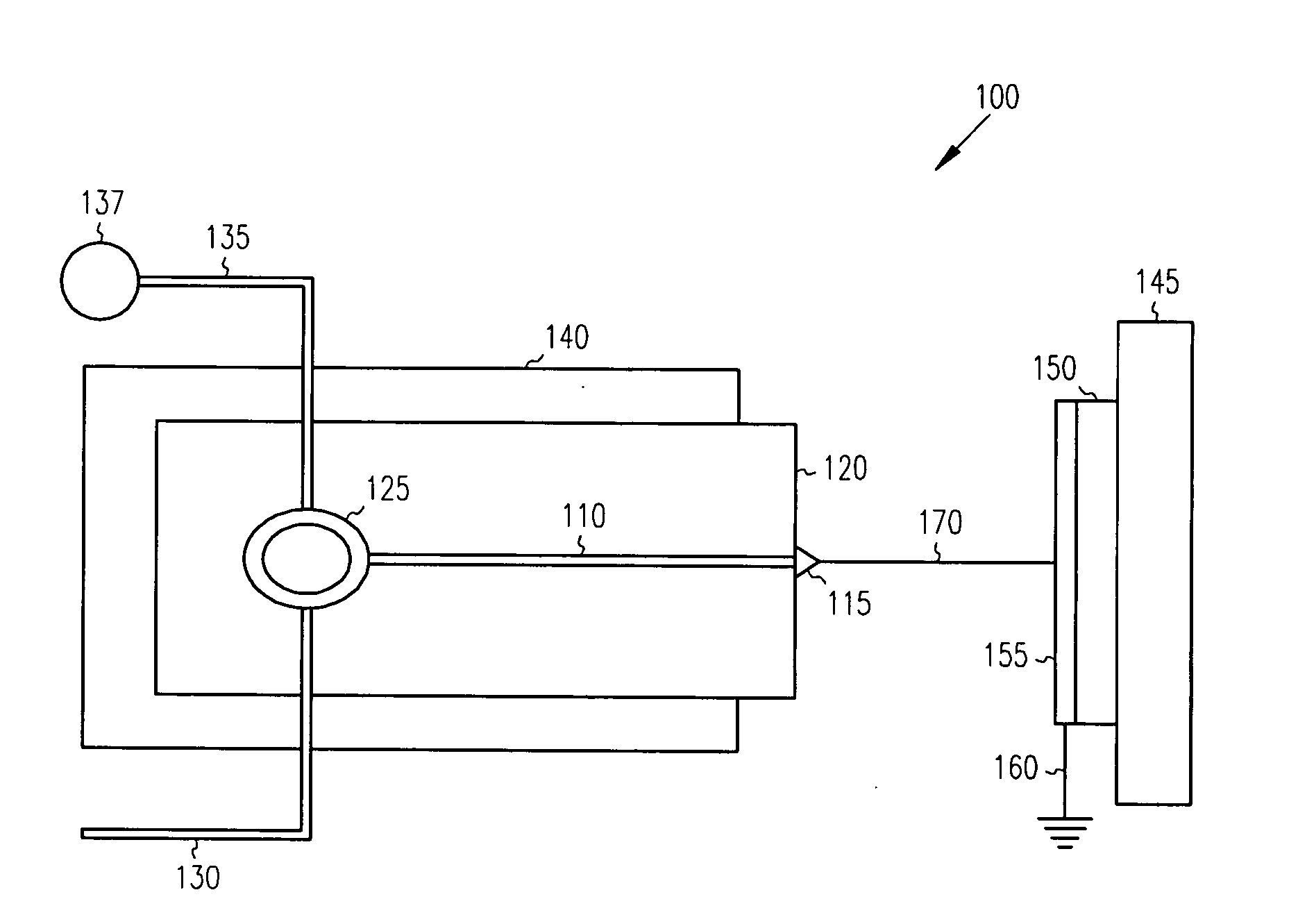

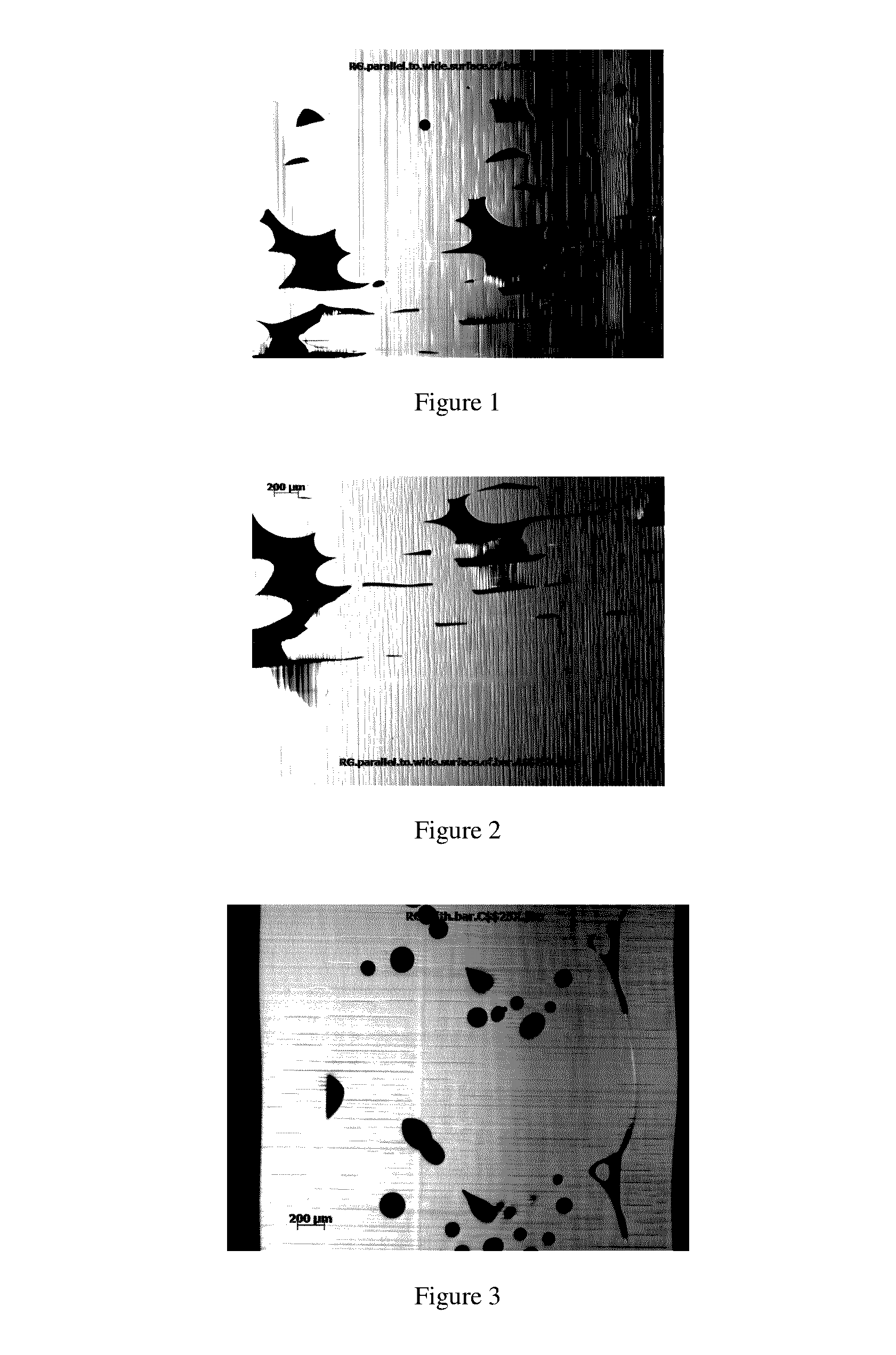

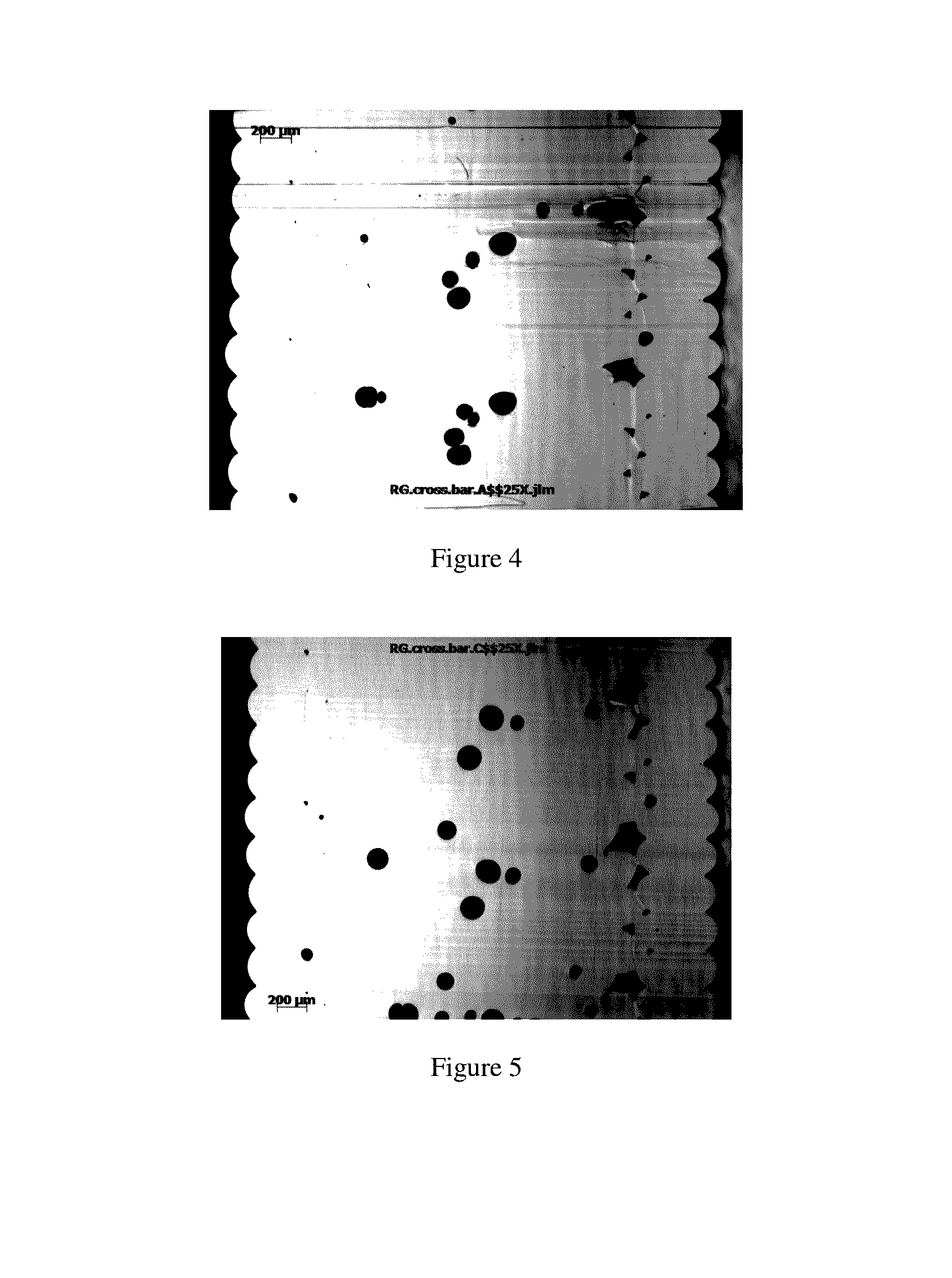

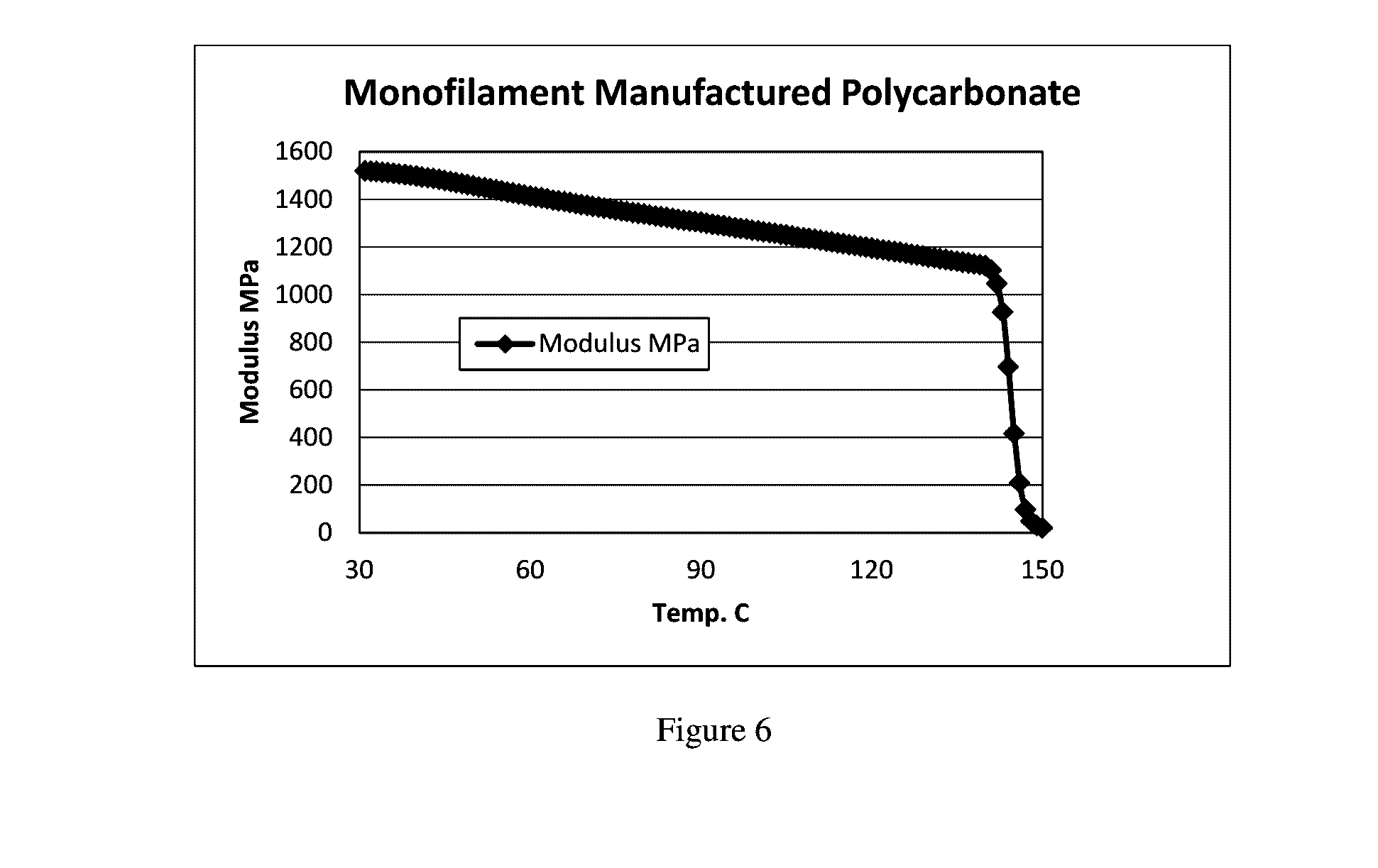

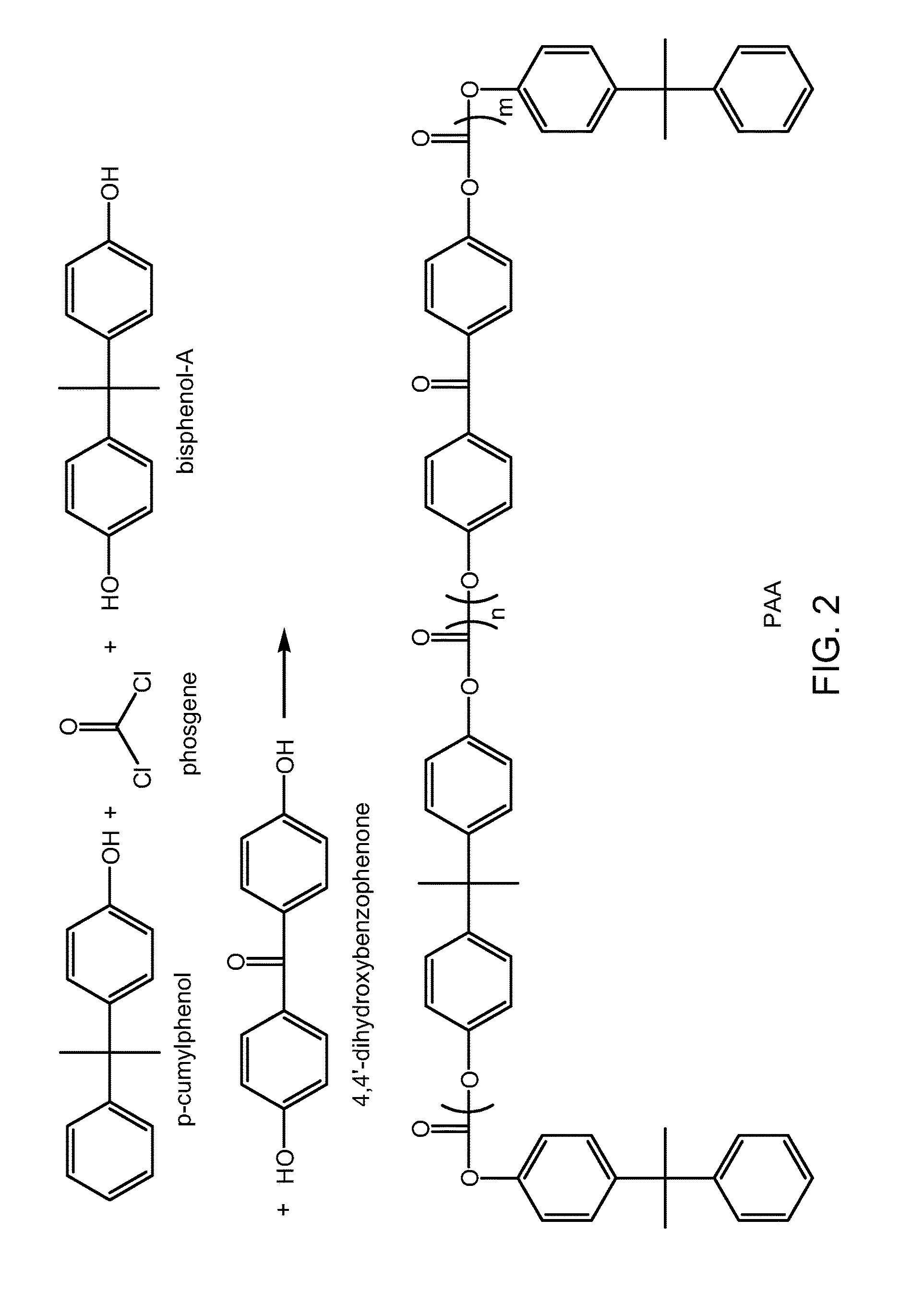

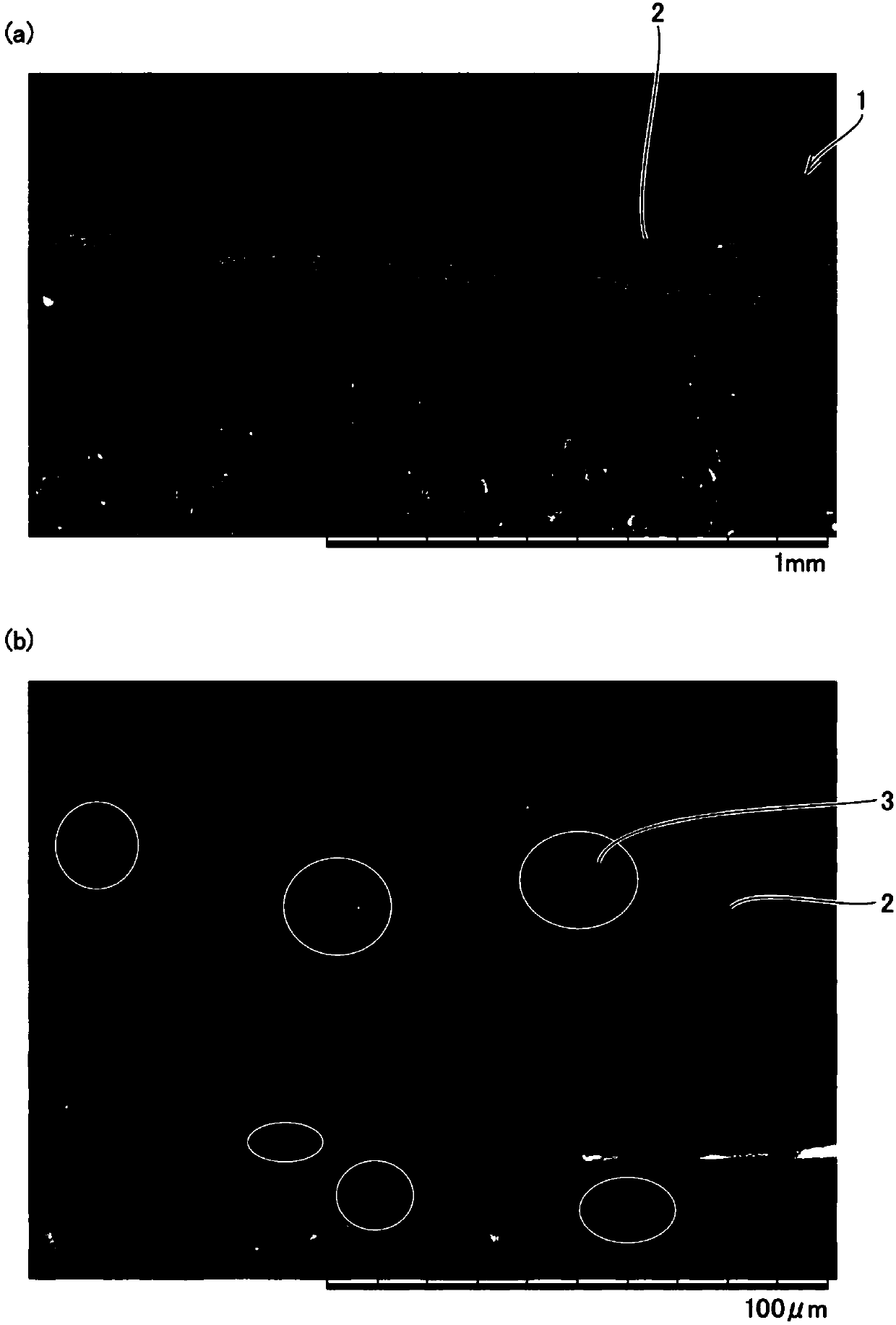

A reduced density article of manufacture, and process for making same, made from a thermoplastic polycarbonate composition. The reduced density article of manufacture has (1) a certain density and (2) a certain micro structure containing from 1% to 20% by volume of voids wherein at least 80% of the voids are high aspect voids and less than 20% of the voids are spherical voids with a diameter of 10 to 100 microns. The polycarbonate thermoplastic composition comprises at least 50 mole % of a certain bisphenol A. The reduced density article of manufacture is made by a monofilament additive manufacturing technique.

Owner:SHPP GLOBAL TECH BV

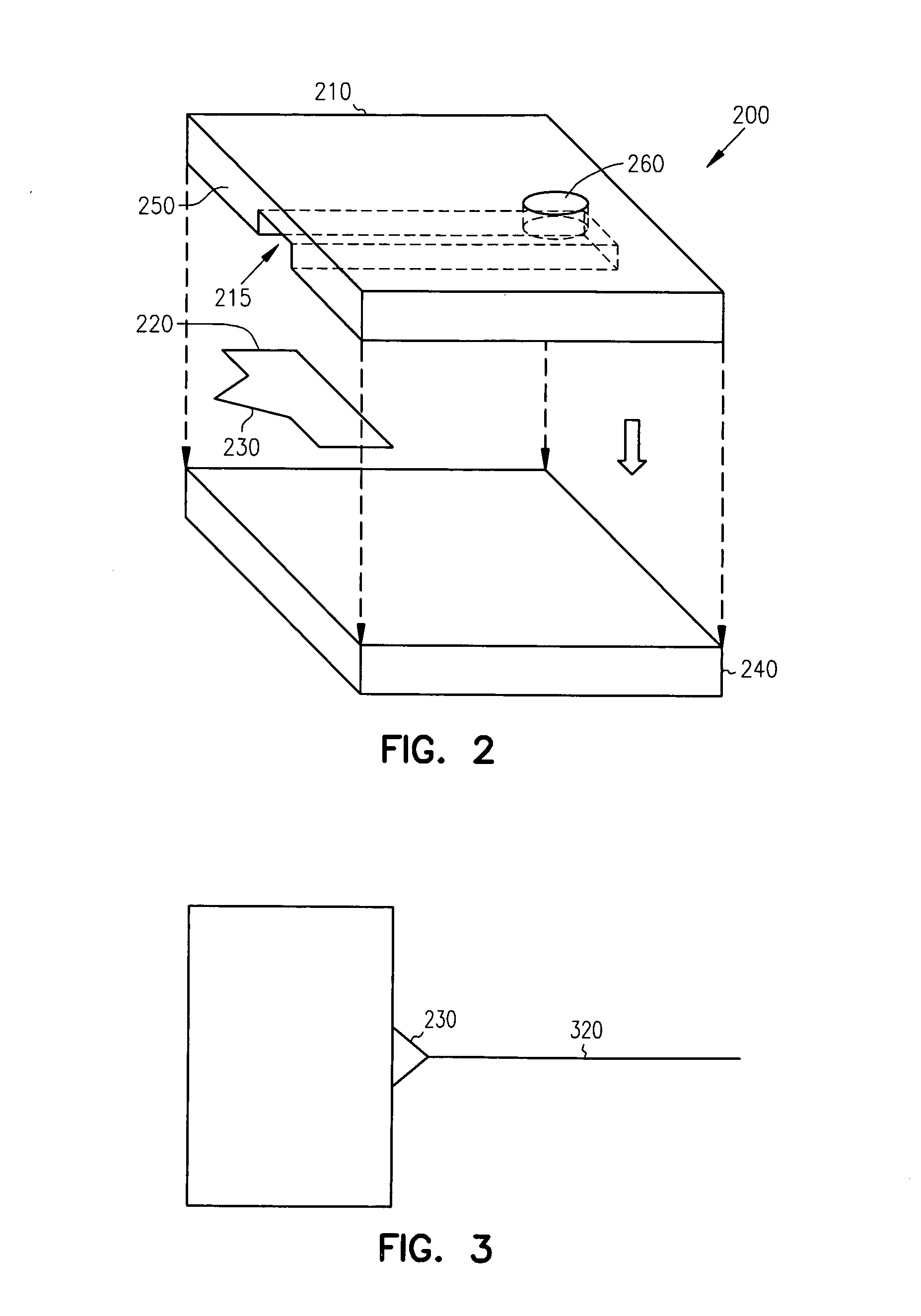

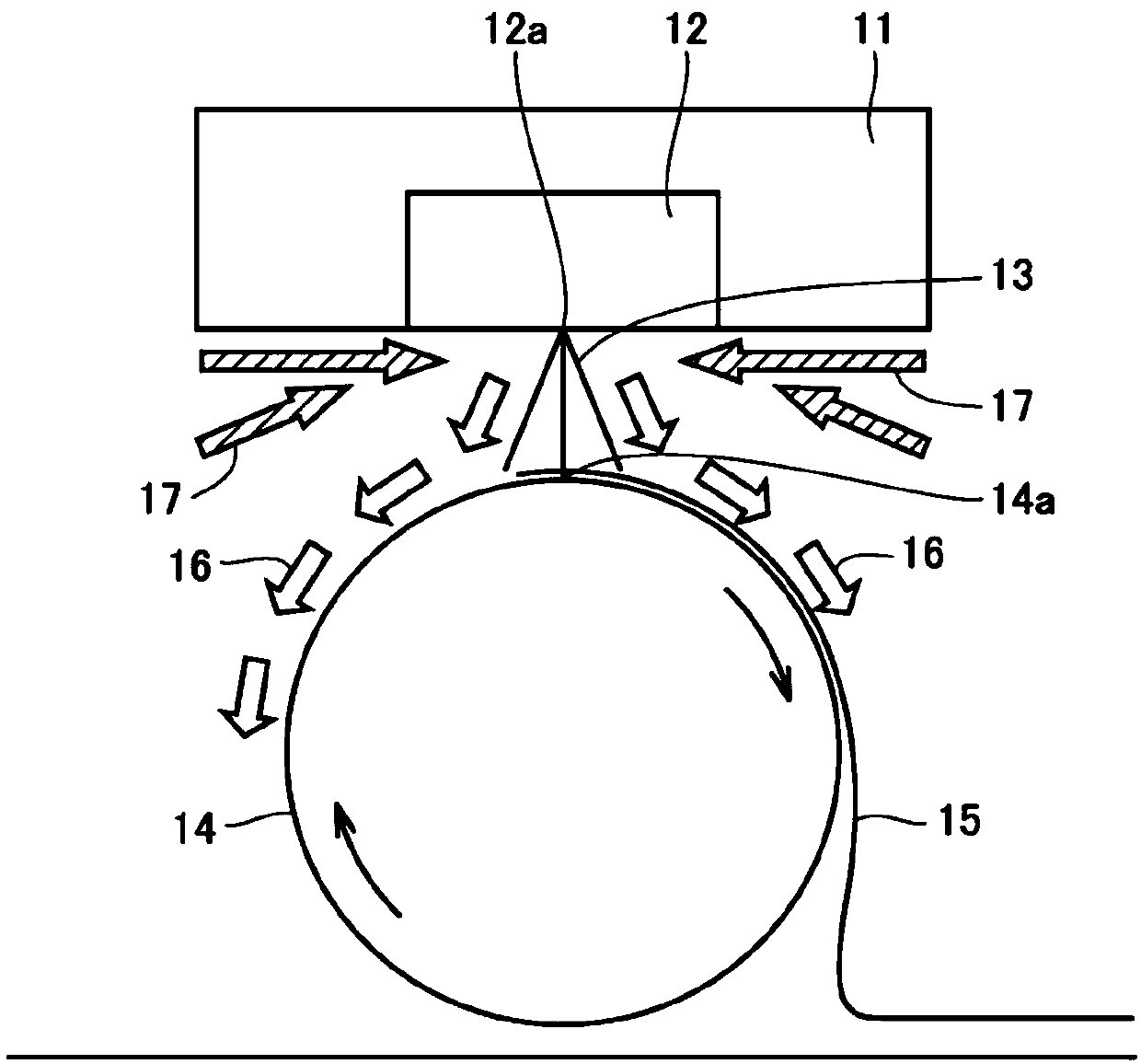

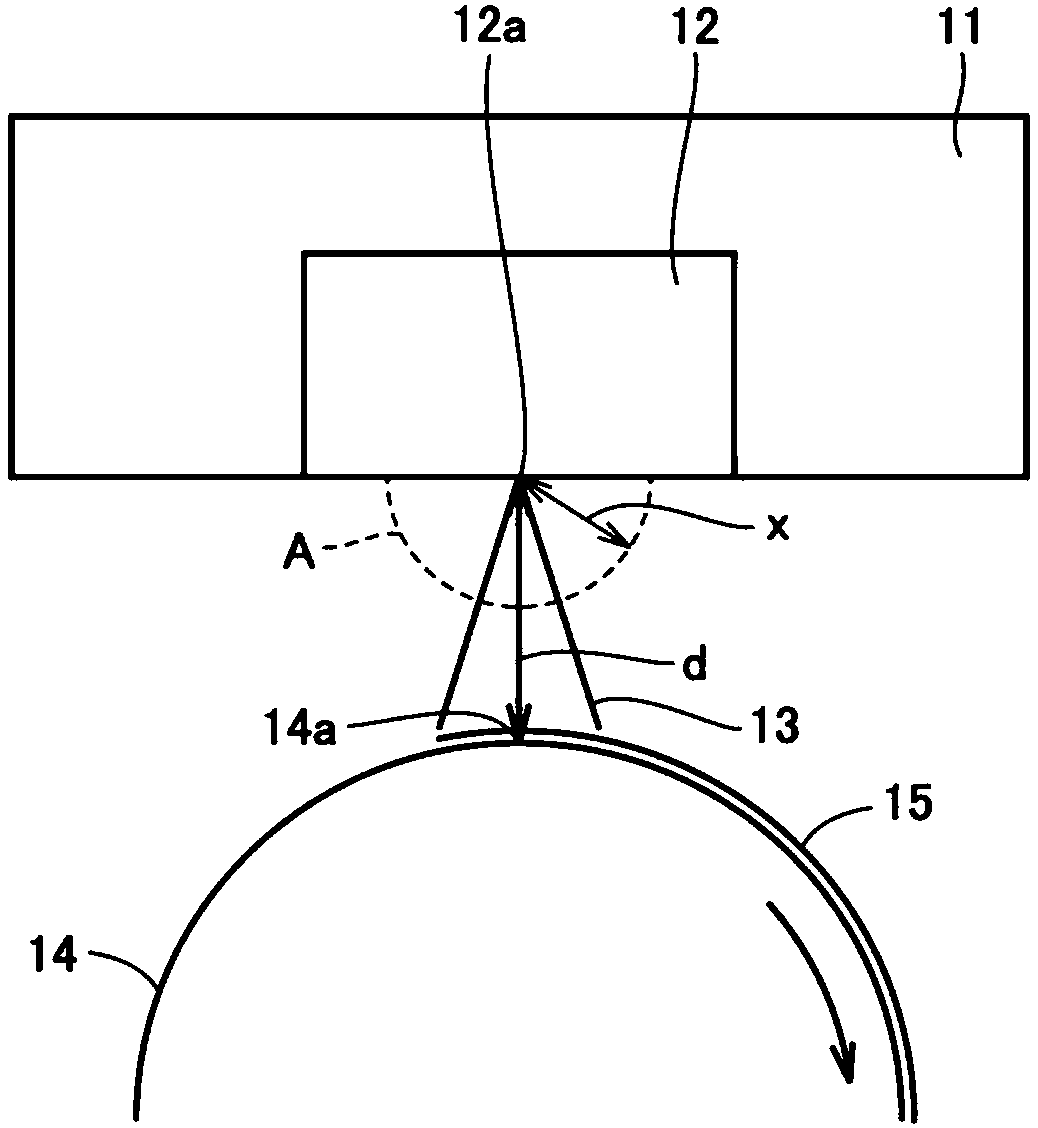

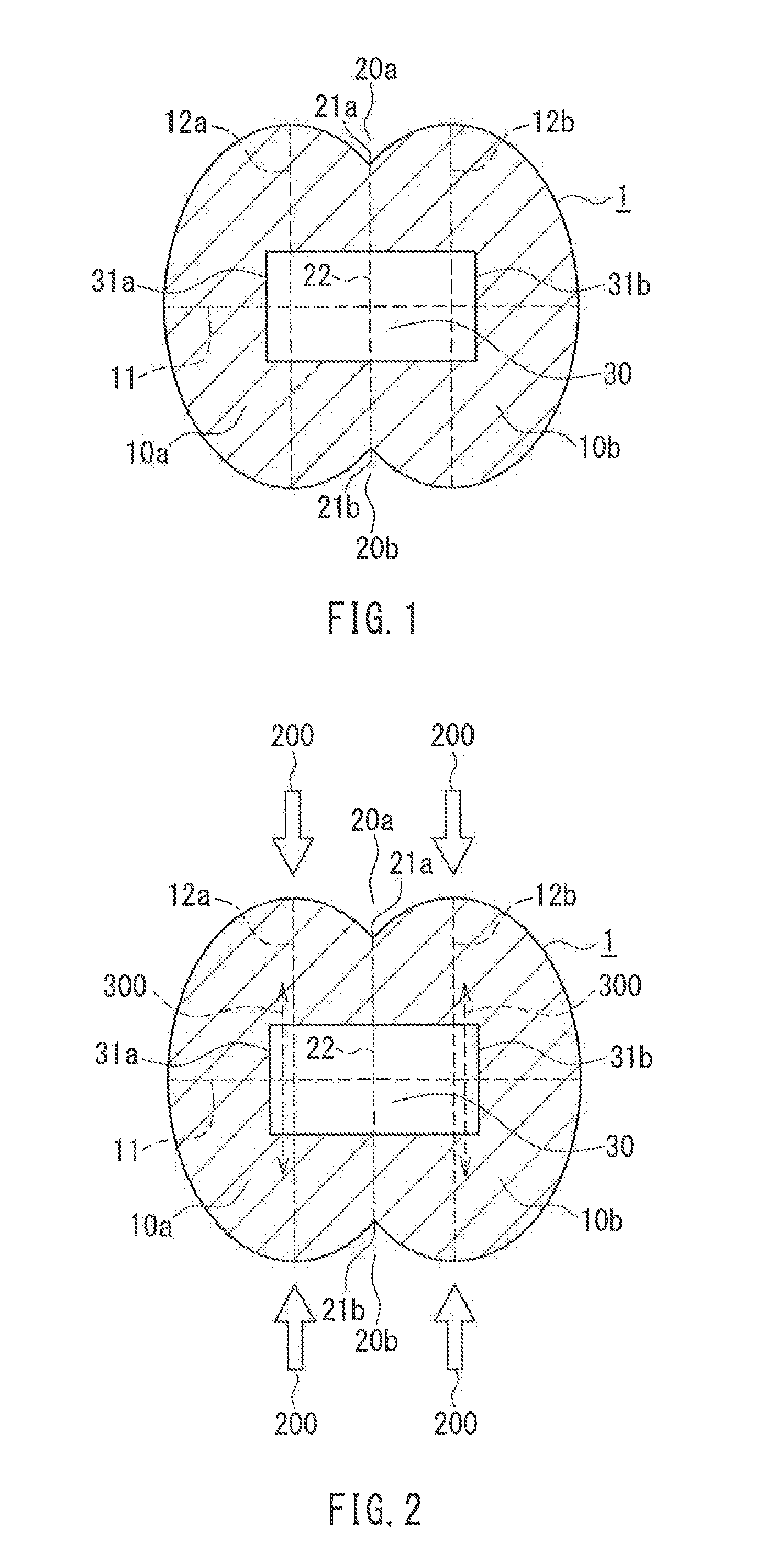

Scanned source oriented nanofiber formation

Nanofibers are formed using electrospray deposition from microfluidic source. The source is brought close to a surface, and scanned in one embodiment to form oriented or patterned fibers. In one embodiment, the surface has features, such as trenches on a silicon wafer. In further embodiments, the surface is rotated to form patterned nanofibers, such as polymer nanofibers. The nanofibers may be used as a mask to create features, and as a sacrificial layer to create nanochannels.

Owner:CORNELL RES FOUNDATION INC

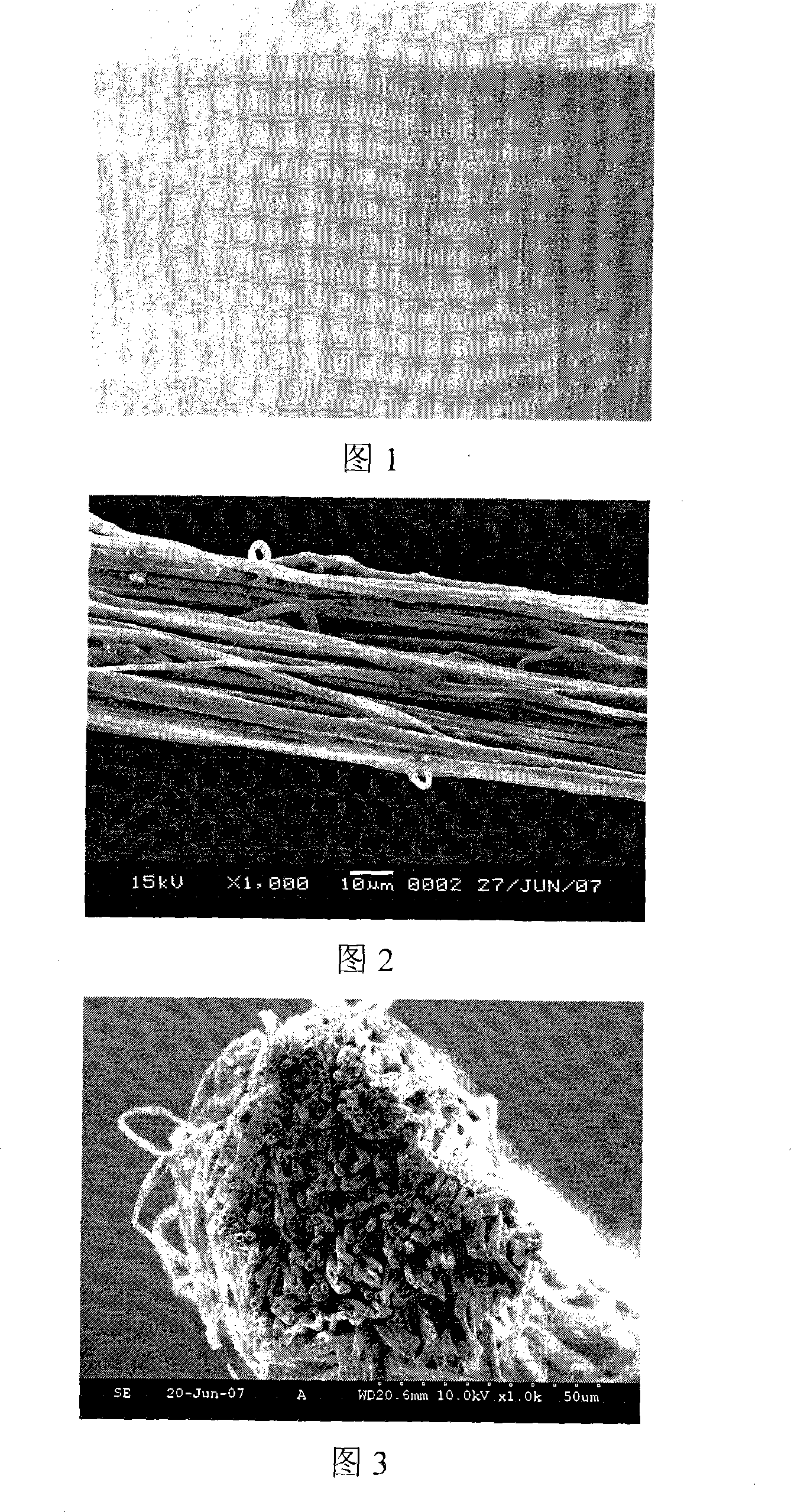

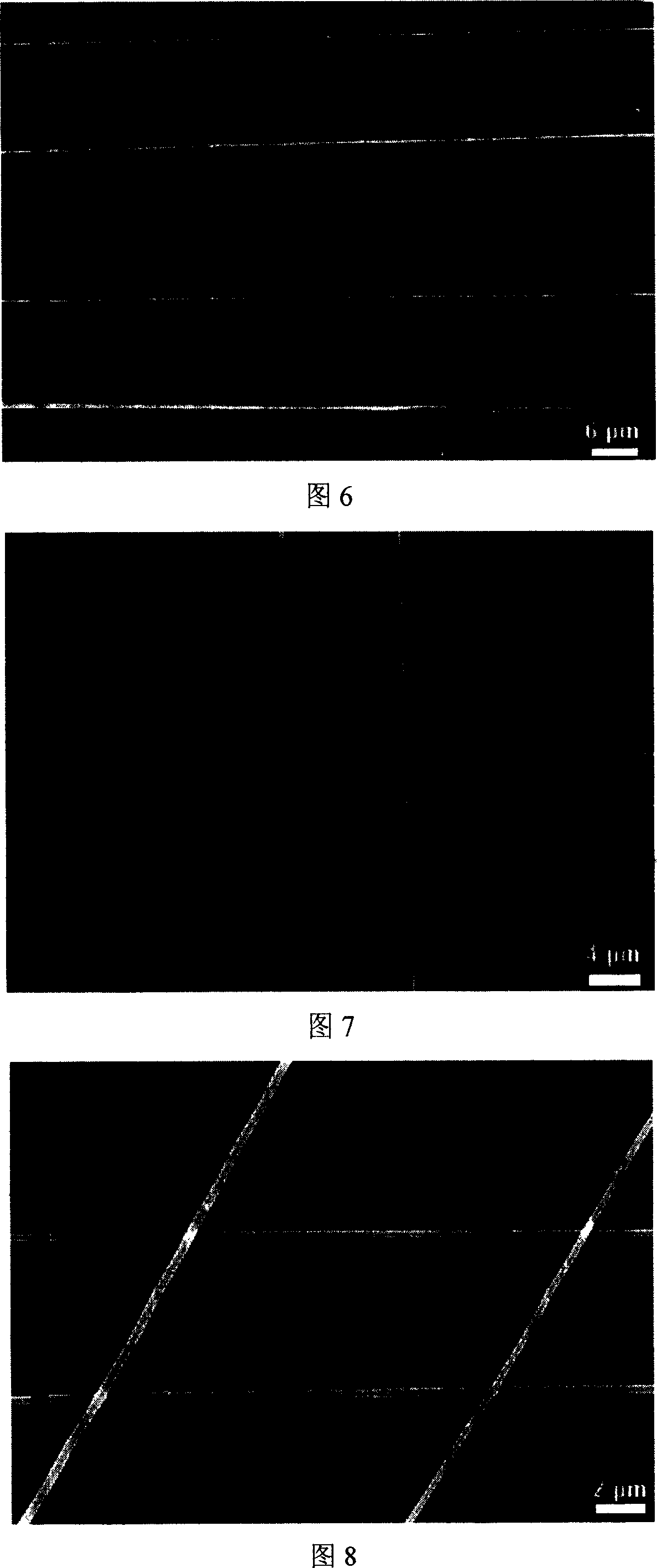

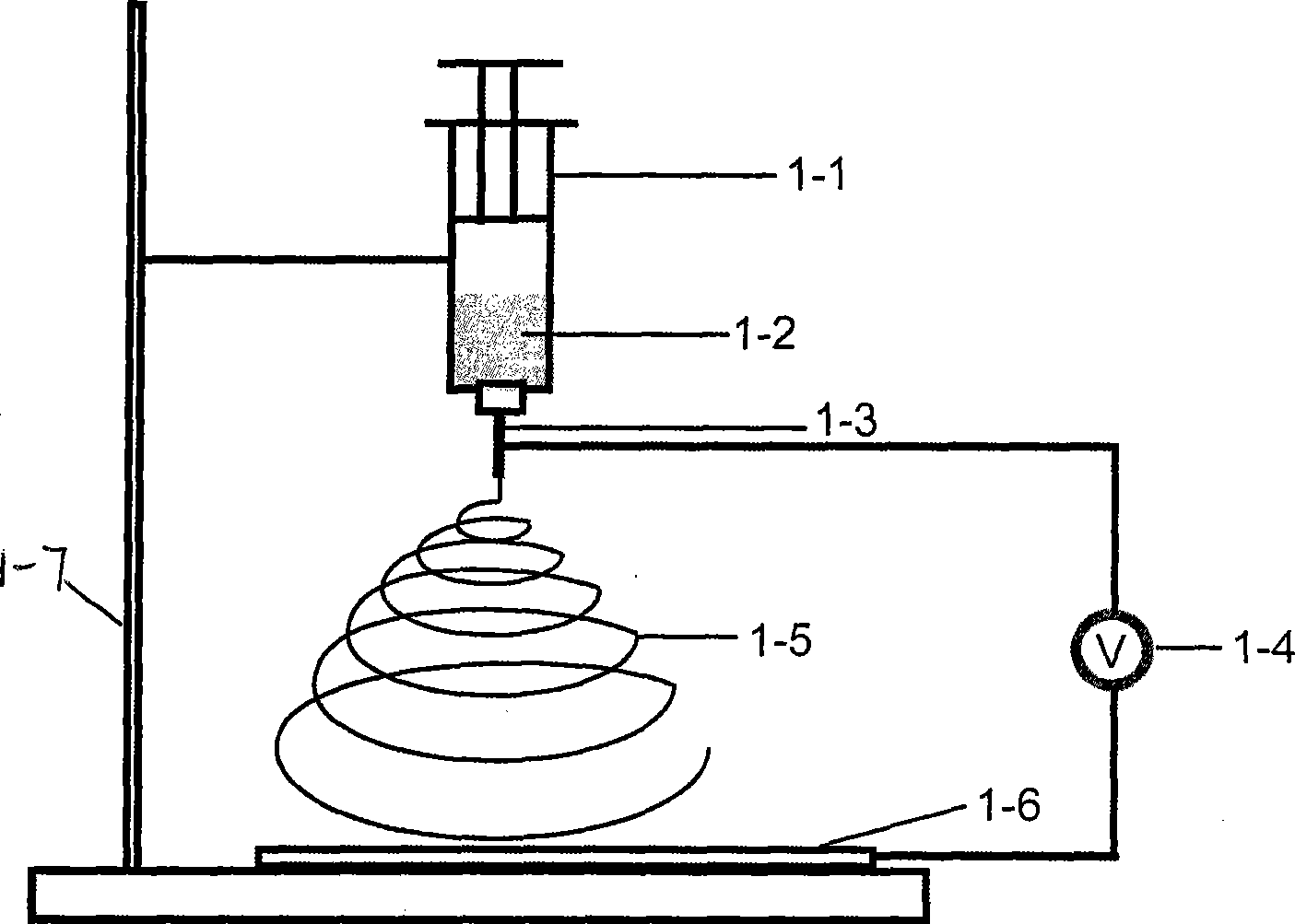

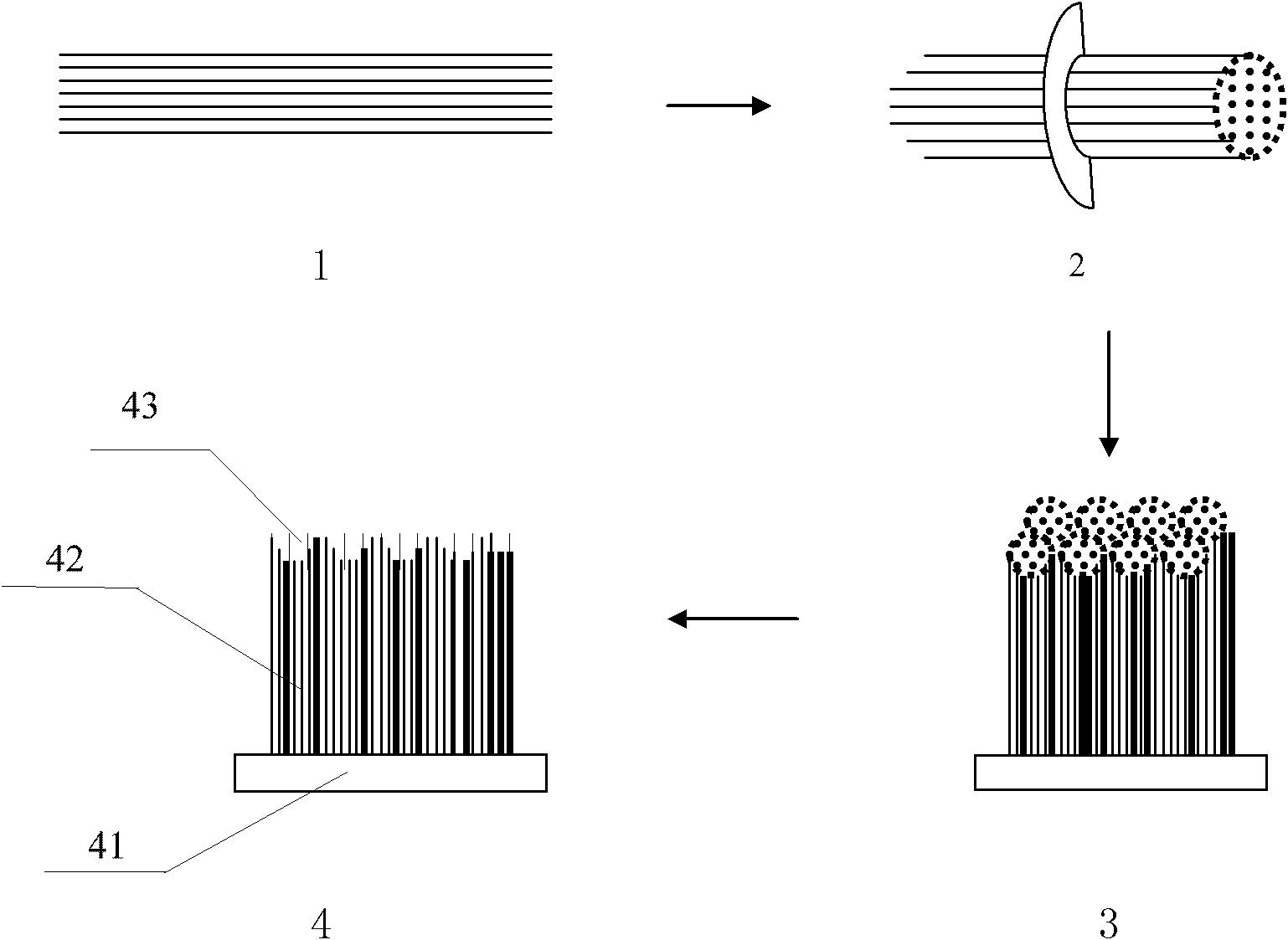

Preparation method for regularly electrostatic spinning hollow fibre

InactiveCN101144196ASimple manufacturing methodHollow filament manufactureArtificial filaments from cellulose derivativesHollow fibreFiber bundle

The present invention relates to a preparation method for regularized static electricity spinning hollow fiber, and the method comprises the procedures that: firstly, high molecular compound is dissolved in good solvent to be made into uniform solution; secondly, poor solvent is added to be dispensed into spinning raw liquid, and the volume ratio of the good solvent and the poor solvent is 10 / 1 to 1 / 3; thirdly, the spinning raw liquid is added into a container, is controlled and extruded by a micro-syringe pump, a jet opening is connected with a high voltage positive pole, a grounding microelectrode with the removable area of 0 to 100 mm 2 is taken as a negative pole, various parameters of static electricity spinning are adjusted, and the spinning raw liquid carries on the static electricity spinning; fourthly, the grounding microelectrode backwards and continuously moves, and a continuous regularized static electricity spinning hollow fiber bundle is obtained; fifthly, the continuous hollow fiber bundle obtains the regularized static electricity spinning hollow fiber through winding and collecting. The preparation method provided by the present invention is simple and feasible, and the obtained static electricity spinning hollow fiber has the potential application and the prospect in the fields such as nanowire devices, filtering materials, and composite reinforcing materials, etc.

Owner:DONGHUA UNIV

Preparation process for fine denier and superfine denier polypropylene fibers

InactiveCN101736416AReduce consumptionSave dyeing energyMonocomponent polypropylene artificial filamentMelt spinning methodsPolymer scienceAbnormal shaped

The invention mainly discloses a preparation process for fine denier and superfine denier polypropylene fibers, which comprises the following steps of: adopting a spinning special material of which the melting point is between 165 and 175 DEG C; in a spinning device, extruding and melting the spinning special material by a single screw extruder, wherein a melt flows evenly; performing spinning through a round or abnormal spinneret orifice of a spinneret plate of a spinning box, wherein the spinning speed is 2,200 miters per minute; cooling and oiling tows; and then performing hot drawing and winding to finally obtain the fine denier and superfine denier polypropylene fibers of 0.5 to 2 deniers, wherein the hot drawing temperature is between 45 and 105 DEG C, the drawing multiple is 1.5 to 4 times, and the winding speed is 80 meters per minute for overfeeding. The preparation process is a nuisanceless, environment-friendly, energy-saving and innovative process, and the finally obtained product has the advantages of light in texture, high strength, good abrasion resistance and elastic resilience, small static electricity, small coefficient of heat conductivity and good electrical insulating property.

Owner:绍兴前瞻化纤有限公司

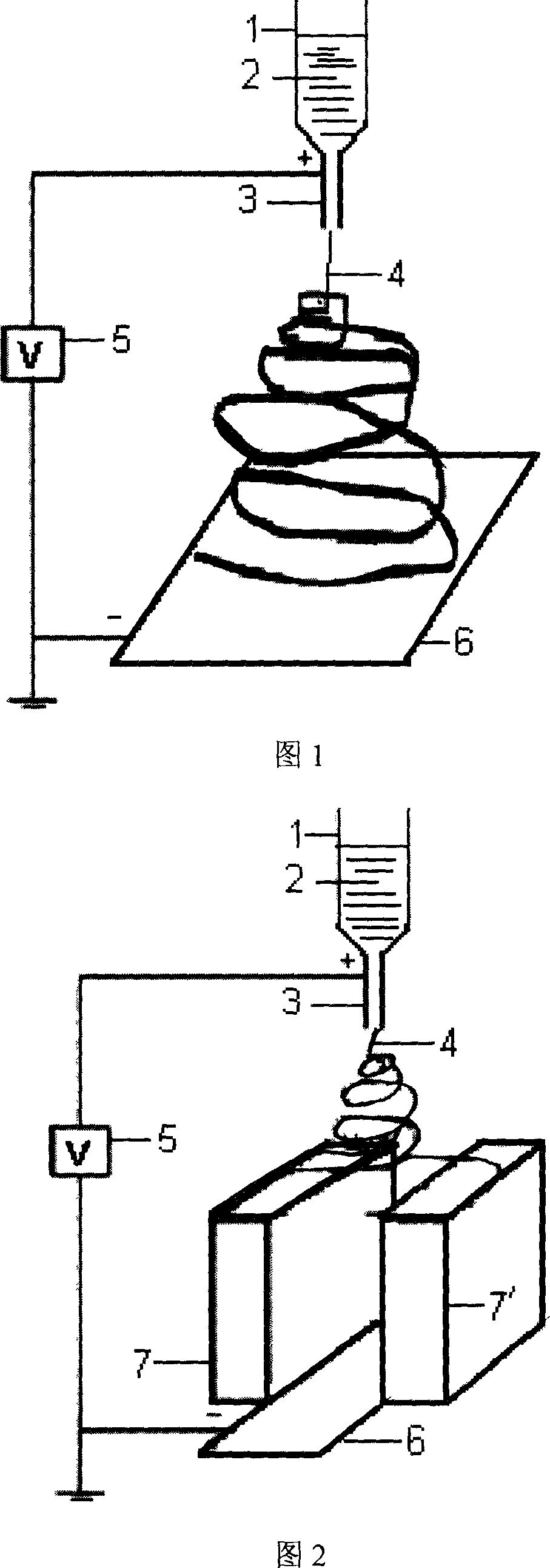

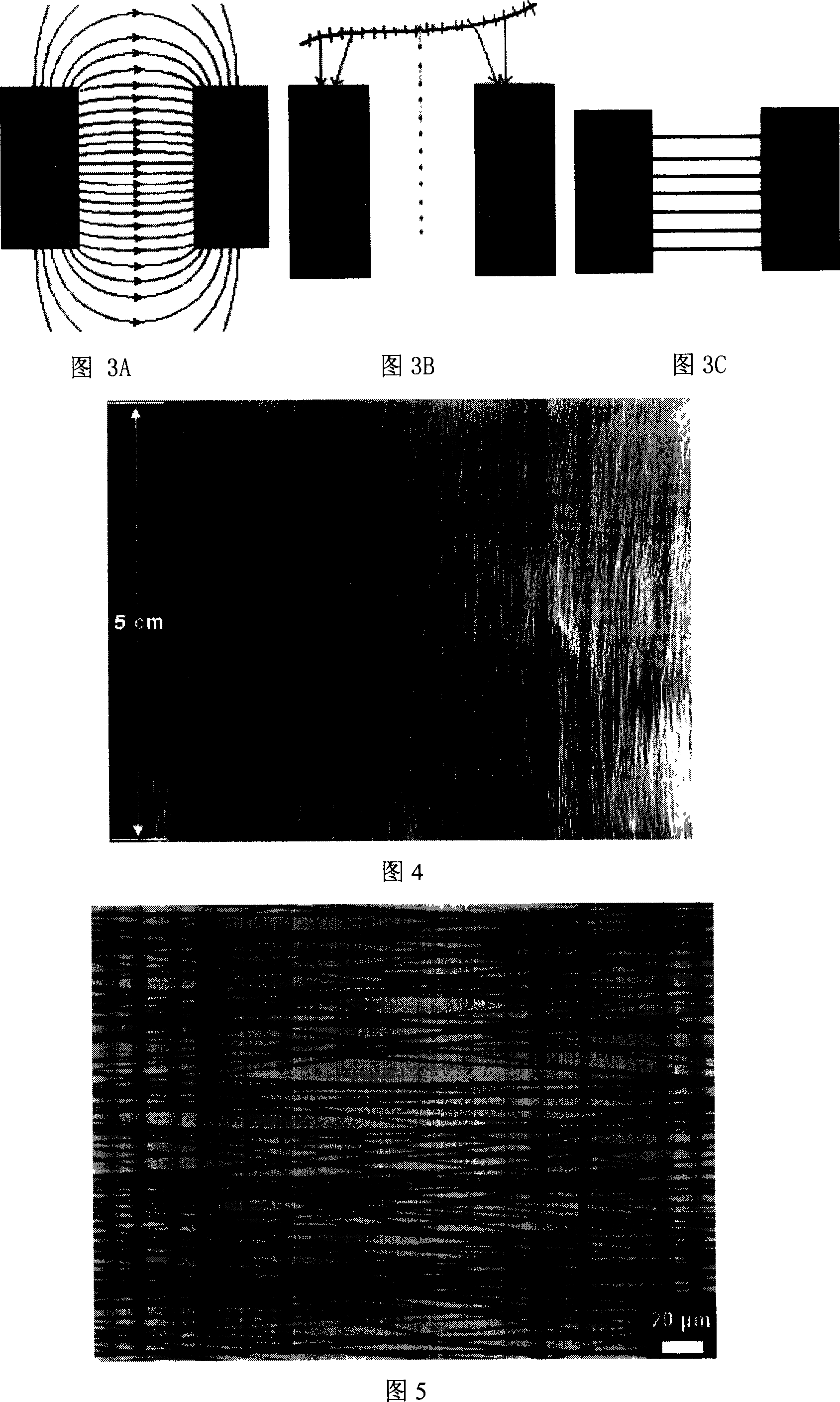

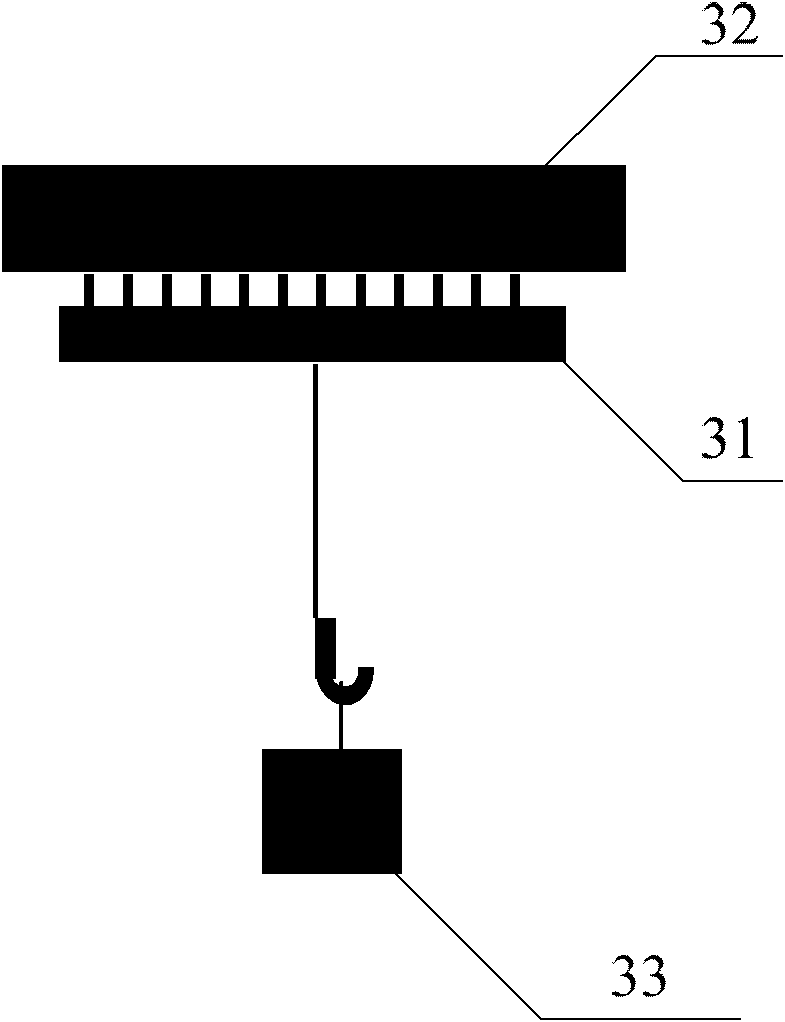

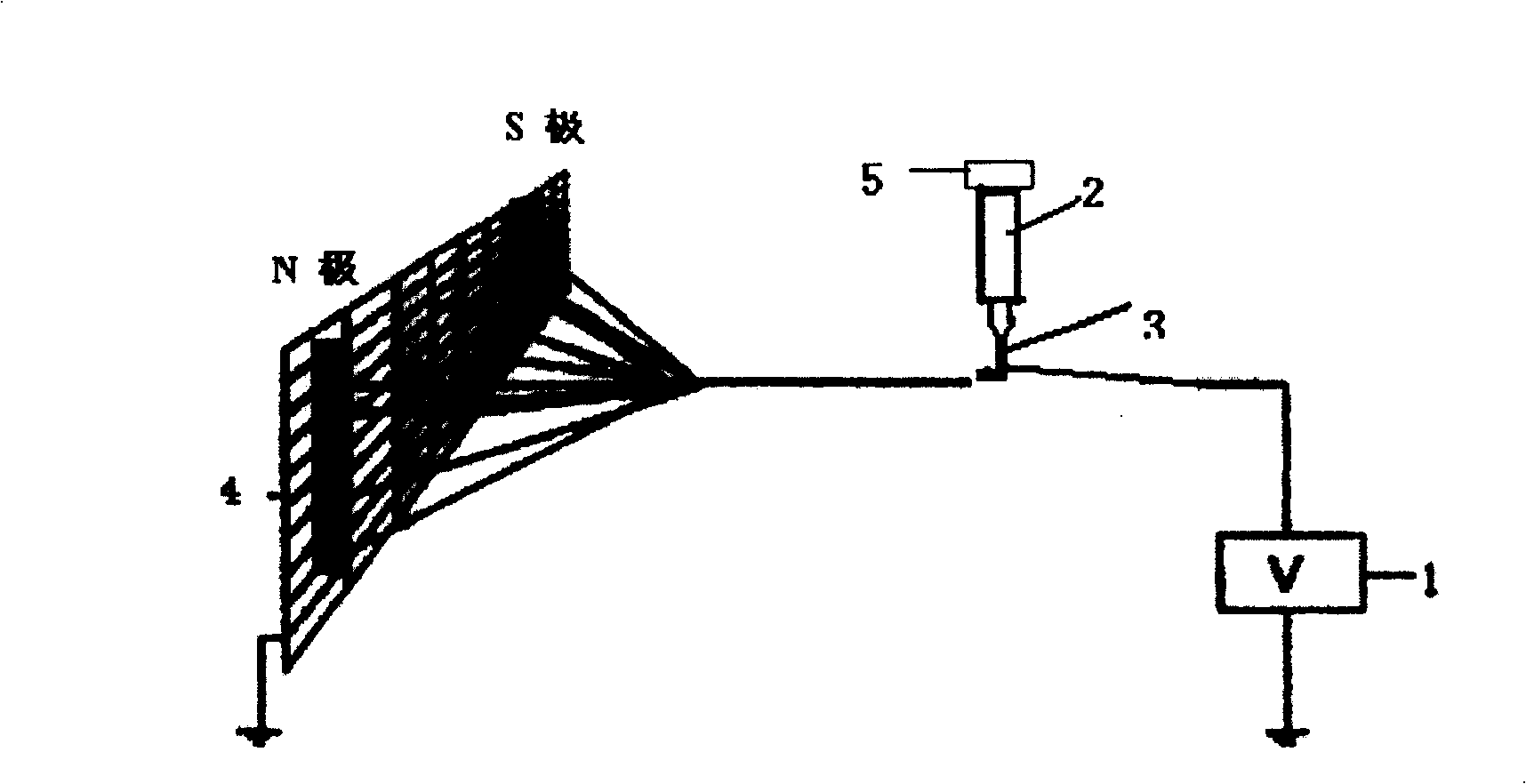

Device and method for preparing regular arranged macromolecular nano-fibre

The invention relates to an equipment for preparing polymer nanometer fiber with regular arrangement and the method. The equipment comprises a spraying silk tube for containing polymer solution. A spraying nozzle is sealed and assembled at the end of spraying silk tube. The nozzle is connected with the positive electrode of high pressure generator and is used as anticathode. An aluminum foil is connected with the negative electrode of high pressure generator and is used as cathode, which is grounded at the same time. The aluminum foil is set between a first permanence magnet and a second one. The nozzle is faced to the aluminum foil. The electrical spinning method controlled by magnet is that soluble macromolecules are put into the corresponding solvent and the concentration is adjusted, the polymer solution with good performance for spinning is confected; magnetic nanometer grains are put into the polymer solution and magnetized polymer solution is formed. In the electrical spinning equipment controlled by magnet, the magnetized polymer solution becomes micro-nano continuous fiber under the effect of electric field and at the same time fibers are arranged along the direction of magnetic line under the effect of external magnetic field to form micro-nano fiber material with parallel arrangement.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

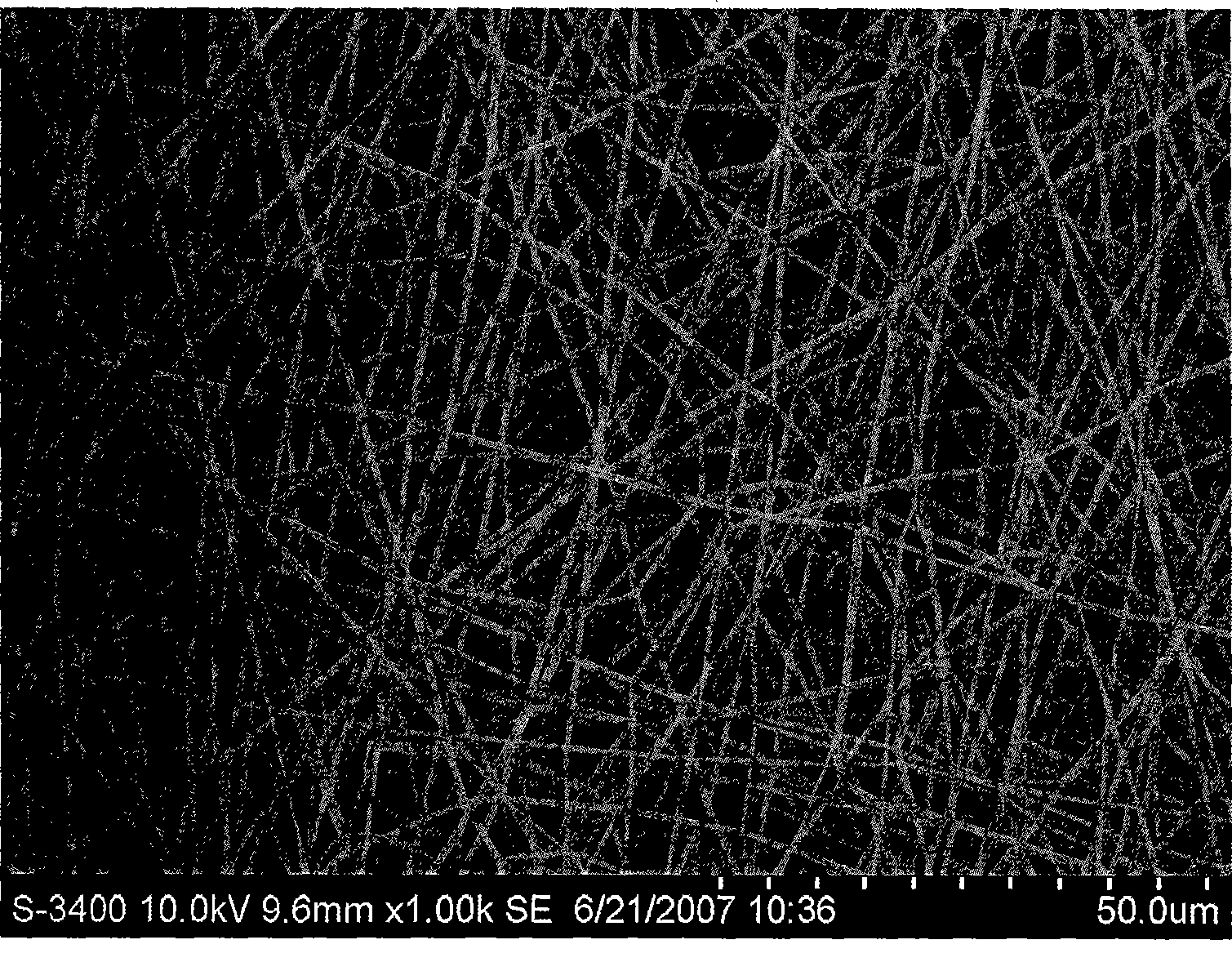

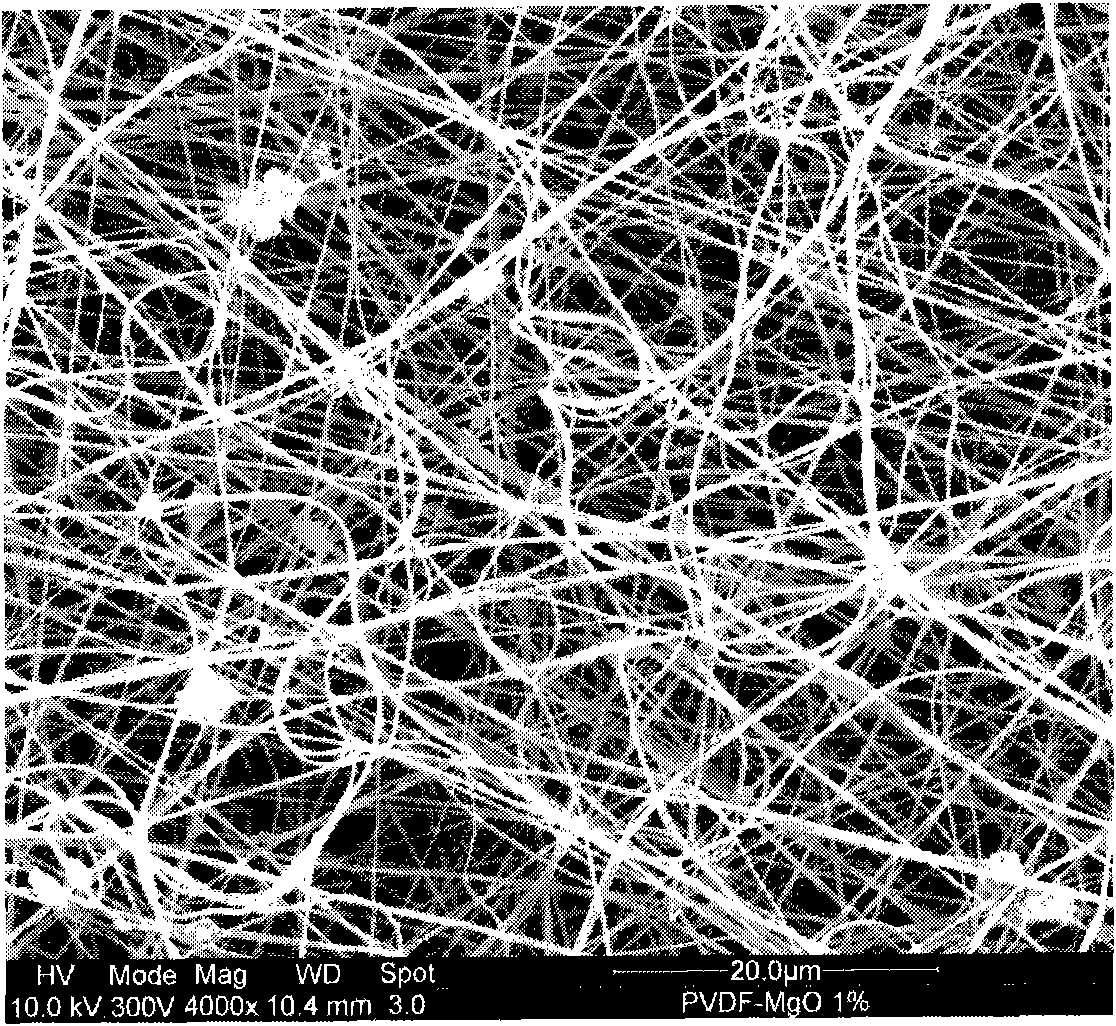

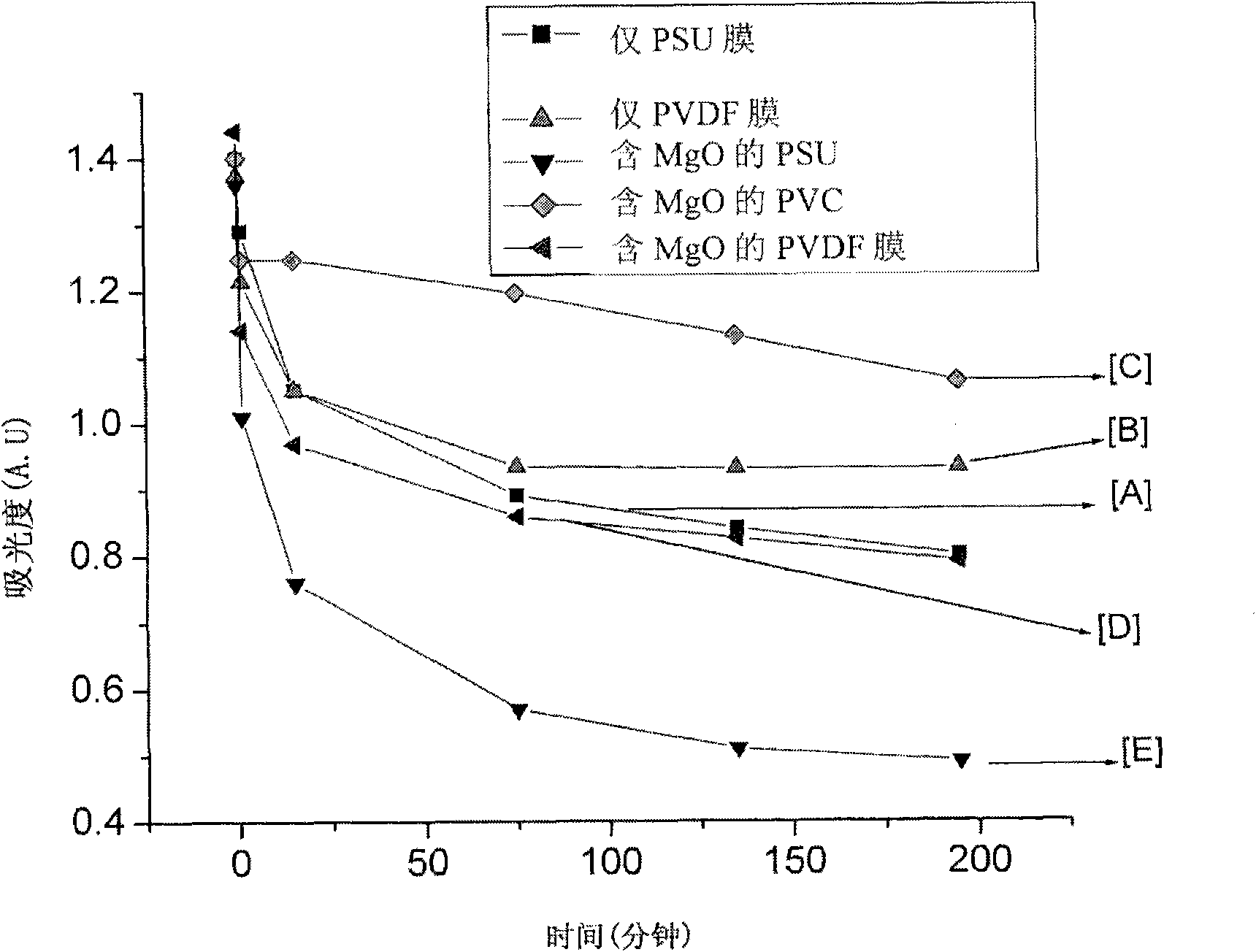

Polymer electrostatic spinning film, preparation and use in biological detection

ActiveCN101413183AEasy to operateEnhanced interactionFilament/thread formingMonocomponent polypropylene artificial filamentElectrospinningOperability

The invention relates to a macromolecular electrostatic spinning film, a preparation method thereof and an application of the macromolecular electrostatic spinning film to bioinstrumentation. The macromolecular electrostatic spinning film is a membranoid substance which is formed by disorderly interlacing macromolecular electrostatic spinning which are not water-soluble; and the diameter of the macromolecular electrostatic spinning is between 50 and 1,000 nanometers, and the thickness of the film is between 5 mu m and 1 millimeter. The preparation method comprises the following steps: electrostatic spinning is performed in an electrostatic spinning device, and the spinning obtained is subjected to pressing, waterlogging and secondary pressing to obtain the dense and smooth macromolecular electrostatic spinning film with strong operability. The film can be applied to bioinstrumentation and taken as a protein absorbing vector, and has a larger absorption quantity compared with the prior protein absorbing vector film. The preparation method for the film is simple, has low cost, can solve the problems that the electrostatic spinning is puffy, unsmooth and easy to fall off, converts electrostatic spinning non-woven fabrics into the electrostatic spinning film used for bioinstrumentation, and can also be applied in the fields of tissue engineering, bioinstrumentation, catalyst load, filter materials and so on.

Owner:BEIJING NANO ACE TECH CO LTD

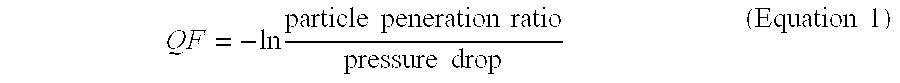

Nanofiber filter medium and method for manufacturing the same

Disclosed is a nanofiber filter medium formed by electrospinning, having a low pressure drop and high filtration performance. The nanofiber layer thereof is constructed by at least two nanofibers, uniformly entangled with each other, with different fiber diameter distributions. Therefore, the nanofiber filter medium of the invention is completed. The described nanofiber filter medium has a low pressure drop and high filtration performance.

Owner:IND TECH RES INST

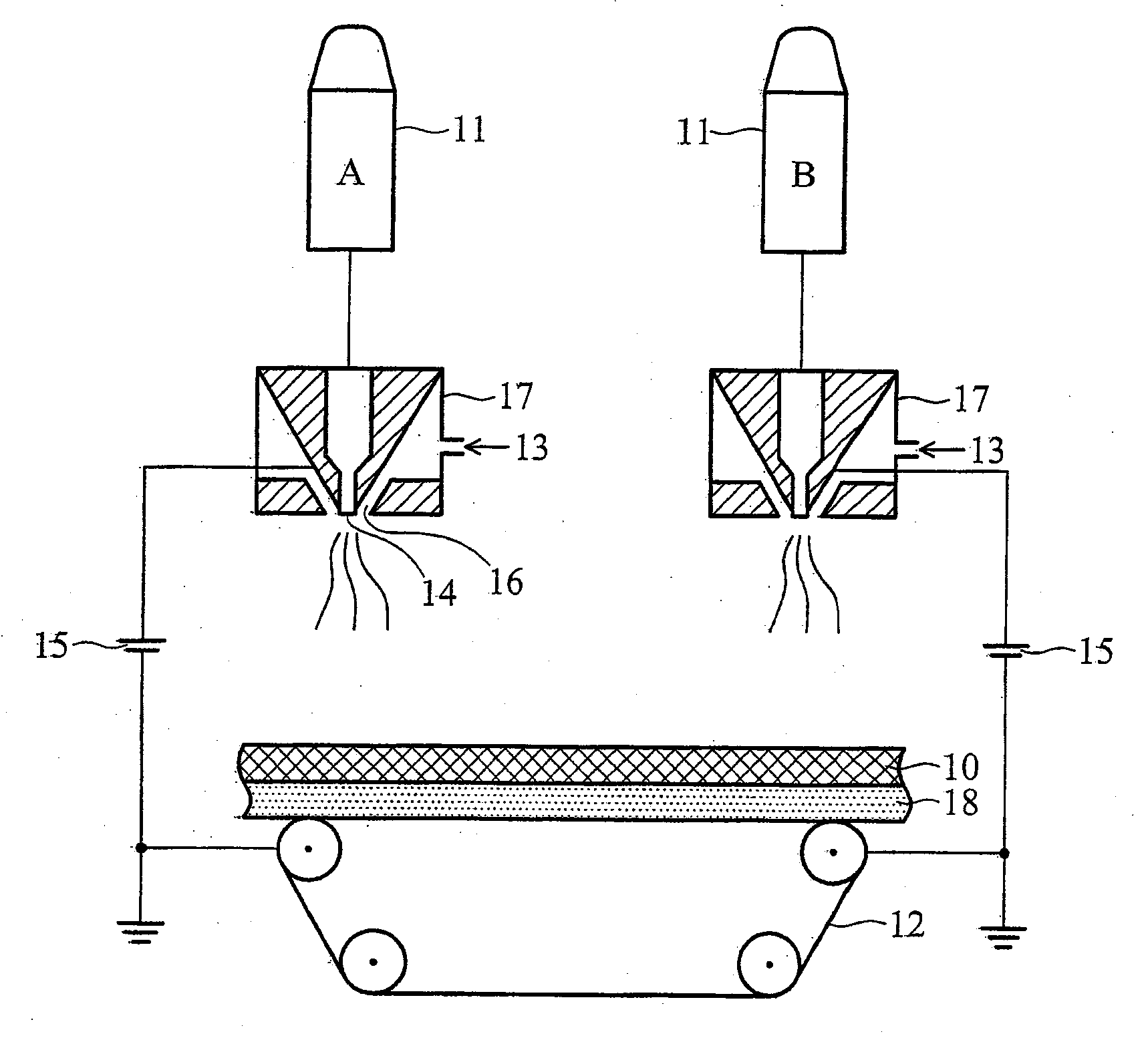

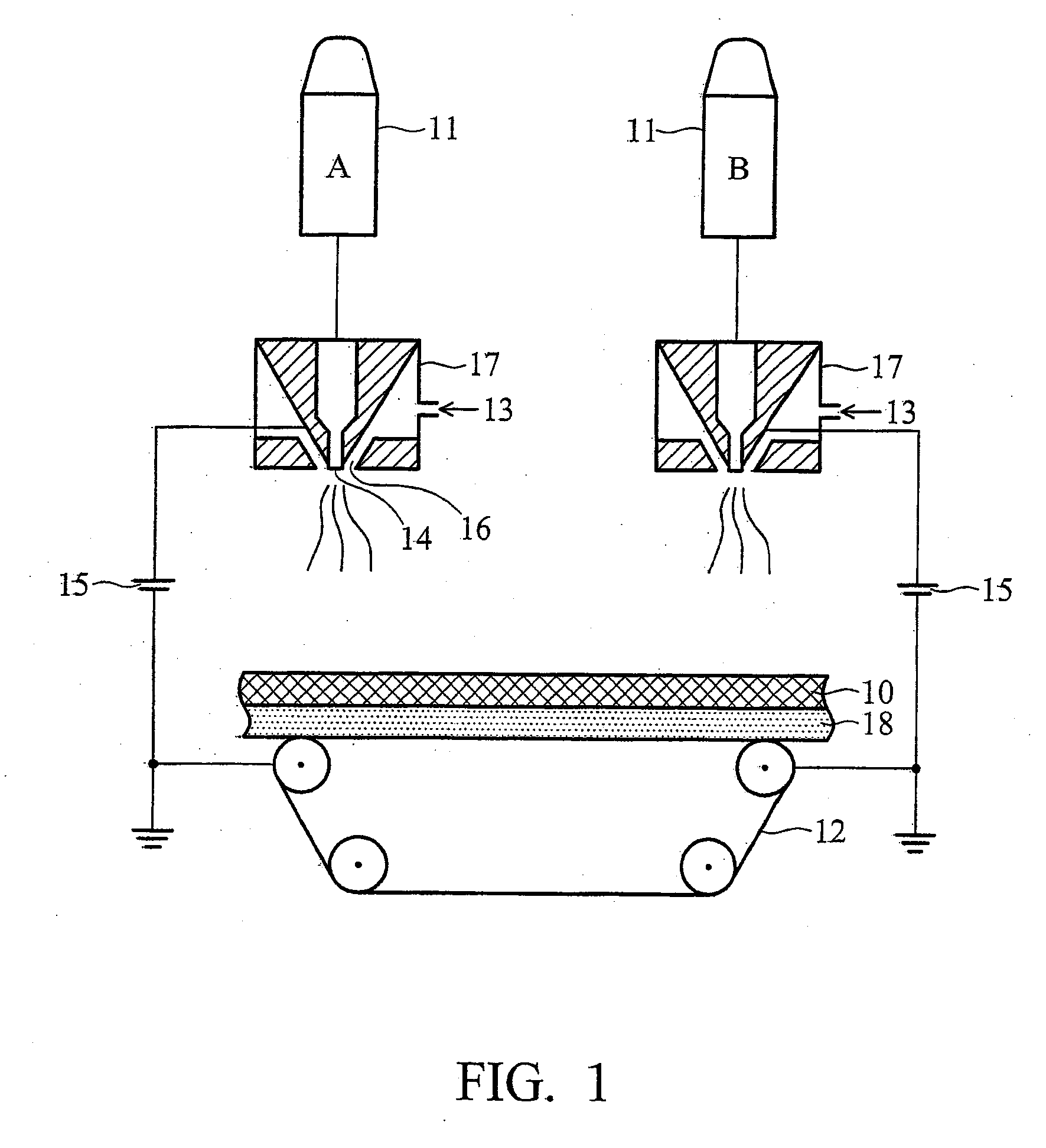

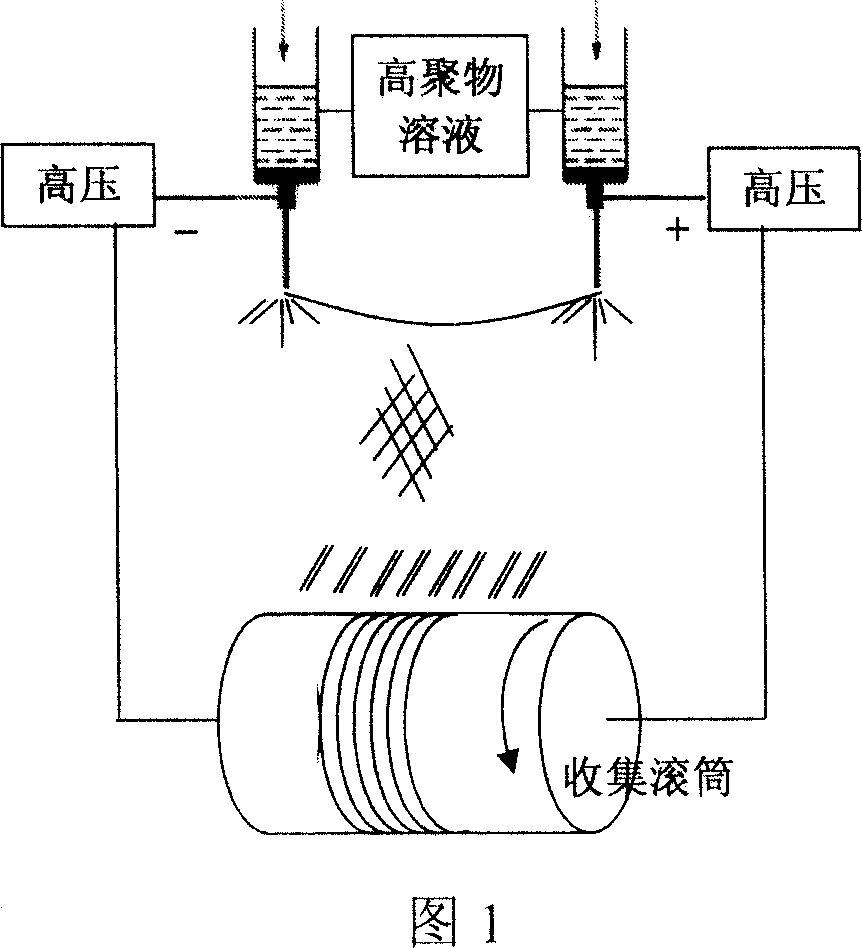

Complex type electrostatic spinning method with positive and negative electrodes in same electric field, and application

InactiveCN101003917AIncrease spinning speedOvercome the defects of single productsFilament/thread formingArtificial filaments from cellulose derivativesComplex typeElectrospinning

Owner:CIVIL AVIATION UNIV OF CHINA

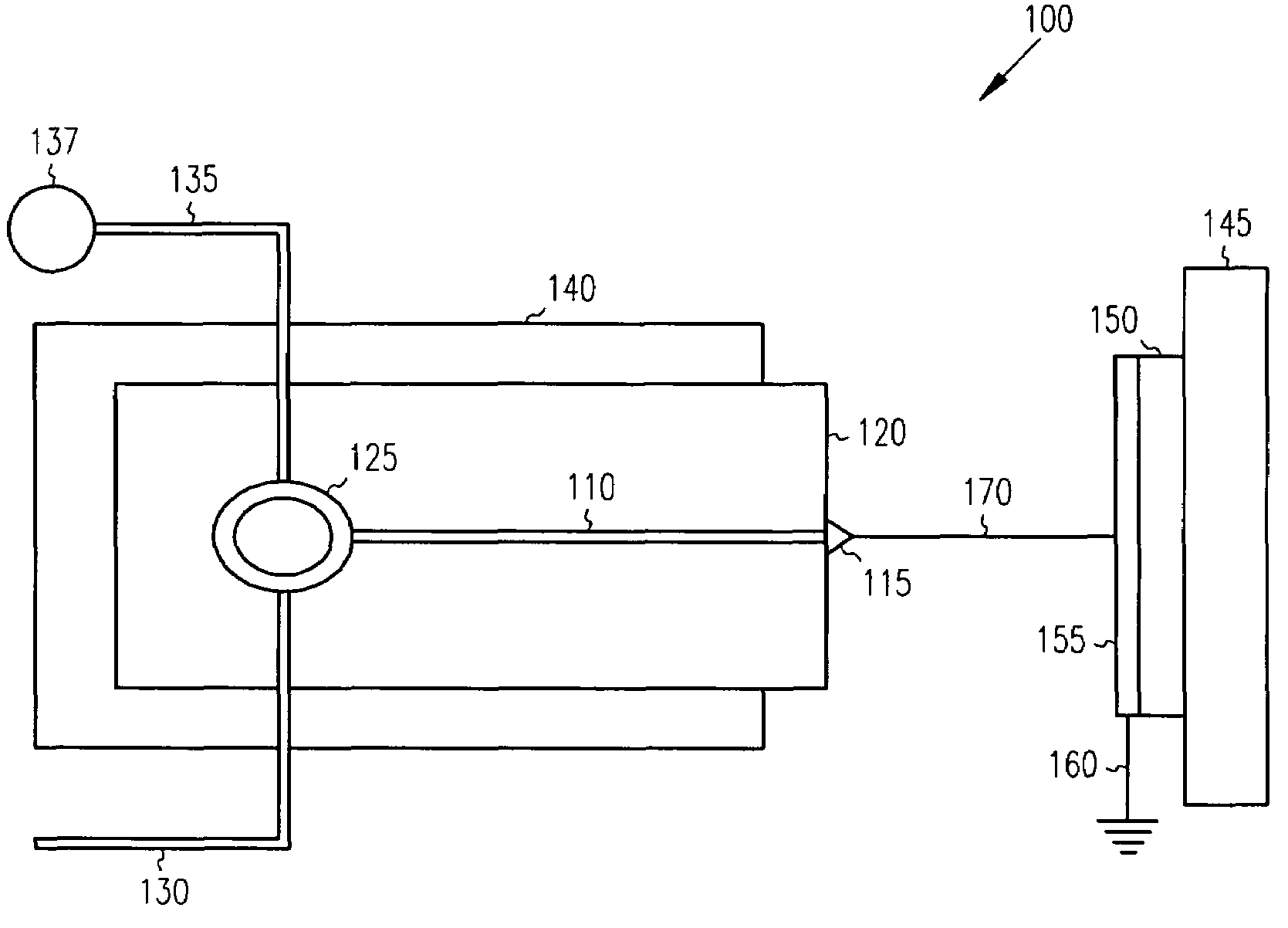

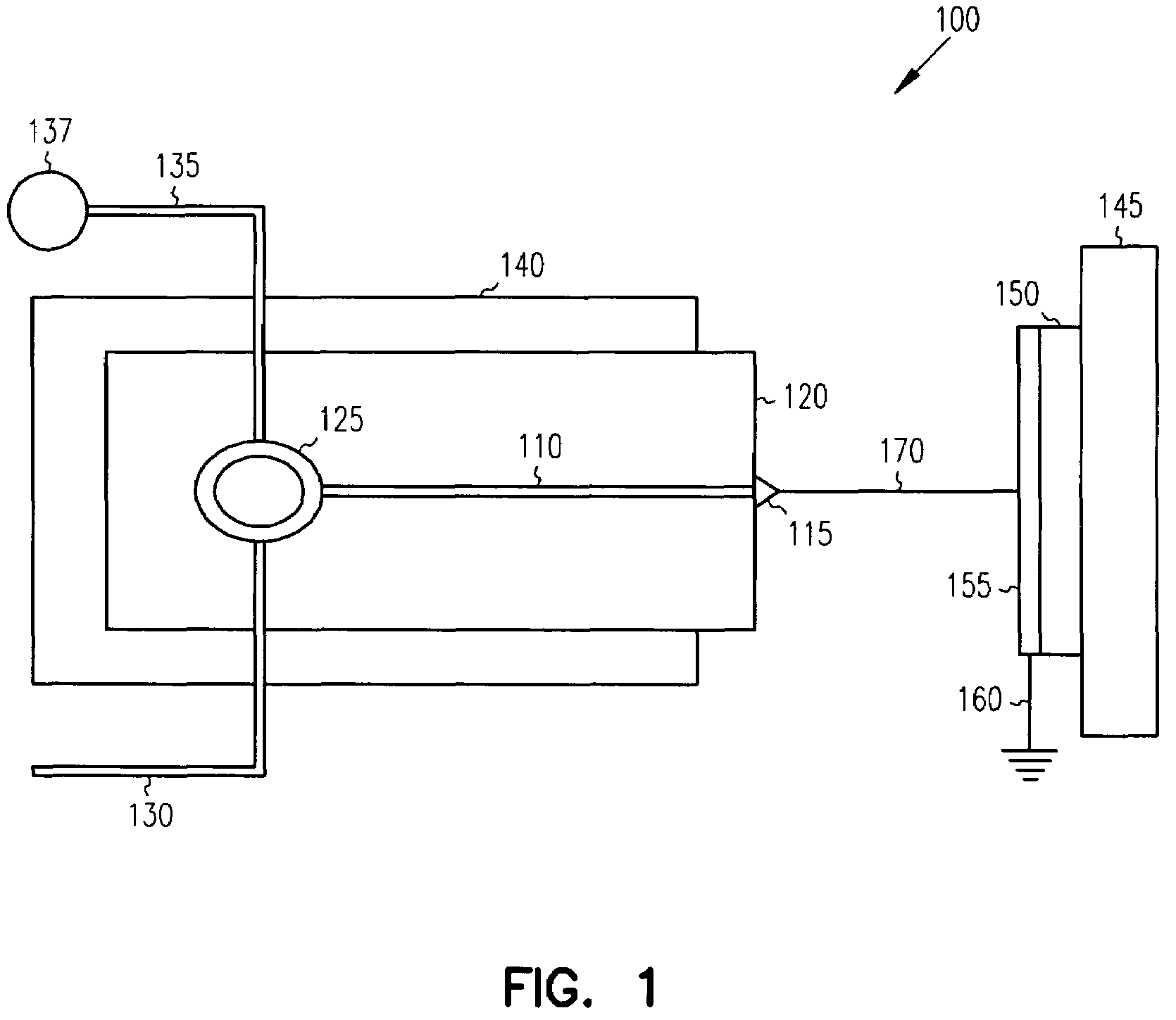

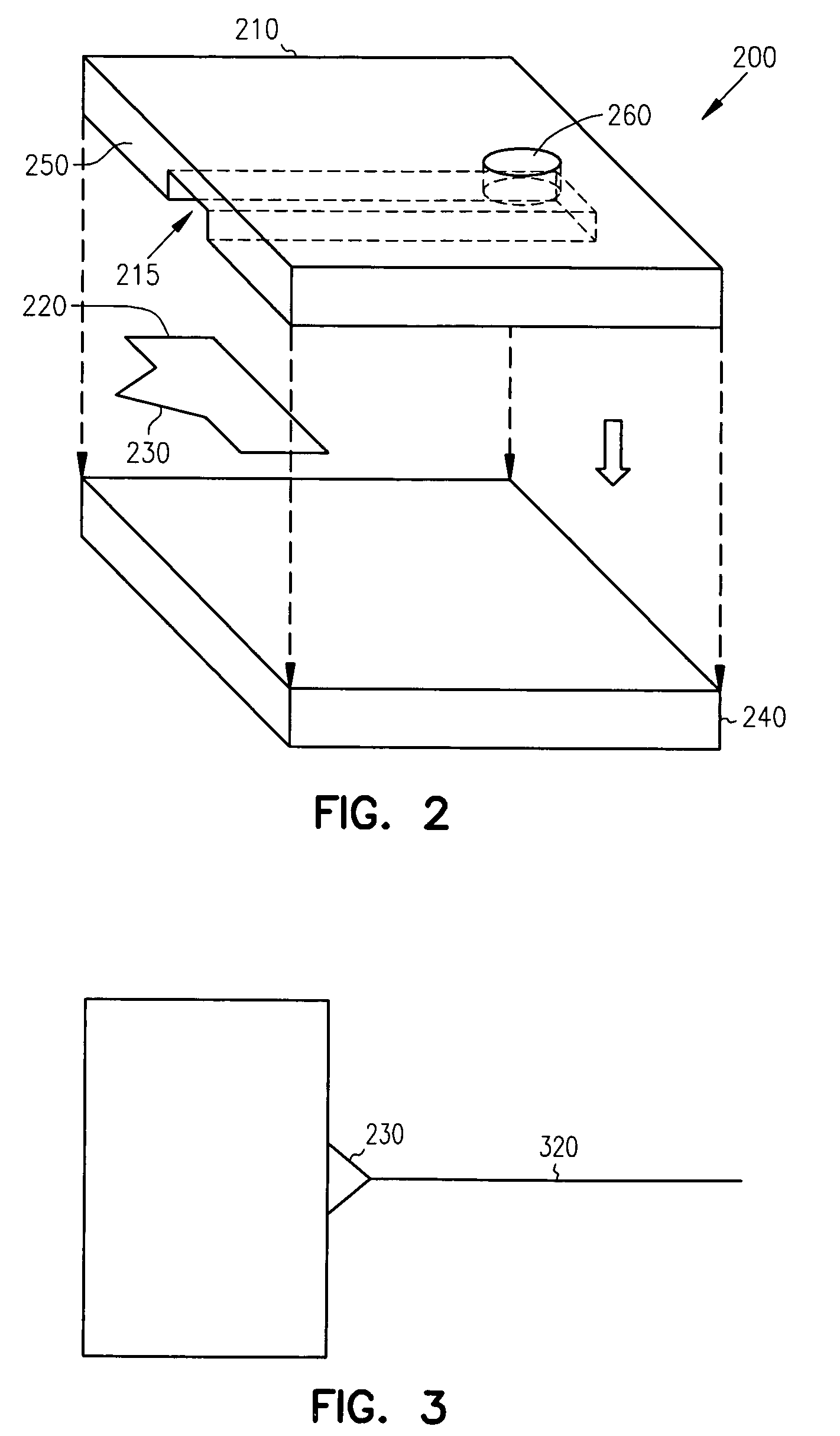

Scanned source oriented nanofiber formation

Nanofibers are formed using electrospray deposition from microfluidic source. The source is brought close to a surface, and scanned in one embodiment to form oriented or patterned fibers. In one embodiment, the surface has features, such as trenches on a silicon wafer. In further embodiments, the surface is rotated to form patterned nanofibers, such as polymer nanofibers. The nanofibers may be used as a mask to create features, and as a sacrificial layer to create nanochannels.

Owner:CORNELL RES FOUNDATION INC

Carbon nanotube coated with aromatic condensation polymer

InactiveCN1738872APigment treatment with macromolecular organic compoundsMonocomponent polyesters artificial filamentPolyesterCarbon nanotube

The present invention relates to carbon nanotubes obtained by coating 100 parts by weight of carbon nanotubes with 0.01 to 100 parts by weight of at least one aromatic condensation polymer selected from the group consisting of a wholly aromatic polyamide, wholly aromatic polyester, aromatic polyester carbonate, aromatic polycarbonate, semiaromatic polyester, and wholly aromatic azole; a process for producing the carbon nanotubes; an aromatic condensation polymer composition which comprises 0.01 to 100 parts by weight of the coated carbon nanotubes and 100 parts by weight of an aromatic condensation polymer; and a molded object formed from the composition.

Owner:TEIJIN LTD

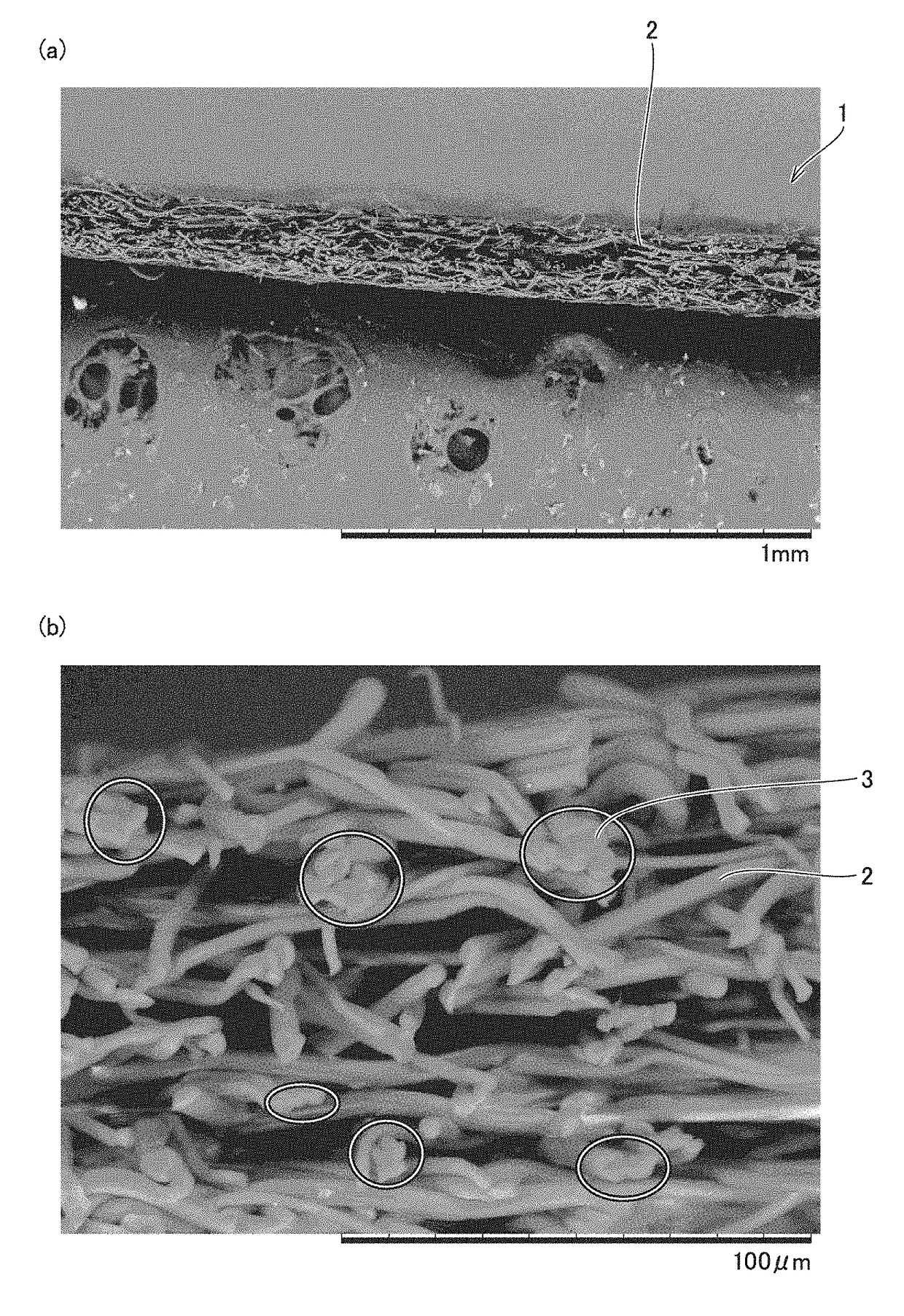

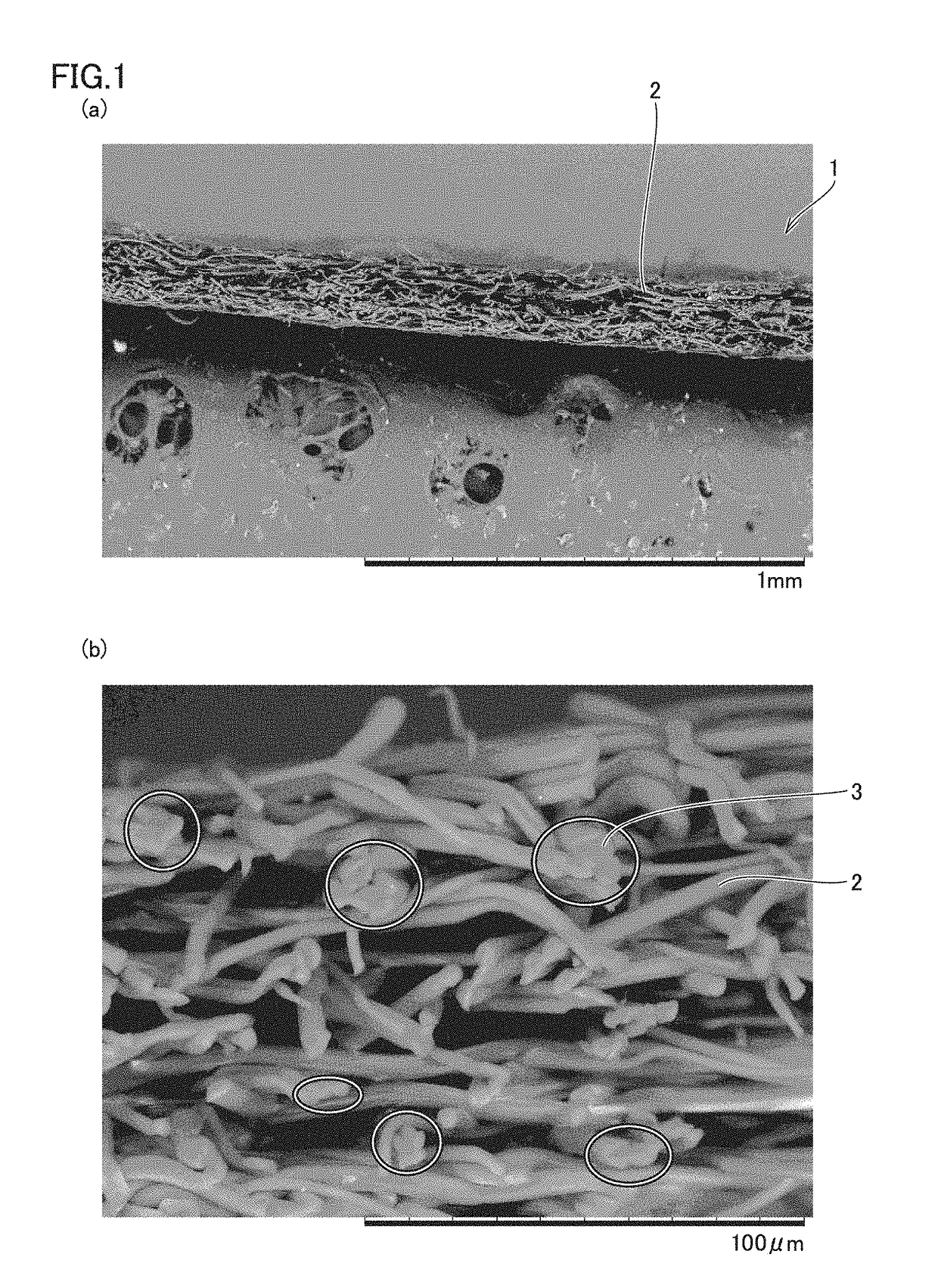

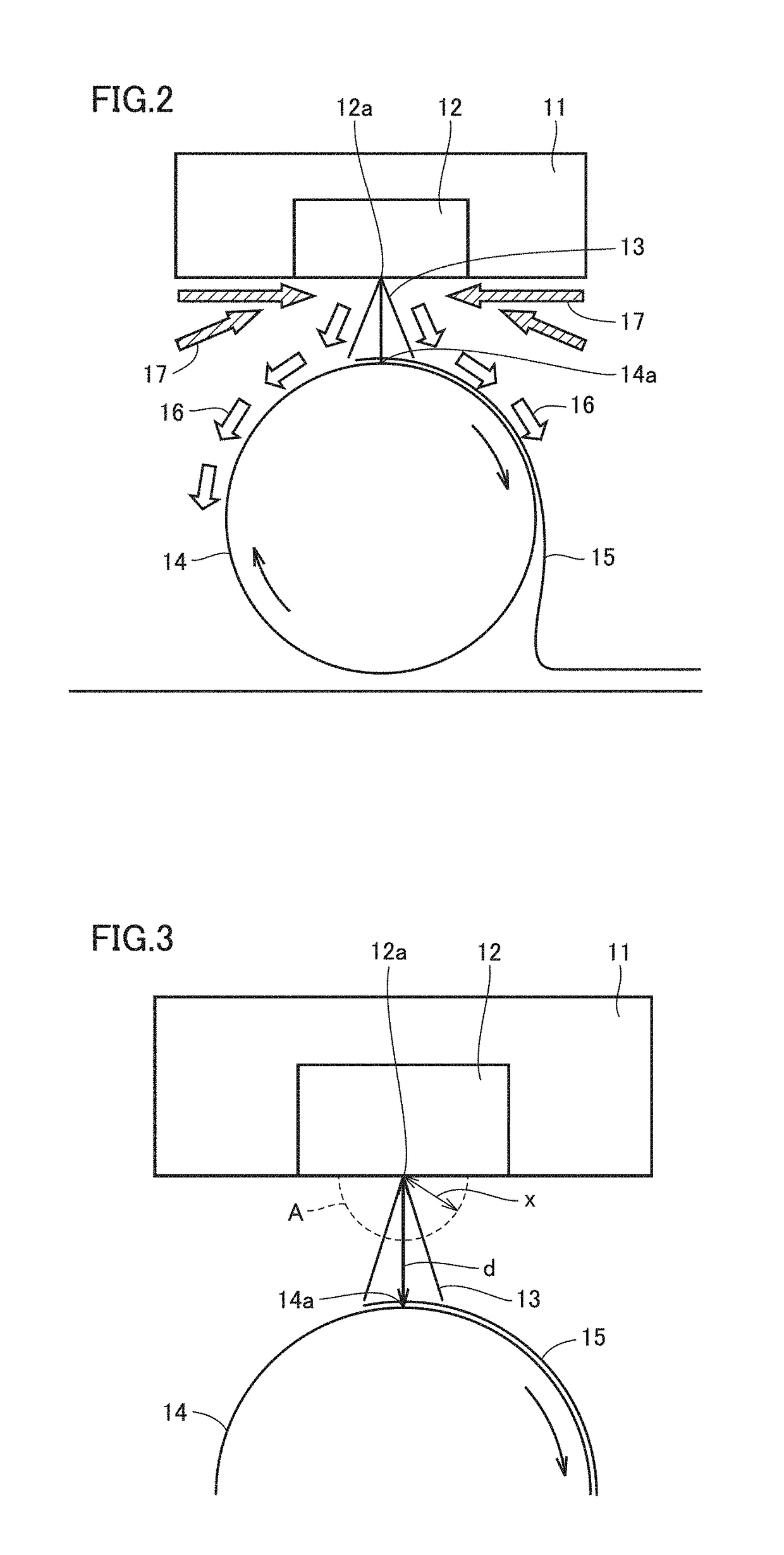

Reduced density article

InactiveUS20160298268A1Low densityAdditive manufacturing apparatusIncreasing energy efficiencyMicro structurePolymer science

A reduced density article of manufacture, and process for making same, made from a thermoplastic polycarbonate composition. The reduced density article of manufacture has (1) a certain density and (2) a certain micro structure containing from 1% to 20% by volume of voids wherein at least 80% of the voids are high aspect voids and less than 20% of the voids are spherical voids with a diameter of 10 to 100 microns. The polycarbonate thermoplastic composition comprises at least 50 mole % of a certain bisphenol A. The reduced density article of manufacture is made by a monofilament additive manufacturing technique.

Owner:SHPP GLOBAL TECH BV

Waterproof noise-reduction multifunctional woven fabric and production method thereof

InactiveCN104652016AImprove spinnabilityImprove spinning qualityWoven fabricsMonocomponent polyesters artificial filamentFiberBenzoyl peroxide

The invention discloses a waterproof noise-reduction multifunctional woven fabric which is formed by weaving warp yarns and weft yarns by an air-jet loom, wherein the warp yarns and the weft yarns are prepared from the following raw materials in parts by weight: 30 to 36 parts of isotatic polypropylene, 10 to 14 parts of polyvinyl chloride, 20 to 24 parts of cowhair, 17 to 19 parts of alpinia fiber, 22 to 26 parts of kenaf fiber, 18 to 23 parts of cotton pulp, 7 to 9 parts of liquid paraffin, 8 to 10 parts of ethyl carbamate, 7 to 11 parts of polytetramethylene glycol, 1.1 to 2.5 parts of benzoyl peroxide, 2.1 to 3.2 parts of chitosan, 0.3 to 0.5 part of magnesium acetate, 2 to 4 parts of shell powder, 1 to 3 parts of rhizoma, 2 to 5 parts of mangnolia officinalis, 85 to 95 parts of 1-butyl-3-methyl imidazole acetate, 95 to 105 parts of 1-allyl-3-methyl imidazole chloride salt, a proper amount of water and 4 to 7 parts of assistant. The woven fabric has the advantages of warmth keeping, ventilation, wear resistance, antibacterial performance and the like.

Owner:章云

Force spun sub-micron fiber and applications

InactiveUS20150024185A1Improved performance benefitReasonable throughputSynthetic resin layered productsCeramic shaping apparatusFiberEngineering

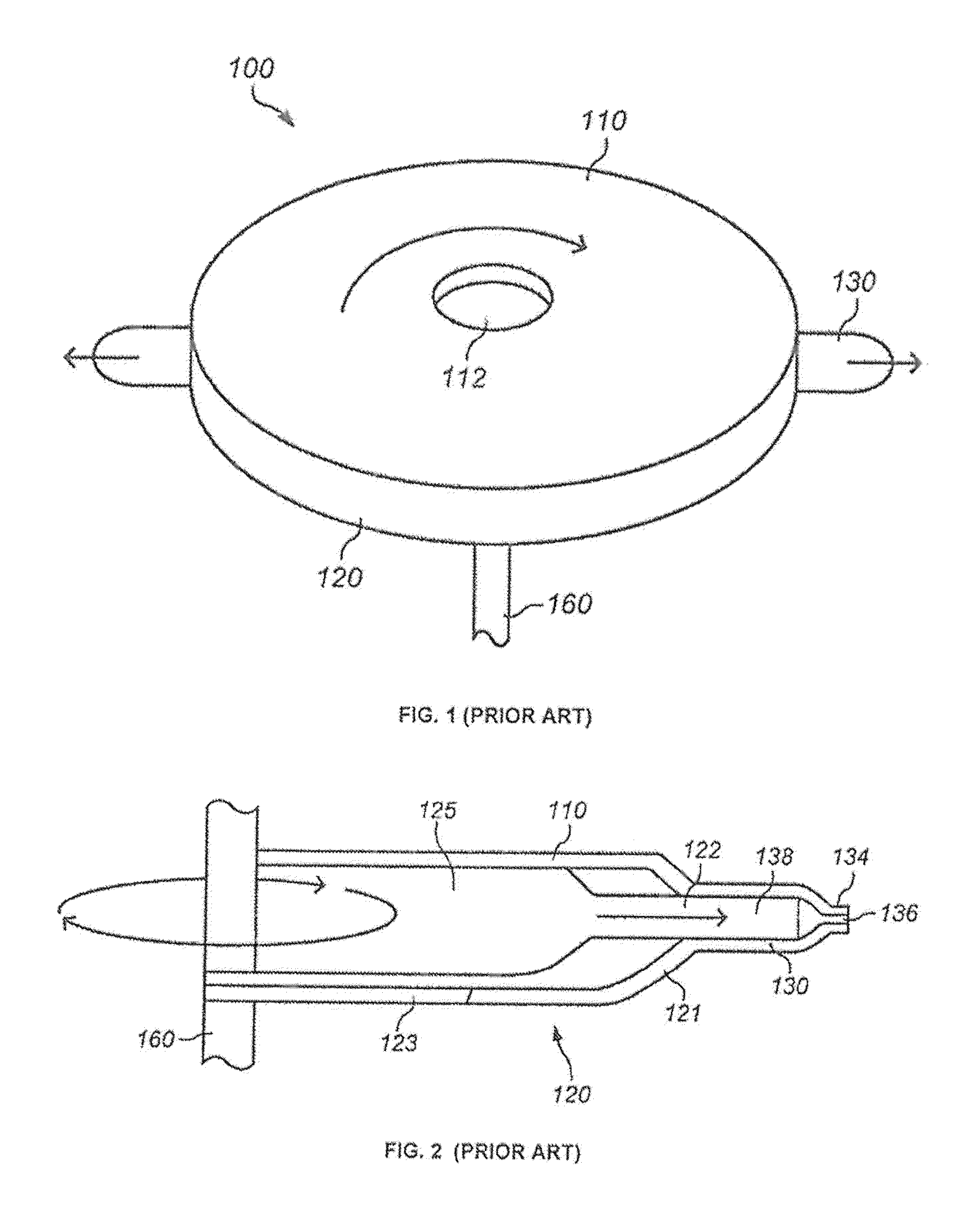

A process of forming a non-woven web including spinning a plurality of continuous polymeric filaments including a polycarbonate homopolymer component, a polycarbonate copolymer component, and combinations thereof at a rate of at least 300 grams / hour / spinneret.

Owner:SABIC GLOBAL TECH BV

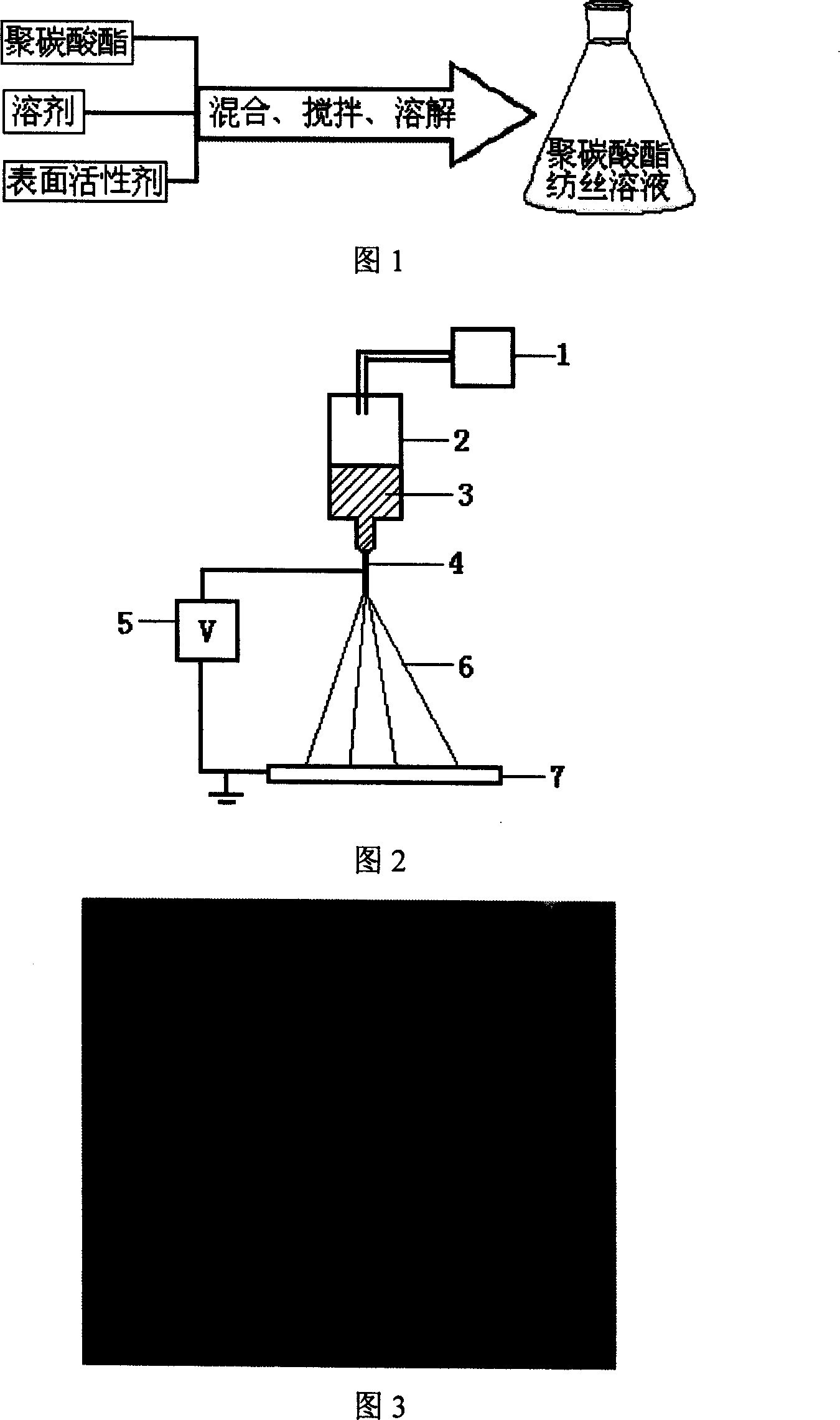

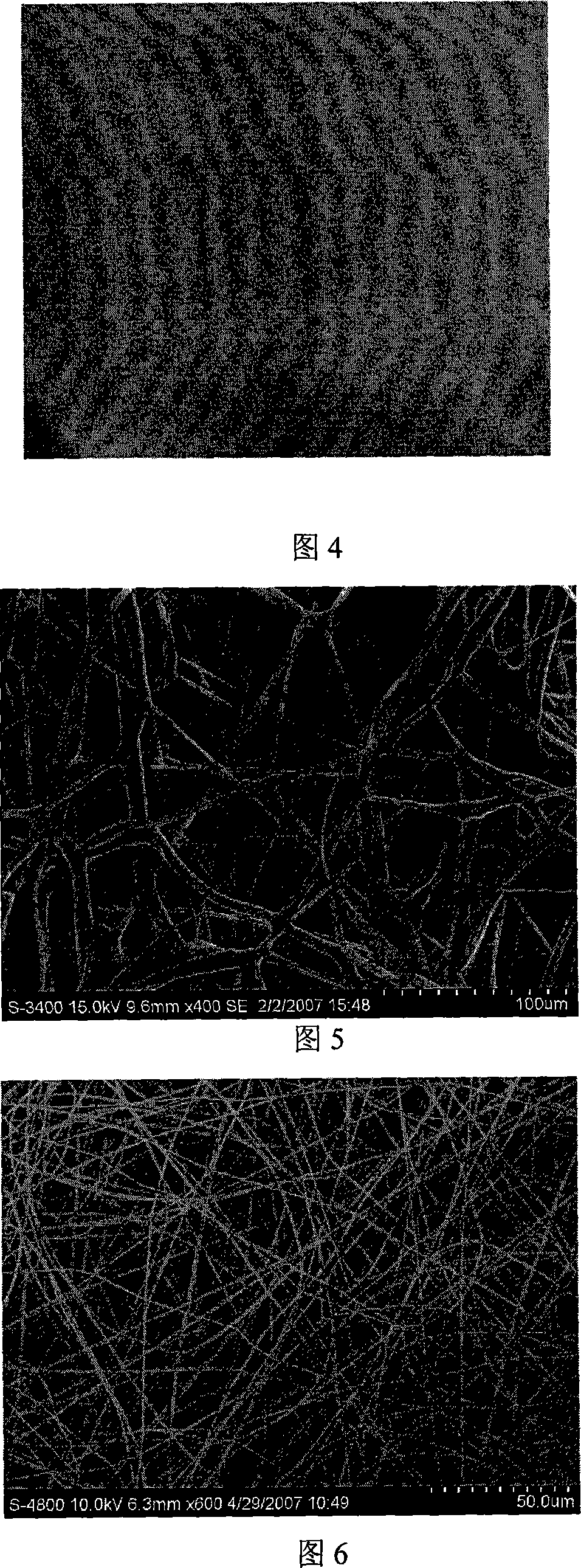

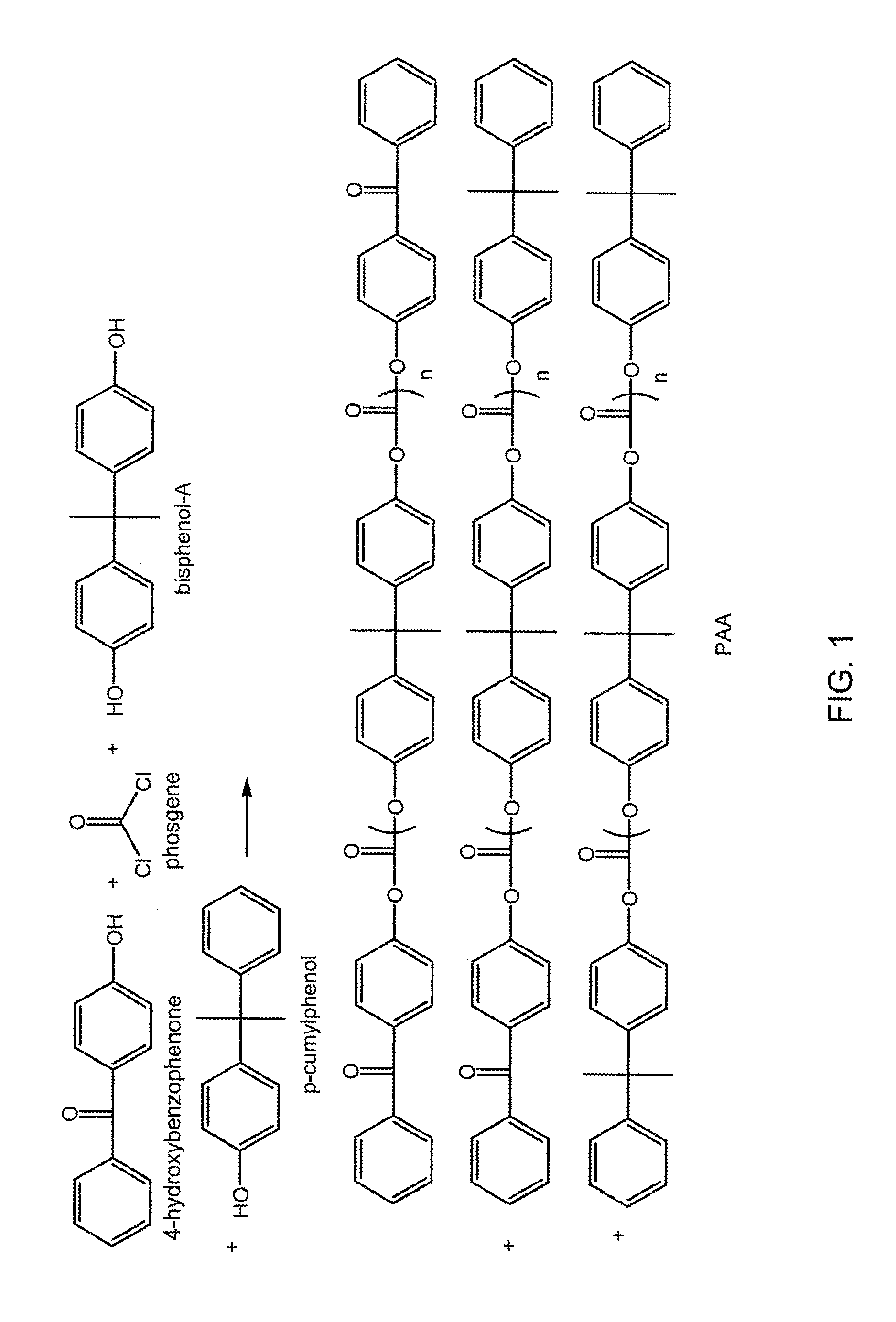

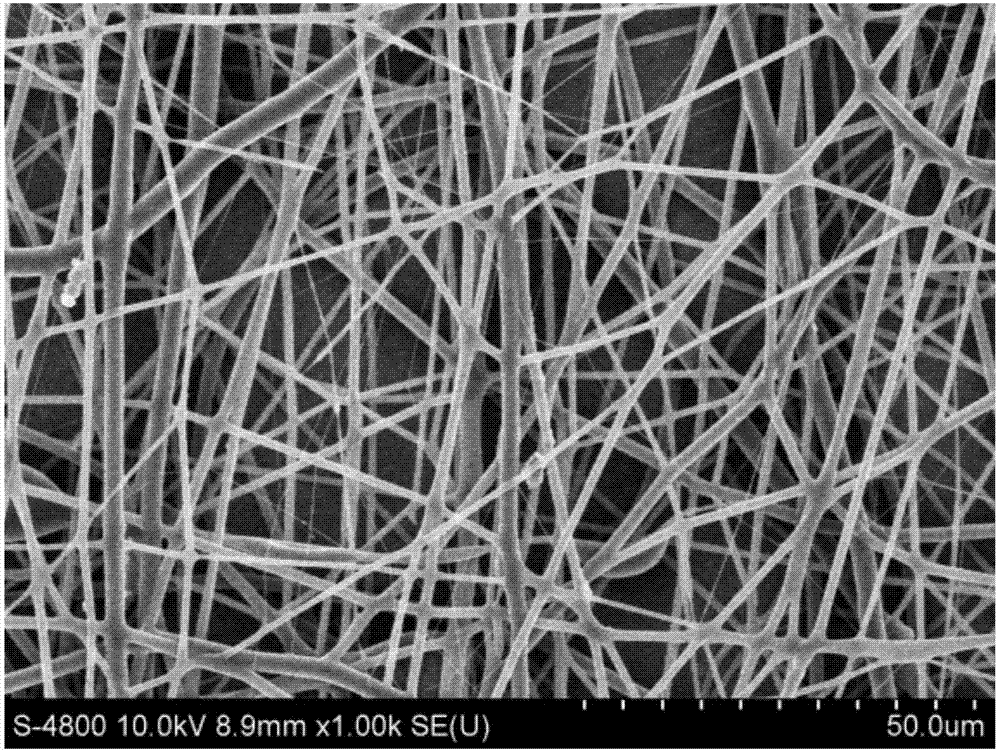

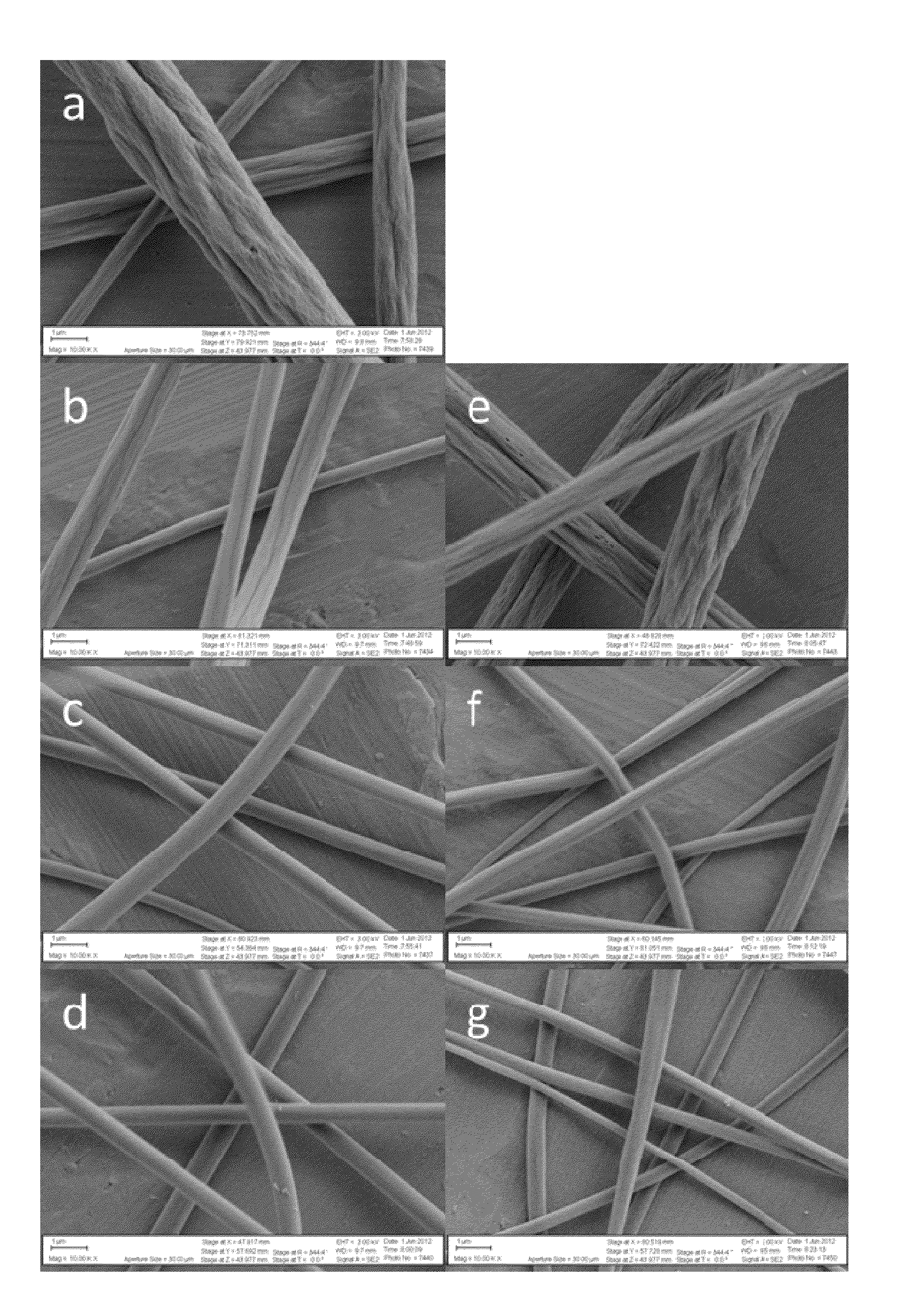

Polycarbonate nonwoven film and preparation method therefor

InactiveCN101117755AUniform shapeImprove performanceFilament/thread formingNon-woven fabricsPorosityElectrospinning

The present invention relates to a polycarbonate non-woven cloth film and the preparing method thereof. The film is a membranous substance composed by staggered overlapping of polycarbonate electrostatic spinning 50nm-10micrometer in diameter; the thickness thereof is determined by the electric spinning time. The method comprises dissolving polycarbonate in a corresponding solvent and adding special surfactants to prepare a polycarbonate spinning solution; adjusting the concentration of the polycarbonate solution and the addition of the surfactants for electrostatic spinning. In the process of electrostatic spinning, the polycarbonate solution is, under the induction of electric fields, tensioned to be micro-nanometer grade fiber, which, then, is assembled into a non-woven cloth film. The polycarbonate non-woven cloth film of the present invention has the advantages of uniform appearance, large specific surface and large porosity, and can be applied to fields of tissue engineering, biological detection, catalyst loading, filtering material, etc.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

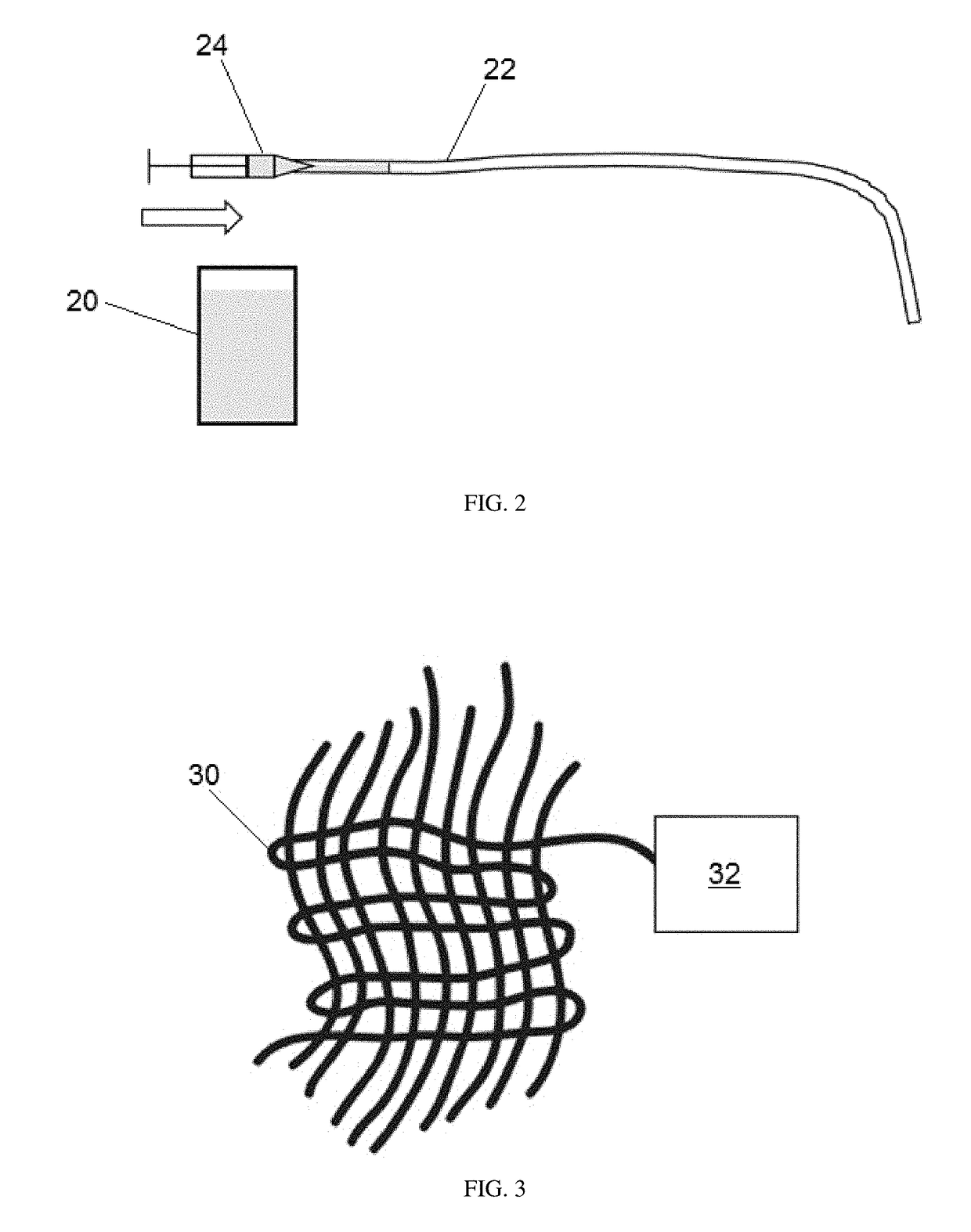

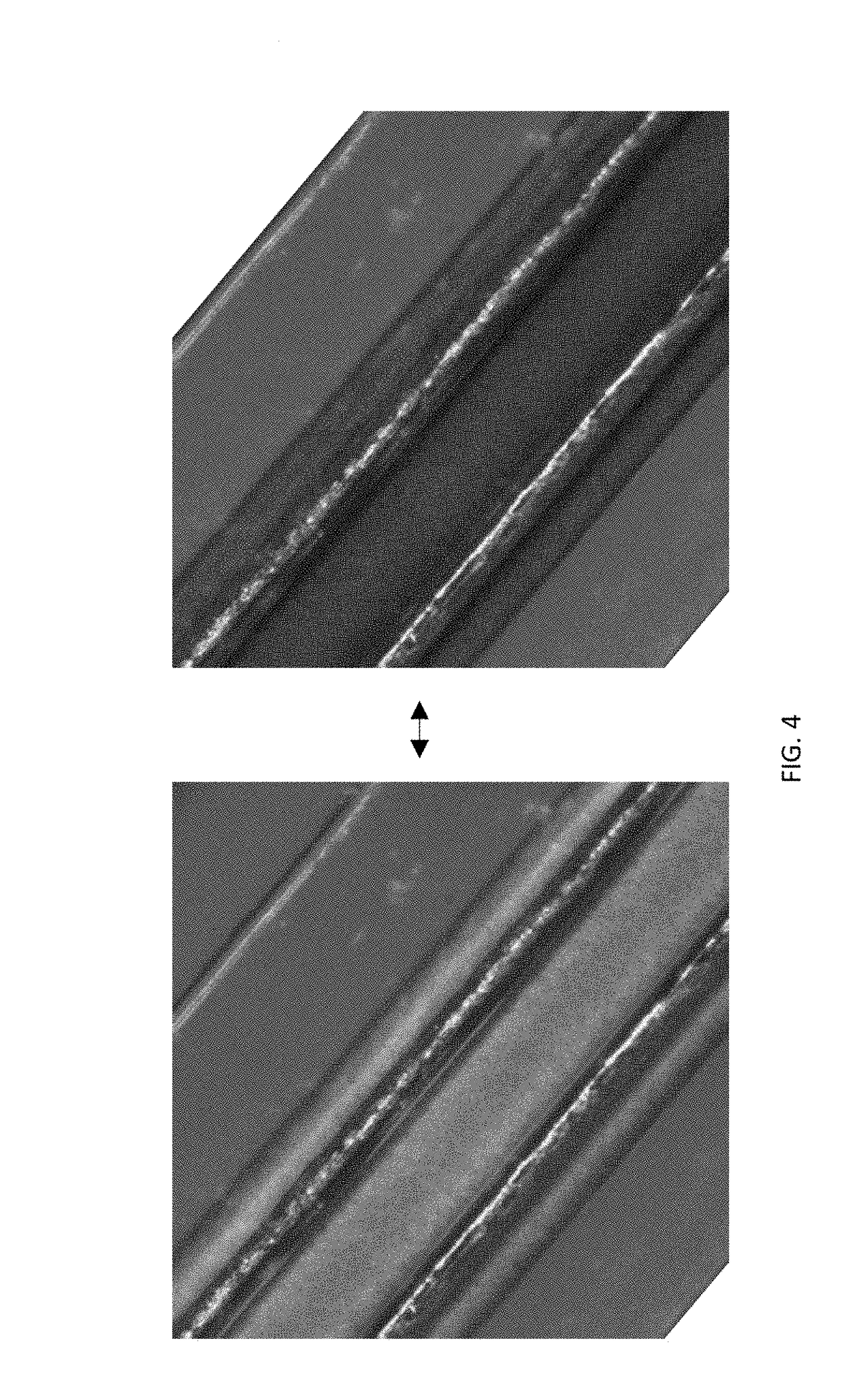

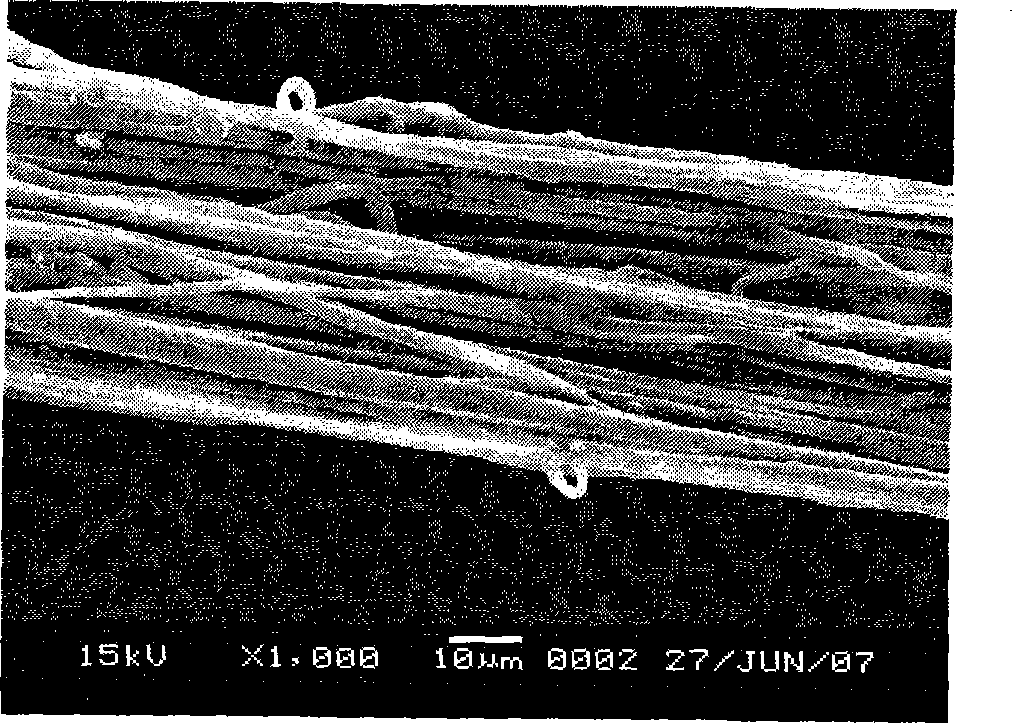

Inorganic-organic melt-extruded hybrid yarns and fibrous composite medical devices thereof

ActiveUS20080183208A1Suture equipmentsMonocomponent polyetheresters artificial filamentYarnThermoplastic

Composite fibrous constructs are made of combinations of inorganic-organic hybrid monofilament or multifilament yarns containing at least 6 weight percent of inorganic micro- / nanoparticles and organic monofilament or multifilament yarn with typical examples of the hybrid yarn matrix made of absorbable or non-absorbable thermoplastic polymers and final constructs being in the form of knitted or woven meshes and braided ligatures intended to perform under specific mechanically, biologically, and / or radiologically related functions.

Owner:POLY MED

Inorganic-organic melt-extruded hybrid yarns and fibrous composite medical devices thereof

ActiveUS7632765B2Suture equipmentsMonocomponent polyetheresters artificial filamentYarnThermoplastic

Composite fibrous constructs are made of combinations of inorganic-organic hybrid monofilament or multifilament yarns containing at least 6 weight percent of inorganic micro- / nanoparticles and organic monofilament or multifilament yarn with typical examples of the hybrid yarn matrix made of absorbable or non-absorbable thermoplastic polymers and final constructs being in the form of knitted or woven meshes and braided ligatures intended to perform under specific mechanically, biologically, and / or radiologically related functions.

Owner:POLY MED

Switching fibers for textiles

ActiveUS20180364518A1Improve breathabilityAchieve strengthElectroconductive/antistatic filament manufactureHollow filament manufactureFiberColor changes

A color-changing fiber that can be incorporated into fabrics and other woven materials. The color changing fibers are hollow and include at least two wire electrodes that provide an electrical potential across an electro-optic medium including a non-polar solvent and at least one set of charged particles.

Owner:E INK CORPORATION +1

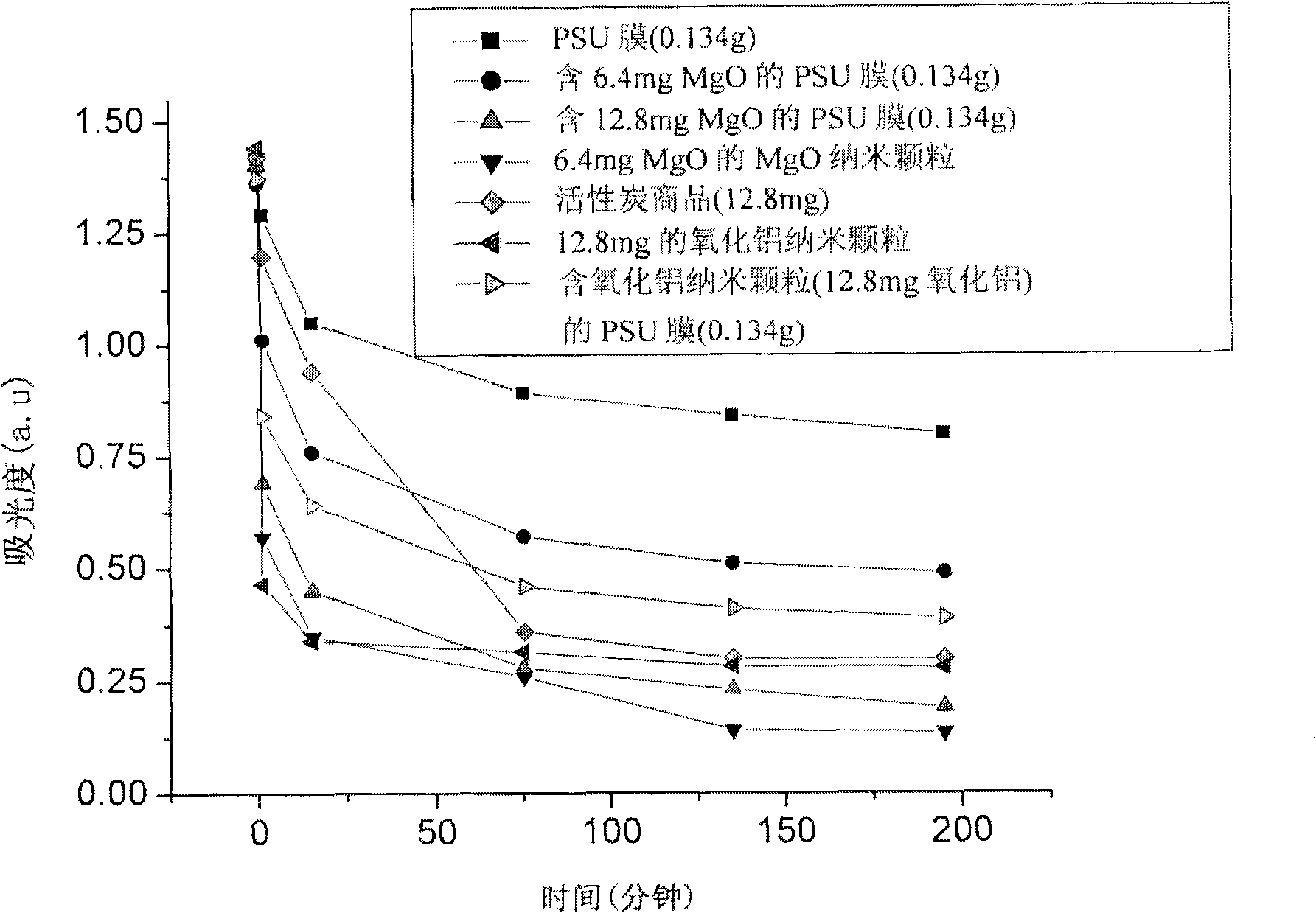

Fibers for decontamination of chemical and biological agents

InactiveCN101680120APrevent disseminationMonocomponent polyurethanes artificial filamentFilament/thread formingFiberNanometre

The invention relates to a nano-sized or micro-sized fiber comprising particles capable of at least partially detoxifying a toxic agent.

Owner:NAT UNIV OF SINGAPORE

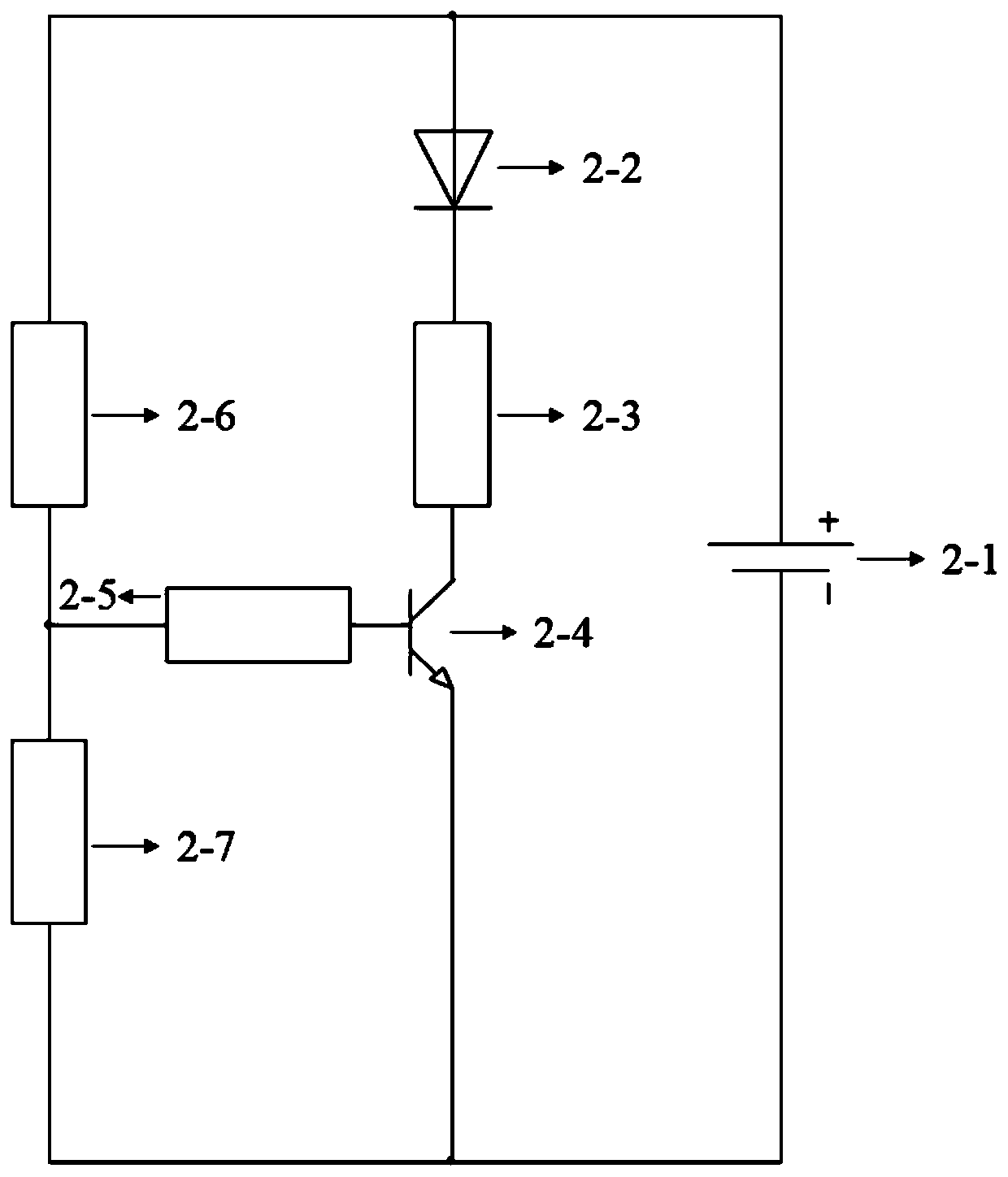

Luminous color-changing monofilament and preparation method thereof

ActiveCN110257932AWith brightnessAchieve glossHollow filament manufactureElectric lightingFiberPolymer science

The invention belongs to the field of functional fiber materials and discloses a luminous color-changing monofilament and a preparation method thereof. The preparation method includes: melting a polymer matrix raw material, and adding an additive identical with the polymer matrix raw material in refraction coefficient; melting, blending and extruding in a melt extruder, performing cooling, stretching, thermosetting and winding to obtain a color-changing fiber monofilament, and thermally fitting one end of the color-changing fiber monofilament onto an LED lamp strip to obtain the luminous color-changing monofilament. With the help of the additive identical with the polymer matrix raw material in refraction coefficient, the monofilament has good light transmission performance; by changing a fiber end light source and color thereof, monofilaments different in color and having brightness are obtained. The monofilament can be used for doll hair, human hairpieces, woven luminous color-developing fabric, warning boards and photoconduction induction control sensing units.

Owner:SOUTH CHINA UNIV OF TECH +1

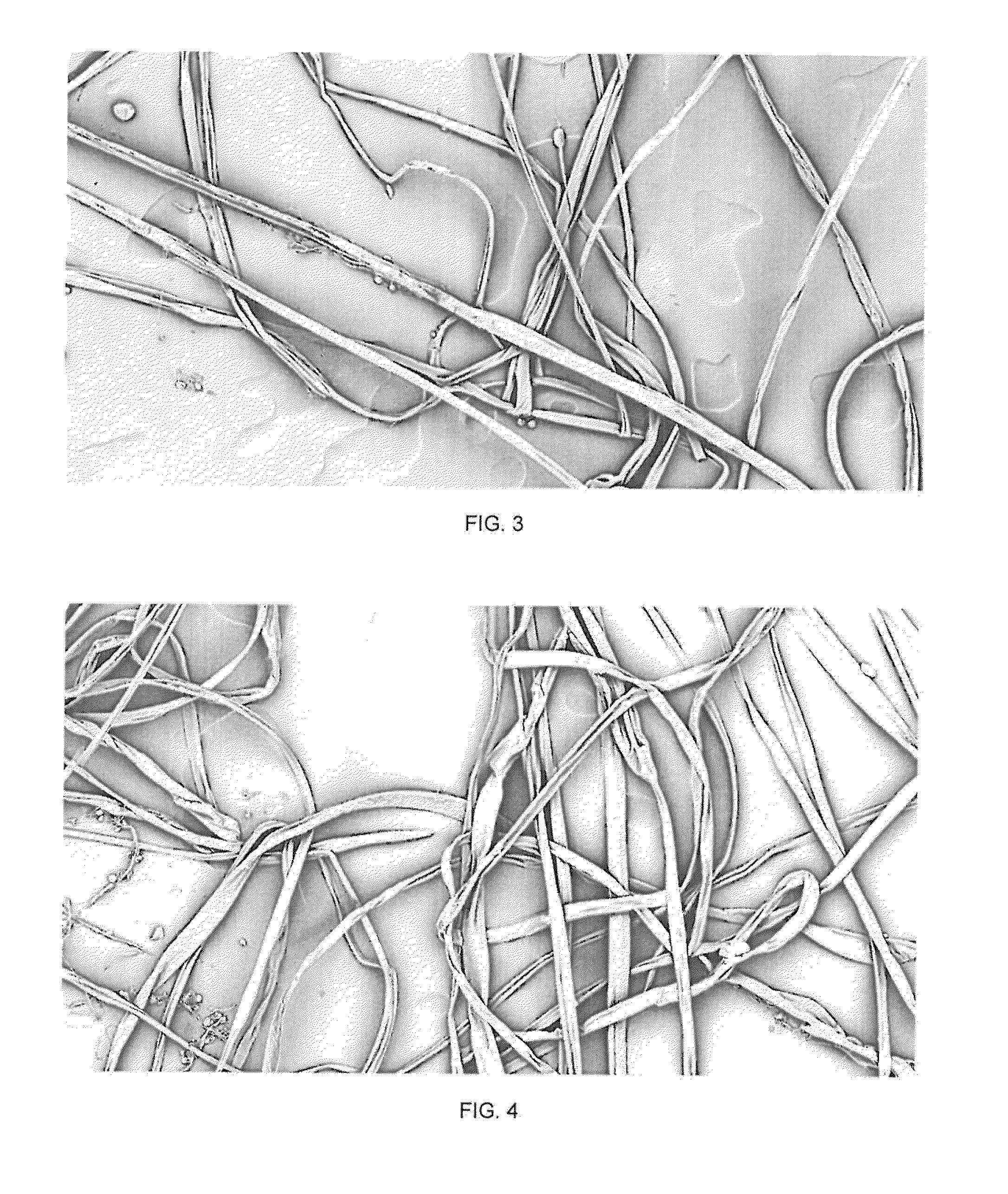

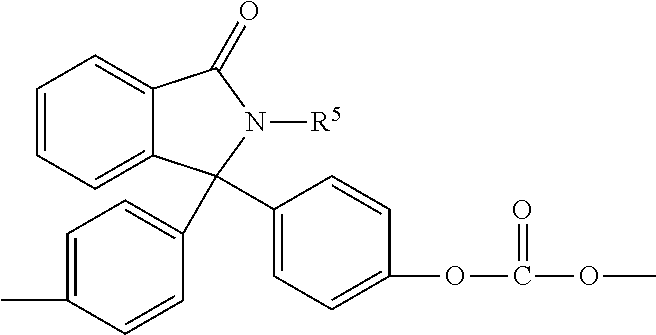

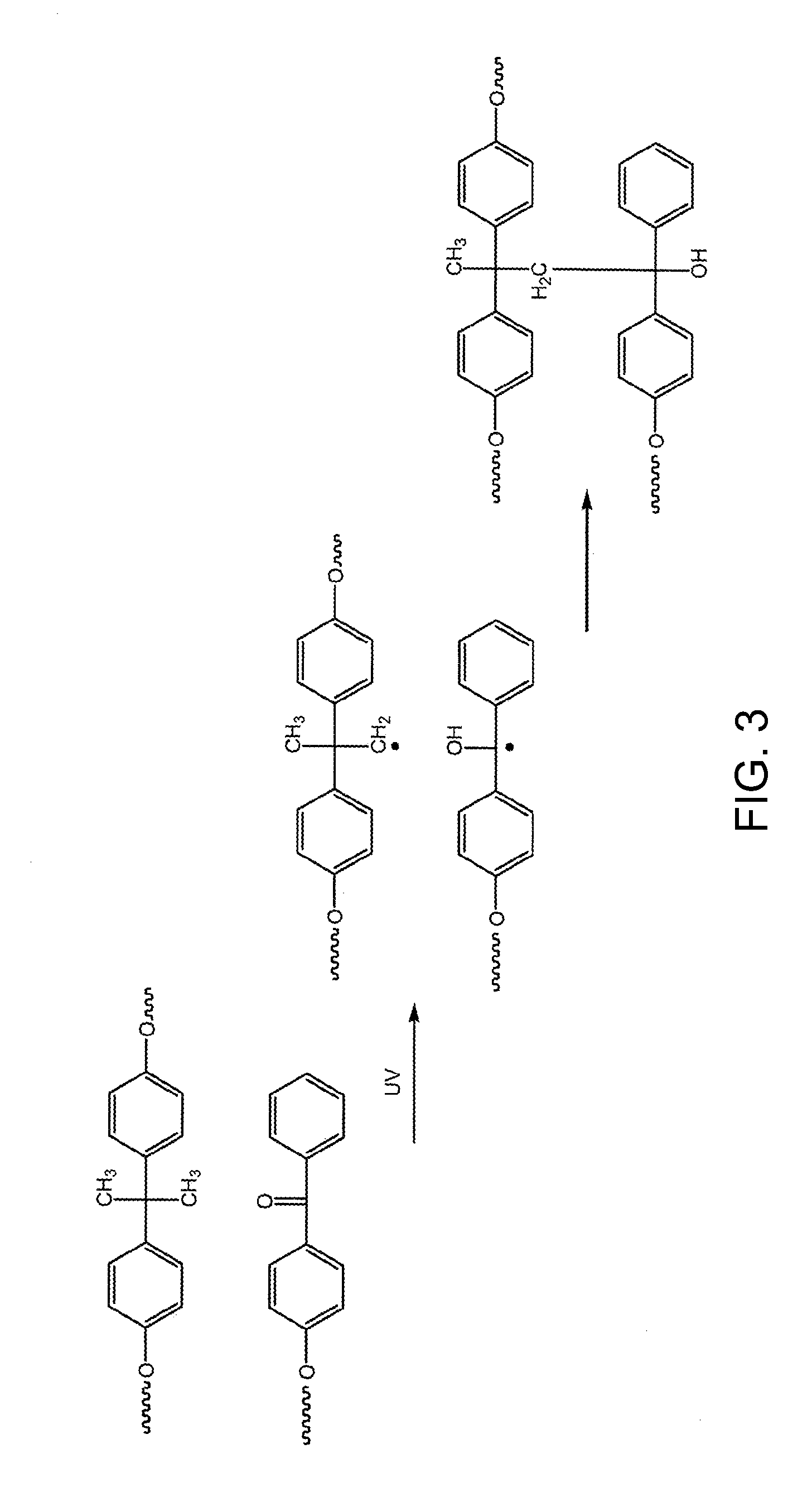

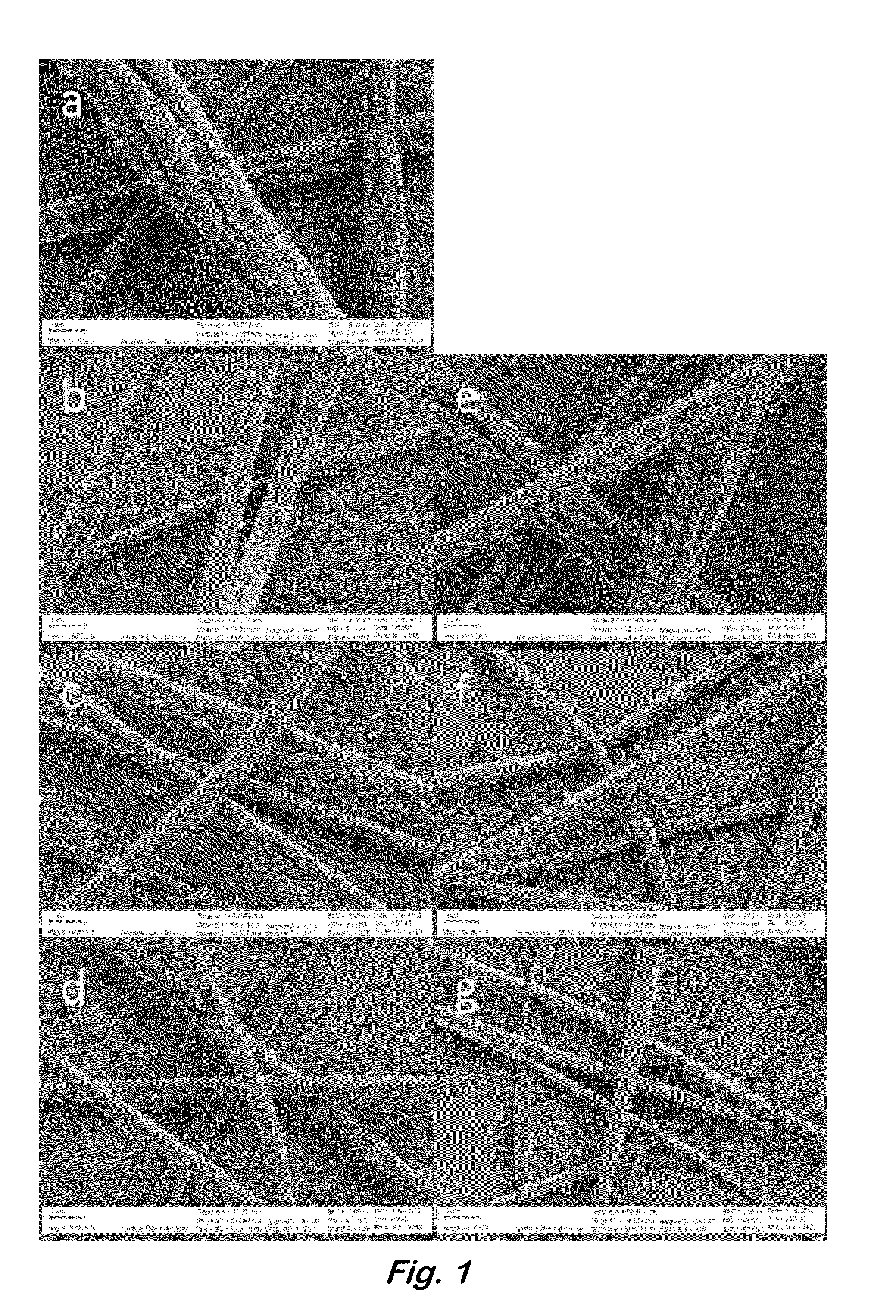

Polycarbonate fibers and substrates comprising same

ActiveUS20170015783A1Artificial filament physical treatmentSynthetic cellulose/non-cellulose material pulp/paperFiberEnd-group

Disclosed herein are polycarbonate fibers and fibrous substrates, such as papers, containing such fibers. The polycarbonate fibers are produced from a polymeric composition comprising a cross-linkable polycarbonate containing endgroups derived from a monofunctional benzophenone or containing repeating units derived from a difunctional benzophenone. The polycarbonate fibers can be combined with other fibers to form the fibrous substrate. Upon exposure to ultraviolet light, crosslinking of the polycarbonate fibers will occur, improving various properties of the fibrous substrate.

Owner:SABIC GLOBAL TECH BV

Preparation method of propylene carbonate/polylactic acid complex fiber film and prepared propylene carbonate/polylactic acid complex fiber film

InactiveCN107475895AUniform distribution of poresElectro-spinningNon-woven fabricsMass ratioElectrospinning

The invention relates to a preparation method of a propylene carbonate / polylactic acid complex fiber film. The method is a conjugate electrostatic spinning method and comprises the following sequential steps that 1, propylene carbonate solutions and polylactic acid solutions of different concentrations are prepared separately; 2, the prepared propylene carbonate solutions and polylactic acid solutions are placed into an injector separately, and then the injector is placed on an electrostatic spinning integrated device; 3, specific parameters of the electrostatic spinning integrated device are set for fiber spinning; 4, drying is performed till the constant weight is reached. The defects that during existing propylene carbonate / polylactic acid complex fiber film preparation, the compatibility is poor, the cost is high, and spinning is not coherent due to solute deposition or excessively large concentration are overcome, and on the basis of the preferential propylene carbonate and polylactic acid mass ratio matched with preferential conjugate electrostatic spinning parameters, the propylene carbonate / polylactic acid complex fiber film with the relatively uniform fiber diameter and multiple evenly-distributed holes is prepared.

Owner:JIAXING UNIV

Nonwoven fabric and production method for same

ActiveCN107709646AStrong enoughMelt spinning methodsNon-woven fabricsNonwoven fabricGlass transition

Provided is a nonwoven fabric that includes fibers the principal component of which is a polymer with a glass transition temperature of 50DC or above, and that has a longitudinal strength of 1 N / 5 cmor greater per 1 g / m2, the nonwoven fabric satisfying both of the following conditions (1) and (2) and making it possible to provide a nonwoven fabric that has ample strength to be handled independently and that contains fibers having as the principal component a polymer with a Tg of 50 DC or above, without performing any post-processing step such as an embossing step, calendaring step and spun lace step. Also provided is a production method for such nonwoven fabric. Condition (1): the density is 0.01-0.4 g / cm3. Condition (2): the proportion of sections having density exceeding 0.4 g / cm3 in across section taken in the thickness direction is 3% or less.

Owner:KURARAY CO LTD

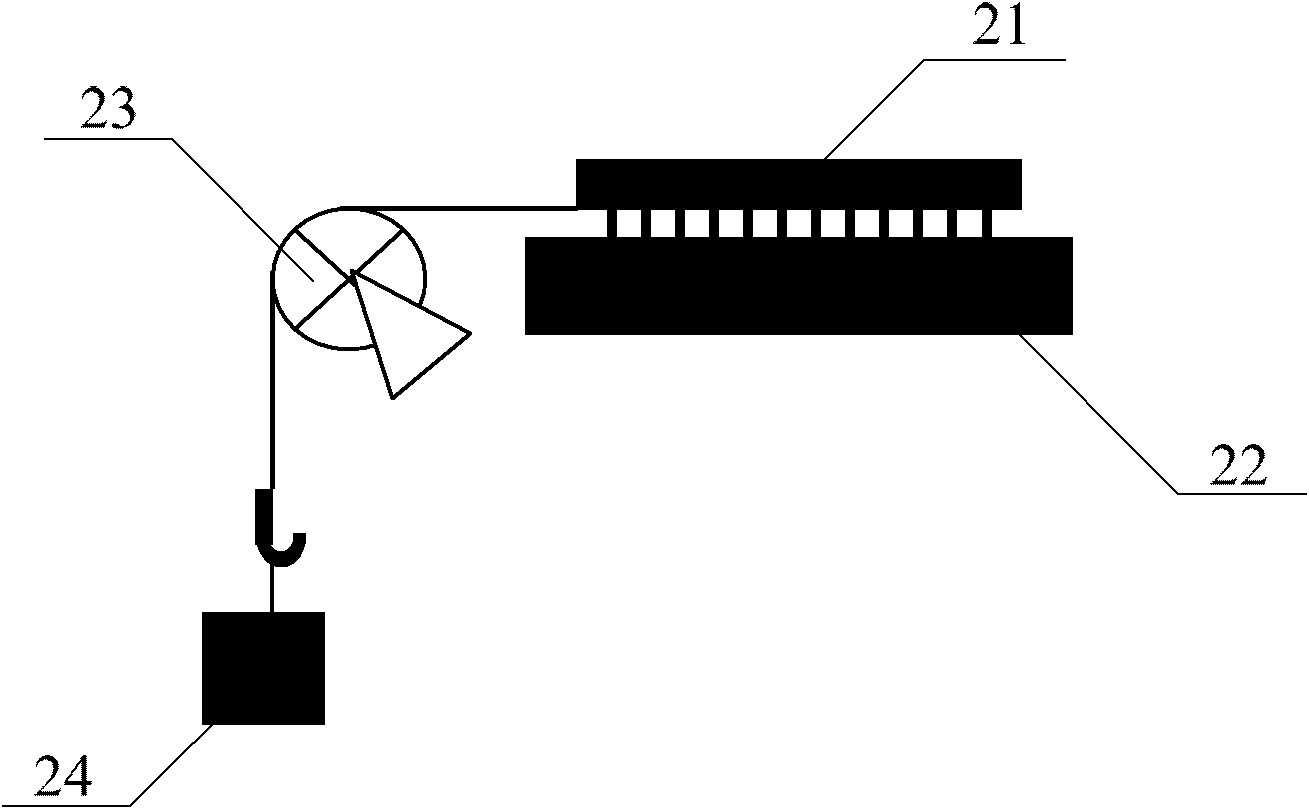

Preparation method of adhesive material

ActiveCN102080272AImprove adhesionSimple processMonocomponent polyurethanes artificial filamentFilament/thread formingPolymer scienceFiber bundle

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Nonwoven fabric and method for producing the same

InactiveUS20180187353A1High strengthMelt spinning methodsNon-woven fabricsPolymer scienceNonwoven fabric

A nonwoven fabric including fibers that contain a polymer having a glass transition temperature of greater than or equal to 50° C. as a main component, and having a vertical strength of greater than or equal to 1 N / 5 cm per 1 g / m2, and by satisfying both of the following conditions (1) and (2), a nonwoven fabric having sufficient strength to be handled alone and including fibers that contain a polymer having a Tg of greater than or equal to 50° C. as a main component without performing a post processing such as emboss processing, calender processing, or spunlace processing, and a method for producing the nonwoven fabric can be provided. (1) A density is 0.01 to 0.4 g / cm3. (2) A proportion of parts with a density exceeding 0.4 g / cm3 is less than or equal to 3% in a cross section in a thickness direction.

Owner:KURARAY CO LTD

Electrospun polymer nanofibers with surface active quaternary ammonium salt antimicrobials

A fiber having a polymeric matrix and a quarternary ammonium salt. The quarternary ammonium salt contains at least one aliphatic group and no aromatic groups, is not covalently incorporated into the polymeric matrix, and is present on both the surface and in the interior of the fiber. The fiber may be made by electrospinning a solution of the polymer and the quarternary ammonium salt.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Inorganic-organic melt-extruded hybrid yarns and fibrous composite medical devices thereof

ActiveUS20090287228A1Suture equipmentsMonocomponent polyetheresters artificial filamentThermoplasticYarn

Composite fibrous constructs are made of combinations of inorganic-organic hybrid monofilament or multifilament yarns containing at least 6 weight percent of inorganic micro- / nanoparticles and organic monofilament or multifilament yarn with typical examples of the hybrid yarn matrix made of absorbable or non-absorbable thermoplastic polymers and final constructs being in the form of knitted or woven meshes and braided ligatures intended to perform under specific mechanically, biologically, and / or radiologically related functions.

Owner:POLY MED

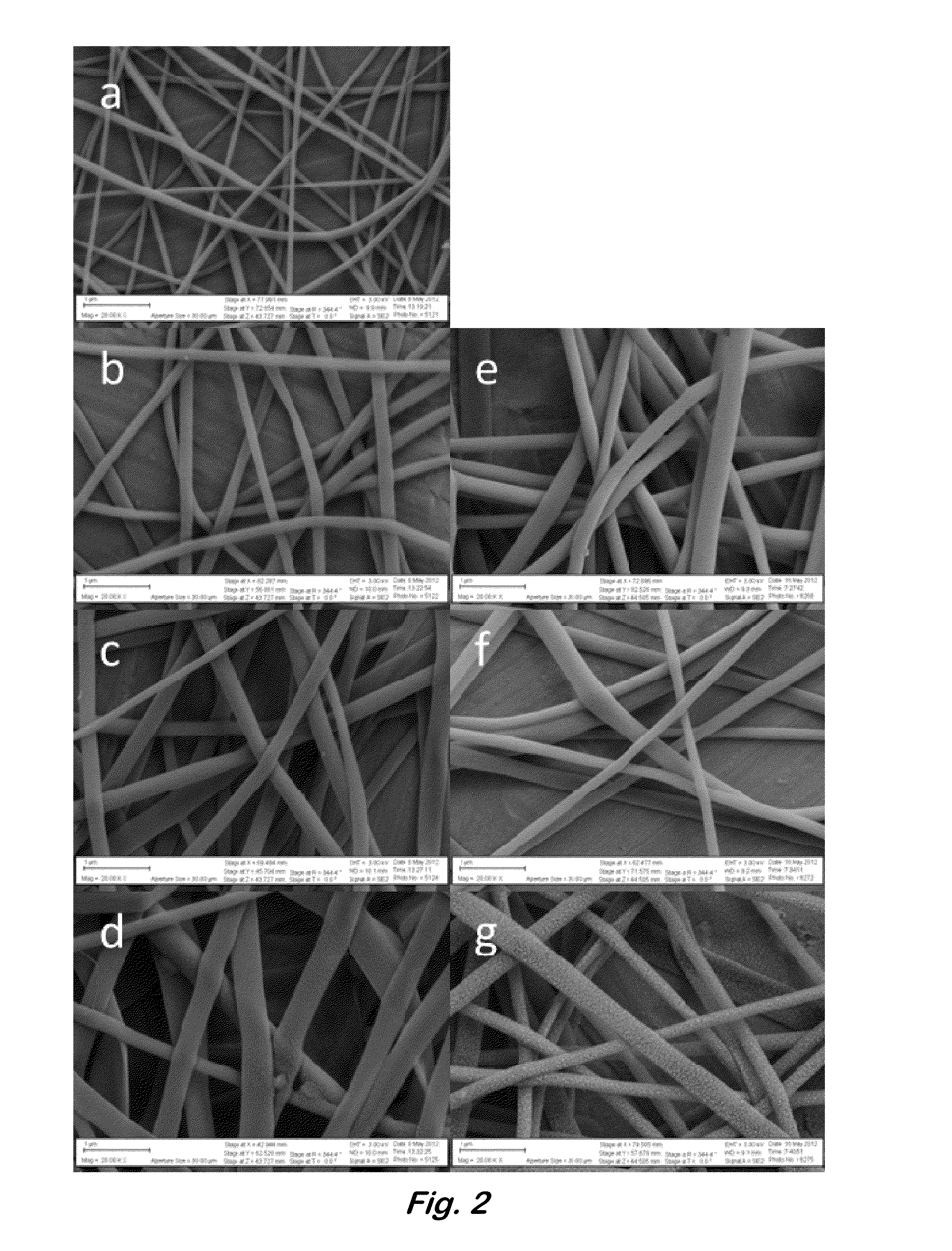

Directional magnetic electrical spinning Nano fibers, preparation method and equipment needed

InactiveCN100432307CFilament/thread formingMonocomponent polyesters artificial filamentFiberNanofiber

A method for preparing directional magnetic nanofiber of electric-spinning type includes utilizing Fe3O4 magnetic fluid and high polymer solution as raw material and applying normal position composite means to carry out electric-spinning under certain conditions, setting magnetic field at receiving unit to use magnetic field to induce high polymer nanofiber containing Fe3O4 to be directionally arranged along magnetic field direction for obtaining nanofiber being set with diameter of 100-600nm and being directionally arranged along magnetic direction. The device for realizing said method is also disclosed.

Owner:BEIJING UNIV OF CHEM TECH

Fiber for artificial hair and hair ornament product including same

InactiveUS20160088888A1Excellent set propertyImprove combing effectHair accessoriesToupeesFiberEngineering

The present invention relates to a fiber for artificial hair having a void in a center of a fiber cross section. A ratio of an area of the void to an entire area of the fiber cross section is 5% to 50%. The fiber cross section has a flat multilobed shape, and the void has a first side and a second side that are inclined 70 to 110 degrees relative to a major axis of the fiber cross section. The present invention also relates to hair ornament products including the above fiber for artificial hair. Thus, the present invention provides a fiber for artificial hair having a favorable curl setting property when curling with a hair iron and a favorable combing property after curling with a hair iron, and hair ornament products including the same.

Owner:KANEKA CORP

Preparation method for regularly electrostatic spinning hollow fibre

InactiveCN101144196BSimple manufacturing methodHollow filament manufactureArtificial filaments from cellulose derivativesHollow fibreFiber bundle

The present invention relates to a preparation method for regularized static electricity spinning hollow fiber, and the method comprises the procedures that: firstly, high molecular compound is dissolved in good solvent to be made into uniform solution; secondly, poor solvent is added to be dispensed into spinning raw liquid, and the volume ratio of the good solvent and the poor solvent is 10 / 1 to 1 / 3; thirdly, the spinning raw liquid is added into a container, is controlled and extruded by a micro-syringe pump, a jet opening is connected with a high voltage positive pole, a grounding microelectrode with the removable area of 0 to 100 mm 2 is taken as a negative pole, various parameters of static electricity spinning are adjusted, and the spinning raw liquid carries on the static electricity spinning; fourthly, the grounding microelectrode backwards and continuously moves, and a continuous regularized static electricity spinning hollow fiber bundle is obtained; fifthly, the continuous hollow fiber bundle obtains the regularized static electricity spinning hollow fiber through winding and collecting. The preparation method provided by the present invention is simple and feasible, and the obtained static electricity spinning hollow fiber has the potential application and the prospect in the fields such as nanowire devices, filtering materials, and composite reinforcing materials, etc.

Owner:DONGHUA UNIV

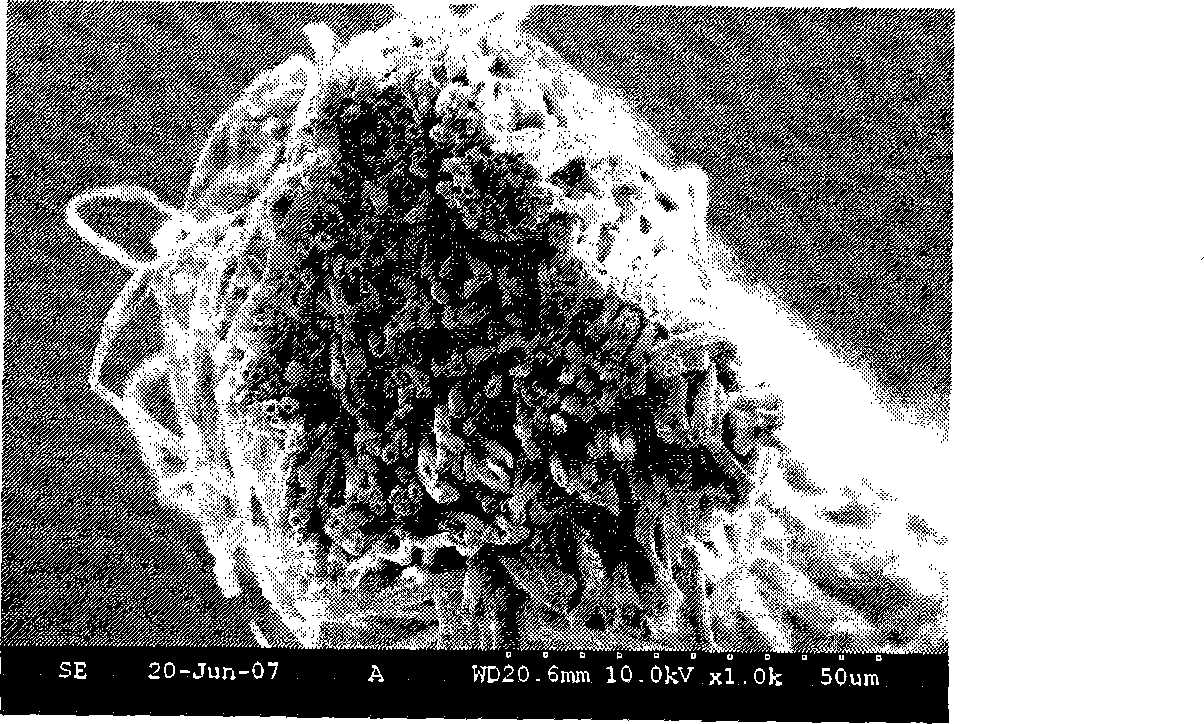

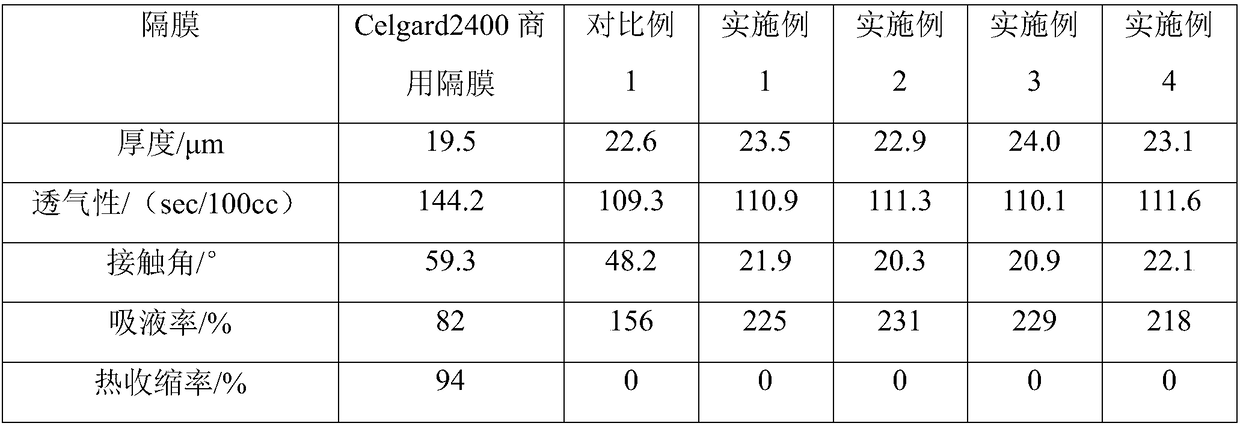

A composite lithium ion battery separator

InactiveCN109244341AFlame retardantImprove flame retardant performanceSecondary cellsElectro-spinningFiberPorosity

The invention belongs to the technical field of lithium ion batteries, in particular to a composite lithium ion battery separator, which is a polytetrafluoroethylene / polycarbonate composite fiber membrane with a skin-core structure; In the skin-core structure, polytetrafluoroethylene is the core and polycarbonate is the skin; 80 to 95 percent of polytetrafluoroethylene and 5 to 20 percent of polycarbonate in that polytetrafluoroethylene / polycarbonate composite fib membrane by mass fraction; The polytetrafluoroethylene / polycarbonate composite fiber membrane is prepared by an electrospinning method, has rich pore channel structure and high porosity, has good gas permeability, is conducive to absorption of electrolyte, maintains ion transmission in the membrane, and improves charging and discharging efficiency of a lithium ion battery. Therefore, the lithium ion battery separator of the present invention exhibits excellent air permeability and thermal stability, remarkably improves affinity with the electrolyte, and is more excellent in contact angle and liquid absorption rate of the electrolyte.

Owner:QINGDAO UNIV

Popular searches

Additive manufacturing with liquids 3D object support structures Monocomponent polycarbonates artificial filament Polycarbonate coatings Artifical filament manufacture Electric shock equipments Monocomponent polyethers artificial filament Coatings Thin material handling Monocomponent polyolefin artificial filament

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com