Polycarbonate nonwoven film and preparation method therefor

A technology of polycarbonate and non-woven fabrics, applied in the direction of one-component polycarbonate rayon, one-component polyester rayon, non-woven fabrics, etc., can solve processing and other problems, and achieve excellent performance and shape Uniform appearance and fast spinning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Specific steps are as follows:

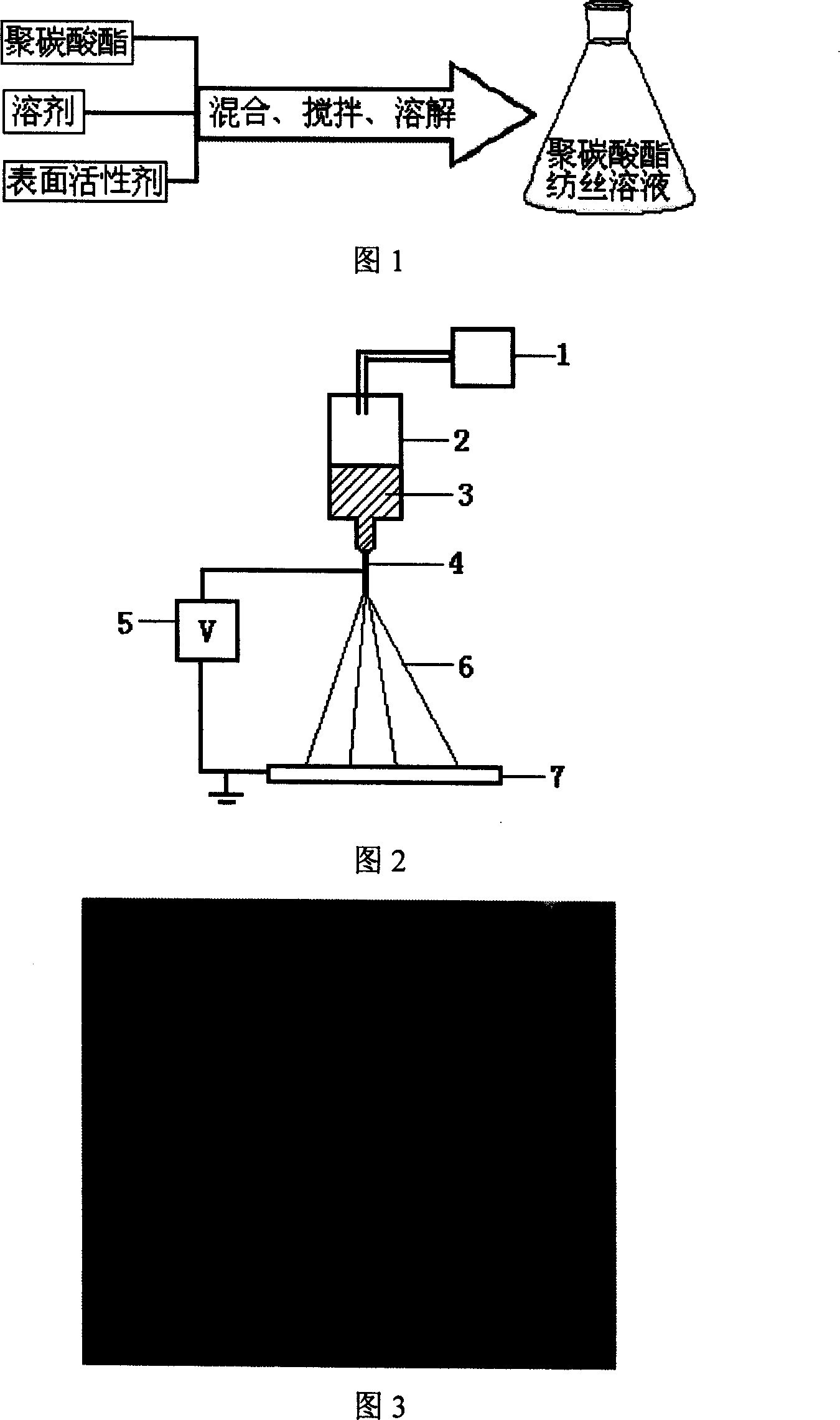

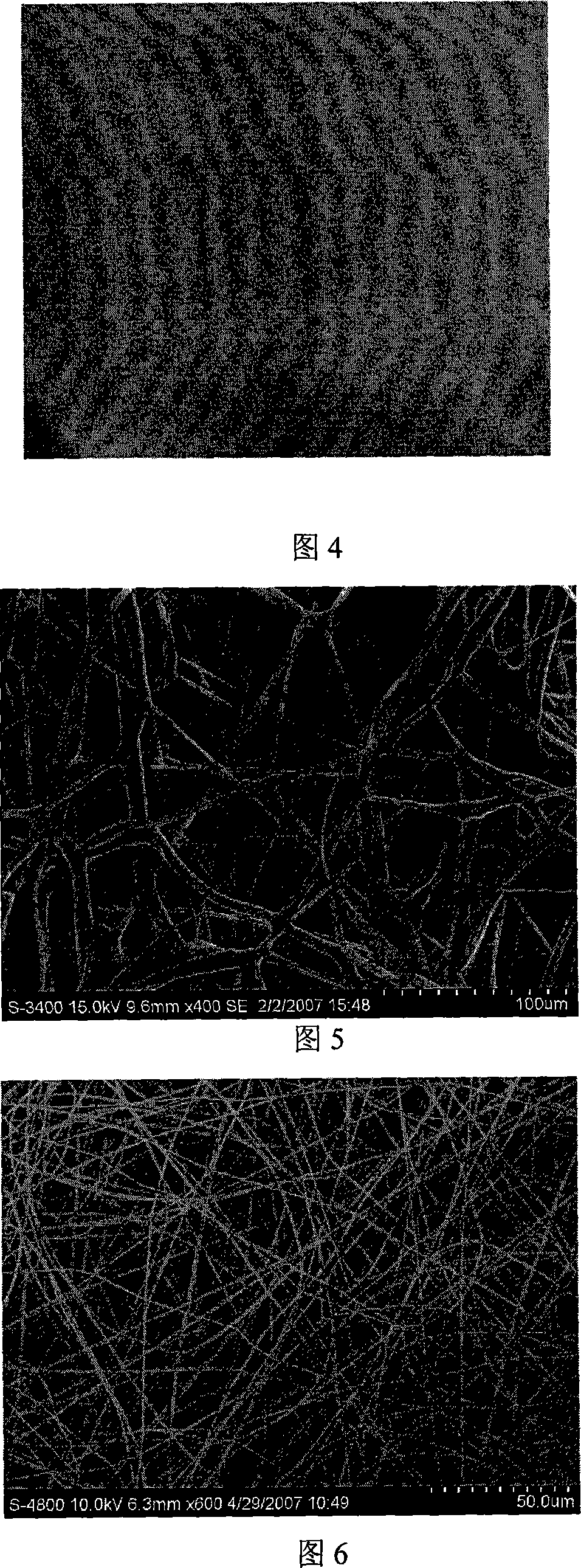

[0039] 20 g of polycarbonate was dissolved in 80 g of chloroform, and magnetically stirred for 12 hours to obtain a 20 wt % transparent polycarbonate solution. Add 0.05wt% Tween-80 surfactant to the polymer solution in the polycarbonate solution, magnetically stir for 4 hours, and prepare the polycarbonate spinning solution process, as shown in Figure 1. Electrospinning is carried out in an electrospinning device as shown in FIG. 2 . During electrospinning, the prepared polycarbonate spinning solution 3 is contained in a spinneret 2 , and the spinning solution is propelled by a syringe pump 1 . The distance between the nozzle and the surface of the aluminum foil is 10cm, the nozzle 4 is connected to the positive pole of the high-voltage generator 5 as an anode, the aluminum foil 7 is connected to the negative pole of the high-voltage generator 5 as a cathode, the high-voltage generator 5 is connected, and the applied voltage is 10-30kV. ...

Embodiment 2

[0042] Using the electrospinning method of Example 1, only changing the solvent, the prepared non-woven film has an area of 5 cm × 5 cm and a thickness of 50 μm, wherein the electrospinning diameter is about 350 nanometers, and they are interlaced to form a film. The specific surface area of the polycarbonate non-woven film can reach 35m 2 / g.

[0043] Specific steps are as follows:

[0044] 18 grams of polycarbonate were dissolved in 82 grams of tetrahydrofuran, and magnetically stirred for 12 hours to obtain a 18wt% transparent polycarbonate solution; 0.05wt% Tween-80 surfactant was added to the polymer solution in the polycarbonate solution During electrospinning, the prepared polycarbonate spinning solution 3 is filled in the spinneret 2, and the distance between the nozzle and the surface of the aluminum foil is 10 cm. 4. Connect the positive pole of the high-voltage generator 5 as the anode, and the aluminum foil 7 is connected with the negative pole of the high-vo...

Embodiment 3

[0046] Using the method of Example 1, changing the solvent, the prepared non-woven film has an area of 5 cm × 5 cm and a thickness of 50 μm, wherein the electrospinning diameter is about 300 nanometers, and they are interlaced to form a film. The specific surface area of the polycarbonate non-woven film can reach 35m 2 / g.

[0047] Specific steps are as follows:

[0048] 15 g of polycarbonate was dissolved in 85 g of dimethylformamide, and magnetically stirred for 12 hours to obtain a 15 wt % transparent polycarbonate solution. Add 0.05wt% Tween-80 surfactant to the polymer solution in the polycarbonate solution, and magnetically stir for 4 hours to prepare a polycarbonate spinning solution. During electrospinning, the prepared polycarbonate spinning solution 3 is contained in the spinneret 2, the distance between the nozzle and the surface of the aluminum foil is 10 cm, the nozzle 4 is connected to the positive electrode of the high voltage generator 5 as an anode, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com