Manufacture of fibre containing functional mineral powder and fibre prepared by the same

A mineral powder, functional technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

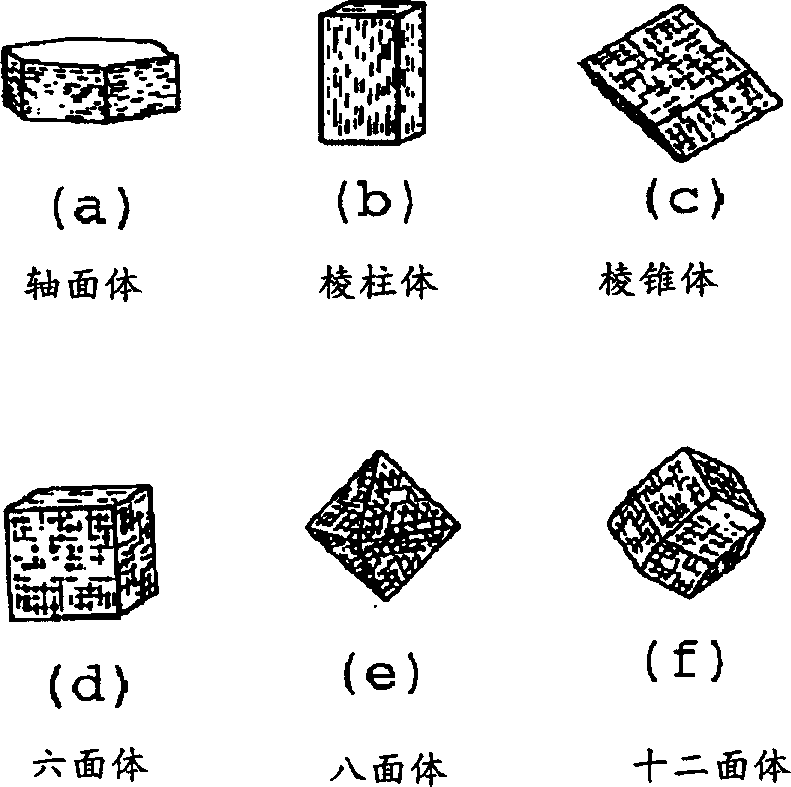

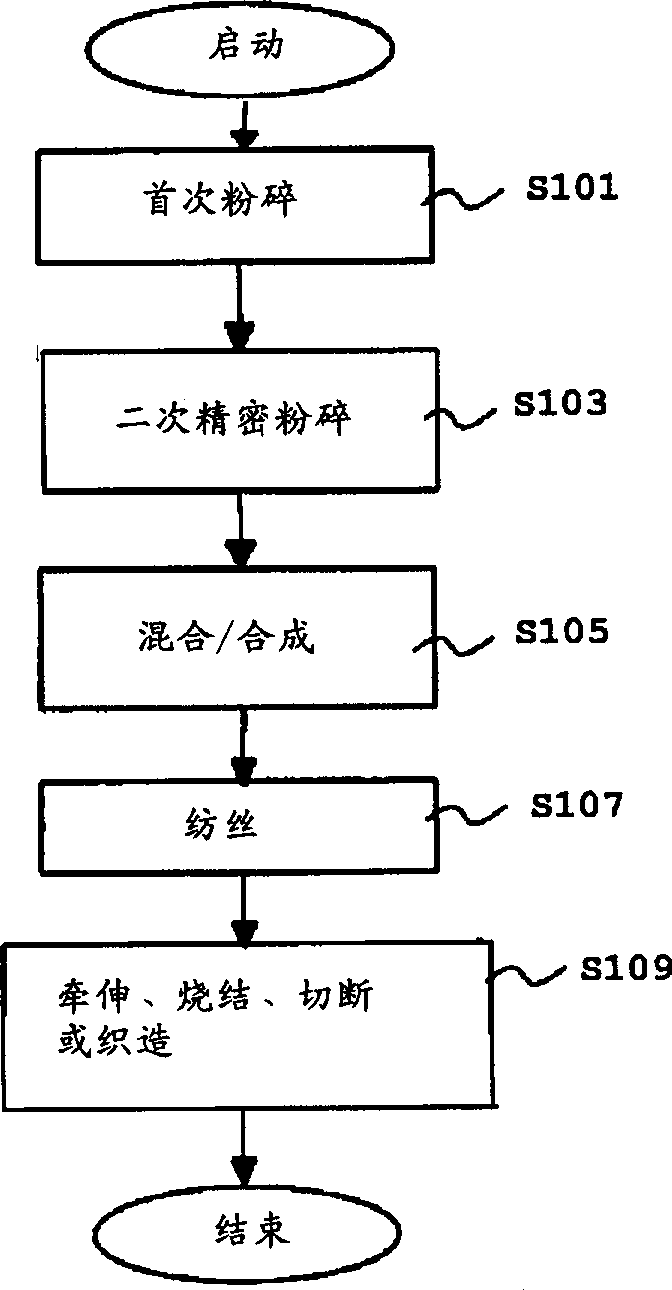

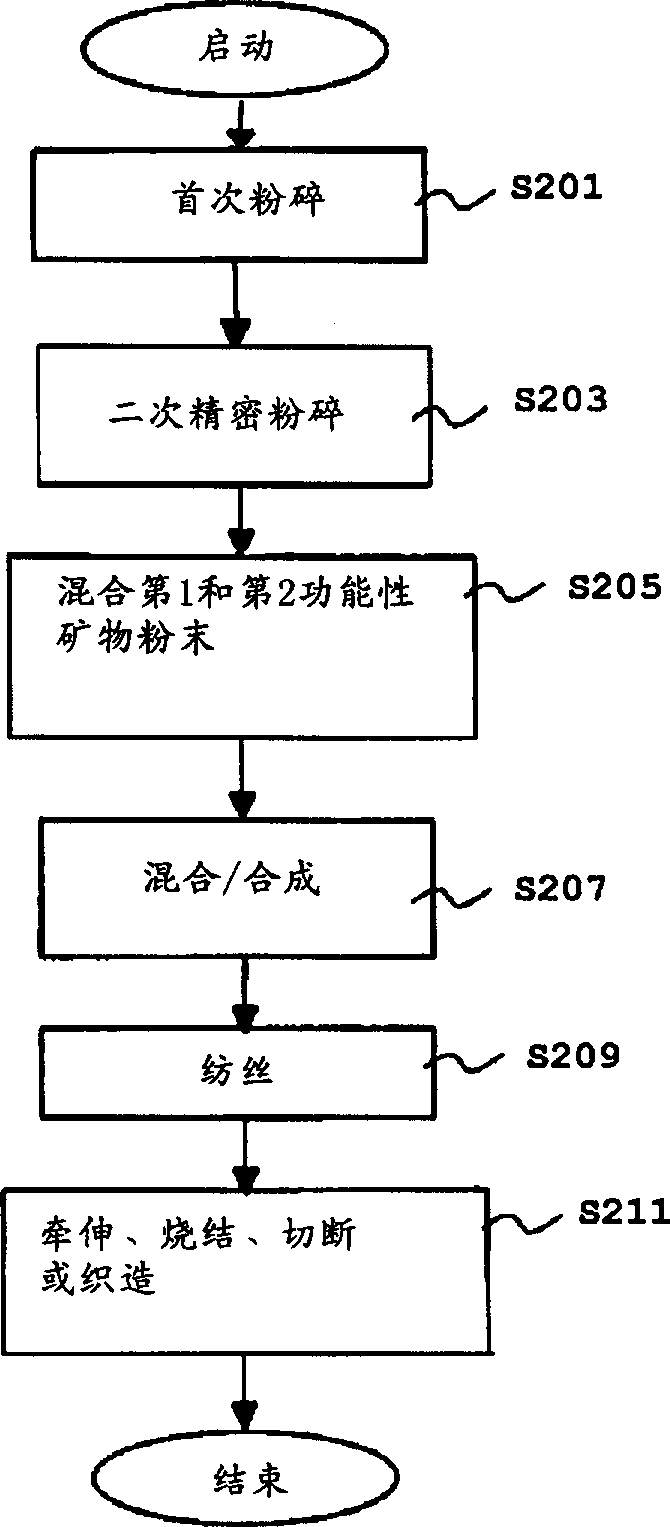

[0107] In order to prepare 2 denier fibers that can radiate far-infrared rays that are beneficial to the human body and have good quality, firstly, the muscovite in the axial form of the crystal is crushed to 325 mesh, and then the first crushed muscovite is sintered at 800℃, and the muscovite is finely crushed for the second time. The mother powder, so that the maximum particle size of the muscovite powder is less than 1 micron. Next, an electromagnet is used to remove metal elements while mixing the mineral powder with water, and the mineral powder is passed through a filter with pressure to obtain a fine mineral powder.

[0108] In addition, 17% by weight of muscovite powder was mixed with an inorganic antibacterial agent, and the mixed powder was polymerized with polyester. Thus, at 283°C, a 2% by weight fiber containing the above-mentioned mixed powder was prepared by a conventional spinning method. As a result, no wear of accessories such as healds, rollers, and guides and f...

Embodiment 2

[0110] This example was carried out in the same manner as in Example 1, except that polyamide was used instead of polyester.

Embodiment 3

[0112] As in Example 1, after the mixed powder was treated with polyester in polymerization, a batch polymerization method was used to prepare chips containing 2% by weight of mineral powder at a polymerization temperature of 290°C, and its viscosity coefficient was 2700 poise. Next, 1.4 denier staple fibers were spun at a temperature of 283°C. As a result, no abrasion of accessories and fiber cutting occurred, and a smooth surface and excellent quality fiber were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com