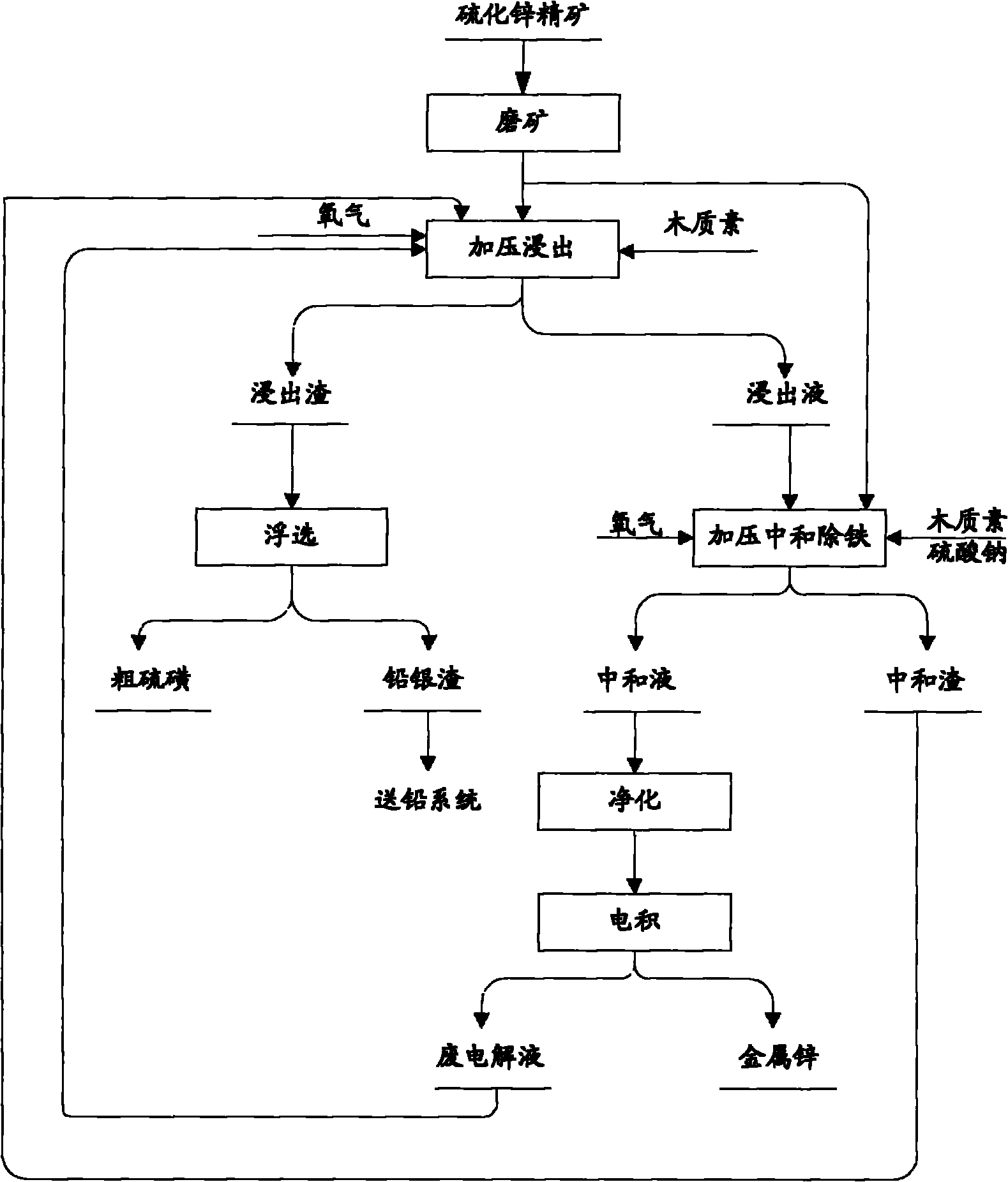

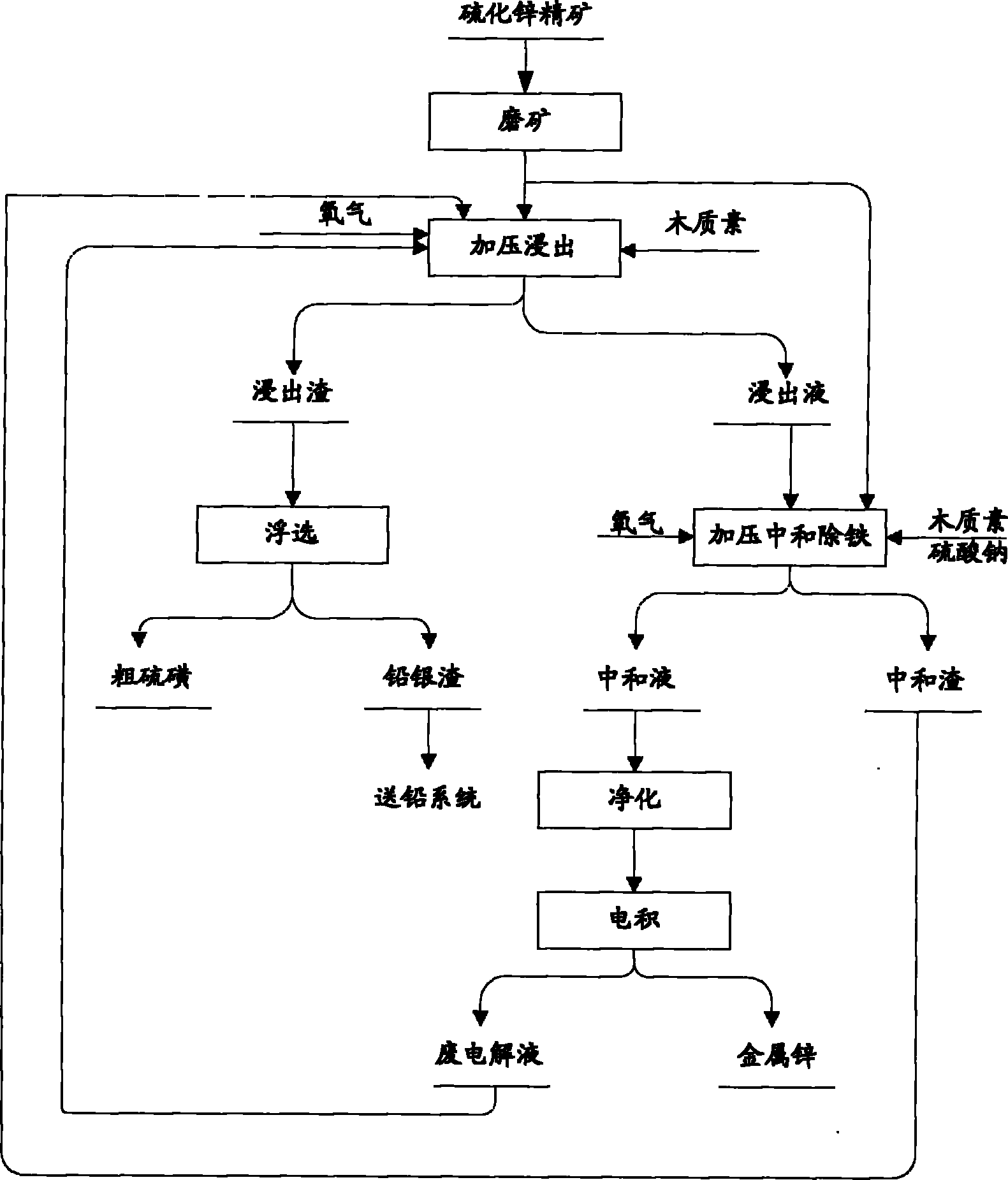

Treatment method of zinc sulfide ore concentrates

A zinc sulfide concentrate and treatment method technology, applied in the direction of improving process efficiency, etc., can solve problems such as difficult cleaning of autoclave, complicated zinc-making process, and complicated next process, so as to reduce process complexity and production costs, The effect of reducing the process flow and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Take zinc sulfide concentrate, wherein the zinc content is 37.5wt%, and the iron content is 5.49wt%.

[0061] The zinc sulfide concentrate is finely ground into a mineral powder whose particle size is less than 320 mesh and 100% of the particles are. Add sulfuric acid solution with a concentration of 140g / L to the finely ground mineral powder, stir fully to make the mineral powder slurry, and inject the slurry into the autoclave.

[0062] Commercially pure oxygen was fed into the first autoclave, and the temperature was raised to 150° C., and the oxygen pressure during the reaction was maintained at 1.2 MPa. After 60 minutes, the reaction was completed, and the reacted slurry was discharged, flashed through a flash tank, and then densely filtered and washed to obtain leaching liquid and leaching residue.

[0063] Among them, the leaching slag is flotation to produce crude sulfur and lead-silver slag, the crude sulfur is sent to produce refined sulfur, and the lead-silv...

Embodiment 2

[0070] Take zinc sulfide concentrate, wherein the zinc content is 42.6wt%, and the iron content is 12.5wt%. The zinc sulfide concentrate is finely ground into mineral powder with a particle size of less than 320 mesh and 95% of the particles.

[0071] Add a sulfuric acid solution with a concentration of 150 g / L to the finely ground mineral powder, stir thoroughly to make the mineral powder slurry, and inject the slurry into the first autoclave. Oxygen was introduced into the first autoclave, and the reaction temperature was raised to 160° C., and the oxygen pressure during the reaction was maintained at 0.8 MPa.

[0072] After 75 minutes, the reaction was completed, and the reacted slurry was discharged, flashed through a flash tank, and then densely filtered and washed to obtain leaching liquid and leaching residue. Among them, the leaching slag is flotation to produce crude sulfur and lead-silver slag, the crude sulfur is sent to produce refined sulfur, and the lead-silver ...

Embodiment 3

[0078] Take zinc sulfide concentrate, wherein the zinc content is 46.8wt%, and the iron content is 12.3wt%. The zinc sulfide concentrate is finely ground into mineral powder with a particle size of less than 320 mesh and a particle size of 98%. Add a sulfuric acid solution with a concentration of 145g / L to the finely ground mineral powder, stir fully to make the mineral powder slurry, and inject the slurry into the first autoclave.

[0079] Oxygen was introduced into the first autoclave, and the reaction temperature was raised to 140° C., and the oxygen pressure during the reaction was maintained at 1.0 MPa.

[0080] After 90 minutes, the reaction is completed, and the reacted slurry is discharged, flashed through a flash tank, and then densely filtered and washed to obtain leaching liquid and leaching residue. Among them, the leaching slag is flotation to produce crude sulfur and lead-silver slag, the crude sulfur is sent to produce refined sulfur, and the lead-silver slag i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com