Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

717 results about "Enrichment methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

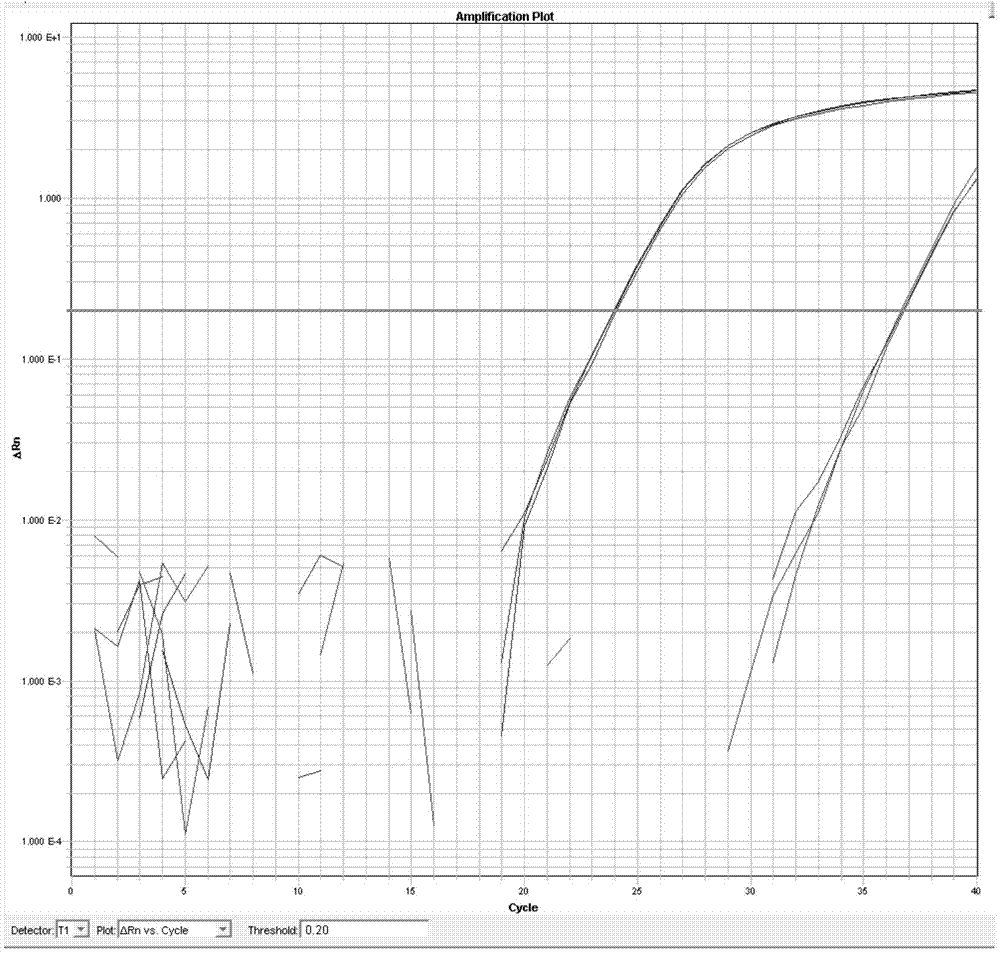

Methods and Compositions for PCR Using Blocked and Universal Primers

ActiveUS20140329245A1Dominate amplificationResistant to dimer formationSugar derivativesMicrobiological testing/measurementEnrichment methodsGenetics

Provided herein are methods and compositions for performing PCR with primers with blocked 3′-ends that are unblocked when these primers anneal to the template. The multiplexed PCR can be used as real-time qPCR, for end-point detection or as enrichment method for next generation sequencing (NGS). Also described herein are methods and compositions to improve sensitivity of mutation-specific PCR when targeting closely-spaced mutations.

Owner:UNITAQ BIO

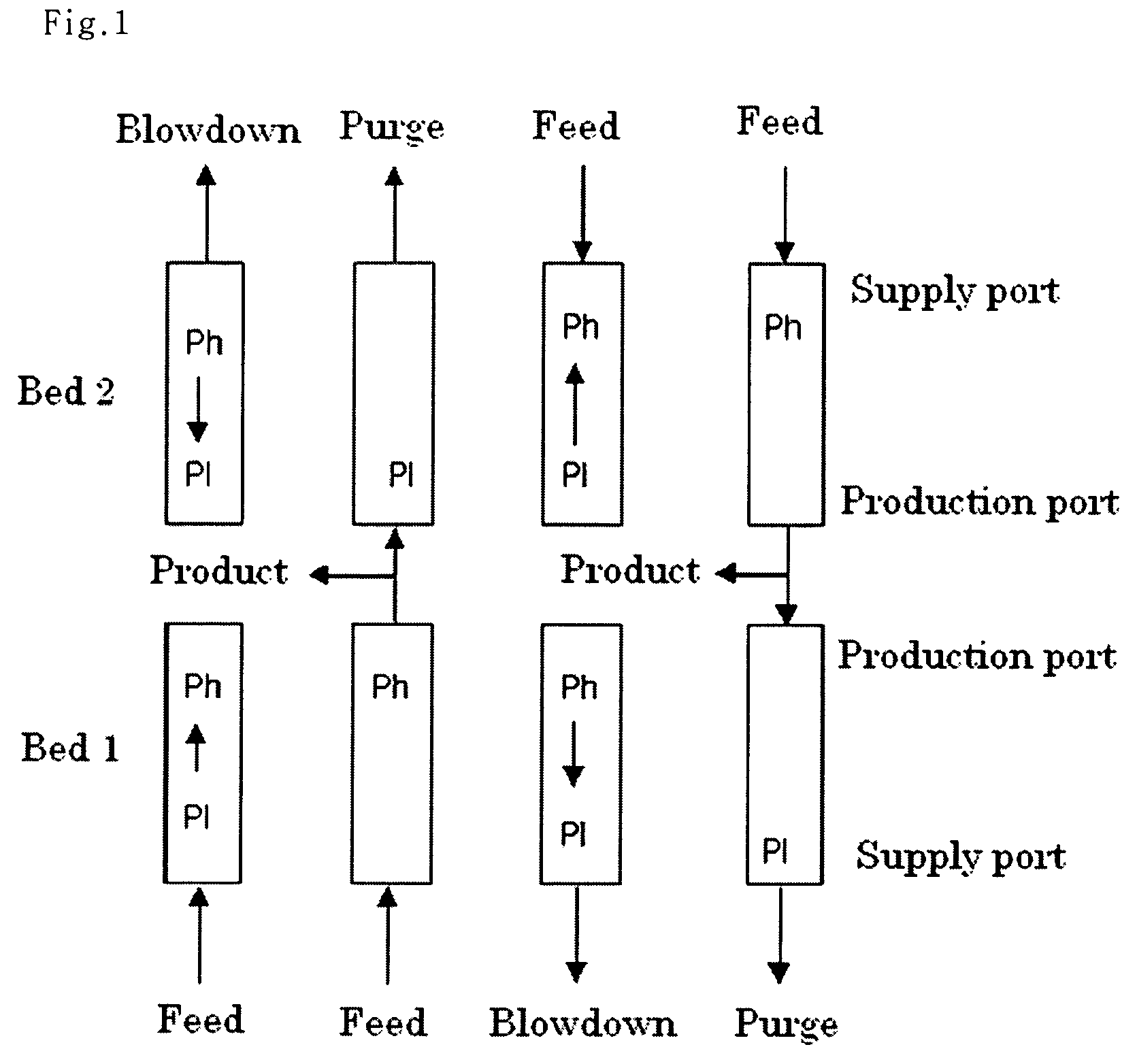

Rapid cycle pressure swing adsorption oxygen concentration method and mechanical valve for the same

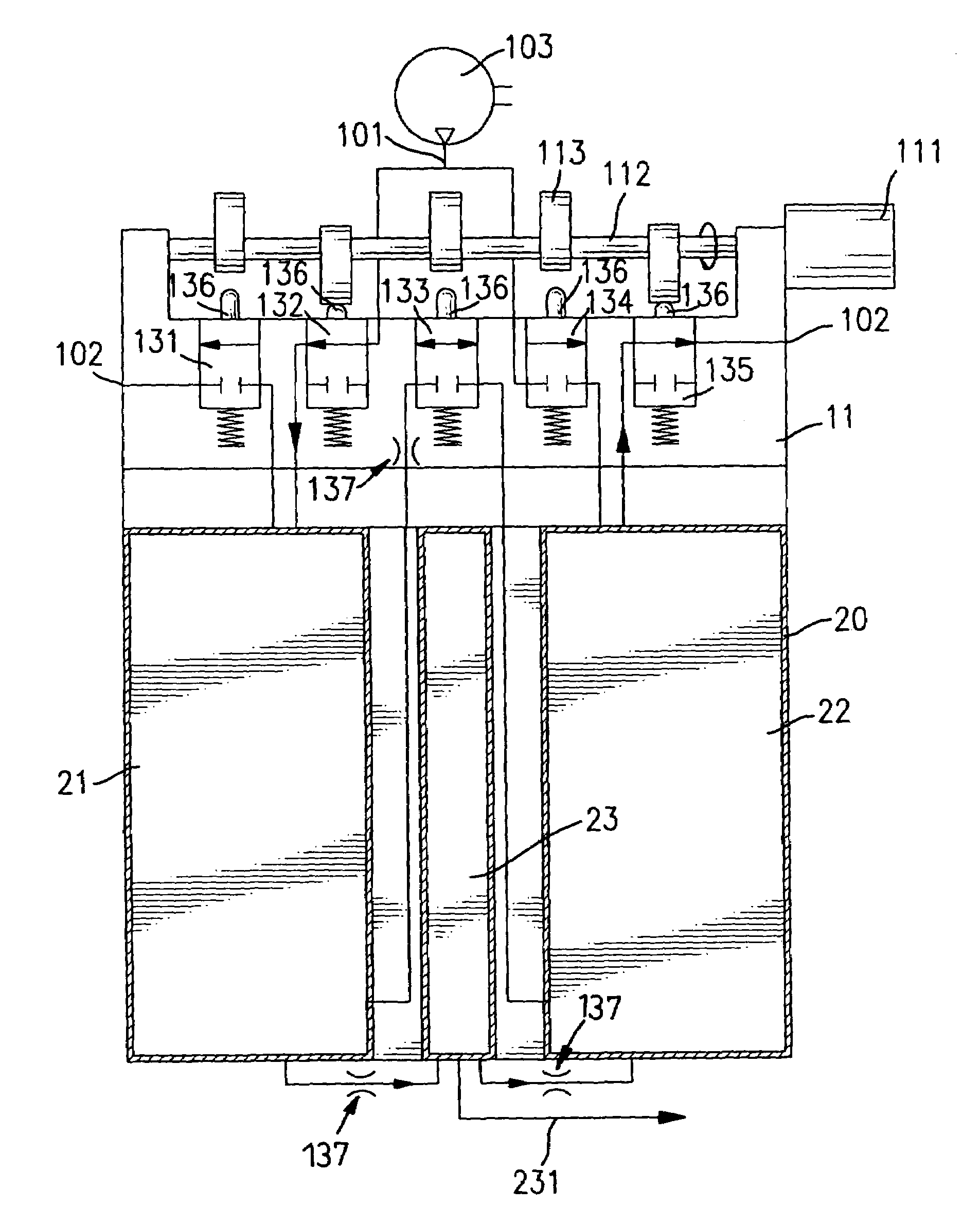

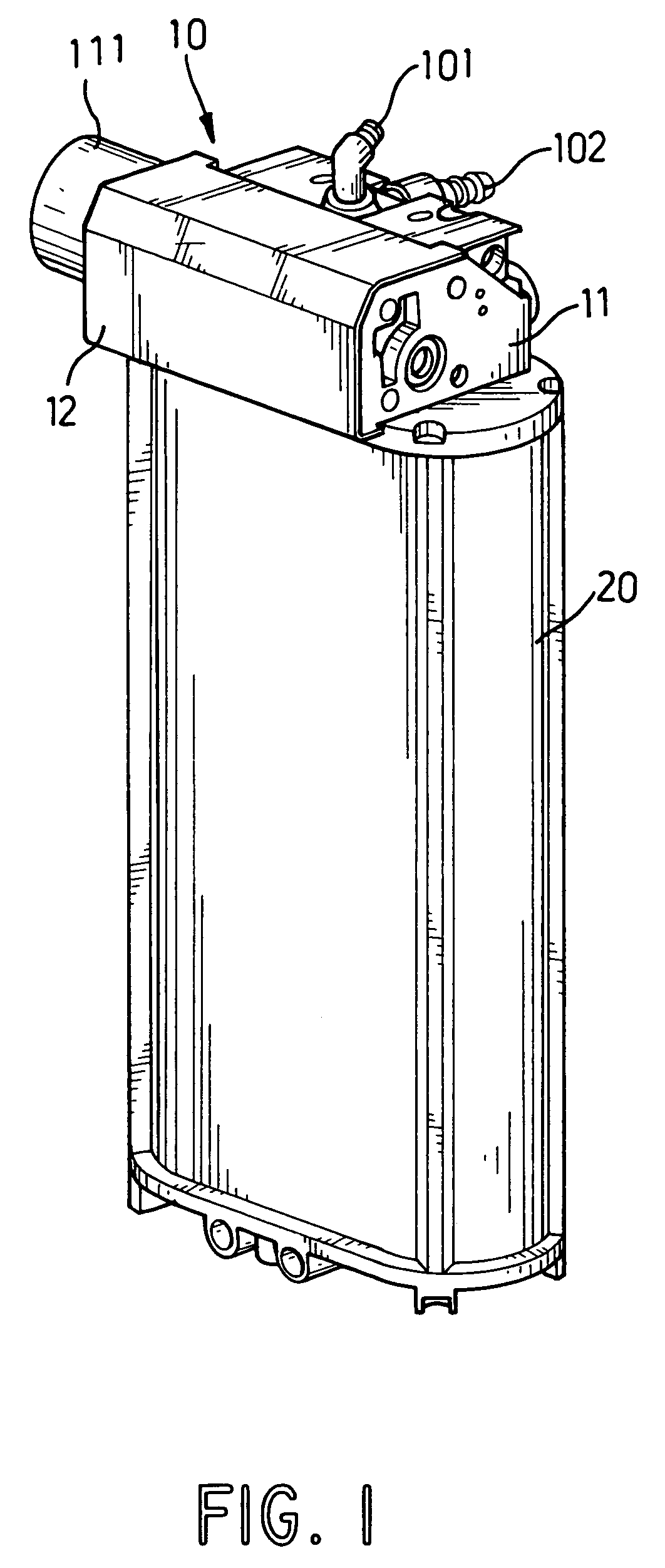

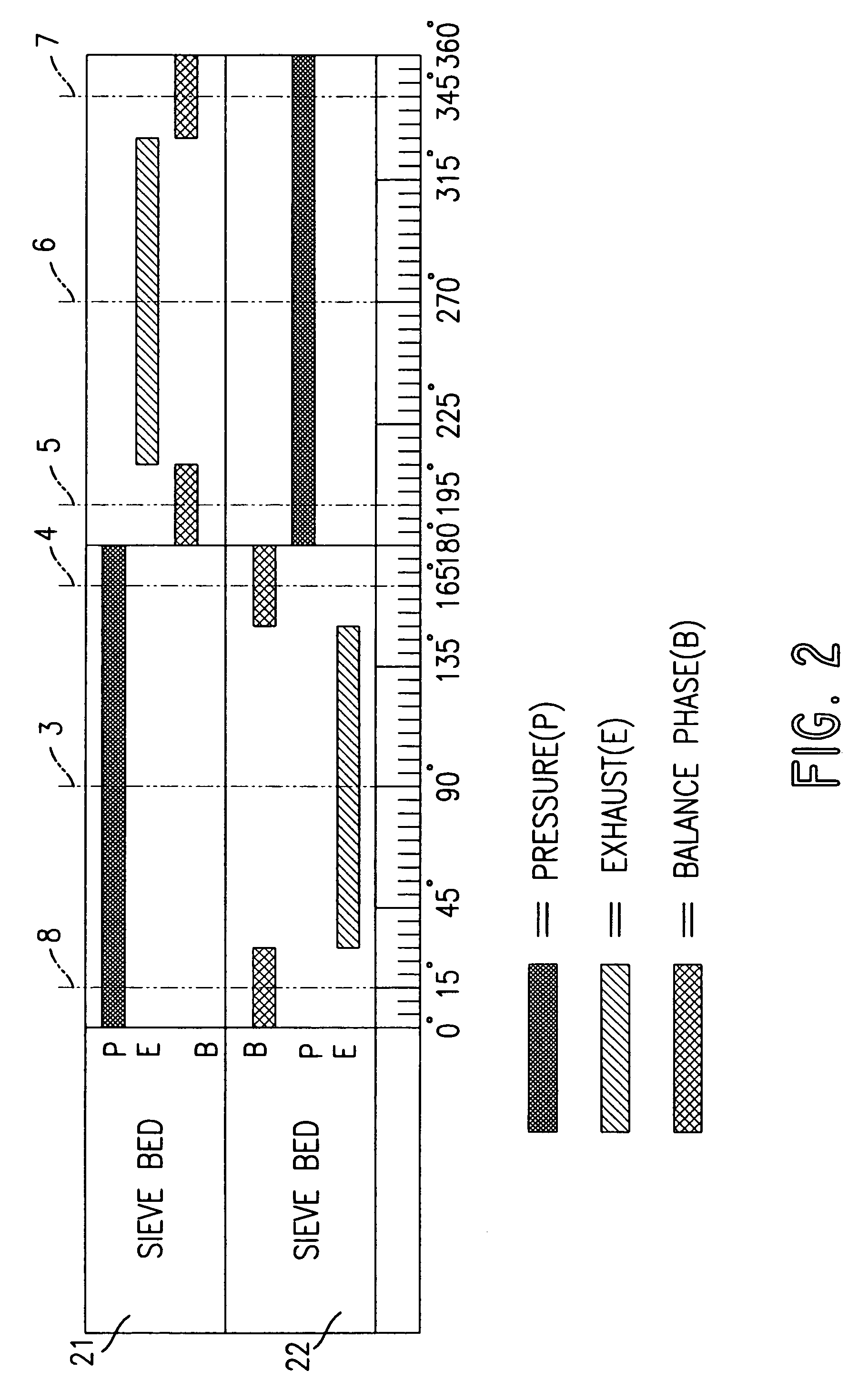

InactiveUS7637989B2Efficiently concentrate oxygenRapid cycle pressure swingGas treatmentBreathing filtersMolecular sieveEnrichment methods

A rapid cycle pressure swing adsorption oxygen concentration method uses a mechanical valve that has at least one cam-actuated flow control valve to switch flow of fluid, such as compressed air coming into a sieve tank that is fitted with molecular sieve materials. The cam-actuated flow control valve is repeatedly actuated by the rotating cams to become open or closed to complete a cycle that precisely controls the flow direction, pressure conditions and pressurized timing in the sieve tank whereby performance and efficiency of producing rapidly oxygen is high.

Owner:MERITS HEALTH PRODS

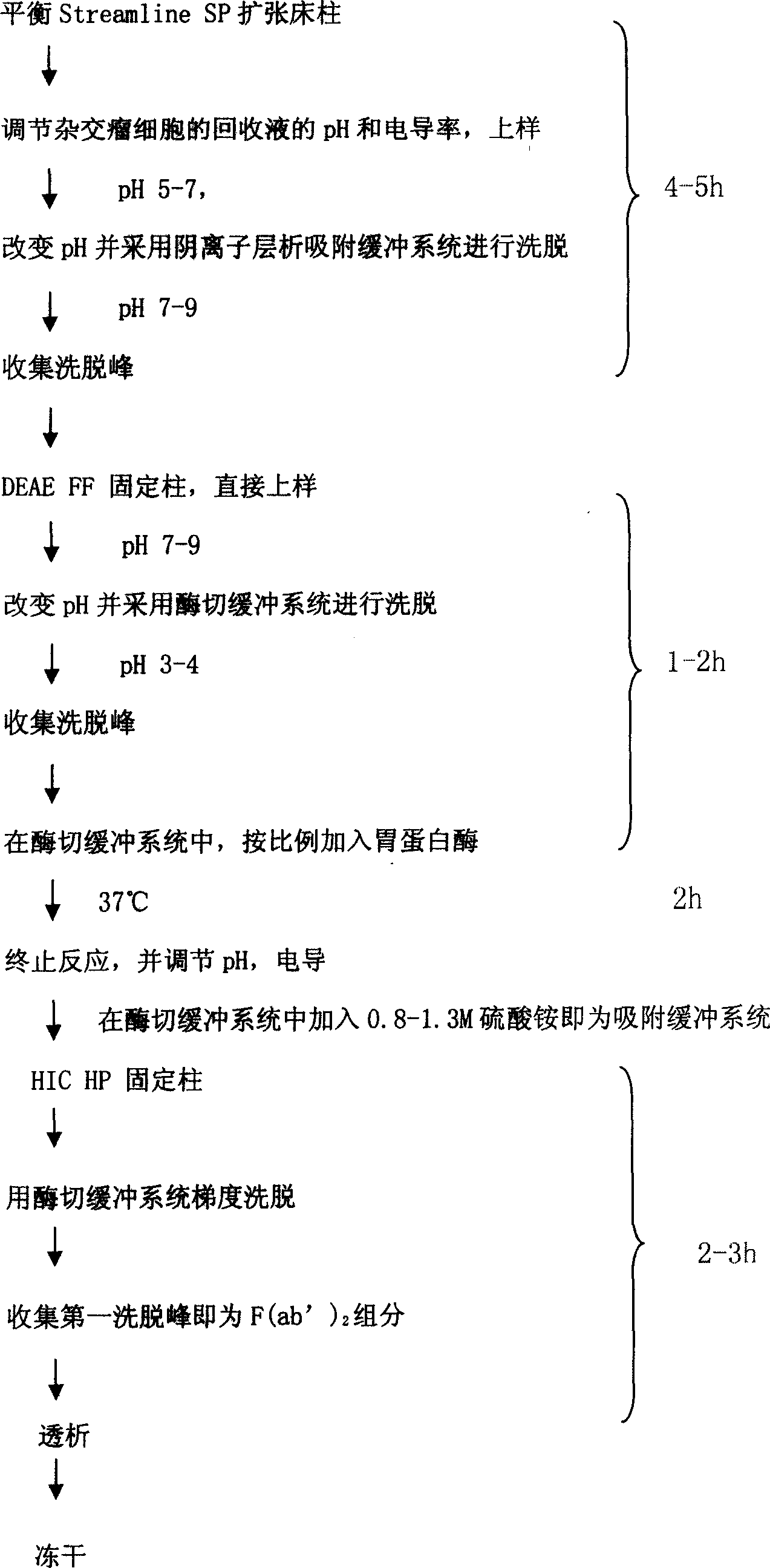

High performance quick purifying method for preparing piecewise antibody

ActiveCN1563090AReduce replacement stepsHigh purityImmunoglobulins against animals/humansPeptide preparation methodsPurification methodsEnrichment methods

The invention discloses a method for high-effectively quickly purifying and preparing fragment antibody from animal cell scale culture. Said method adopts the processes of dilatant column bed adsorption, anion chromatography concentration and hydrophobic chromatography purification, and includes the following steps: using dilatant column bed cation chromatography to adsorb antibody IgG from large-scale cell culture, changing pH value of buffer system to make elution, making collected elution peak be directly andergone the process of anion chromatography, using pepsinum to directly enzyme-out the fully-concentrated and purified antibody IgG to obtain fragment antibody, making hydrophobic chromatography and purification so as to obtain final fragment antibody whose purity is up to above 97%, and its whole purification process can be completed within 12 hr. Said invented method can be substituted for traditional ammonium sulfate precipitation, concentration method, and has the characteristics of high efficiency, rapid speed, high purity and stable operation and result, etc.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

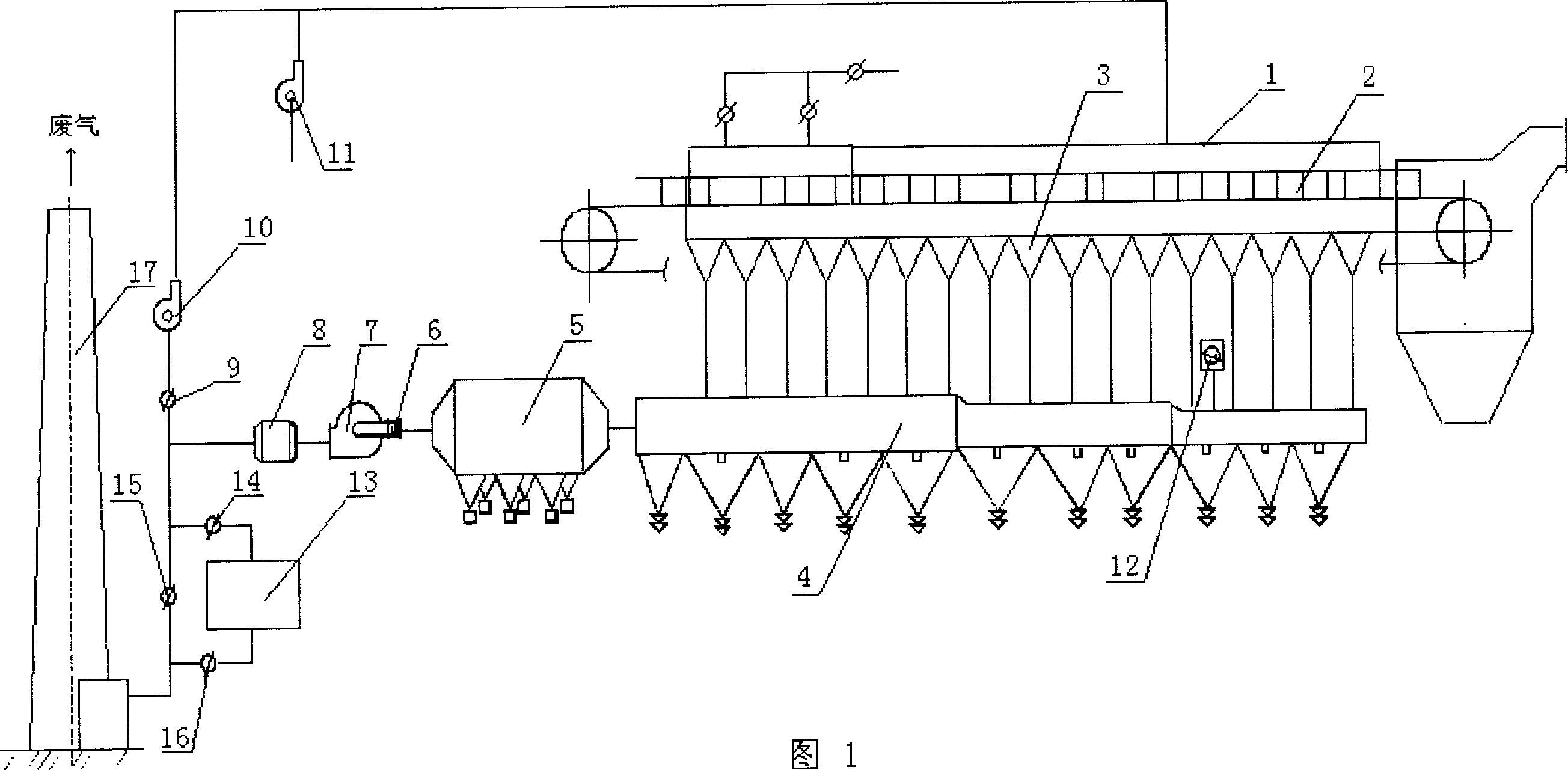

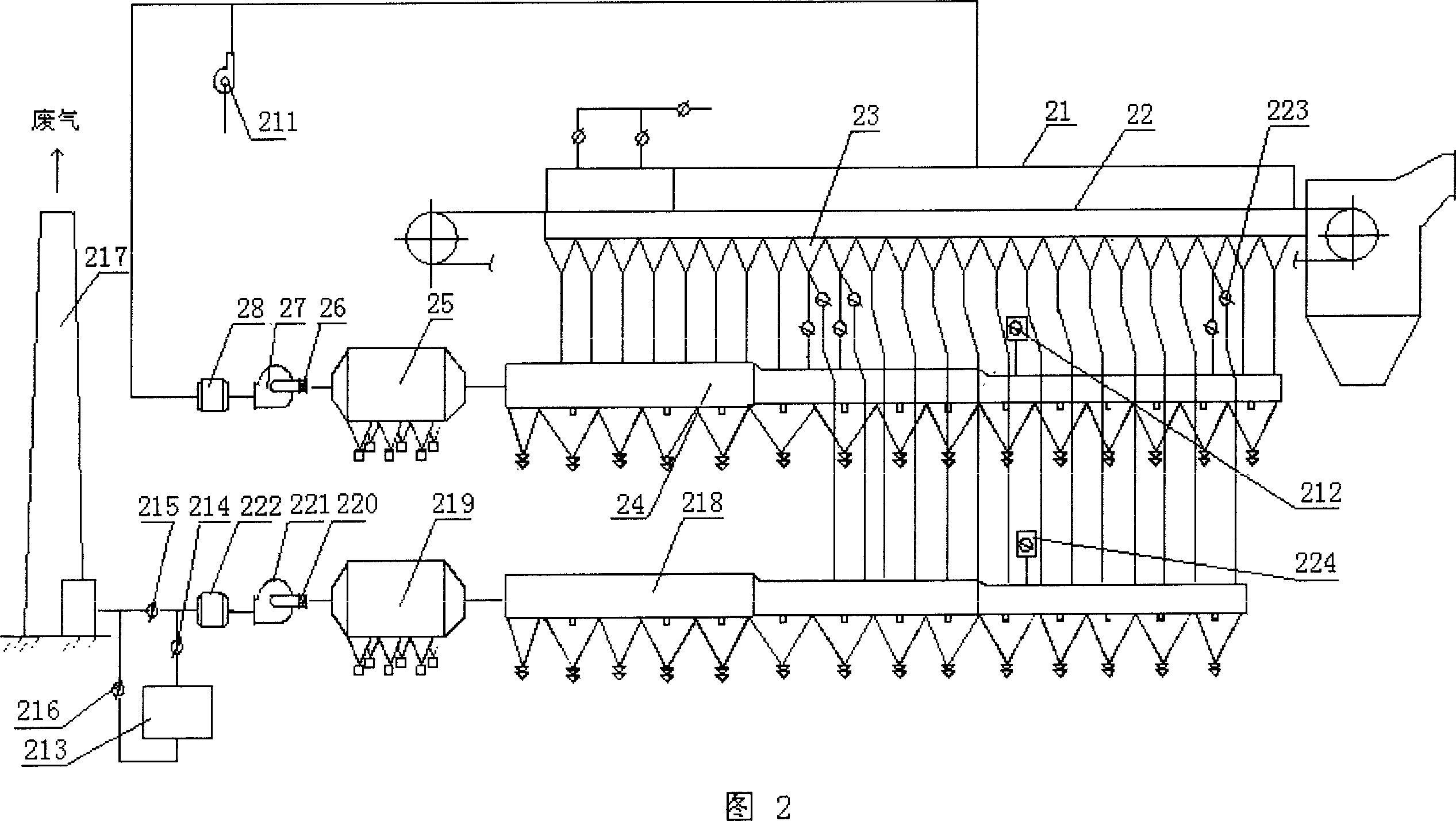

Sinter-smoke circulation collected desulfurizing method and apparatus

InactiveCN101024143AEmission reductionReduce effluxDispersed particle separationFurnace typesFlue gasEnrichment methods

The invention discloses a sintering flue gas desulfurization cycle enrichment methods and device, the described method from the sintering machine take part gas return to the top of sintering machine sealed enclosures within cycle, while complementing sintering machine burning need oxygen, the remaining part of the flue gas discharge after desulfurization. In devices, including dedusting device of flue gases between the chimney and flue, in the road before the desulfurization setup a branch pipeline to connect sintering machine sealed enclosures, in the branches of pipe setup cycle fan and supplement device. This invention due to sintered exhaust gas partly return to the seal trolley of sintering machine to reduce the displacement of gas, thereby reducing the total of dust and exhaust gas, while the SO2 of the sintering process play a enrichment role, to increase desulfurization efficiency, and reduce release total of burning exhaust gas, reducing the processing load of desulfurization device.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

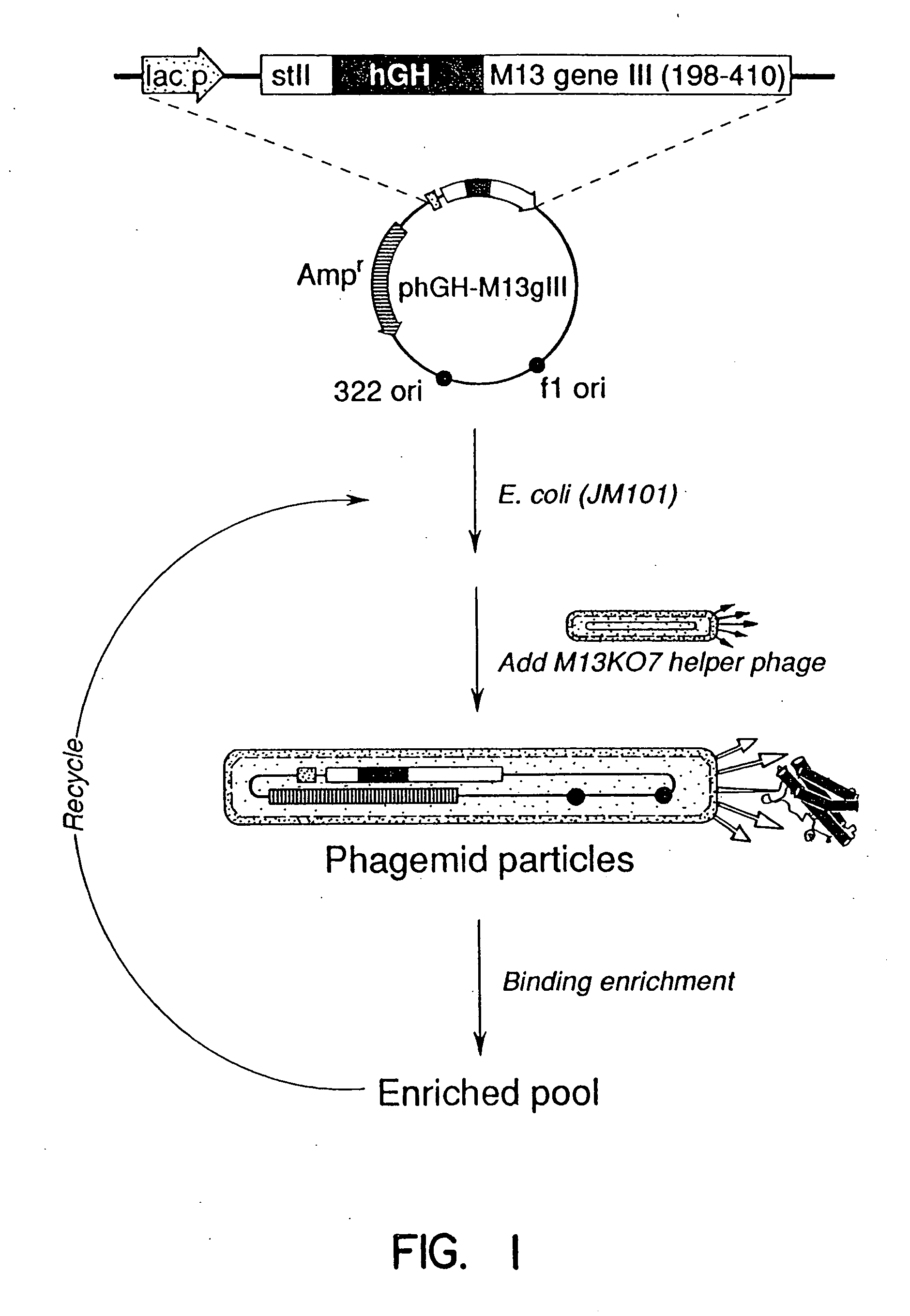

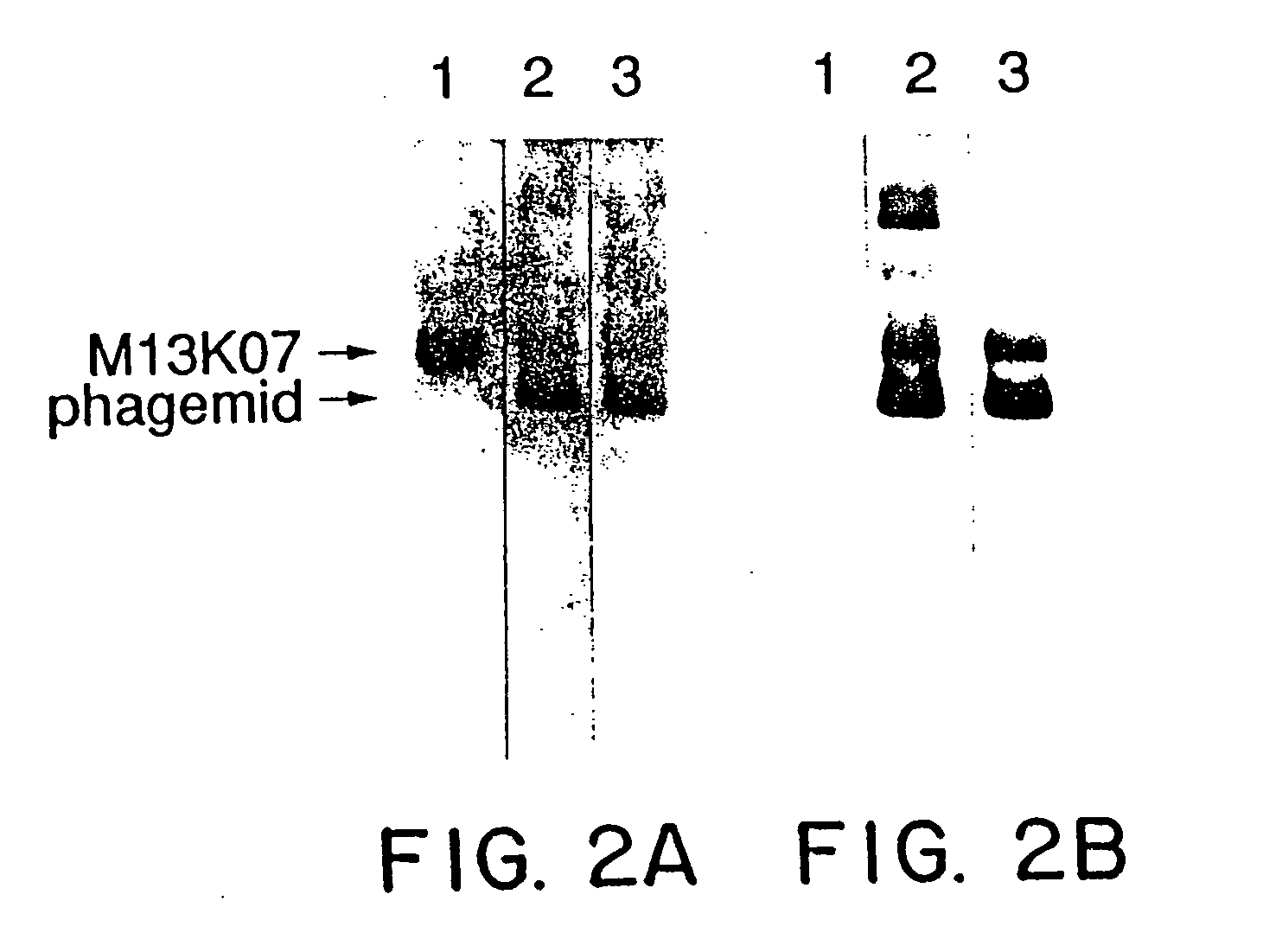

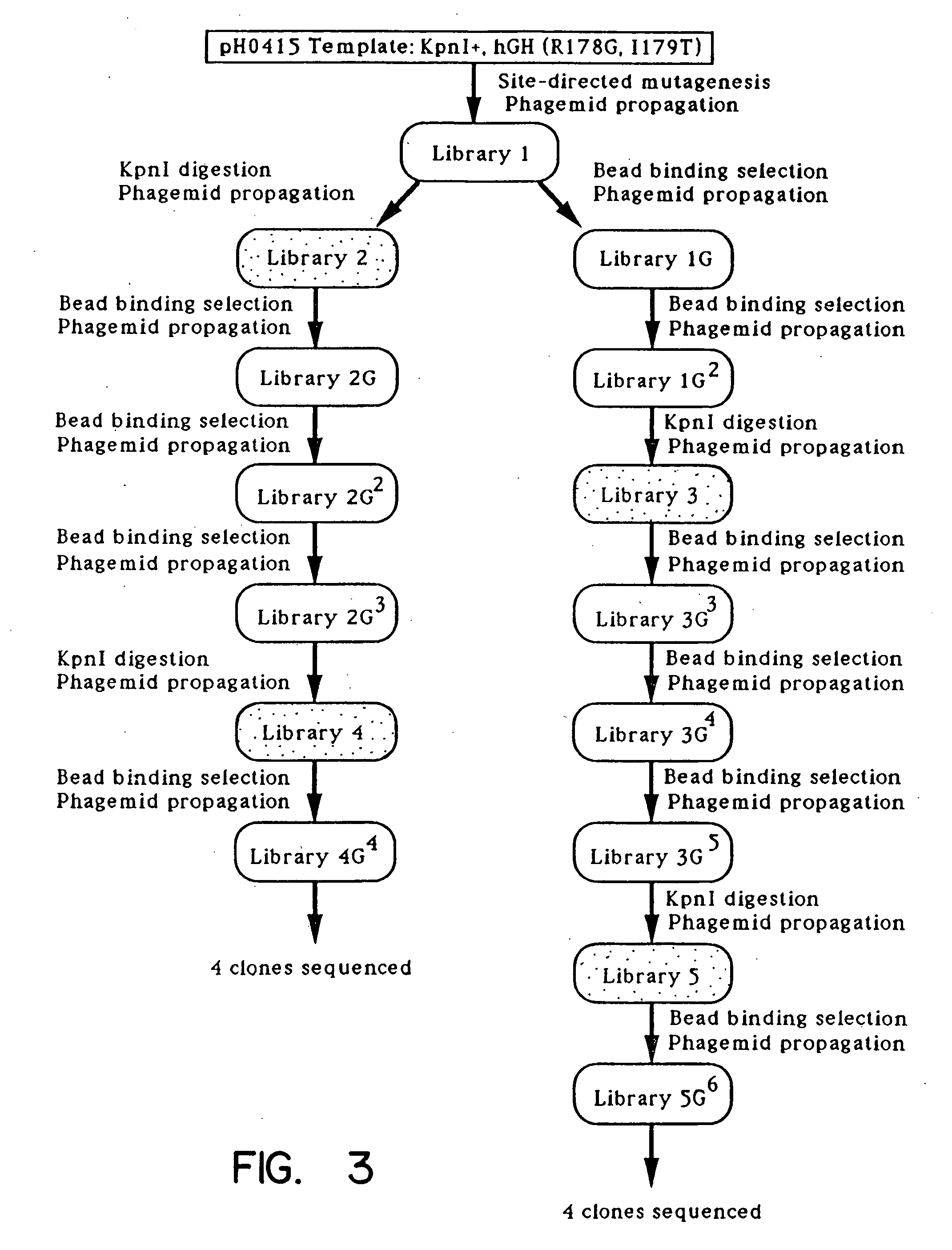

Enrichment method for variant proteins with altered binding properties

InactiveUS20060115874A1Valid choiceHigh affinity bindingVirusesPeptide/protein ingredientsEnrichment methodsAntibody fragments

A method for selecting novel proteins such as growth hormone and antibody fragment variants having altered binding properties for their respective receptor molecules is provided. The method comprises fusing a gene encoding a protein of interest to the carboxy terminal domain of the gene III coat protein of the filamentous phage M13. The gene fusion is mutated to form a library of structurally related fusion proteins that are expressed in low quantity on the surface of a phagemid particle. Biological selection and screening are employed to identify novel ligands useful as drug candidates. Disclosed are preferred phagemid expression vectors and selected human growth hormone variants.

Owner:GENENTECH INC

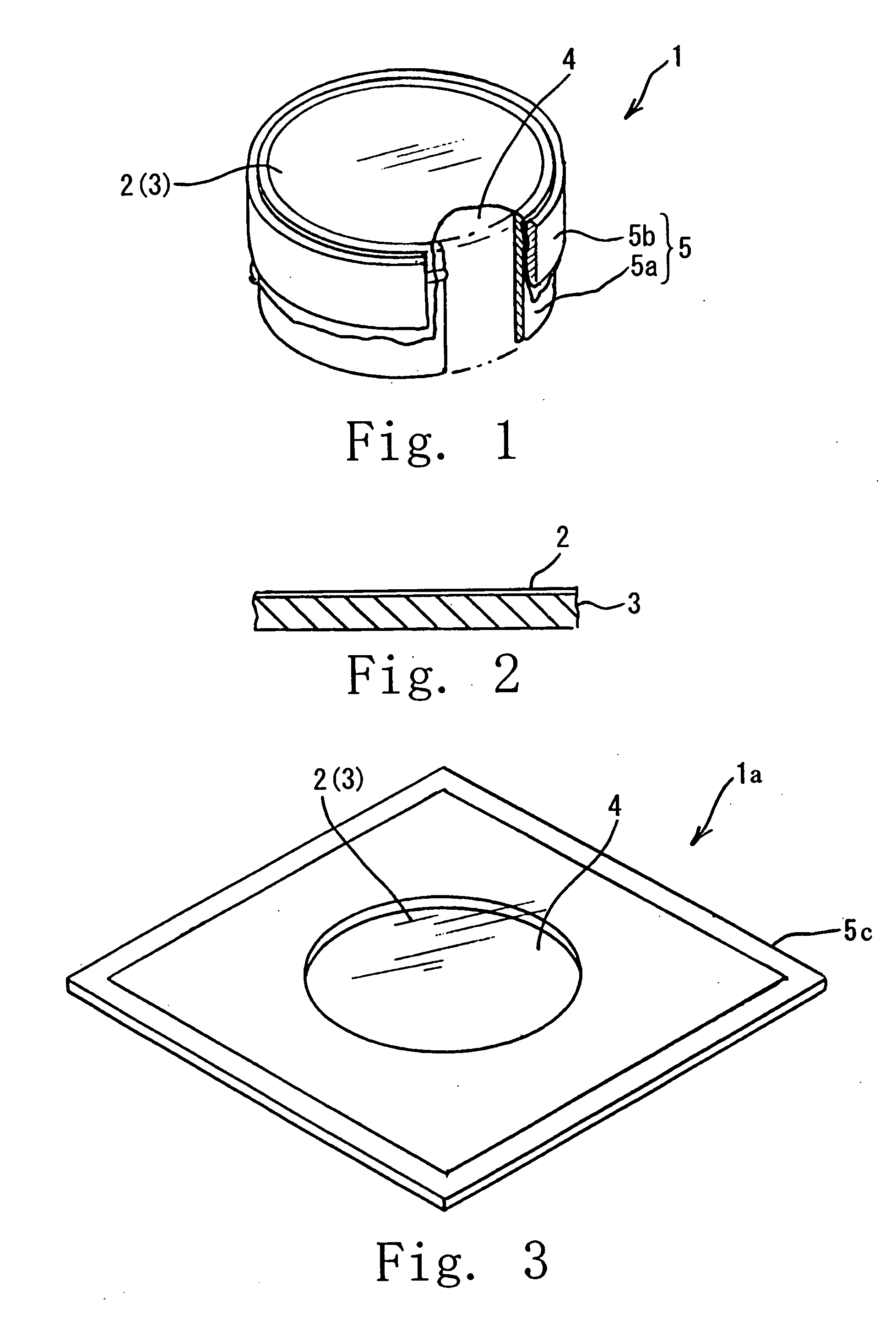

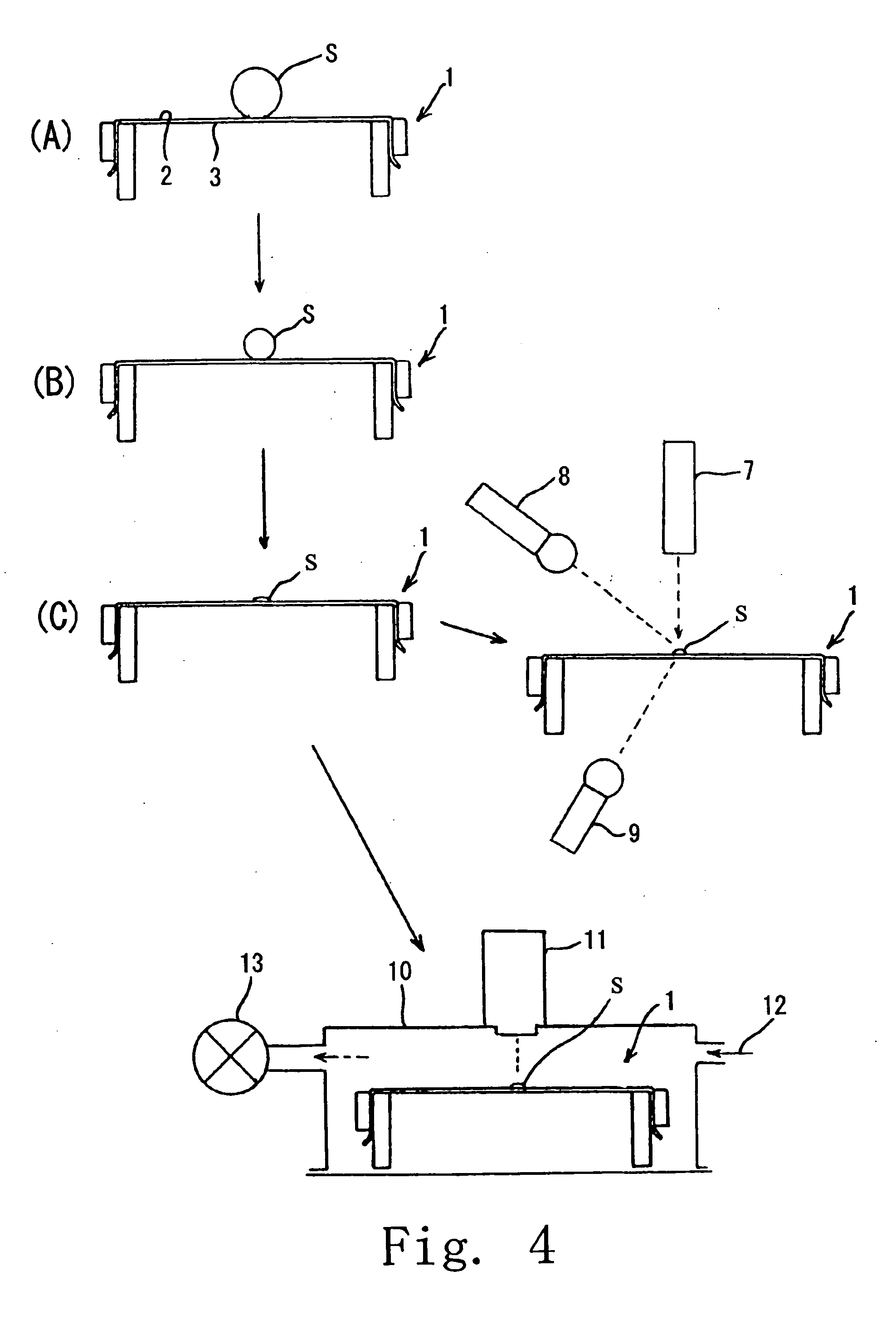

Preparation for tussore silk fibroin solution and concentration method thereof

InactiveCN101445546AHigh molecular weightAvoid extensive hydrolysisPeptide preparation methodsAnimals/human peptidesFiberHigh concentration

The invention relates to a preparation for a tussore silk fibroin solution and a concentration method thereof. Fibroin fiber of tussores like tussah, japanese tusser, costor silkworm, and Actias selene Hubner are decontaminated, degummed and then dipped into a dissolving liquid containing neutral salt and alcohol materials, treated by ultrasonic for 5 to 120 minutes, and then dissolved under the temperature between 30 and 98 DEG C to obtain a silk dissolving fibroin. The fibroin dissolving liquid is dialyzed and desalted to obtain a tussore fibroin aqueous liquid; then the aqueous liquid is dewatered and concentrated by a semipermeable membrane by using a high water-absorbing matter to obtain the high concentration tussore fibroin solution with a molecular weight of 15 to 250 kDa and a concentration of 6 to 35 percent. As the neutral salt is used, the large extent hydrolyzation of acid and alkali to the silk fibroin is avoided; therefore, the molecular weight of the obtained tussore silk protein is higher; the tissore silk fibroin can be used for manufacturing tussore silk fibroin gel, powder, films, porous sponges, regenerated fibers, and the like. The invention provides new material for the fields of biomedicine, medicine, make-up, food, health product, and the like.

Owner:SUZHOU UNIV

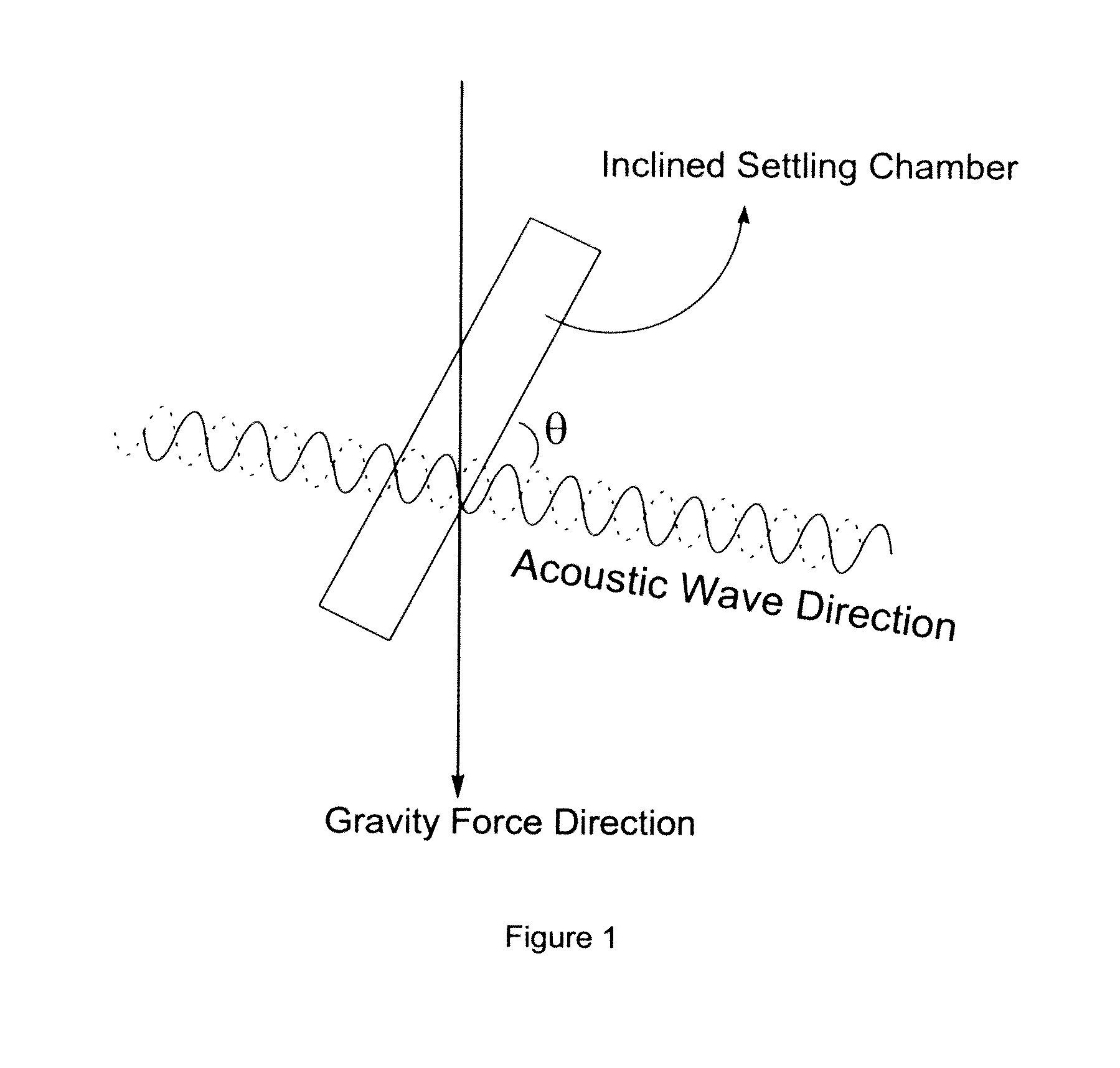

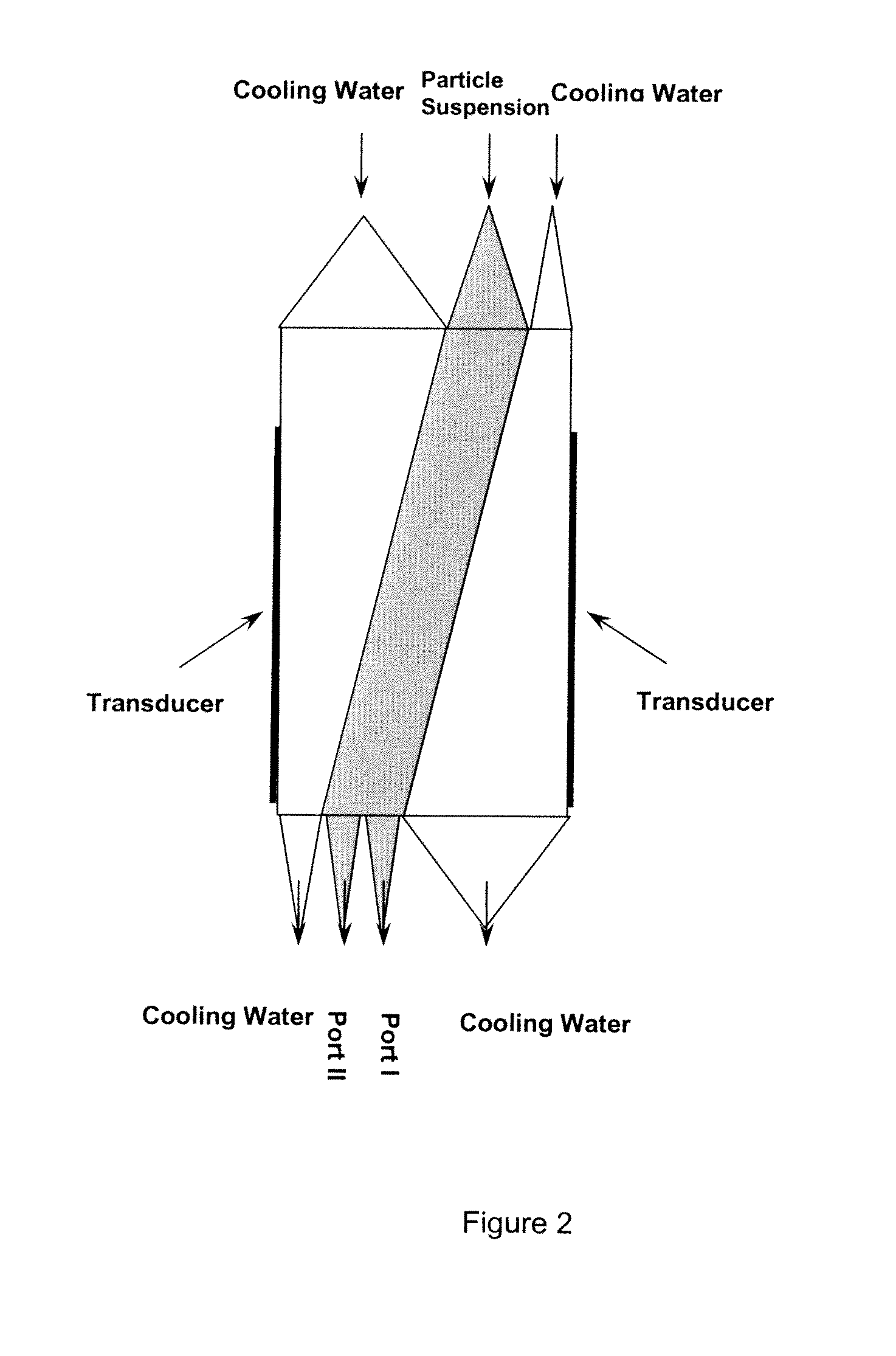

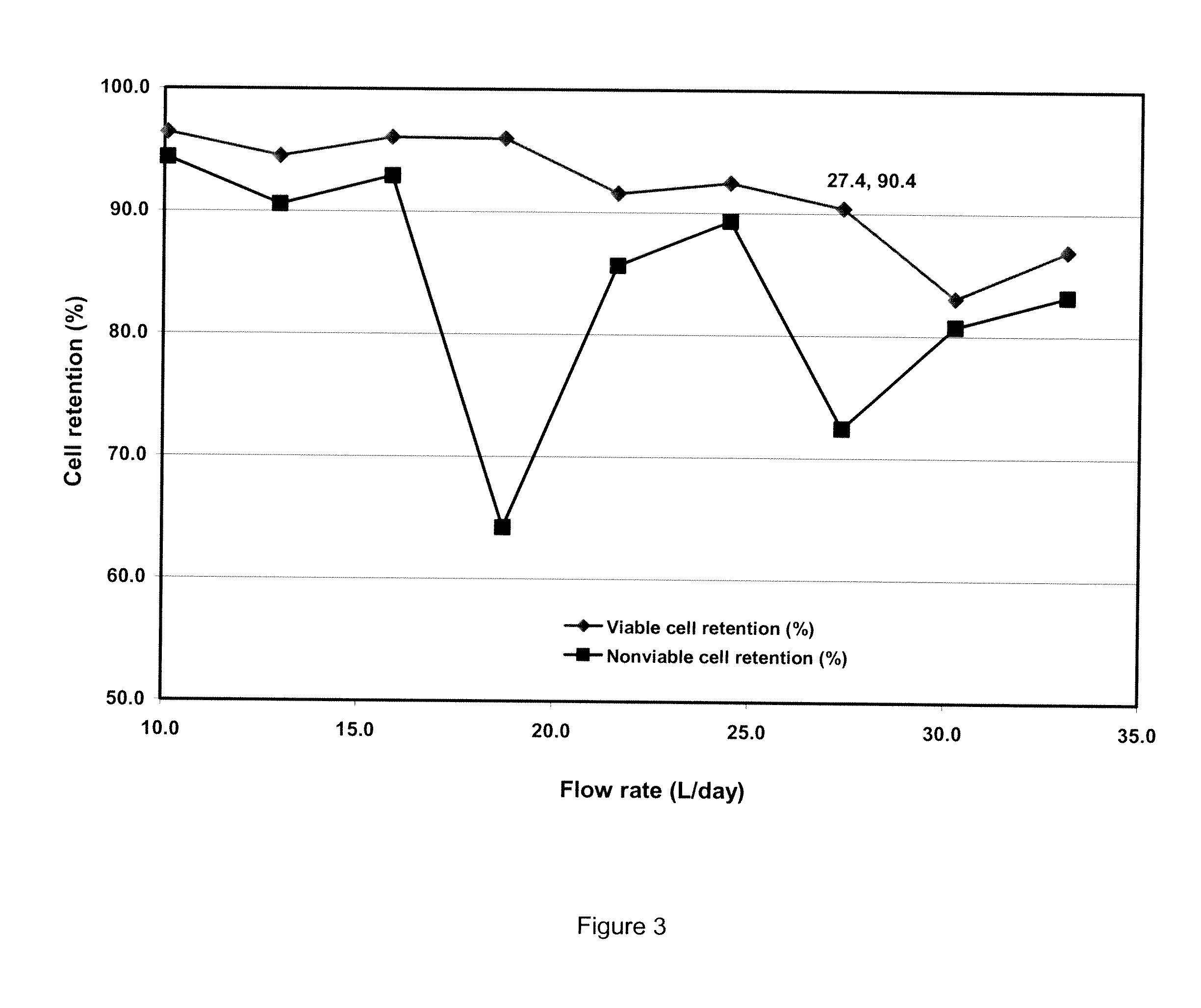

Acoustic device and methods thereof for separation and concentration

InactiveUS8889388B2Bioreactor/fermenter combinationsBiological substance pretreatmentsYeastCost effectiveness

The invention provides a settling device comprising an acoustic wave generator and an inclined settling chamber. The angle θ between the acoustic wave direction and the inclined settling chamber is greater than 0 and less than 90°. The invention also provides a concentration method and a separation method using the device. The invention can be used to concentrate or separate particles such as inorganic particles, organic particles, and biological particles, for example, mammalian cells, bacteria, yeast, algae, and plant cells. The invention exhibits technical merits such as higher efficiency, cost-effectiveness, and large-scale production.

Owner:WANG ZHAOWEI +2

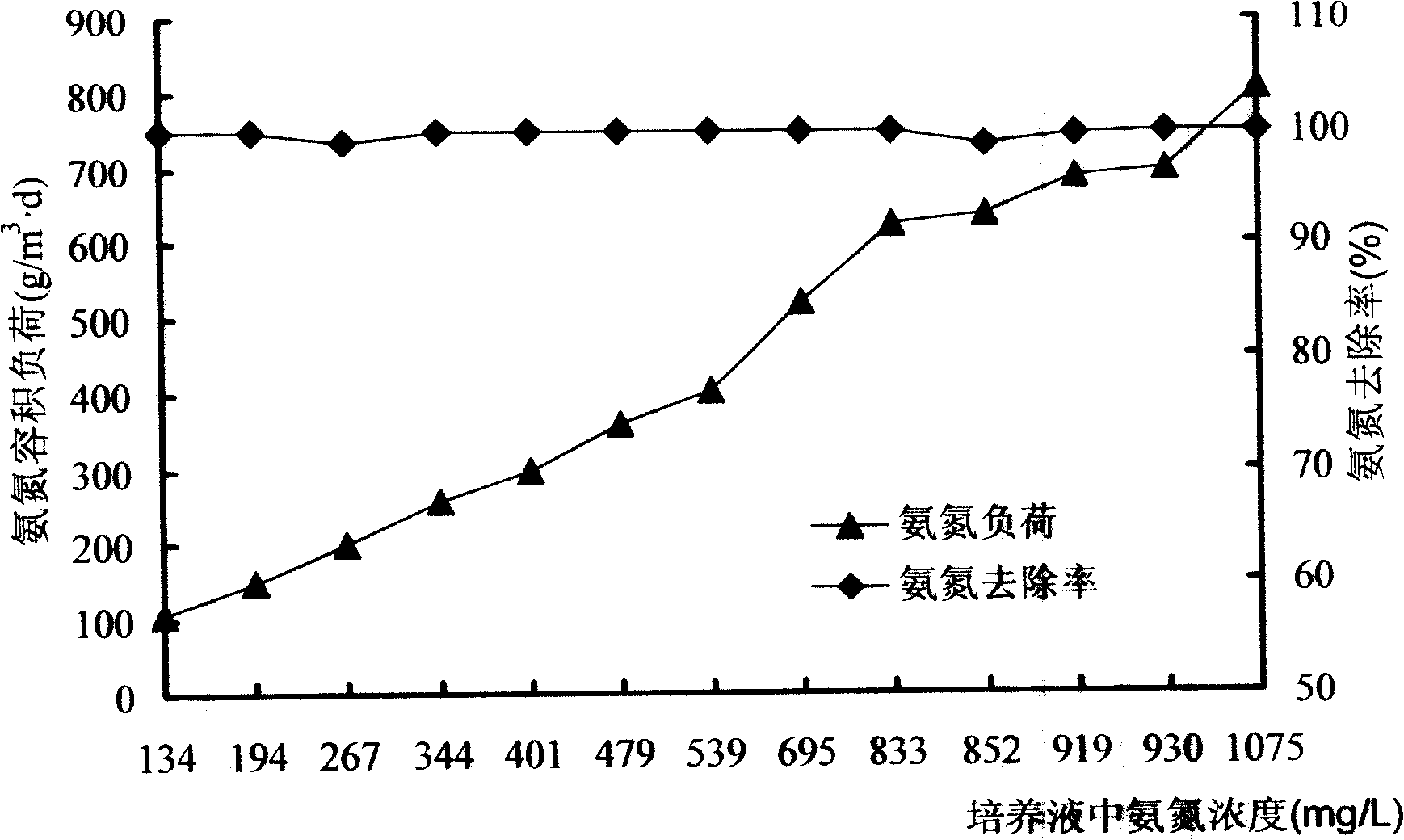

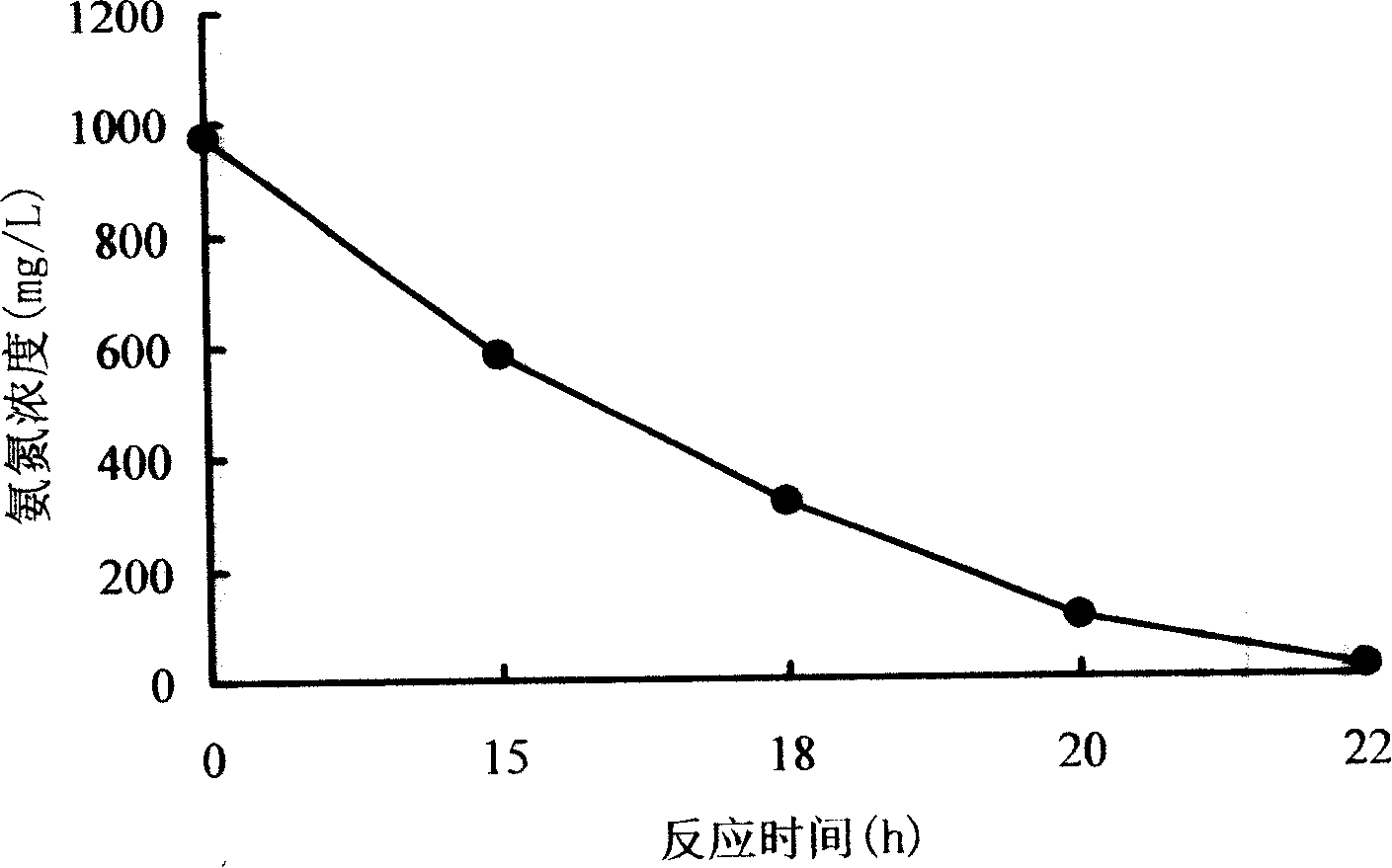

Method for concentrating highly effective nitrobacteria in active sludge

ActiveCN101240253AGrowth inhibitionGood removal effectBacteriaSustainable biological treatmentActivated sludgeHigh concentration

The invention discloses a enrichment method of nitrifying organism. The method adapts discontinuous activated sludge process by gradually improving ammonia nitrogen ph indicator in nutrient fluid to enrich. The main component of the enrichment nutrient fluid is inorganic salt comprising microelement Fe, Mg, Na, K and amortization liquor, in which inceptive concentration of NH(4)(+-N) is 100mg / L to 200mg / L, final concentration is 500mg / L to 1200mg / L and COD is less than or equal to 200mg / L. The method can restrain evidence the growth of sundry bacterium such as carbonizing bacterium, is propitious for nitrifying organism to become ascendency bacterium and resist more and more high ammonia nitrogen concentration, and finally disposing concentration of the ammonia nitrogen wasted water is up to 1200mg / L and high concentration ammonia nitrogen in wasted water can be reduce to less 10mg / L.

Owner:CHINA PETROLEUM & CHEM CORP +1

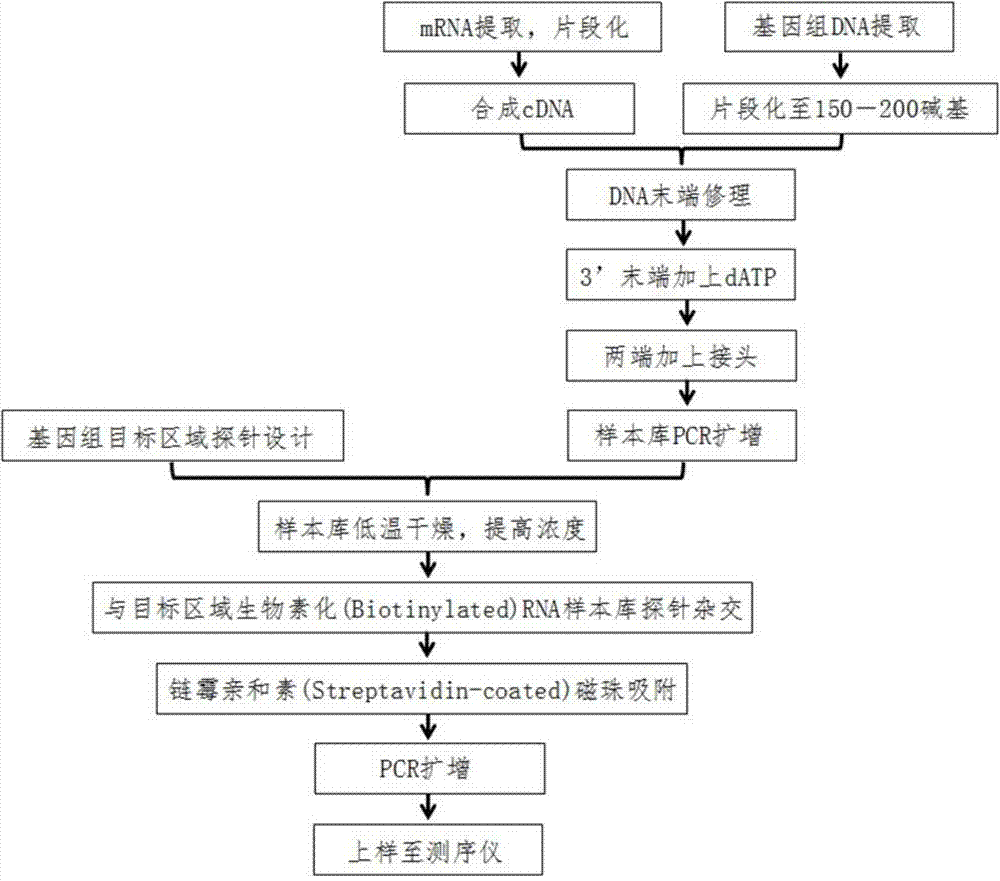

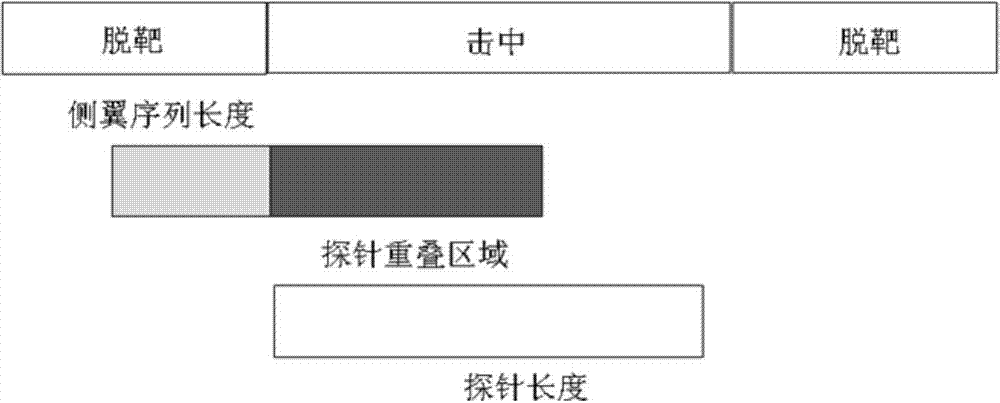

Enrichment and detection method of target gene fragment

ActiveCN103667254AGuaranteed accuracyImprove accuracyMicrobiological testing/measurementDNA preparationMessenger RNAEnrichment methods

The invention provides a method for enriching target gene fragments. The method comprises the following steps: (1) obtaining a partial or whole-length DNA (deoxyribonucleic acid) sample library containing a target gene; (2) obtaining a DNA probe library capable of hybridizing with the target gene; (3) hybridizing the DNA probe library and the DNA sample library; (4) separating a hybrid product obtained in the step (3), and releasing the target gene fragments subjected to hybridizing and enriching. According to the enrichment method, the invention further provides a method for detecting the gene structure mutation of the target gene. The method for detecting the gene structure mutation of the target gene comprises the following steps: (1) enriching the target gene fragments according to the method; (2) detecting the structure mutation of the target gene. The target gene fragments enriched by using the method can be used for next-generation sequencing technique to detect the gene structure mutation and comprise single-alkali base mutation, mRNA (Messenger RNA) absence or increase, mRNA structure transversion and mRNA splicing change.

Owner:GENESEEQ TECH INC

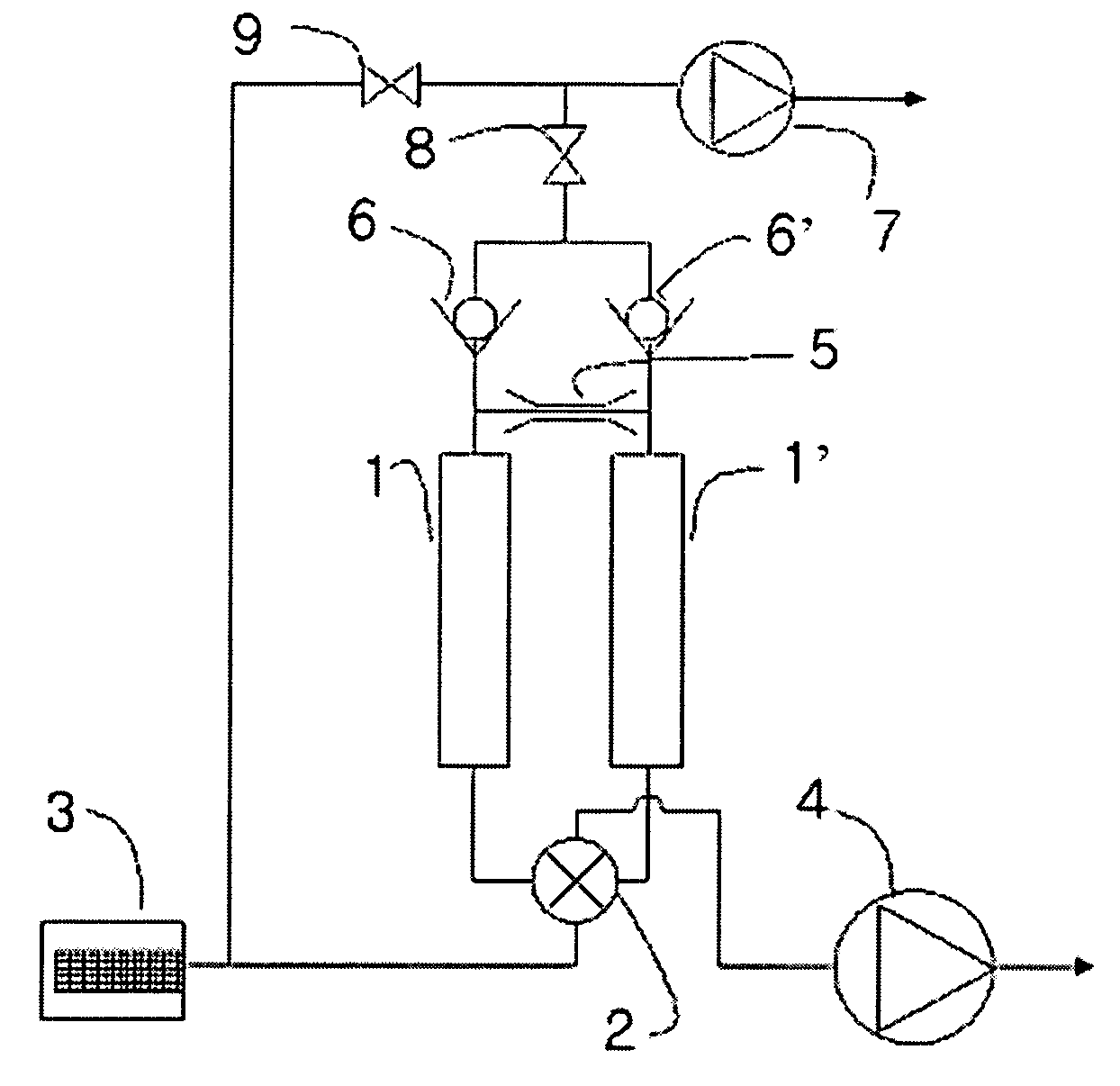

Gas concentration method and its apparatus

InactiveUS7105038B2Improve productivitySimple equipmentGas treatmentIsotope separationEnrichment methodsSorbent

The present invention relates a method for concentrating a gas by applying a pressure difference to an adsorbent and an apparatus therefor, and particularly, a method for producing an enriched gas in a large amount by introducing a continuous production into every step of the process focusing on productivity rather than concentration of the product gas and an apparatus therefor. The present invention relates to a method incorporating the vacuum swing adsorption method with the pressure swing adsorption method, particularly the rapid pressure swing adsorption method which can continuously produce a desired material in a depressurization step to improve recovery rate of the desired material and productivity and an apparatus therefor. The apparatus according to the present invention is advantageously applied in a small size machine rather than for industrial uses. Particularly, when applied in a small size oxygen concentrator, it can be used in electric home appliances, air conditioners and water purifier, as well as medical products.

Owner:JEJ +1

Method and apparatus for micro hydrocyclone separation of MTO quench water and water of water-washing factory, and for concentration of fine catalyst in the same

InactiveCN101352620AVortex flow apparatusCentrifugal force sediment separationEnrichment methodsQuenching

The invention provides a micro-vortex flow concentration method used for fine catalyst in MTO quenching water and washing water, comprising the steps as follows: micro-vortex flow separation of MTO quenching water is carried out so as to carry out the concentration processing on the contained catalyst and micro-vortex flow separation of MTO washing water is carried out so as to carry out the concentration processing of the contained catalyst. The invention also provides a micro-vortex flow concentration device used for the fine catalyst in the MTO quenching water and washing water.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

Video concentration method and system

InactiveCN103686095AAvoid collisionSatisfy Time ConsistencyImage analysisClosed circuit television systemsEnrichment methodsRanking

The invention discloses a video concentration method and a video concentration system, and belongs to the technical field of video processing. The method comprises the following steps that video frames are subjected to background modeling analysis, foreground targets and background images of each frame are divided, the moving target track of each target is extracted, in addition, the target sequence and background images are stored, the target sequence of the moving target track are subjected to optimized ranking, a new frame number sequence is generated and stored, according to a pixel merging algorithm, the foreground targets and the background images are subjected to seamless merging, the stored new frame number sequence and the stored background images are read, and a compressed video is generated. When the method and the system provided by the embodiment of the invention are adopted, the length of the compressed video is shortened, in addition, the moving object information in the video is retained as far as possible, the collision among multiple targets can be effectively prevented, and better visual effects are realized.

Owner:CHINA SECURITY & FIRE TECH GRP

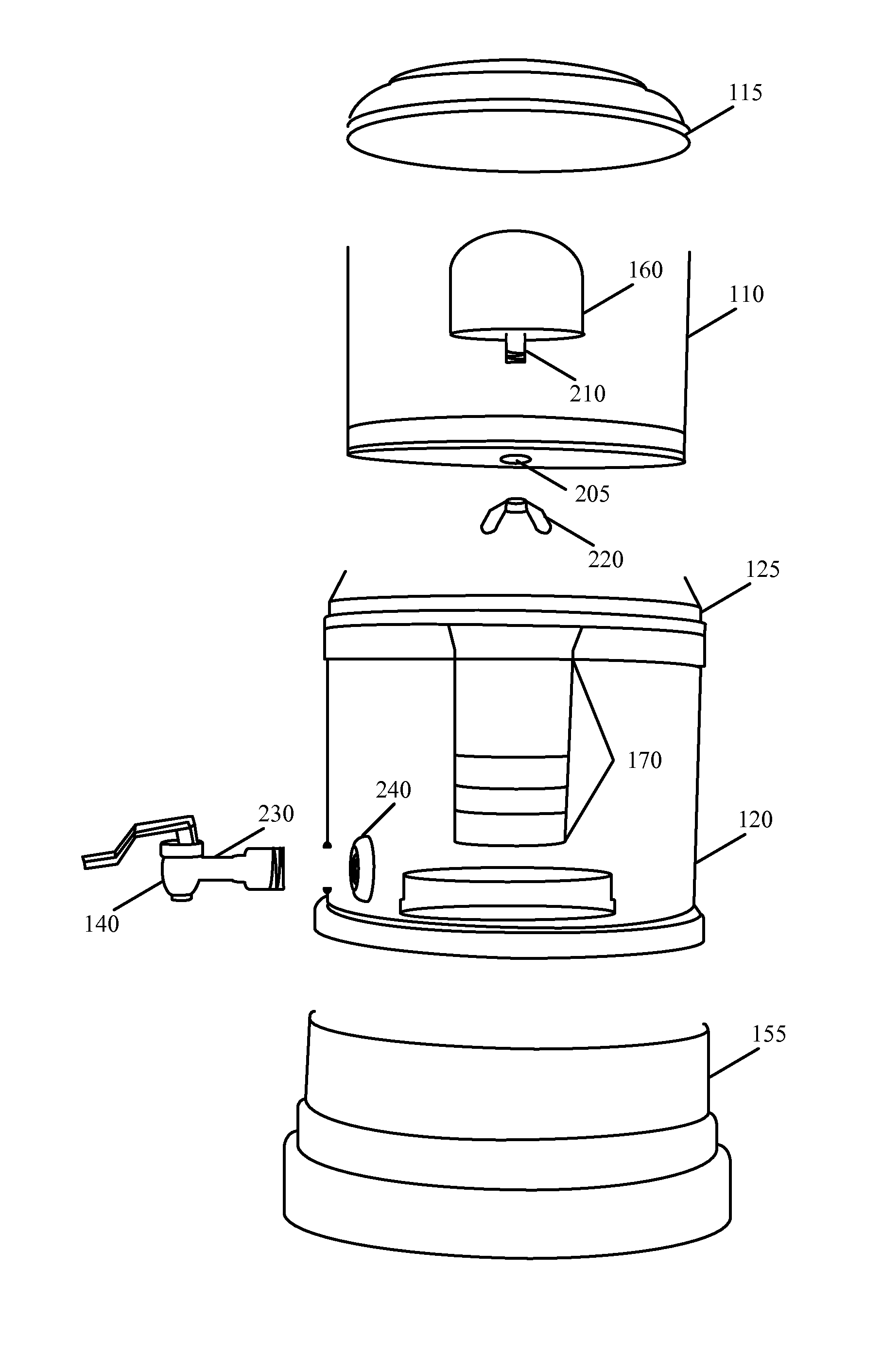

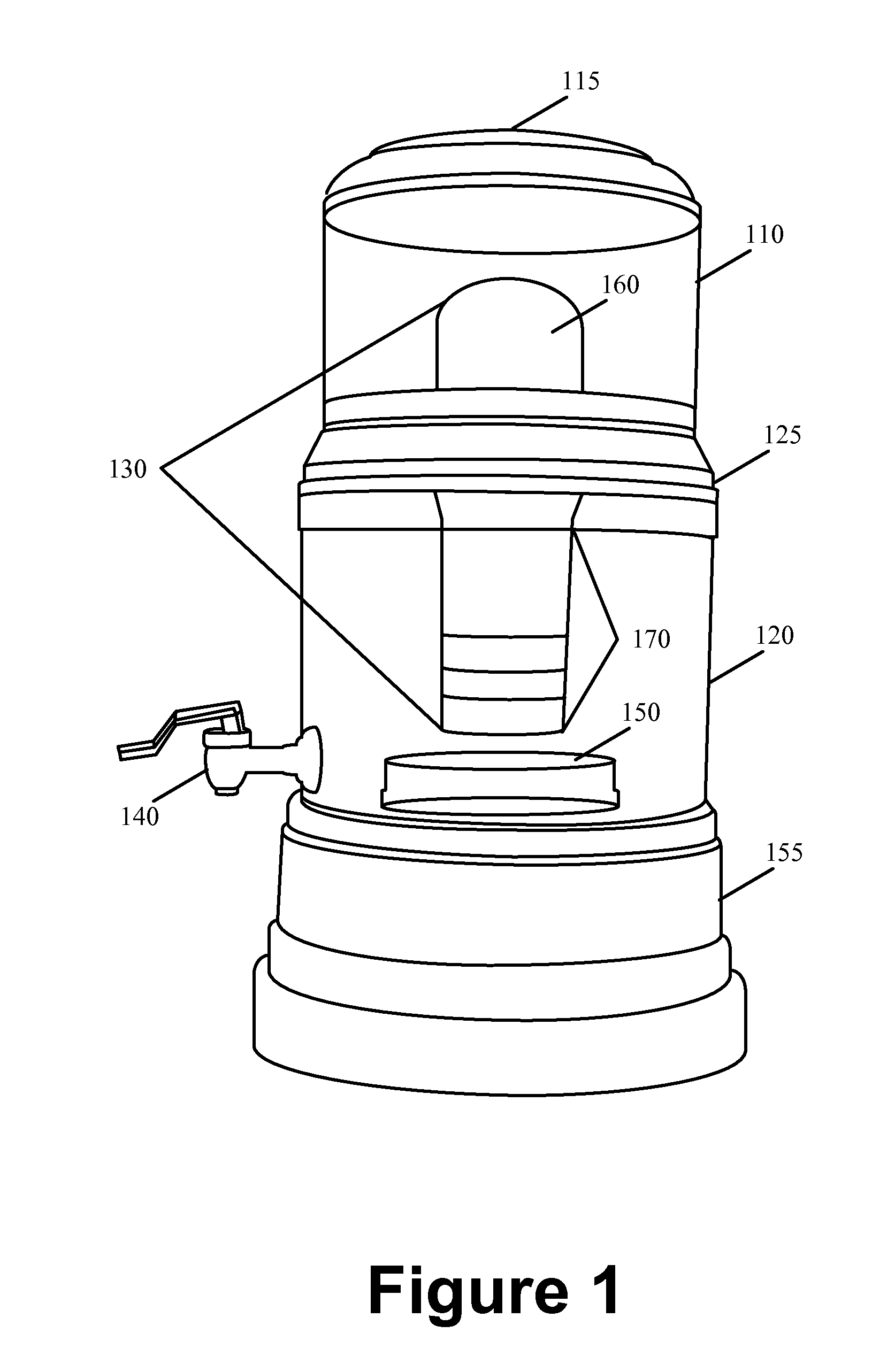

Multi-Stage Water Treatment and Enrichment Method and Apparatus

InactiveUS20120091070A1Easy constructionFlexible operationWater treatment parameter controlOther chemical processesFiltrationEnrichment methods

Some embodiments provide a multi-stage water treatment and enrichment apparatus with an upper water reservoir, a lower water reservoir, a cartridge that is composed of a porous filter and multiple seep through chambers that treat and enrich water, a water dispensing tap valve, and a preservation cartridge. Collectively, these components function (1) to provide multiple levels of treatment including filtration and purification, (2) to provide enrichment of water via mineralization, magnetization, softening, and alkalinization, (3) to provide for customizability of the treatment and enrichment so that different consumers can adapt these processes to satisfy their own personal preferences, (4) to provide an apparatus that operates using gravitational forces and without the need for external power or pressure to perform the multi-stage treatment and enrichment of water, and (5) to provide an inexpensive apparatus that is suitable for primary usage in the home.

Owner:ABACUS CONSULTING

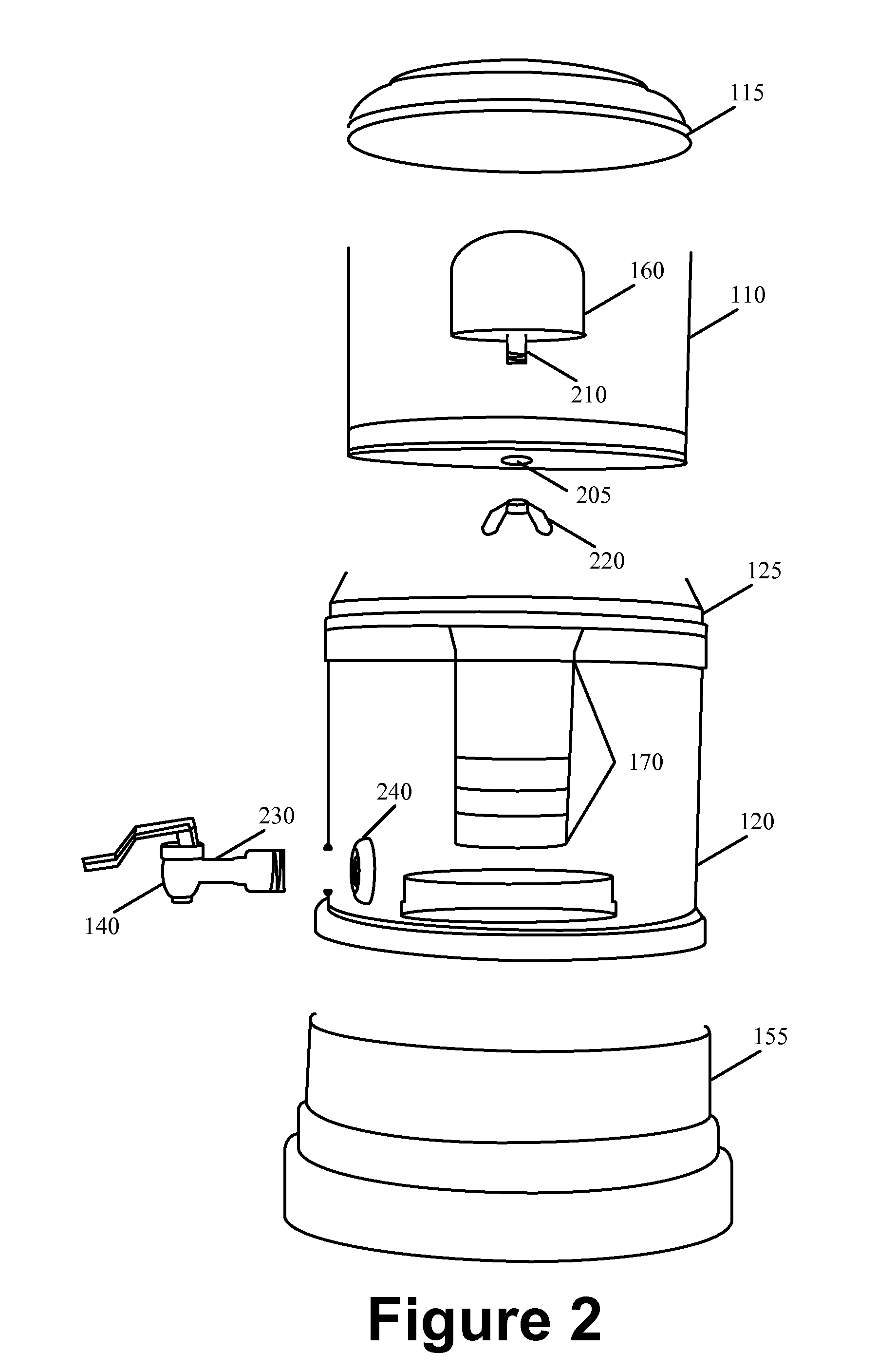

Concentrating method and device in acesulfame potassium production

Owner:ANHUI JINGHE IND

Method for compressing marine microalgae

InactiveCN101095459AFast flocculationVigorousDead plant preservationAnimal feeding stuffFlocculationOrganic acid

The invention relates to a method for condensing ocean micro-algae, which comprises following steps: adding organic acid solution of chitosan into micro-algae culture solution to make the chitosan solution concentration in micro-algae culture solution be 0.3-8.0 mg / l, adjusting micro-algae culture solution pH to be 4.5-8.5 for micro-algae flocculation, collecting floccule with static hierarchical or gas-floating method. The invention is characterized by non-toxic chitosan, simple solution preparation, fast flocculation speed, good activity of flocculated micro-algae. The micro-algae can be dispersed into single cells in water after a certain time of storage, and can be used for breeding as algae seed. The chitosan can improve the animal immunity, and micro-algae can be used in foodstuff and medical treatment field.

Owner:MARICULTURE INST OF SHANDONG PROVINCE

Concentration method and apparatus of preparing a liquid specimen for a trace element analysis system

InactiveUS20050239211A1High sensitivity analysisSmall spreadMaterial analysis using wave/particle radiationPreparing sample for investigationEnrichment methodsIrradiation

The present invention provides a concentration method and apparatus for preparing a liquid specimen for a trace element analysis system. A holder positions a thin film that is prepared to have a liquid repellency so that a liquid sample containing a specimen can be uniformly evaporated to be concentrated at one location. An irradiation source of energy can be applied to enable a detector to determine the trace element.

Owner:HORIBA LTD

Online dynamic video compression method

ActiveCN104093001AReduce consumptionSave resourcesImage analysisClosed circuit television systemsEnrichment methodsCompression method

The invention discloses an online dynamic video compression method. According to the method, the traditional video abstraction technology is improved a lot and is inherited and developed. By the adoption of the method, target bodies and events which people are interested in can be automatically extracted from a large number of monitoring videos; the information such as positions and velocities of the target bodies in each frame of the monitoring videos is obtained by tracking the target bodies; the target bodies appearing in different time periods are extracted respectively and temporarily stored in a moving target list; after an appropriate background is selected, the stored target bodies are spliced into the same background one by one. Consequently, the visual effect that the target bodies appearing in different time periods are simultaneously displayed in the same time period is achieved, and the purpose of dynamic video compression is achieved.

Owner:SHANDONG JIANZHU UNIV

Enrichment methods for the detection of pathogens and other microbes

ActiveUS20090269760A1Cost-effective and accurateMicrobiological testing/measurementFermentationMicroorganismAssay

Owner:INST FOR ENVIRONMENTAL HEALTH

Resequencing methods for identification of sequence variants

InactiveUS20090233809A1Improve accuracyHelp studyMicrobiological testing/measurementLibrary screeningTarget captureEnrichment methods

Methods for detection of variant alleles are disclosed. In preferred aspects variants are detected by hybridization patterns to arrays of probes that are contain a single mismatch to a reference sequence, thus reducing the number of probes needed for resequencing by hybridization. The target capture method used is Target Amplification by Capture and Ligation (TACL), and is capable of amplifying many thousands of loci together. Mismatch Repair Detection (MRD) is used as an allele enrichment method to efficiently sort variant and non-variant alleles in thousands of loci simultaneously.

Owner:AFFYMETRIX INC

Method for concentration of gold in copper sulfide minerals

ActiveUS20100242681A1Efficient separationEffective recoveryPhotography auxillary processesGold compoundsEnrichment methodsHydrometallurgy

Disclosed herein is a method for concentrating gold contained in a leach residue obtained in a copper hydrometallurgical process for recovering copper from a copper sulfide mineral to efficiently separate and recover gold from the leach residue. According to the method, a gold-bearing copper sulfide mineral is subjected to pressure leaching with sulfuric acid at a temperature higher than 102° C. and 112° C. or lower to obtain a leach residue, and the leach residue is subjected to flotation to separate it into a float fraction and a sink fraction. The float fraction obtained by flotation is desulfurized by heating at a temperature of 250 to 800° C. under an inert atmosphere to obtain a desulfurized product. The desulfurized product is subjected to oxidative roasting by heating at a temperature of 600 to 800° C. under an atmosphere of flowing oxygen or air to obtain an oxidatively-roasted product. The oxidatively-roasted product is dissolved in a sulfuric acid solution to obtain a copper solution, and a gold-bearing residue is separated and recovered from the copper solution.

Owner:SUMITOMO METAL MINING CO LTD

Enrichment method of virus

InactiveUS20110053250A1Maintaining their infection abilityImprove concentrationBiological material analysisRecovery/purificationEnrichment methodsViral vector

The present invention provides a novel method that can increase readily a virus or viral vector concentration in a solution having a low concentration and a kit for performing the method. Conventional methods require complicated operations, expensive equipment, or highly trained experts for efficiently concentrating viruses from low-concentration virus solutions. The method of the present invention can concentrate viral vectors readily while maintaining infection abilities of the viral vectors, and thus it can be used as a safe and simple technique for concentrating a vector useful in the field of a genetic therapy or a vaccine therapy using a viral vector.

Owner:JAPAN TOBACCO INC +1

Enrichment methods for the detection of pathogens and other microbes

ActiveUS7531163B2Cost-effective and accurateBacterial antigen ingredientsMicroorganismsMicroorganismAssay

The present invention provides novel enrichment, testing and detection methods for detection of pathogens or other microbes in a food, water, wastewater, industrial, pharmaceutical, botanical, environmental samples and other types of samples analyzed by enrichment-detection methods. In preferred aspects, a sample is obtained at a first location and is diluted (e.g., in the case of a solid or semi-solid sample or liquid) at the first location at a ratio of about 1:0 (wt. / vol.) to 1:2 (wt. / vol.), or greater, preferably at a ratio of about 1:0.1 (wt. / vol.) or greater, or more preferably, at a ratio of about 1:2 (wt. / vol.) or greater. The diluted sample is incubated at an optimal temperature in an incubator and either tested locally, or sent in a shipping incubator to a second location that is a remote test location. The incubated sample is received and tested at the second location by assaying the sample, or a portion thereof, with an assay suitable to detect the pathogen or other microbe. In alternate embodiments, no dilution at the first location is required, and optionally minimal additions to adjust intrinsic deficiencies may be made, but the sample is nonetheless incubated during transit to the test location.

Owner:INST FOR ENVIRONMENTAL HEALTH

Treatment method for rare earth phosphate rock and enrichment method for rare earth

ActiveCN103184356AReduce eutectic adsorptionEasy accessProcess efficiency improvementRare-earth elementEnrichment methods

The invention discloses a treatment method for a rare earth phosphate rock and an enrichment method for rare earth. The treatment method comprises the following steps: mixing the rare earth phosphate rock and phosphoric acid to form mixed slurry; adding concentrated sulfuric acid into the mixed slurry in such a manner that the concentration of Ca<2+> in the mixed slurry is decreased from at least 1 wt% to the equilibrium concentration of Ca<2+> and SO4<2->, then the concentration of SO4<2-> in the mixed slurry is increased from the equilibrium concentration of Ca<2+> and SO4<2-> to at least 2 wt% and the mixed slurry is added during addition of the concentrated sulfuric acid to allow the rare earth phosphate rock to be dissolved so as to obtain hemihydrate gypsum; and subjecting the obtained hemihydrate gypsum to recrystallization to obtain dihydrate gypsum. The enrichment method for rare earth comprises a step of recovering rare earth elements from liquid obtained after recrystallization of the hemihydrate gypsum and / or liquid obtained after heating of the mixed slurry. In the process of generation of the hemihydrate gypsum, the addition speed of the concentrated sulfuric acid is controlled, and SO4<2-> in the mixed slurry is allowed to be insufficient at first and then controlled to be excess, which aids rare earth in entering into the phosphoric acid.

Owner:GRIREM ADVANCED MATERIALS CO LTD

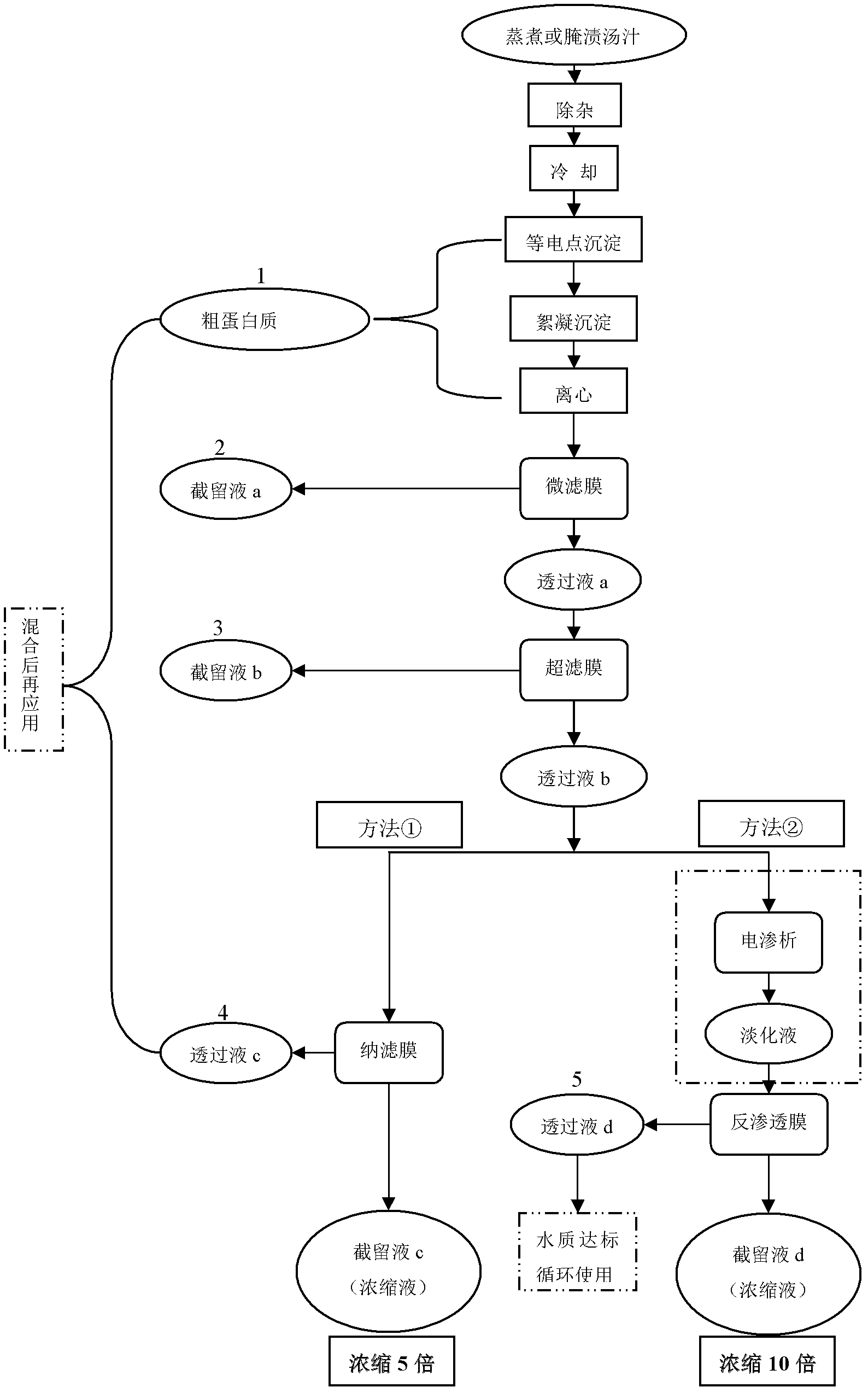

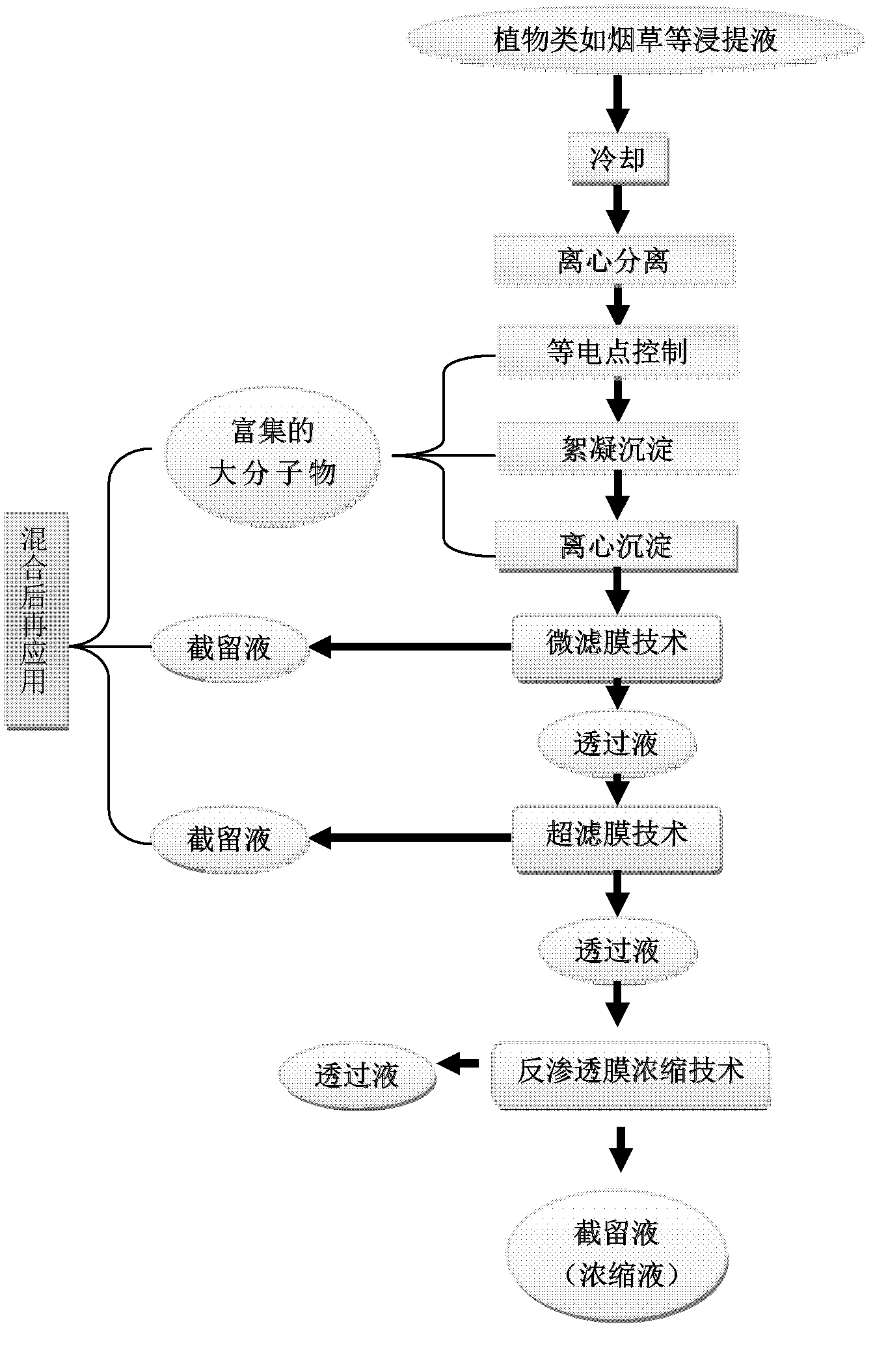

Cryo-concentration method of juice obtained by processing organisms

ActiveCN102657320AEmission reductionReduce pollutionTobacco treatmentFood preparationConcentration polarizationEnrichment methods

The invention discloses a cryo-concentration method of juice obtained by processing organisms, comprising the following steps: firstly pretreating the juice by using isoelectric precipitation, flocculation precipitation, centrifugal separation and the like to gather protein and reduce the protein content in the juice, so as to reduce the concentration polarization of membrane concentration; and then integratedly cascading membrane modules to concentrate small-molecule nutrient and flavor substances by fully utilizing the advantages of microfiltration, ultrafiltration, stepwise rejection of reverse osmosis, and desalination of electrodialysis to reduce osmotic pressure. The method is suitable for the juice obtained by processing organisms having a content of concentrated amino acid nitrogen being 5-100 mg / 100ml and has a wide application range. The method can not only concentrate and recover nutrient and flavor substances, transforms the juice into something valuable, raises the product additional values, reduces the discharge of food processing waste water, reduces environmental pollution, and can basically realize the basically complete recycling of the nutrient and flavor substances of the juice.

Owner:ZHEJIANG UNIV OF TECH

Ammonia nitrogen removal and ammonium salt enrichment method for high-concentration ammonia-nitrogen wastewater through membrane method

InactiveCN106186492AEliminate the concentration stepSimple processWater contaminantsMultistage water/sewage treatmentHigh concentrationDistillation

The invention discloses an ammonia nitrogen removal and ammonium salt enrichment method for high-concentration ammonia-nitrogen wastewater through a membrane method. The ammonia nitrogen removal and ammonium salt enrichment method comprises the steps that firstly, impurity removal through sedimentation is conducted to obtain purified high-concentration ammonia-nitrogen wastewater; secondly, the pH of the wastewater is regulated to be 10-11 by adding alkali to enable ammonia nitrogen to exist in the form of volatile NH3; finally, ammonia nitrogen in the wastewater is removed through the gas membrane process, the operation conditions are strictly controlled, the osmotic distillation process of water which has the same mass transfer direction as ammonia and is accompanied in the gas membrane process is effectively inhibited, the condition that an absorption solution is diluted is avoided, a high-concentration ammonium salt solution is obtained, and the step of concentration of the diluted absorption solution is omitted. According to the method, efficient and low-consumption ammonia removal of the high-concentration ammonia nitrogen wastewater can be achieved, no secondary pollution is generated, and environmental friendliness is achieved.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

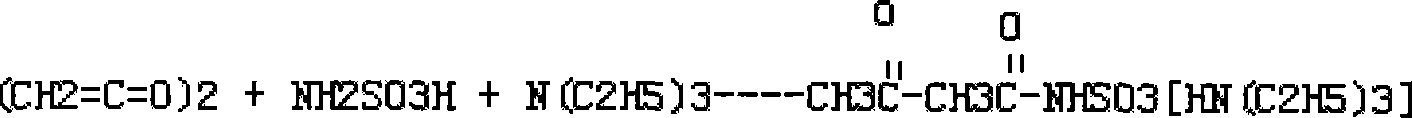

Polymer having an upper critical solution temperature

InactiveUS7195925B2Promote recoveryEasy to separateSugar derivativesMicrobiological testing/measurementPurification methodsEnrichment methods

The invention relates to a stimulus-responding polymer obtained by polymerizing at least a monomer represented by a general formula (1) and a monomer represented by a general formula (2), and a separation method or concentration method of microorganisms, a purification method, detection method or concentration method of nucleic acids, a separating agent, a separation method of biomaterials and a conversion method of materials, which use this polymer,(in the formula, R11 represents hydrogen atom or methyl group, and R12 represents single bond or a straight or branched alkylene group having from 1 to 5 carbon atoms)(in the formula, R13 represents hydrogen atom or methyl group, and R14 represents hydrogen atom, a straight, branched or cyclic alkyl group, alkoxyl group or alkylamino group having from 1 to 10 carbon atoms, an aryl group or a heterocyclic group).

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

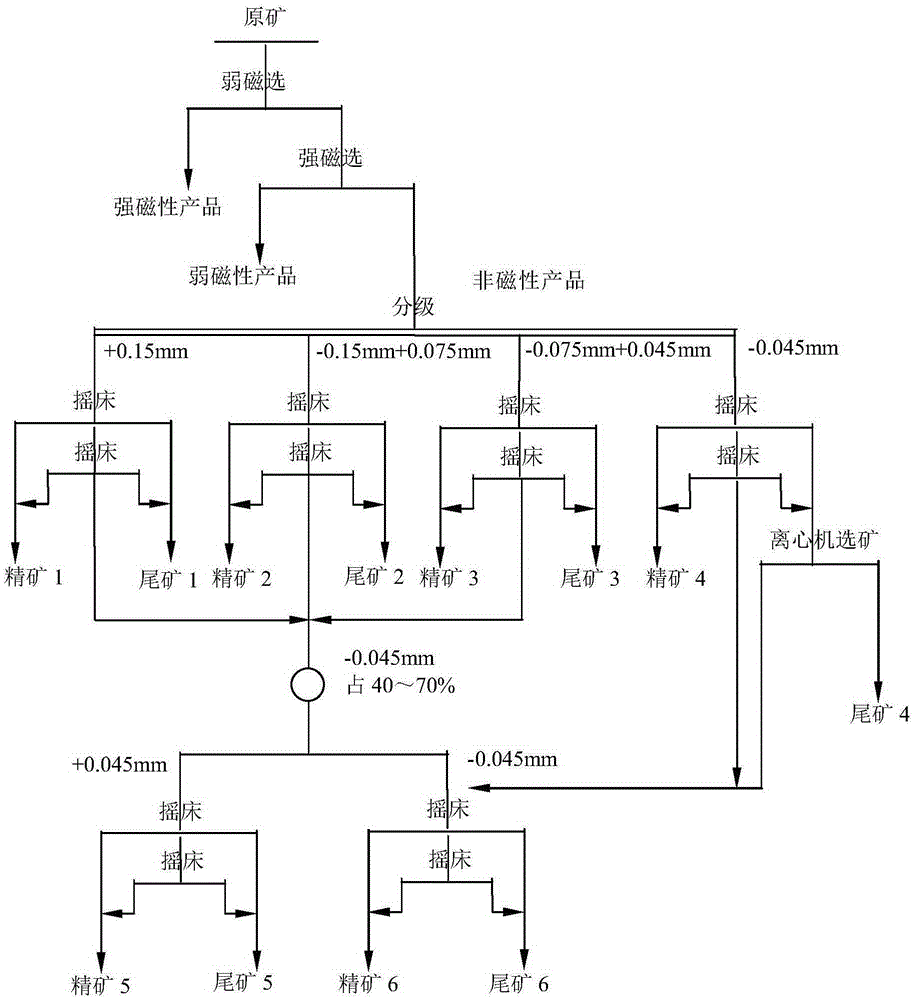

Mineral separation and enrichment method suitable for associated scheelite in molybdenite floatation tailings

InactiveCN105312148AReduce processingImprove sorting efficiencyMechanical material recoveryWet separationEnrichment methodsNon magnetic

The invention provides a mineral separation and enrichment method suitable for associated scheelite in molybdenite floatation tailings. The method includes the steps of low-intensity magnetic separation, high-intensity magnetic separation, non-magnetic ore pulp material size fraction grading, gravity separation, middling regrinding, regrading gravity separation and the like. A high-grade and high-recovery scheelite concentrate product is obtained, the associated low-grade scheelite resource in Cu-Mo polymetallic mixed associated ore is effectively and comprehensively recovered and used. The method can be widely applied to the field of recovering and using the associated low-grade scheelite resource.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Efficient enrichment method for precious metal secondary resources

InactiveCN105886770AAdaptableSimple processProcess efficiency improvementElectrolysisEnrichment methods

The invention discloses an efficient enrichment method for precious metal secondary resources. The method comprises the steps that precious metal secondary resource materials, a copper collecting agent, a reducing agent, a slag forming constituent, a binding agent and water are subjected to full wet-grinding in a ball mill, and are mixed evenly and manufactured into pellets through a ball forming machine, and the pellets are dried to obtain composite pellets; after waste copper is molten in an intermediate-frequency furnace, the composite pellets are added into the intermediate-frequency furnace in batches and are subjected to mixing smelting for a period of time, smelting slag is fished out, and molten copper is poured into a casting mold to form a copper anode plate; cathode copper is obtained through an electrolysis method, precious metals enter anode mud, and electrolytic residual anodes return to conduct smelting and pouring on the anode plate and conduct electrolysis again; the anode mud is subjected to pressure acid leaching, filtering and washing to obtain precious metal concentrate, and accordingly precious metal enrichment is realized. By means of the method, the process is simple, the raw materials are high in adaptability, high efficiency and environmental friendliness are achieved, the enrichment ratio is high, cost is low, and industrialization is facilitated.

Owner:KUNMING METALLURGY COLLEGE

Dynamic gradient thorough selenium enrichment method for wheat seedlings

The invention provides a method for growing selenium-enriched wheat seedlings by dynamic gradient thorough selenium enrichment, which comprises: repeatedly and alternatively soaking wheat seeds in base culture solution and selenium-containing culture solution; and cutting off from the part which is 1 centimeter away from the root of the wheat seedlings after the seedlings of the wheat grow come out for 13 to 18 days and grow to 10.5 to 16 centimeters. In order to adapt the growth process of the wheat seedlings to the selenium enrichment process gradually, the method adopts the base culture solution and the selenium-containing solution to culture the wheat seedlings repeatedly and alternatively and constantly changes the selenium concentration in the selenium-containing culture solution, thereby enriching a large amount of organic selenium in the wheat seedlings and improving the emerge rate of the wheat seedlings, seedling rate and yield. According to test, the total selenium content of the selenium-enrich wheat seedling products is 18 to 24mg / kg and the organic selenium content is 16 to 21.5mg / kg; and compared with the wheat seedlings grown by thorough base culture solution culture, the selenium enrichment times increases to 6 to 8 times, the organic selenium conversion rate reaches 80 to 90 percent, the emerge rate is increased by 20 to 30 percent, and the seedling rate is increased by 60 to 95 percent.

Owner:焦宇知 +2

Enrichment method of semiconductor type carbon nanotubes

InactiveCN103482607AReduce processing timeImprove separation efficiencyCarbon nanotubesEnrichment methodsCarbon nanotube

The invention discloses an enrichment method of semiconductor type carbon nanotubes. The enrichment method comprises the steps as follows: firstly, a solid oxidizing compound is dissolved in a liquid reagent to obtain a solid oxidizing compound solution; then, single-wall carbon nanotubes required to be purified are uniformly dispersed into the obtained solid oxidizing compound solution to obtain a carbon nanotube dispersion liquid with a concentration of 0.1-0.5 mg / ml; the obtained carbon nanotube dispersion liquid is placed in a microwave reactor for reaction at a reaction temperature controlled to range from 40 DEG C to150 DEG C for 25-120 min; and an obtained reaction liquid is sequentially filtered, washed, dried and annealed in vacuum or inert atmosphere to obtain the semiconductor type carbon nanotubes. According to the enrichment method of the semiconductor type carbon nanotubes, stability of structures and performance of separated carbon nanotubes is guaranteed, accuracy control for the separation process of the carbon nanotubes is realized, and a product with the semiconductor type carbon nanotube content of 90%-93% is obtained finally.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com