Process for preparing dissolved pulp by oxidative degradation of linters

A technology of cotton linter and dissolving pulp, applied in pulp beating/refining method, pulping with inorganic alkali, digester, etc., can solve the problems of shortage of resources, low yield, long cycle, etc., to reduce alkaline hydrolysis , Improve product quality, reduce the effect of organic matter concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] a. The sample is cotton linters, dry weight 1Kg

[0021] b. Cold alkali impregnation, impregnation alkali concentration: 60g / l

[0022] c. Impregnation concentration: 12%

[0023] d. Amount of additives added: 0.3%

[0024] e. Dipping time: 5 minutes

[0025] f. Dehydration with a dehydrator after immersion

[0026] g. Squeeze to adjust the bath ratio to 1:3.5

[0027] h. Oxygenation oxygen pressure is 0.6Mpa

[0028] i. Oxygen decomposition oxygen pressure is 0.6Mpa

[0029] j. Oxygen decomposition temperature is 120°C

[0030] k, oxygen decomposition time is 120 minutes.

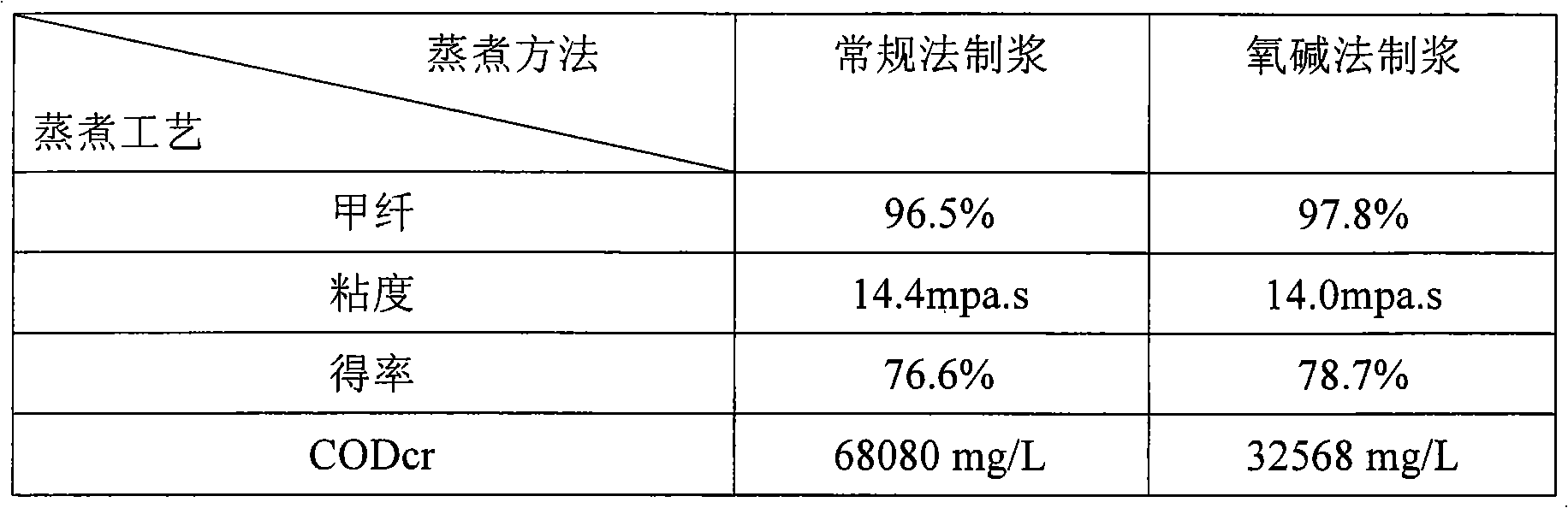

[0031] This embodiment compares with conventional method:

[0032]

[0033] Example 2:

[0034] a. The sample is cotton linters, dry weight 1Kg

[0035] b. Cold alkali impregnation, impregnation alkali concentration: 80g / l

[0036] c. Impregnation concentration: 10%

[0037] d. Amount of additives added: 0.2%

[0038] e. Dipping time: 5 minutes

[0039] f. Dehydration with a dehydra...

Embodiment 3

[0048] a. The sample is cotton linters, dry weight 1Kg

[0049] b. Cold alkali impregnation, impregnation alkali concentration: 120g / l

[0050] c. Impregnation concentration: 15%

[0051] d. Amount of additives added: 0.2%

[0052] e. Dipping time: 3 minutes

[0053] f. Dehydration with a dehydrator after immersion

[0054] g. Squeeze to adjust the bath ratio to 1:2.7

[0055] h. Oxygenation oxygen pressure is 0.5Mpa

[0056] i. Oxygen decomposition oxygen pressure is 0.5Mpa

[0057] j. Oxygen decomposition temperature is 100°C

[0058] k, oxygen decomposition time is 150 minutes.

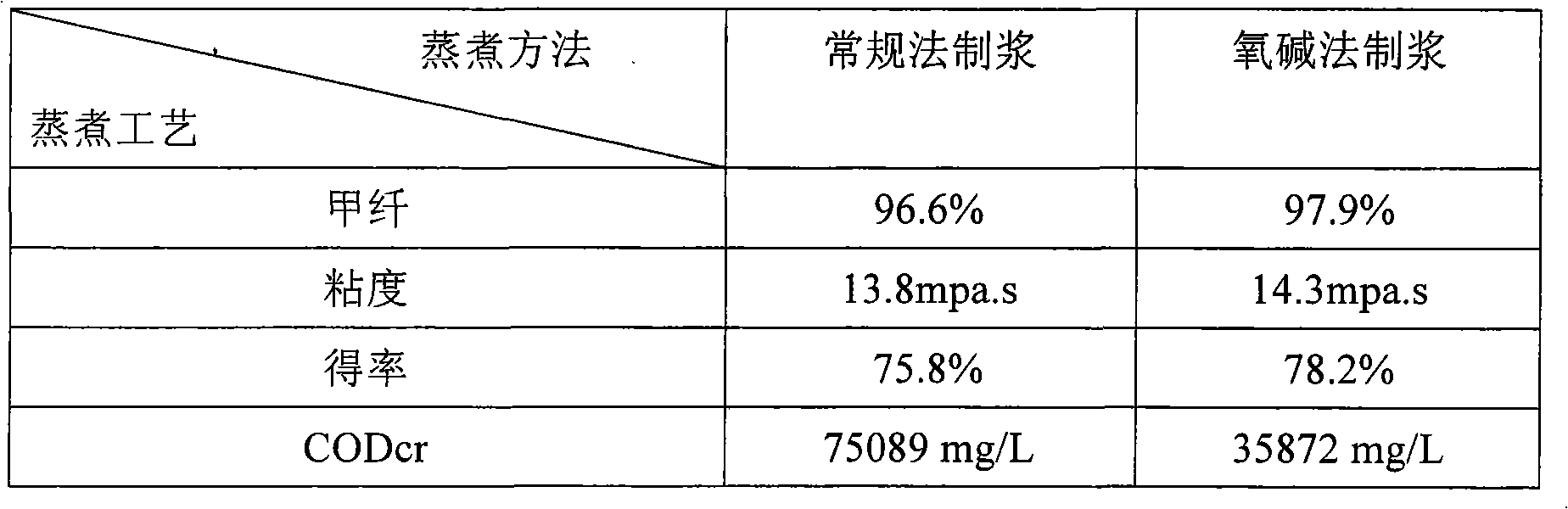

[0059] This embodiment compares with conventional method:

[0060]

Embodiment 4

[0062] a. The sample is cotton linters, dry weight 1Kg

[0063] b. Cold alkali impregnation, impregnation alkali concentration: 100g / l

[0064] c. Impregnation concentration: 15%

[0065] d. Amount of additives added: 0.2%

[0066] e. Dipping time: 5 minutes

[0067] f. Dehydration with a dehydrator after immersion

[0068] g. Squeeze to adjust the bath ratio to 1:3

[0069] h. Oxygenation oxygen pressure is 0.4Mpa

[0070] i. Oxygen decomposition oxygen pressure is 0.4Mpa

[0071] j. Oxygen decomposition temperature is 115°C

[0072] k, oxygen decomposition time is 90 minutes.

[0073] This embodiment compares with conventional method:

[0074]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com