Polymer electrostatic spinning film, preparation and use in biological detection

An electrospinning and polymer technology, which is applied in the field of polymer electrospinning film and its preparation, and the post-processing field of polymer electrospinning, can solve the problems that cannot be directly applied and difficult to operate, and achieve low production cost, Low cost, uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

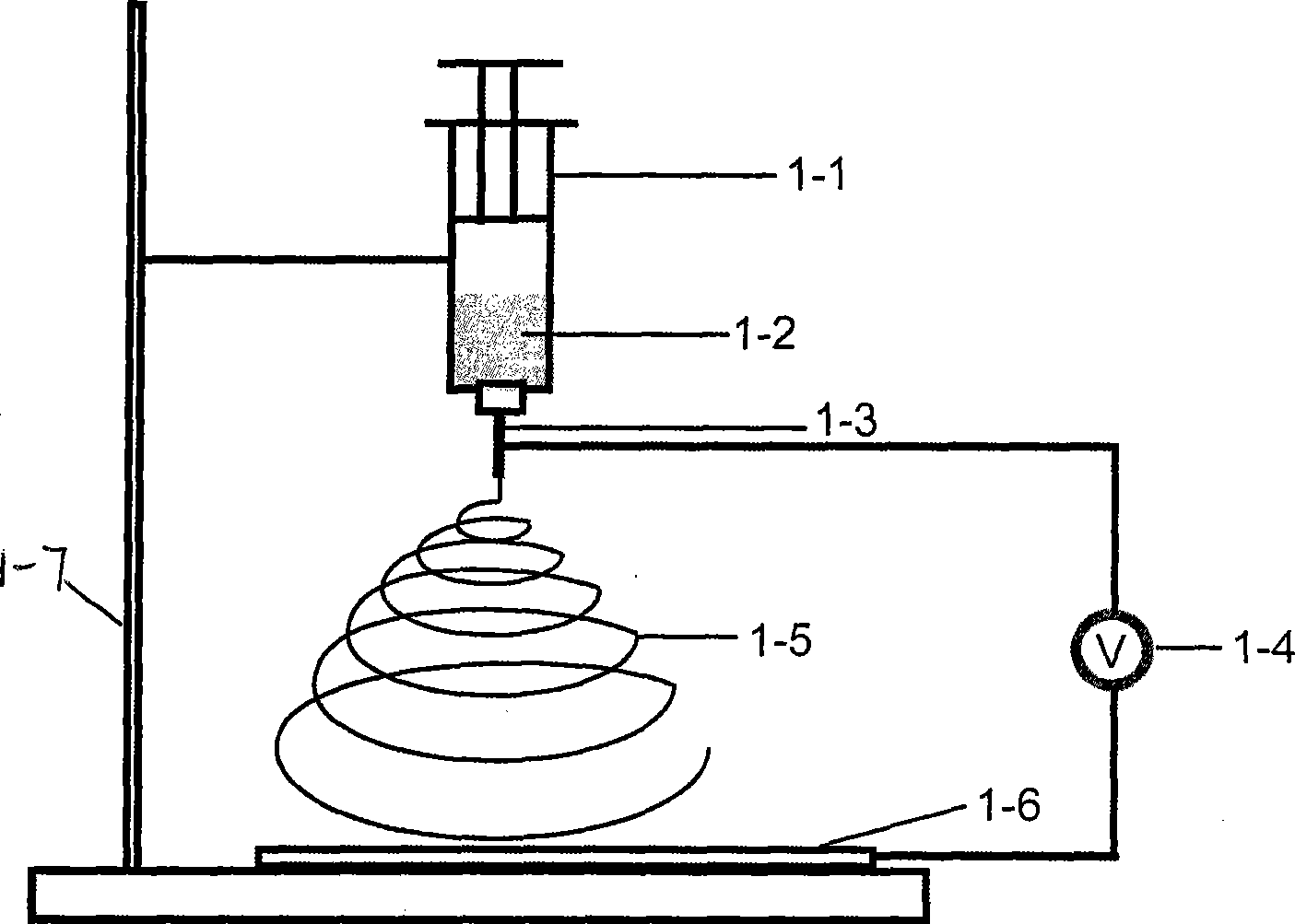

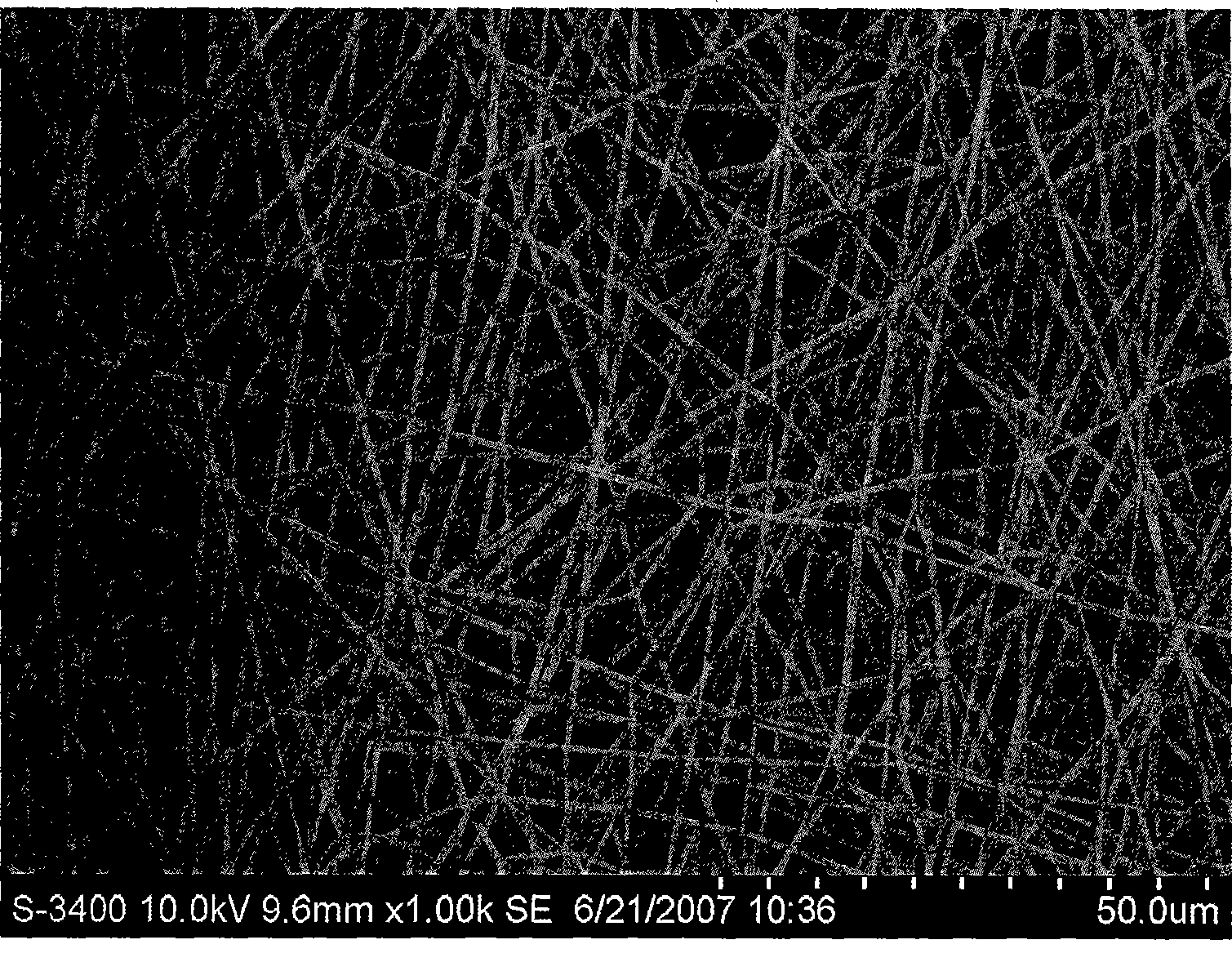

[0044] Use as attached figure 1 The electrospinning device shown in the electrospinning device adopts the method involved in the present invention to carry out electrospinning, and its flow process is as follows Figure 5 As shown, the prepared polycarbonate (PC) electrospun film is as follows figure 2 , 4 shown. Specific steps are as follows:

[0045]a). Prepare a polycarbonate solution for electrospinning, dissolve 20g polycarbonate in 80g chloroform to obtain a 20wt% polycarbonate solution, and carry out electrospinning with this solution. During electrospinning, the prepared The polycarbonate spinning solution 1-2 is contained in the spinning tube 1-1, and the spinning solution is propelled by a syringe pump; the distance between the spinning nozzle 1-3 and the surface receiving the aluminum foil 5-2 is 10 cm, and the spinning nozzle 1-3 3 Connect the positive pole of the high voltage generator 1-4 as the anode, accept the aluminum foil 5-2 and connect the negative po...

Embodiment 2

[0051] The polystyrene (PS) electrostatic spinning film is prepared by adopting the method involved in the invention. Specific steps such as

[0052] Down:

[0053] a). Prepare polystyrene solution for electrospinning, dissolve 14g polystyrene in 86g dimethylformamide (DMF), prepare 14wt% polystyrene solution, carry out electrospinning with this solution, apply The voltage was 10-30kV, and electrospinning was performed for 15 minutes. During the electrospinning process, the polystyrene solution is formed into nanofibers under the action of an electric field, with an average spinning diameter of 200 nm and a film thickness of 15 μm;

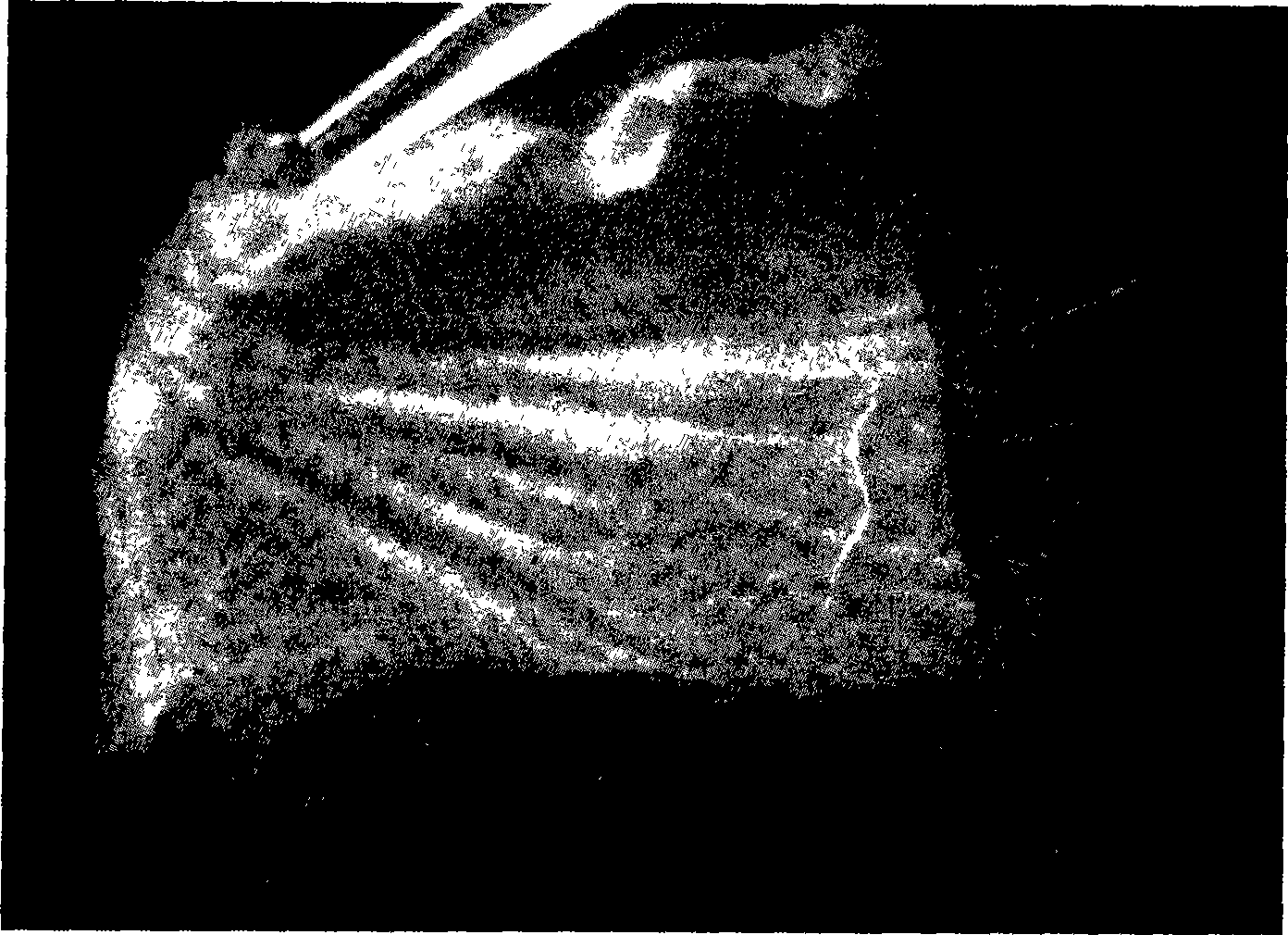

[0054] b). Place the fluffy polystyrene spinning film obtained in step a) flatly on the platform, cover the polystyrene spinning film with aluminum foil, and apply a weight on it with a pressure of 600Pa. The pressure was maintained for 5 hours, the flat polystyrene spun film obtained by removing the weight and covering the spun aluminum foil; ...

Embodiment 3

[0059] The polymethyl methacrylate (PMMA) electrostatic spinning film is prepared by adopting the method involved in the invention.

[0060] Specific steps are as follows:

[0061] a). Prepare a polymethyl methacrylate solution for electrospinning, dissolve 10g polymethyl methacrylate in 90g tetrahydrofuran (THF), and prepare a 10wt% polymethyl methacrylate solution. Perform electrospinning, apply a voltage of 10-30 kV, and electrospin for 20 minutes. During the electrospinning process, the polymethyl methacrylate solution is formed into nanofibers under the action of an electric field, with an average spinning diameter of 300 nm and a film thickness of 15 μm;

[0062] b). Place the fluffy polymethyl methacrylate spinning film obtained in step a) flatly on the platform, cover the polymethyl methacrylate spinning film with aluminum foil, and apply a weight on it with a pressure of 600Pa. The pressure was maintained for 5 hours, and the heavy objects were removed and the alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com