Preparation method of propylene carbonate/polylactic acid complex fiber film and prepared propylene carbonate/polylactic acid complex fiber film

A polypropylene carbonate and composite fiber membrane technology, applied in the direction of one-component polycarbonate rayon, fiber treatment, one-component polyester rayon, etc., can solve poor compatibility, high cost, Problems such as incoherent spinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

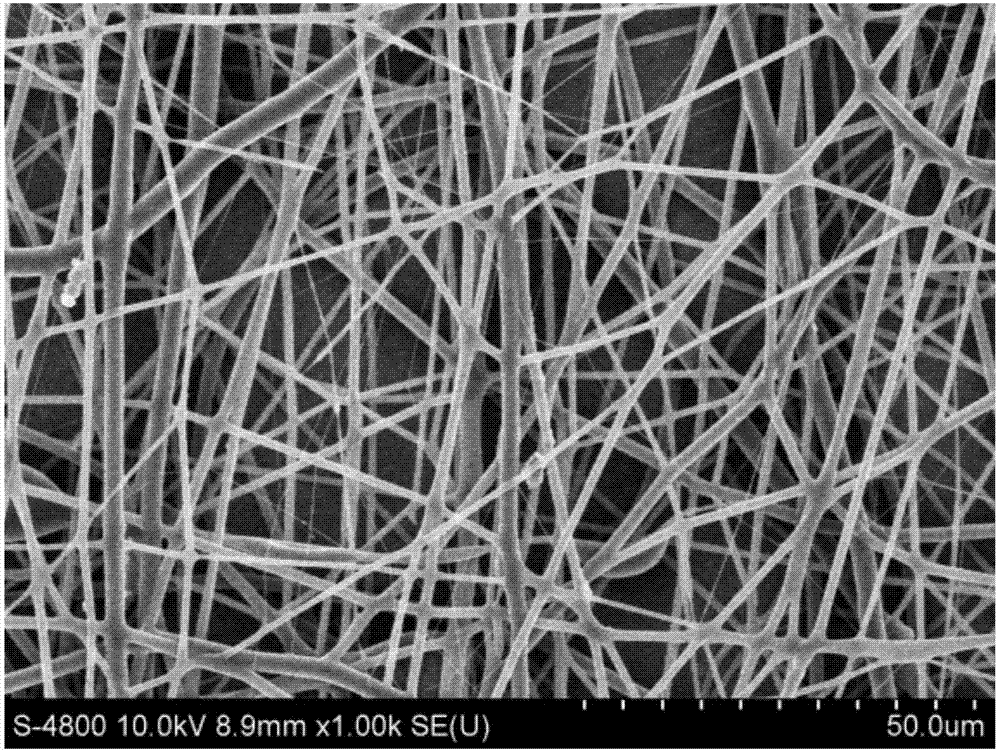

Image

Examples

Embodiment 1

[0032] Select dichloromethane as solvent, and the preparation concentration is 8% PPC solution and 4% PLA solution, the number average molecular weight of described polypropylene carbonate is 90000, and the molecular weight distribution width is 1.3; The number average molecular weight of described polylactic acid is 73396, the molecular weight distribution width is 1.24. The spinning temperature is 24°C, the spinning humidity is 40%, the inner diameter of the syringe needle of the PPC solution is 0.60mm, the pushing speed is 0.08mm / min, the voltage is 8kV, and the spinning distance is 10cm; the inner diameter of the syringe needle of the PLA solution is 0.60mm, the pushing speed is 0.04mm / min, the voltage is 10kV, the spinning distance is 10cm; the speed of the receiving roll is 40rpm, the obtained fiber is received by tinfoil paper, and after spinning for 4 hours, place it in a fume hood to remove the solvent 30min, then transfer the sample into a vacuum drying oven, dry at ...

Embodiment 2

[0034] Select dichloromethane as solvent, and the preparation concentration is 10% PPC solution and 5% PLA solution, the number average molecular weight of described polypropylene carbonate is 89000, and the molecular weight distribution width is 1.2; The number average molecular weight of described polylactic acid is 73500, the molecular weight distribution width is 1.3. The spinning temperature is 26°C, the spinning humidity is 40%, the inner diameter of the syringe needle of the PPC solution is 0.51mm, the pushing speed is 0.10mm / min, the voltage is 9kV, and the spinning distance is 13cm; the inner diameter of the syringe needle of the PLA solution is 0.51mm, the pushing speed is 0.06mm / min, the voltage is 10kV, the spinning distance is 12cm; the speed of the receiving roll is 60rpm, the obtained fiber is received by tinfoil paper, and after spinning for 4 hours, place it in a fume hood to remove the solvent 30min, then transfer the sample into a vacuum drying oven, dry at ...

Embodiment 3

[0036] Select dichloromethane as solvent, and the preparation concentration is 10% PPC solution and 8% PLA solution, the number average molecular weight of described polypropylene carbonate is 91000, and the molecular weight distribution width is 1.4; The number average molecular weight of described polylactic acid is 73000, molecular weight distribution width is 1.2. The spinning temperature is 28°C, the spinning humidity is 45%, the inner diameter of the syringe needle of the PPC solution is 0.33mm, the pushing speed is 0.08mm / min, the voltage is 10kV, and the spinning distance is 15cm; the inner diameter of the syringe needle of the PLA solution is 0.51mm, the pushing speed is 0.08mm / min, the voltage is 10kV, the spinning distance is 15cm; the speed of the receiving roll is 80rpm, the obtained fiber is received by tinfoil paper, and after spinning for 4 hours, place it in a fume hood to remove the solvent 30min, then transfer the sample into a vacuum drying oven, dry at roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com