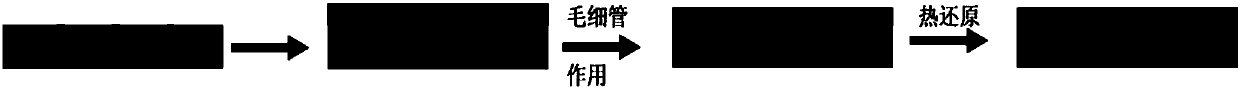

Preparation method of ordered nano fiber-based flexible graphene film by induction of capillary action

A capillary action, flexible graphite technology, used in fiber processing, plant fibers, textiles and papermaking, etc., can solve the problems of incompatibility with complex curved surfaces, difficult to accurately control thickness, and large influence on electrical conductivity, to improve physical interaction. Action and adhesion, good flexibility, workable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] a) Dissolve cellulose acetate in acetic acid with a concentration of 17wt.%, mix and stir evenly to obtain a spinning solution; at 29.5℃, humidity 20%, spinning voltage 25kV, receiving roller speed 2000rpm, injection needle flow rate 1.5 mL / h, when the receiving distance between the injection needle and the receiving roller is 15cm, electrospinning is performed, and the cellulose acetate film is obtained after drying;

[0023] b) Graphene oxide is prepared by the modified Hummers method, and purified and separated by a 3μm microporous membrane to obtain graphene oxide sheets of uniform size dissolved in water; the specific method for preparing graphene oxide by the Hummers method is: 1g graphite Mix powder and 0.05g sodium chloride, wash with water to remove sodium chloride, dry, add 23mL concentrated sulfuric acid and stir for 22h, add 6g potassium permanganate to the above solution, and keep the temperature at this time not exceeding 20℃, then heat up to The temperature ...

Embodiment 2

[0027] a) Dissolve cellulose acetate in acetic acid with a concentration of 17wt.%, mix and stir evenly to obtain a spinning solution; at 29.5℃, humidity 20%, spinning voltage 25kV, receiving roller speed 2000rpm, injection needle flow rate 1.5mL / h, the receiving distance between the injection needle and the receiving roller is 14cm for electrospinning, and the cellulose acetate film is obtained after drying;

[0028] b) Graphene oxide is prepared by the modified Hummers method, and purified and separated by a microporous filter membrane to obtain graphene oxide sheets of uniform size dissolved in water; the specific method for preparing graphene oxide by the Hummers method is: 1g graphite powder Mix with 0.05g sodium chloride, wash with water to remove sodium chloride, dry, add 23mL concentrated sulfuric acid and stir for 22h, add 6g potassium permanganate to the above solution, and keep the temperature at this time not exceeding 20℃, then heat up to 40 The temperature was kept...

Embodiment 3

[0033] a) The graphene conductive film in Example 1 is hot-pressed again, the hot-pressing condition is 180°C, the pressure is 2 standard atmospheres, and the hot-pressing time is 1800s;

[0034] b) Use a multimeter to test the resistance value of the graphene film under different bending degrees.

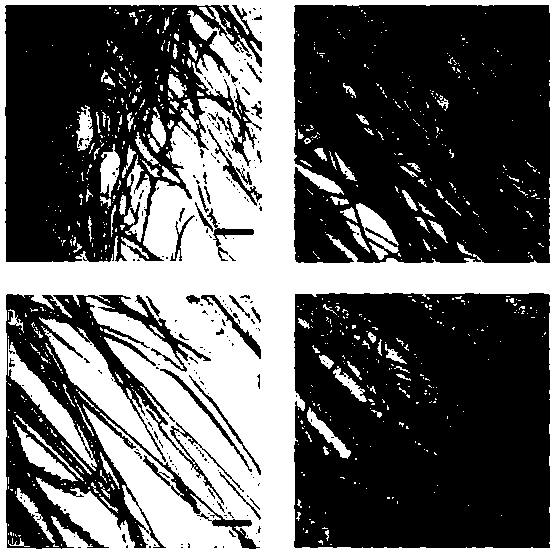

[0035] Figure 5 with Image 6 It is the flexibility test of the graphene film, which shows that the greater the degree of bending, the graphene film bends as the cellulose acetate substrate is bent, and the distance between the sheets increases, which leads to an increase in the relative resistance value, which proves that the resistance is more than 2 times through different bending Flexible response to value changes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com