Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

713 results about "Oxygen pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The partial pressure of oxygen, also known as PaO2, is a measurement of oxygen in arterial blood. It shows how well oxygen is able to move from the lungs to the blood. The PaO2 is one of the components measured in the arterial blood gas (ABG) test, which also reports carbon dioxide,...

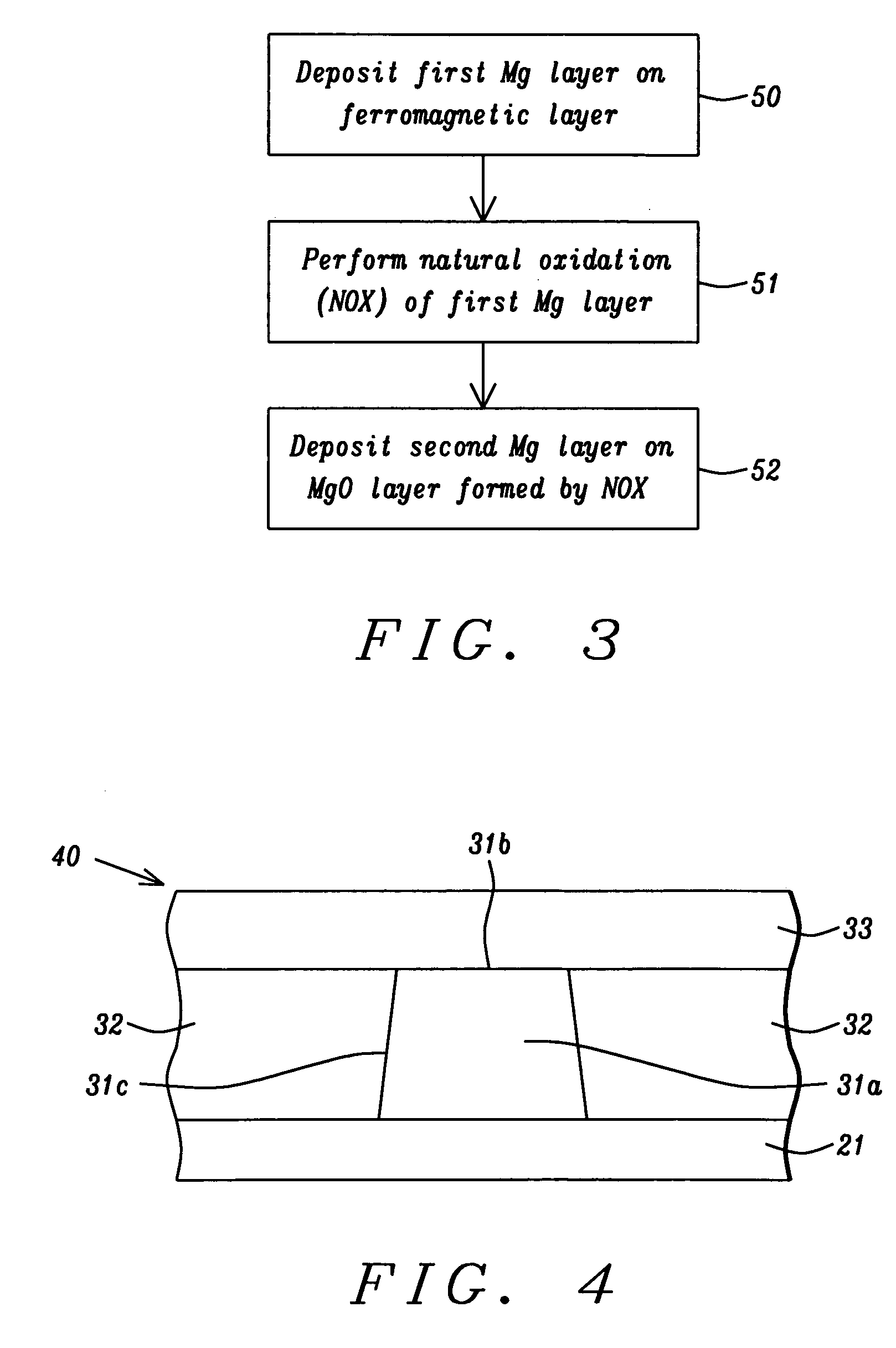

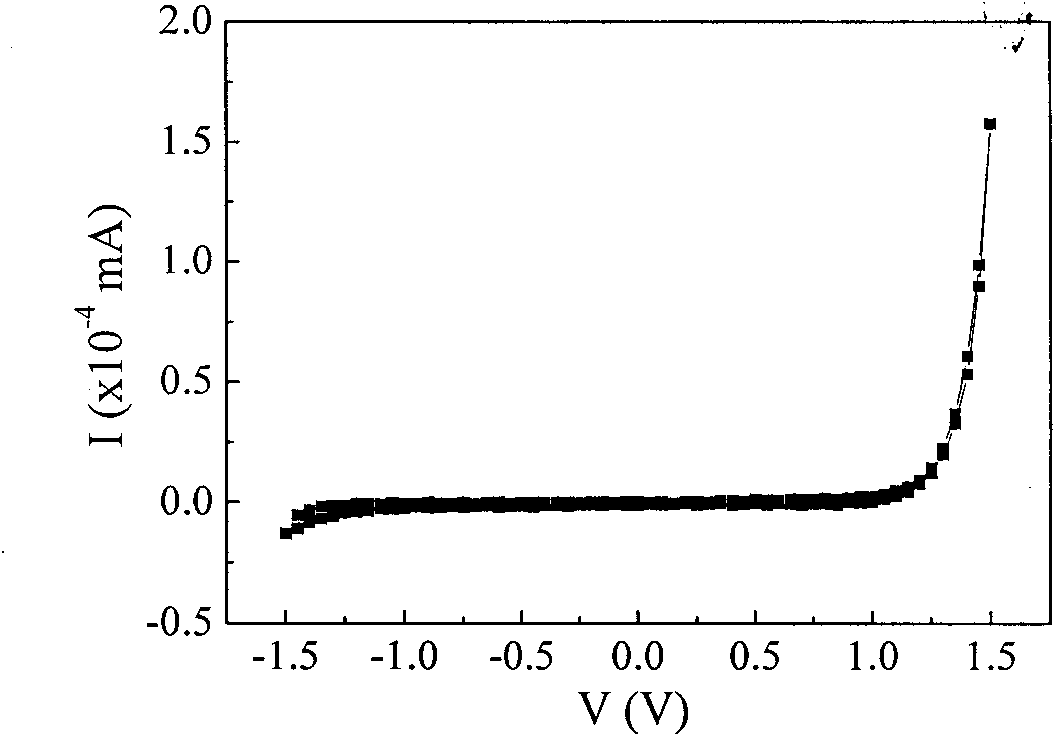

Low resistance tunneling magnetoresistive sensor with natural oxidized double MgO barrier

ActiveUS20070111332A1Improve uniformityHigh MR ratioNanomagnetismMagnetic measurementsSpin valveMaterials science

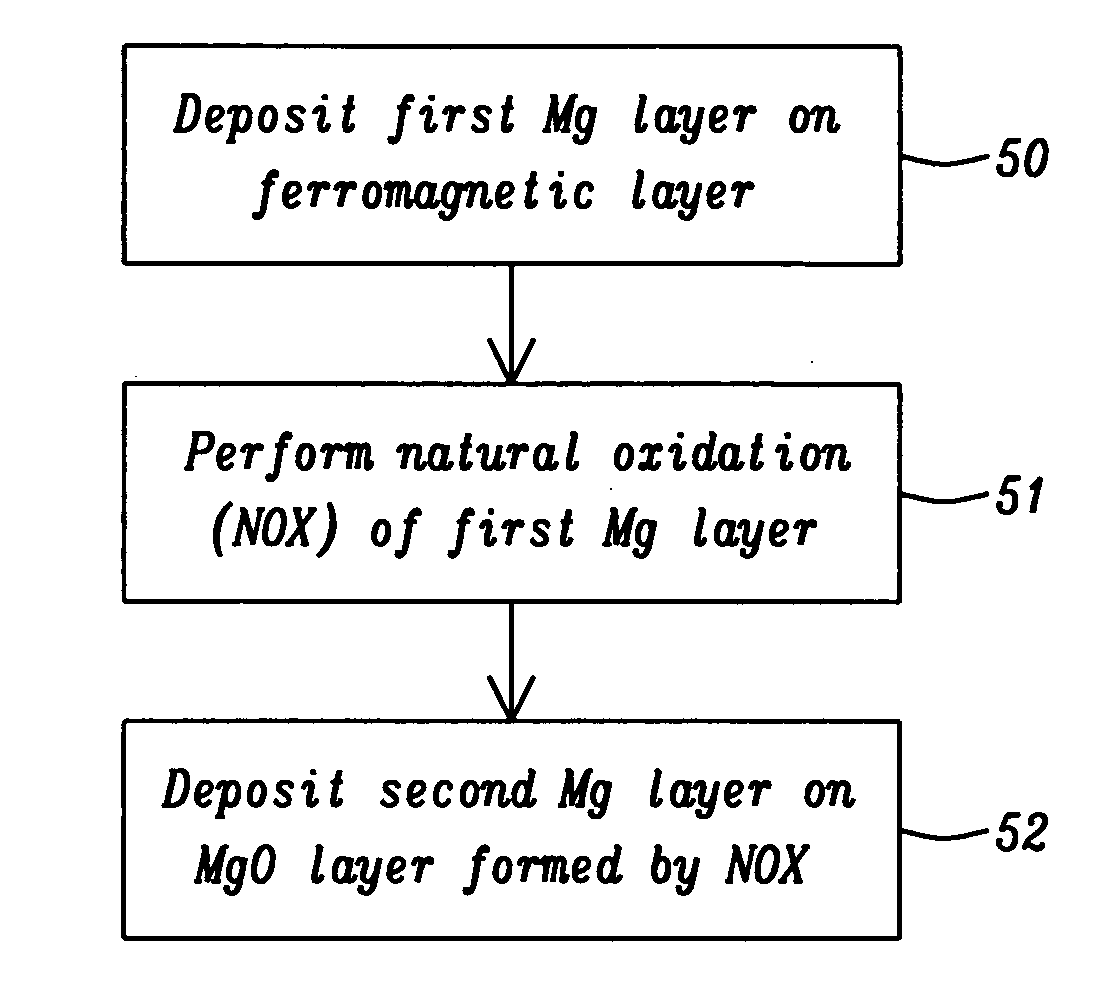

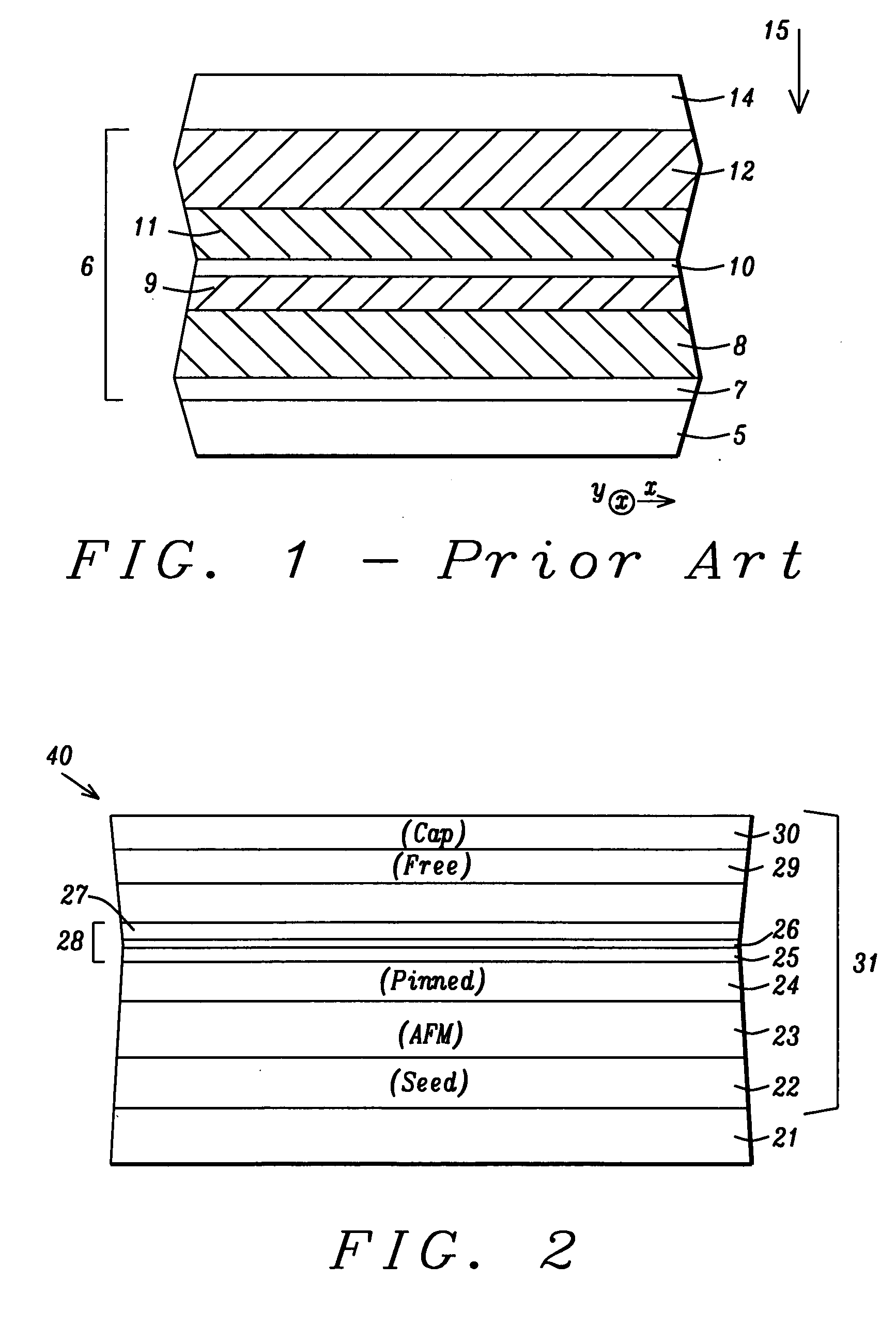

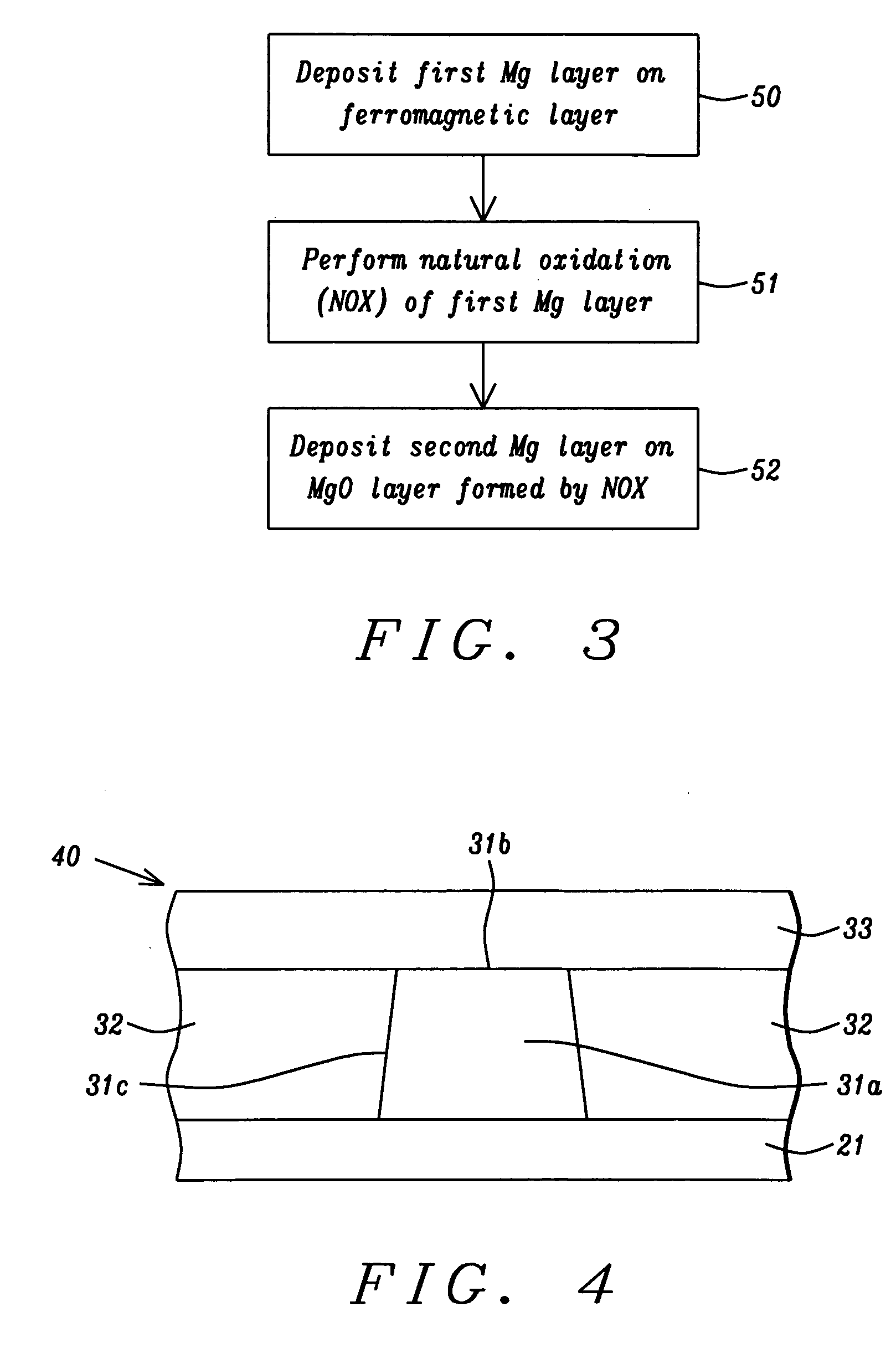

A high performance TMR sensor is fabricated by incorporating a tunnel barrier having a Mg / MgO / Mg configuration. The 4 to 14 Angstroms thick lower Mg layer and 2 to 8 Angstroms thick upper Mg layer are deposited by a DC sputtering method while the MgO layer is formed by a NOX process involving oxygen pressure from 0.1 mTorr to 1 Torr for 15 to 300 seconds. NOX time and pressure may be varied to achieve a MR ratio of at least 34% and a RA value of 2.1 ohm-um2. The NOX process provides a more uniform MgO layer than sputtering methods. The second Mg layer is employed to prevent oxidation of an adjacent ferromagnetic layer. In a bottom spin valve configuration, a Ta / Ru seed layer, IrMn AFM layer, CoFe / Ru / CoFeB pinned layer, Mg / MgO / Mg barrier, CoFe / NiFe free layer, and a cap layer are sequentially formed on a bottom shield in a read head.

Owner:HEADWAY TECH INC

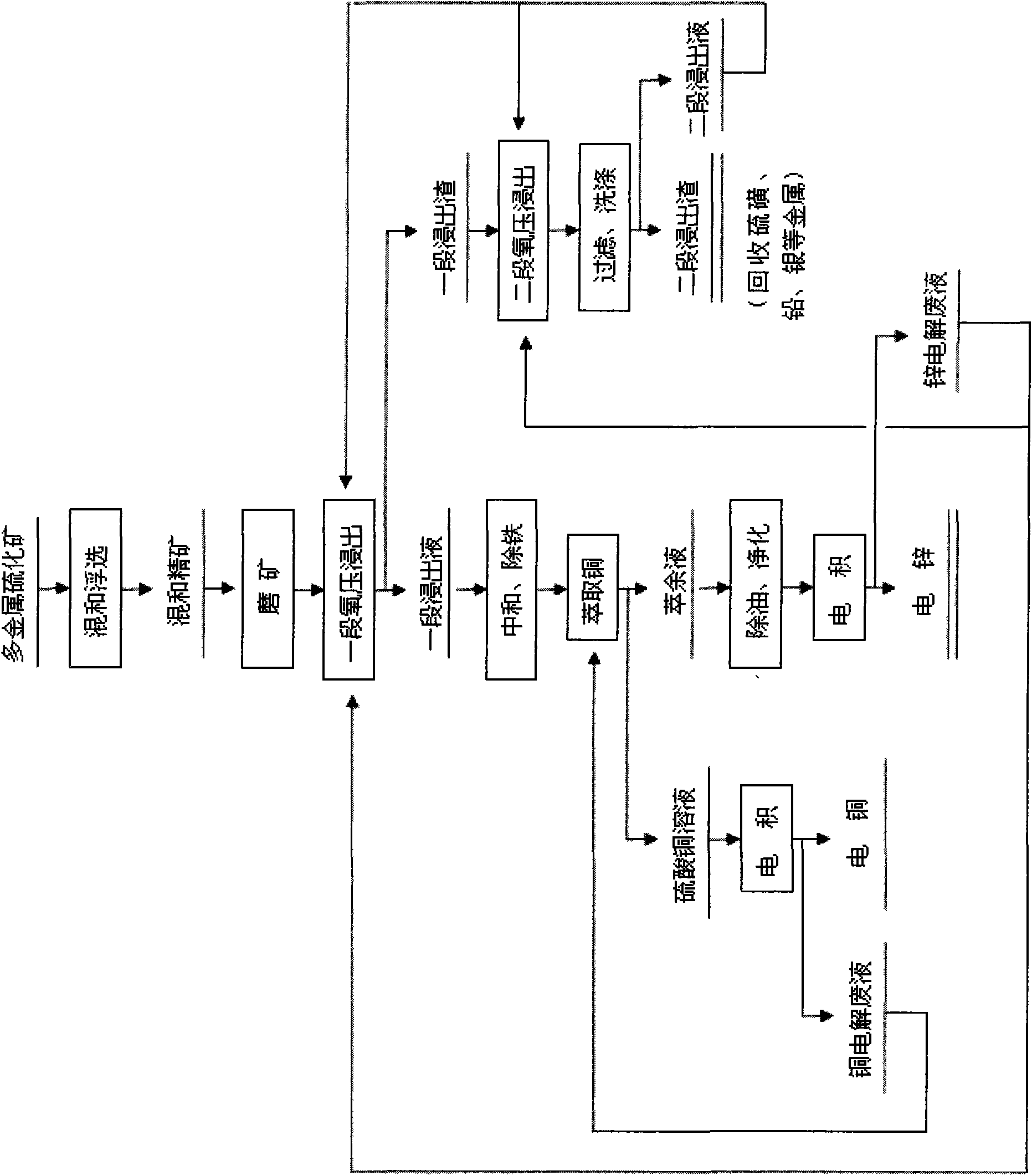

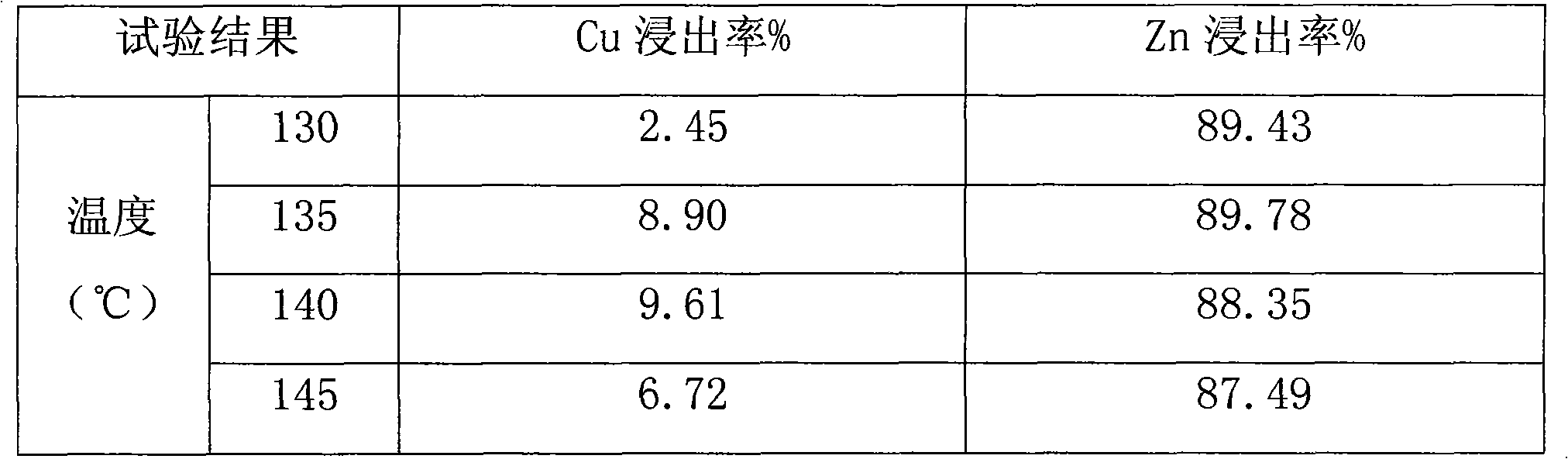

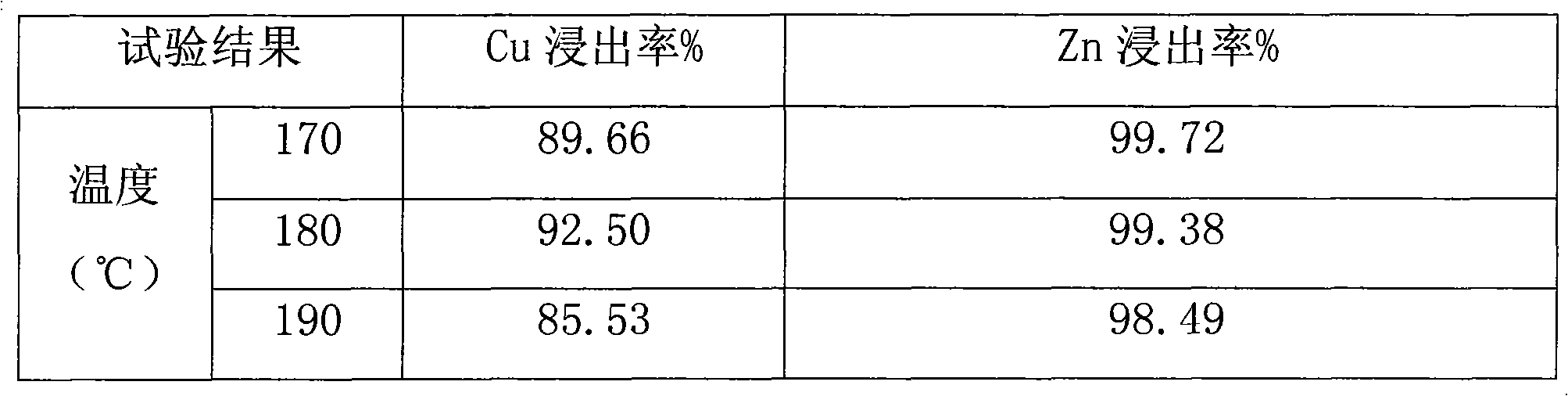

Comprehensive recovery method of complex polymetal sulphide ore containing copper, lead and zinc

InactiveCN101643857AHigh recovery rateSimple processSulfur preparation/purificationFlotationRecovery methodLead smelting

The invention discloses a comprehensive recovery method of complex polymetal sulphide ore containing copper, lead and zinc and adopts dressing-metallurgy combination method and hydrometallurgy-pyrometallurgy combination method to recover metals. The recovery method comprises the following steps: first performing bulk flotation to the complex polymetal sulphide ore, fine grinding the obtained concentrate, leaching by using two-step counter flow oxygen pressure leaching process, extracting and separating copper and zinc from the obtained leachate, electrodepositing the strip liquor of copper-loaded organic phase to obtain cathode copper, cleaning the obtained raffinate and electrodepositing to obtain cathode zinc; pressurizing leaching residue to perform flotation separation and obtain sulfur concentrate and lead silver residue, distilling sulfur concentrate to obtain sulfur; performing lead smelting process to lead silver residue to obtain electrolytic lead product and lead anodic slime; and comprehensively recovering noble metals such as gold, silver and the like from lead anodic slime. The method can greatly improve the metal recovery rate, resource utilization and the economic efficiency of mines and generate a lot of sulfur so as to obviously reduce the sulfur dioxide pollution to the atmosphere.

Owner:WESTERN MINING CO LTD

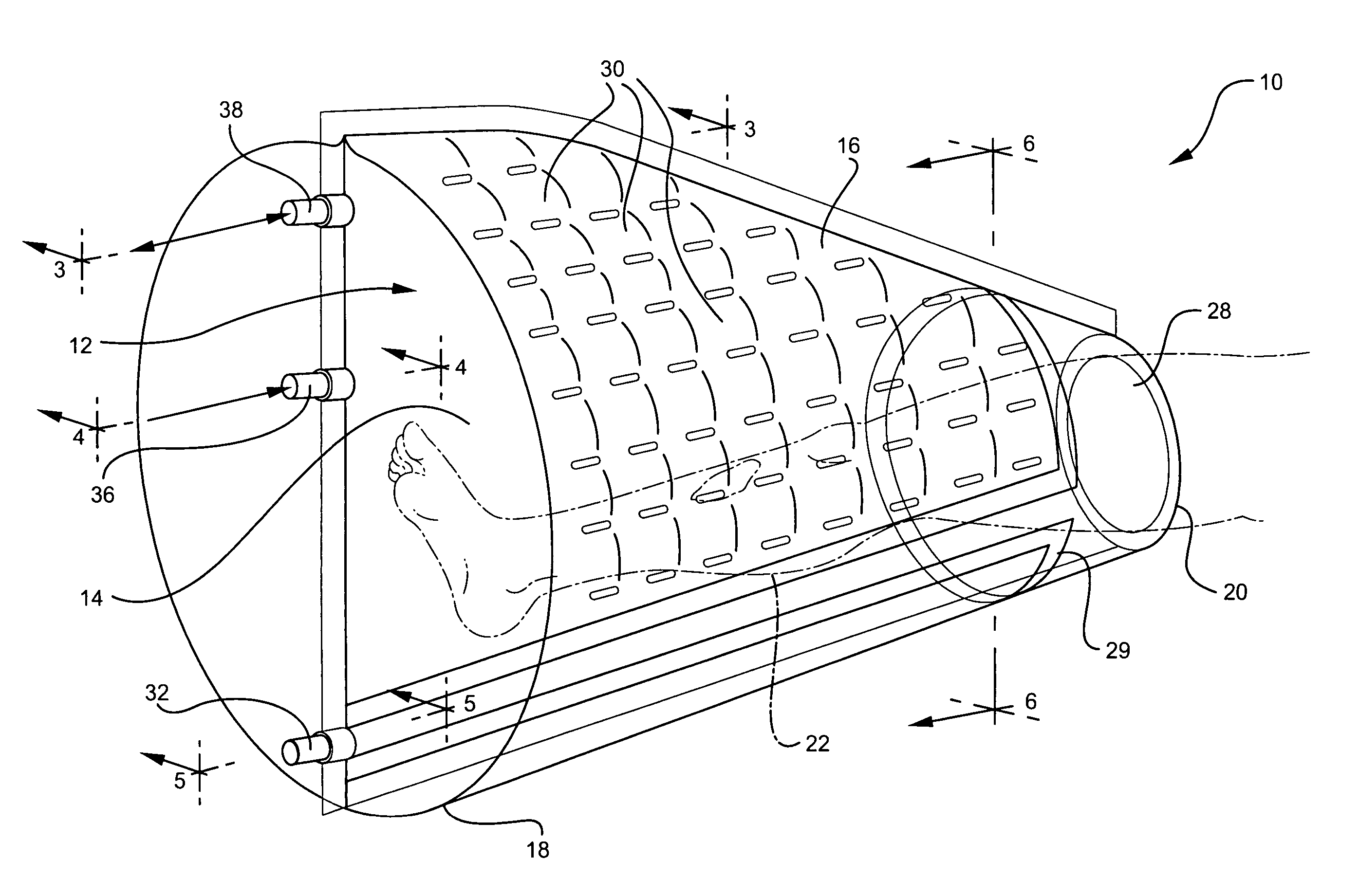

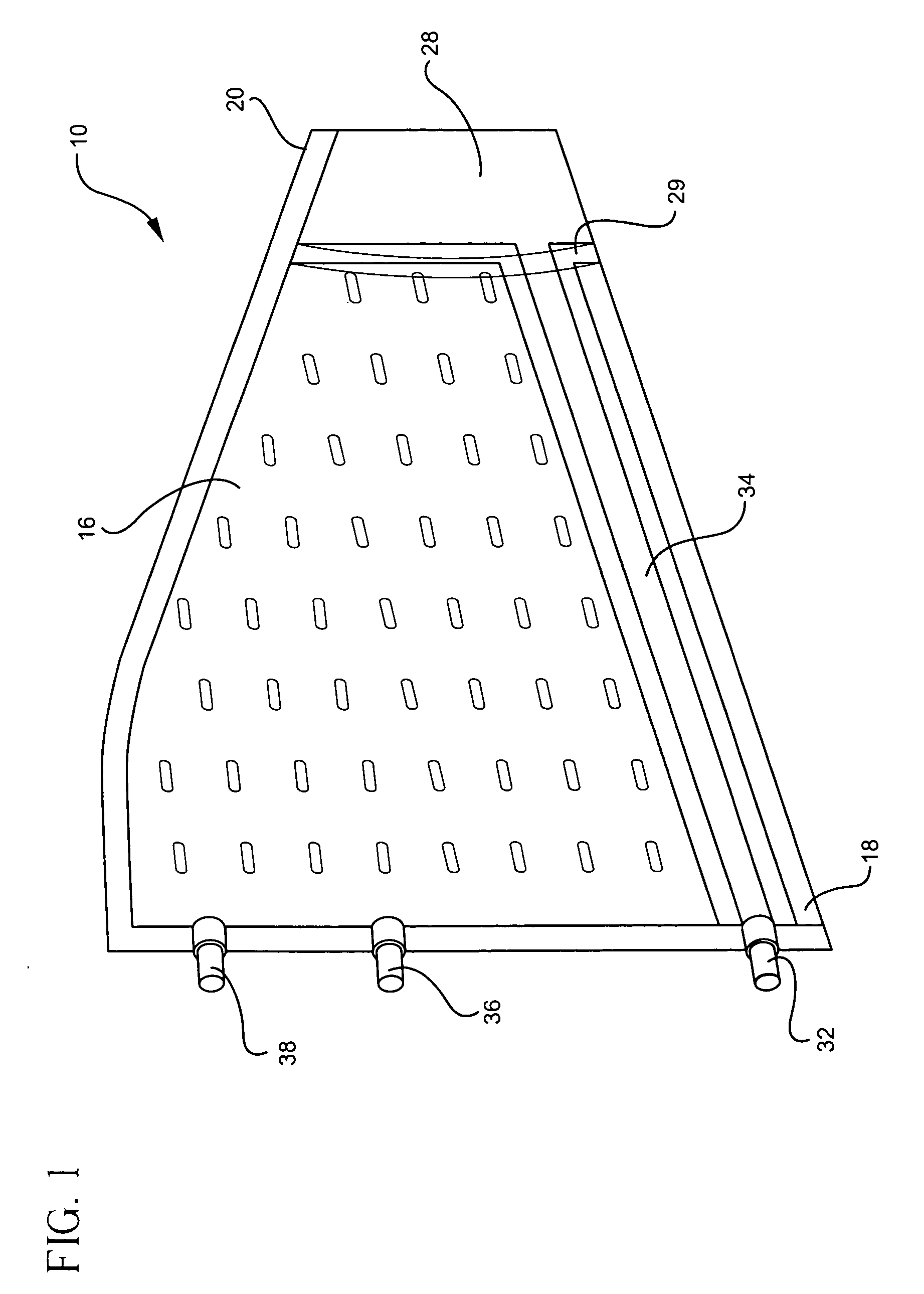

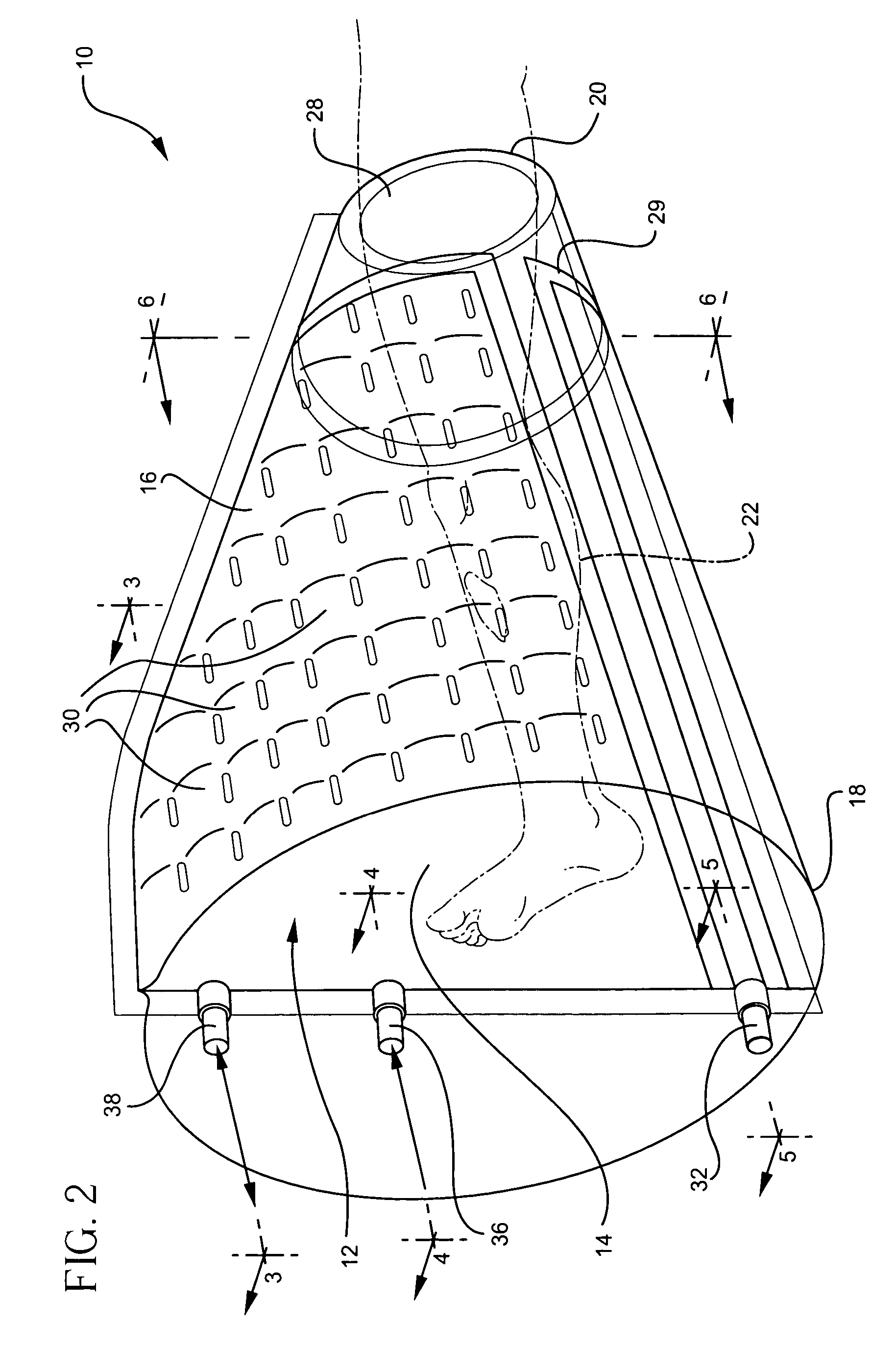

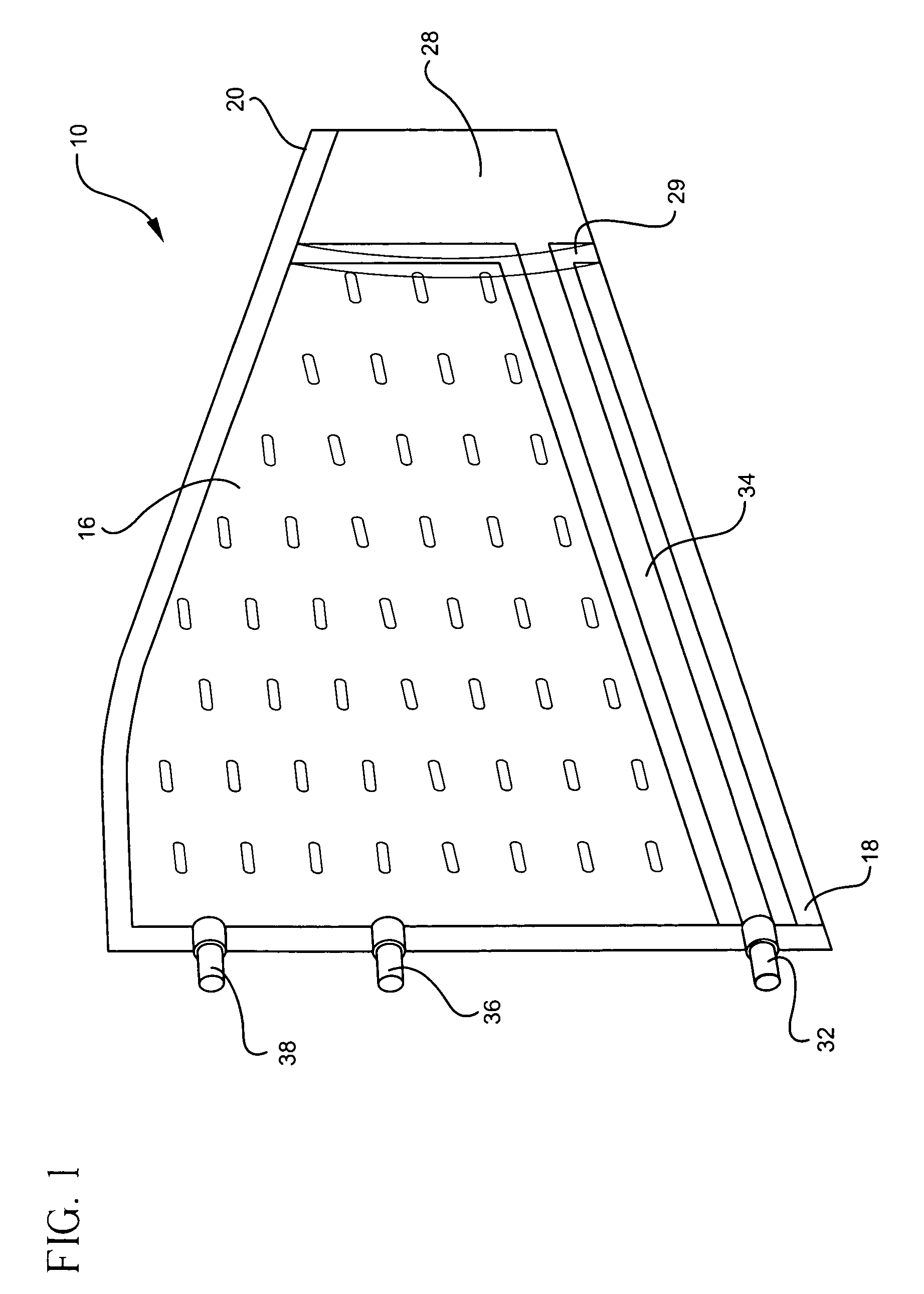

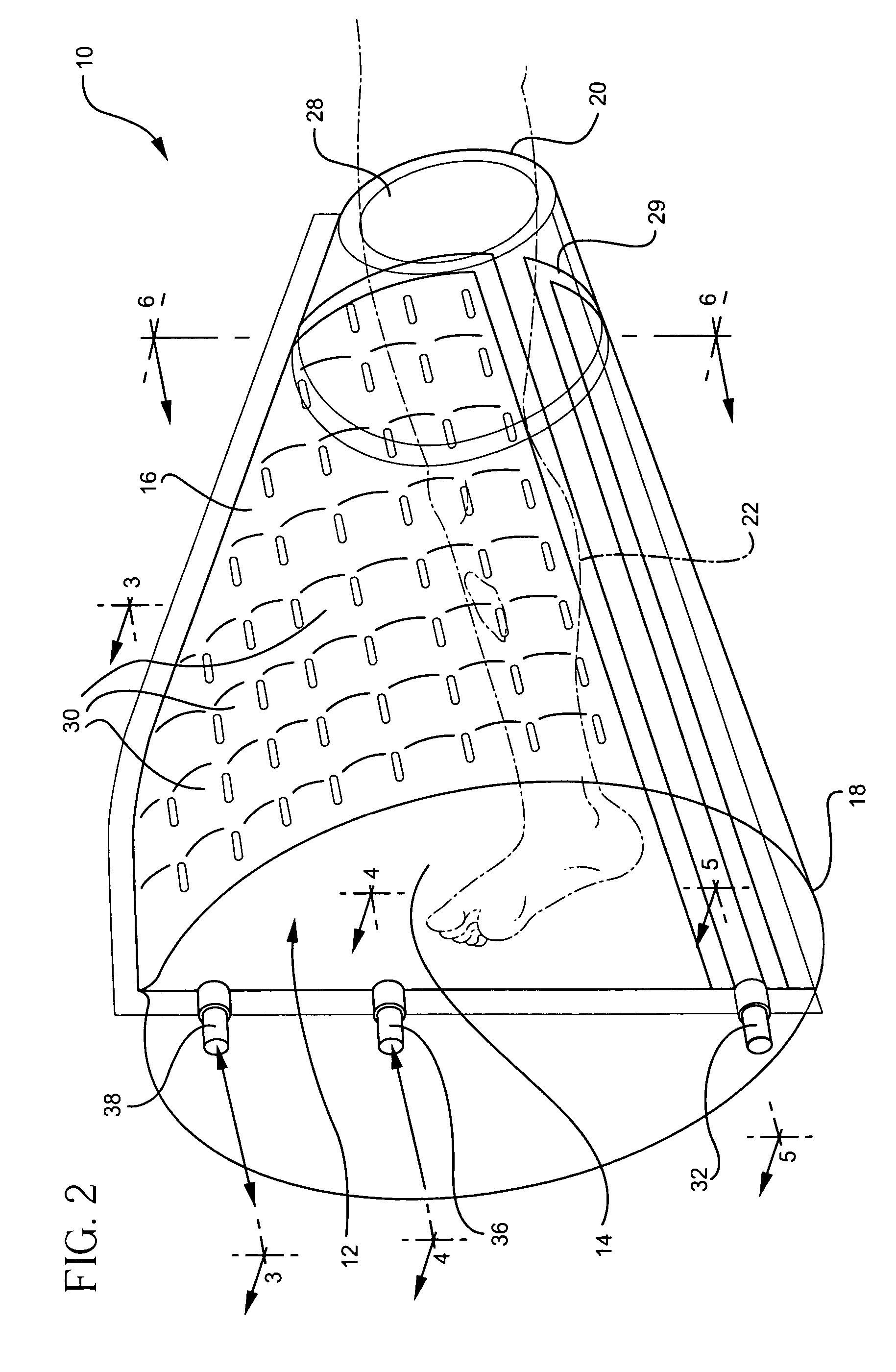

Hyperbaric oxygen devices and delivery methods

A hyperbaric oxygen device and methods of applying hyperbaric oxygen are disclosed. The device comprises an enclosure including a collapsible bag defined by two sheets of fluid impervious material sealed together at both ends such that gas can be delivered between the sheets to inflate the enclosure to a rigid state and maintain the enclosure in the rigid state when oxygen pressure in the interior of the enclosure is cycled between ambient pressure and above ambient pressure.

Owner:AOTI

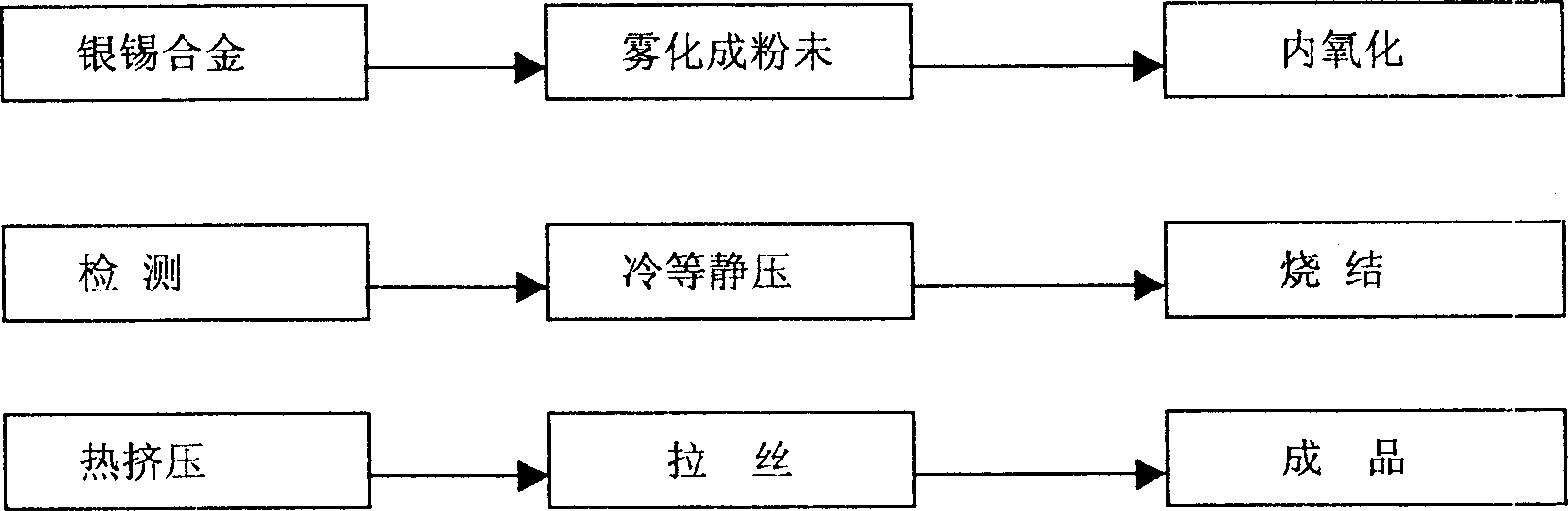

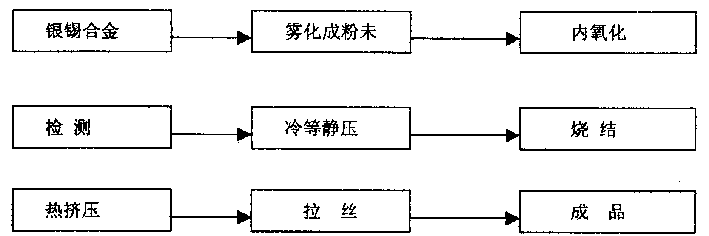

Process for preparing silver tin oxide material

InactiveCN1425790AGuaranteed uniformity of distributionNot limited by product sizeMedium frequencyIngot

The present invention relates to the preparation of contact material and is especially the preparation of silver-tin oxide material. The preparation process includes smelting silver and tin in certain ratio in a medium frequency furnace, alloy atomizing inside one high pressure water atomizing equipment, stoving to obtain powder, sieving, oxidation inside aninternal oxodizing furnace at certain temperature and oxygen pressure, cold hydrostatic processing to obtain ingot, sintering, extruding into wire and drawing into the product. The silver-tin oxide material has full oxidation of tin, firm combination between tin oxide and silver base and high comprehensive performance.

Owner:陈达峰

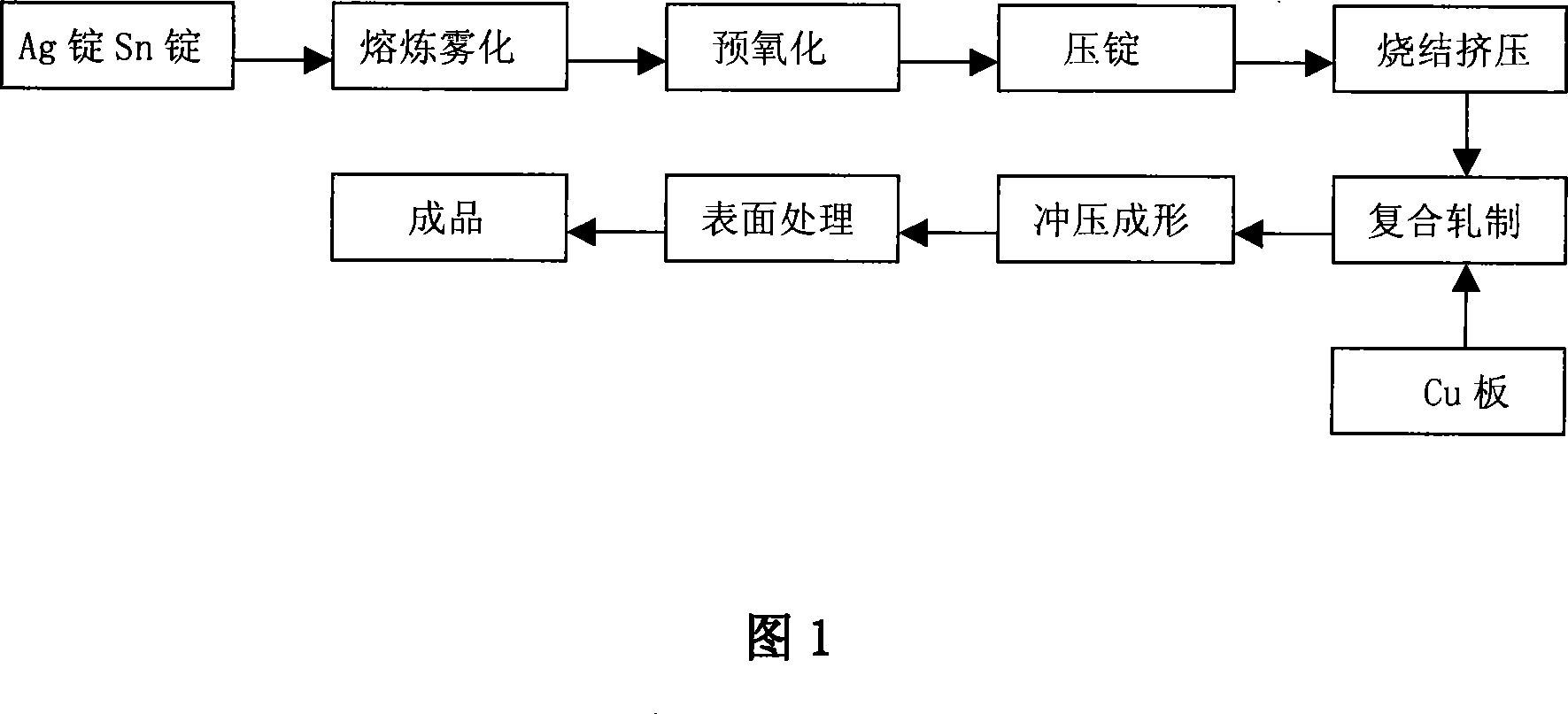

A silver tin/copper oxide compound electrical contact and preparation method

The invention relates to a silver tin oxide / copper compound electrical contact, a working layer of the electrical contact material is composed of silver, tin oxide and mixed rare earth oxide, the weight content of all the components is: 85 percent to 94 percent of Ag, 6 percent to 15 percent of SnO2 and 0.1 percent to 2.0 percent of mixed rare earth oxide, and a welding layer is T2 copper. The weight content of SnO2 is 8 to 12 percent preferentially. The mixed rare earth oxide is a mixture of cerium oxide, lanthanum oxide and yttrium oxide. The preparation method is that the silver and the tin are first mixed according to certain proportion and then are smelted in an intermediate frequency furnace, then high-pressure water atomization equipment is used for carrying out alloy atomization, powder is obtained by drying after the atomization, the powder is screened and arranged in an internal oxidation furnace to carry out the oxidation at certain temperature and oxygen pressure, then billet is obtained by the processing of isostatic cool pressing after the oxidation, after that, a plate is formed by carrying out the sintering and extruding, and finally the finished product is obtained by compound rolling with the copper. The electrical contact is characterized by high conductivity, even and exquisite texture, high bonding strength of the working layer and the welding layer, welding resistance and arc erosion resistance.

Owner:SHANGHAI LONGSUN ALLOY CO LTD

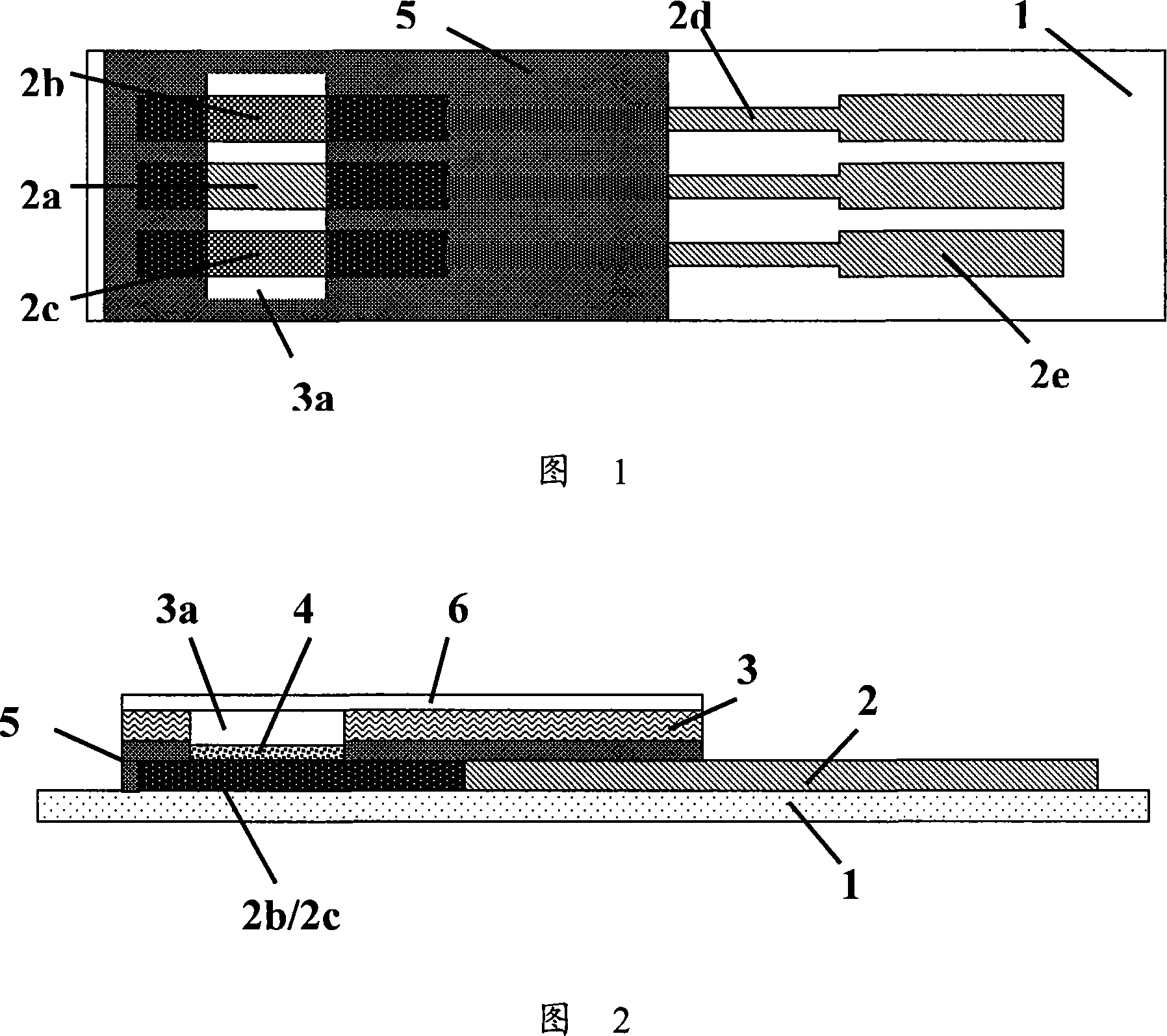

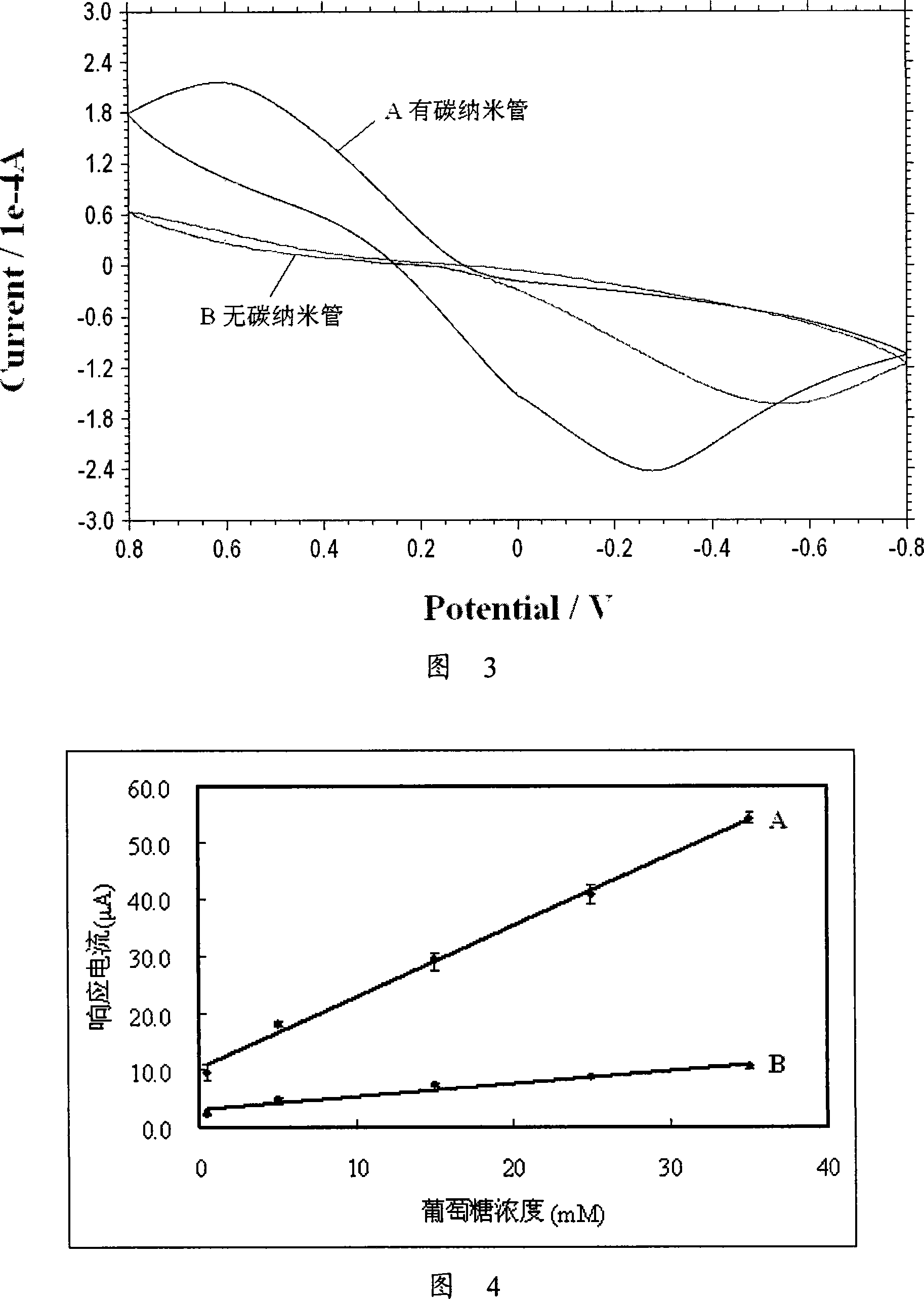

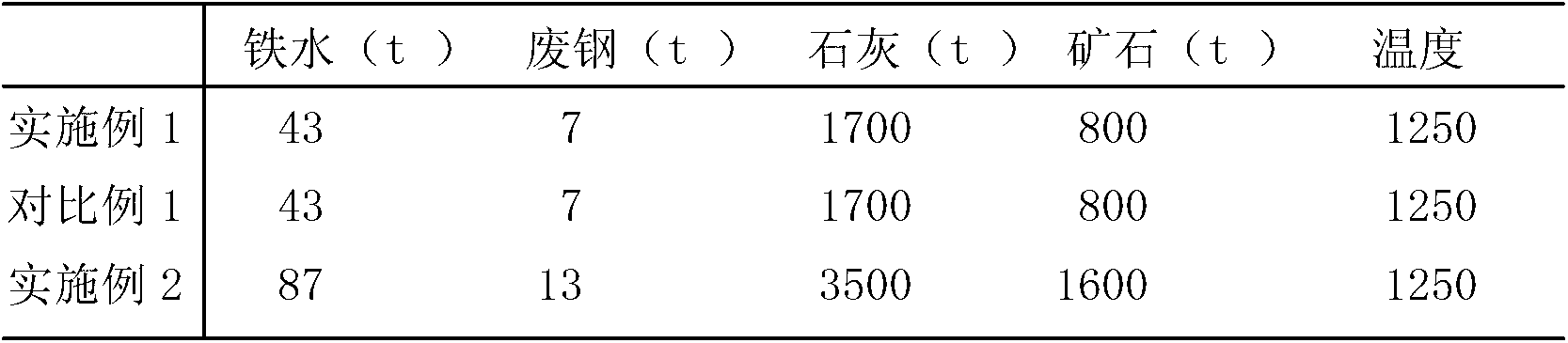

Carbon nano tube modified blood sugar biosensor

InactiveCN101101273AImprove responsivenessIncreased contact surface areaDiagnostic recording/measuringSensorsQuinoneConcentrations glucose

The invention provides a blood sugar biosensor of carbon nanometer tube, it includes floor, three electrode system, insulation, forming the reaction lumen body around three electrode system, setting the conversion zone in the reaction lumen body, laying over the cover plate on the reaction lumen body, the conversion zone includes, enzyme and electron transport agent, the enzyme is the glc dh pyrrole and quinone for coenzyme. The transducer's corresponding sensitivity improves evidently, it has not infection for measuring the dextrose deepness in the blood with the oxygen pressure, thickness in the measuring site and oxygen content of blood sample. The invention has the excellence of easy manufacture artwork, low cost, suited to volume-produce and the low sample quantity etc.

Owner:ZHEJIANG UNIV +1

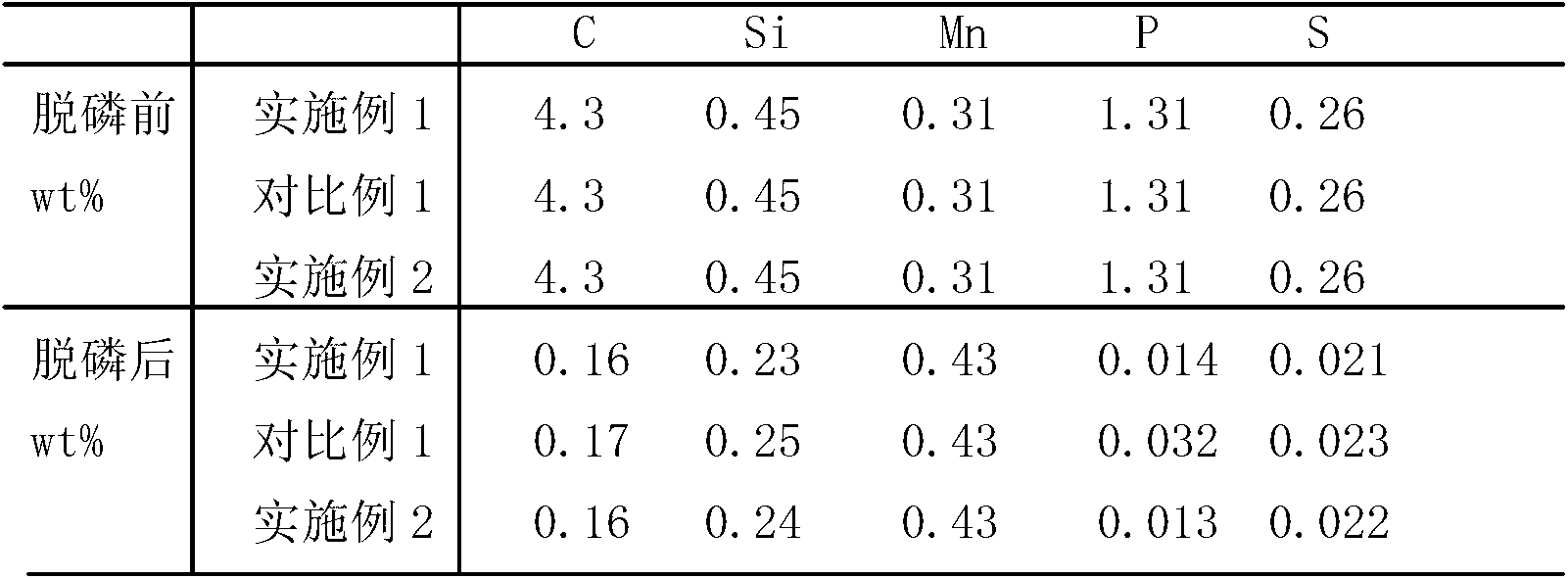

Smelting method for improving phosphorus removal rate of converter

ActiveCN103060508ALower oxygen pressureFoamy splash preventionManufacturing convertersSmelting processOxygen pressure

The invention discloses a smelting method for improving the phosphorus removal rate of a converter. The method comprises the following steps of: at the later stage when steel splashing slag is emptied in the converter, adding 500 to 800 kilograms of lime, slightly stirring, pre-heating, adding waste steel, and blending molten iron; adding a bath of slag forming material such as lime, lightly burnt magnesium blocks, ores and the like when blowing to 45 to 60 seconds, lifting an oxygen lance by 200 millimeters when blowing for 4.5 minutes, continuously adding 4 to 5 batches of ores, and uniformly controlling the heating speed of a molten pool to increase the FeO content of slag; when blowing to 7 minutes, properly lowering the lance for 50 to 100 millimeters, meanwhile, reducing the oxygen pressure to 0.80MPa, and continuously adding 2 to 3 batches of rest lime; and keeping the position of the final point pressure lance at 1,000 millimeters for 1 minute. By adopting the method, full-process slag smelting can be realized, the slag is not re-dried, a good phosphorus removal effect is obtained, the phosphorus removal rate is improved by 10 percent compared with the conventional smelting process, and the requirement for smelting the molten iron with a high content of phosphorus can be met.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

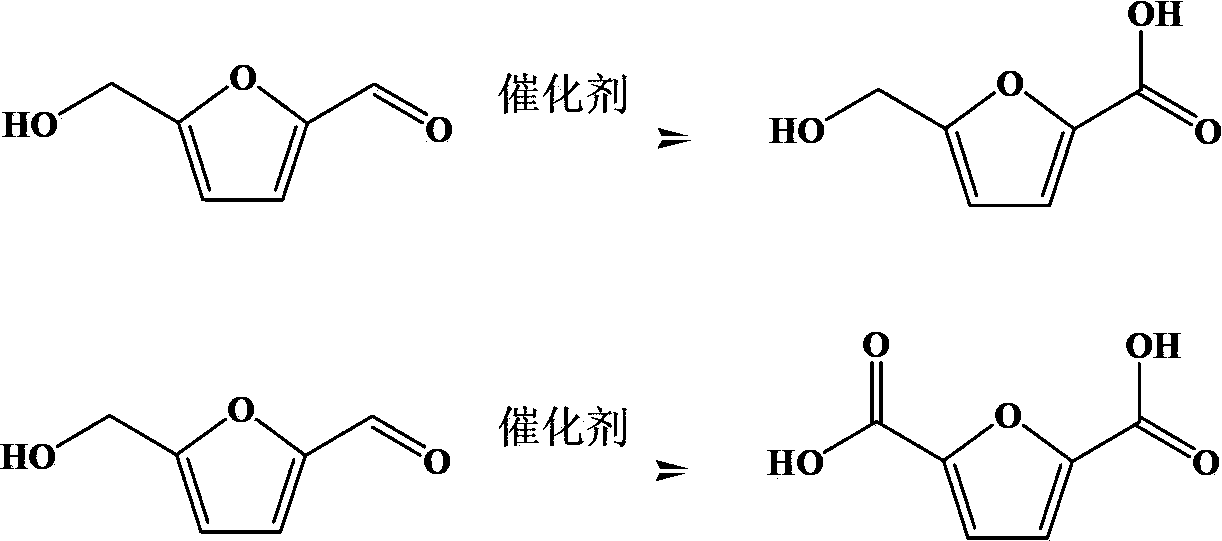

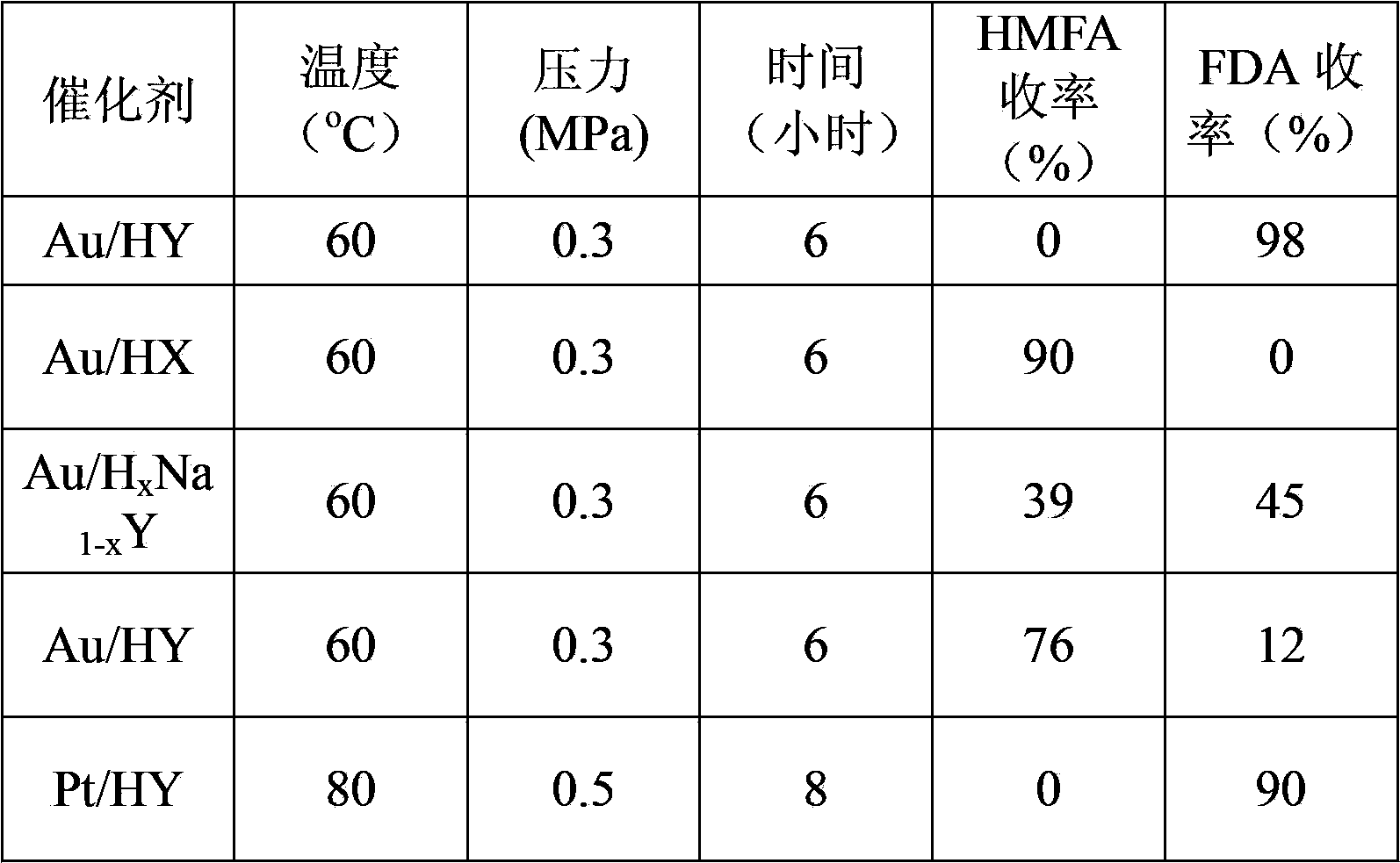

Preparation method of 5-hydroxymethyl furoic acid and 2,5-furandicarboxylic acid

ActiveCN103626726AEasy to makeModification operation is simpleOrganic chemistryMolecular sieve catalystsHydroxymethylfurfuralHydroxymethyl

The invention discloses a preparation method of 5-hydroxymethyl furoic acid and 2,5-furandicarboxylic acid by selective oxidation of 5-hydroxymethylfurfural. The method comprises the following steps: taking a precious metal loaded acidic carrier as the catalyst, under mild conditions (temperature is in a range of 25 to 100 DEG C, and the oxygen pressure is in a range of 0.1 to 3.0 MPa), and modulating the temperature, pressure and reaction time so as to rapidly and high-efficiently oxidize 5-hydroxymethylfurfural to generate 5-hydroxymethyl furoic acid or 2,5-furandicarboxylic acid. The conversion rate of 5-hydroxymethylfurfural can reach 100%, the selectivity of 5-hydroxymethyl furoic acid reaches 98%, and the selectivity of 2,5-furandicarboxylic acid reaches 99%. The method has the advantages of high efficiency and environment-friendliness, and the products have a big application value and a wide application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process for extracting vanadium form oxygen tension pickle liquor of high ferro vanadium-containing stone coal

InactiveCN101289703AHigh recovery rateReduce consumptionProcess efficiency improvementKeroseneSolvent

The invention provides a method for extracting vanadium from ferri containing vanadium bone coal oxygen pressure acid leach solution. The invention relates to a method for extracting vanadium from ferri containing vanadium bone coal oxygen pressure acid leach solution, belonging to the metallurgic-chemical technical field. The method is characterized in that according to the content of iron impurity (Fe<3+>) in leach solution and the percentage needed for completion of the reaction, inorganic salt reducing agents are added, which reduce Fe<3+> in the leach solution into Fe<2+>, and the leach solution is cooled to the room temperature, and the pH value of the leach solution is adjusted by NaOH solution, and the synergistic extraction of vanadium is made by mixing kerosene solvent of P204 and TBP. The method has the advantages of simple technical process, little reagent consumption, low disposal cost, high recovery rate of vanadium and high purity, etc., and is widely applied to the process of extracting vanadium from stone coal acid leach solution.

Owner:KUNMING UNIV OF SCI & TECH

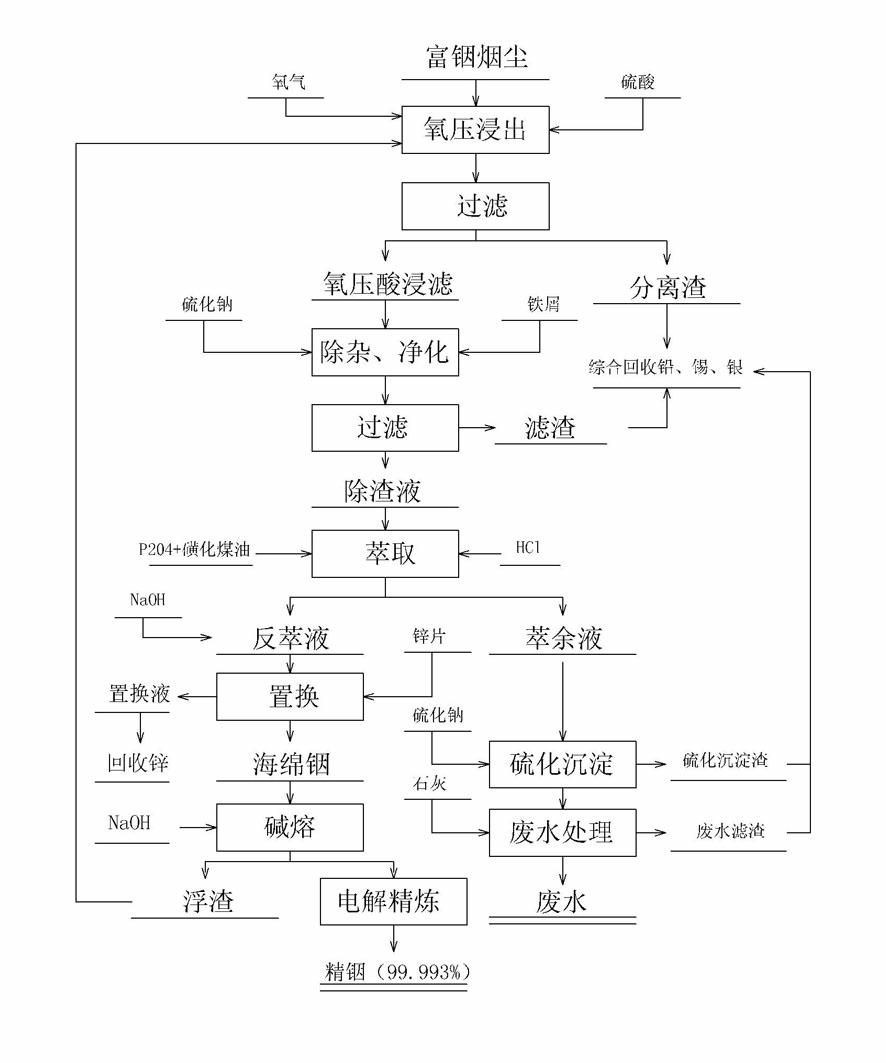

Method for extracting indium from indium-rich smoke dust by using oxygen pressure technology

The invention provides a method for extracting indium from indium-rich smoke dust by using an oxygen pressure technology. The method is characterized by comprising the following steps of: carrying out leaching indium extraction of the difficult-to-handle indium-rich smoke dust of a Pb-Sn reverberatory furnace by adopting a wet-process metallurgical oxygen pressure acid leaching technology, and highly enriching and recycling valuable metals in the raw material; and purifying to remove impurities of leachate, and carrying out extraction, replacement and electrolytic refining, thereby obtaining greater than 99.995% of electrical indium products. The technology method has the advantages that the indium leaching rate of the indium-rich smoke dust of the Pb-Sb reverberatory furnace and the enrichment rate of the valuable metals can be obviously increased, and the comprehensive recycling effect can be achieved, thereby waster water of indium smelting can be discharged up to the standard after being processed with low cost, the environmental pollution in the indium extraction process is eliminated. In the process, the leaching rate of the indium is more than 97%, leaching residues containless than 0.01% of indium, the enrichment rate of plumbum, tin, bismuth and zinc is more than 98%, the quality of refined indium products is more than 99.995%, and plumbum enriching slag containing greater than 60% of Pd is obtained. The technical scheme can independently form a system, can also be used for improving and perfecting old technologies and has higher popularization and application value.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

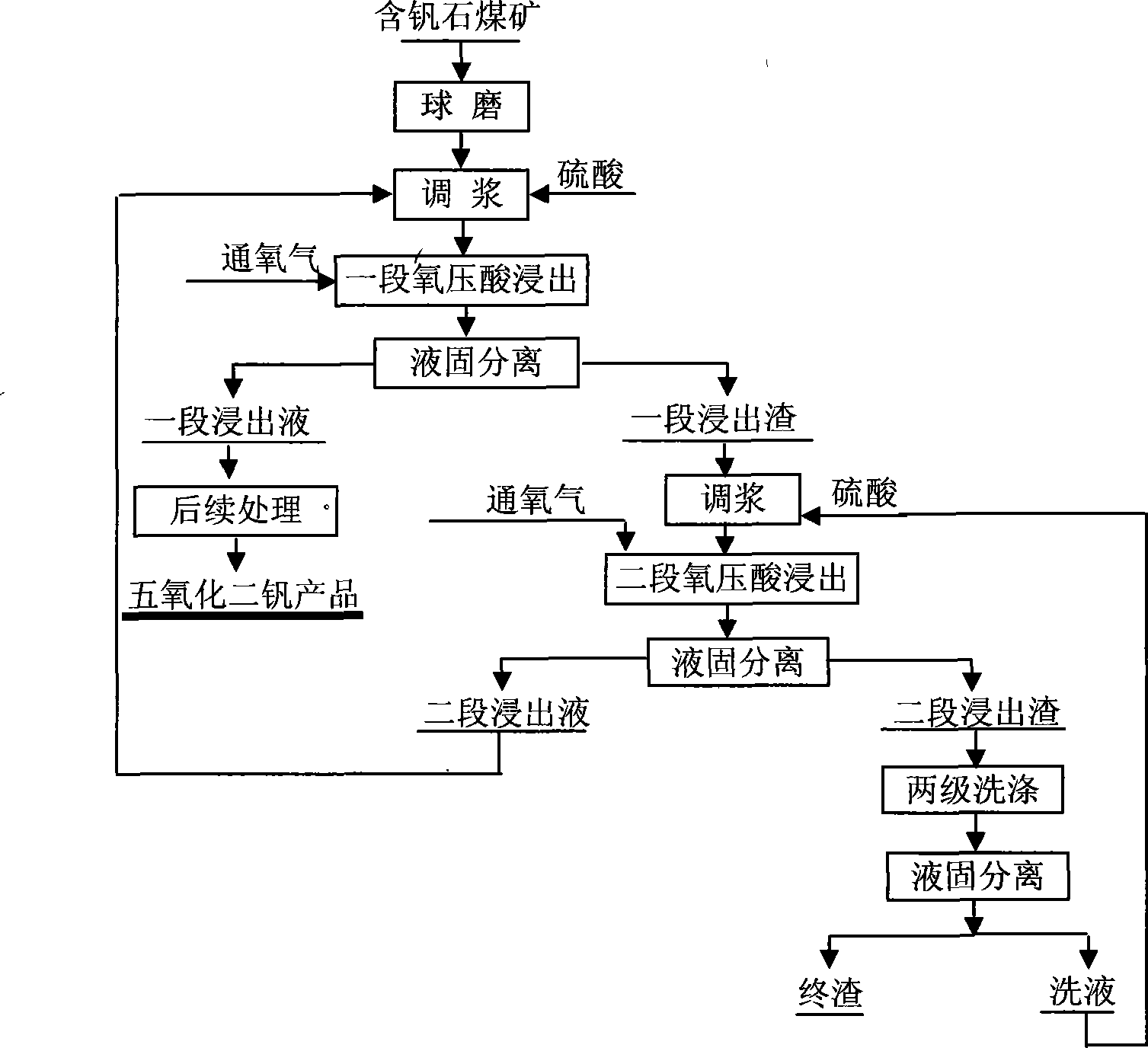

Method for leaching vanadium from vanadium-containing coal mine

Owner:KUNMING UNIV OF SCI & TECH

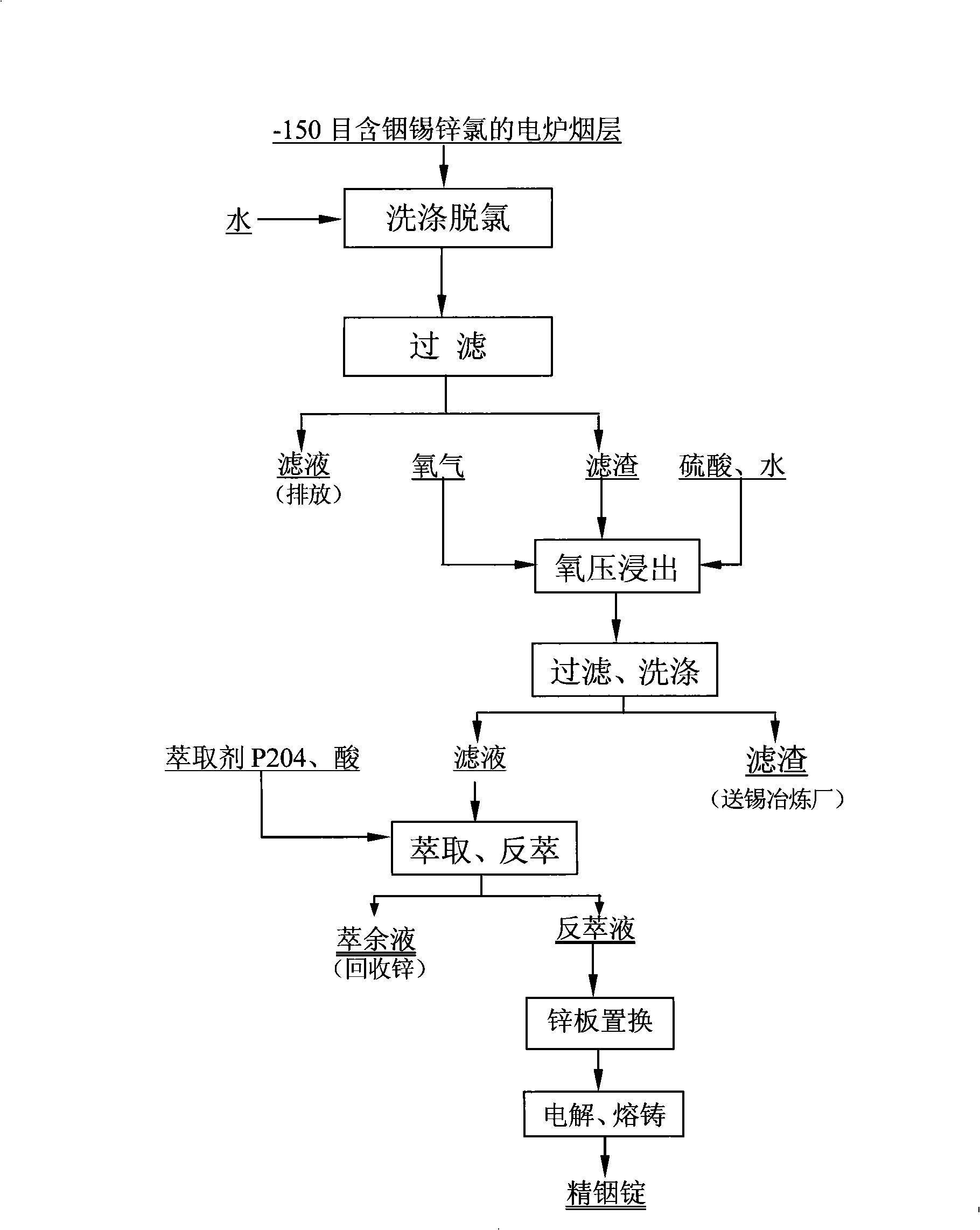

Method for treating indium stannum smoke raw material

InactiveCN101307385AEasy to settleEasy to settle into slagProcess efficiency improvementIndiumResource utilization

The invention relates to a treatment method for raw materials containing indium, tin, zinc and chlorine, in particular to a method for reclaiming valuable metal aiming at producing smoke dust containing the indium and the chloride during the smelting of the zinc, lead, and the tin. The method uses water to wash and remove the chloride in smoke dust raw material, then a dechlorination material is added into a pressure titanium kettle, is added with sulphuric acid and is aerated with oxygen to perform oxygen pressure heating leaching so that the indium and the zinc are leached and enter solution, the tin is leached out and transformed into metastannic acid to sink into residue, and the filtered tin-containing filter residue is reclaimed and reused; the indium and the zinc enter the solution, extracting agent P204 is adopted to extract the indium to realize the indium-zinc separation, extraction liquid is subject to the back extraction and the zinc plate replacement to produce sponge indium, the sponge indium is electrolyzed, purified, and melted and cast to produce an indium ingot product; and remaining liquid is extracted to reclaim the zinc. The method solves the corrosion resistant problem of the prior equipment, namely the pressure titanium kettle, improves the leaching rate of the indium, deposits the tin at the same time, solves the problem of indium-tin separation, and has the characteristics of reducing energy consumption and production cost, high resource utilization rate, and environmental protection.

Owner:YUNNAN TIN GROUP HLDG

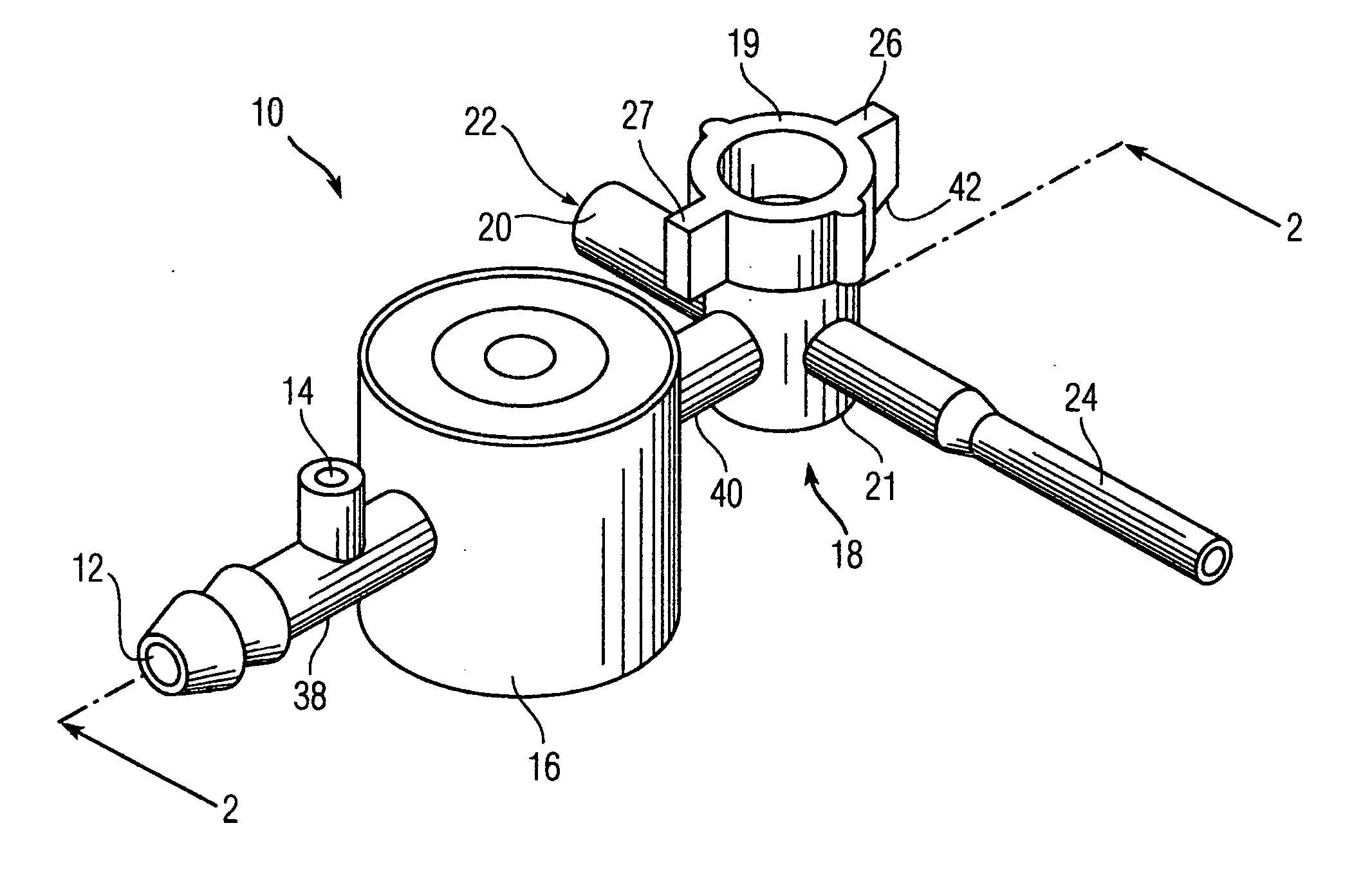

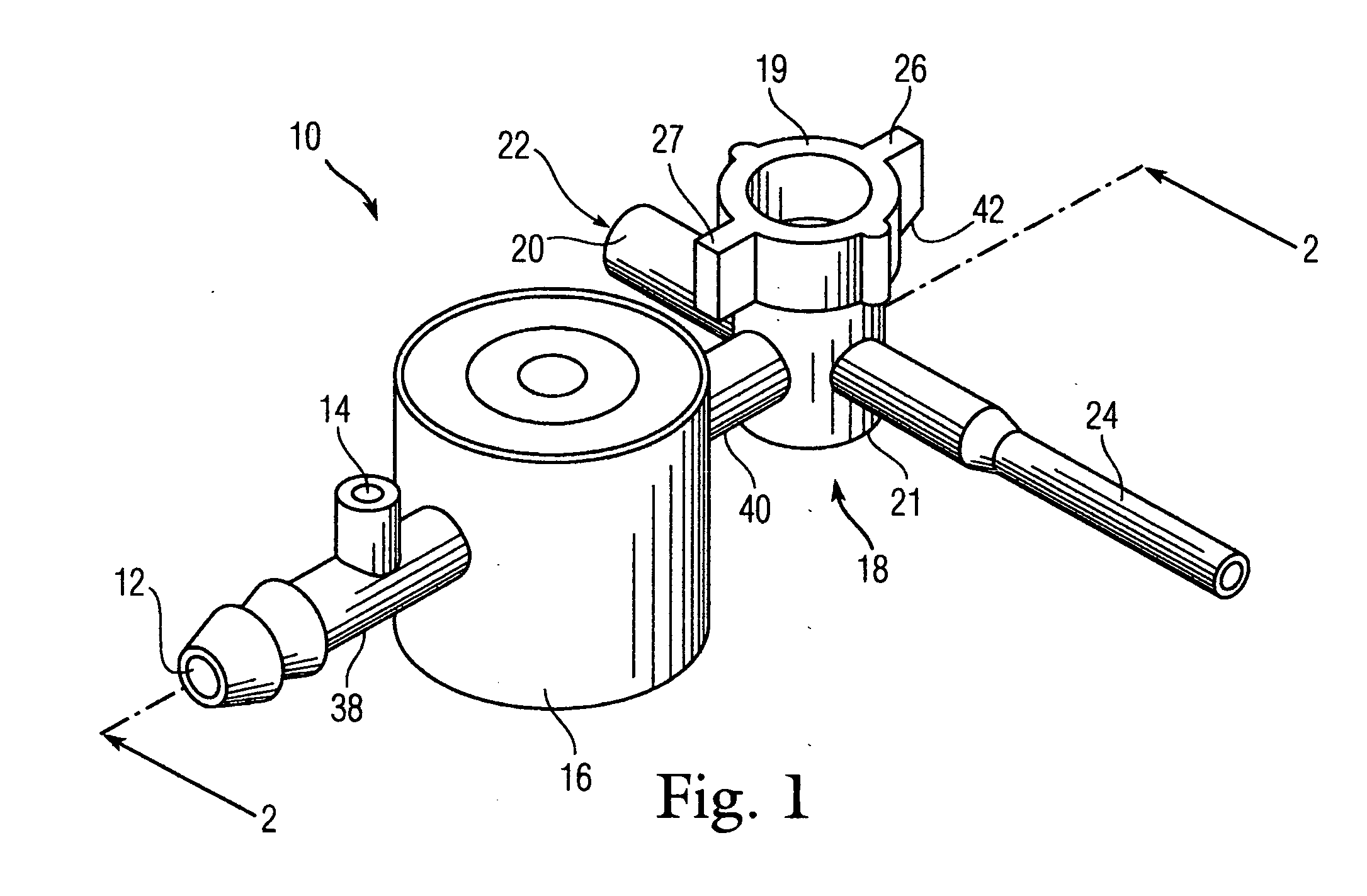

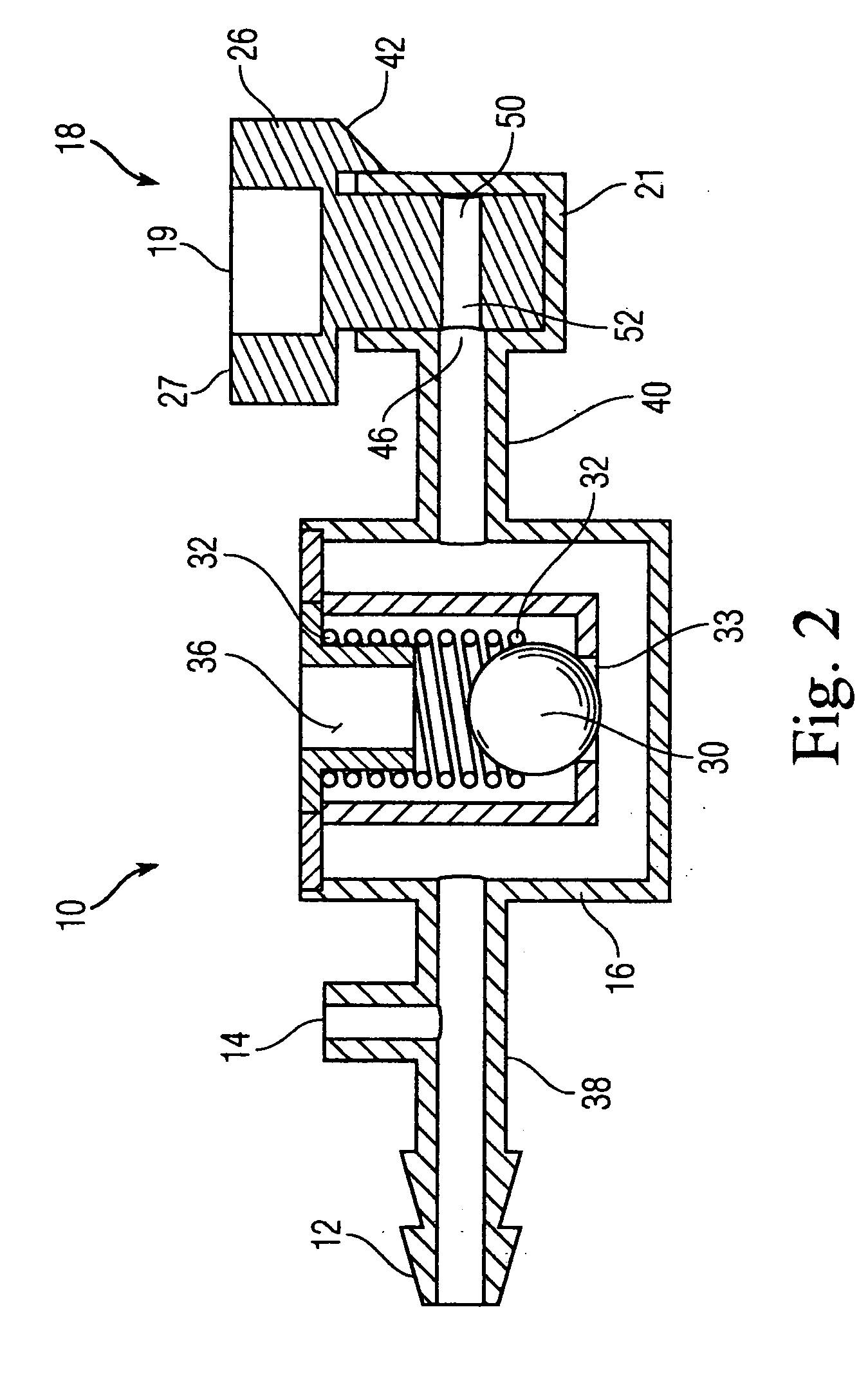

Bronchoscopy oxygenation system

A bronchoscopy oxygenation system having a channel for inserting alternately an instrument or fluids and for delivering oxygen to a patient. The system being provided with pressure relief vent and a pressure relief valve for the relief of excessive oxygen pressure. The bronchoscopy oxygenation system may be used during bronchoscopy and with patient suctioning, bronchoalveolar lavage or biopsy. The bronchoscopy oxygenation system is intended to be used with a conventional bronchoscope.

Owner:WILLEFORD KENNETH L

Top-bottom combined blowing converter technology for high-carbon low-phosphor molten steel with single-slag process

ActiveCN102230052AAchieve productionCarbon oxygen reaction is stableManufacturing convertersPhosphorSlag

The invention discloses a top-bottom combined blowing converter technology for high-carbon low-phosphor molten steel with a single-slag process. The top-bottom combined blowing converter technology for high-carbon low-phosphor molten steel with the single-slag process is characterized in that: the technology comprises preliminary blowing, interim blowing and post blowing; raw materials comprise middle phosphor molten iron; and in post blowing, the content of FeO in furnace lag is controlled in a range of 15% to 20% through employing continuously changed dynamic oxygen lance position on a high lance position, an oxygen supply intensity of 2.5 to 3.5 Nm<3> / t*min, an oxygen pressure of 0.8 to 0.85 Mpa. According to the top-bottom combined blowing converter technology for high-carbon low-phosphor molten steel with the single-slag process, high-carbon low-phosphor molten steel production with the single-slag process is realized by controlling the content of FeO in the furnace lag in the range of 15% to 20% through employing continuously changed dynamic oxygen lance position on the high lance position.

Owner:SHANDONG IRON & STEEL CO LTD

Process for extracting nickel from nickel sulfide material with low copper content

The nickel extracting process of the present invention relates to the one-stage pressurized leaching extraction of nickel from nickel concentrate with low copper content or high sulfur nickel concentrate separated through milling and floating procedure. The process features that under oxygenation and adding sulfur or sulfuric acid, and in 100-180 deg.c and oxygen pressure 50-300 KPa, nickel concentrate is one-step pressurized leached to complete the Ni, Co and Cu leaching process with Fe being fixed in slag. Nickel sulfate solution after liquid-solid separation may be used in production pure nickel sulfate or electrolyte while recovering Co, Cu and other valuable metals. The process is simple and high in production efficiency.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

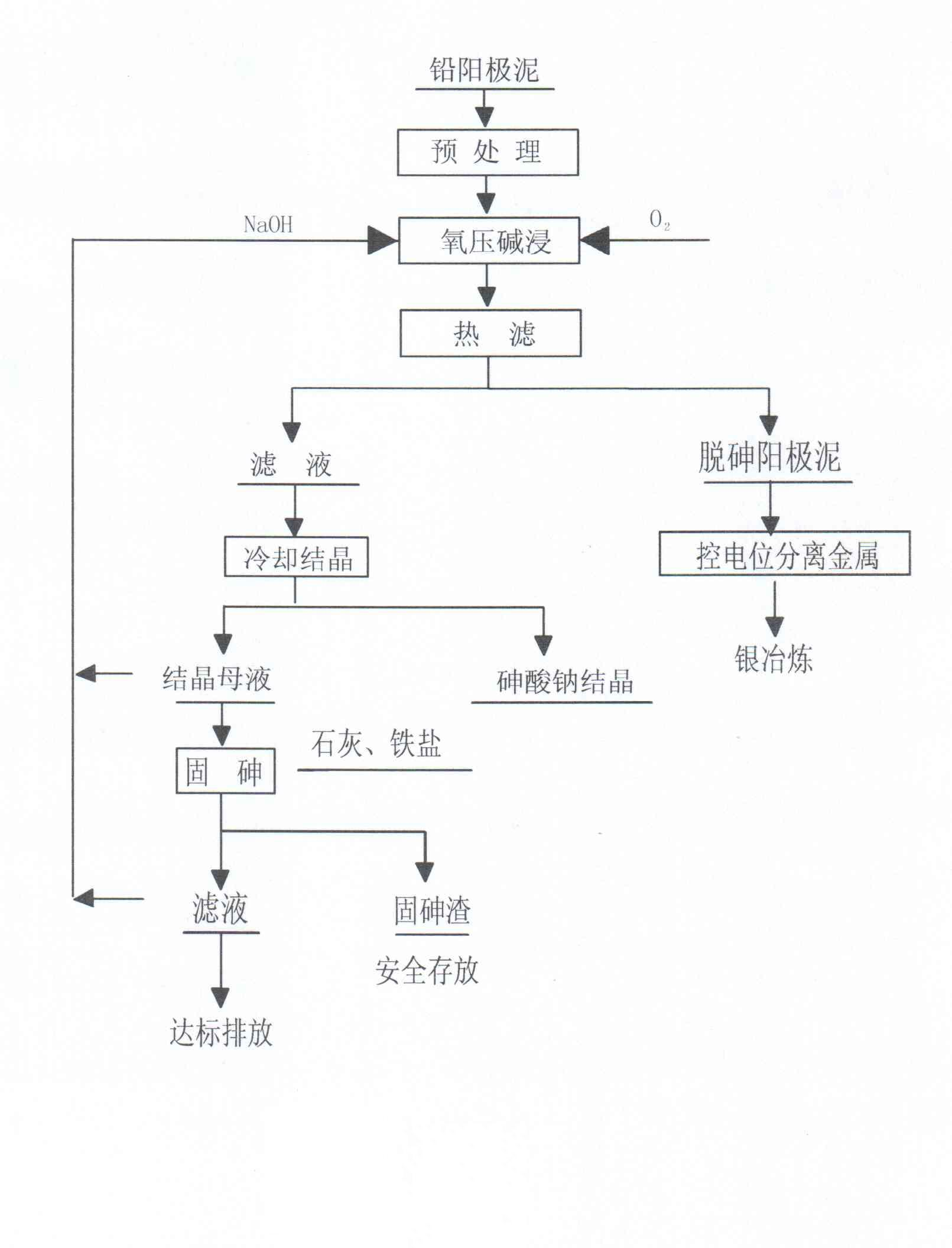

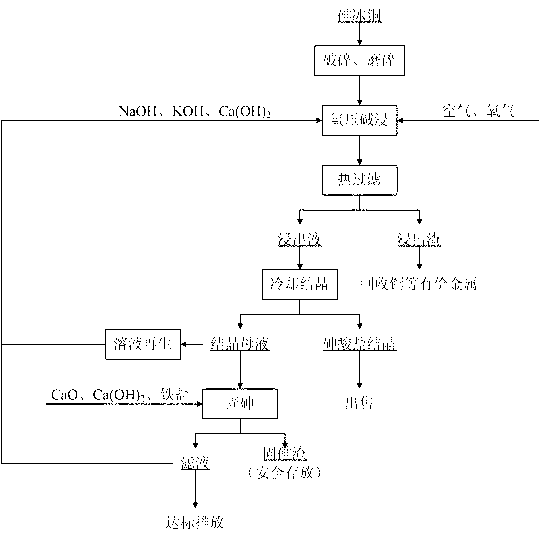

Method for dearsenicating fresh high-arsenium lead anode slime under oxygen pressure

InactiveCN102634666AEfficient removalSlag contains little arsenicProcess efficiency improvementFiltrationLow oxygen

The invention provides a method dearsenicating fresh high-arsenium lead anode slime under oxygen pressure, which comprises the following steps: pretreating lead anode slime, adding alkali, introducing oxygen, carrying out alkali dip under oxygen pressure, and carrying out hot filtration to form a filtrate and dearsenicated anode slime; after separating metals from the dearsenicated anode slime, smelting to acquire silver; and cooling to crystallize the filtrate, and separating sodium arsenate crystals and crystallization mother liquor, wherein the crystallization mother liquor is subjected toarsenium fixation to form arsenium fixed residues which are stored, and the filtration after arsenium fixation is subjected to environment-friendly emission. The method provided by the invention has the characteristics of strong selectivity in the reaction process, favorable dearsenication effect, high recovery rate of noble metals (gold and silver), low oxygen consumption and low energy consumption, and is simple to operate. The invention is suitable for dearsenicating lead anode slime in the hydrometallurgical process.

Owner:HULUDAO ZINC IND CO LTD

Low resistance tunneling magnetoresistive sensor with natural oxidized double MgO barrier

A high performance TMR sensor is fabricated by incorporating a tunnel barrier having a Mg / MgO / Mg configuration. The 4 to 14 Angstroms thick lower Mg layer and 2 to 8 Angstroms thick upper Mg layer are deposited by a DC sputtering method while the MgO layer is formed by a NOX process involving oxygen pressure from 0.1 mTorr to 1 Torr for 15 to 300 seconds. NOX time and pressure may be varied to achieve a MR ratio of at least 34% and a RA value of 2.1 ohm-um2. The NOX process provides a more uniform MgO layer than sputtering methods. The second Mg layer is employed to prevent oxidation of an adjacent ferromagnetic layer. In a bottom spin valve configuration, a Ta / Ru seed layer, IrMn AFM layer, CoFe / Ru / CoFeB pinned layer, Mg / MgO / Mg barrier, CoFe / NiFe free layer, and a cap layer are sequentially formed on a bottom shield in a read head.

Owner:HEADWAY TECH INC

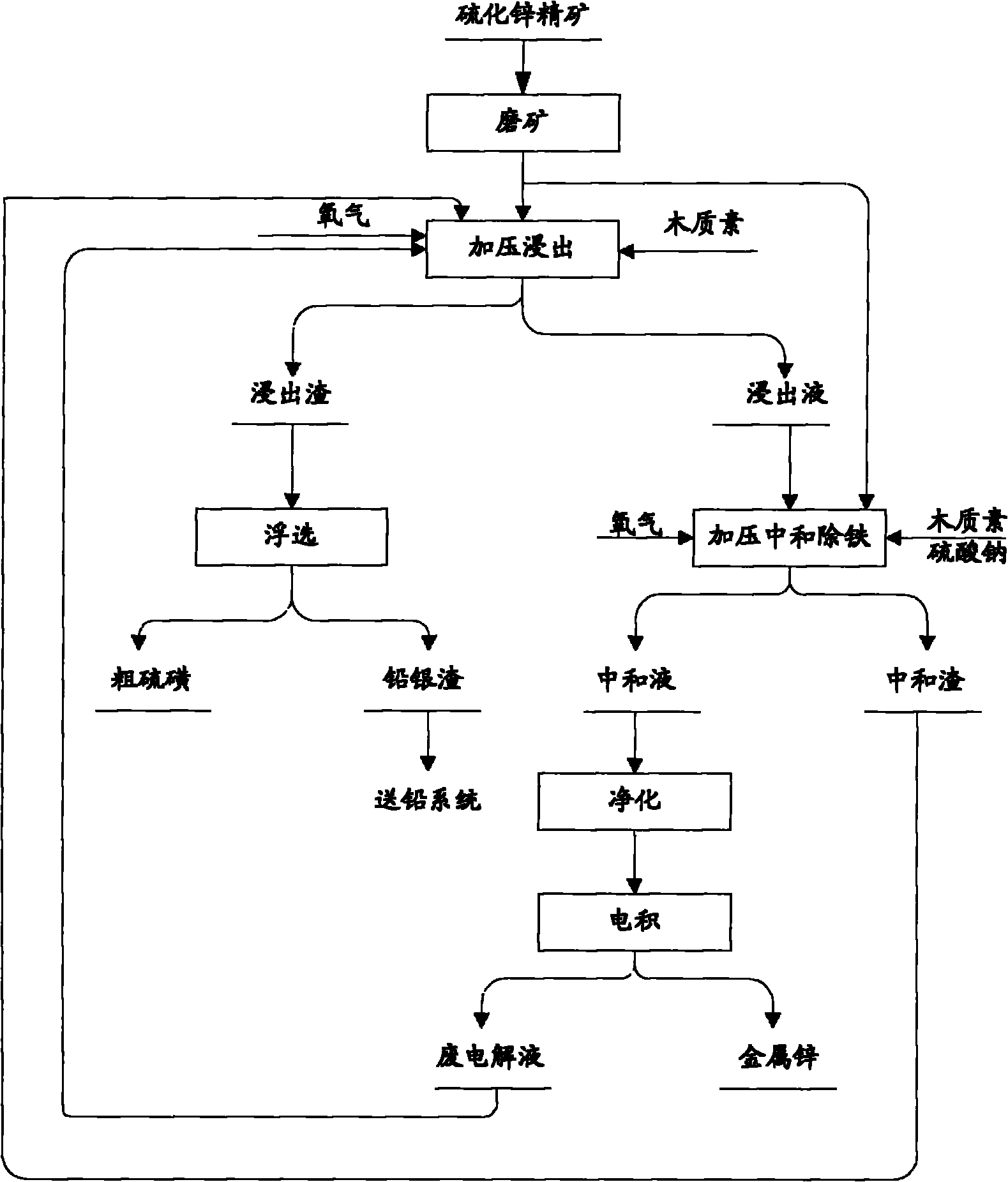

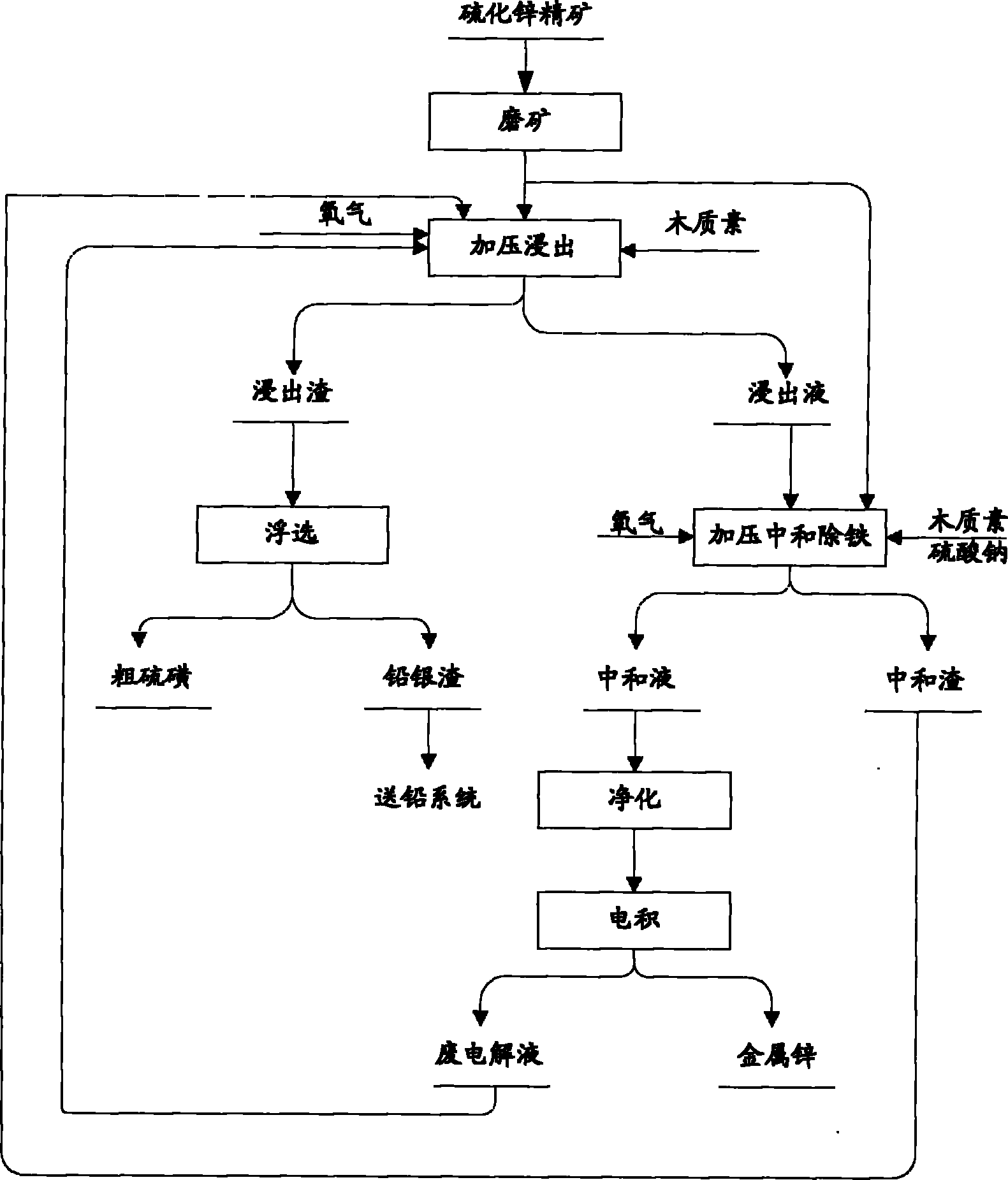

Treatment method of zinc sulfide ore concentrates

InactiveCN102134654AImprove leaching rateShort processProcess efficiency improvementPregnant leach solutionHydrometallurgy

The invention discloses a treatment method of zinc sulfide ore concentrates, which comprises the following steps of: (a) mixing and size-mixing the zinc sulfide ore concentrates with a sulfuric acid solution with the concentration of 120 to 170g / L, and supplying to a first pressurizing kettle; (b), subjecting the zinc sulfide ore concentrates to acid leaching to obtain a leaching solution and leaching residue; (c) supplying the leaching solution to a second pressurizing kettle, adding a neutralizing agent and an iron removal agent and simultaneously introducing pure oxygen in, and reacting for a second predetermined time in order to implement neutralization and iron removal and obtain a neutralization solution and neutralization residue; and (d) treating a second leaching solution by adopting zinc hydrometallurgy process in order to obtain metal zinc. Thus, full zinc hydrometallurgy in the true sense is accomplished by using the zinc sulfide ore concentrates as a neutralizing agent, oxygen pressure leaching, neutralization and iron removal are combined in one reaction kettle, thereby simplifying the process flow; and the reaction process is intensified through high temperature and pressurization, thereby further raising the leaching rate of zinc.

Owner:YUNNAN METALLURGICAL GROUP

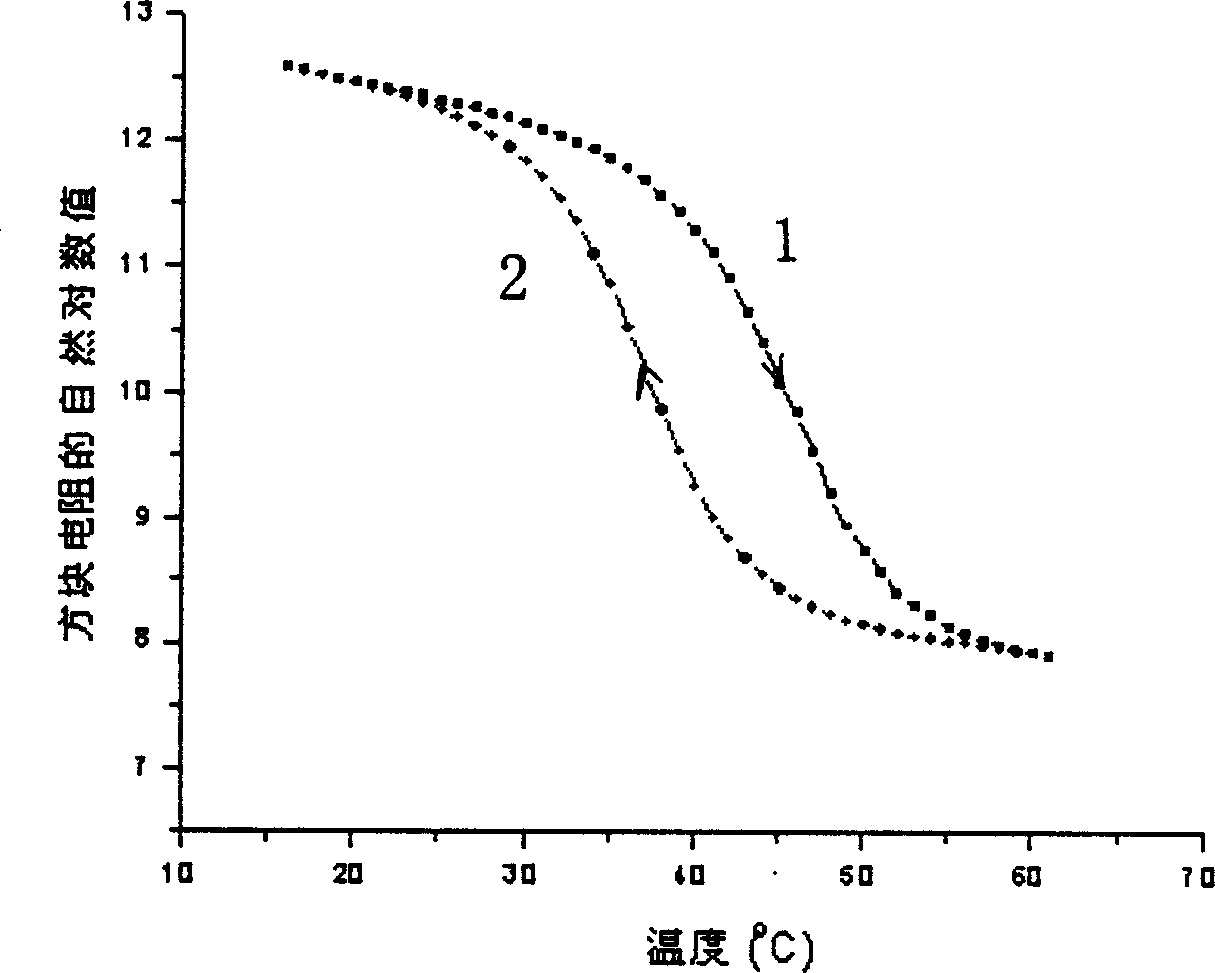

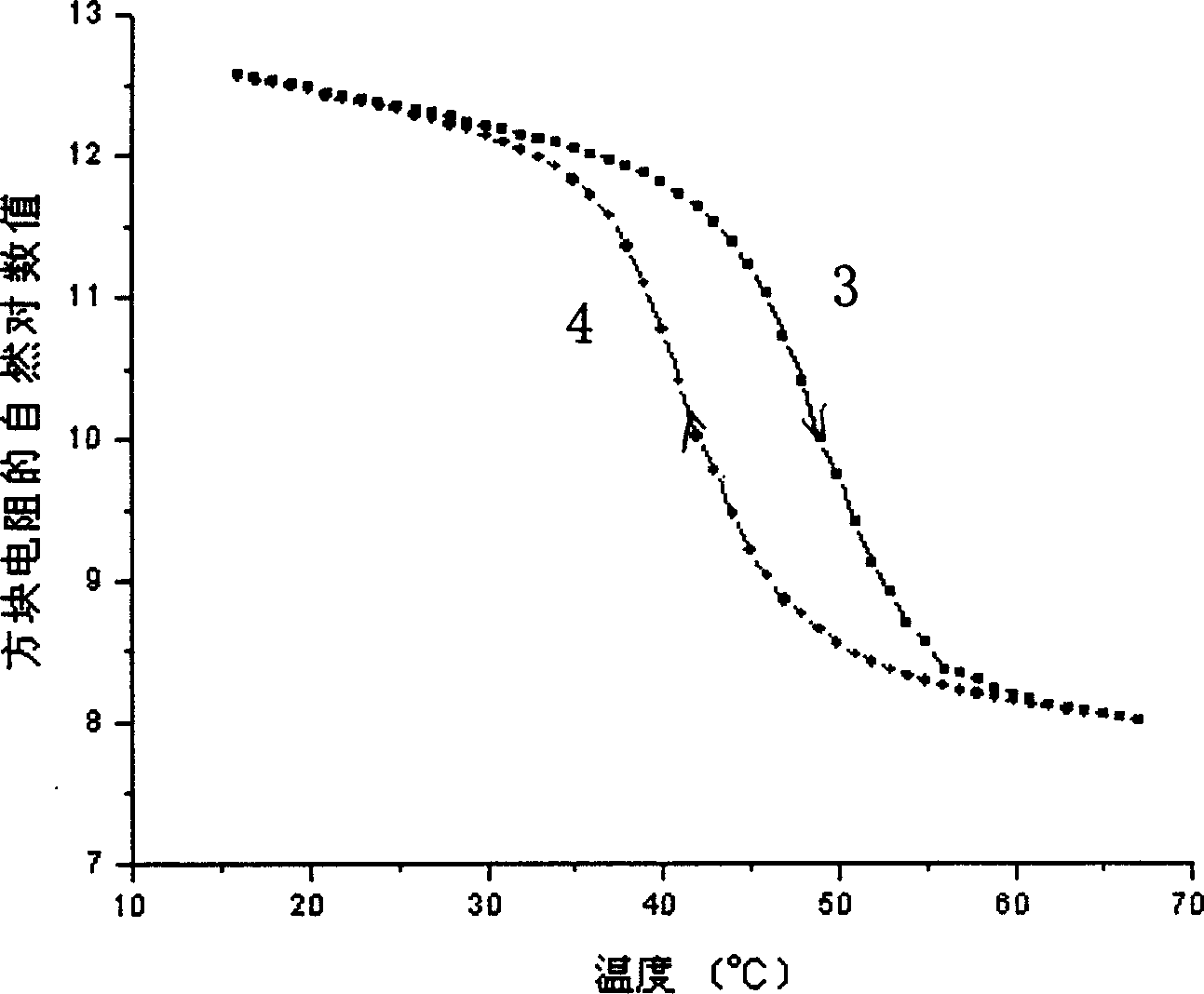

Process for preparing vanadium oxide film capable of regulating phase change temp.

InactiveCN1598040AEasy to moveReduce infrared transmittanceVacuum evaporation coatingSputtering coatingNitrogen gasVanadium oxide

This invention provides a preparation method of vanadium oxides film whose phase change temperature is variable. Siliconoxide film and silicon nitride film deposit on the silicon slice. The method of ion beam reactive sputtering is used to deposit vanadium oxide film. The processing conditions as followings: back bottom vacuum 4X10-4Pa-3X10-3Pa, oxygen pressure 6X10-4Pa-8X10-3Pa, argon gas pressure: 1X10-2Pa-2.3X10-2Pa,ion beam power: 8W-60W, substrate temperature: 120deg.C-450deg.C, sputter time: 10-45min, the vanadium target is butt material. The annealing treatment is for the sample. The processing conditions gas: argon or nitrogen gas, annealing temperature: 250deg.C-580deg.C, annealing time: 20-240 min, and then getting phase change vanadium oxide film.

Owner:HUAZHONG UNIV OF SCI & TECH

Process for gold and silver recovery from a sulphide concentrate

ActiveUS20080286180A1Simple processAcceptable precious metal recoveryPhotography auxillary processesSolvent extractionRetention timeSource material

A process for the extraction of a precious metal, such as gold or silver, from a sulphide ore or concentrate or other source material comprises subjecting the source material to pressure oxidation to produce a pressure oxidation slurry. The pressure oxidation slurry is flashed down to a lower temperature and pressure and is then subjected to a liquid / solid separation to obtain a pressure oxidation solution and a solid residue containing the precious metal. The solid residue is then subjected to cyanidation to extract the precious metal. The formation of thiocyanide during cyanidation is minimized or counteracted by effecting the cyanidation at an elevated oxygen pressure and a reduced retention time, such as 30 to 90 minutes. A method for the reduction of copper cyanide formation during cyanidation leaching is also provided.

Owner:CESL LIMITED

Torch-flame cutting process for super-thick steel plates

InactiveCN102528210AQuality assuranceMeet quality requirementsGas flame welding apparatusNumerical controlSlag

The invention discloses a torch-flame cutting process for super-thick steel plates, which includes steps of utilizing a numerical-control torch-flame cutting machine for torch-flame cutting of the super-thick steel plates, placing a to-be-cut steel plate on the numerical-control torch-flame cutting machine while keeping the surface of the to-be-cut steel plate perpendicular to a cutting torch of the numerical-control torch-flame cutting machine and keeping the distance from the cutting torch to the surfaces of the to-be-cut steel plates ranging from 10mm to 30mm; setting cutting speed, preheating time, preheating oxygen pressure, cutting oxygen pressure and dimethylmethane pressure of the numerical-control torch-flame cutting machine; regulating flame strength of the cutting torch by utilizing the right-angle position formed between the surface of the to-be-cut steel plate and the lateral side thereof as an initial cutting point, enabling the secondary flame to be longer enough to reach the bottom of the to-be-cut steel plate, preheating the initial cutting point for a preset preheating time before initial cutting, and then turning on cutting oxygen, moving the cutting torch forwards when slag flows downwards along edges, and finally increasing moving speed of the cutting torch when the slag is discharged from the bottom until completing the normal cutting operation. The torch-flame cutting process for the super-thick steel plates is capable of guaranteeing quality of cut surfaces, is simple and stable, is safe in use and meets production requirements.

Owner:CITIC HEAVY INDUSTRIES CO LTD

Hyperbaric oxygen devices and delivery methods

A hyperbaric oxygen device and methods of applying hyperbaric oxygen are disclosed. The device comprises an enclosure including a collapsible bag defined by two sheets of fluid impervious material sealed together at both ends such that gas can be delivered between the sheets to inflate the enclosure to a rigid state and maintain the enclosure in the rigid state when oxygen pressure in the interior of the enclosure is cycled between ambient pressure and above ambient pressure.

Owner:AOTI

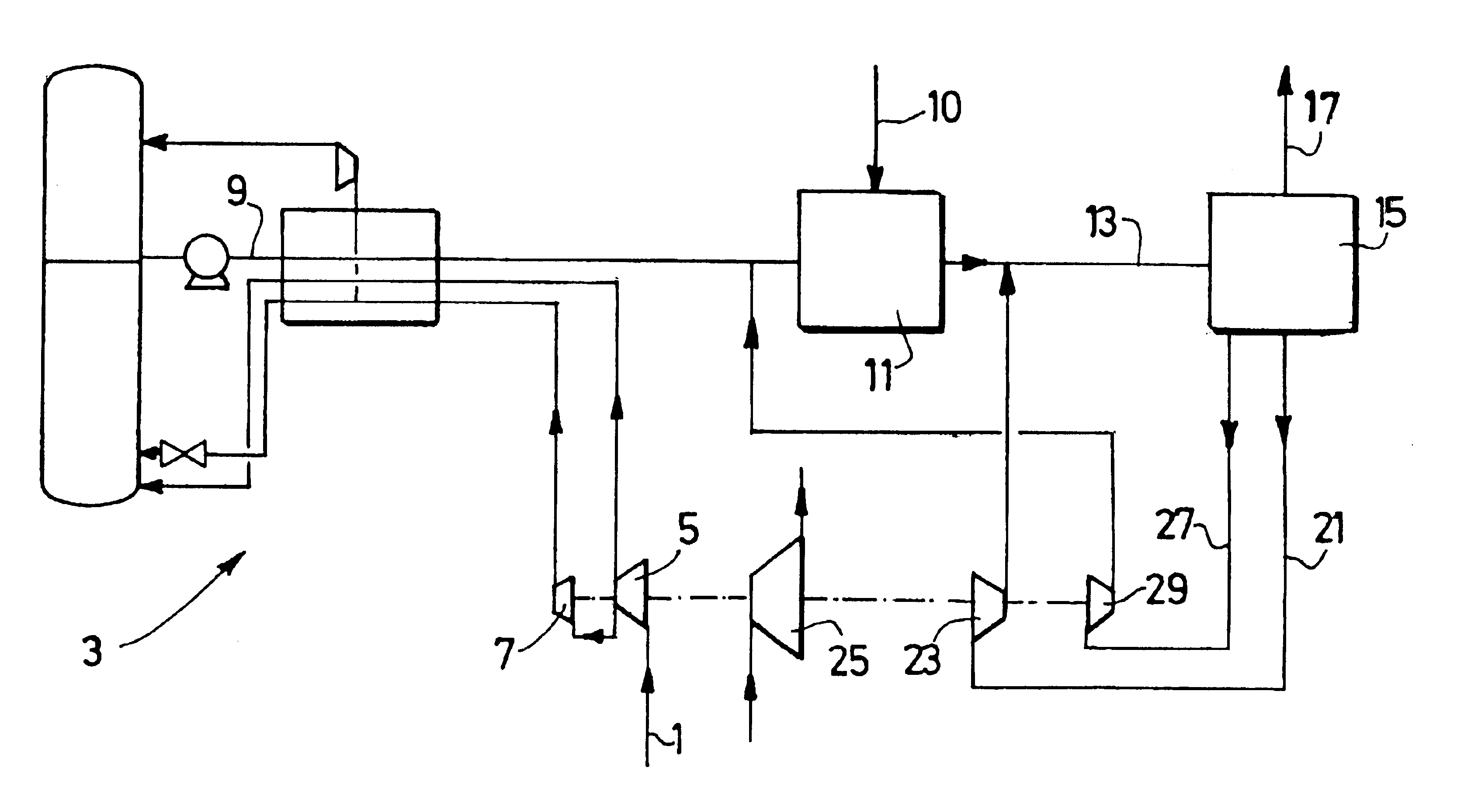

Process and apparatus for the production of methanol

In a process-for the use of a hydrocarbon feedstock (10) by reacting the feedstock in a reactor (11) with oxygen (9) to form a synthesis gas containing at least carbon monoxide, carbon dioxide and hydrogen and subjecting the synthesis gas to a conversion process comprising an exothermic reaction to produce methanol as a final product in a converter (15), the converter operating at an operating pressure, said oxygen being provided to the reactor at an oxygen pressure, the synthesis gas is produced at a pressure higher than the operating pressure of the converter.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Comprehensively-utilizing process of waste residue containing vanadium, molybdenum, nickel and cobalt

The invention discloses a comprehensively-utilizing process of waste residue containing vanadium, molybdenum, nickel and cobalt, which is characterized in that the process flow comprises the steps of crushing and grinding crude nickelferrite, carrying out acid leaching by oxygen pressure, comprehensively recovering the vanadium and the molybdenum from leached residue, removing ferrite, copper, silicon and aluminum in the leaching liquid, deeply removing impurities by P204 extraction, separating nickel and cobalt by P507 extraction, electrolyzing and deposing the nickel and deposing cobalt carbonate. The acid leaching by oxygen pressure is carried out in a pressure kettle and oxygen instead of nitric acid is introduced during leaching. The acid leaching by oxygen pressure comprises the following steps of: mixing size and pre-leaching, adding water and crude nickelferrite powder into a size mixing tank, stirring the calculated sulfuric acid and mixing into size; and inputting the mixed size into the pressure kettle by a size mixing pump, introducing oxygen for acid leaching by oxygen pressure, filtering and washing after leaching, carrying out reverse flow washing on the leached residue for three times and using washed water returned for mixing size as a supplemented preparation solution; and recovering vanadium and the molybdenum from the washed leached residue. According to the technical scheme, small testes and semi-industrial tests are finished and achieve favorable effects, a production workshop capable of annually producing 1,000t / a of electrolytic nickel and 434t / a of CoCo3 is established and is presently converted into production after debugging and trial production. Compared with the prior art, the invention obtains remarkable effect.

Owner:雷在荣

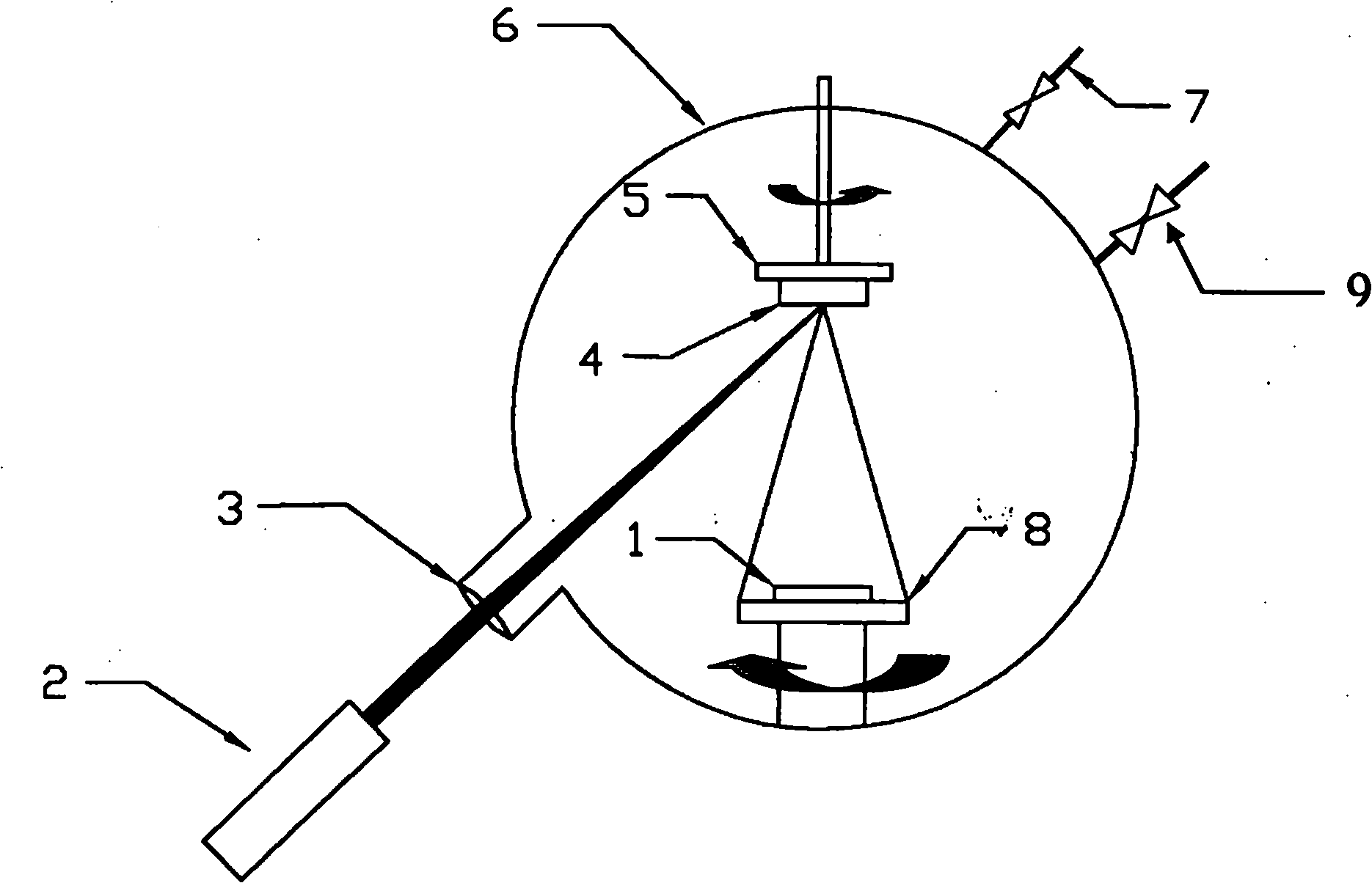

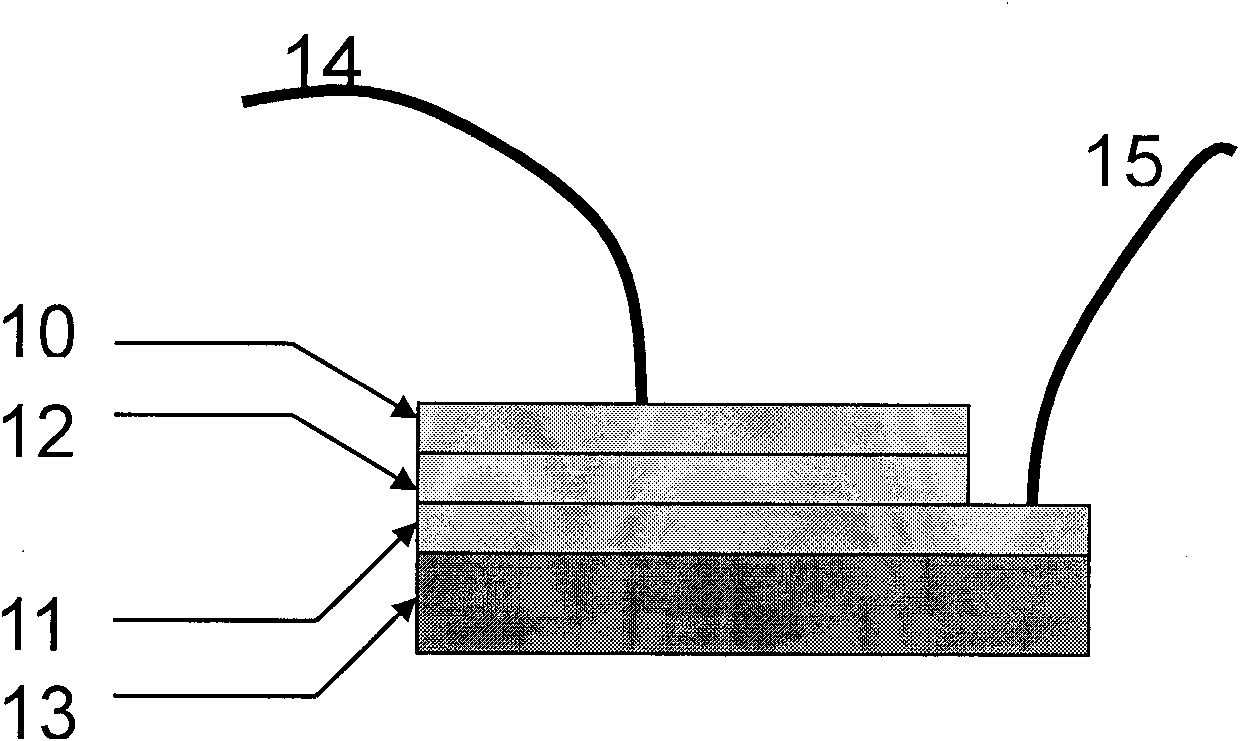

Ferroelectric metal hetero-junction based memristor and preparation method thereof

InactiveCN101864592ASmooth transitionThe periodicity of the resistance state is smallPolycrystalline material growthAfter-treatment detailsOptoelectronicsLithium niobate

The invention relates to a ferroelectric metal hetero-junction based memristor; wherein the memristor material-ferroelectric lithium niobate is prepared by a pulse laser deposition system; monocrystal LN target material (4) is fixed on a target platform (5) of the pulse laser deposition system, and is placed in a growth chamber (6) of a pulse laser deposition film-making system; the vacuum in the growth chamber is pumped to be below 0.8*10-4Pa, oxygen gas flows in, and the oxygen pressure is from 25 to 35Pa, the substrate temperature is heated from 600-650 DEG; a KrF excimer laser is started, and the deposition time is determined according to monopulse energy; in-situ 500-650 DEG annealing is carried out 20-90min; the film has spontaneous polarization and 180-degree domain boundary; the memristor ferroelectric lithium niobate film is clamped between two metal electrode films to form a memristor unit with a miniature sandwich structure; the device can be applied to a high-density low-energy-consumption nonvolatile resistance random access memory.

Owner:NANJING UNIV

Method for removing arsenic matte by alkaline leaching at oxygen pressure and recovering arsenic

ActiveCN103255289AReduce pollutionReduce energy consumptionProcess efficiency improvementPregnant leach solutionLiquid ratio

The invention relates to a method for removing arsenic matte by alkaline leaching at oxygen pressure and recovering arsenic, and belongs to the technical field of hydrometallurgy. The method comprises the following steps of: crushing arsenic matte and adding the crushed arsenic matte according to the solid-to-liquid ratio of 1:(3-20mg / ml) to form pulp; adding the pulp to a pressurizing kettle; introducing a gas oxidizing medium and performing an alkaline leaching reaction at oxygen pressure for 1-5 hours by controlling the pressure at 0.2-1.8MPa, the leaching temperature at 100-200 DEG C, and the stirring speed at 300-600r / min; flashing and filtering the pulp after alkaline leaching at oxygen pressure to obtain leached residue for recovering copper; and cooling and crystallizing leaching liquid subjected to alkaline leaching at oxygen pressure and recovering arsenic. According to the method provided by the invention, the reaction process is strong in selectivity, good in arsenic removal effect, high in degree of automation, high in production efficiency, small in environmental pollution and low in energy consumption.

Owner:郴州金铖环保科技有限公司

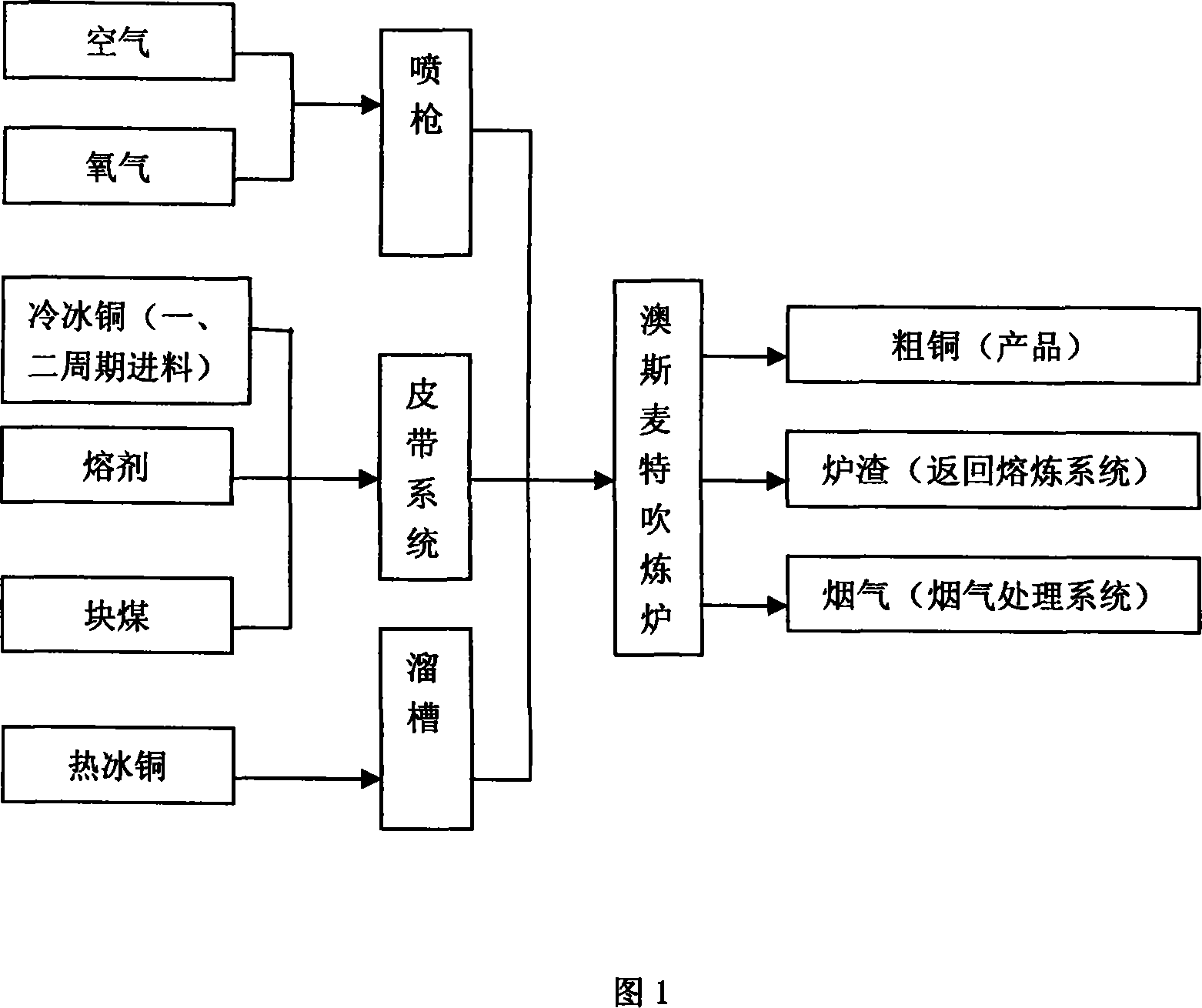

Oxygen-enriched air refining method for copper by using converting furnace

ActiveCN101148705AFix security issuesEasy to handleRotary drum furnacesCrucible furnacesFurnace temperatureMelting tank

The present invention is oxygen-enriched air copper refining process in a converting furnace. The process features the oxygen-enriched air converting in the condition of oxygen pressure higher than the inner layer air pressure and common air converting in other condition, the control of the furnace temperature with cold copper material in oxygen-enriched air converting, the control of the coarse copper product quality through stopping addition of cold copper material before finishing the air refining of coarse copper product, and the alternate addition of oxygen-enriched air and common air to avoid generation of foamed slag. The present invention has improved operation environment, raised converting rate, lowered fuel consumption and raised economic benefit.

Owner:山西北方铜业有限公司

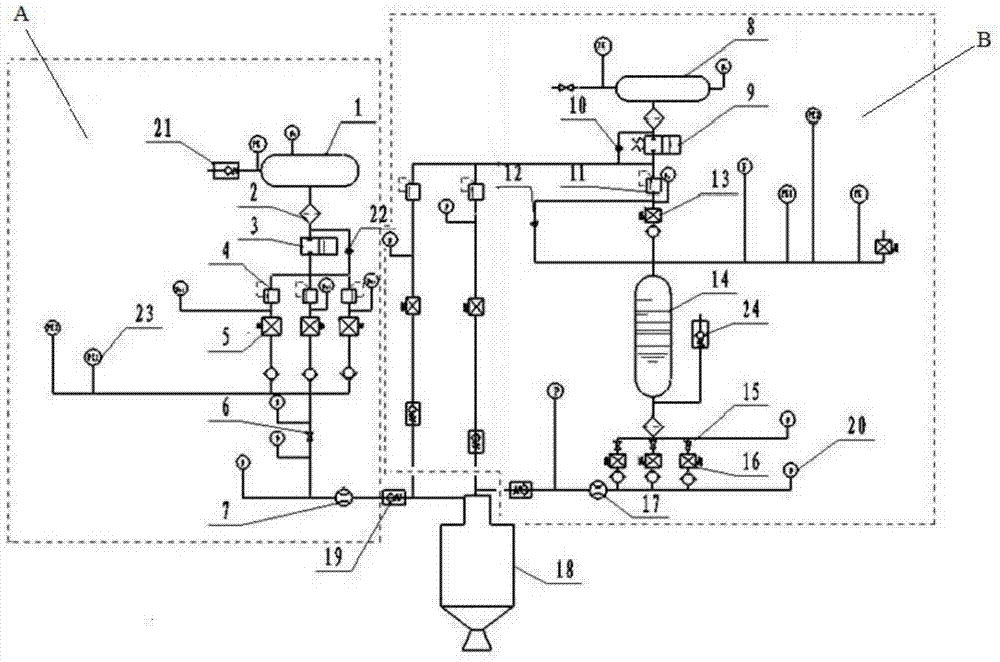

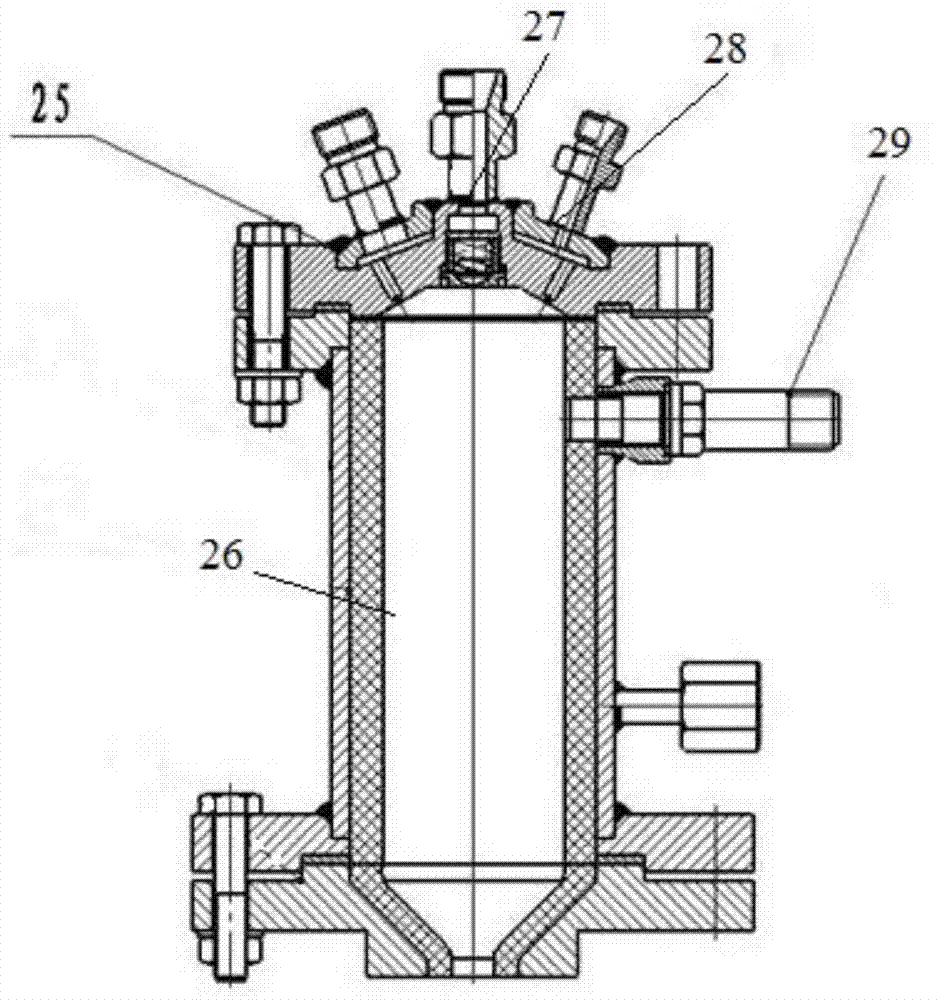

Variable working condition type primary rocket system of rocket based combined cycle engine

The invention discloses a variable working condition type primary rocket system of a rocket based combined cycle engine. The variable working condition type primary rocket system comprises a propellant supply system and a primary rocket engine thrust chamber which are connected through a pipeline, wherein the propellant supply system comprises an oxidant supply system and a fuel supply system, the oxidant supply system comprises an oxygen flow rate control system, the oxygen flow rate control system comprises a plurality of oxygen conveying pipelines, each oxygen conveying pipeline is provided with an oxygen pressure relief valve for opening and closing the corresponding oxygen conveying pipeline, an outlet of each oxygen conveying pipeline is connected with an oxygen perforating plate, the fuel supply system comprises a plurality of fuel conveying pipelines, an outlet of each fuel conveying pipeline is provided with a cavitation venturi pipe, and an inlet of each fuel conveying pipeline is connected with a nitrogen pressure relief device. The variable working condition type primary rocket system of the rocket based combined cycle engine has the advantages that the flow rate of a propellant can be accurately, controllably, stably and quickly adjusted, the complexity is low, and the operation is simple.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Device and method for producing oxyhydrogen through vehicle-mounted oxyhydrogen producer using residual electricity supplied by internal combustion engine

ActiveCN102128107AAvoid hazards such as flashbackImprove stabilityElectrolysis componentsInternal combustion piston enginesHydrogen pressureExternal combustion engine

The invention relates to a device and method for producing oxyhydrogen through a vehicle-mounted oxyhydrogen producer using residual electricity supplied by an internal combustion engine. The system keeps the entire main body and a control system of the original internal combustion engine, one set of vehicle-mounted oxyhydrogen producer control system and one set of oxyhydrogen production, storage and supply system are added. The device mainly comprises the vehicle-mounted oxyhydrogen producer, a hydrogen storage tank, a hydrogen pressure reducer, a hydrogen flame retarding valve, an oxygen storage tank, an oxygen pressure reducer, an oxygen flame retarding valve, a storage battery loop relay connected between the engine and a storage battery, an oxyhydrogen producer loop relay connected between the engine and the oxyhydrogen producer, an electronic control unit and the like, wherein the hydrogen storage tank, the hydrogen pressure reducer and the hydrogen flame retarding valve are connected with a hydrogen outlet of the vehicle-mounted oxyhydrogen producer; and the an oxygen storage tank, the oxygen pressure reducer and the oxygen flame retarding valve are connected with an oxygen outlet of the vehicle-mounted oxyhydrogen producer. The electronic control unit controls the operation of the oxyhydrogen producer according to the relationship between the engine and the voltage ofthe storage battery and the pressure of hydrogen and oxygen in the storage tanks, preferably ensures the charge of the storage battery and stops the operation of the oxyhydrogen producer when the gases in the hydrogen and oxygen storage tanks have overpressure.

Owner:南通秀丽环保科技发展中心(有限合伙)

Method for recovering sulfur element from zinc sulphide concentrate direct leaching residues

InactiveCN101734626ASimple processPromote environmental protectionSulfur compoundsNatural resourceNatural source

The invention relates to a method for recovering sulfur element from zinc sulphide concentrate direct leaching residues. The method comprises the following steps of: (1) carrying out floatation separation on zinc sulphide concentrate direct leached residues to obtain sulfur concentrate and floatation tailings, and stacking floatation tailings after pressure filtration; (2) carrying out filtration, heat fusing and heat filtration on the sulfur concentrate in step (1) to obtain a sulfur element solution; and 3) keeping the temperature of the sulfur element solution in step (2), and delivering into a sulfur granulator for granulating. The invention can recover sulfur element from zinc concentrate direct leached residues, and obtain industrial sulfur through granulation, thereby reducing the filtration stacking amount of oxygen pressure leached residues, and enabling the sulfur in natural sources to be utilized and not wasted.

Owner:CINF ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com