Fiber for artificial hair and hair ornament product including same

a technology of artificial hair and fiber, which is applied in the field of fiber for artificial hair, can solve the problems of poor curl setting property of artificial hair of patent document 1 and cannot be fixed at the heating temperature, and achieve the effect of favorable curl setting property and favorable combing property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

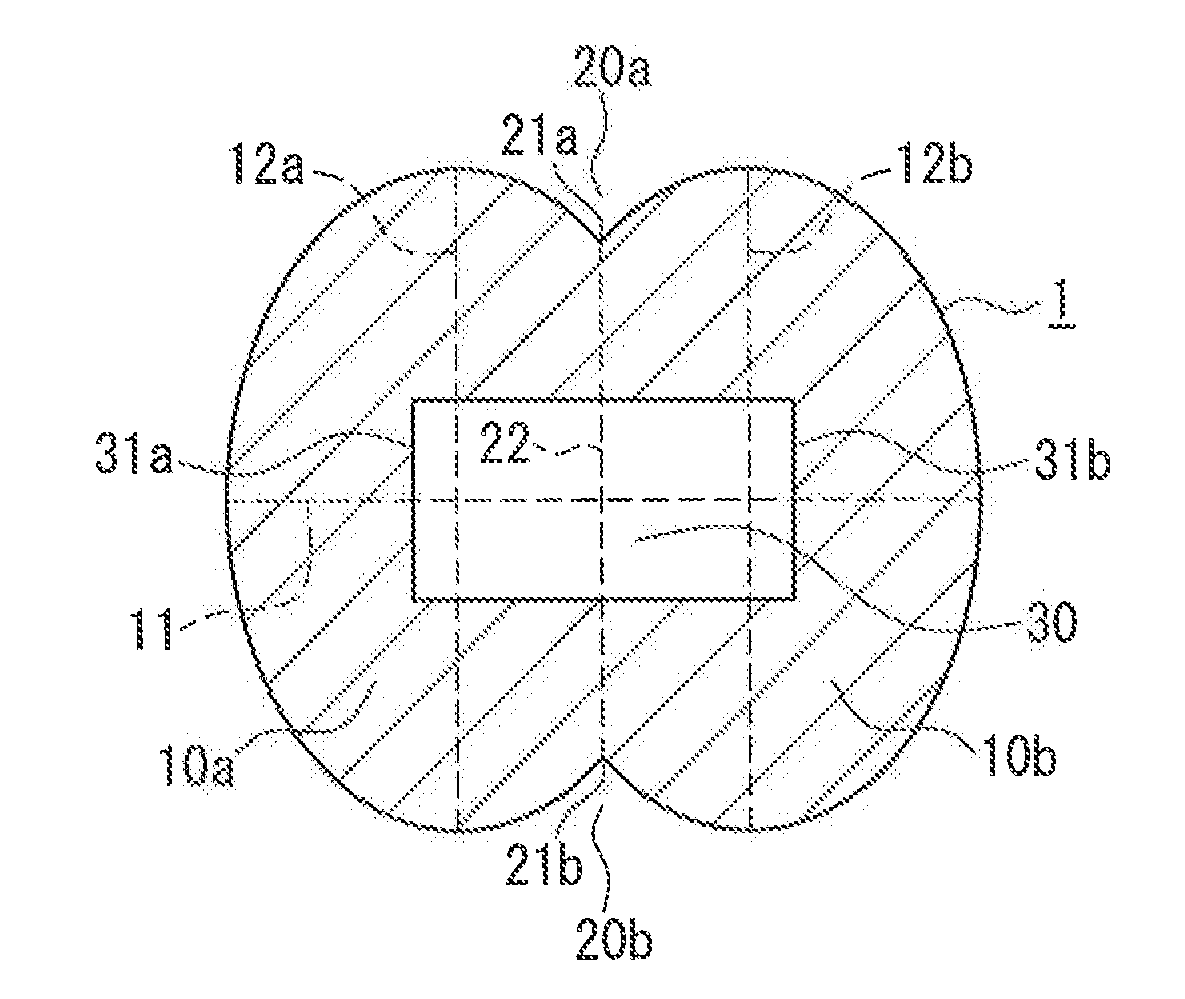

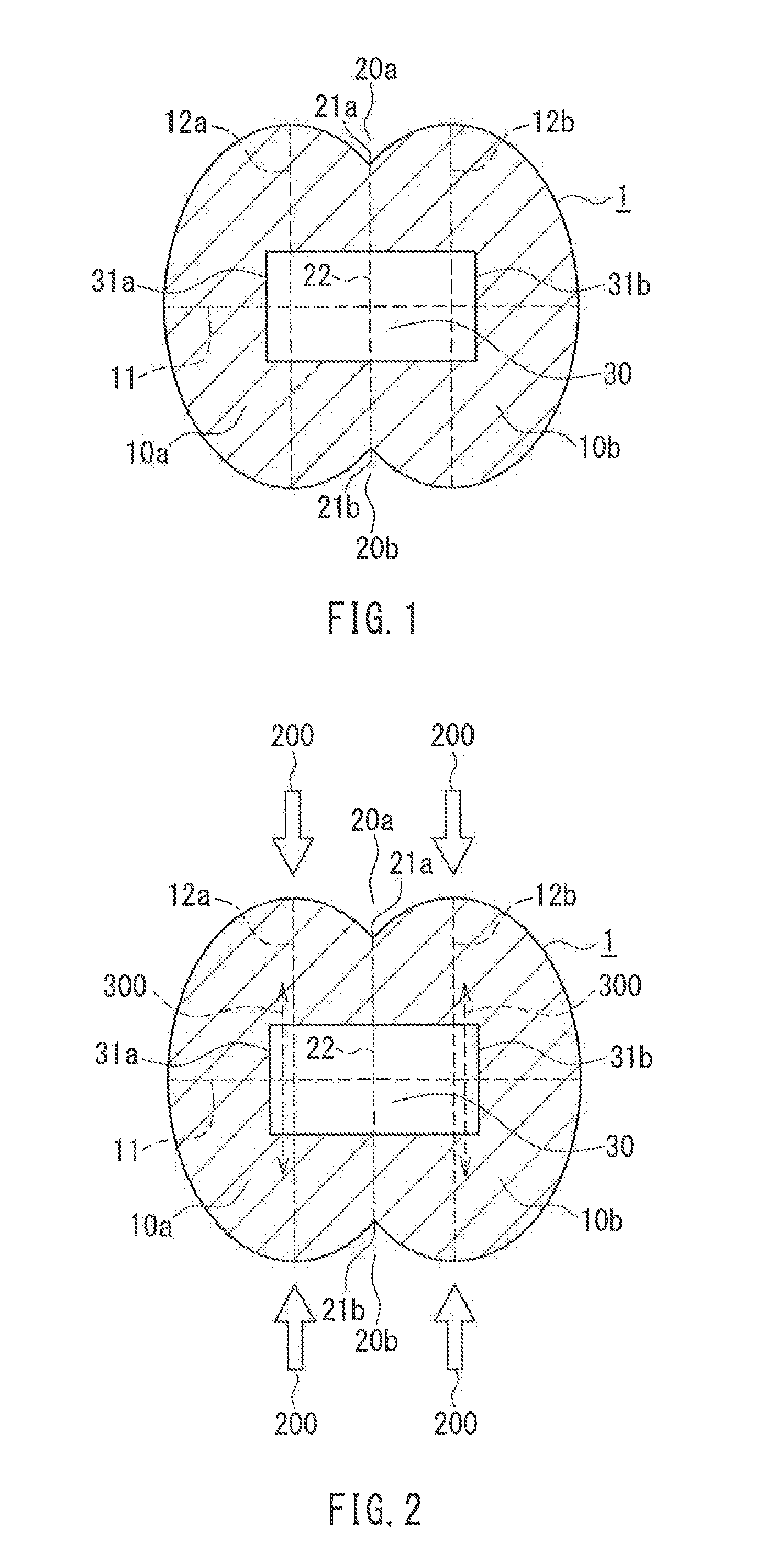

Image

Examples

example 1

[0104]100 parts by weight of polyethylene terephthalate that was dried to a moisture content of 100 ppm or less, 20 parts by weight of brominated epoxy-based flame retardant, and 2 parts by weight of sodium antimonate were dry blended. The mixture obtained was supplied to a twin-screw extruder and melt kneaded at 280° C., and then was formed into pellets. The pellets obtained were dried to a moisture content of 100 ppm or less. Next, the dried pellets were supplied to a melt spinning machine, and a molten polymer was extruded through a spinneret with a nozzle having the shape indicated in Table 1 below at a barrel temperature of 280° C. The extruded polymer was passed through a heated tube, cooled to a temperature of not more than the glass transition temperature of the polyethylene terephthalate, and wound up at a speed of 60 to 150 m / min. Thus, spun yarns (undrawn yarns) were obtained. Fibers of Example 1 were obtained by configuring a nozzle hole in the nozzle having the shape in...

example 2

[0105]Polyester-based fibers (multifilaments) with a single fiber fineness of about 60 dtex were produced in the same manner as in Example 1 except that in the nozzle shown in FIG. 8A, sizes a, b, c, d, and e in the outer circumference portion and the hollow portion were changed to 1.10 times, 0.93 times, 1.04 times, 0.87 times, and 0.88 times, respectively.

example 3

[0106]Polyester-based fibers (multifilaments) with a single fiber fineness of about 60 dtex were produced in the same manner as in Example 1 except that in the nozzle shown in FIG. 8A, the sizes a, b, c, d, and e in the outer circumference portion and the hollow portion were changed to 1.10 times, 0.93 times, 1.04 times, 1.00 time, and 0.92 times, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| shrinkage percentage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com