Method for preparing activated carbon fibers with high specific surface by use of cotton linters

A technology for preparing activated carbon and cotton linters, which is applied in the chemical characteristics of fibers, chemical instruments and methods, and other chemical processes, etc., can solve the problems of pollution, shortage of raw materials for activated carbon fiber preparation, etc. The effect of condo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Biological pretreatment of raw materials: wash the cotton linters with water to keep the moisture content at about 55wt%, put them in a fermenter, inoculate 8wt% of polyporus bacteria, keep the temperature at 30-33°C for 6 days, and wash again Finally, it is dried at 80°C-100°C to achieve the effect of purifying cotton linters.

[0027] Alkali melting: Put KOH into the reactor and melt at 380°C;

[0028] Activation of charcoal: According to the mass ratio of cotton linters raw material: KOH=1:3, add cotton linters into molten KOH, stir while adding to make it evenly mixed; continue to heat up to 600°C, keep for 1 hour and then close power supply, naturally cooled to room temperature and taken out; washed with deionized water to a pH value of 6.7, dried or naturally air-dried to obtain cotton linter activated carbon fibers.

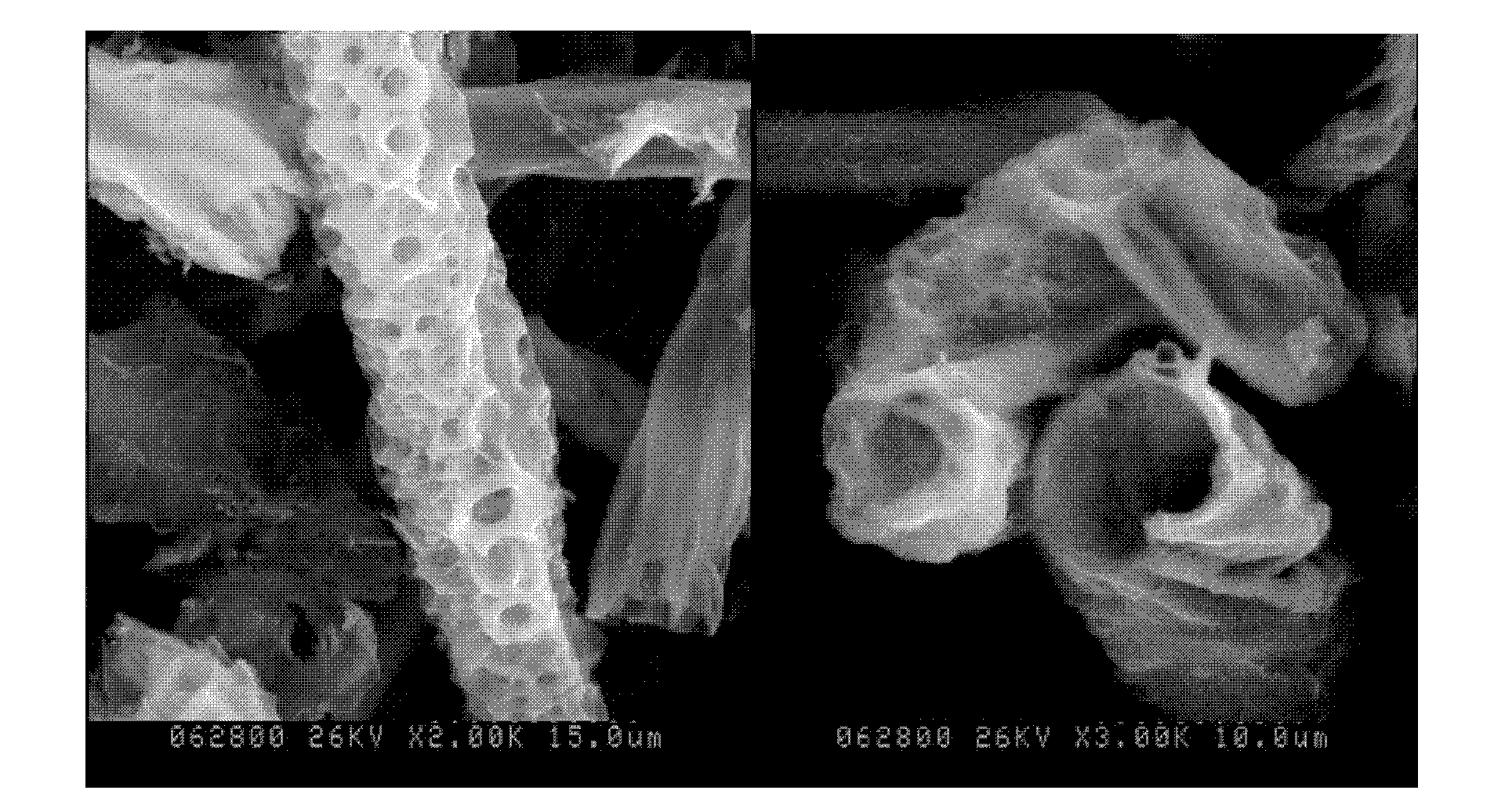

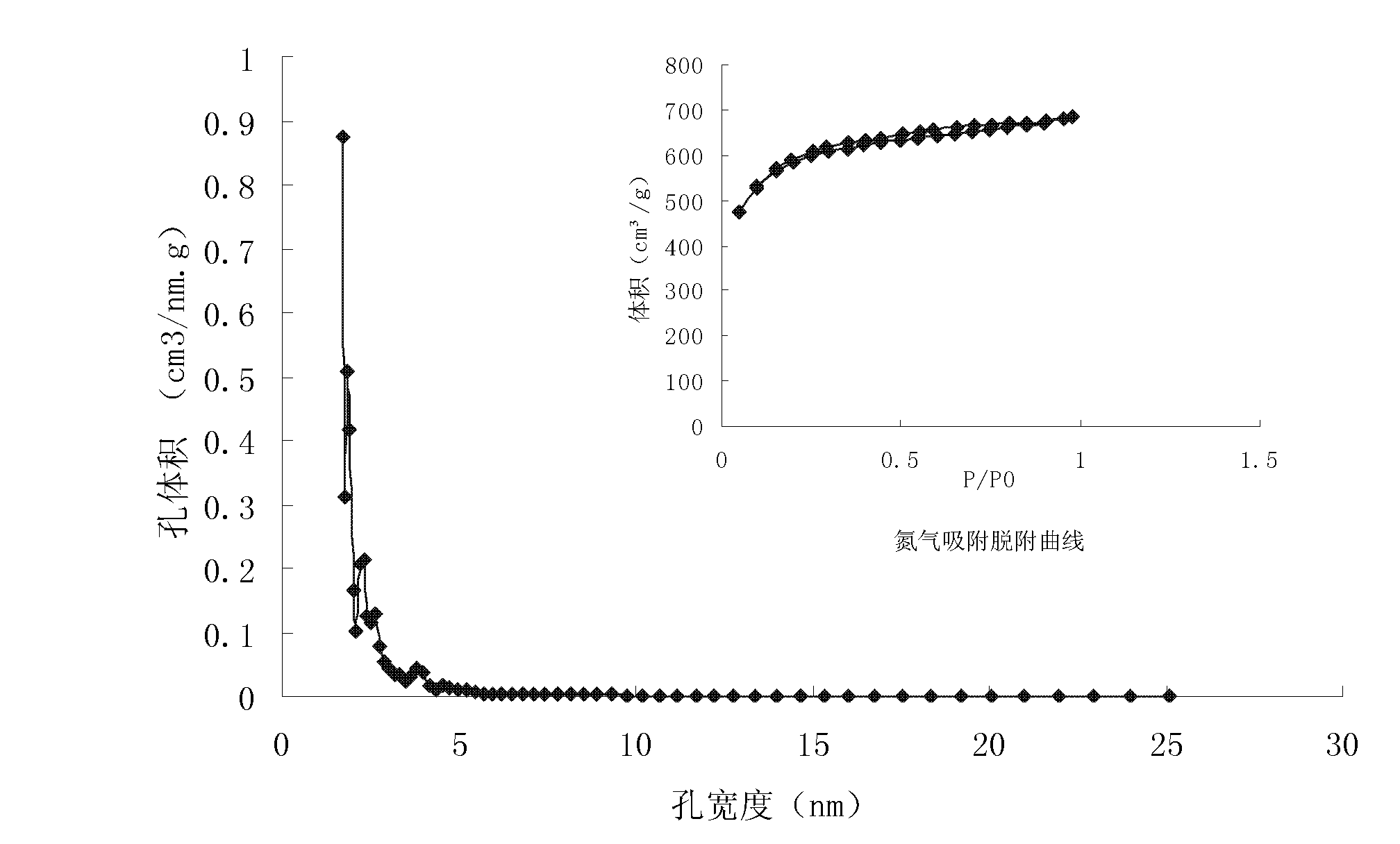

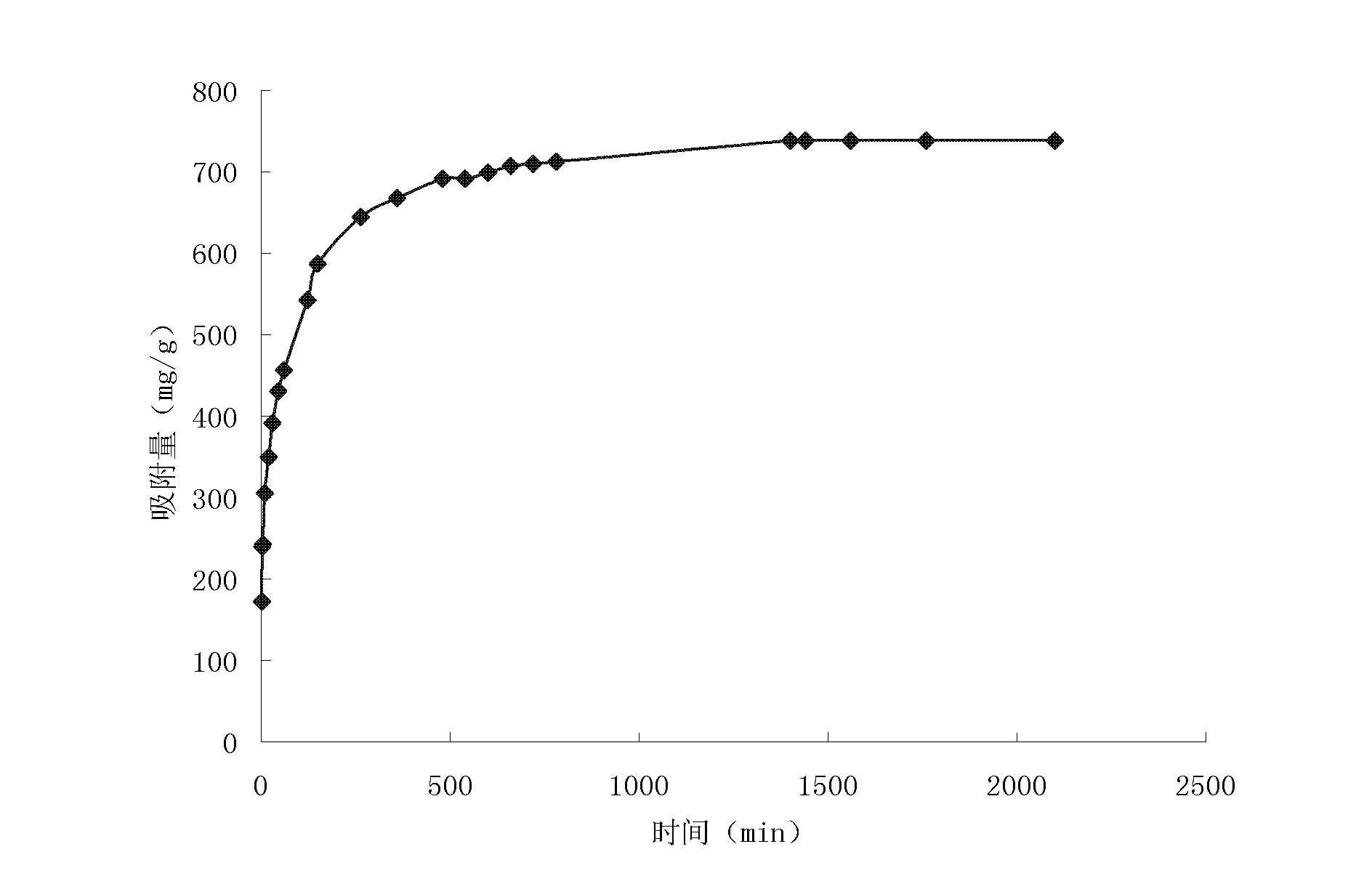

[0029] Gained cotton linter activated carbon fiber electron microscope photo is as follows figure 1 As shown, the pore size distribution and N 2...

Embodiment 2

[0033] Biological pretreatment of raw materials: Wash the cotton linters in advance to keep the moisture content at about 58wt%, put them in a fermentation tank, inoculate 8wt% of white rot fungi, and keep the temperature at 30°C-33°C for 4-6 days of fermentation treatment , after washing with water again, dry at 80°C-100°C to achieve the effect of purifying cotton linters; put NaOH into the reaction kettle and melt at 320-360°C; according to cotton linters: NaOH=1 : 2.5 mass ratio The cotton linters after the aforementioned treatment are added in the NaOH that melts, stir while adding, make it mix evenly; Continue to heat up to 700 ℃, turn off the power after keeping 1 hour, naturally cool to room temperature and take out; Washing with deionized water to a pH value of 7, drying or drying naturally, the cotton linter activated carbon fiber is obtained.

Embodiment 3

[0035] Biological pretreatment of raw materials: wash the cotton linters in advance to keep the moisture content at 56-58wt%, put them in a fermentation tank, inoculate 9wt% of white rot fungi, and keep the temperature at 30-33°C for 5 days of fermentation treatment. After washing with water again, dry at 80°C-100°C to achieve the effect of purifying cotton linters; put NaOH into the reaction kettle and melt at 320-360°C; press cotton linters: NaOH=1:3 Mass ratio Add the treated cotton linters to the melted NaOH, stir while adding to make it evenly mixed; continue to heat up to 600°C, keep it for 1 hour, turn off the power, naturally cool to room temperature and take it out; use deionized water After washing to a pH value of 6.5, drying or drying naturally, the cotton linter activated carbon fiber is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com