Detection test paper for detecting benzoyl peroxide in flour and preparation method of detection test paper

A benzoyl peroxide, detection test paper technology, applied in material analysis by observing the effect on chemical indicators, analysis by chemical reaction of materials, color/spectral property measurement, etc., can solve the problem of relying on professional and technical personnel. , long cycle, low detection limit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

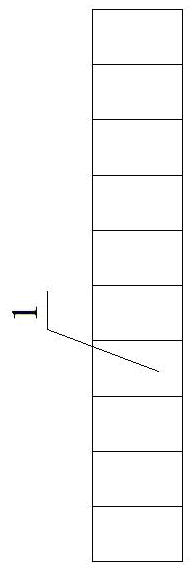

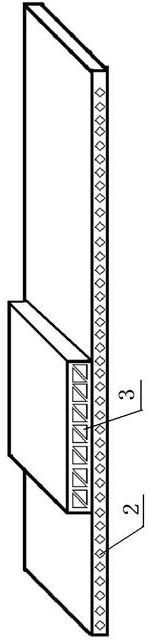

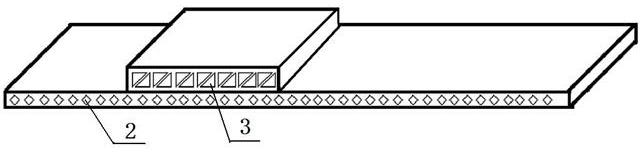

[0036] The preparation method of the detection test strip is as follows: immerse the color detection layer (3) in the mixed liquid of the color developer for 2-5 minutes, and then vacuum-dry it at 40-80° C. for 20-50 minutes.

[0037] The color developer mixed solution is composed of: 5%-10% potassium iodide, 0.2%-0.8% soluble starch, and 2%-8% sodium carbonate.

[0038] Described sodium carbonate is anhydrous sodium carbonate.

Embodiment 1

[0040] 1. Preparation of test paper: Preparation of mixed solution: 5% potassium iodide, 0.2% soluble starch, and 2% sodium carbonate are mixed evenly. Take a cellulose acetate film with good water absorption and immerse it in the color developer mixture for 2 minutes, take it out, put it in a vacuum at 40°C and dry it in the dark for 30 minutes, and cut the obtained dry test paper into 0.5cm 2 The small piece is pasted on the front end of the substrate. The substrate is made of PVC sheet, the length of the substrate is 8cm, and the width is 0.5cm 2 .

[0041] 2. Production of standard color card:

[0042] (1) Prepare benzoyl peroxide standard of 0mg / L, 12mg / L, 36mg / L, 60mg / L, 84mg / L, 108mg / L, 132mg / L, 156mg / L, 180mg / L, 228mg / L product solution, take different concentrations of benzoyl peroxide solution on the prepared detection test paper color layer to carry out color reaction.

[0043] (2) Measure the L*, a* and b* value data of the test paper with a color measuring ins...

Embodiment 2

[0047] 1. Preparation of test paper: Preparation of mixed solution: 10% potassium iodide, 0.8% soluble starch, and 8% sodium carbonate are mixed evenly. Take a cellulose acetate film with good water absorption and immerse it in the color developer mixture for 5 minutes, take it out, put it in a vacuum at 50°C and dry it in the dark for 20 minutes, and cut the obtained dry test paper into 0.8cm 2 The small piece is pasted on the front end of the substrate. The substrate is made of PVC sheet, the length of the substrate is 8cm, and the width is 0.8cm 2 .

[0048] 2. Production of standard color card:

[0049] (1) Preparation of peroxide containing concentration gradient 0mg / L, 12mg / L, 36mg / L, 60mg / L, 84mg / L, 108mg / L, 132mg / L, 156mg / L, 180mg / L, 228mg / L respectively For the benzoyl standard solution, benzoyl peroxide solutions of different concentrations are added to the prepared detection test paper color layer for color development.

[0050] (2) Utilize the computer Adobe Ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com