Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

232 results about "Metal working fluid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Complex chemical mixtures used on metal while the metal is machined.

Water-soluble total-synthesis metal working fluid and application thereof

The invention discloses a water-soluble total-synthesis metal working fluid and application thereof. The working fluid is prepared from the following raw materials in percentage by weight: 1wt%-30wt% of a lubricant, 1wt%-40wt% of a corrosion inhibitor, 1wt%-40wt% of organic amine, 1wt%-20wt% of a cleaning agent, 1wt%-20wt% of a coupling agent, 0.5wt%-5wt% of an antifoaming agent and the balance of water. The working fluid can form water-based steam with anti-rust property in an induction manner in the use procedure, so that the problem of rusting caused by steam which is easily generated by a closed machine tool is solved, and therefore, the working fluid is suitable for a high-precision machine tool, especially a numerical control machine tool with a closed structure.

Owner:TSINGHUA UNIV

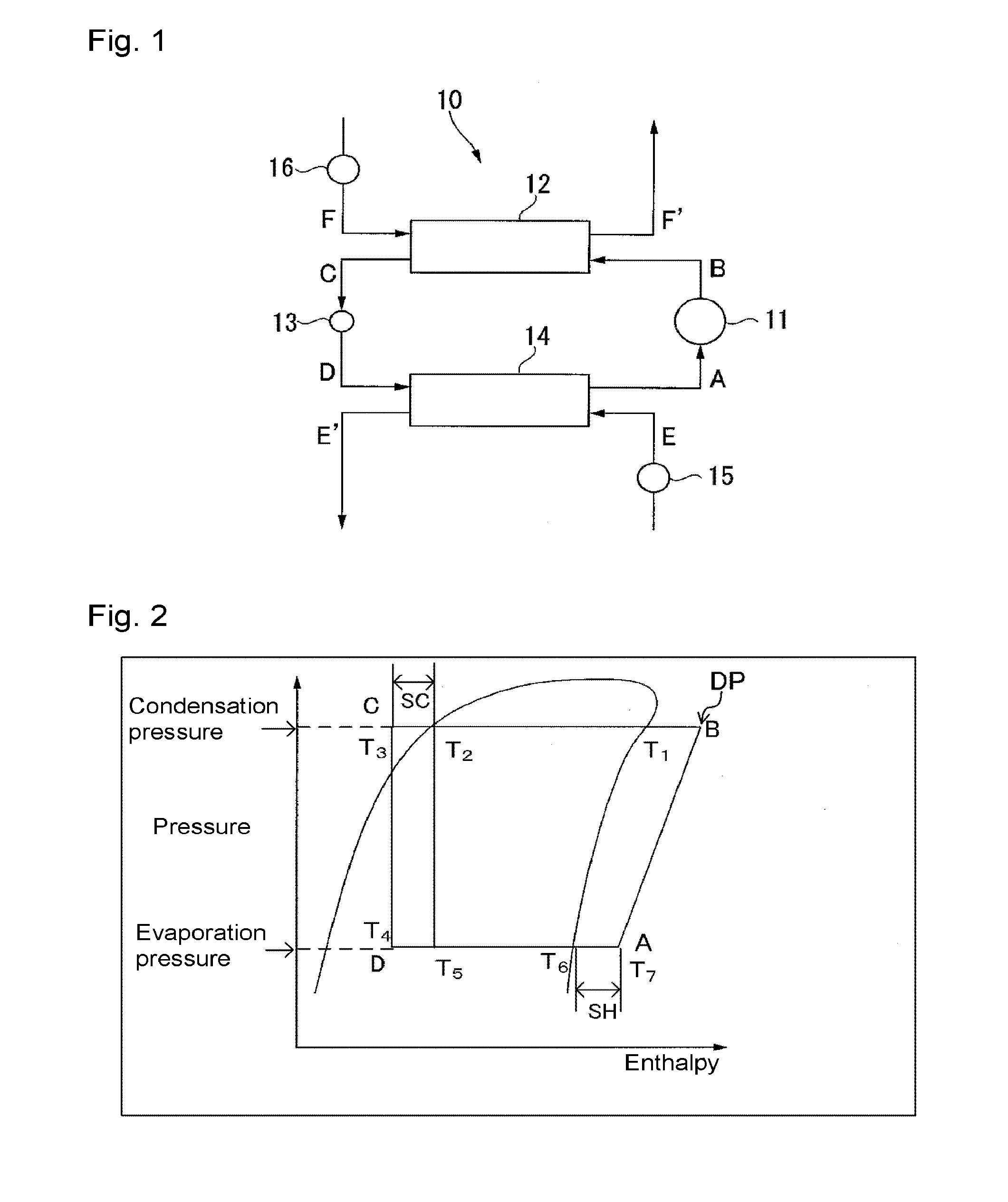

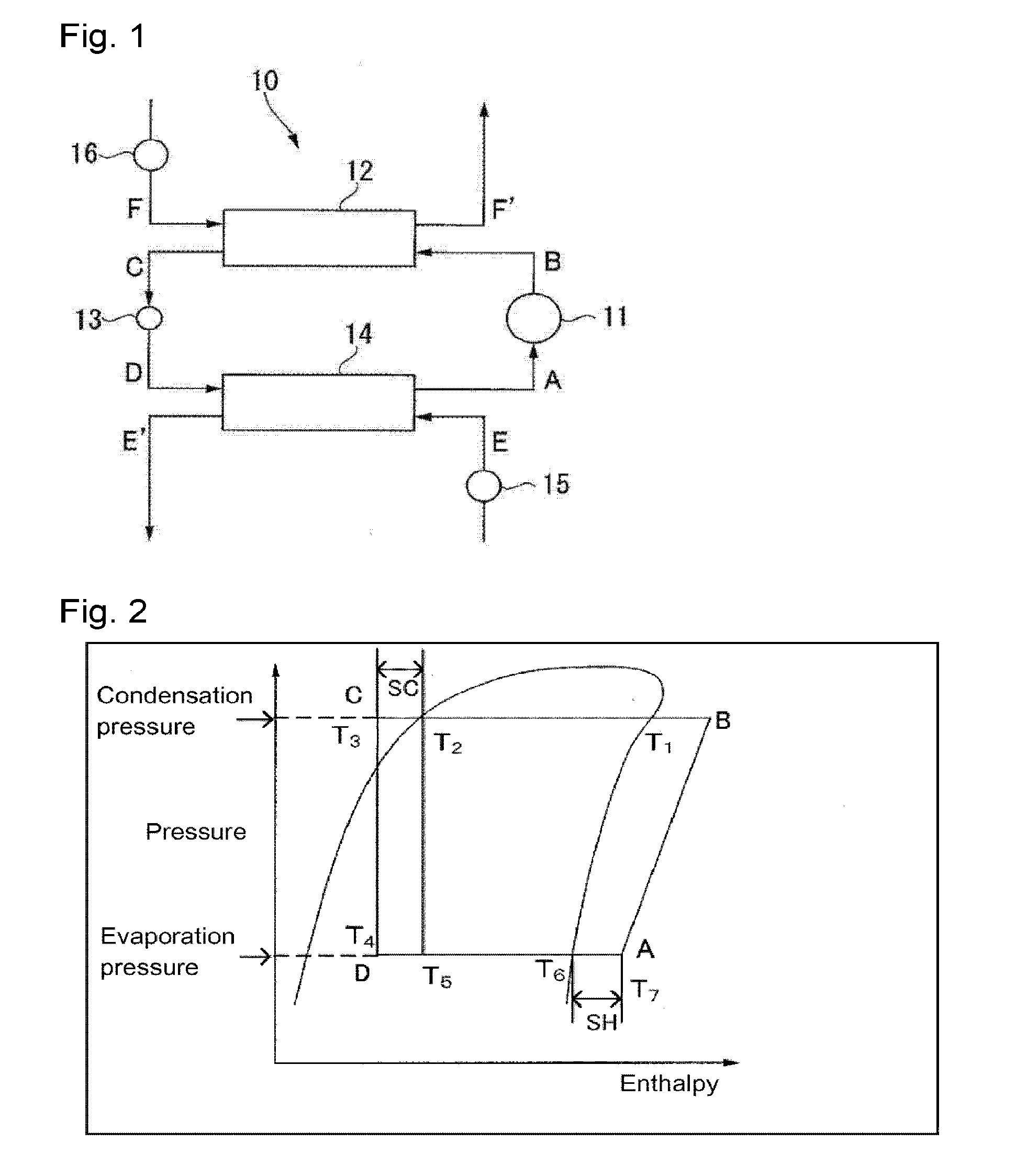

Working fluid for heat cycle, composition for heat cycle system, and heat cycle system

ActiveUS20160333243A1Stably used continuouslyCycle performance sufficientHeat-exchange elementsWorking fluidMetal working fluid

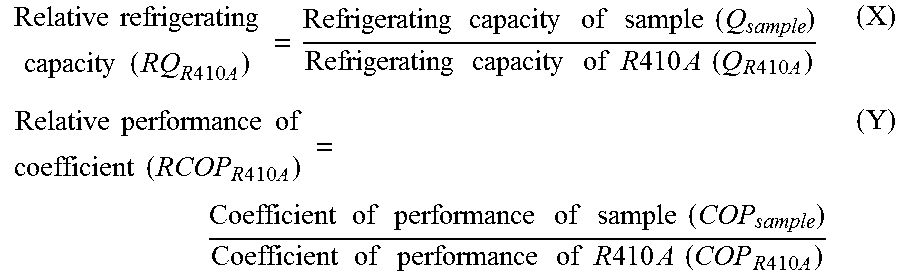

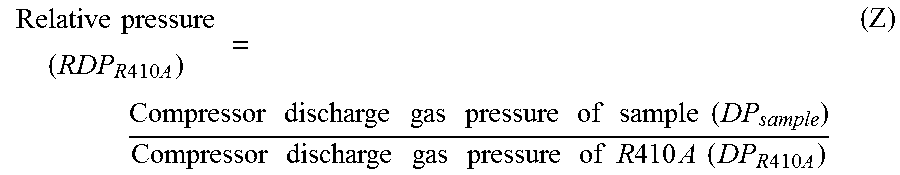

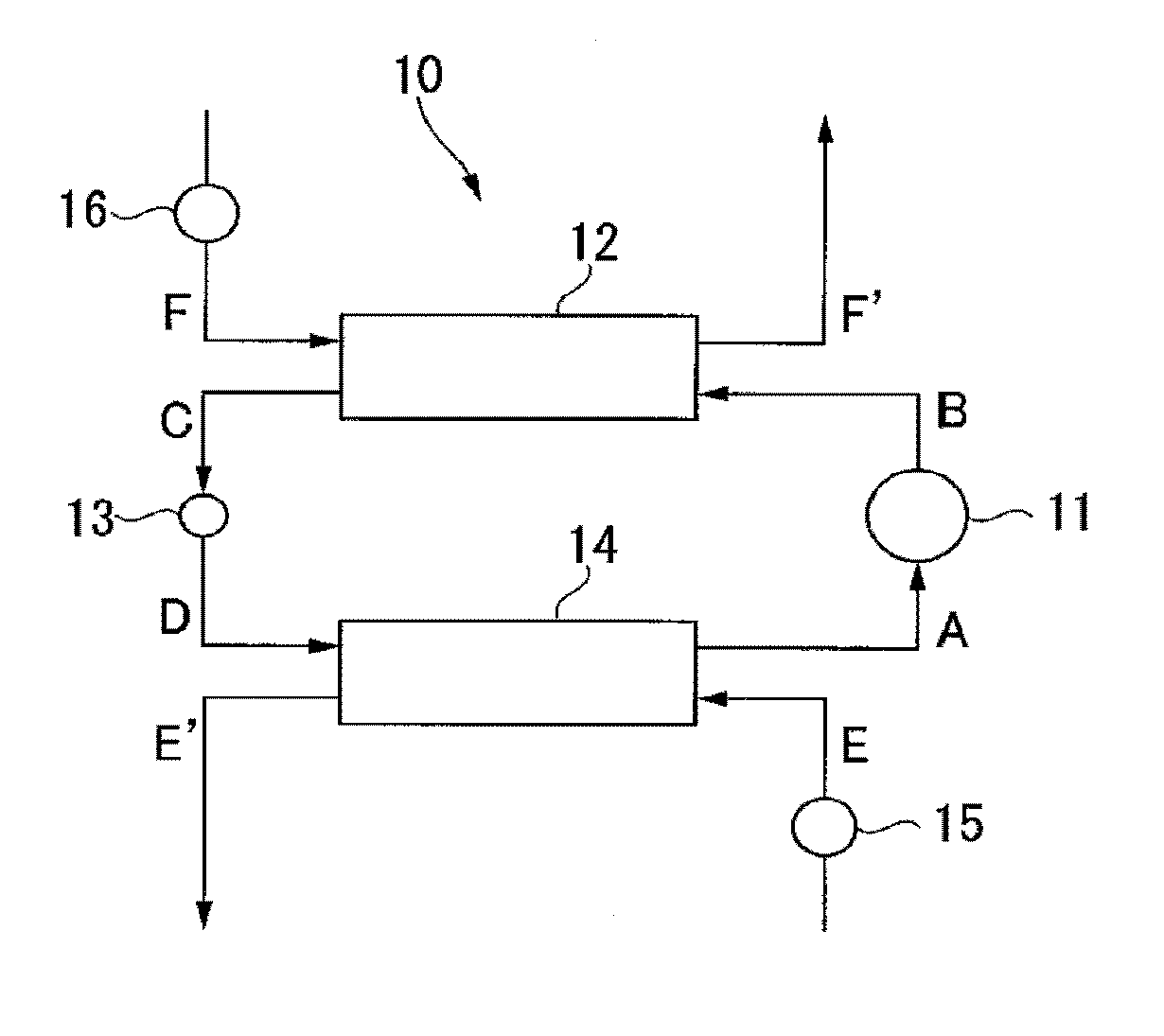

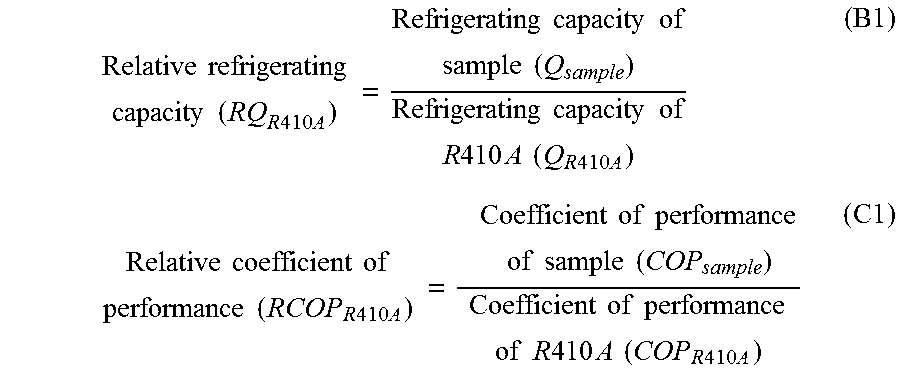

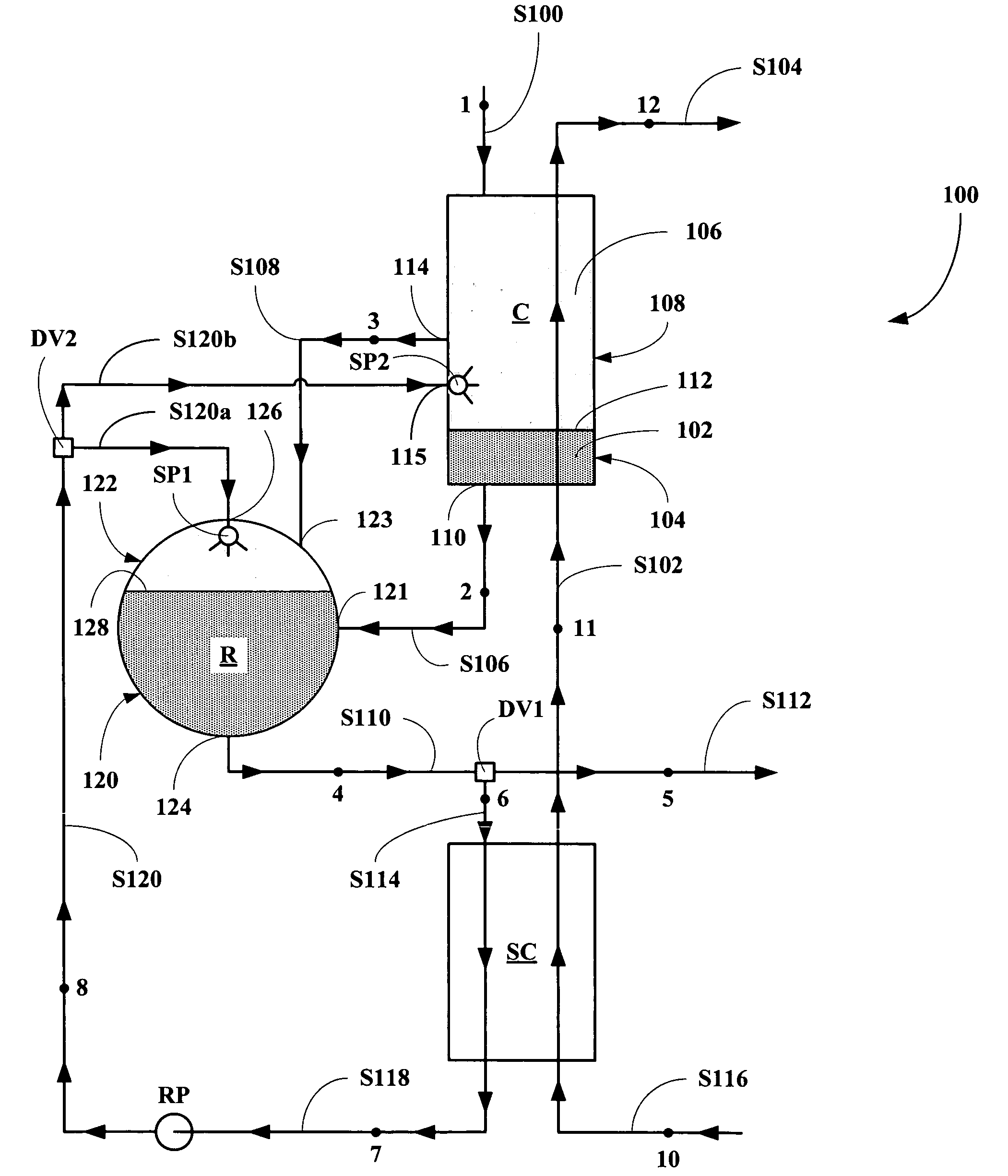

To provide a working fluid which has cycle performance sufficient as an alternative to R410A while the influence over global warming is sufficiently suppressed, which does not significantly increase the load to an apparatus as compared with a case where R410A is used, and which can be stably used continuously without any special measures, a composition for a heat cycle system comprising the working fluid, and a heat cycle system employing the composition.A working fluid for heat cycle, wherein the global warming potential is less than 300; the product of the relative coefficient of performance and the relative refrigerating capacity is at least 0.820 relative to R410A in a standard refrigerating cycle under conditions of an evaporation temperature of 0° C., a condensing temperature of 40° C., a supercoiling degree of 5° C. and a degree of superheat of 5° C.; the relative compressor discharge gas pressure is at most 1.100; the lower limit of the combustion range by method A in High Pressure Gas Safety Act is at least 5 vol %; and the pressure will not exceed 2.00 MPaG in a combustion test by method A in High Pressure Gas Safety act under 0.98 MPaG at 250° C.

Owner:ASAHI GLASS CO LTD

Working fluid for heat cycle, composition for heat cycle system, and heat cycle system

InactiveUS20170058173A1Improve stabilityCycle performance sufficientCompressorCompression machines with non-reversible cycleWorking fluidMetal working fluid

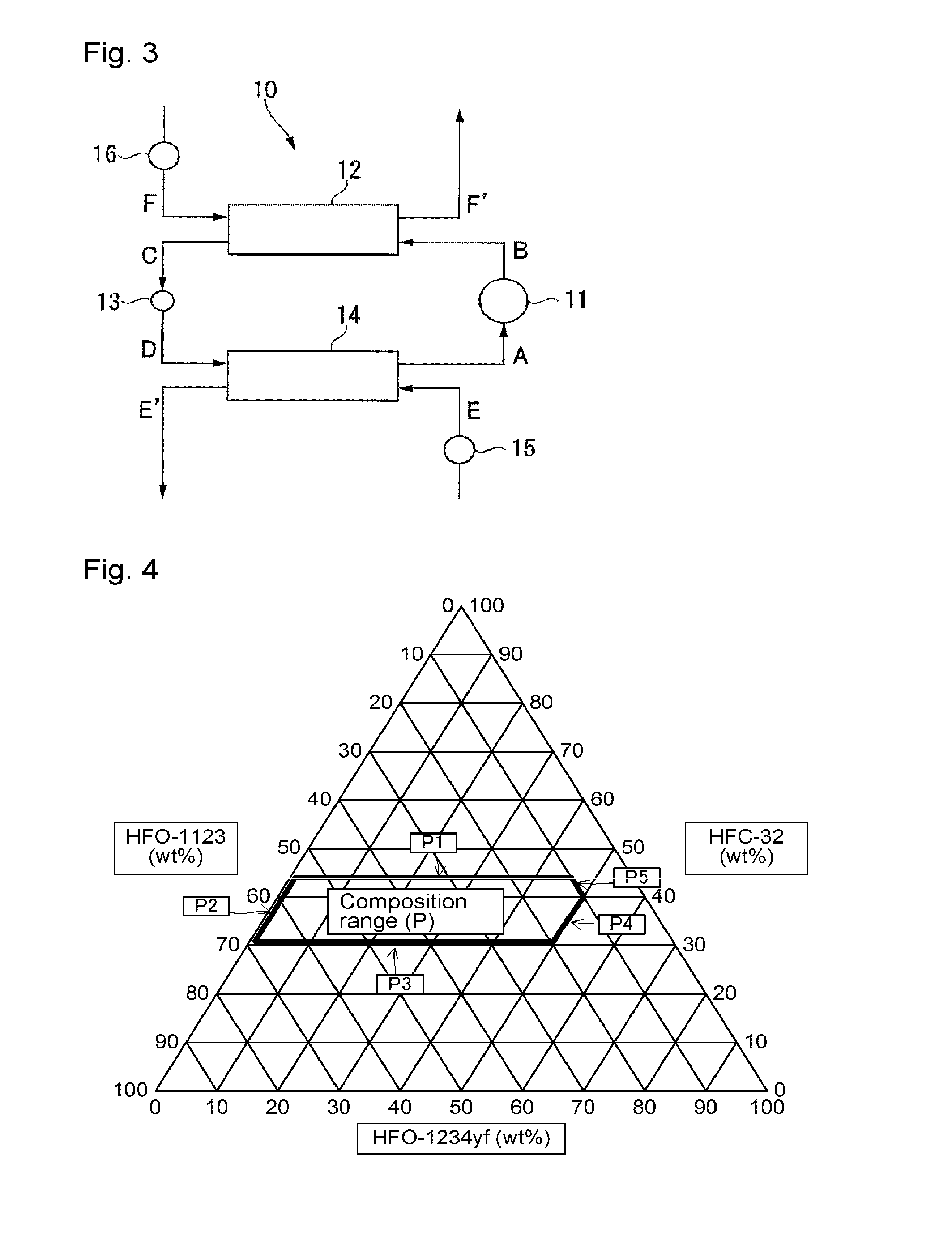

To provide a working fluid for heat cycle containing 1,2-difluoroethylene, which has high stability, and which has cycle performance sufficient as an alternative to R410A (a pseudoazeotropic mixture refrigerant of difluoromethane and pentafluoroethane in a mass ratio of 1:1) or 1,1,1,2-tetrafluoroethane while the influence over global warming is suppressed, a composition for a heat cycle system comprising it, and a heat cycle system employing the composition.A working fluid for heat cycle, which contains at least two members selected from a saturated hydrofluorocarbon and a hydrofluorocarbon having a carbon-carbon double bond other than 1,2-difluoroethylene, and 1,2-difluoroethylene.

Owner:ASAHI GLASS CO LTD

Environment-friendly safe solvent cleaning agent

InactiveCN103468434ANarrow distillation rangeHigh distillation recoveryNon-surface-active detergent solventsAlkaneWater based

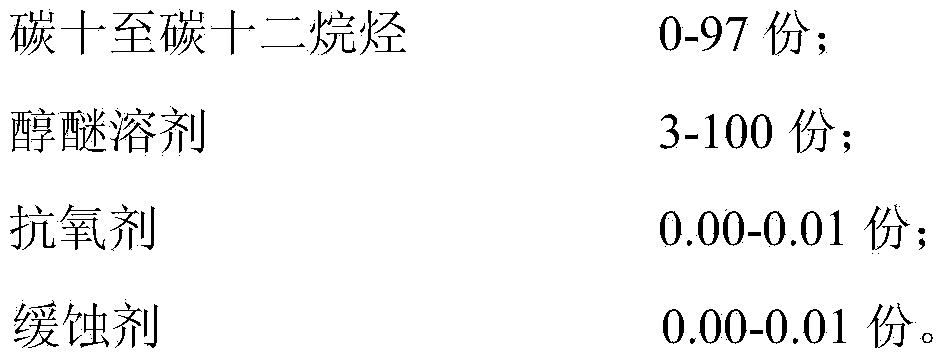

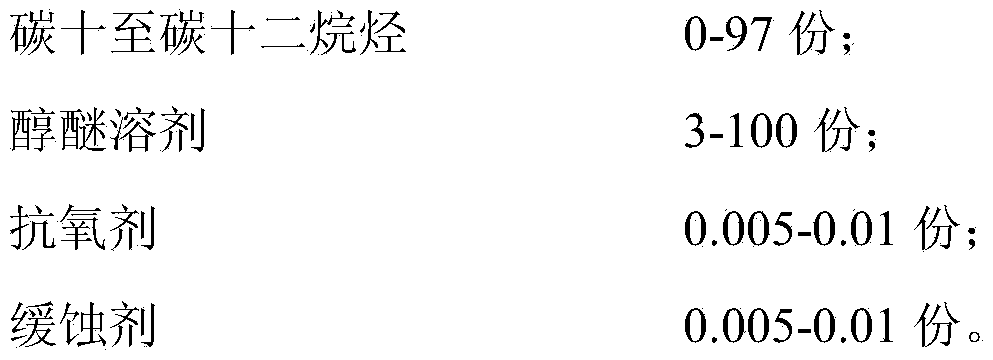

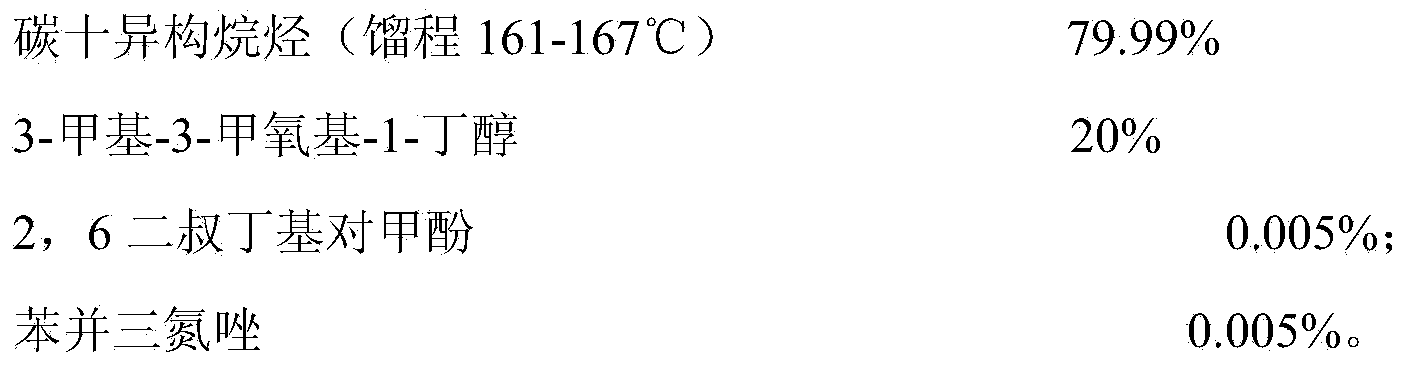

The invention relates to an environment-friendly safe solvent cleaning agent which specifically comprises the following components in parts by weight: 0-97 parts of C10-C12 alkanes, 3-100 parts of alcohol ether solvent, 0.00-0.01 part of antioxidant and 0.00-0.01 part of corrosion inhibitor. The environment-friendly safe solvent cleaning agent provided by the invention is narrow in boiling range and the distillation recovery rate of the environment-friendly safe solvent cleaning agent can be above 95%; the environment-friendly safe solvent cleaning agent is also high in clearing ability, and has strong cleaning ability for polar dirt and nonpolar dirt; especially, the environment-friendly safe solvent cleaning agent can be used for thoroughly cleaning various metal working fluids, and oil-based and water-based cutting fluids without any residual and corrosion on metals; moreover, the shortcoming that the previous hydrocarbon type cleaning agents are wide in boiling range and only capable of dissolving and cleaning the nonpolar dirt are overcome. The cleaning agent is perfect in balance of cleaning ability, safety, dryness and reproducibility.

Owner:TIANJIN PRIMETECH CHEM

Working fluid for heat cycle, composition for heat cycle system, and heat cycle system

ActiveUS20160333244A1Less influencePractically sufficient cycle performanceHeat-exchange elementsWorking fluidMetal working fluid

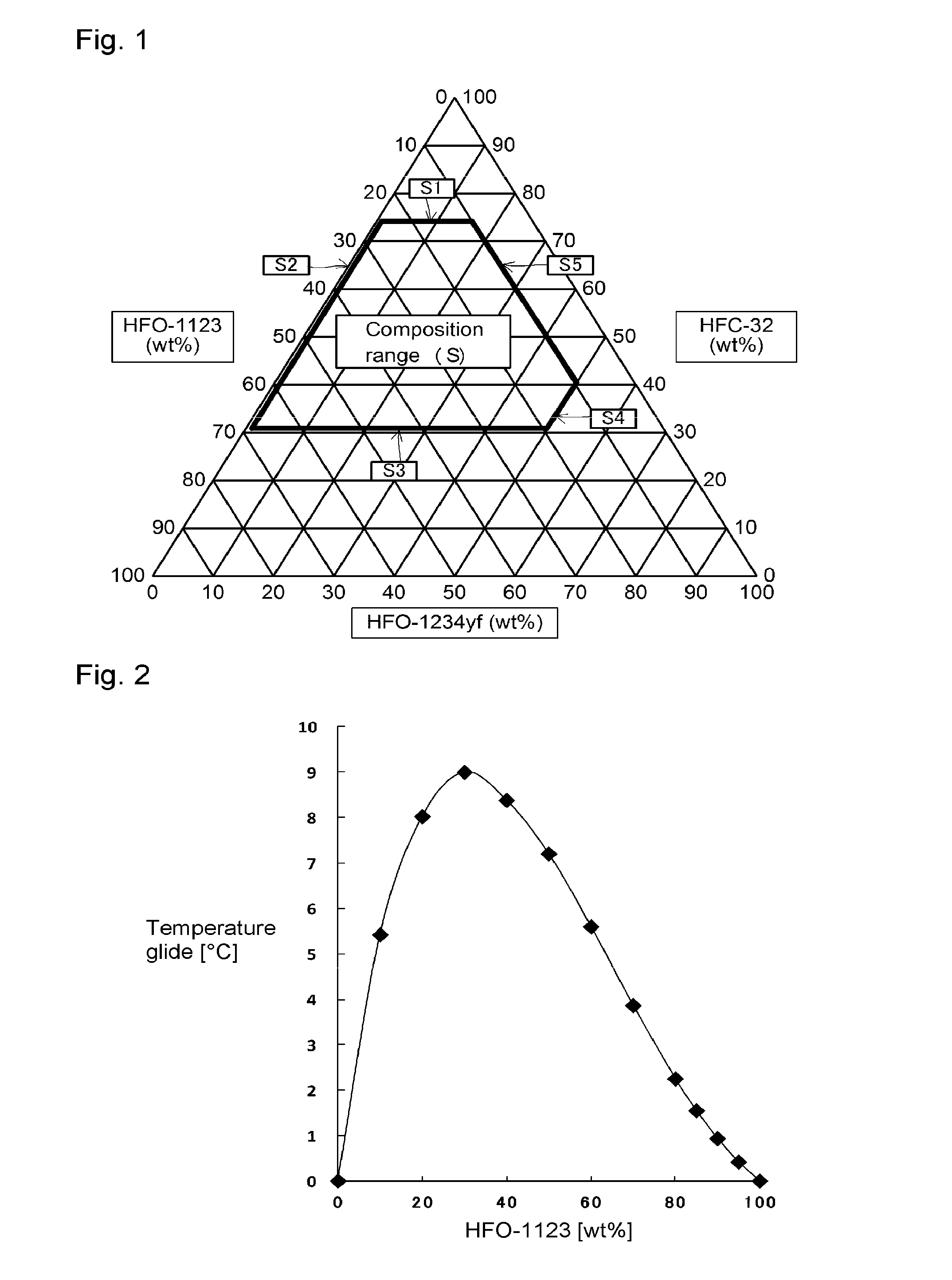

To provide a working fluid for heat cycle having a low global warming potential and having high durability, which can replace R410A, a composition for a heat cycle system comprising it, and a heat cycle system employing the composition.A working fluid for heat cycle, which contains trifluoroethylene, 2,3,3,3-tetrafluoropropene and difluoromethane, wherein the proportion of the total amount of trifluoroethylene, 2,3,3,3-tetrafluoropropene and difluoromethane based on the entire amount of the working fluid is higher than 90 mass % and at most 100 mass %, and based on the total amount of trifluoroethylene, 2,3,3,3-tetrafluoropropene and difluoromethane, the proportion of trifluoroethylene is at least 10 mass % and less than 70 mass %, the proportion of 2,3,3,3-tetrafluoropropene is at most 50 mass %, and the proportion of difluoromethane is higher than 30 mass % and at most 75 mass %.

Owner:ASAHI GLASS CO LTD

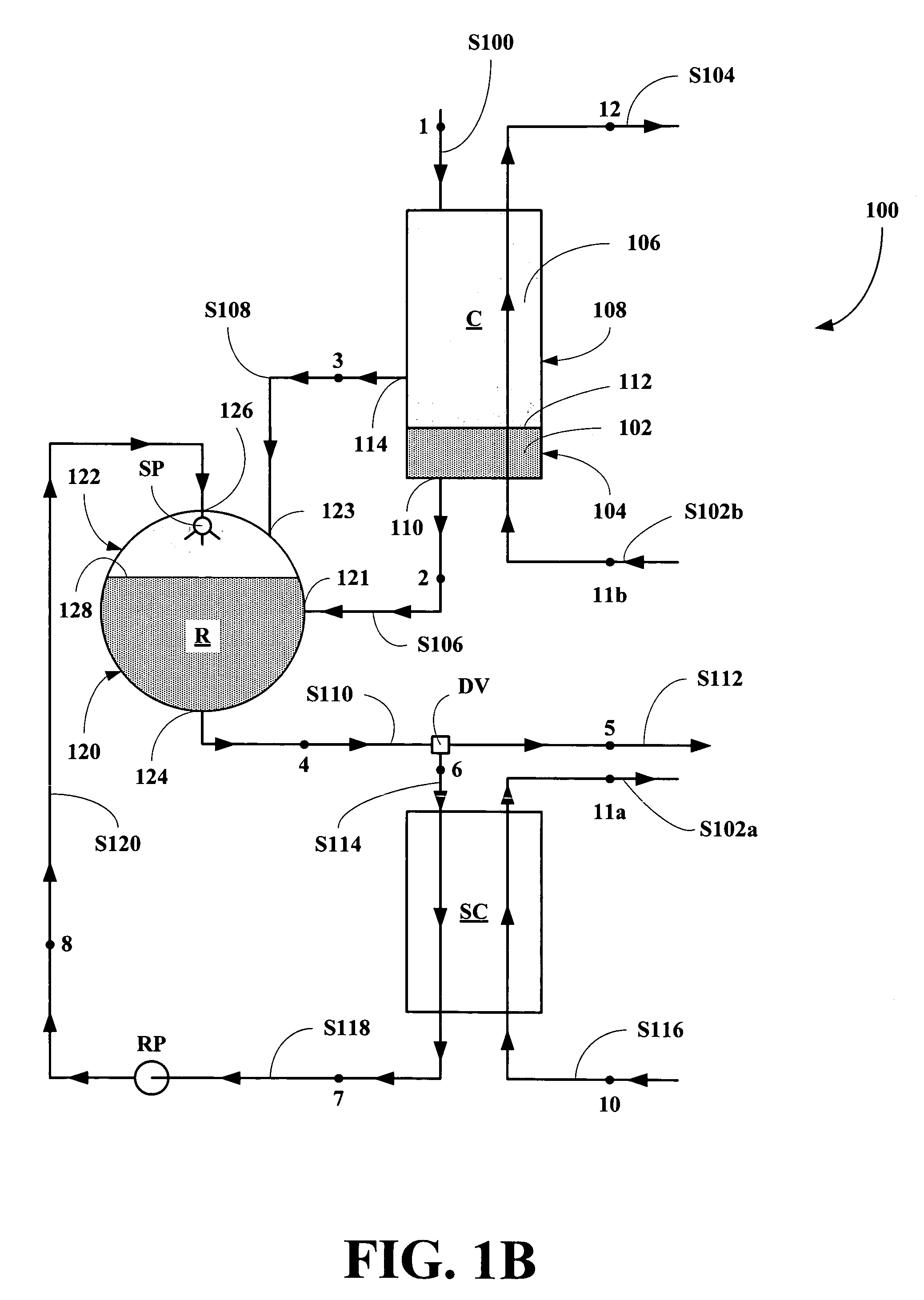

System and apparatus for complete condensation of multi-component working fluids

InactiveUS7600394B2Improve efficiencyImprove stabilitySolidificationLiquefactionWorking fluidMetal working fluid

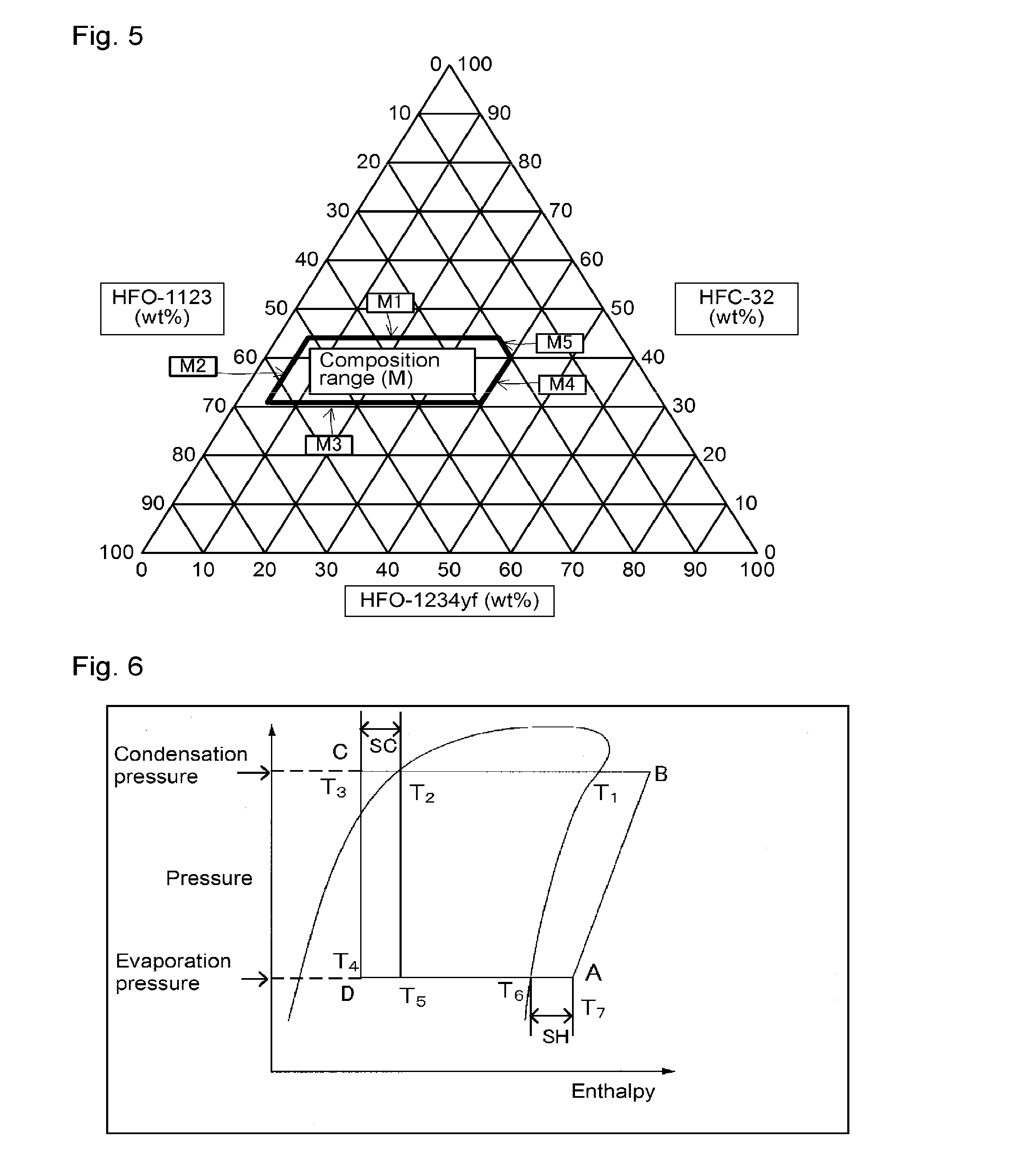

A condensation system is disclosed where a multi-component fluid is condensed to form a condensate, a portion of which is sub-cooled and mixed with non-condensable vapor in the system to reduce the accumulation of non-condensable vapor and to improve the stability and efficiency of the condensation system.

Owner:KALINA POWER LTD

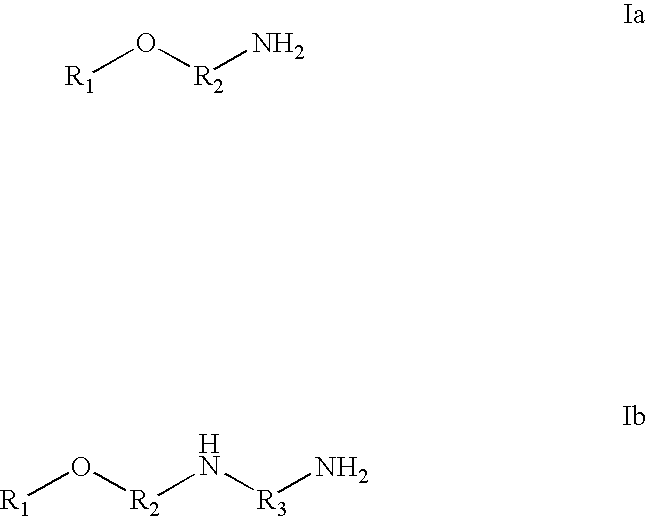

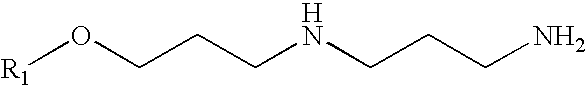

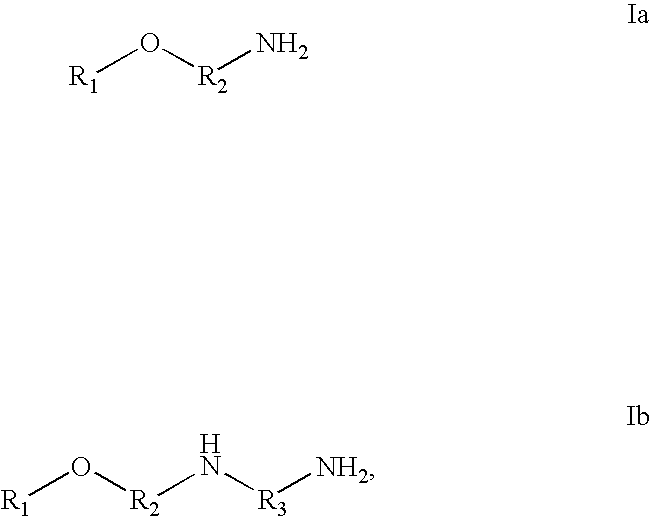

Water soluble metal working fluids

InactiveUS6706670B2Simple compositionReduce the temperatureOrganic chemistryWork treatment devicesMetal working fluidPhysical chemistry

This invention relates to novel water soluble metal working fluid compositions, their use to work metal, a process for working metal using such compositions and the metal worked article of manufacture. More particularly, this invention relates to fluid compositions useful in cutting, grinding, shaping and other metal working operations which require a lubricant. The terms "first Group A" and "second Group B" are used herein to denote different groups and not to indicate any sequence of use or selection as any possible combination or sequence of use of a component(s) is envisioned without limit of any kind. The disclosed fluid compositions are also anticorrosive and environmentally more acceptable than current oil based fluids. There has now been discovered an essentially odorless, substantially non-oil misting, water-soluble metal working fluid comprising at least one component selected from a first Group A herein and optionally one or more components selected from a second Group B herein preferably with the balance of the composition being water and other (optional) minor ingredients. When a component is employed from Group A and a component is employed from Group B the action of the combination generally enhances performance of the resulting combination with contain moieties from both Group A and Group B.

Owner:SOLUTIA INC

Breakdown fluid and preparation method thereof

The invention relates to a breakdown fluid and a preparation method thereof. The breakdown fluid comprises the following components: thickener 0.3-1.2%, clay stabilizer 0.5-2%, bactericide 0.01-0.2%, cleanup additive 0.2-1%, and the balance of water-borne working fluid, wherein the thickener is a betaine-type amphoteric thickener based on guar gum derivatives and has a structural formula (I): wherein R is selected from hydroxylpropyl group, hydroxyethyl group, carboxymethyl group and 2-hydroxylpropyl-N,N,N-trimethyl group; R1 and R2 independently represent C1-C4 alkyl group, R3 represents carboxylate radical COO<-> or sulfonate radical SO3<->; and the degree of substitution of R is 0.02-0.6, and the degree of substitution of the betaine type amphoteric ions is 0.02-0.6.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Use of triazoles in reducing cobalt leaching from cobalt-containing metal working tools

A method using one or more of certain triazoles in an amount effective to reduce cobalt leaching during a metal working process from a metal working tool comprising cobalt, such as tungsten carbide particles bonded by cobalt, wherein the one or more triazoles comprise at least butyl-benzotriazole, and optionally one or more other benzotriazoles. Also, a composition is provided which comprises a metal working fluid and one or more of these triazoles in an amount effective to reduce cobalt leaching from metal working tools comprising cobalt, such as tungsten carbide particles bonded by cobalt.

Owner:WINCOM

Ionic liquid stabilizer compositions

InactiveUS20100200799A1Improve stabilityAvoid instabilityOther chemical processesLighting and heating apparatusWorking fluidMetal working fluid

The present invention relates to compositions comprising at least one ionic liquid and at least one fluoroolefin. Such compositions may be useful as low GWP working fluids. These compositions have a variety of utilities in working fluids, which include for example, blowing agents, solvents, aerosol propellants, fire extinguishants, sterilants or heat transfer mediums (such as heat transfer fluids and refrigerants for use in refrigeration systems, refrigerators, air conditioning systems, heat pumps, chillers, and the like).

Owner:EI DU PONT DE NEMOURS & CO

Ionic liquid stabilizer compositions

InactiveUS20110005723A1Improve stabilityAvoid instabilityOther chemical processesIndirect heat exchangersWorking fluidMetal working fluid

The present invention relates to compositions comprising at least one ionic liquid and CF3I; and mixtures thereof. Such compositions may be useful as low GWP working fluids. These compositions have a variety of utilities in working fluids, which include for example, blowing agents, solvents, aerosol propellants, fire extinguishants, sterilants or heat transfer mediums (such as heat transfer fluids and refrigerants for use in refrigeration systems, refrigerators, air conditioning systems, heat pumps, chillers, and the like).

Owner:EI DU PONT DE NEMOURS & CO

Drainage pavement asphalt modifier with improved viscosity and method for preparing same

Disclosed is a tar modifier which comprises: 1) 100 shares weight star styrene butadiene styrene compound block copolymer base material, wherein the styrene monomer is 15 to 50 weight percentage, andthe molecular weight of copolymer is 50000 to 300000; 2) 10 to 60 shares weight sticking resin; 3) 5 to 70 shares weight at least one from aromatic radical metal working fluid, paraffinic base metal working fluid, mining metal working fluid, liquid polymer metal working fluid or fat metal working fluid; wherein the compound block copolymer comprises 1) 40 to 100 weight percentage star styrene butadiene styrene block copolymer with 2 to 6 branches, 2) 0 to 40 weight percentage linear styrene butadiene styrene block copolymer, 3) 0 to 30 weight percentage multi block styrene butadiene styrene copolymer and 4) 0 to 10 weight percentage styrene butadiene double block copolymer.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD +1

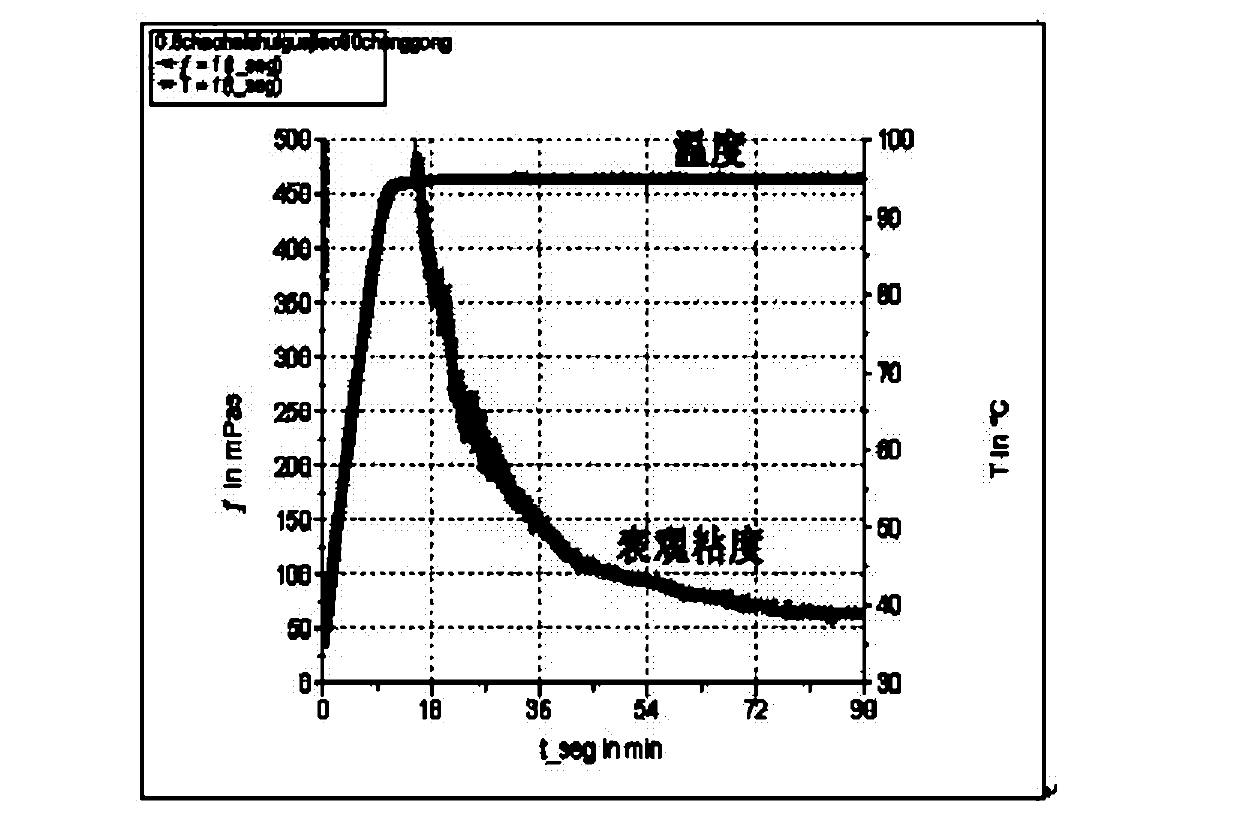

Wellbore servicing fluid comprising a cellulose ether

A cellulose ether having (i) one or more substituents selected from the group consisting of methyl, hydroxyethyl and hydroxypropyl, (ii) one or more hydrophobic substituents, and (iii) one or more cationic, tertiary amino, or anionic substituents, and having a retained dynamic viscosity, % η80 / 25, of at least 30 percent, wherein % η80 / 25=[dynamic solution viscosity at 80° C. / dynamic solution viscosity at 25° C.]×100, the dynamic solution viscosity at 25° C. and 80° being measured as 1% aqueous solution, is useful for modifying the viscosity of a composition selected from the group consisting of wellbore servicing fluids, cementitious formulations, ceramics, metal working fluids and cutting fluids.

Owner:UNION CARBIDE CORP

Environment-friendly emulsion cutting oil with high lubricity and high permeability for metal working

ActiveCN102250673ANo stimulationLittle mechanical pollutionLubricant compositionEmulsionMetal working fluid

The invention discloses an environment-friendly emulsion cutting oil with high lubricity and high permeability for metal working. The emulsion cutting oil is composed of a polymer carboxylic acid, an amine, a surfactant, mineral oil, a synthetic lubricant, a defoamer and an anti-corrosive agent. The emulsion cutting oil disclosed by the invention causes small pollution during processing, has excellent lubricity and permeability, and is safe to human and environment.

Owner:QIDONG YUSHIRO CHEMICAL INDUSTRY CO LTD +1

Salt resistant high-temperature resistant solid-free environment-friendly well drilling and completing integrated working fluid

The invention discloses a salt resistant high-temperature resistant solid-free environment-friendly well drilling and completing integrated working fluid. Every cubic meter of the solution comprises the following components by mass: 10-260 kg of formate, 0.5-0. 6 kg of tackifier, 3.0-4.0 kg of fluid loss additive, 2.0-3.0 kg of oil layer protectant, 2.0-3.0 kg of polyol anti-sloughing agent and the balance water. The well drilling and completing integrated working fluid has scientific and reasonable formula and is a salt resistant high-temperature (230 DEG C) resistant solid-free degradable environment-friendly novel working fluid, overcomes the defects of the prior art, has good rheological property, low shear force value, low system filtration loss, good compatibility and low cost and is environment-friendly.

Owner:北京千永科技股份有限公司

High-performance environmentally-friendly semisynthetic water-soluble metal working fluid

ActiveCN102250676AExtended service lifeImprove the lubrication effectLubricant compositionMetal working fluidSynthetic Polymeric Macromolecules

The invention discloses a high-performance environmentally-friendly semisynthetic water-soluble metal working fluid which is composed of an organic acid, organic amine, a corrosion inhibitor, a synthetic lubricant, a surfactant, water and a defoaming agent. By compounding the organic acid, organic amine and a specially modified synthetic polymer compound used as the lubricant with multiple corrosion inhibitors, an anticorrosion agent and the surfactant, the product has excellent lubrication property and penetration property, and can be used for greatly improving the surface finish degree and prolonging the service life of a cutter; the product has the advantages of good impure oil resistance, sterilization and corrosion prevention properties and obviously prolonged service life of the product; the product is a stable semisynthetic liquid, and can provide cooling property and cleaning property better than emulsion; and the product is environmentally-friendly, and is the high-performance environmentally-friendly semisynthetic water-soluble metal working fluid.

Owner:QIDONG YUSHIRO CHEMICAL INDUSTRY CO LTD

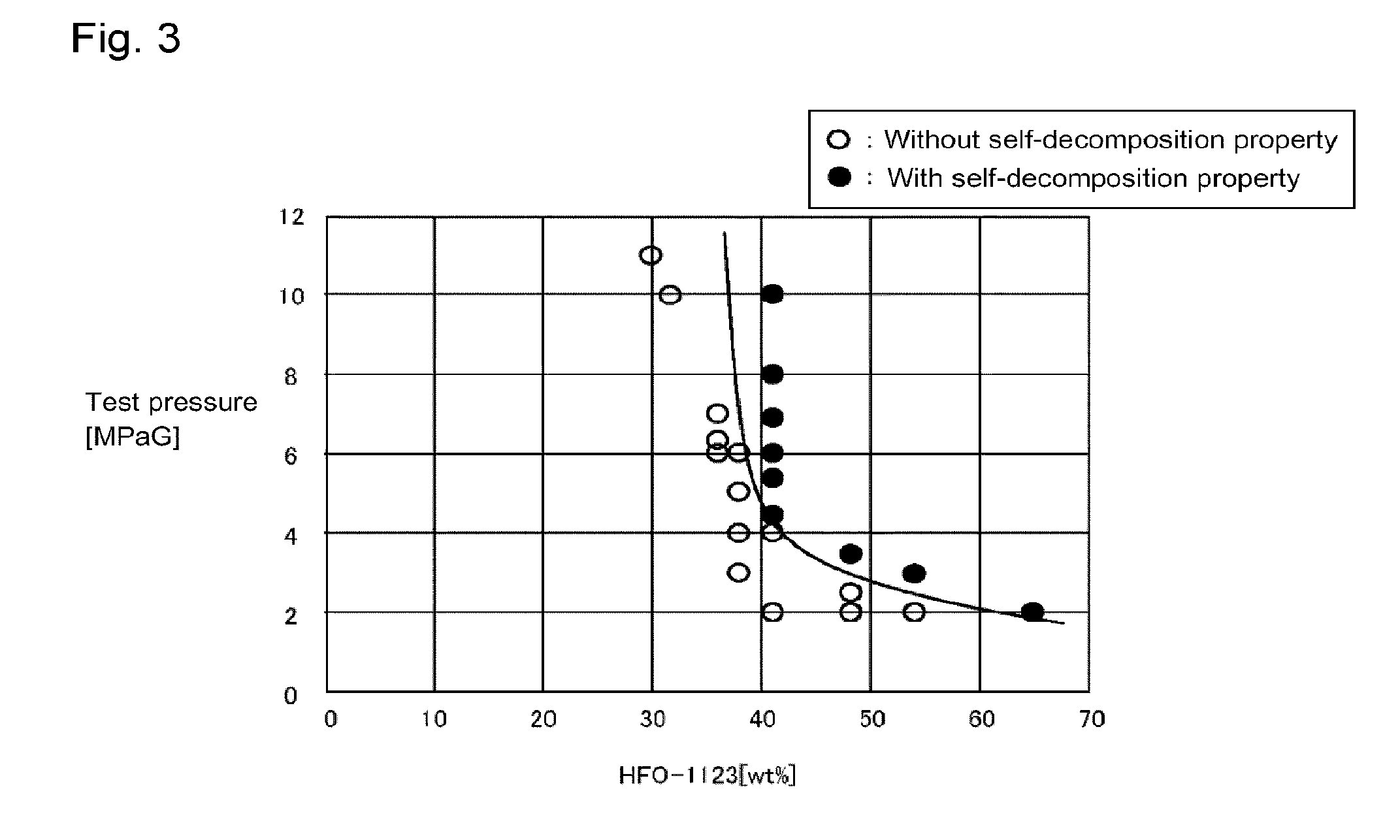

Working fluid for heat cycle, composition for heat cycle system, and heat cycle system

ActiveUS20160369145A1Increased durabilityPractical cycle performanceCompressorCompression machines with non-reversible cycleWorking fluidDecomposition

A working fluid for heat cycle which has a low global warming potential and which has self-decomposition property suppressed, a composition for a heat cycle system comprising it, and a heat cycle system employing the composition.A working fluid for heat cycle, which contains trifluoroethylene and 2,3,3,3-tetrafluoropropene, wherein the proportion of the total amount of trifluoroethylene and 2,3,3,3-tetrafluoropropene based on the entire amount of the working fluid is higher than 90 mass % and at most 100 mass %, and the proportion of trifluoroethylene based on the total amount of trifluoroethylene and 2,3,3,3-tetrafluoropropene is at least 21 mass % and at most 39 mass %, a composition for a heat cycle system, which comprises the working fluid for heat cycle, and a heat cycle system, which employs the composition.

Owner:ASAHI GLASS CO LTD

Esters for drilling emulsions and metal working fluids

ActiveUS20150210914A1Improved filtrate propertyStable rheologyTransportation and packagingMixingAlcoholEmulsion

The present invention relates to an emulsion comprising at least (a) an organic phase, (b) a water phase and (c) an ester based on an ether carboxylic acid and an alcohol. Also within the ambit of the invention is the use of an ester as defined in (c) as emulsifier, as a thickening agent and / or as an anti-foaming agent in particular in drilling emulsions and metal working fluids.

Owner:EMERY OLEOCHEMICALS GMBH

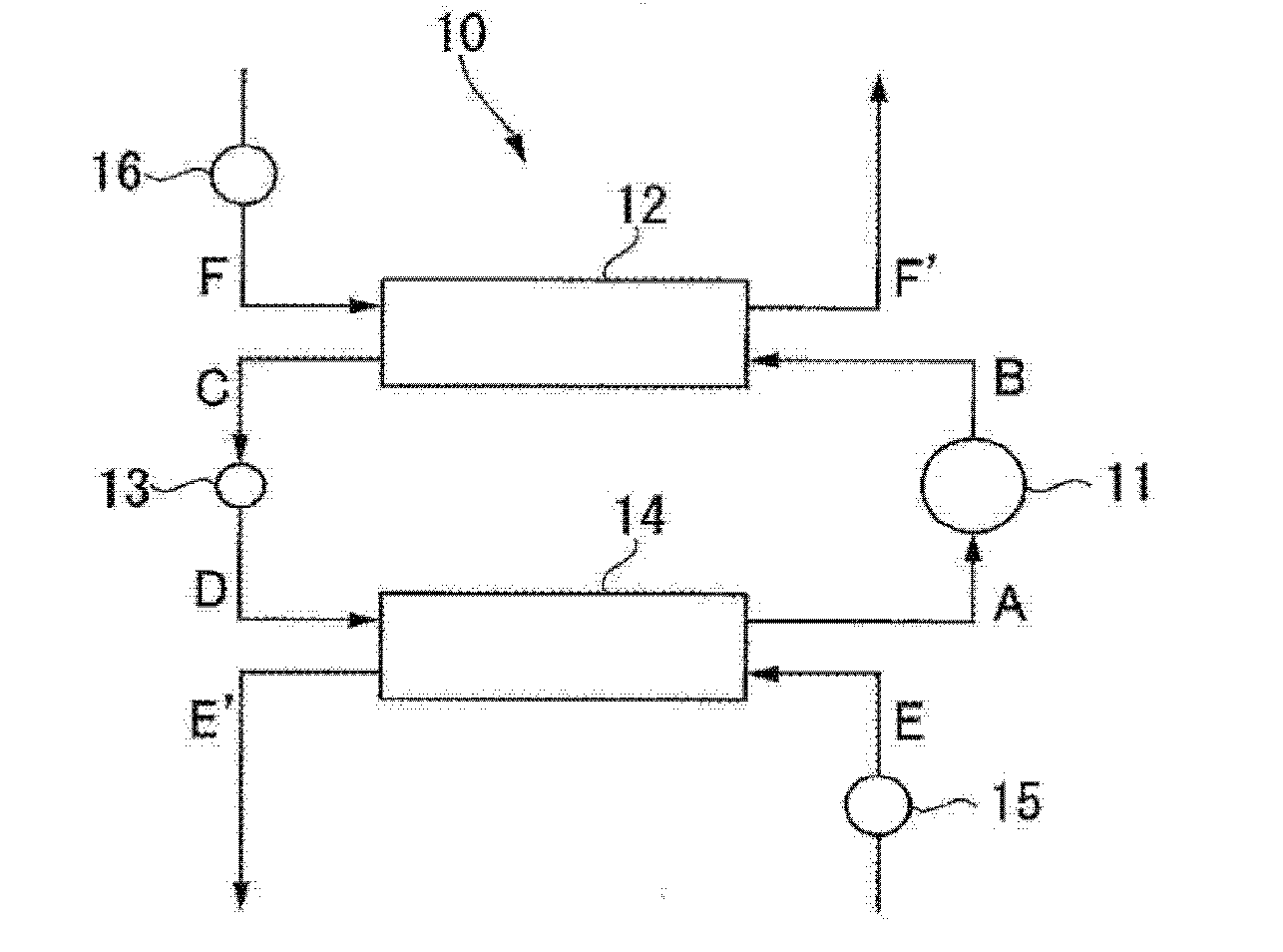

Apparatus and method for sampling and correcting fluids

InactiveUS20070202603A1Eliminates “ guess work ”Withdrawing sample devicesBiological testingMetal working fluidEngineering

The present invention provides an apparatus and method for sampling a metal working fluid and dispensing a corrective fluid to adjust the fluid in a tank or reservoir from which the sample was drawn. The apparatus, which in certain embodiments is transportable, includes an inlet configured to receive a fluid sample from a reservoir, a measuring station configured to determine at least one parameter of the fluid sample, a dispensing station configured to select a type and amount of fluid(s) to be added to the metal working fluid to restore its desired parameters, and an outlet configured to dispense the corrective fluid. The inventive apparatus provides an advantageous computerized comparison of the contaminates and concentrations of key constituents in a sample fluid against desired operating parameters and dispenses a corrective fluid, which, when added to the reservoir from which the sample fluid was drawn, corrects the adverse conditions of that fluid.

Owner:COUNTS STEVEN WAYNE

Organosilicon composition and preparation and application thereof

ActiveCN107115694AImprove dispersion uniformityImprove stabilityFoam dispersion/preventionAdditive ingredientMetal working fluid

The invention relates to an organosilicon composition and preparation and application thereof and belongs to the technical field of fine chemical preparations. The invention is characterized in that the prepared organosilicon composition is composed of organosilicon active matter, polyether modified polysiloxane, saturated polyether and silicon dioxide. A preparation method comprises the following steps: (1) an organosilicon composition and saturated polyether are uniformly mixed to obtain a mixture I; (2) silicon dioxide and saturated polyether are uniformly mixed to obtain a mixture II; (3) after specific polyether modified polysiloxane is synthesized, the mixture I is added into polyether modified polysiloxane to obtain a mixture III; and (4) the mixture II is added into the mixture III so as to obtain the stable organosilicon composition. The prepared organosilicon composition is stable. The disadvantage that all the ingredients are not compatible with each other is solved. The organosilicon composition, as an internal additive, is applied to industrial auxiliary agents, such as a metal working fluid, a textile auxiliary agent, an industrial cleaning agent and the like. The organosilicon composition has excellent compatibility and antifoaming performance.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

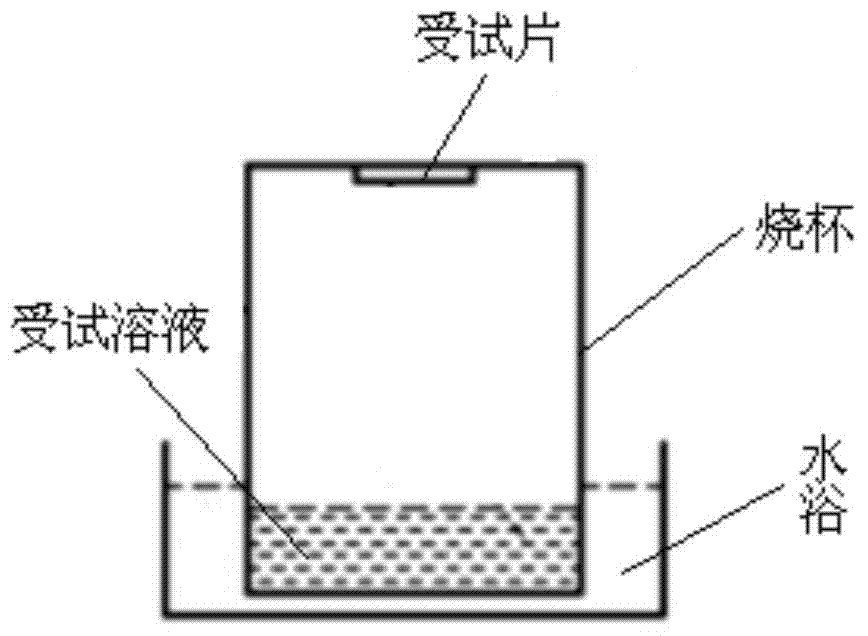

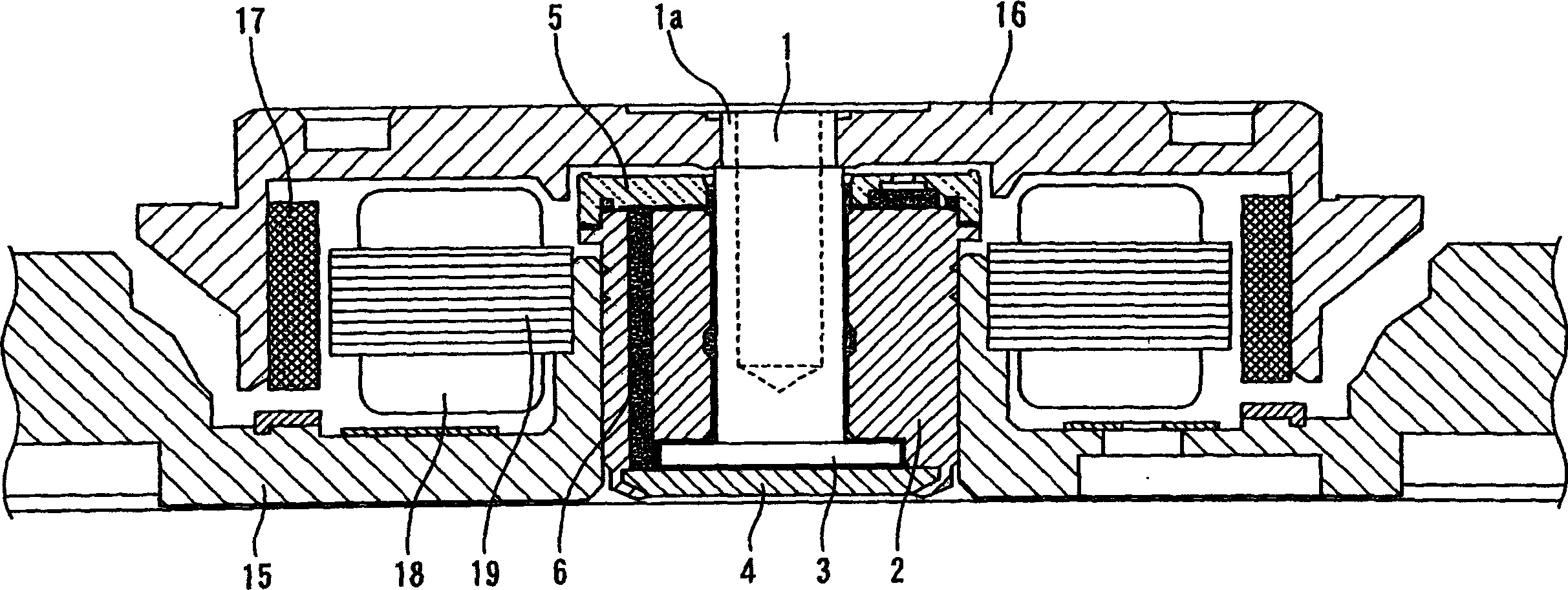

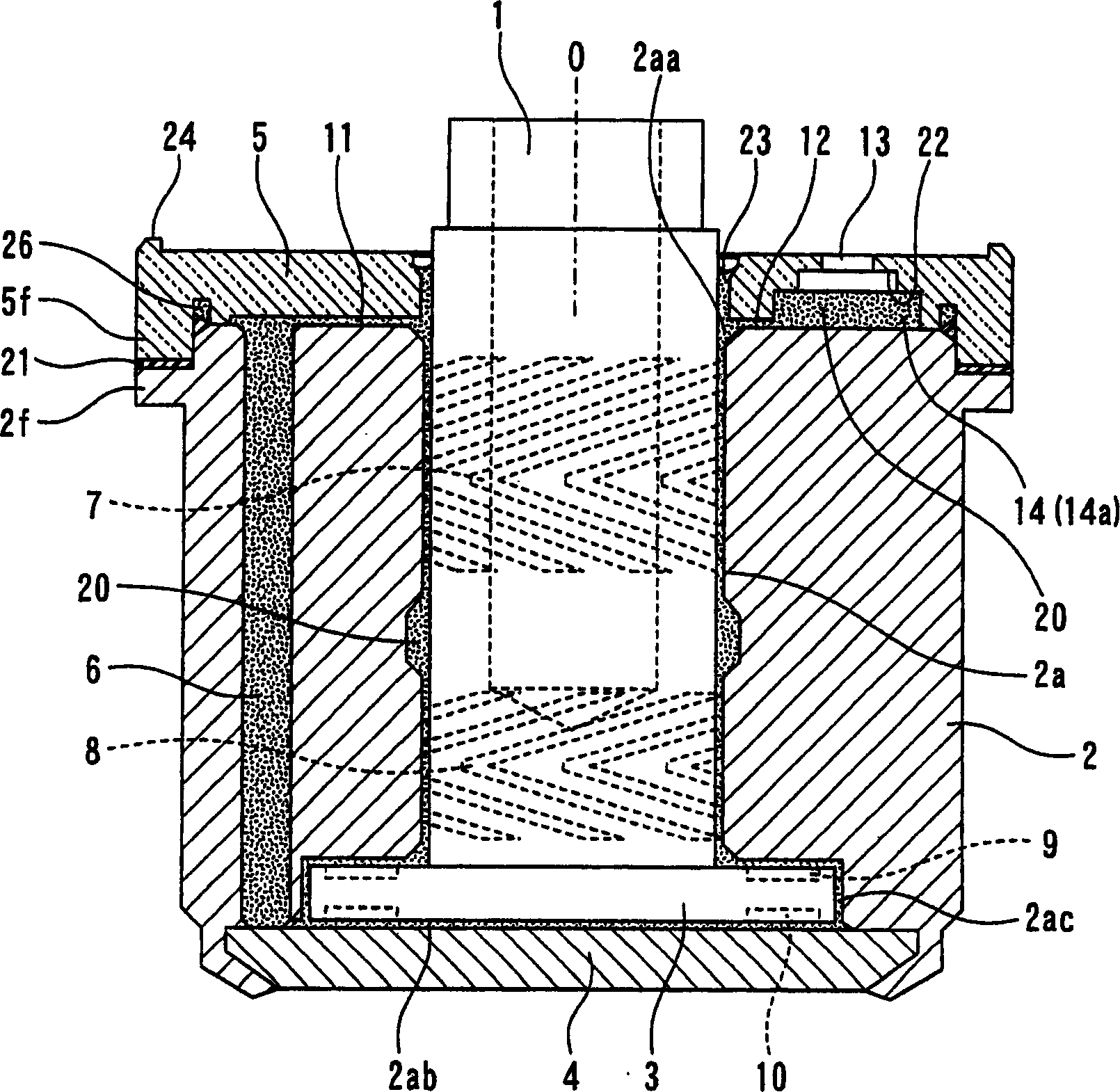

Hydrodynamic bearing device and inspection method of amount of working fluid

InactiveCN1789738AManagement lifespanAdjust lifeShaftsBearing componentsWorking fluidMetal working fluid

The present invention provides a fluid bearing device and a method for inspecting the amount of working fluid. In a fluid bearing device with a cover plate (5) covering a shaft sleeve (2), it can be easily confirmed that the working fluid is well filled in the cover plate and the shaft sleeve. between them, and it can be easily confirmed that the adhesive bonding the cover plate and the bushing is well filled. A translucent material is used as the cover plate, and the filling state of the working fluid can be easily confirmed visually or by an imaging member through the cover plate.

Owner:PANASONIC CORP

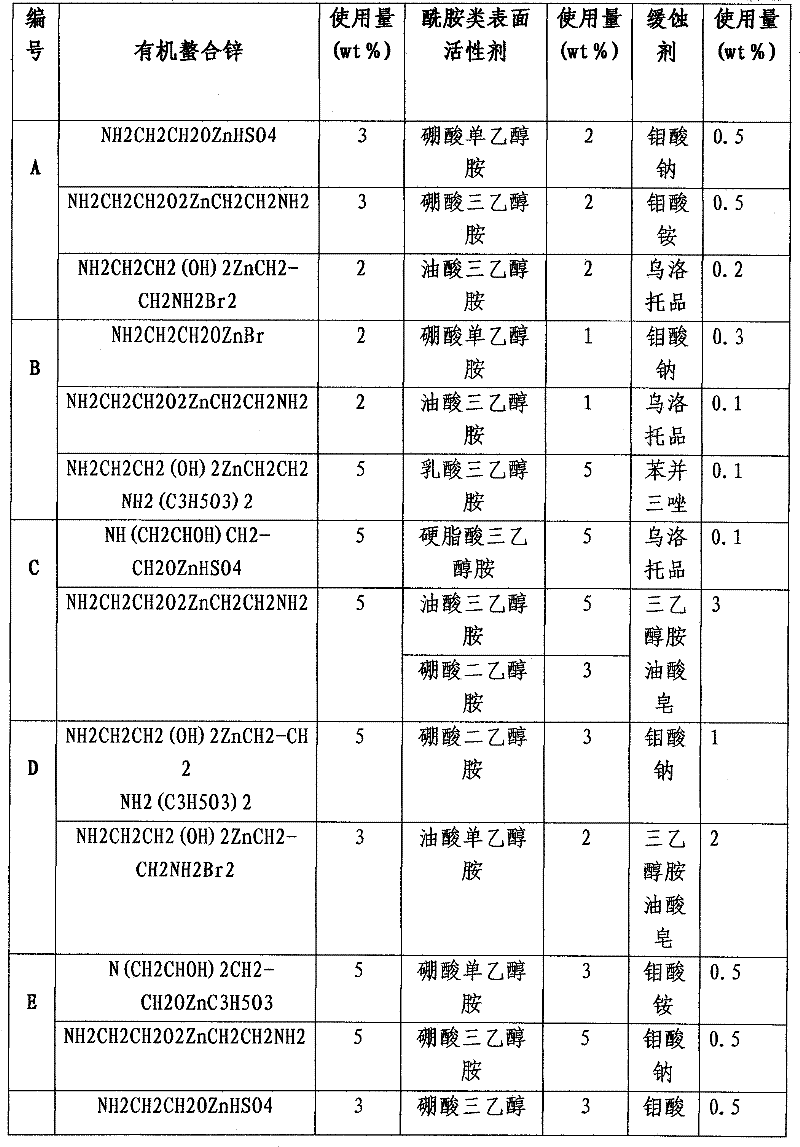

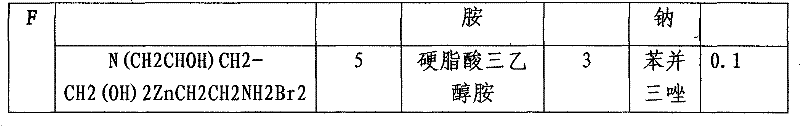

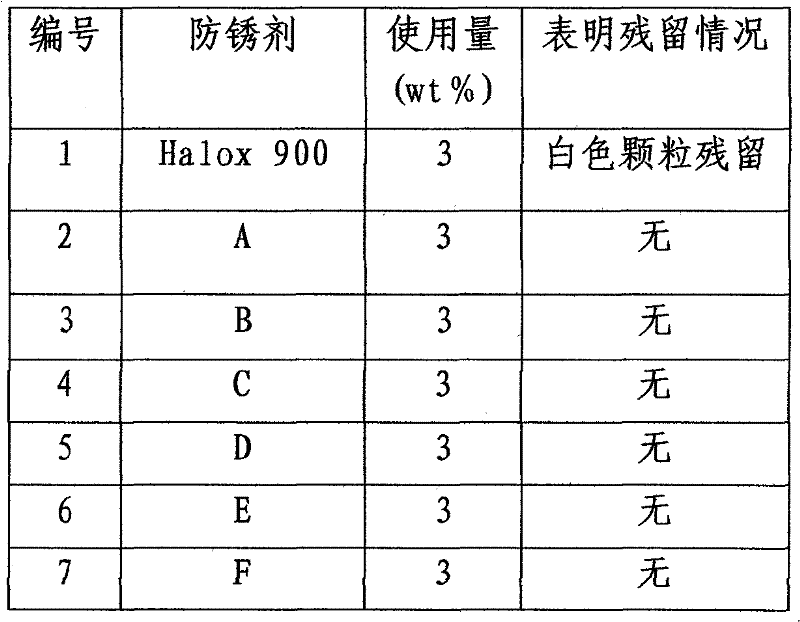

A new type of water-based rust inhibitor

The invention discloses a novel water-based rust inhibitor and a preparation method and a use method thereof, belonging to the technical field of metal material corrosion prevention. The rust inhibitor can substitute for antirust oil and grease to prevent rust in the inter-process of metal processing and store and prevent rust of finished products, and also can be used as antirust additive of metal working fluid such as metal cutting fluid, grinding fluid, washing agent and the like, so as to reduce the antirust cost in metal processing and storage and conveying processes. The rust inhibitor is obtained by adopting the following technical scheme: combining 5-15wt% of organic zinc chelate, 5-10wt% of amide-type surfactant and 1-5wt% of water-soluble antirust additive.

Owner:JIANGSU XINLU NEW MATERIALS CO LTD

Synergistic antimicrobial mixtures

A broad spectrum antimicrobial composition consisting essentially of an iodopropynyl compound in combination with a benzimidazole and a metal borate is disclosed. The composition can be used to protect industrial systems against microbial growth and, more particularly, to protect substrates such as paints, coatings, stucco, concrete, stone, cementaceous surfaces, wood, wood-plastic composites, caulking, sealants, textiles, leather, wood, preservatives, metal working fluids, drilling muds, clay slurries, glazes, optical brighteners, carpet backing, and pigments against microbial growth. The composition can be used as a preservative for aqueous products.

Owner:GAGLANI KAMLESH +1

Long-life high-load metal working fluid and preparation method thereof

ActiveCN105462662AIncrease polarityGood storage stabilityAdditivesBase-materialsMetal working fluidRapeseed

The invention discloses a long-life high-load metal working fluid and a preparation method thereof. At least one of polyol ester, II type hydrogenated oil, epoxidized soybean oil and epoxidized rapeseed oil is taken as base oil, an emulsification lubricant, an extreme pressure agent, a preservative, an anti-rusting agent, an oil-water balance agent, an aid and a defoaming agent are added, and the metal working fluid is prepared. The prepared metal working fluid has a good lubricating extreme pressure property, is long in anti-rusting period and service life, belongs to an environment-friendly metal working fluid and can meet the working environment under high-load conditions of drilling, tapping, reaming and the like of cast iron, carbon steel, stainless steel, aluminum alloys and other materials, and the production efficiency is greatly improved.

Owner:NEUFTECH BIOTECH HEFEI

Tall oil acid diacetyl amide borate and preparation method thereof

ActiveCN104193774APrevent or minimize direct contactReduce direct contactGroup 3/13 element organic compoundsAdditivesMetal working fluidHard water

The invention relates to a tall oil acid diacetyl amide borate which is prepared from the following components in percentage by weight: 40-65% of tall oil fatty acid, 30-45% of diethanolamine, 3.2-12.5% of boric acid and 1.8-2.5% of catalyst. The invention also relates to a formula and preparation method of the tall oil acid diacetyl amide borate. The components proportionally react according to the steps to prepare the tall oil acid diacetyl amide borate. The tall oil acid diacetyl amide borate can be directly diluted and used as a cutting fluid in metal working. The product has the advantages of favorable lubricating property, favorable rust resistance and favorable hard water resistance.

Owner:德旭新材料(广州)股份有限公司

Method for preparing multifunctional environmentally-friendly boric acid ester surfactant

The invention relates to a method for preparing a multifunctional environmentally-friendly boric acid ester surfactant. The method comprises the following steps of: mixing high-grade fatty acid with a polyatomic alcohol amine compound in the mass ratio of 1.0:(1.3-2.4), putting the mixture into an electrothermal reaction kettle, and reacting under the action of a catalyst at the temperature of 120-175 DEG C for 2-5 hours to obtain an alcohol amine intermediate; and uniformly mixing the alcohol amine intermediate obtained in the first step with boric acid in the mass ratio of 1.0:(0.04-0.1); reacting at the temperature of 110-150 DEG C for 1-2 hours, and cooling to obtain a multifunctional environmentally-friendly boric acid ester surfactant product. Due to the adoption of a preparation process, organic solvents such as methylbenzene, dimethylbenzene and the like are not taken as water-carrying agents, nitrogen protection is not required in the entire synthesizing process, and waste water, waste gas, pollutants and the like are not discharged in the producing and using processes; and the boric acid ester surfactant is an environmentally-friendly water-based metal working fluid additive.

Owner:韶关市广化科技有限公司

Antimicrobial metal working fluids

ActiveUS7595288B2Reduced tool wearWork fasterBiocideLiquid carbonaceous fuelsMetal working fluidMetal working

Owner:HENKEL KGAA

Solidified water temporary plugging well-killing working fluid and preparation method and draining method thereof

ActiveCN106833572AEasy to prepareSimple preparation processDrilling compositionSealing/packingWell killWorking fluid

The invention provides solidified water temporary plugging well-killing working fluid. The solidified water temporary plugging well-killing working fluid is prepared from 10 to 40 percent of solidified water system and 60 to 90 percent of anti-swelling stabilizing fluid, wherein the solidified water system is prepared from the following components in percentage by mass: 1.1 to 1.5 percent of main agent, 0.3 to 0.5 percent of solidification initiator and the balance of water. The preparation method of the working fluid comprises the following steps: 1), taking the main agent in an amount determined in a formula; 2) taking the solidification initiator and the anti-swelling agent in amounts determined in the formula; 3) injecting clear water into a container in an amount determined in the formula, adding the main agent and the solidification agent initiator in amounts determined in the formula in sequence, and uniformly stirring to obtain the solidified water system; 4) adding the anti-swelling stabilizing fluid in an amount determined in the formula to obtain the solidified water temporary plugging well-killing working fluid. A draining method combining acidifying-demulsifying and liquid nitrogen drainage is adopted. The working fluid is simple in preparation process, a colloid protective agent is not needed, the plugging efficiency is increased greatly, the plugging cost is lowered, damage to strata is reduced, and the problems of coexistence of collapse and leakage and low reservoir protection performance in a gas well construction process are solved. The solidified water temporary plugging well-killing working fluid has important practical significance to increase of the oil gas exploration and development speeds.

Owner:PETROCHINA CO LTD

Synthetic multiple-effect lubricant additive and preparation method thereof

The invention relates to a synthetic multiple-effect lubricant additive and a preparation method thereof and in particular relates to a fully-synthetic multiple-effect lubricant additive which does not contain S and Cl and takes a metal processing lubricant as a main product. The fully-synthetic multiple-effect lubricant additive is a mixture containing glycerol single ricinoleate, a carboxylic acid synthetic ester lubricant, iso-tridecanol polyoxyethylene ether, an antirust agent, amine phosphate, a non-ferrous metal corrosion inhibitor and a carboxyl hexyl-2-cyclohexene-1-octadeca-carbonic acid. The fully-synthetic multiple-effect lubricant additive has the advantages of good wear resistance, good anti-rust performance, good synergy and environmental friendliness. The fully-synthetic multiple-effect lubricant additive is applicable to blending emulsified oil, micro-emulsifying liquid, fully-synthetic metal working fluid, metal rolling liquid and metal molding working fluid as well as lubricating oil products such as water-based fire-resistant hydraulic oil.

Owner:GUANGDONG AOLIDAN IND

Amine-free voc-free metal working fluid

The present application concerns an aqueous metalworking composition comprising in a concentrate or after dilution of a concentrate with water in a diluent: 0.002 to 40 % by weight of component (a) which is a lubricity agent comprising at least one water-insoluble compound (a) having at least one hydrophobic aliphatic chain and at least one polar group and having a water solubility at 20 DEG C of less than 0.1 g / liter; 0.002 to 40 % by weight of component (b)comprising at least one water-soluble corrosion inhibiting compound(b) having a water-solubility at 20 DEG C of more than 0.1g / liter; 0.002 to 45 % by weight of at least one emulsifying and dispersing agent(c)which contains at least one emulsifying and / or dispersing compound (c) which is water-soluble, water-miscible or water-dispersable and which is selected from the group consisting of non-ionic, anionic and zwitterionic surfactants; 0.002to 30 % by weight of an alkalinity agent (d) containing at least one alkaline water-soluble compound (d) selected from the group consisting of hydroxides and carbonates; and 0.004 to 99 % by weight of a transport component(e)containing predominantly water. Further on, the present application concerns a method of use of such aqueous metalworking composition as a coolant, as a lubricant, etc., and concerns further on a method to prepare an aqueous metalworking composition and a metalworking process.

Owner:CHEMETALLGMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com