Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48 results about "Vacuum swing adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacuum swing adsorption (VSA) is a non-cryogenic gas separation technology. Using special solids, or adsorbents, VSA segregates certain gases from a gaseous mixture under minimal pressure according to the species' molecular characteristics and affinity for the adsorbents. These adsorbents (e.g., zeolites) form a molecular sieve and preferentially adsorb the target gas species at near ambient pressure. The process then swings to a vacuum to regenerate the adsorbent material.

Process for removing a target gas from a mixture of gases by swing adsorption

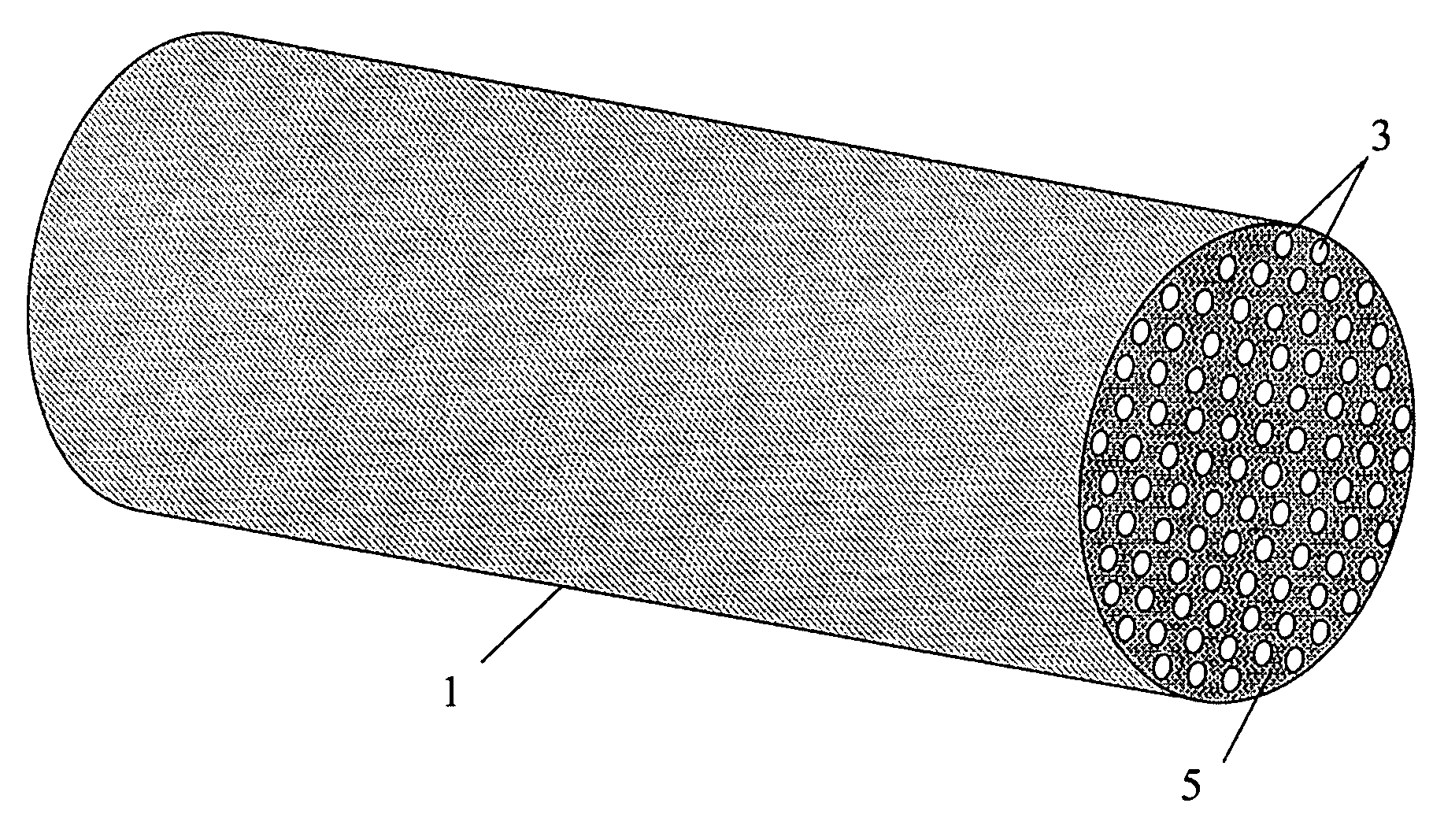

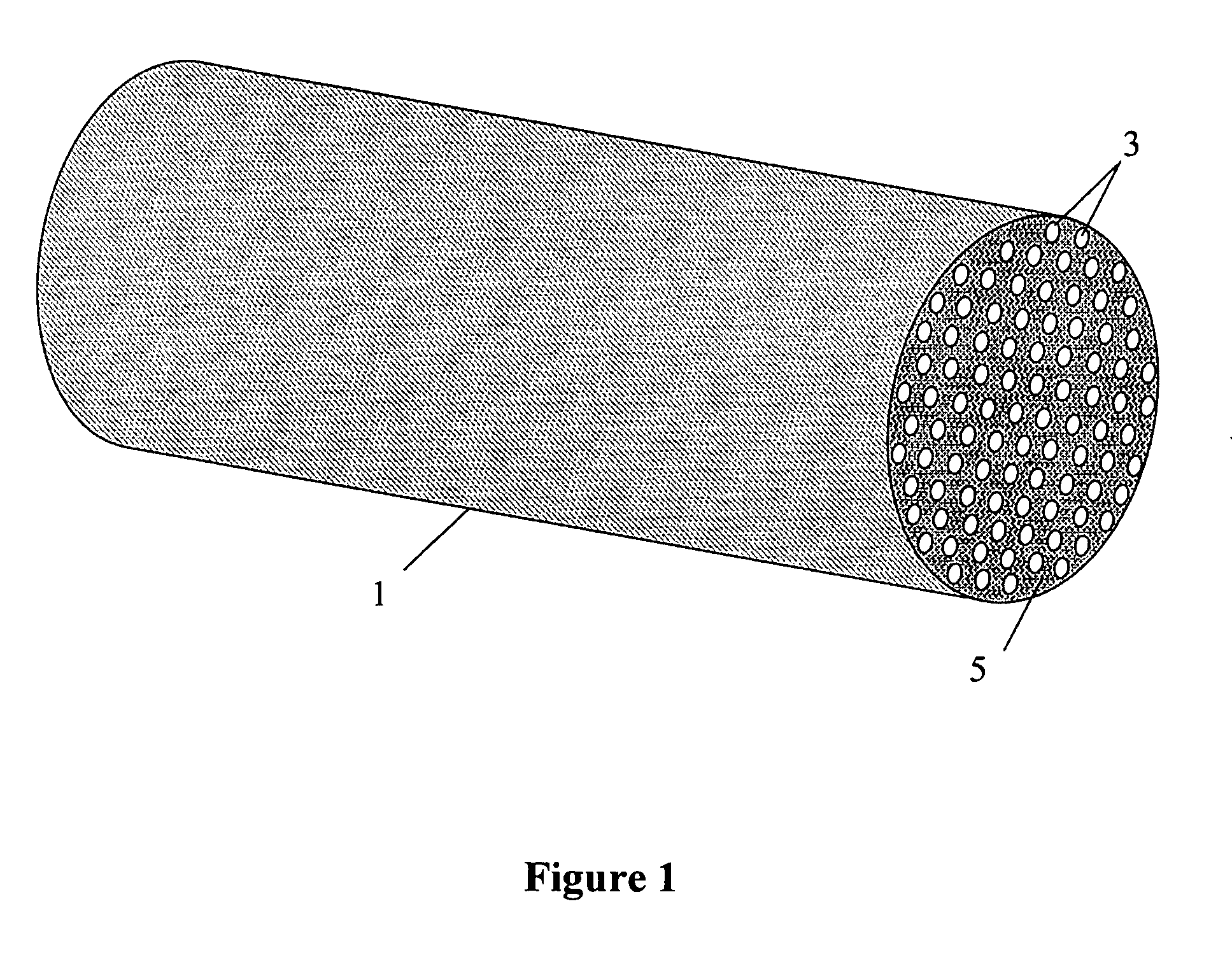

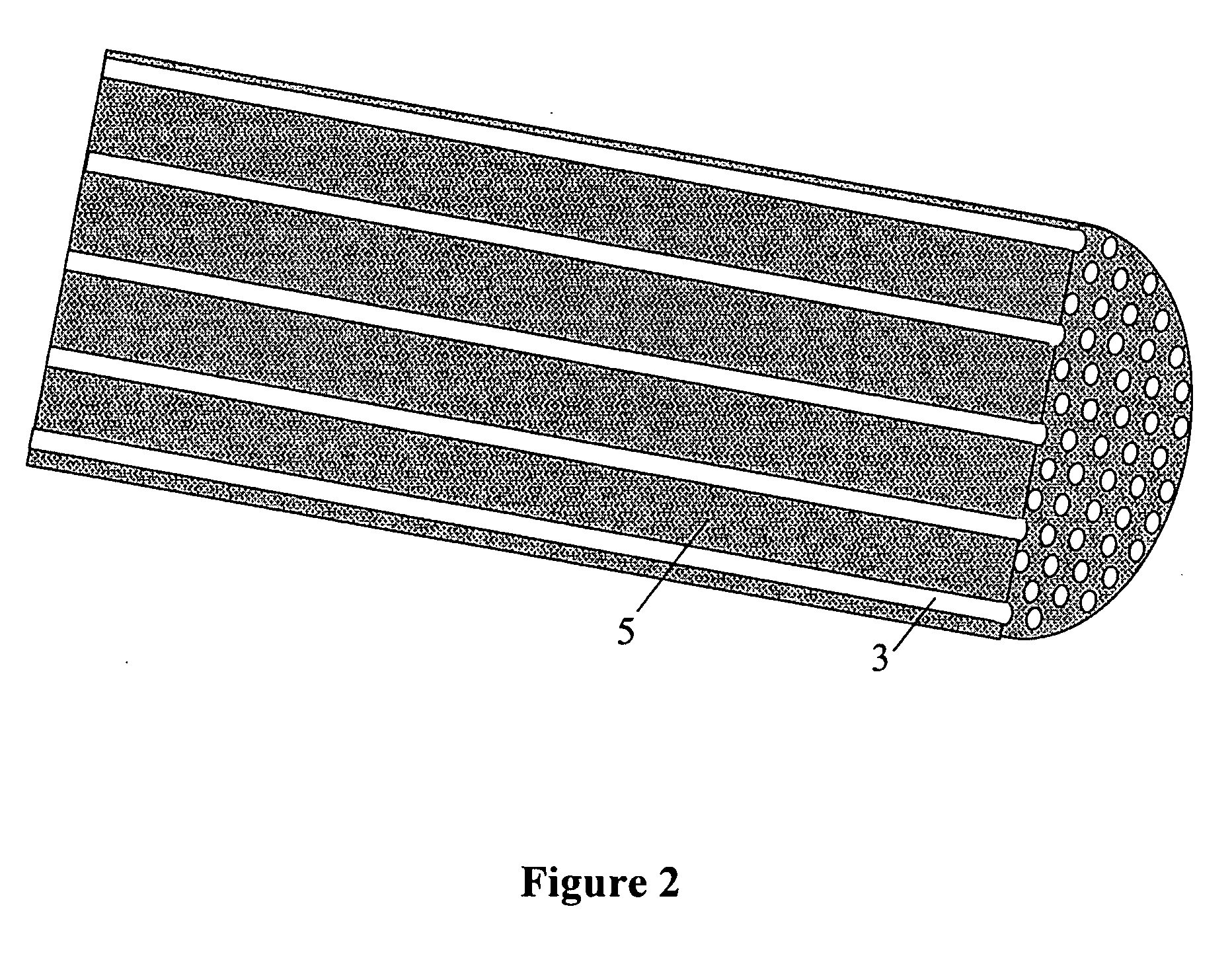

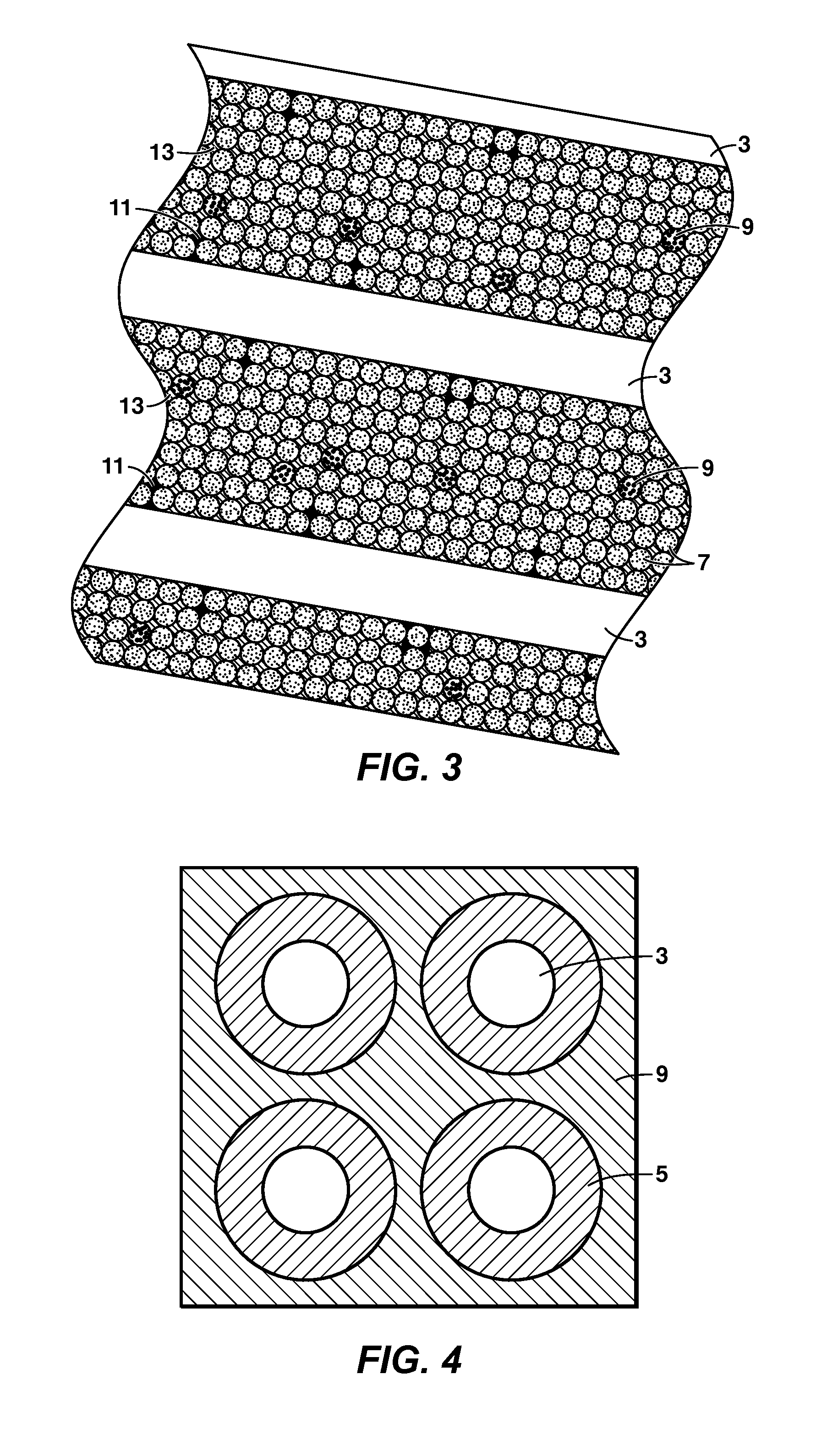

The present invention relates the separation of a target gas from a mixture of gases through the use of engineered structured adsorbent contactors in pressure swing adsorption and thermal swing adsorption processes. Preferably, the contactors contain engineered and substantially parallel flow channels wherein 20 volume percent or less of the open pore volume of the contactor, excluding the flow channels, is in the mesopore and macropore range.

Owner:EXXON RES & ENG CO

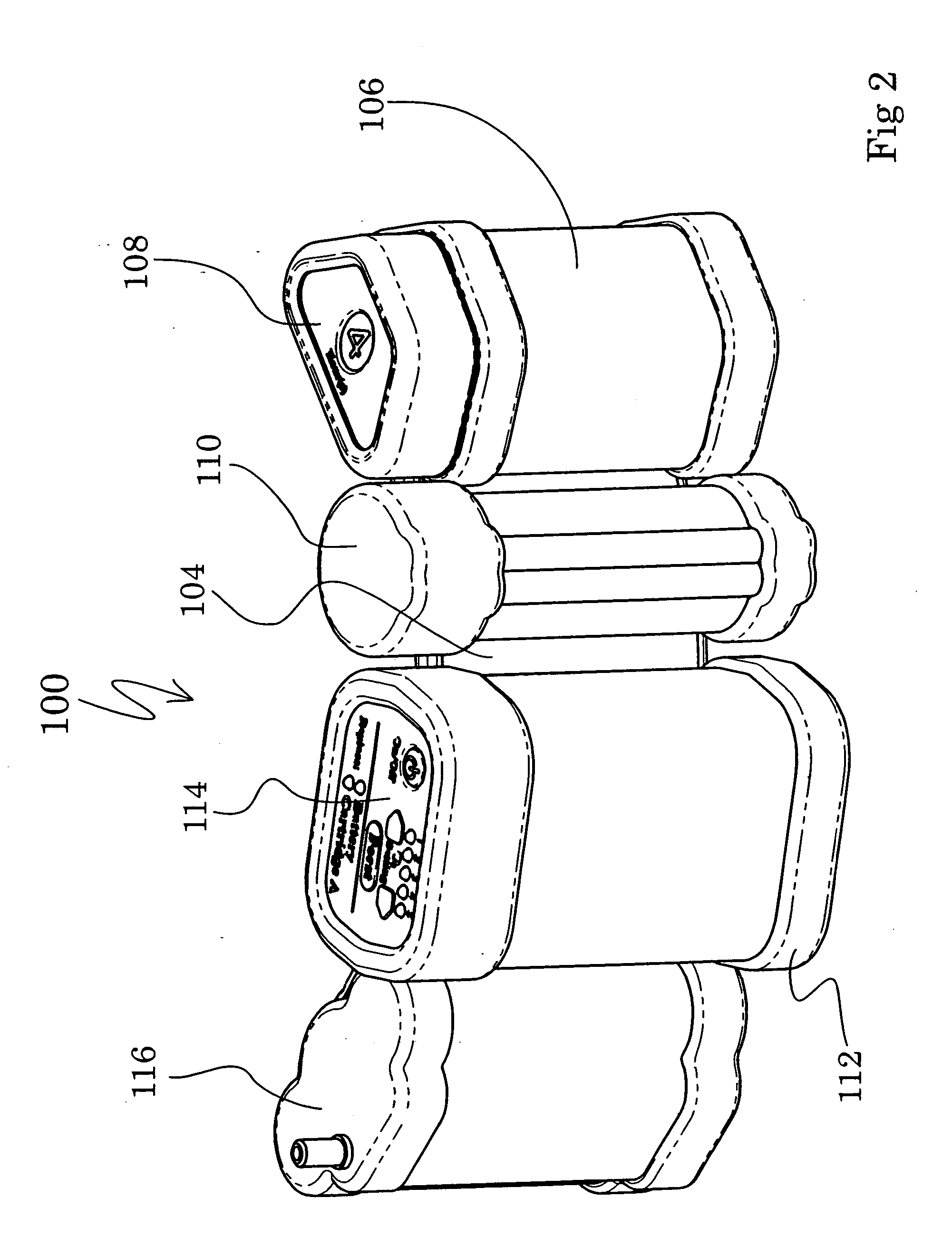

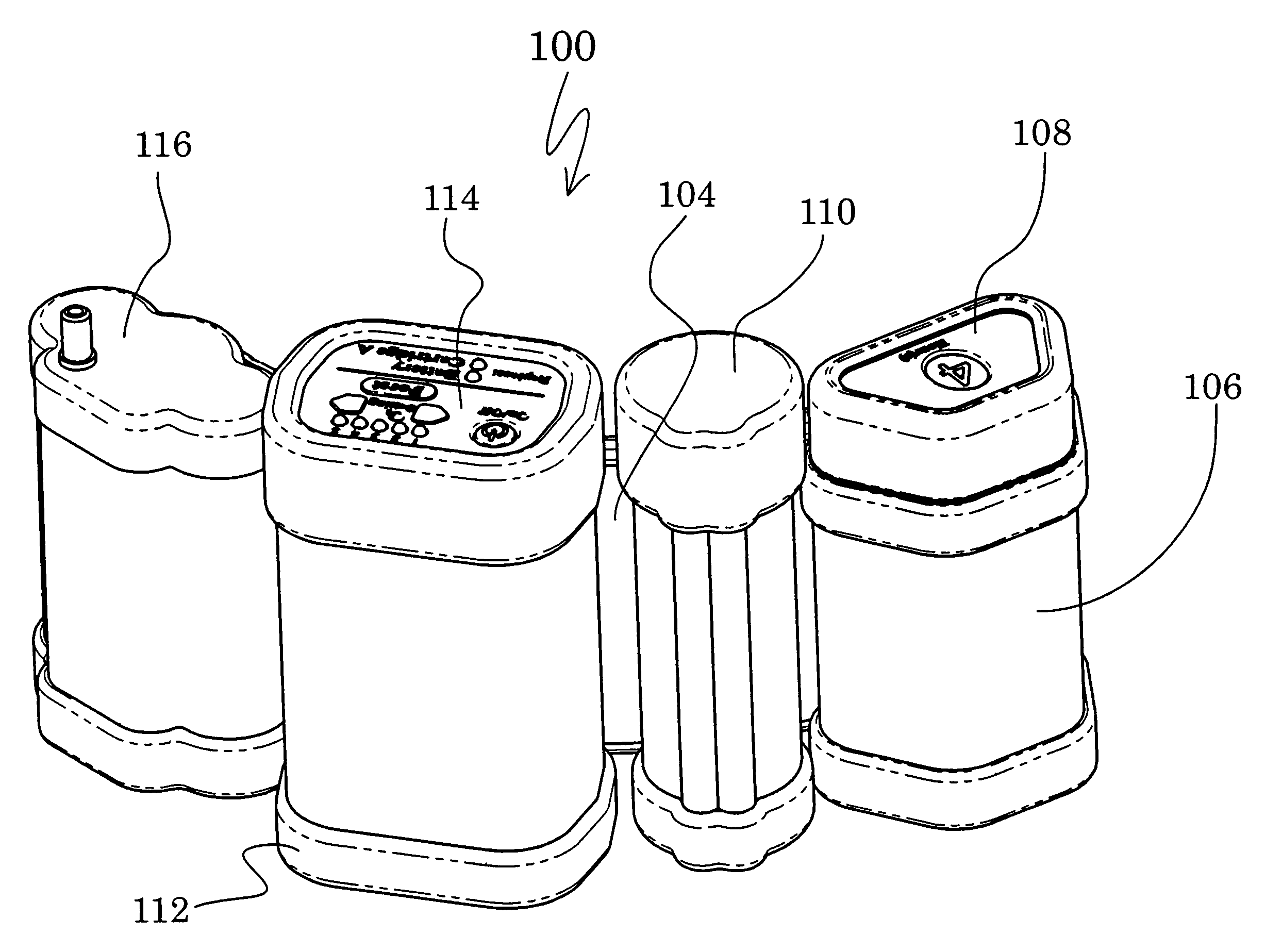

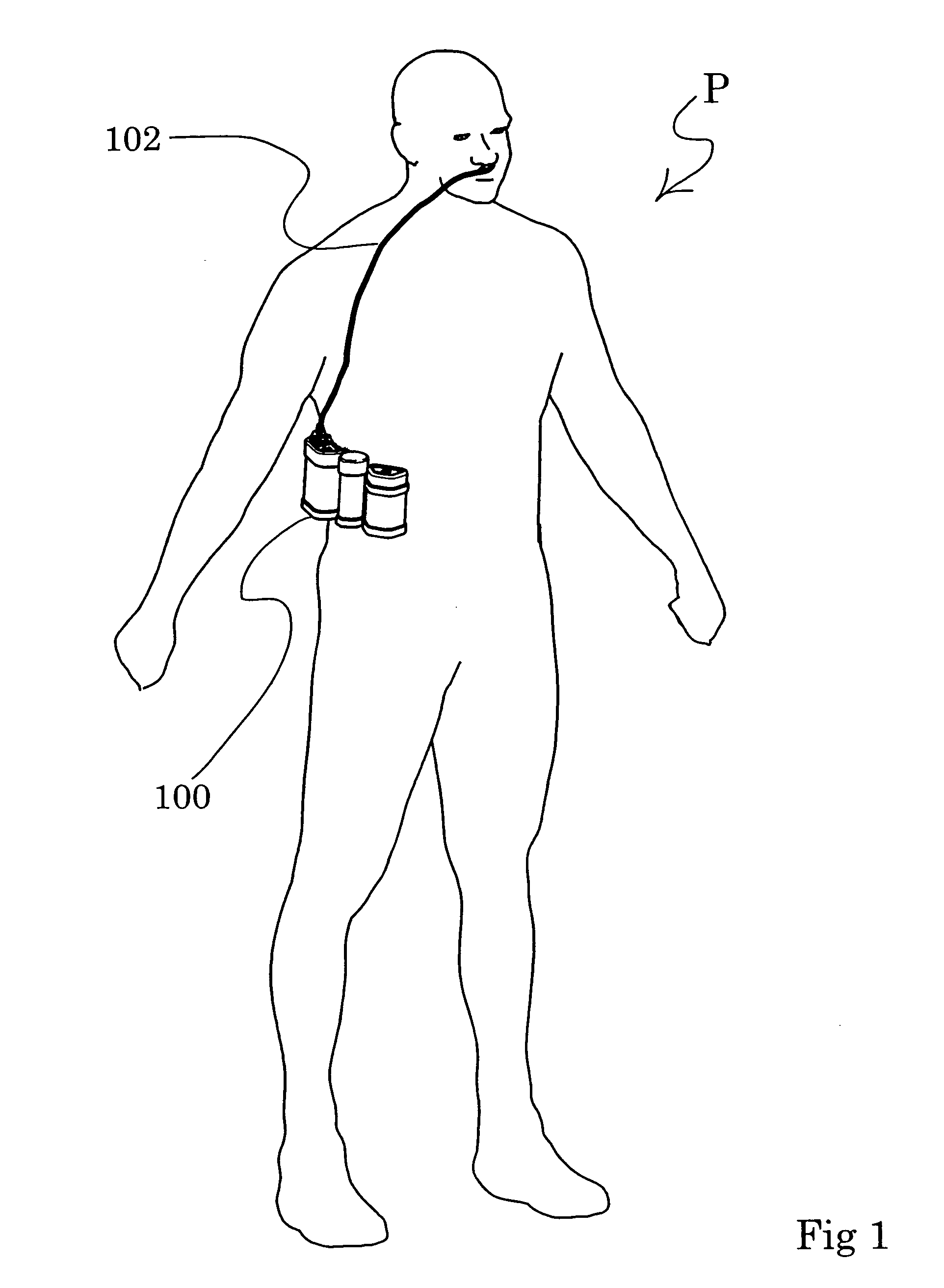

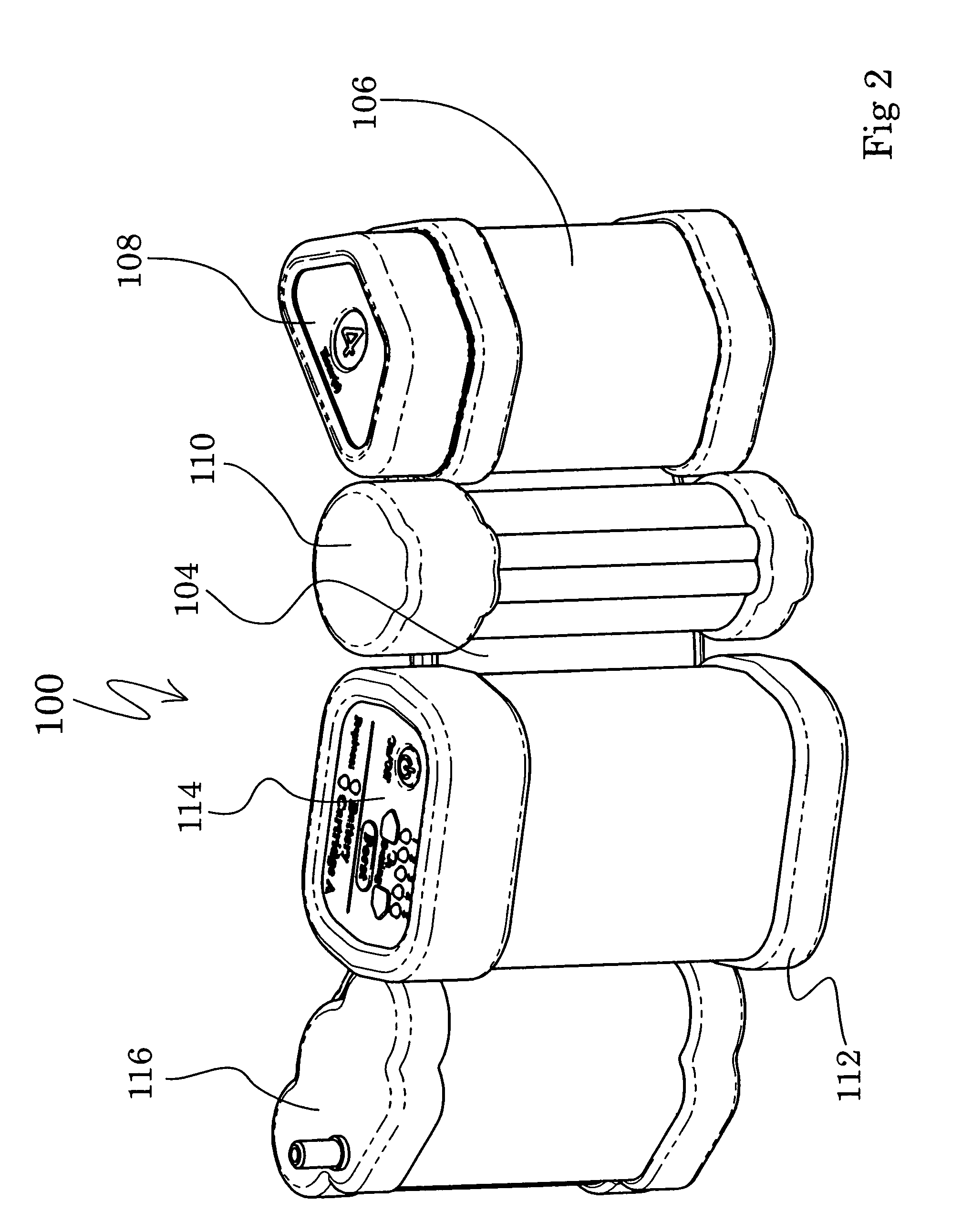

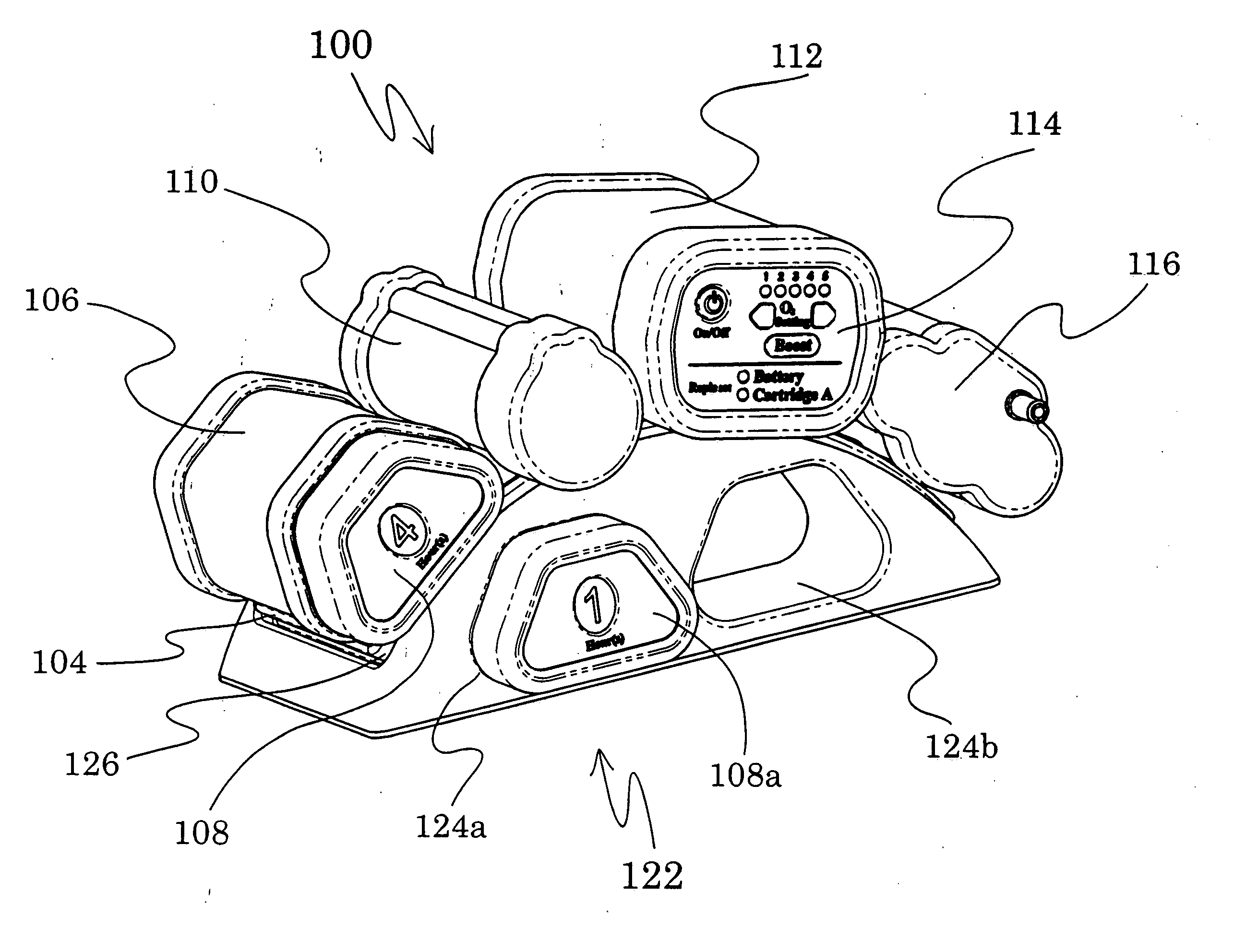

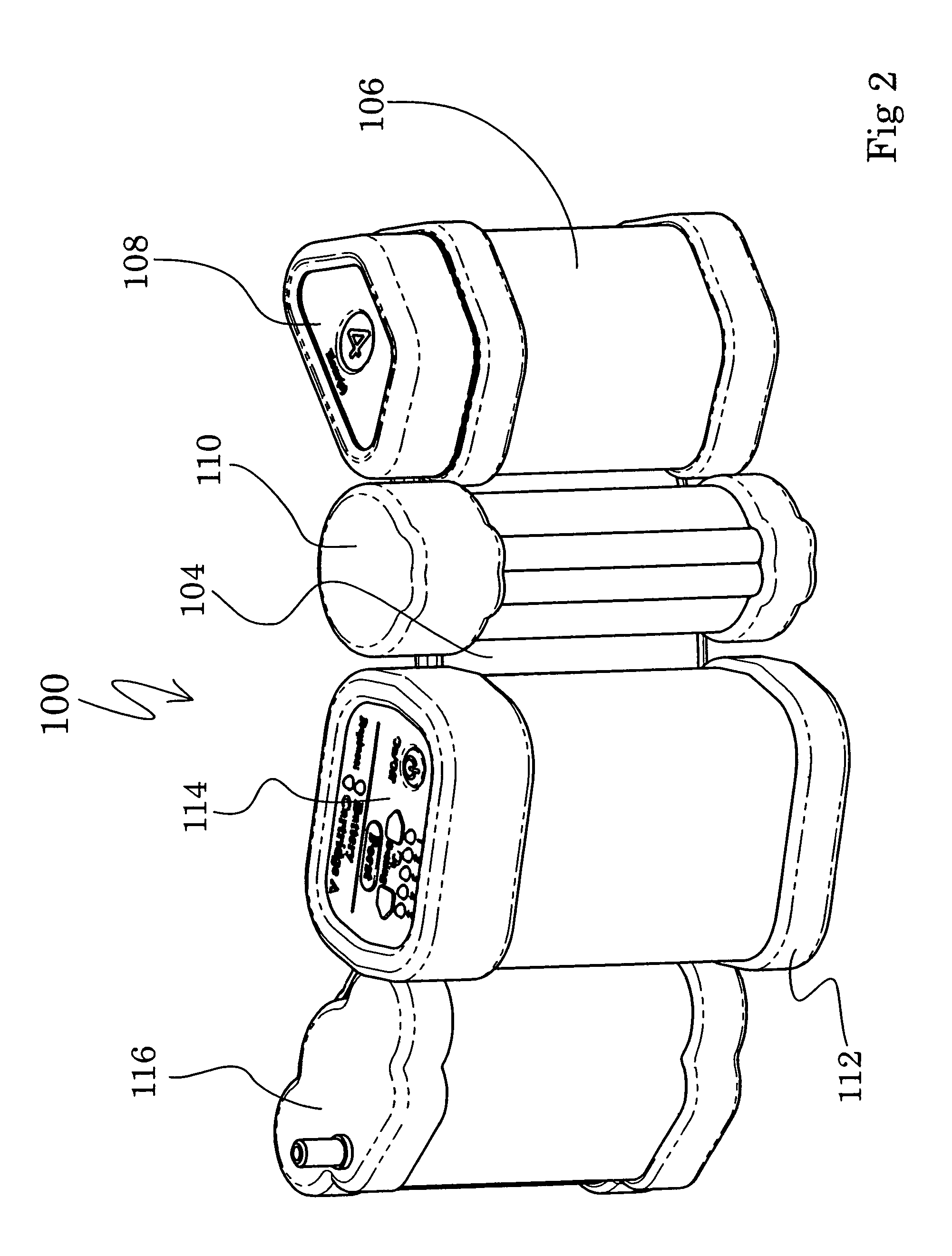

Weight-optimized portable oxygen concentrator

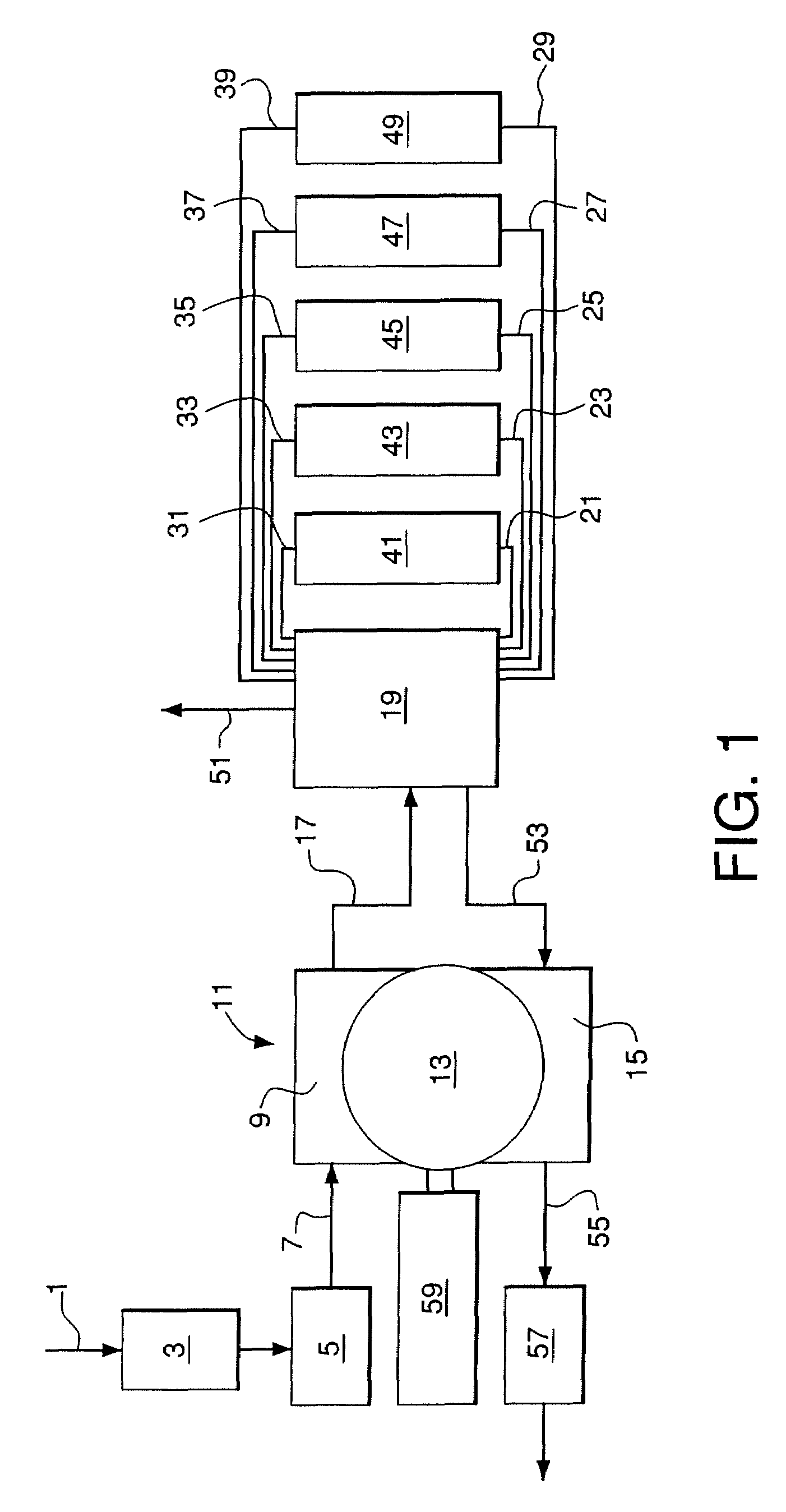

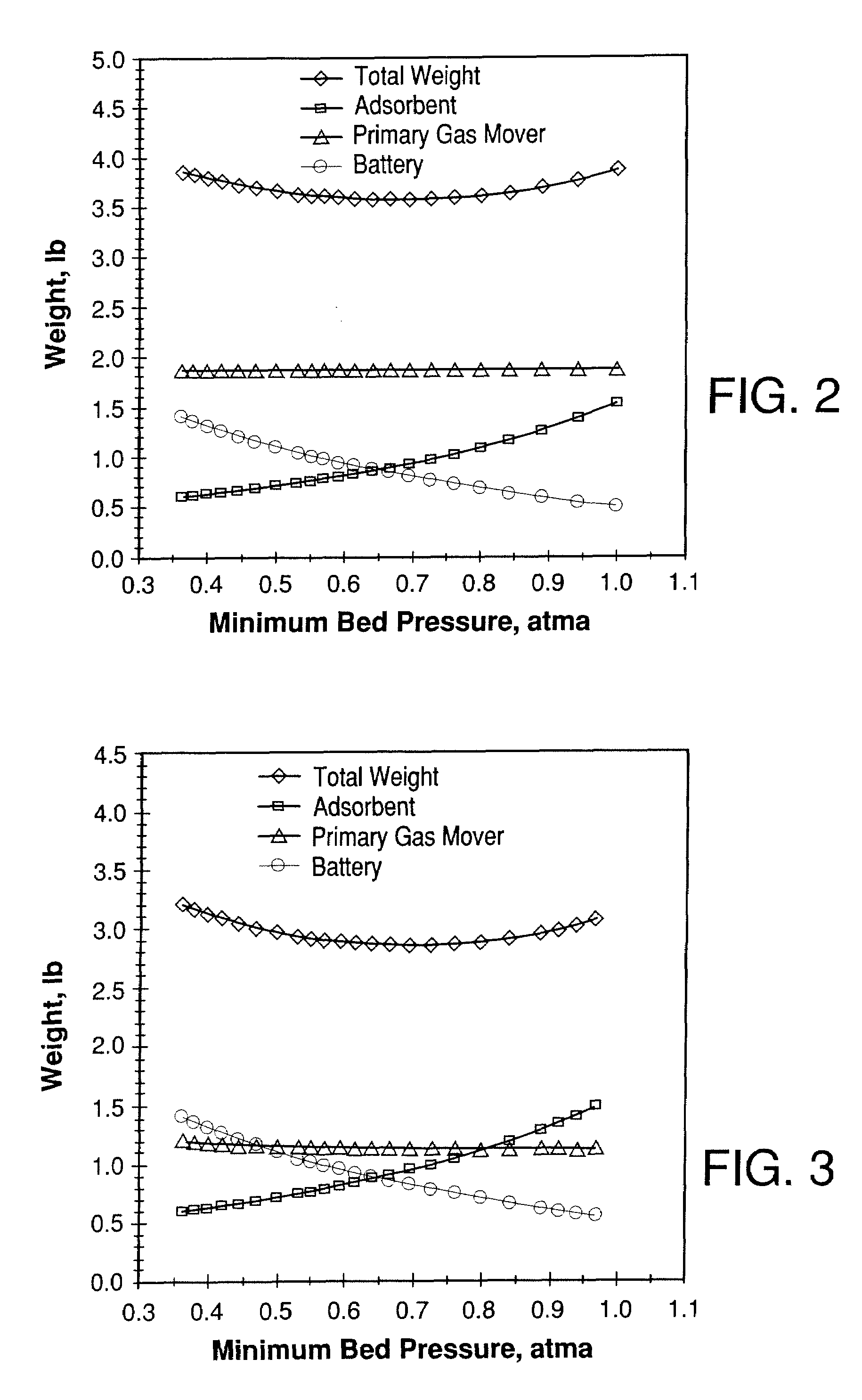

System for producing an oxygen-rich gas comprising (a) a primary gas mover including a first and a second compressor, wherein the primary gas mover is characterized by a weight Wp; (b) a drive motor adapted to drive the first and second compressors; (c) a rechargeable power supply characterized by a weight, Wb; and (d) a pressure / vacuum swing adsorption unit adapted to separate the pressurized feed air into an oxygen-rich product at a product flow rate Fp and an oxygen-depleted waste gas, wherein the adsorption unit comprises a plurality of adsorber beds containing an adsorbent and characterized by a total adsorbent weight Wa; and wherein the combined weight, Wt, of the adsorbent, the primary gas mover, and the rechargeable power supply is characterized by the expression0.75 Fp<Wt<2.02 Fpwhere Fp is in liters per min (at 23° C. and 1 atma pressure), and Wa, Wp, and Wb are in pounds.

Owner:INOGEN INC

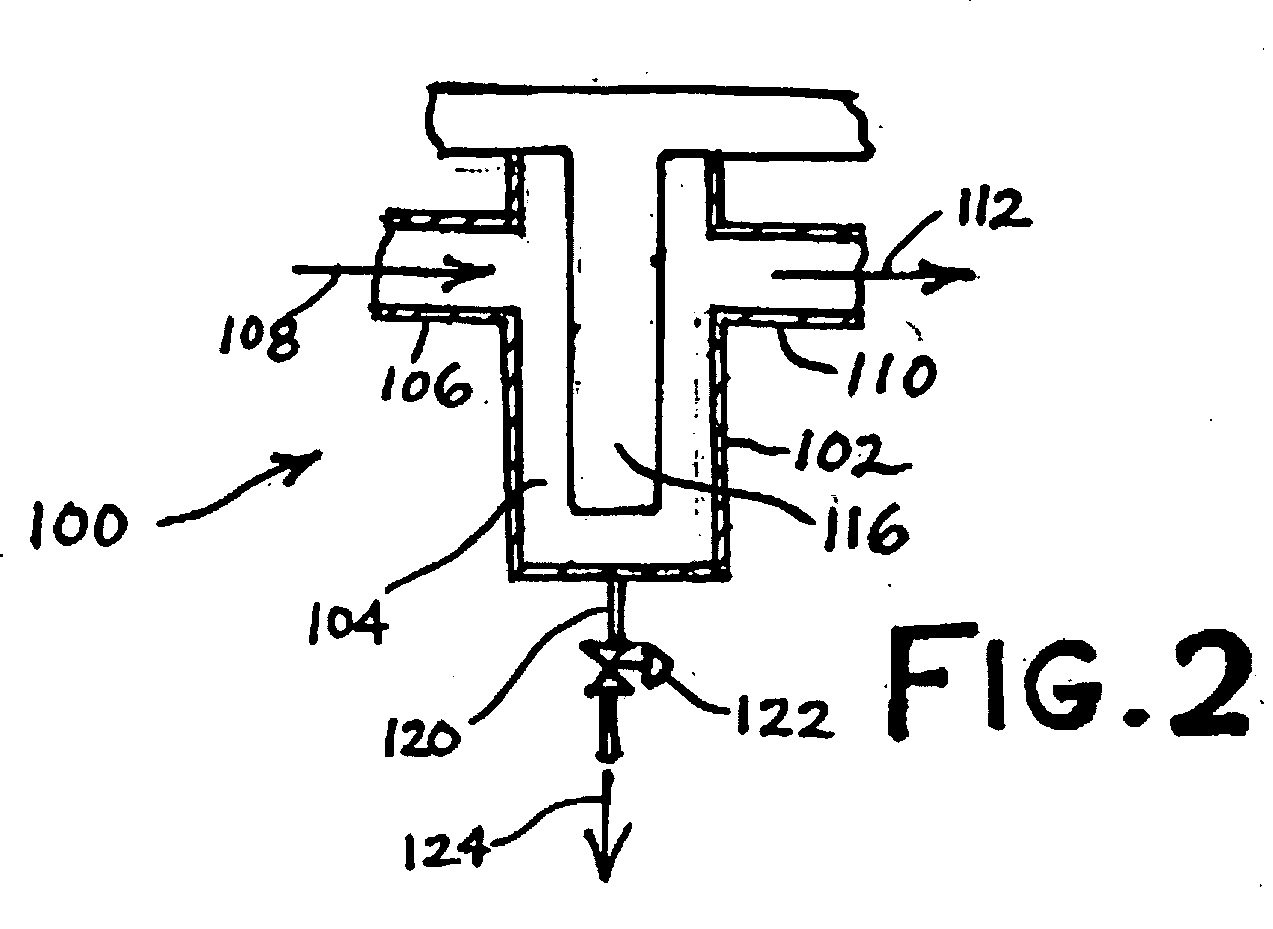

Product pump for an oxygen concentrator

Owner:VBOX

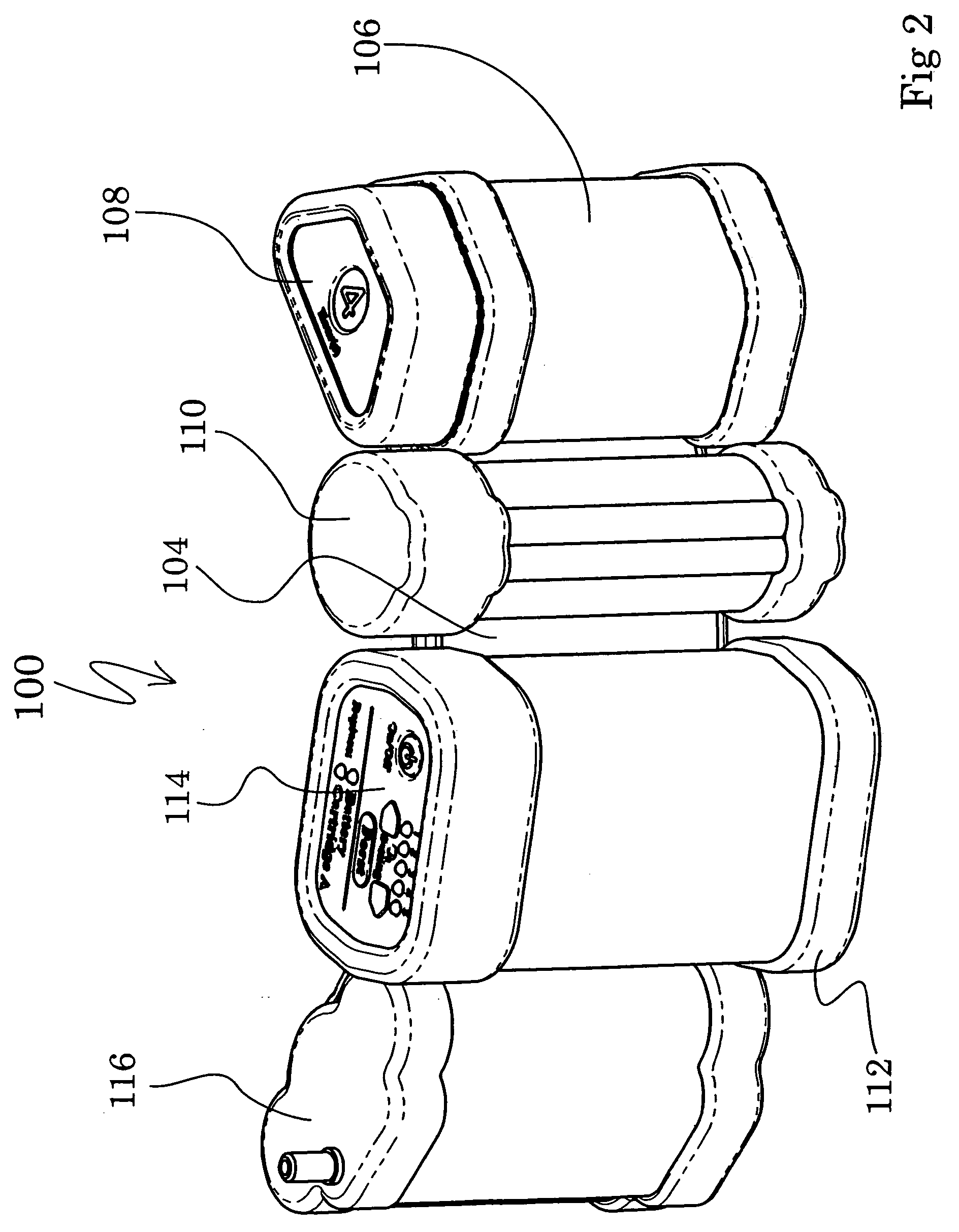

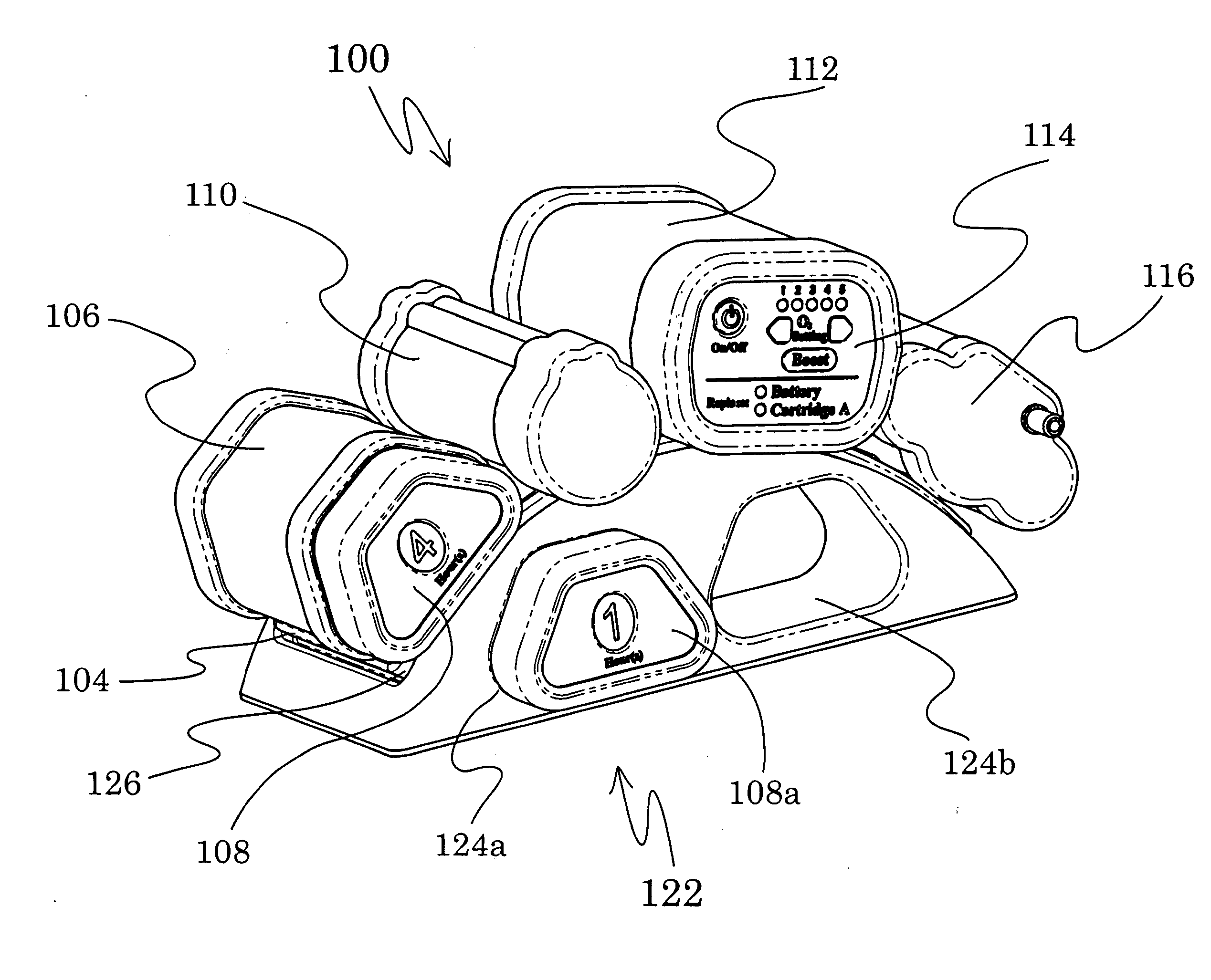

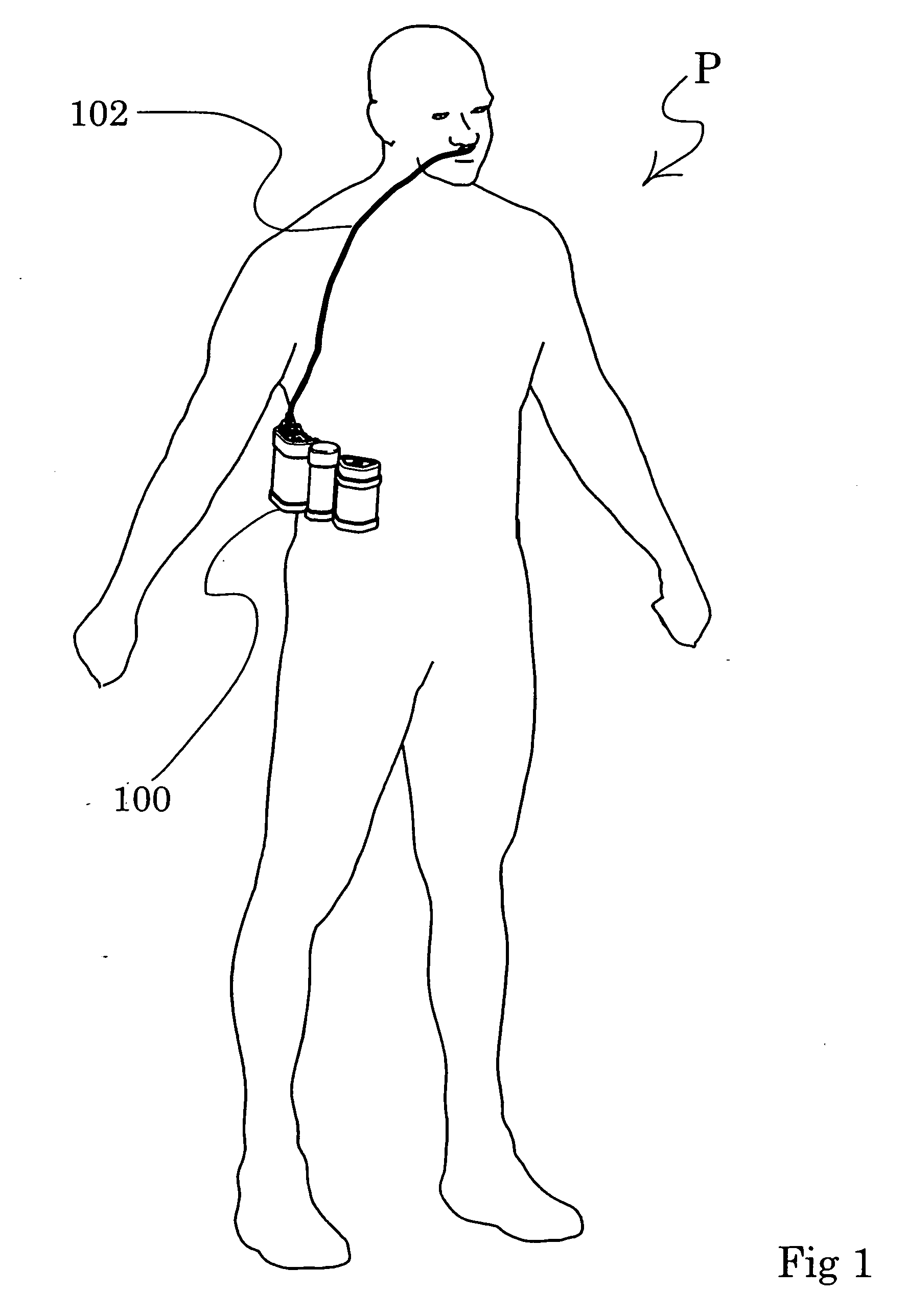

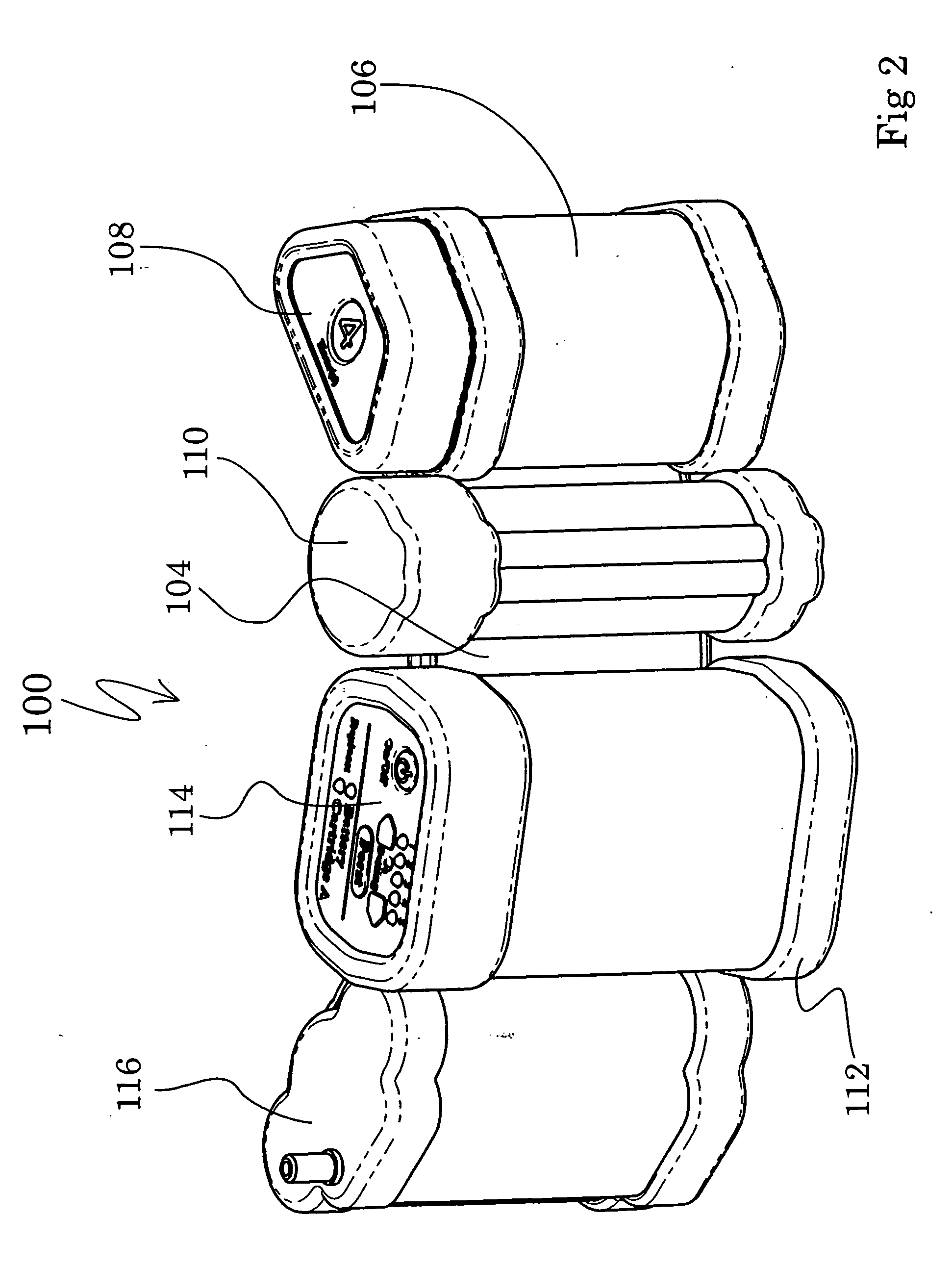

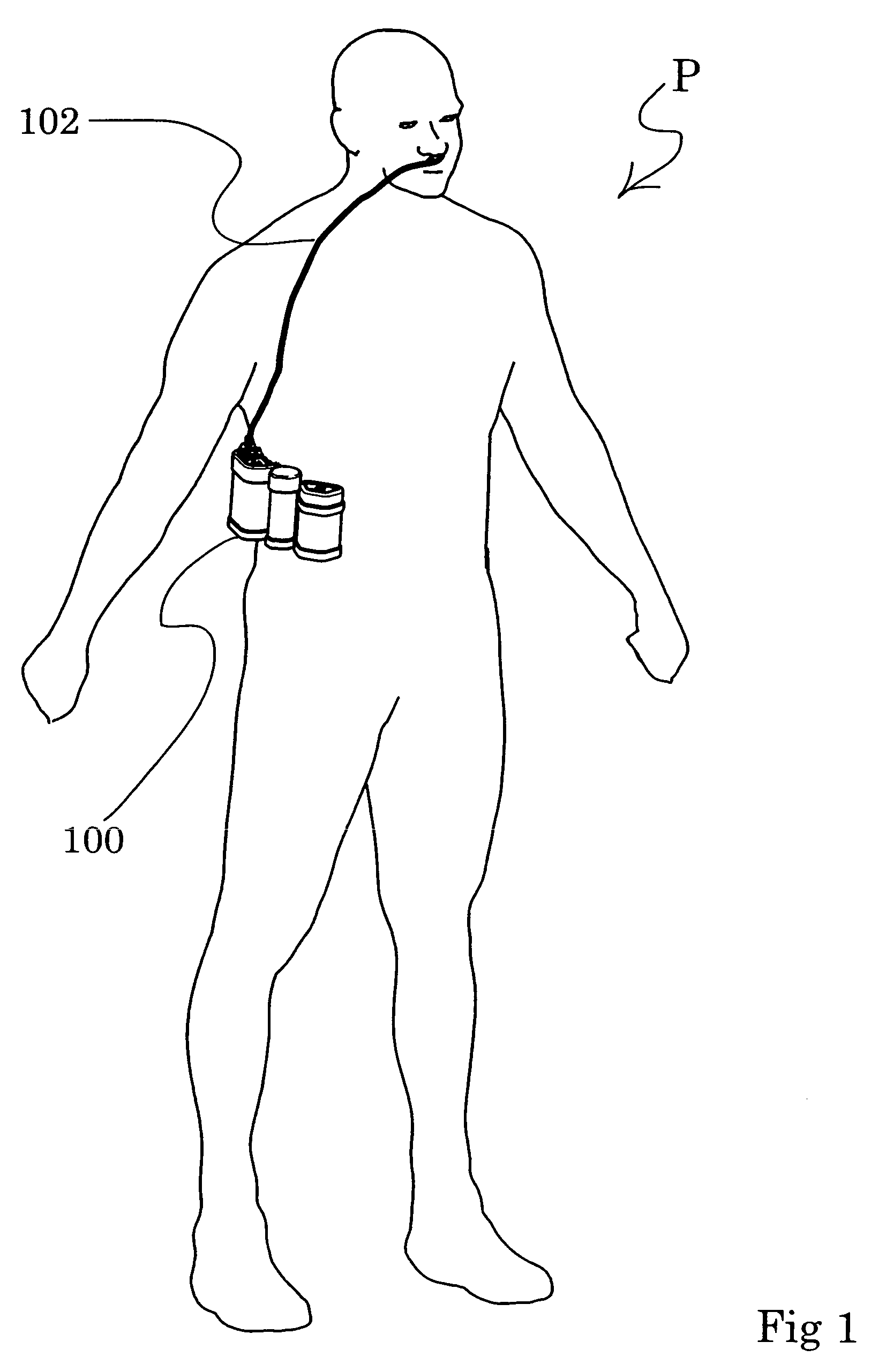

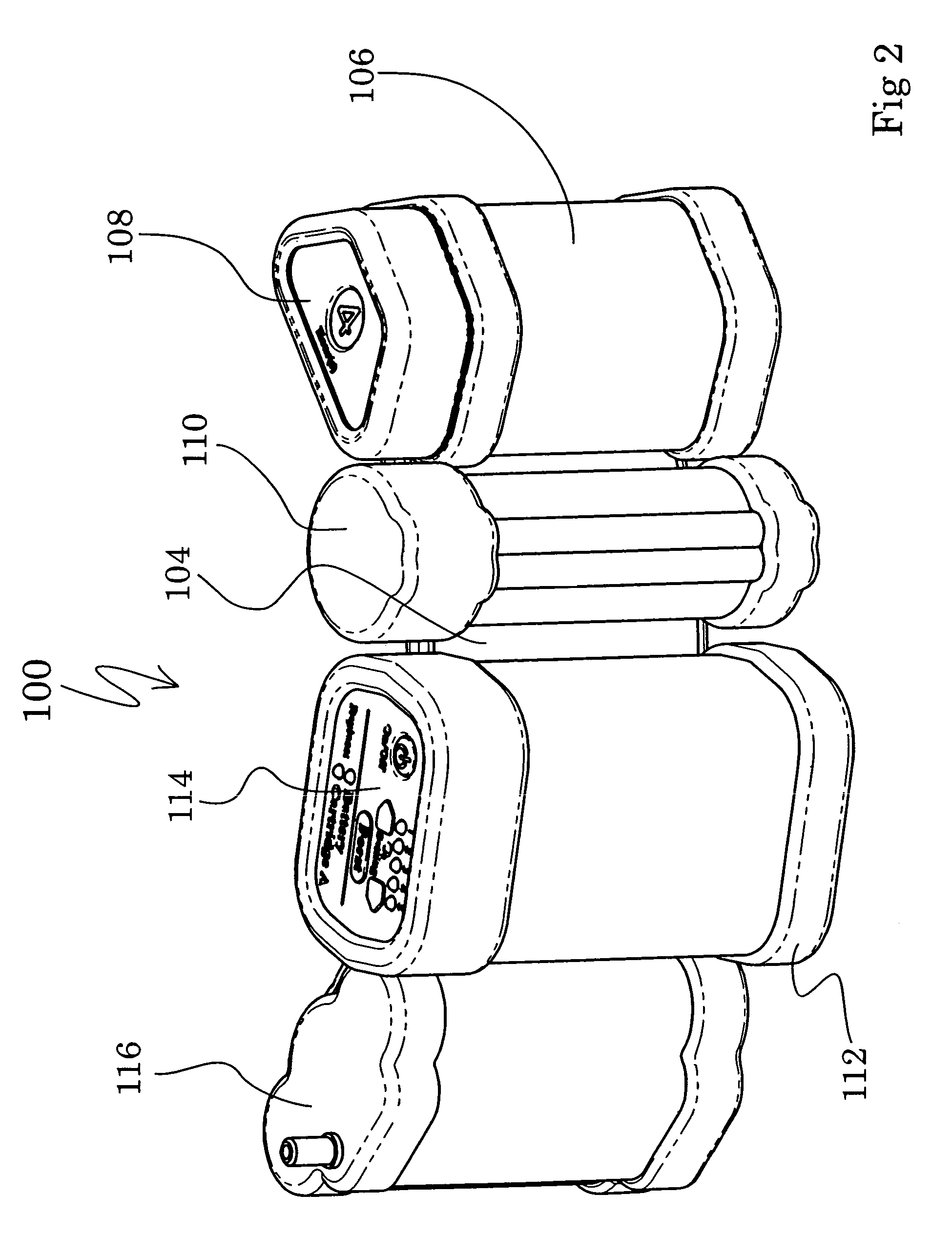

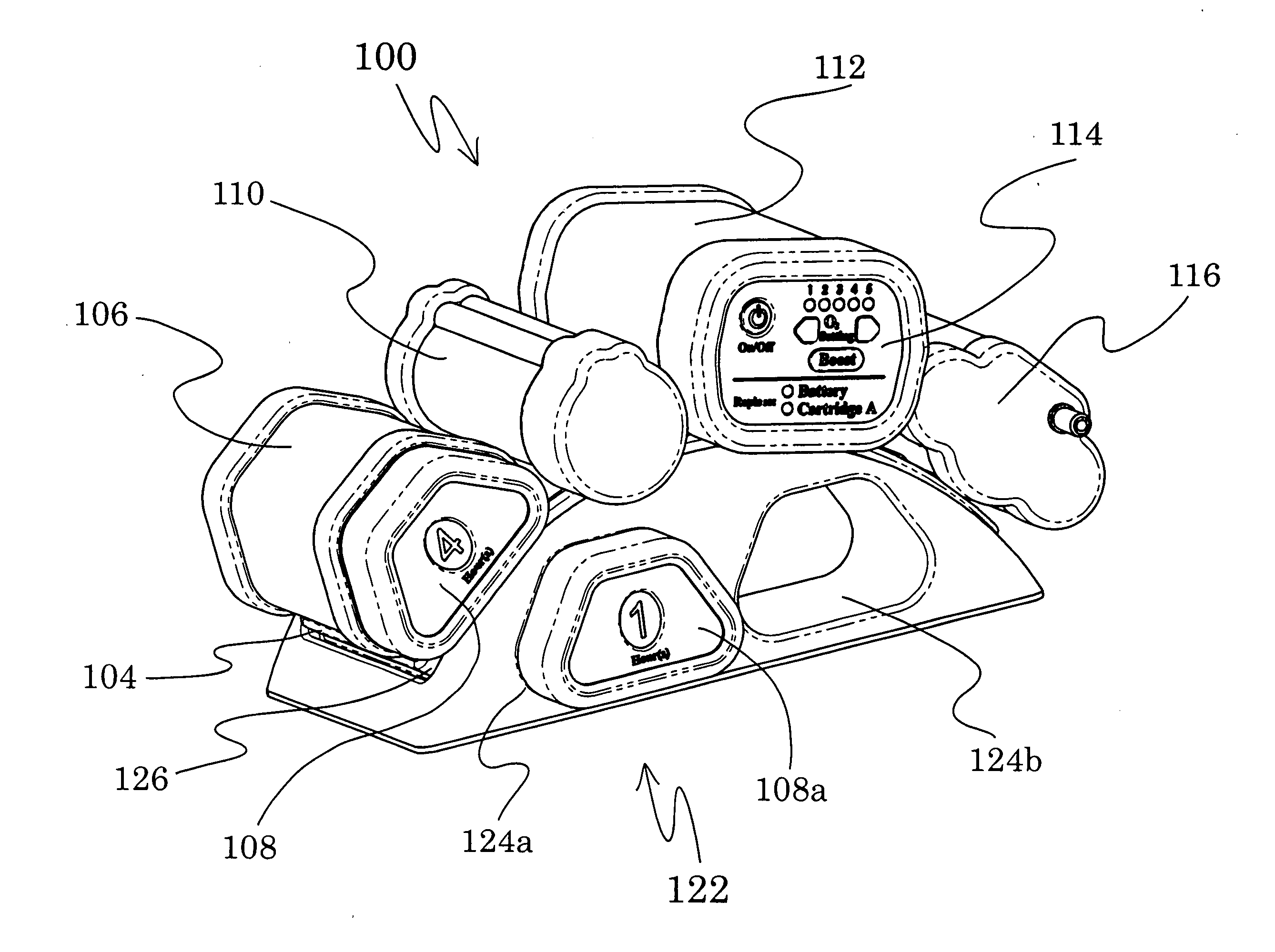

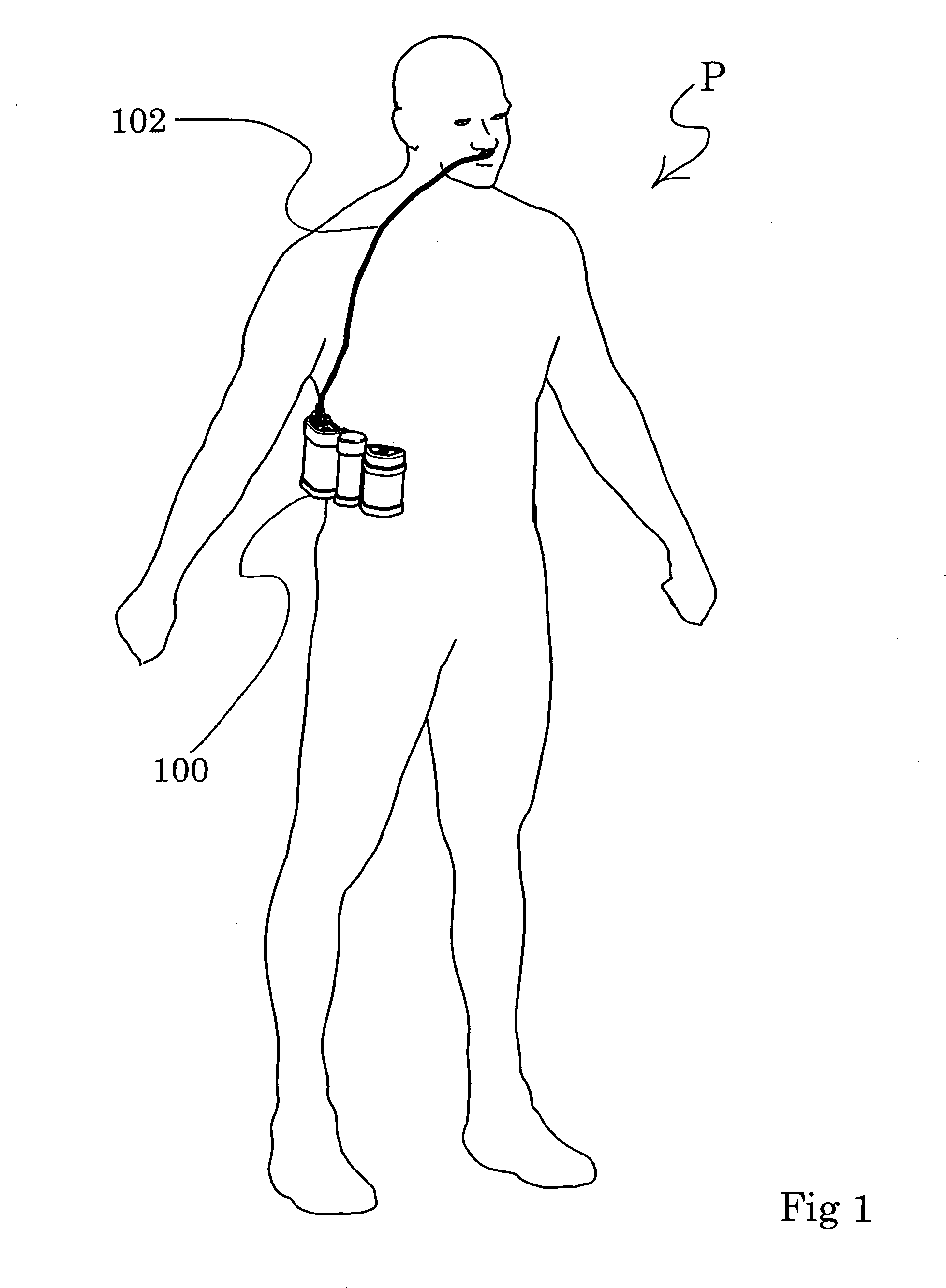

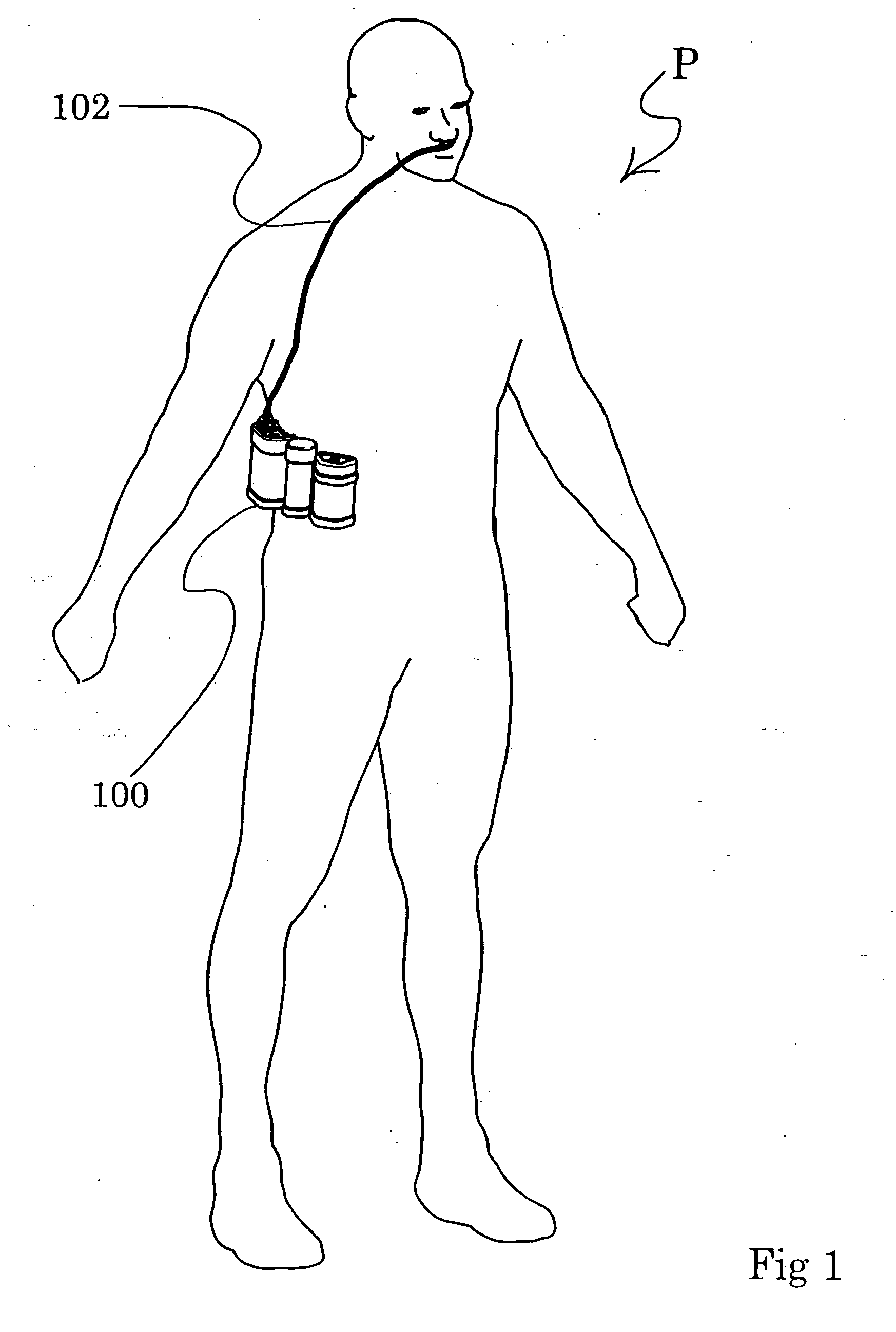

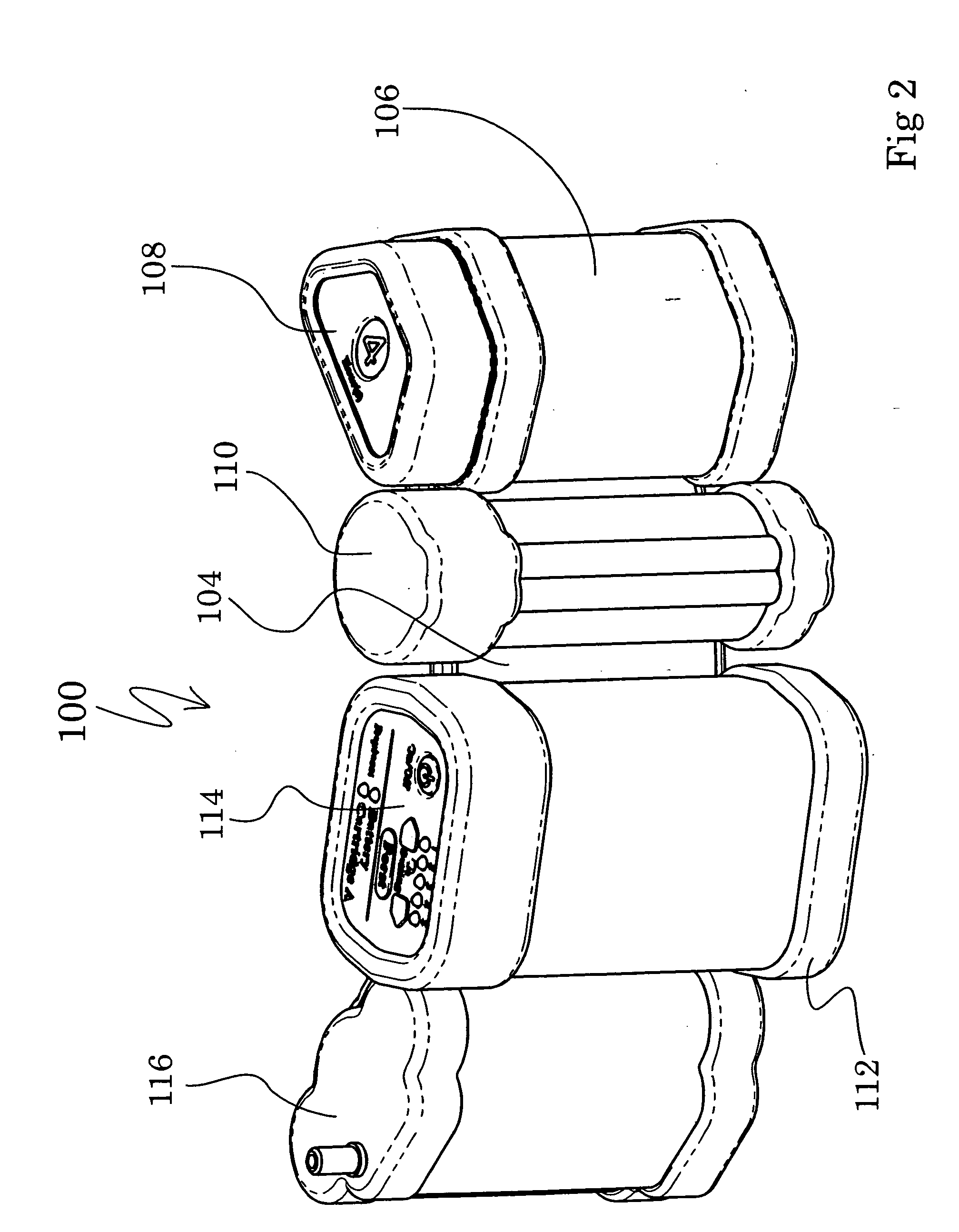

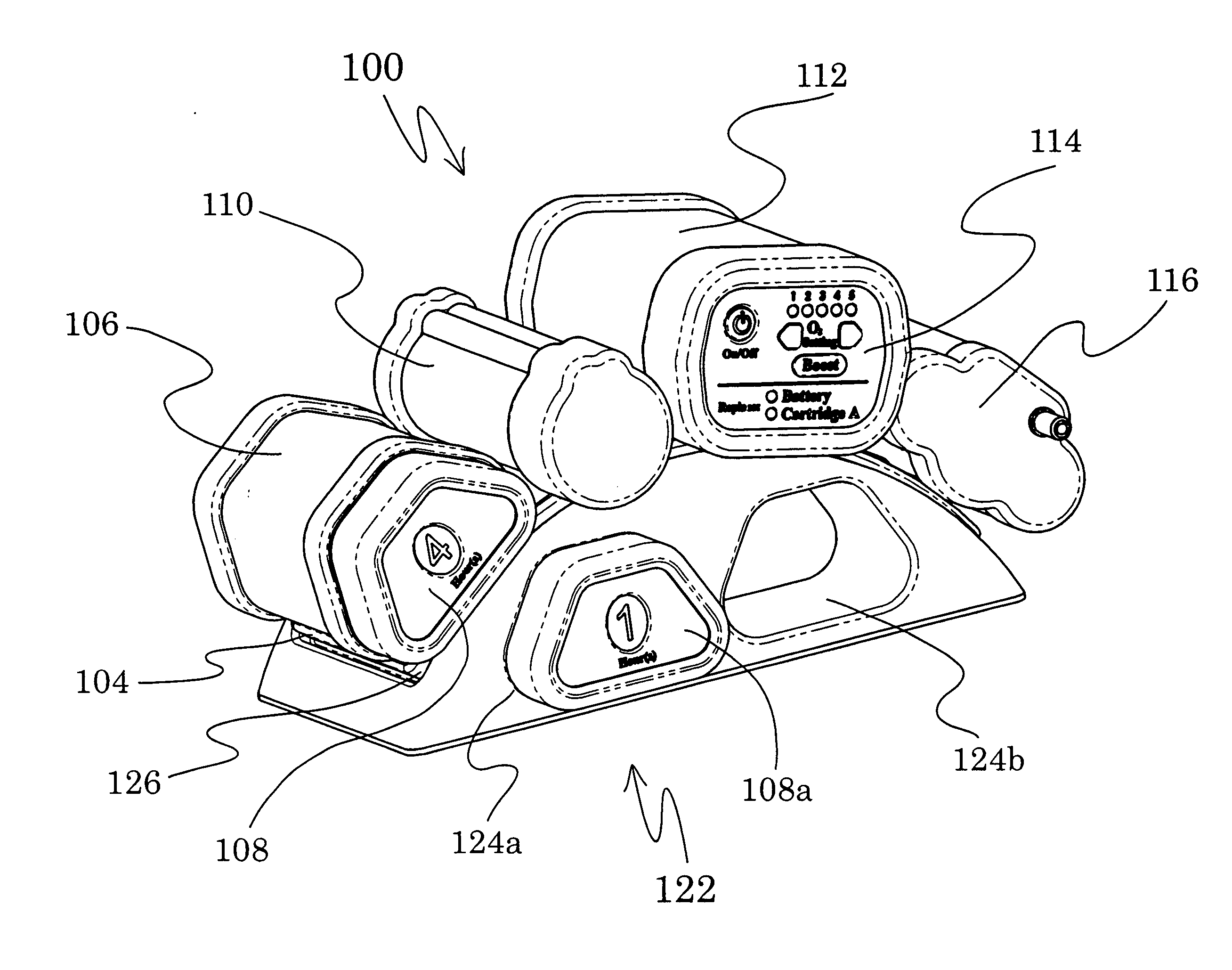

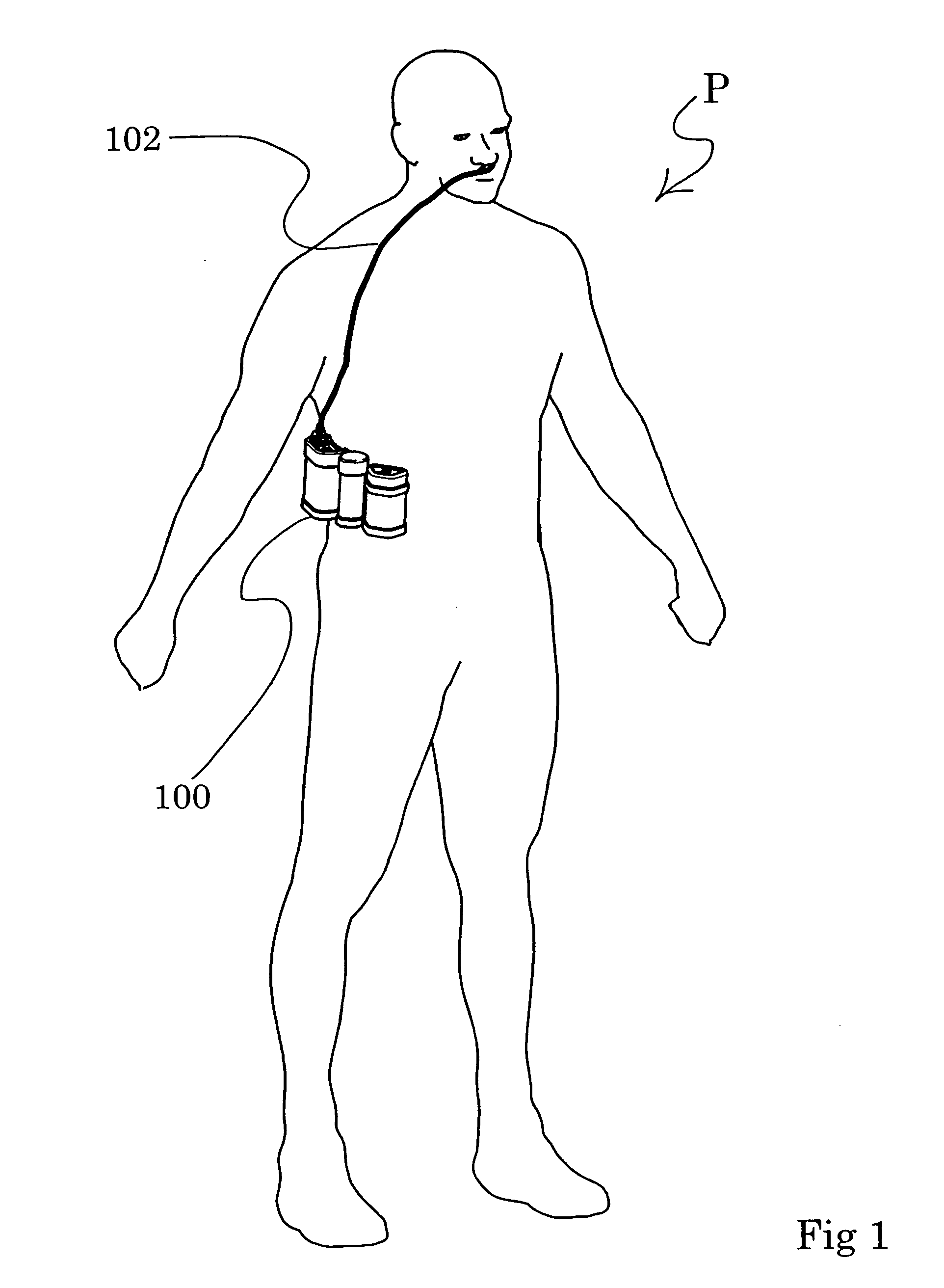

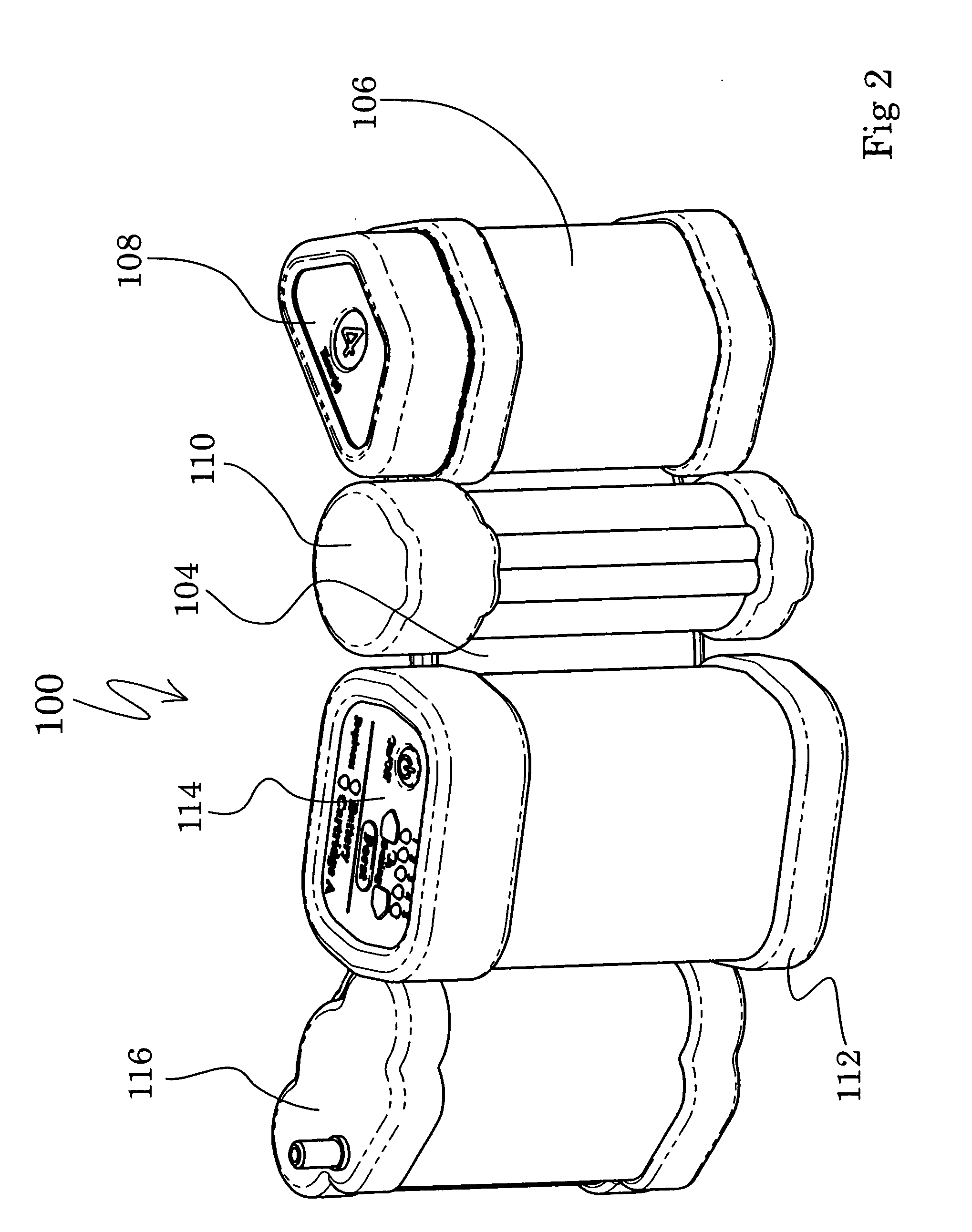

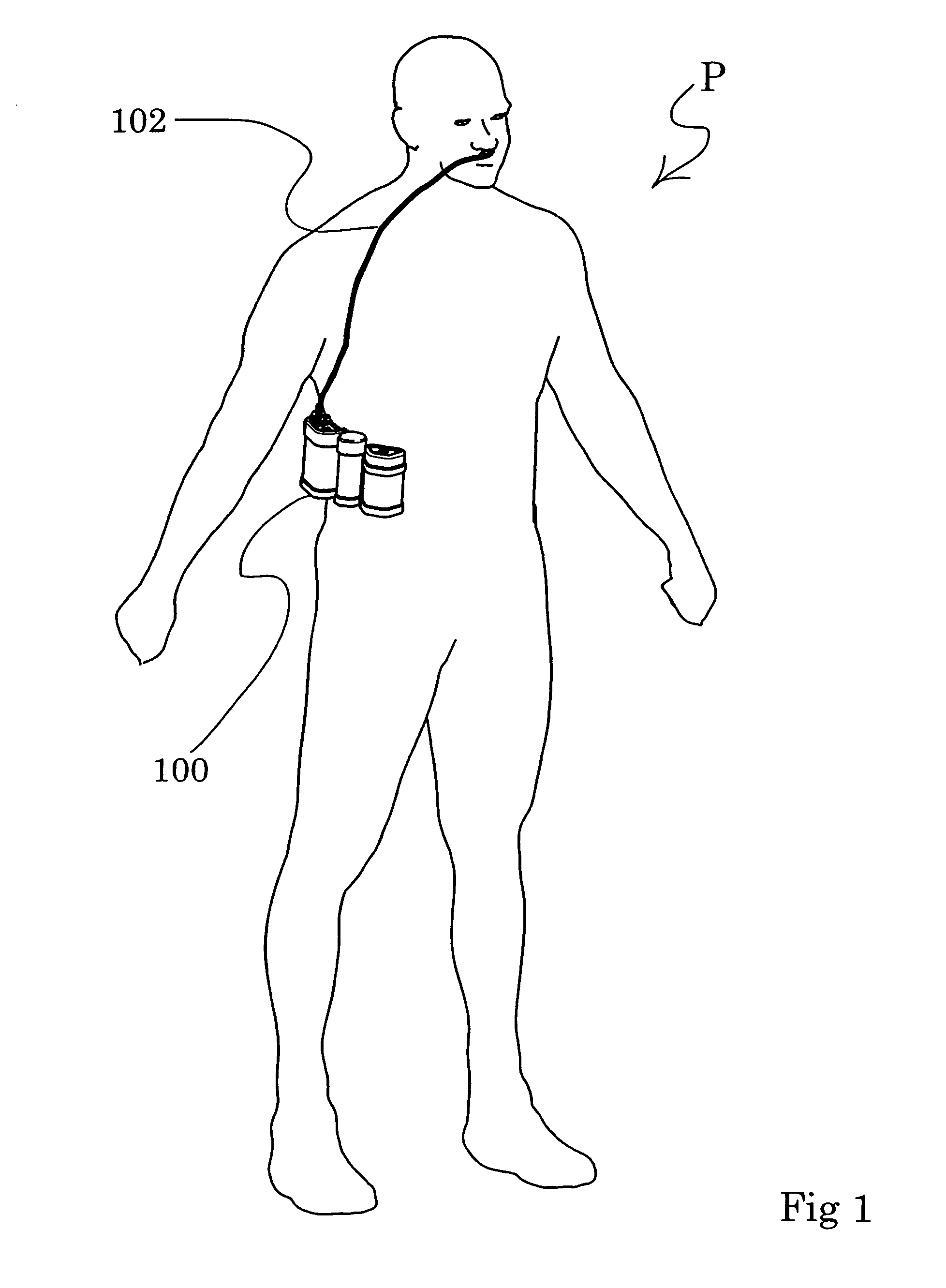

Ambulatory oxygen concentrator containing a power pack

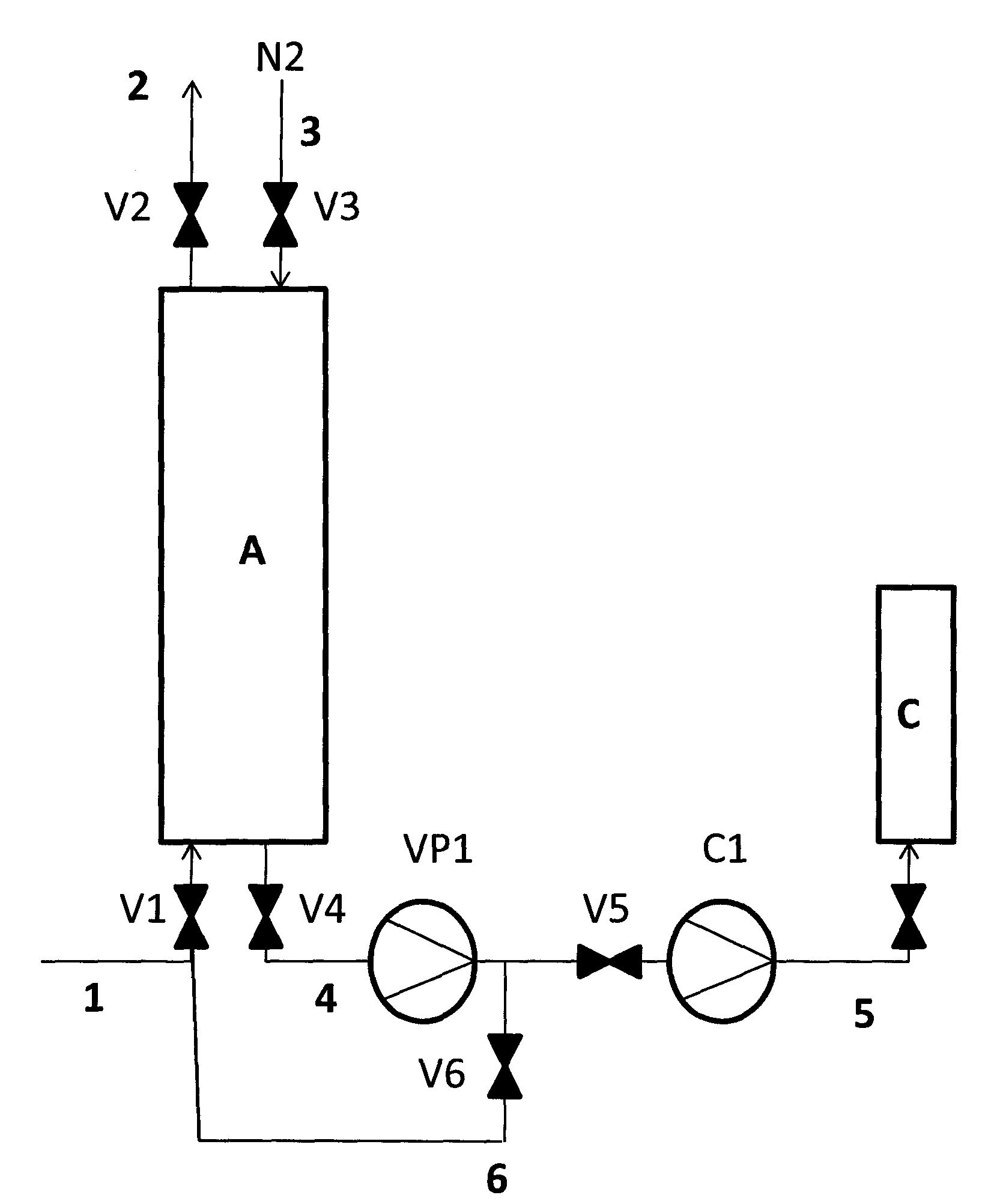

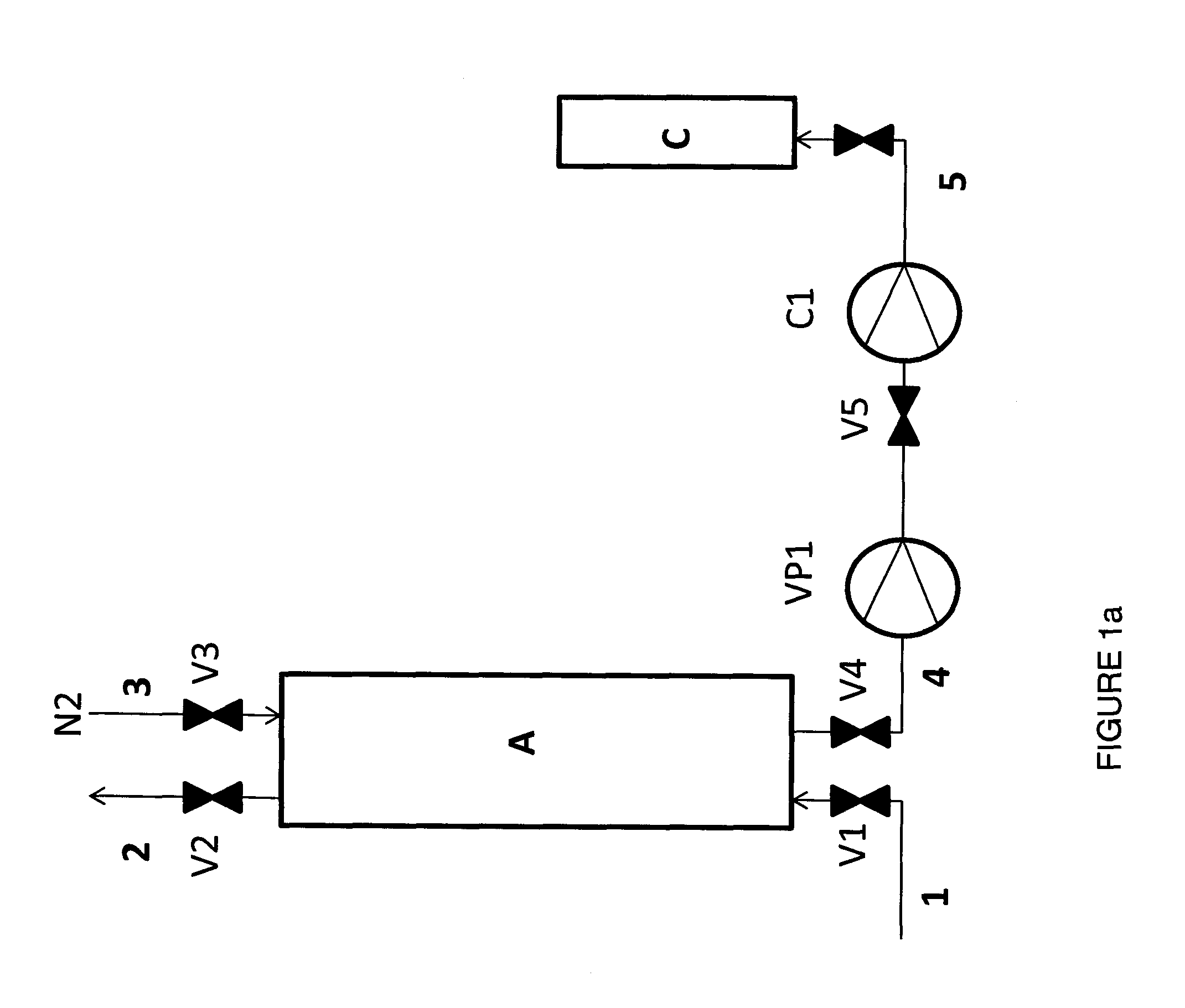

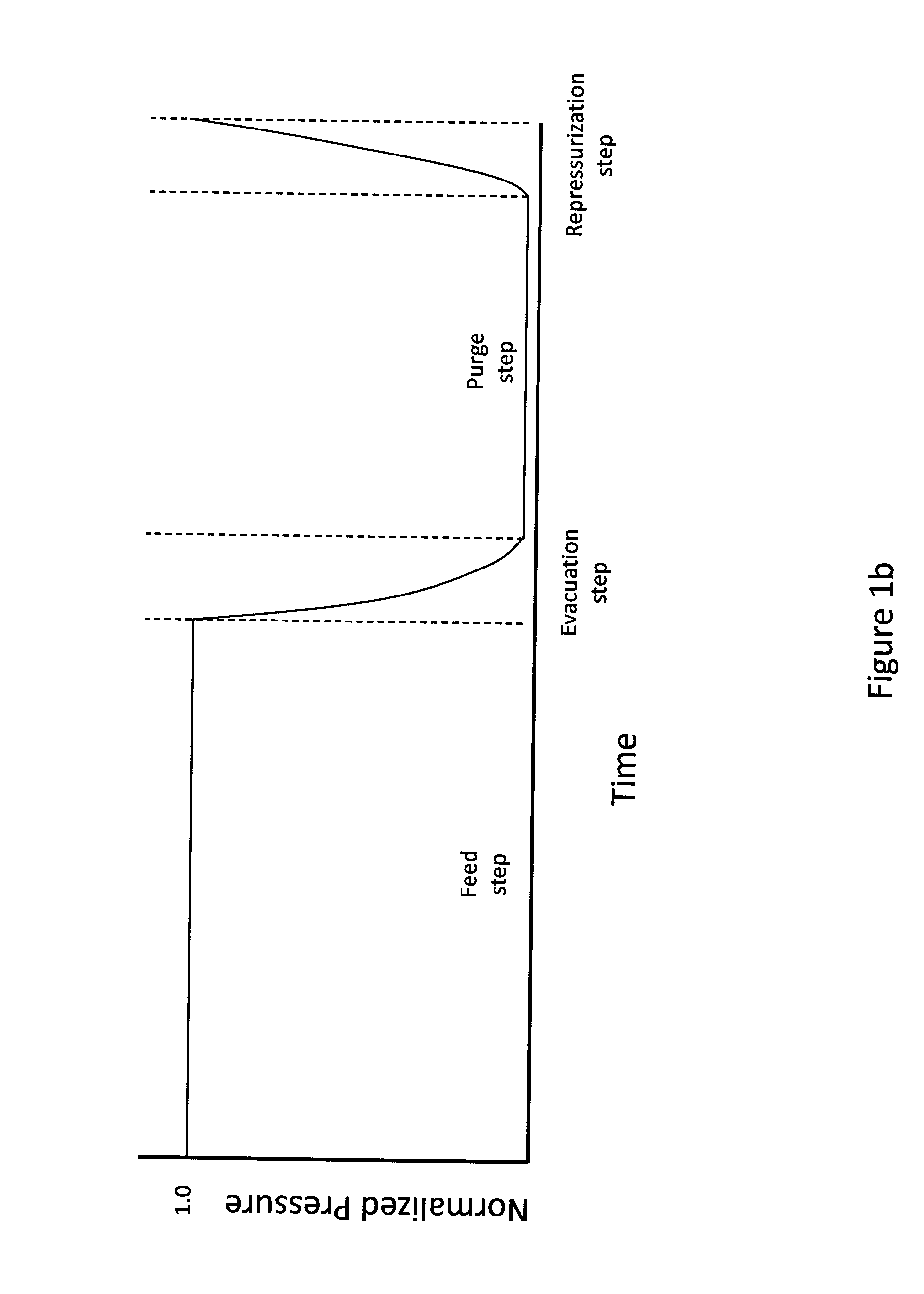

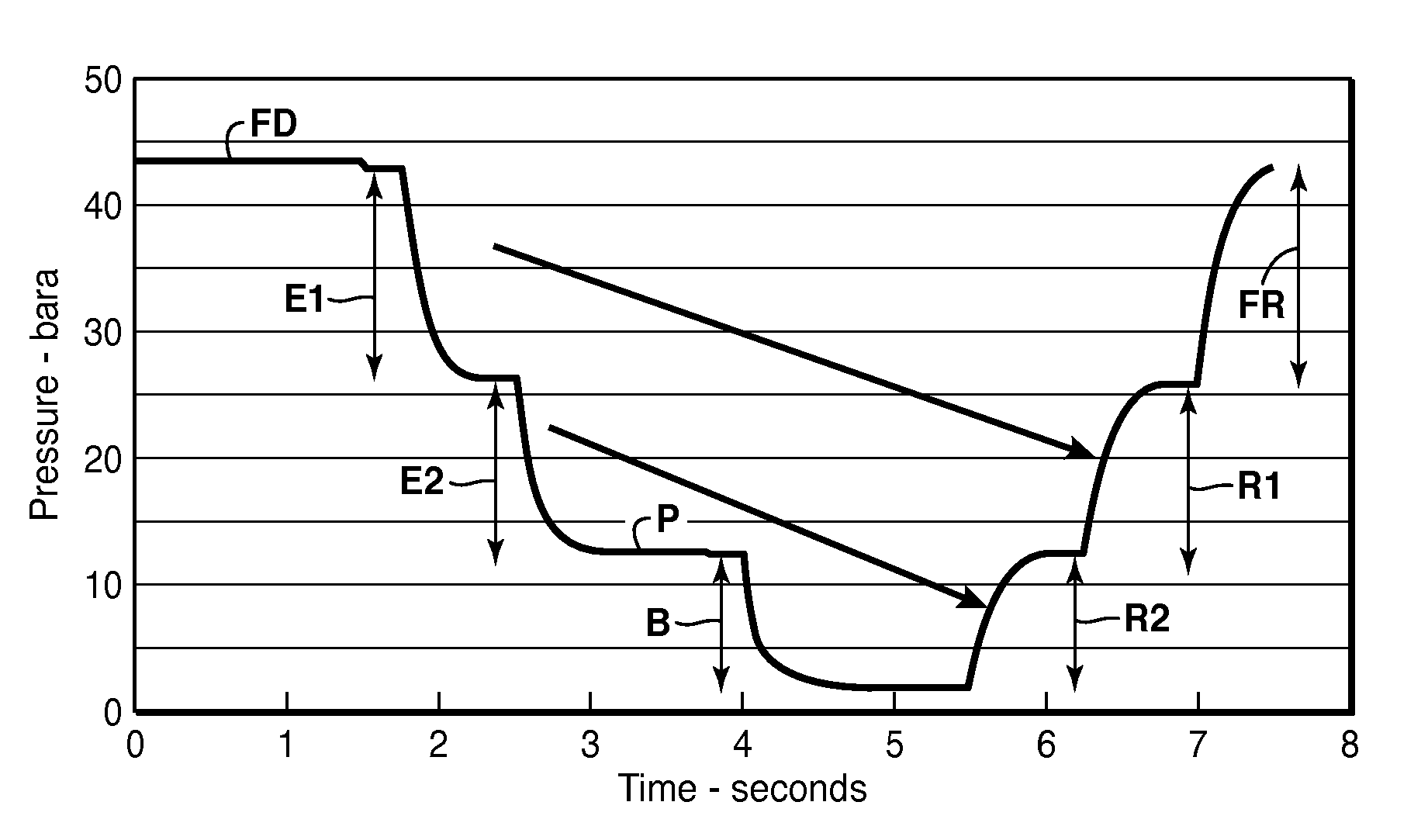

An oxygen concentrator for providing ambulatory oxygen containing a vacuum swing adsorption (VSA) oxygen separator powered by a power pack. The separator has a plurality of nitrogen-selective adsorbent beds, each operating in VSA cycles including feed, evacuation and repressurization phases. The concentrator also contains a reservoir for storing oxygen-rich product gas produced by the VSA oxygen separator.

Owner:VBOX

Method of controlling the rate of oxygen produced by an oxygen concentrator

A method of providing concentrated oxygen product gas to a patient. The method comprises producing product gas by a vacuum swing adsorption (VSA) process with an oxygen concentrator comprising a plurality of separation columns connected to a vacuum source driven by a motor. Separated product gas is then pumped to a product reservoir. The pressure of the reservoir is monitored and used to adjust the speed of the motor based on the reservoir pressure. The separated gas is then delivered to the patient.

Owner:VBOX

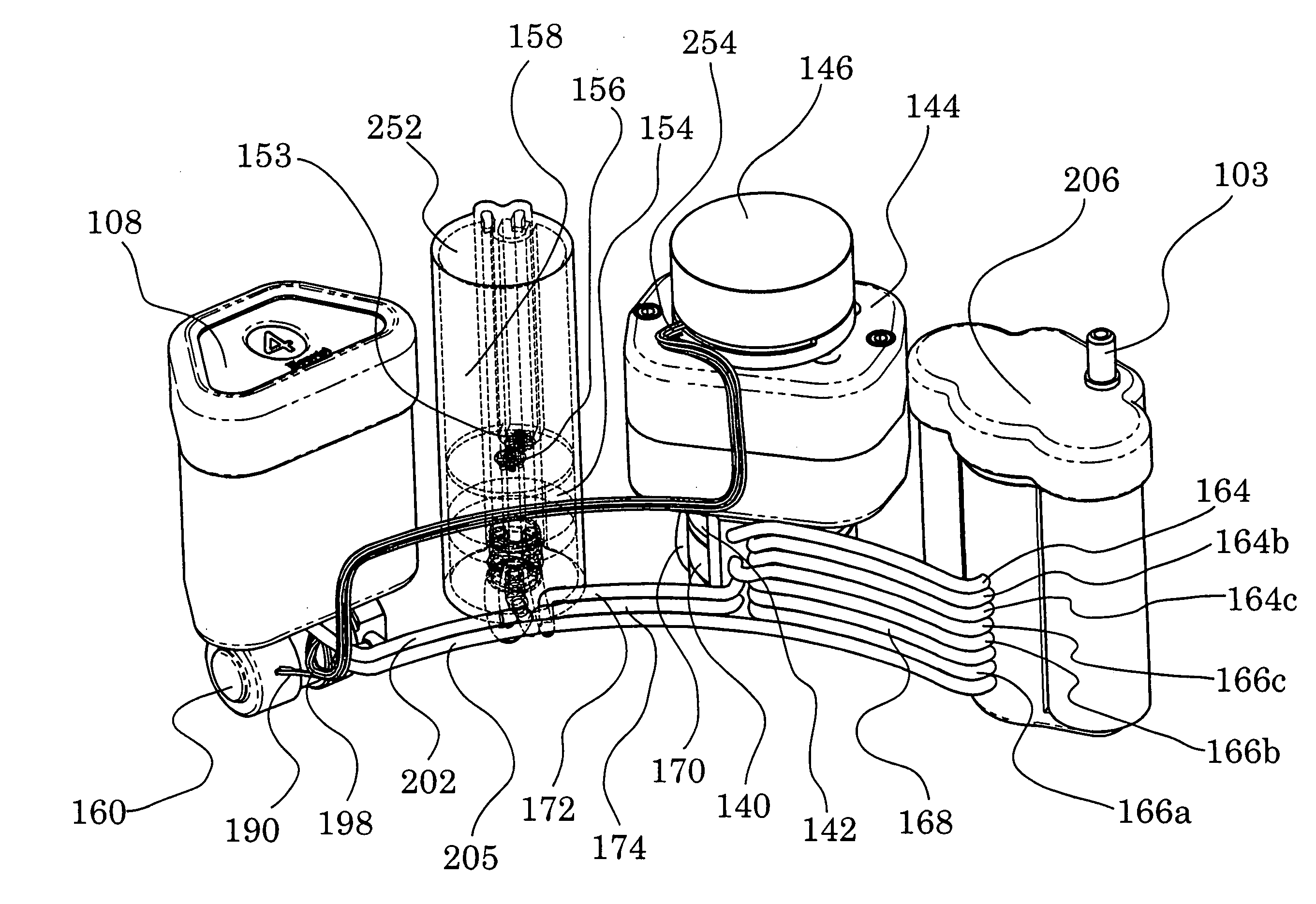

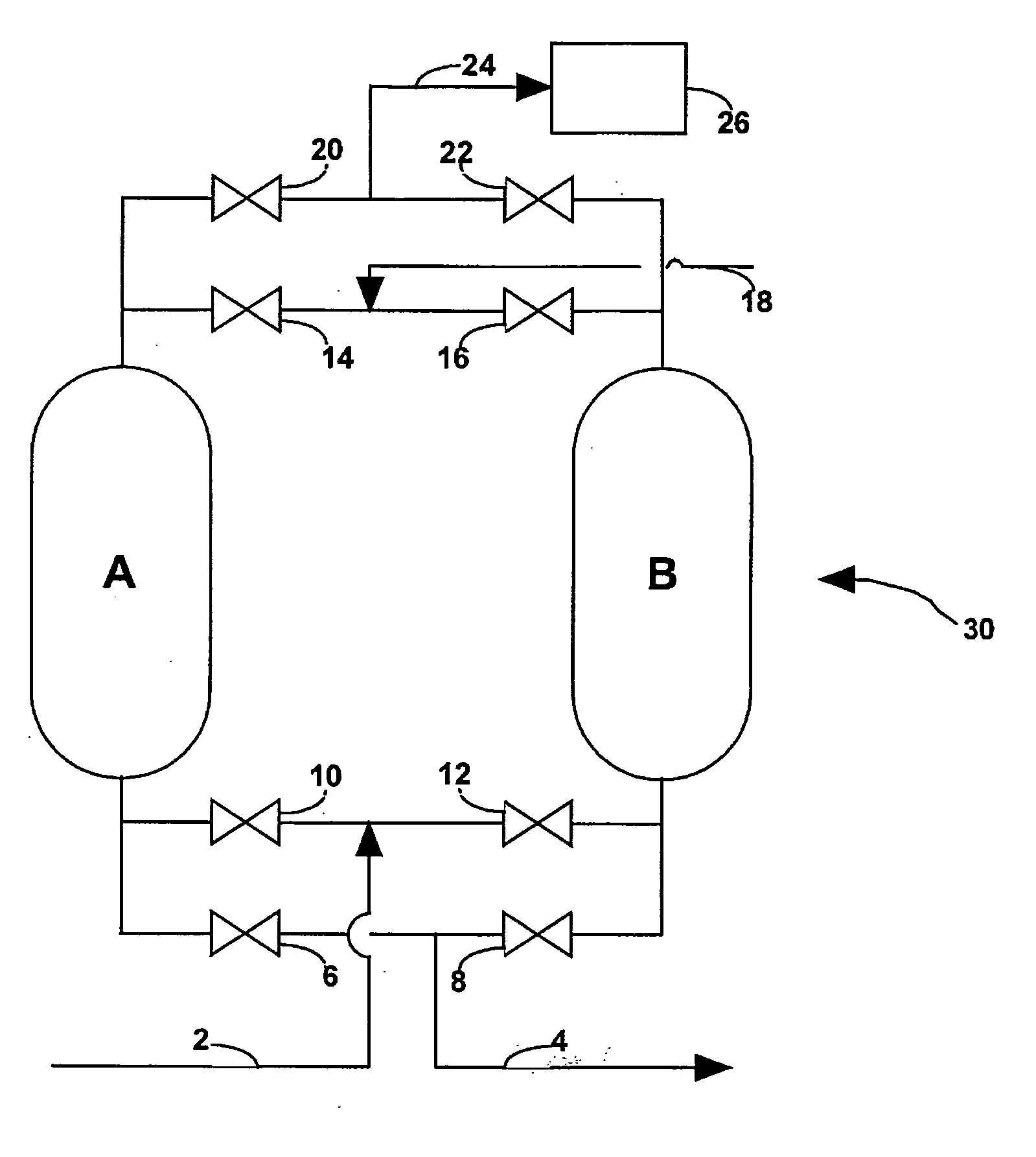

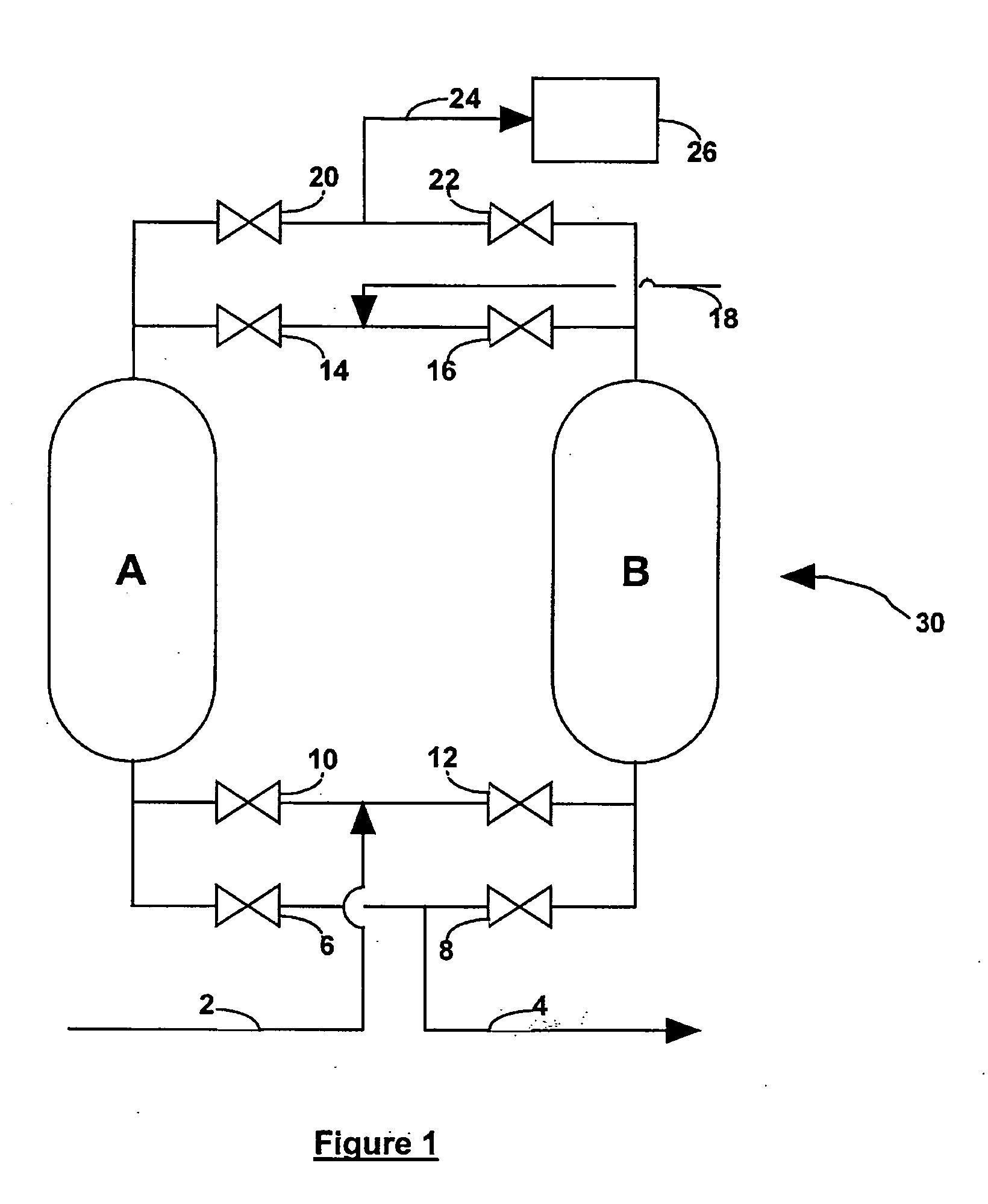

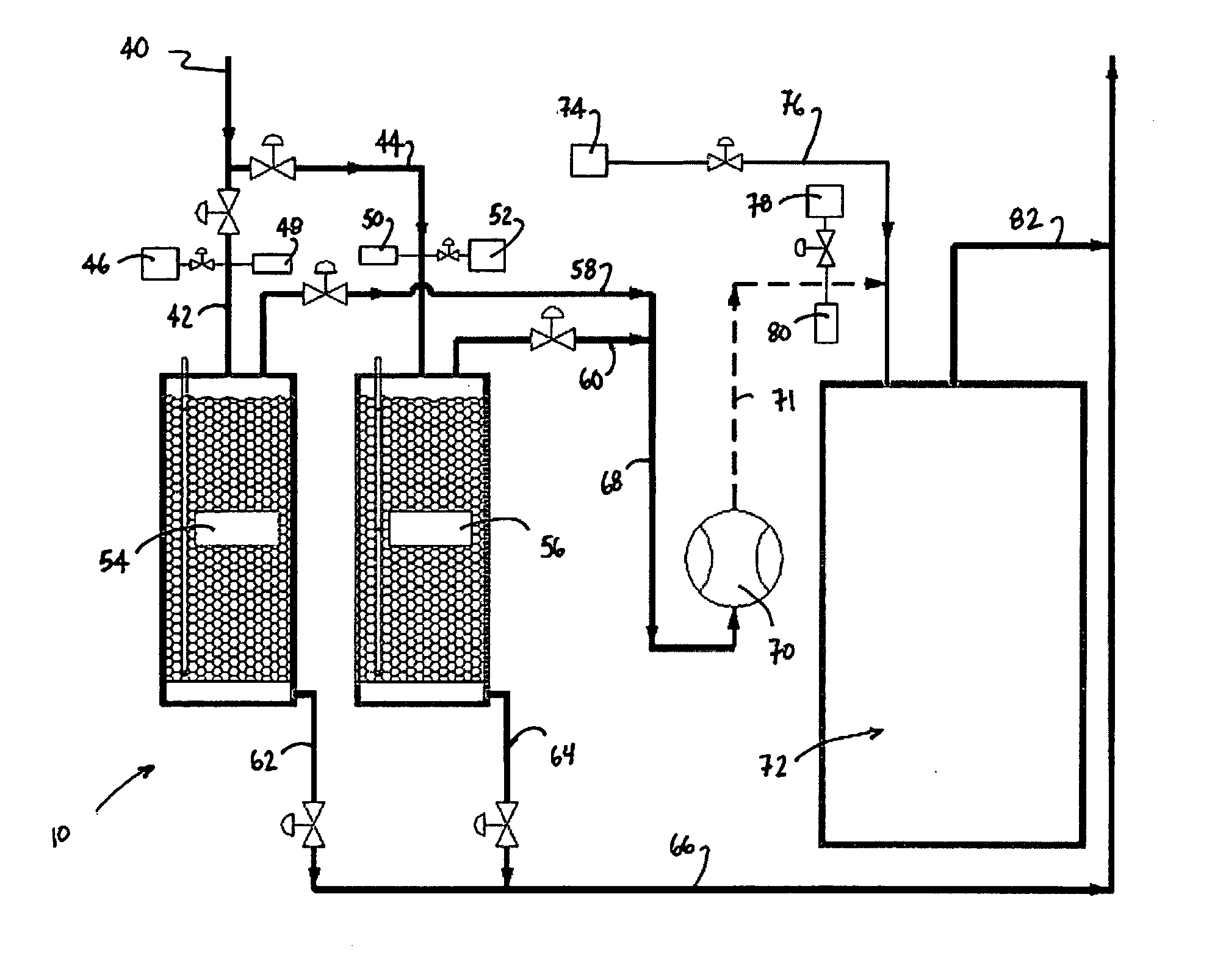

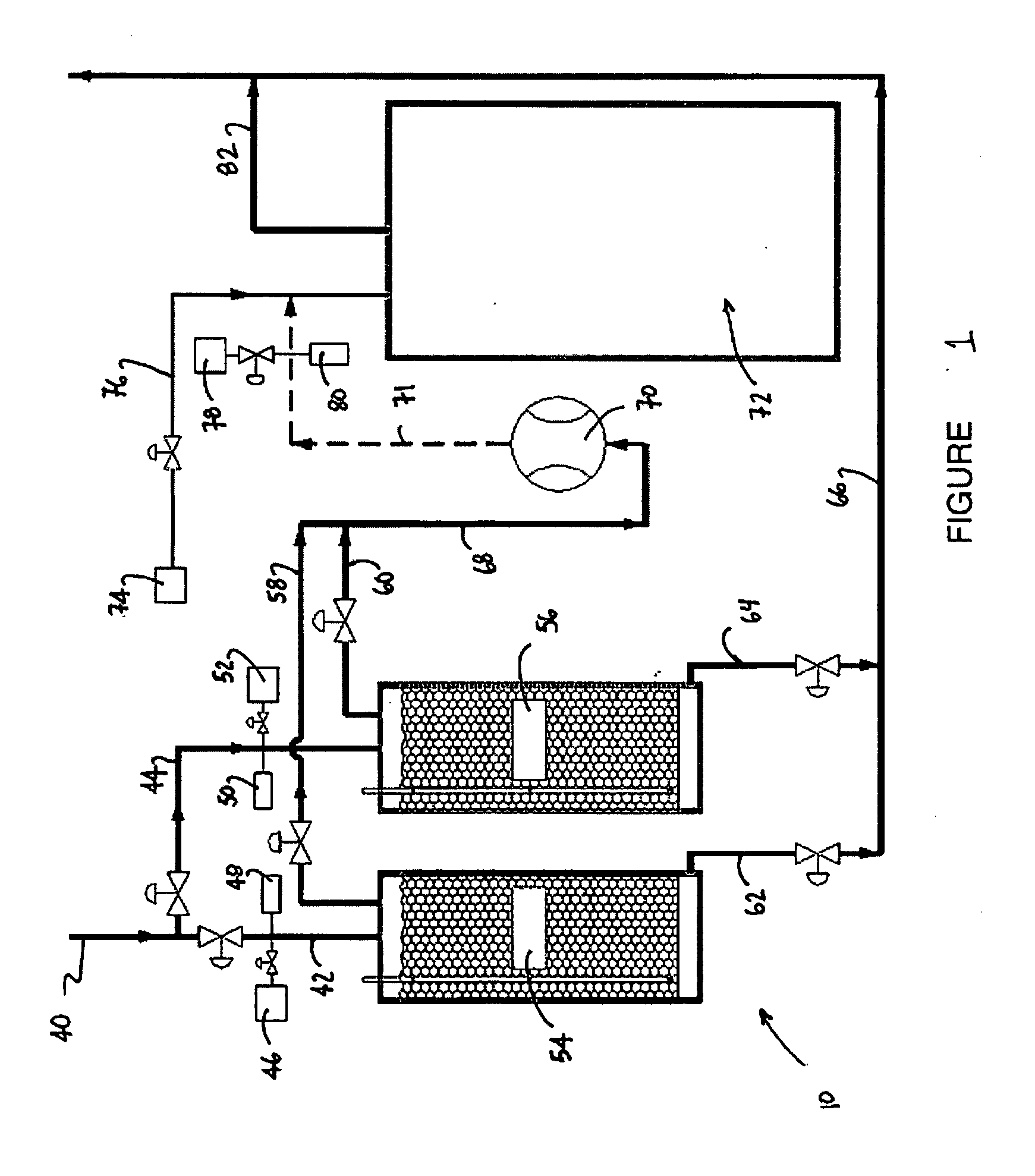

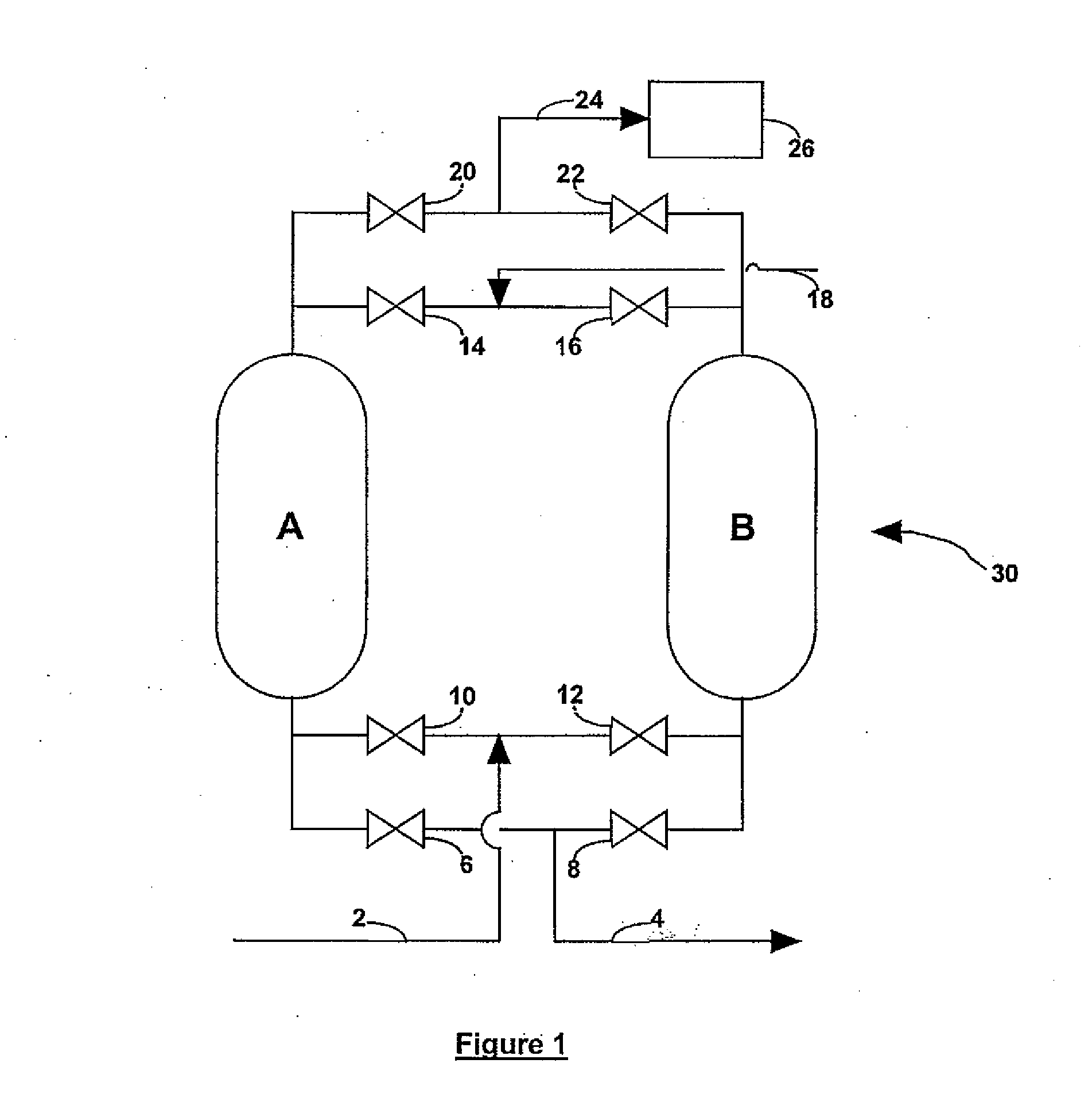

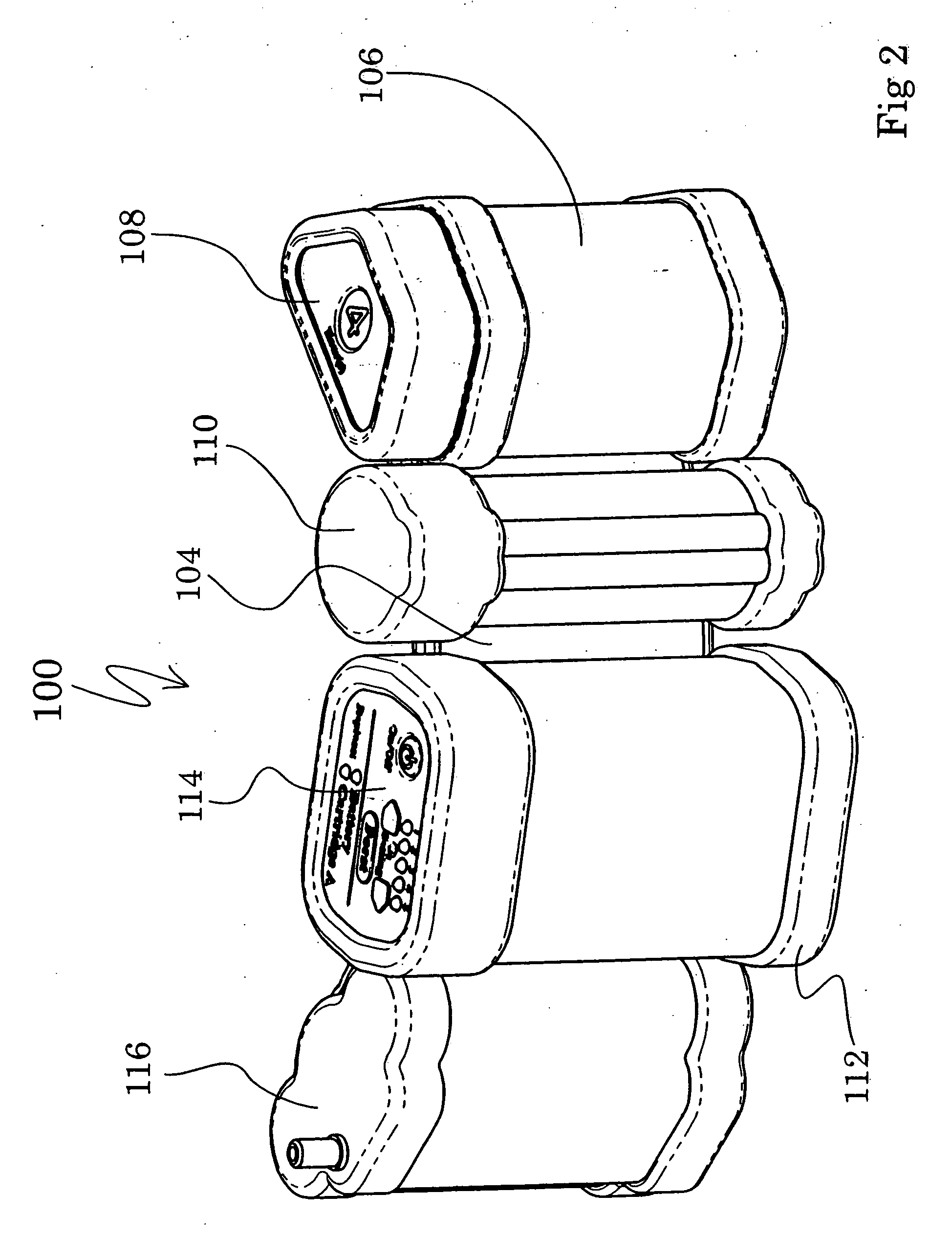

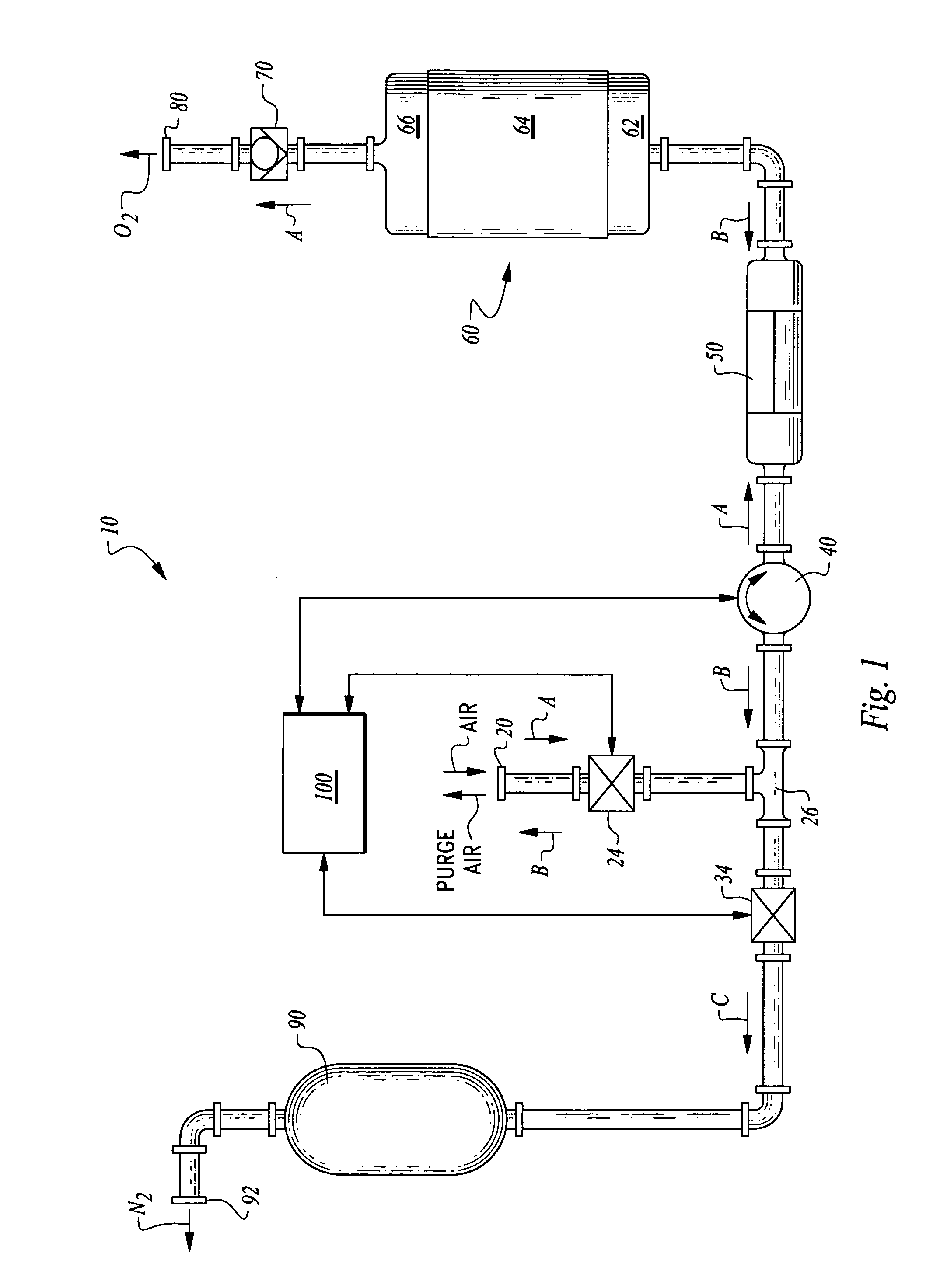

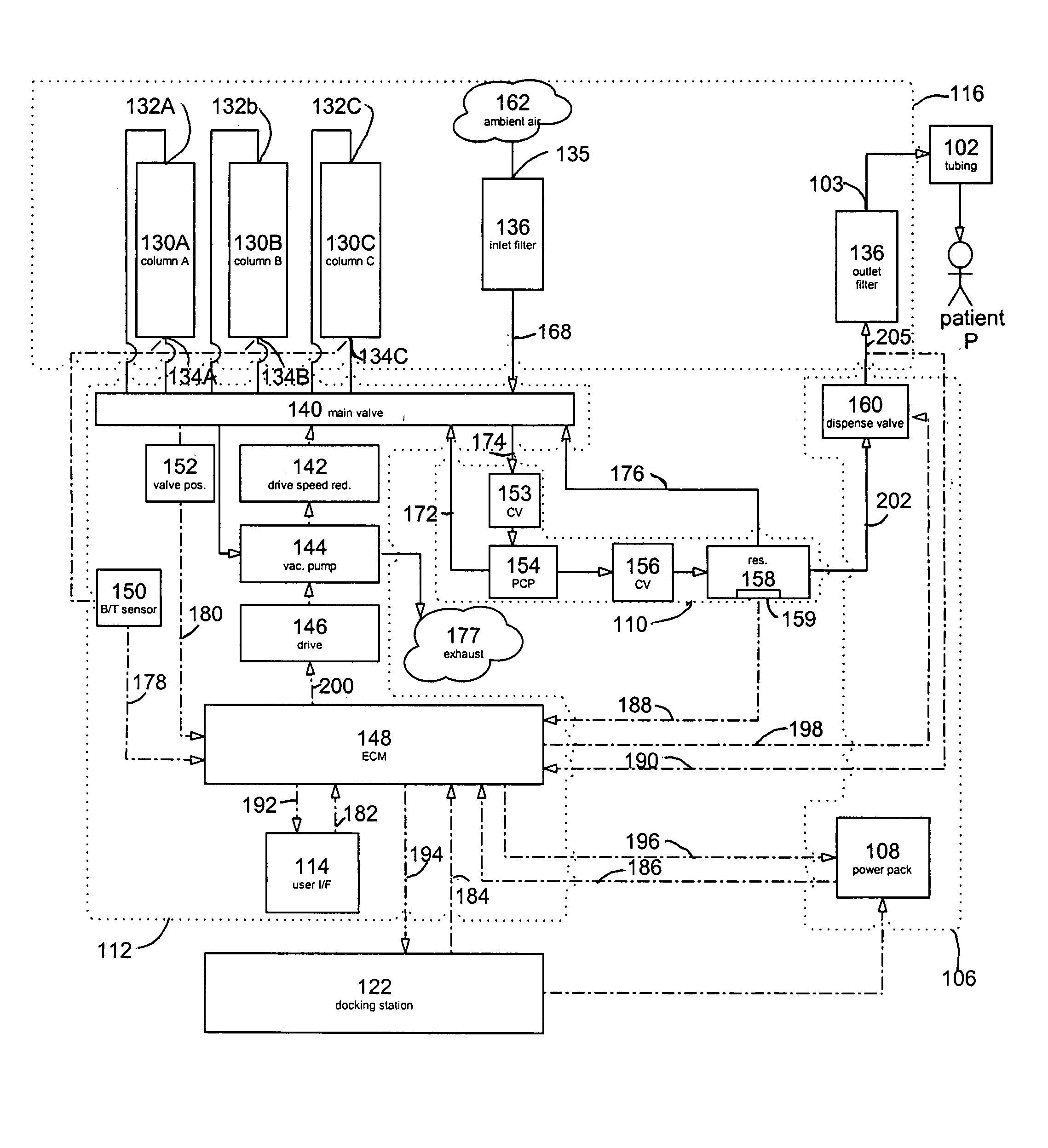

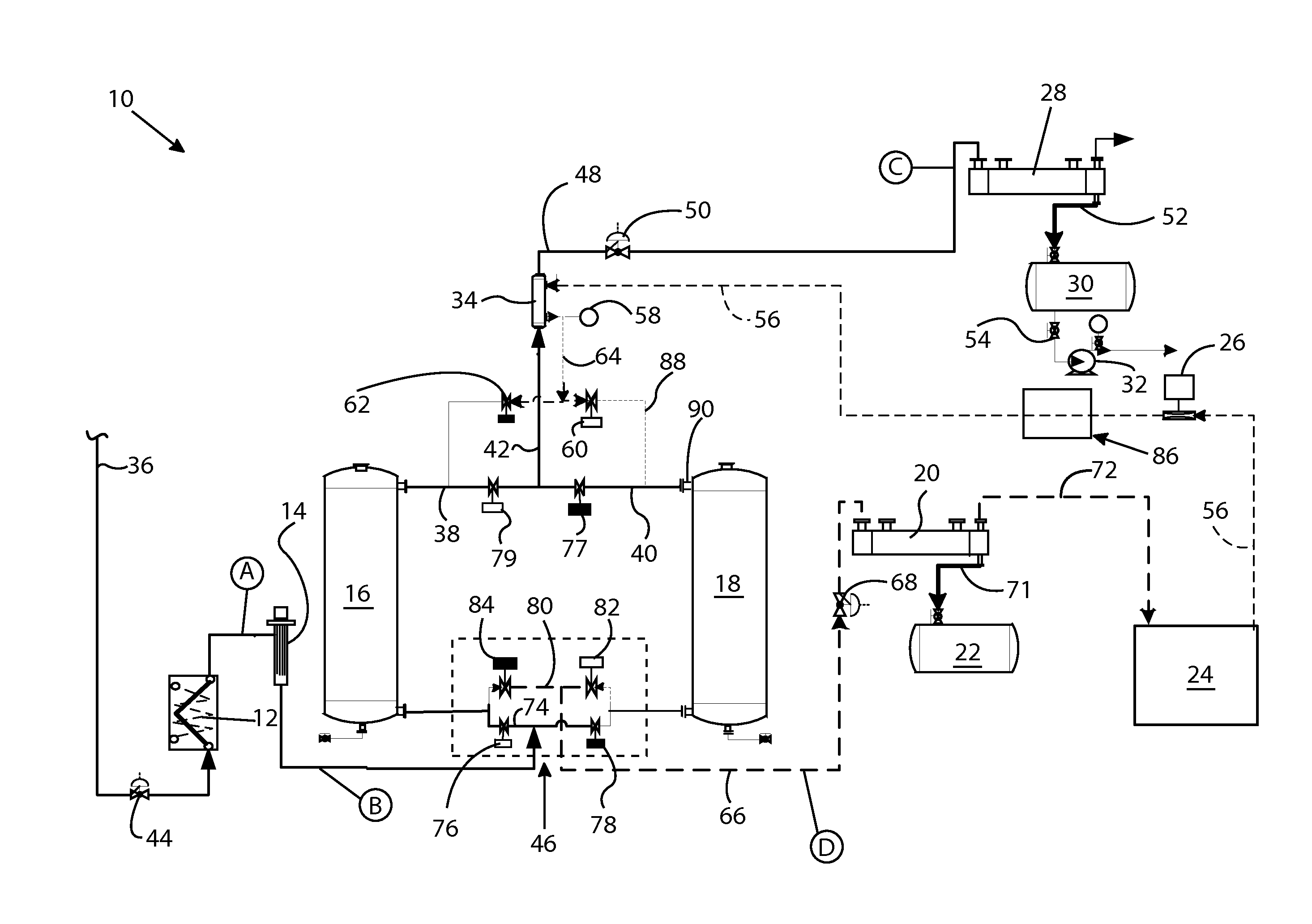

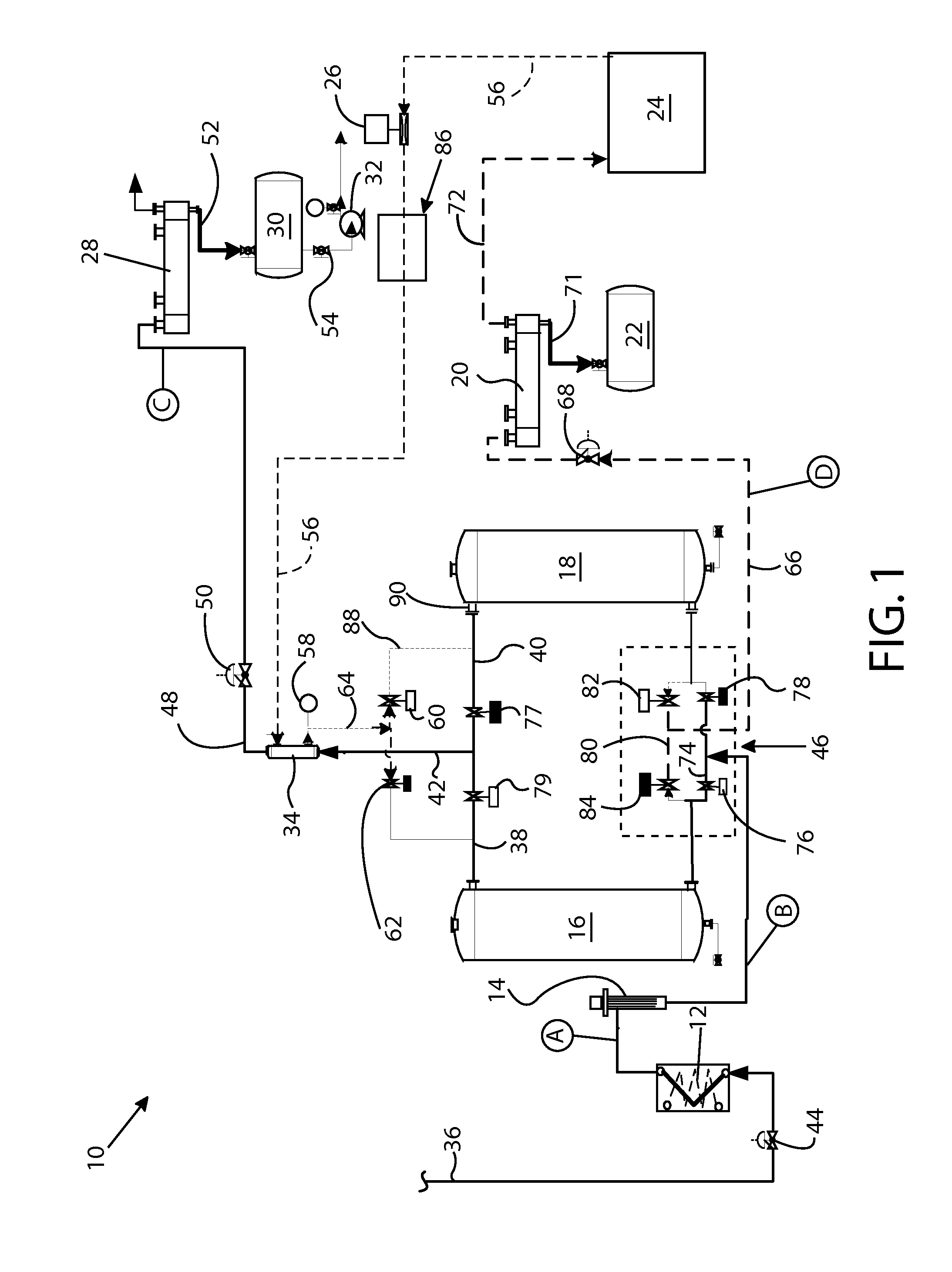

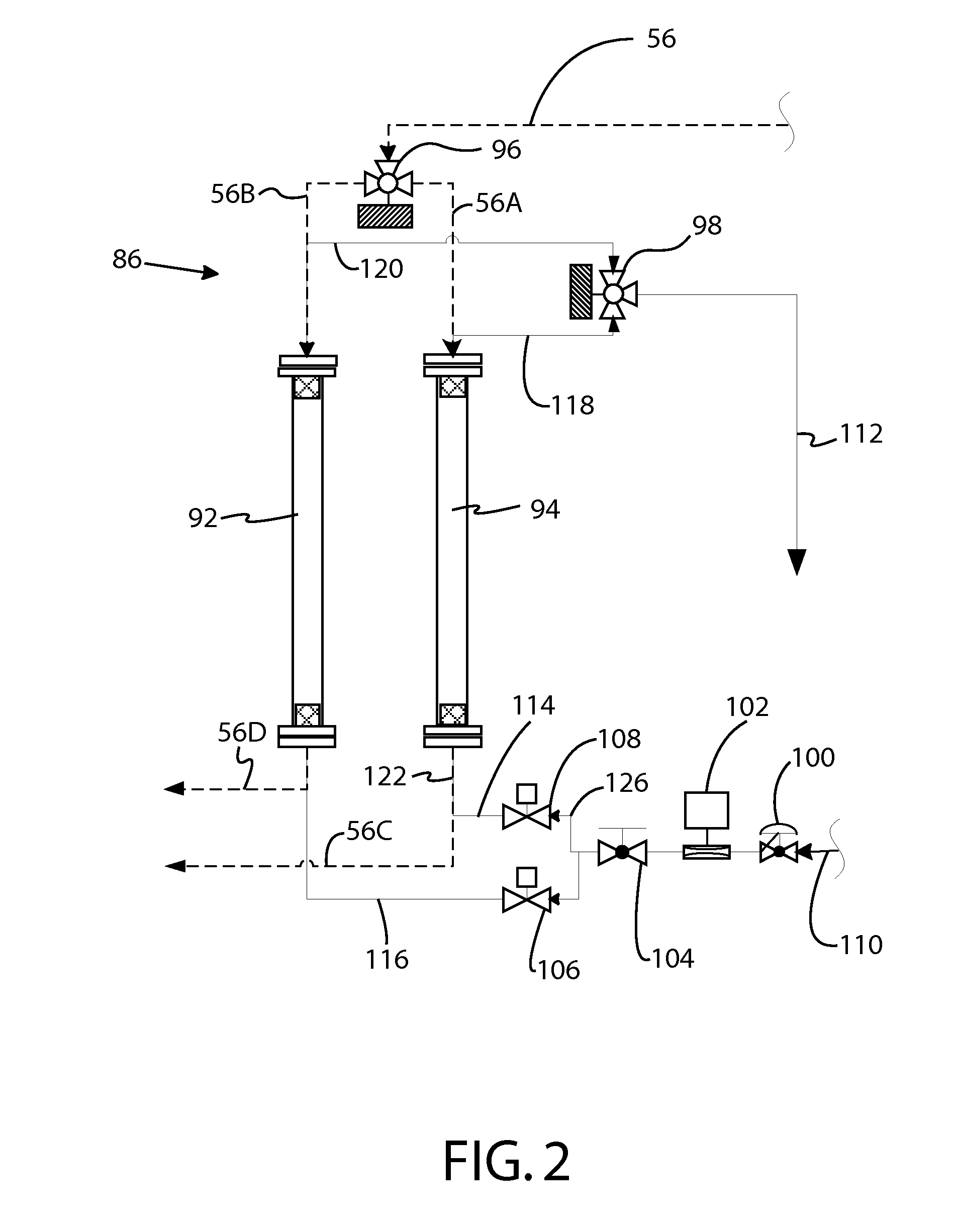

Ambulatory oxygen concentrator containing a three phase vacuum separation system

An oxygen concentrator comprises an oxygen reservoir and adsorbent columns that each have an inlet, an outlet, and a bed of adsorbent material. The concentrator also comprises an air inlet, an exhaust outlet, and a vacuum pump for pumping nitrogen rich gas from one of the column inlets to the exhaust outlet. A product control pump pumps oxygen rich gas from one of the column outlets to the oxygen reservoir. A control valve controls flow in and out of the columns by selectively connecting the air inlet to one column inlet, connecting the vacuum pump to another column inlet, and connecting the product control pump to a column outlet. A motor drives the vacuum pump and control valve to produce vacuum swing adsorption (VSA) cycles in which oxygen-rich product gas is separated and accumulated in the reservoir.

Owner:VBOX

Recovering of xenon by adsorption process

Owner:VERSUM MATERIALS US LLC

Methods of removing contaminants from hydrocarbon stream by swing adsorption and related apparatus and systems

A pressure swing adsorption process for removal of CO2 from natural gas streams through a combination of a selective adsorbent material containing an effective amount of a non-adsorbent filler, adsorbent contactor design, and adsorption cycle design. The removal of contaminants from gas streams, preferably natural gas streams, using rapid-cycle swing adsorption processes, such as rapid-cycle pressure swing adsorption (RC-PSA). Separations at high pressure with high product recovery and / or high product purity are provided through a combination of judicious choices of adsorbent material, gas-solid contactor, system configuration, and cycle designs. For example, cycle designs that include steps of purge and staged blow-down as well as the inclusion of a mesopore filler in the adsorbent material significantly improves product (e.g., methane) recovery. An RC-PSA product with less than 10 ppm H2S can be produced from a natural gas feed stream that contains less than 1 mole percent H2S.

Owner:EXXONMOBIL UPSTREAM RES CO

Process for gas purification

The present invention provides for a process for purifying carbon monoxide-containing gas streams that contain impurities such as hydrocarbons by using a cryogenic adsorption process. Preferably this process is a temperature swing adsorption process at cryogenic temperatures below −75° C. Alternatively, the carbon monoxide-containing gas streams may be purified using the cryogenic adsorption process with membrane separation units or vacuum swing adsorption units or cryogenic distillation.

Owner:BOC GRP INC

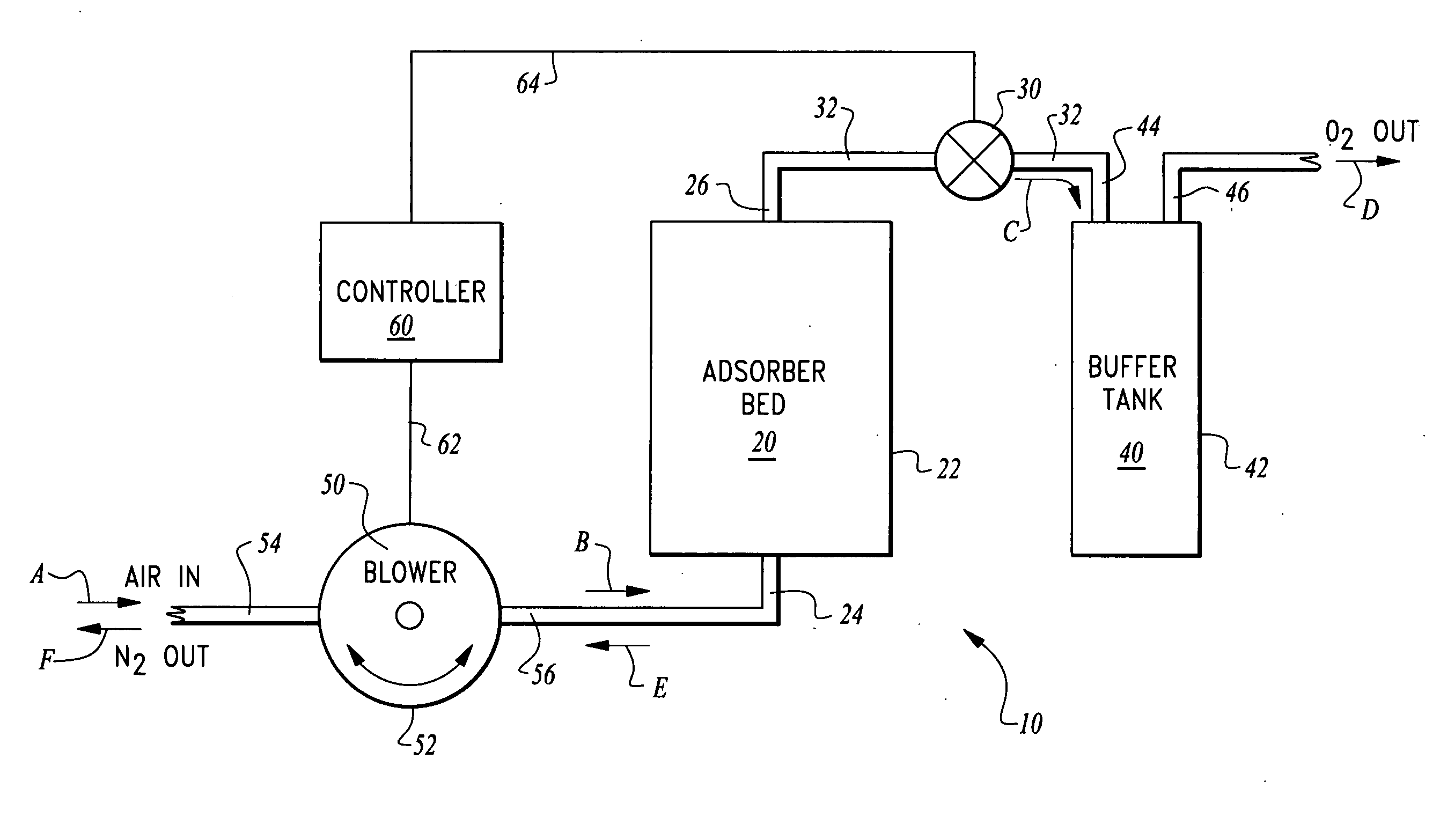

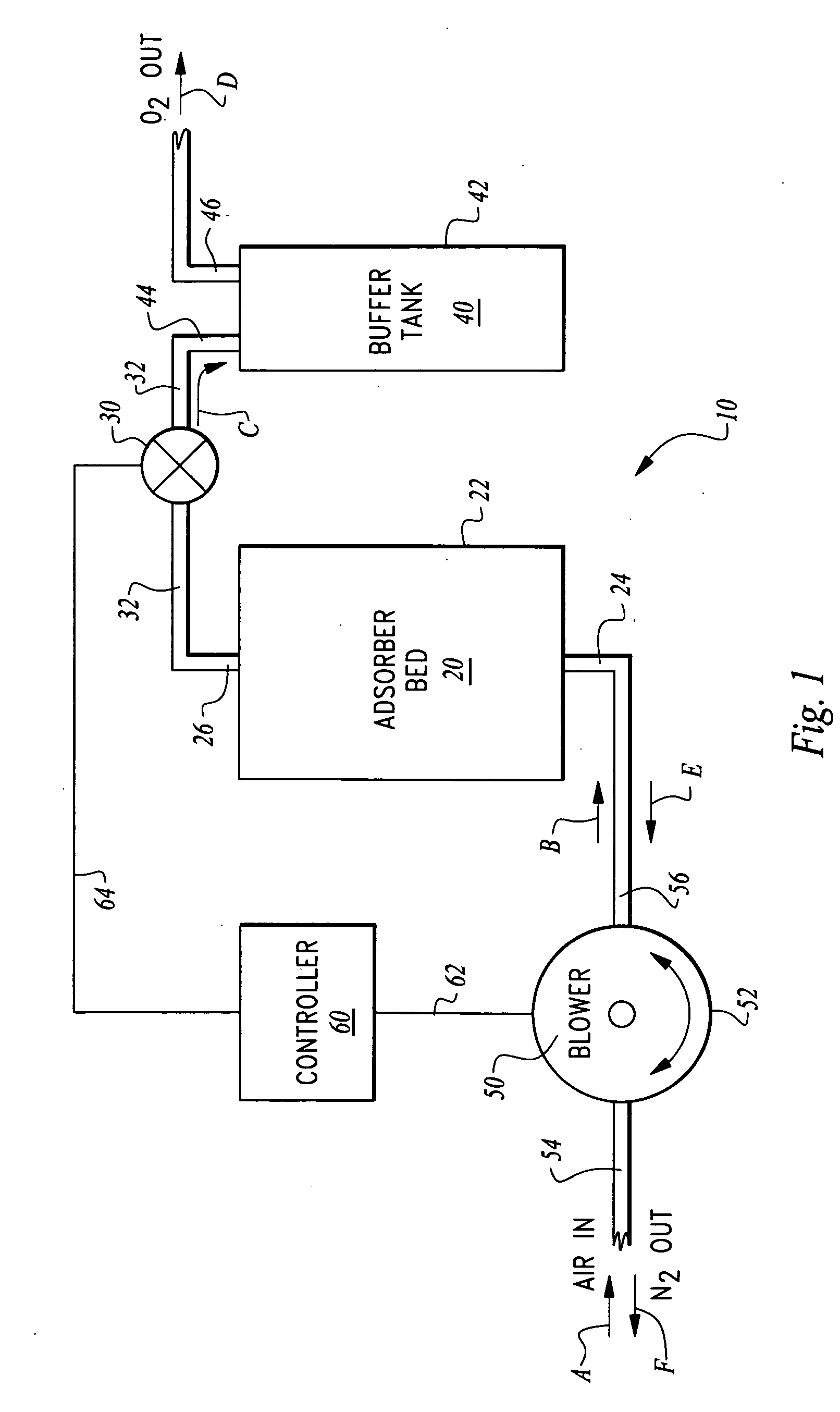

VSA gas concentrator using a reversing blower

InactiveUS20100095841A1Easy to operateSimple configurationGas treatmentDispersed particle filtrationNitrogenEngineering

Owner:PACIFIC CONSOL INDS

Method and apparatus for the recovery of volatile organic compounds and concentration thereof

A gas recovery apparatus and method for reclaiming and concentrating volatile organic compounds from the effluent of a semiconductor manufacturing operation is described. Vacuum Swing Adsorption is used to treat effluent containing volatile organic compounds to reversibly capture and subsequently release the volatile organic compounds, followed by recycle and / or cogeneration of the captured volatile organic compounds.

Owner:APPLIED MATERIALS INC

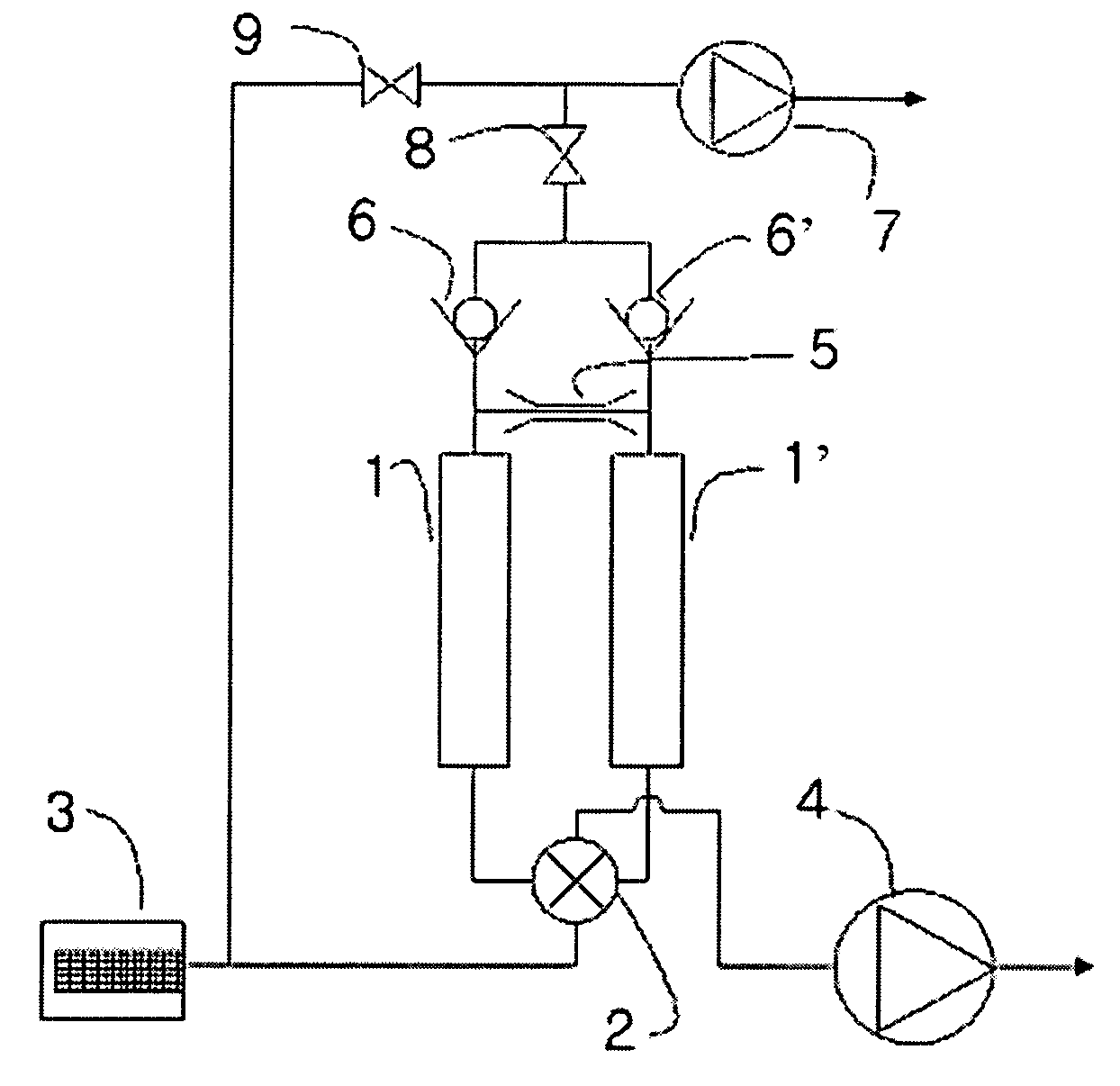

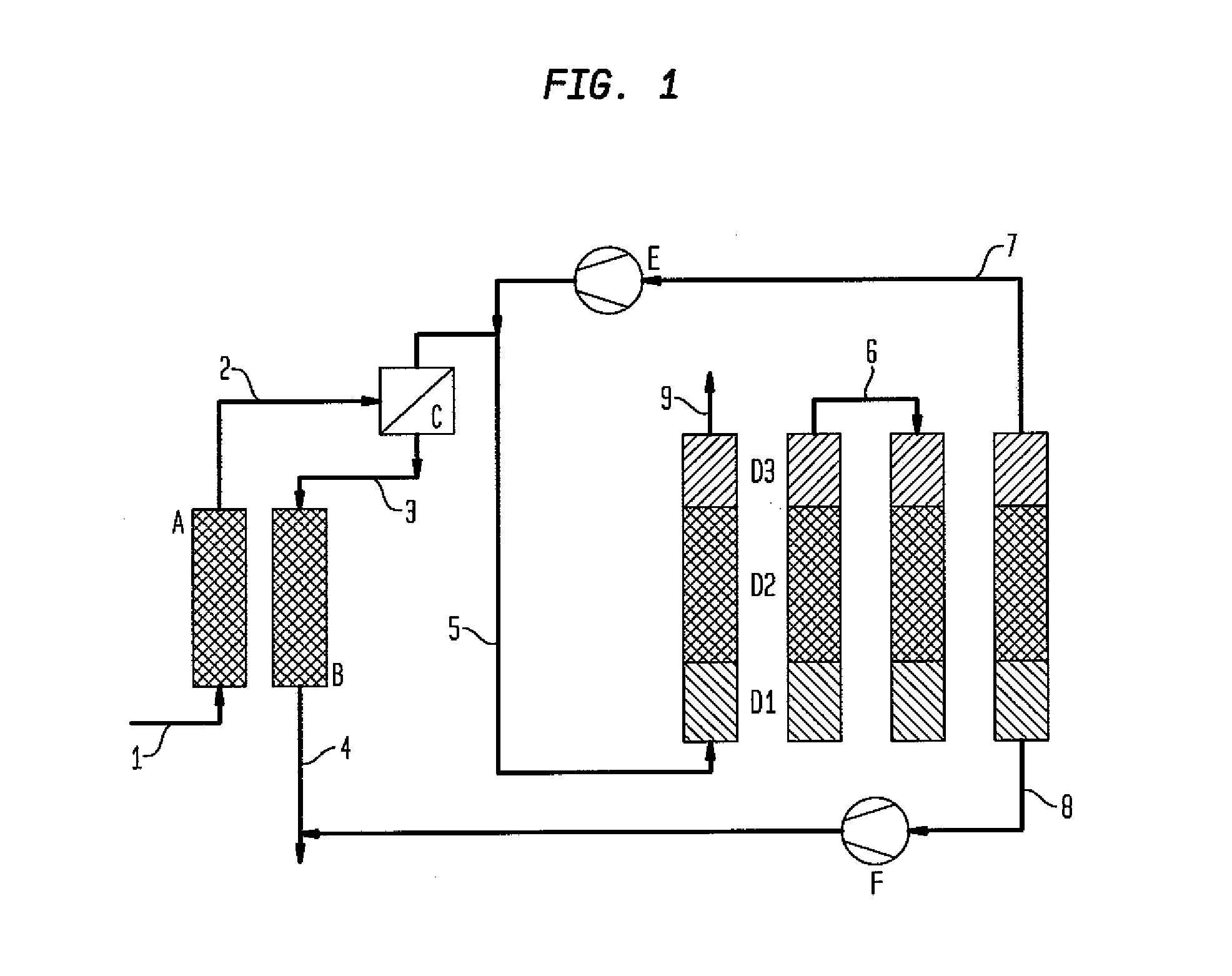

Gas concentration method and its apparatus

InactiveUS7105038B2Improve productivitySimple equipmentGas treatmentIsotope separationEnrichment methodsSorbent

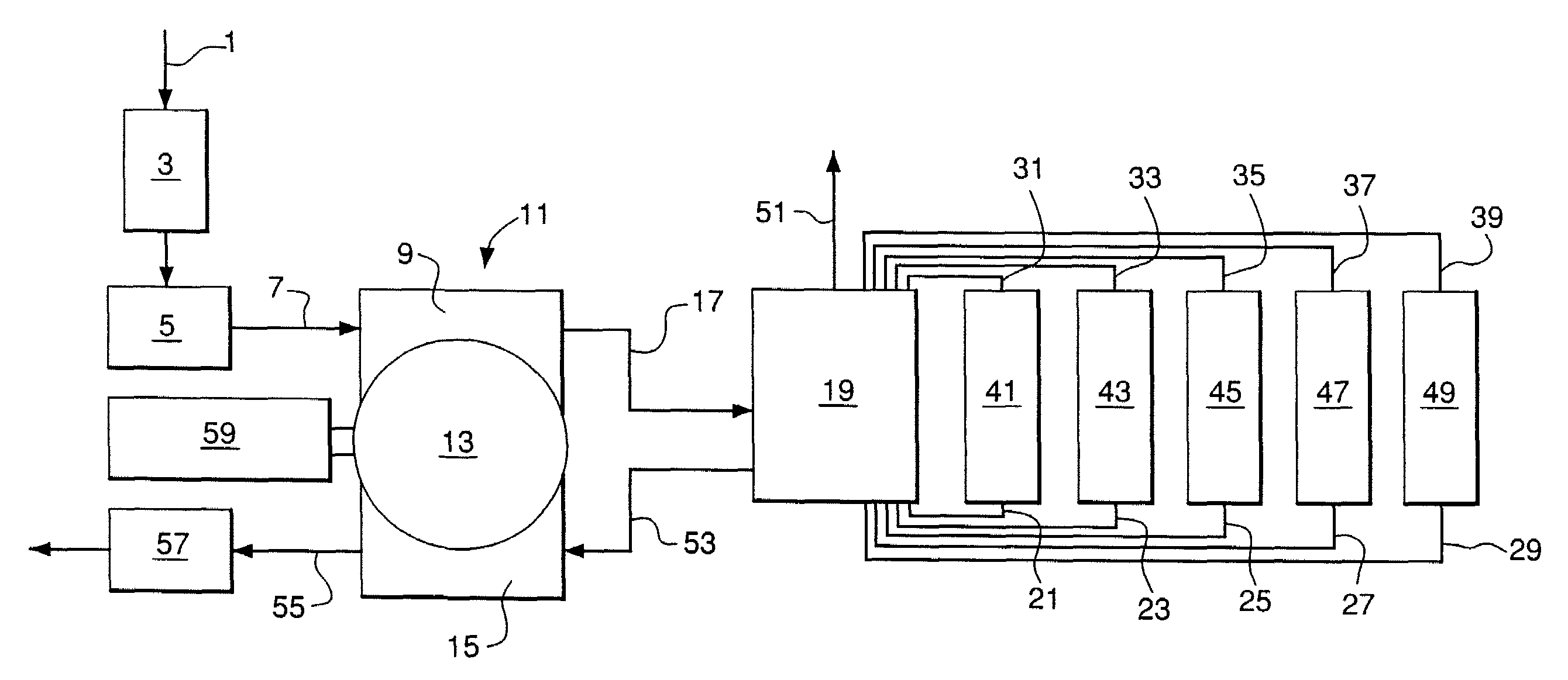

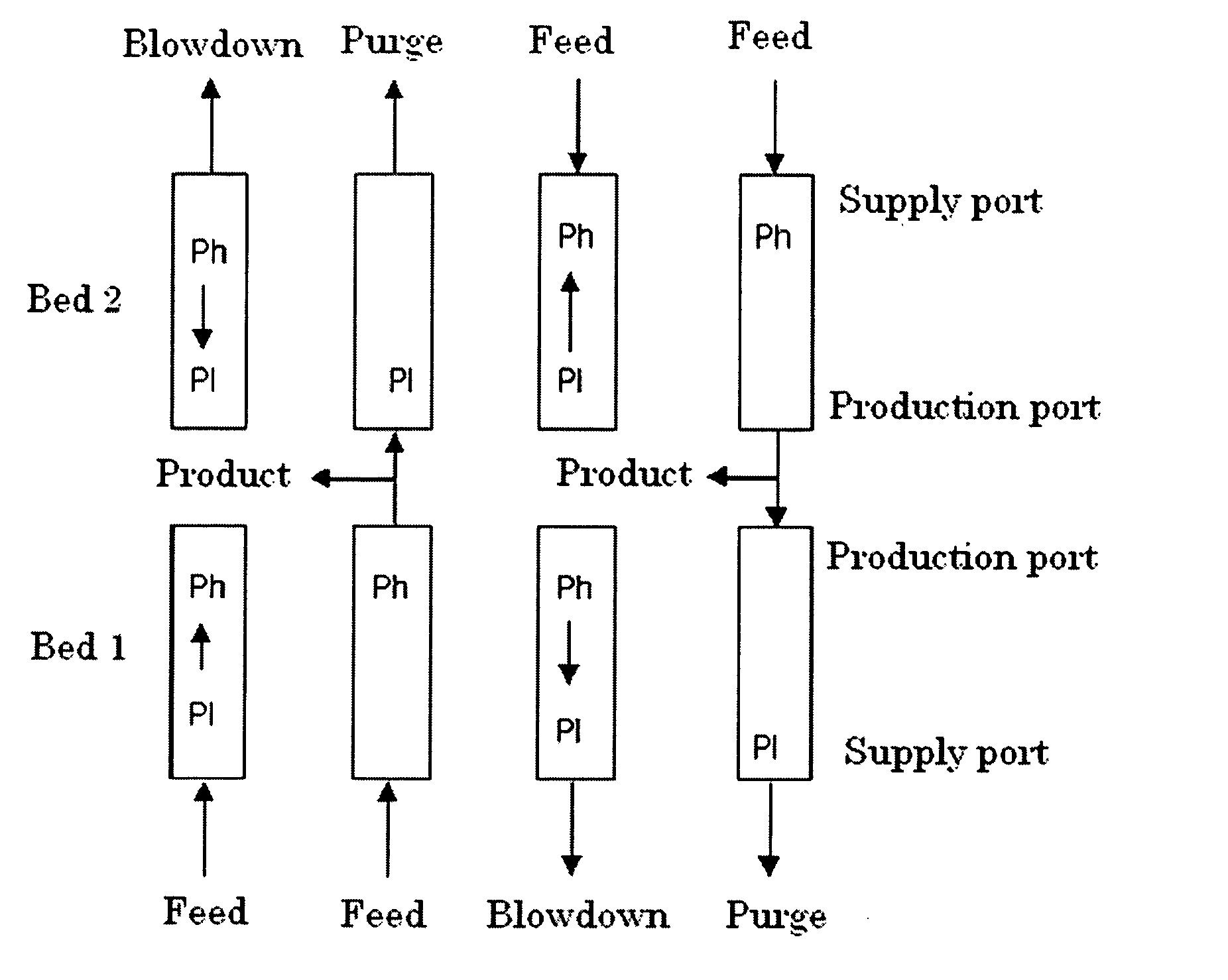

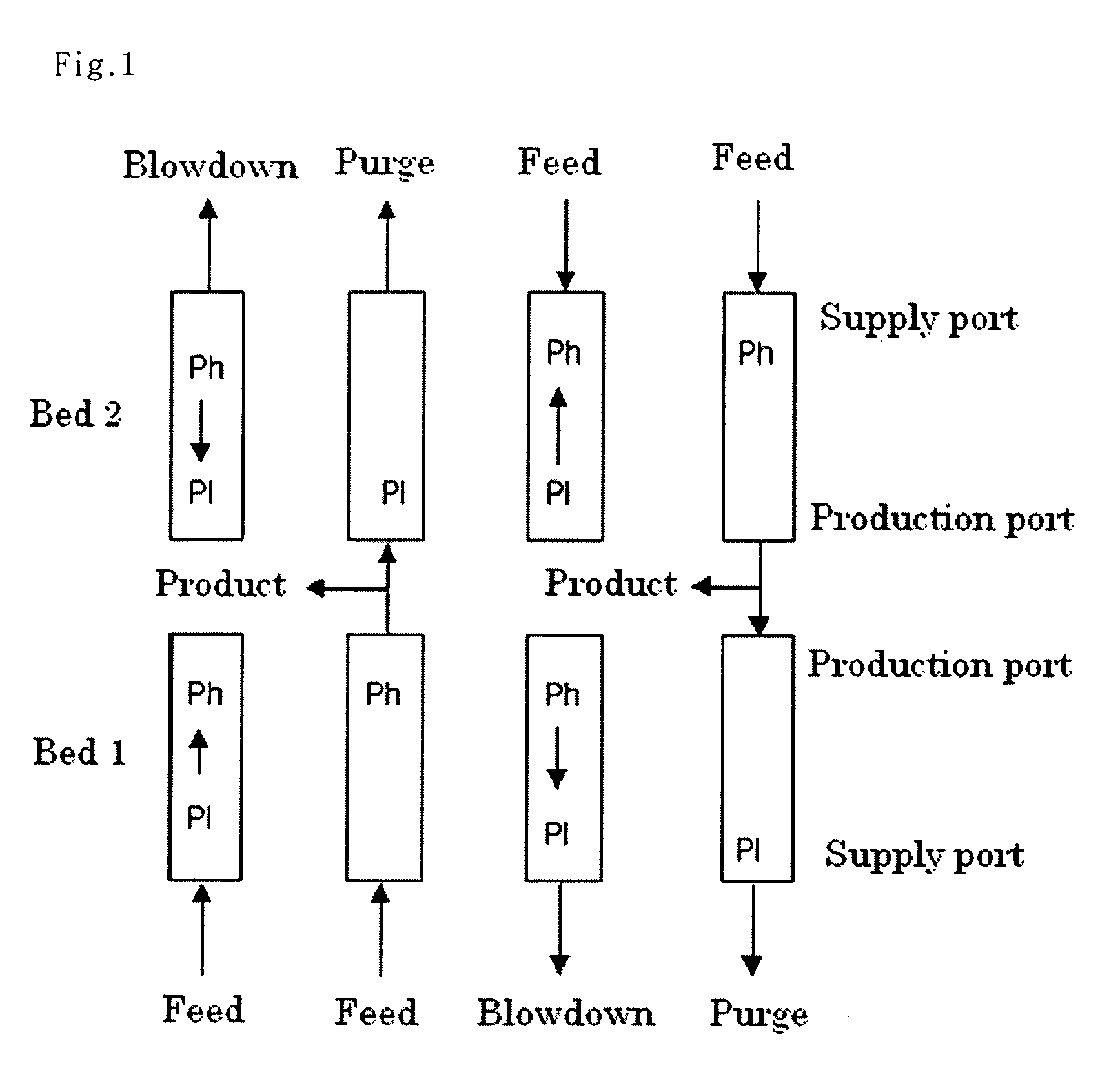

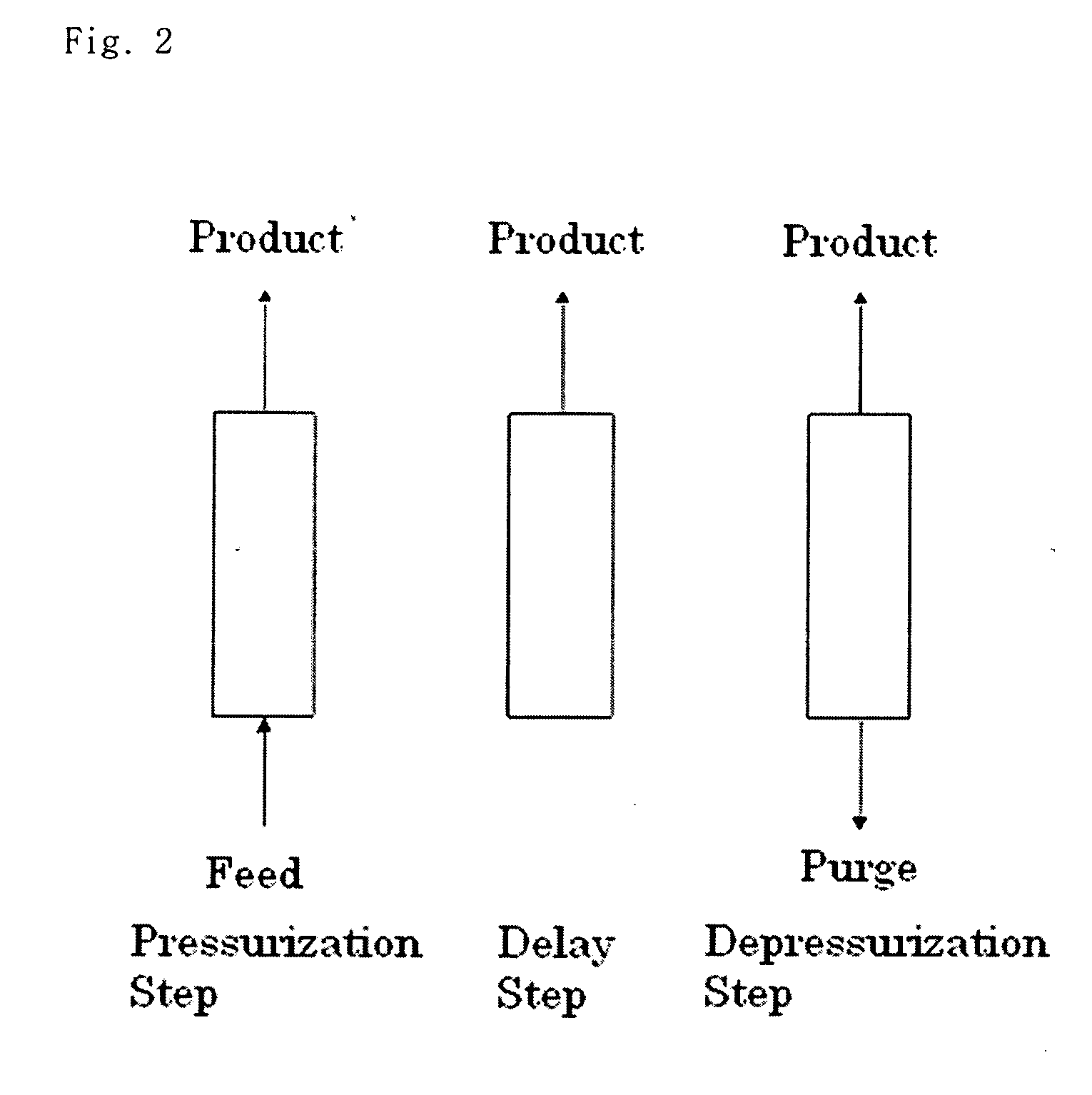

The present invention relates a method for concentrating a gas by applying a pressure difference to an adsorbent and an apparatus therefor, and particularly, a method for producing an enriched gas in a large amount by introducing a continuous production into every step of the process focusing on productivity rather than concentration of the product gas and an apparatus therefor. The present invention relates to a method incorporating the vacuum swing adsorption method with the pressure swing adsorption method, particularly the rapid pressure swing adsorption method which can continuously produce a desired material in a depressurization step to improve recovery rate of the desired material and productivity and an apparatus therefor. The apparatus according to the present invention is advantageously applied in a small size machine rather than for industrial uses. Particularly, when applied in a small size oxygen concentrator, it can be used in electric home appliances, air conditioners and water purifier, as well as medical products.

Owner:JEJ +1

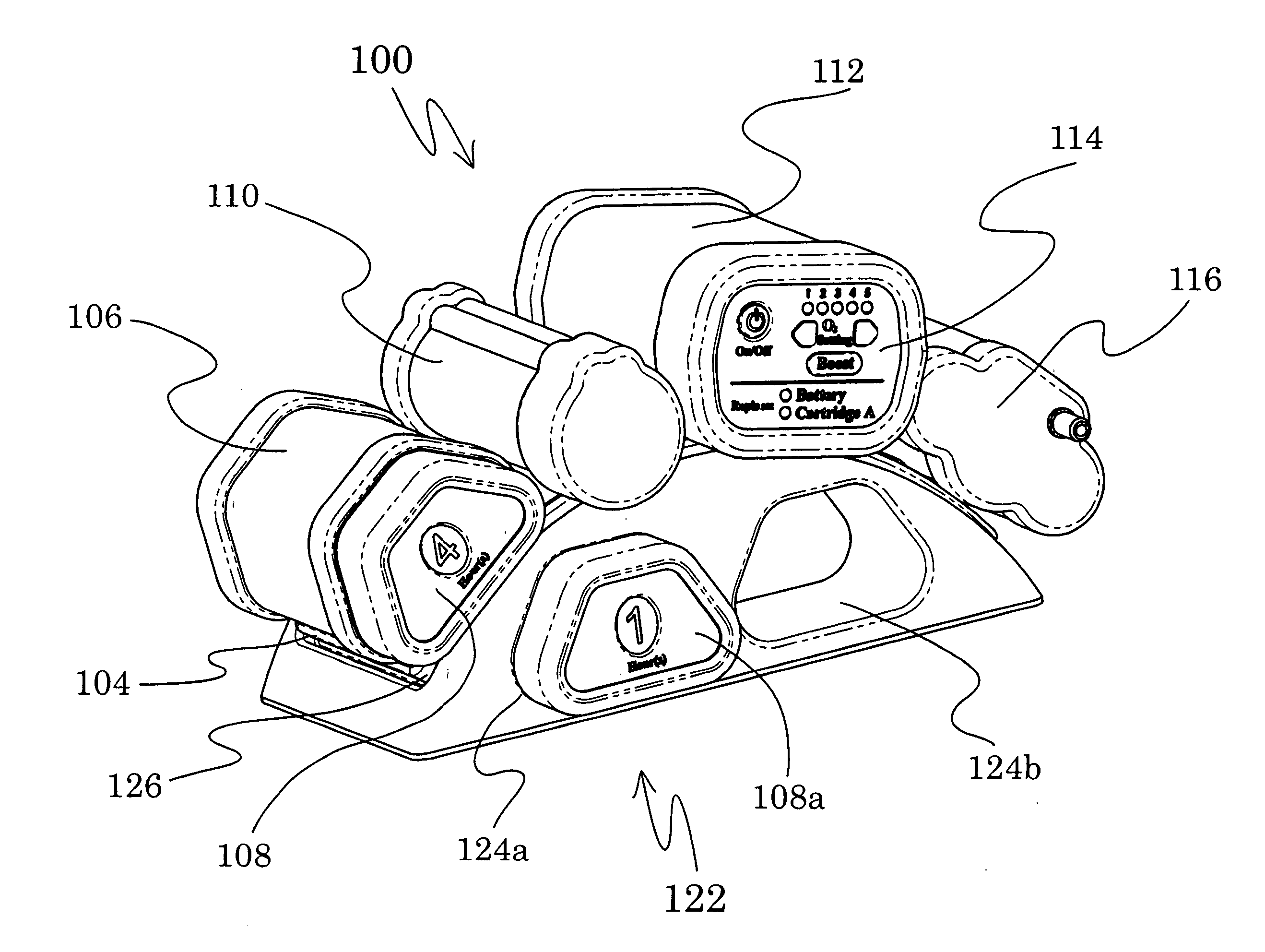

Low power ambulatory oxygen concentrator

ActiveUS7431032B2Reduce energy consumptionReduce quality problemsRespiratorsGas treatmentSorbentProduct gas

An oxygen concentrator comprises a vacuum swing adsorption (VSA) gas separation system which includes a cartridge containing a mass of adsorbent material for producing oxygen, a drive which activates the gas separation system, and a power source comprising a mass. A ratio of the mass of the power source to a flow rate of oxygen produced by the oxygen concentrator is between 0.047 and 0.29 kg / LPM·hr.

Owner:VBOX

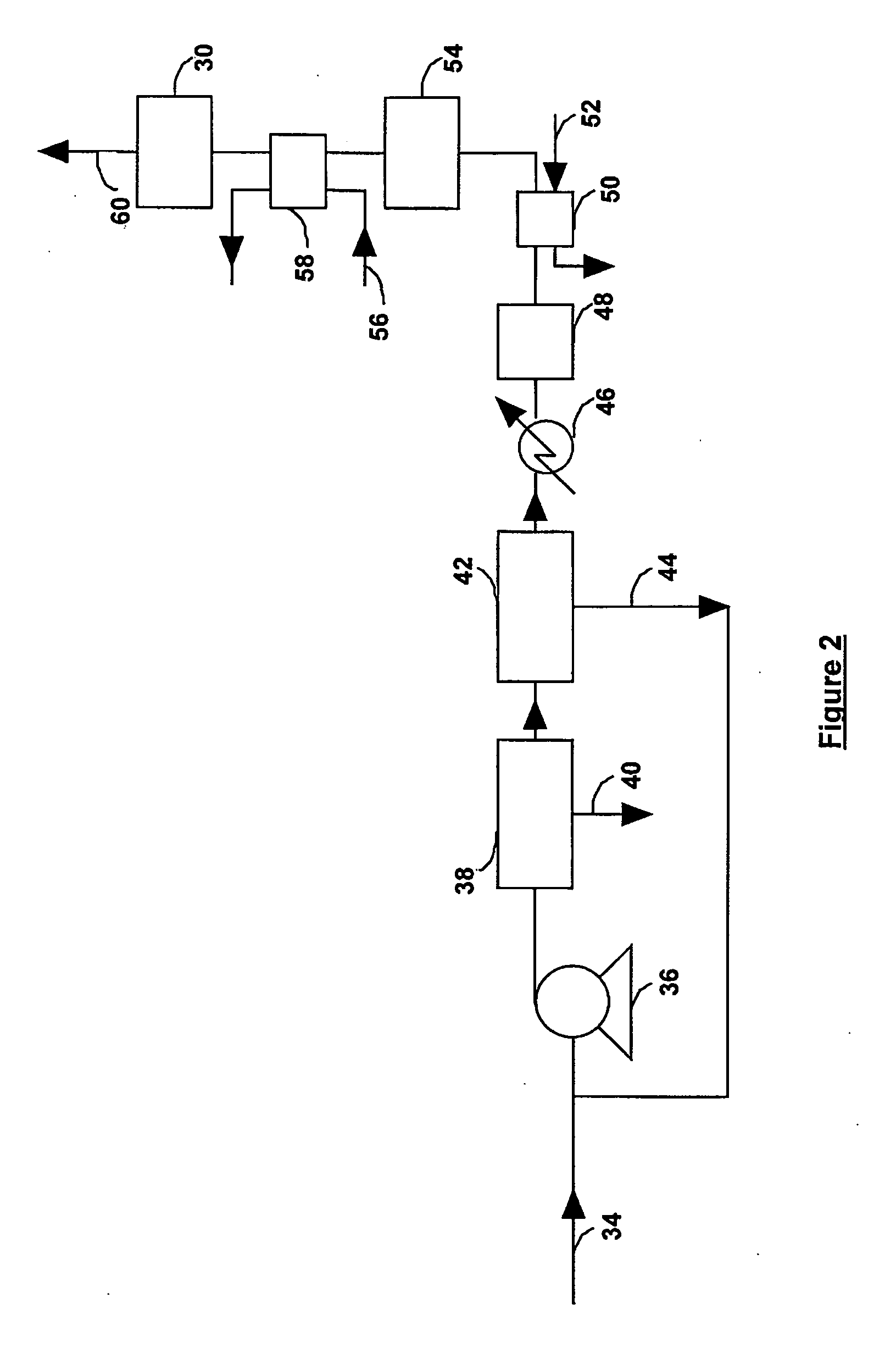

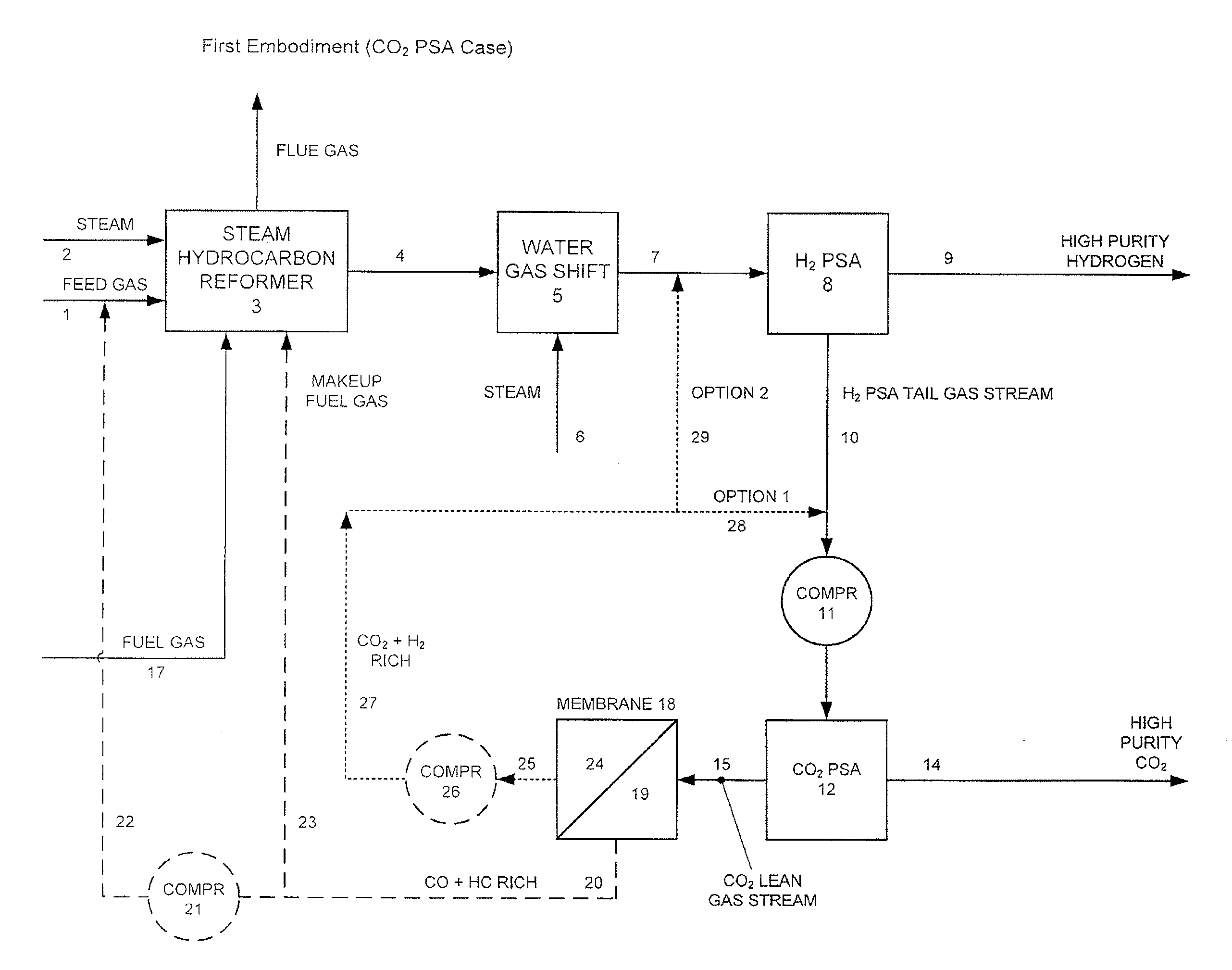

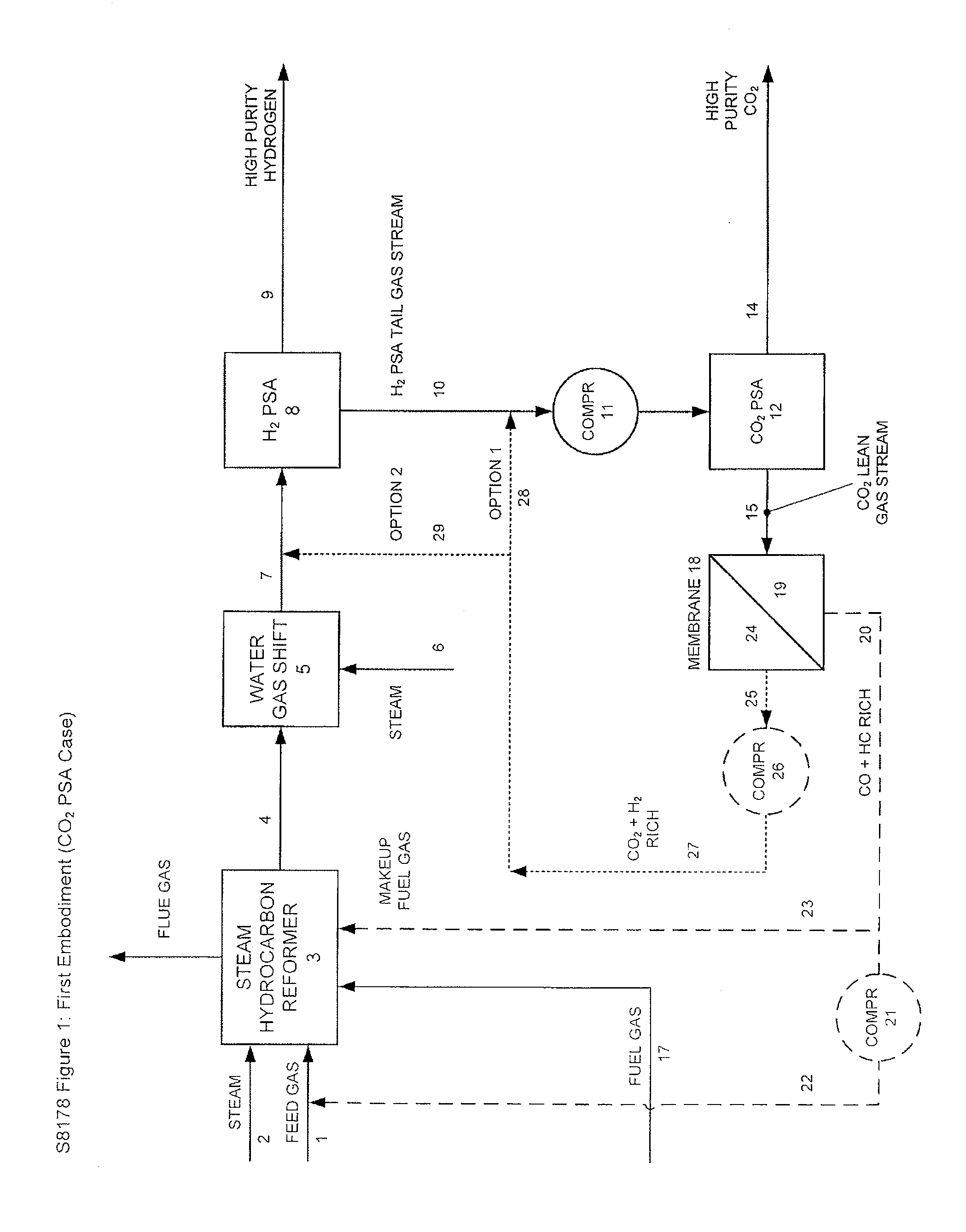

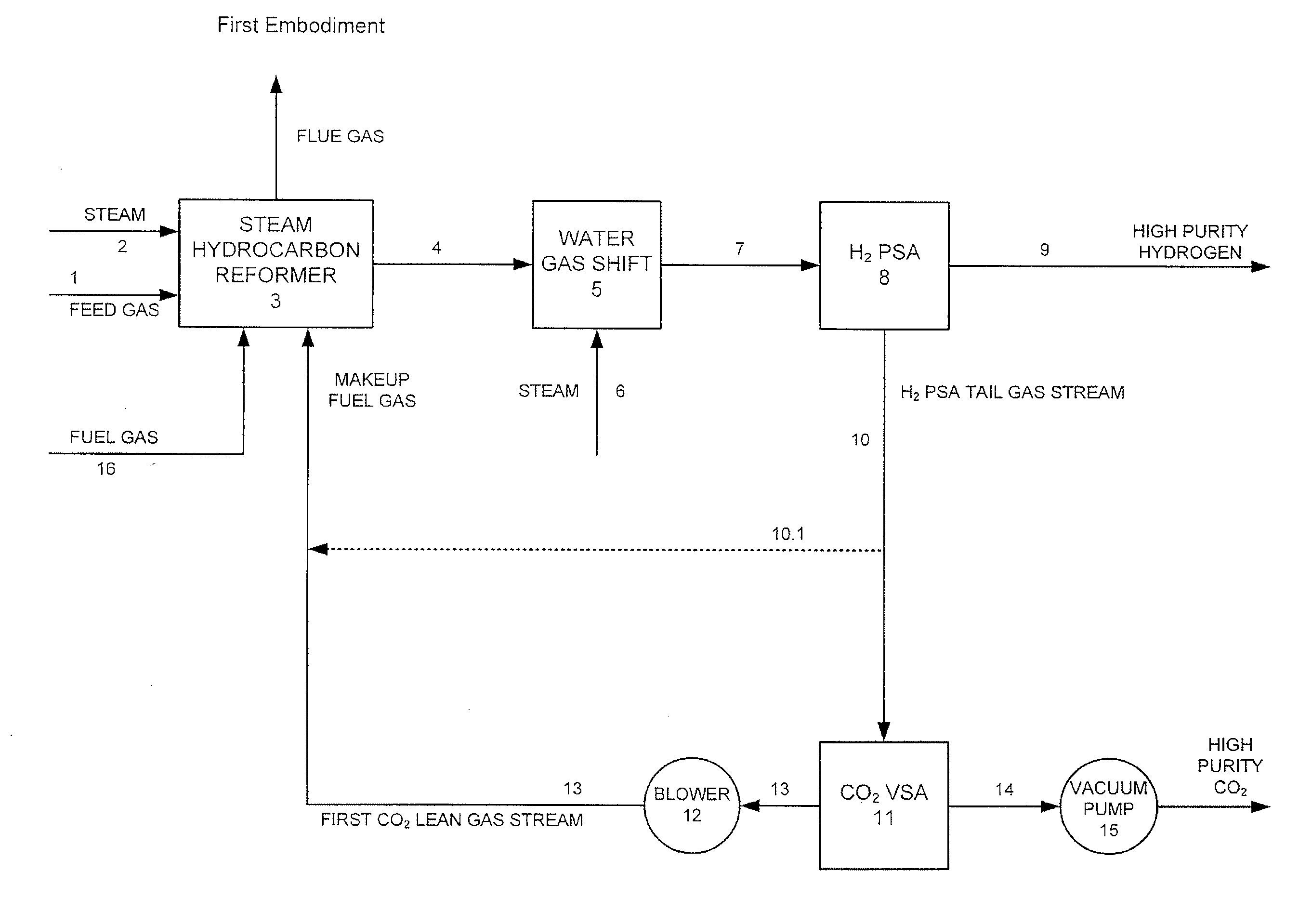

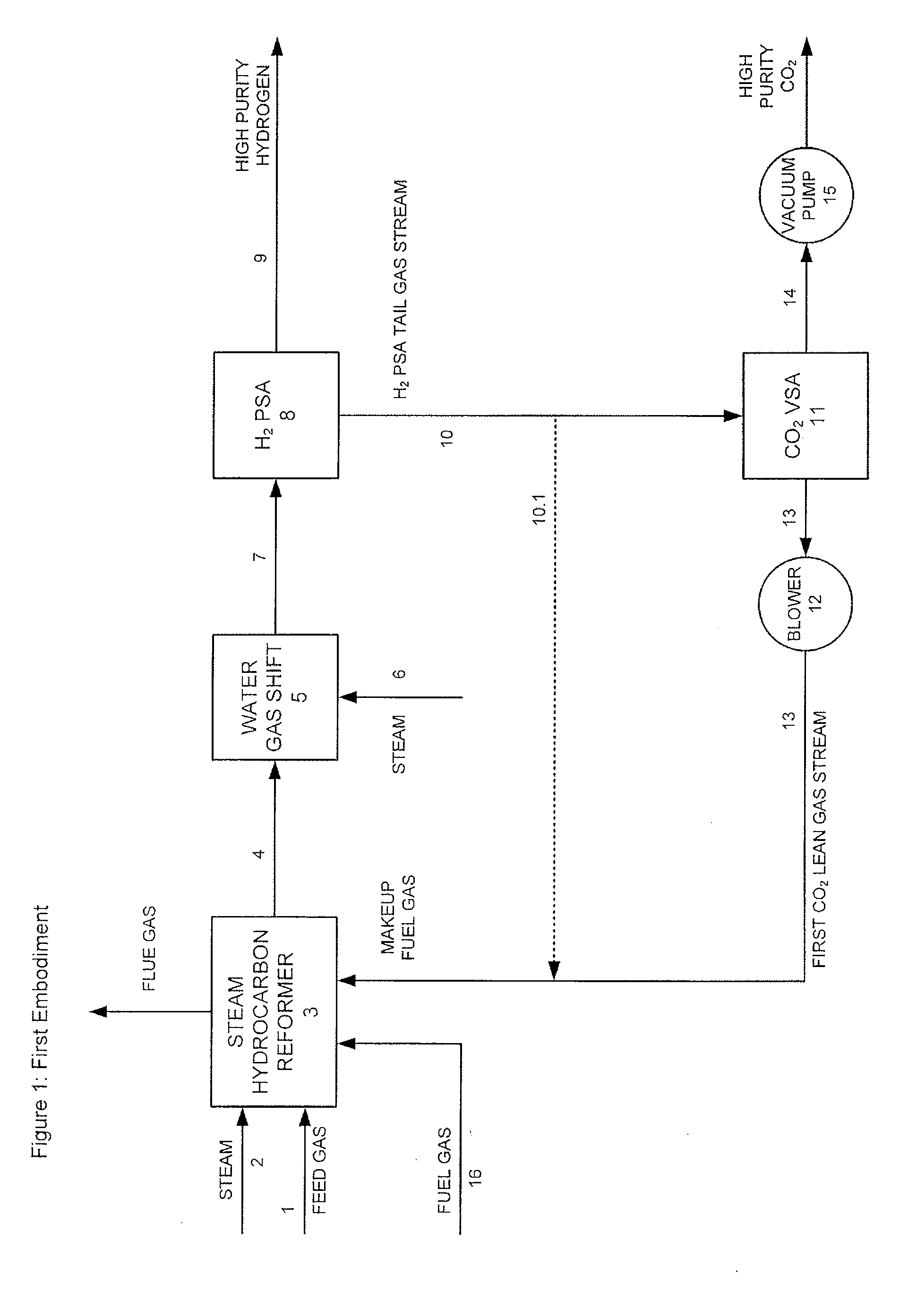

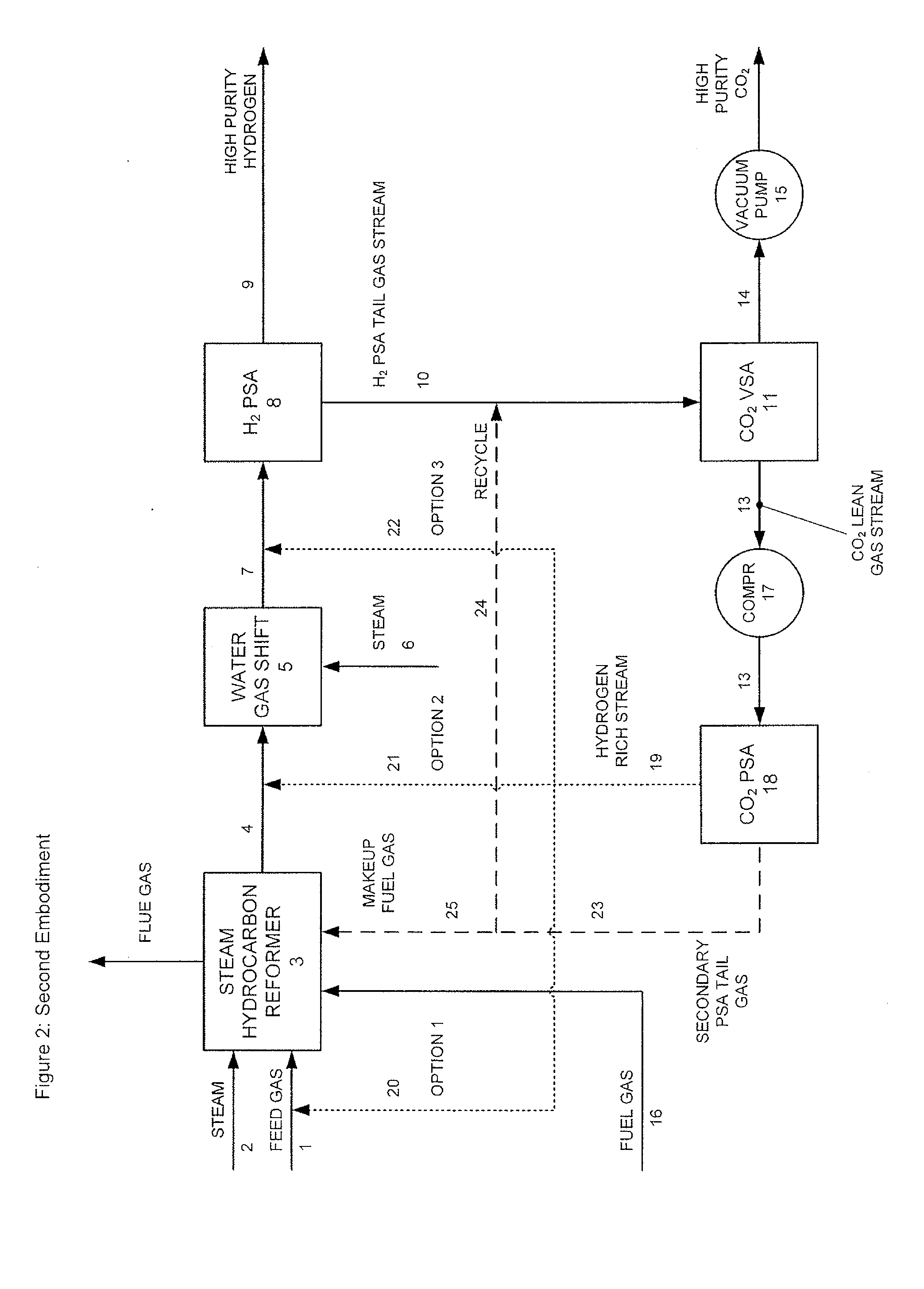

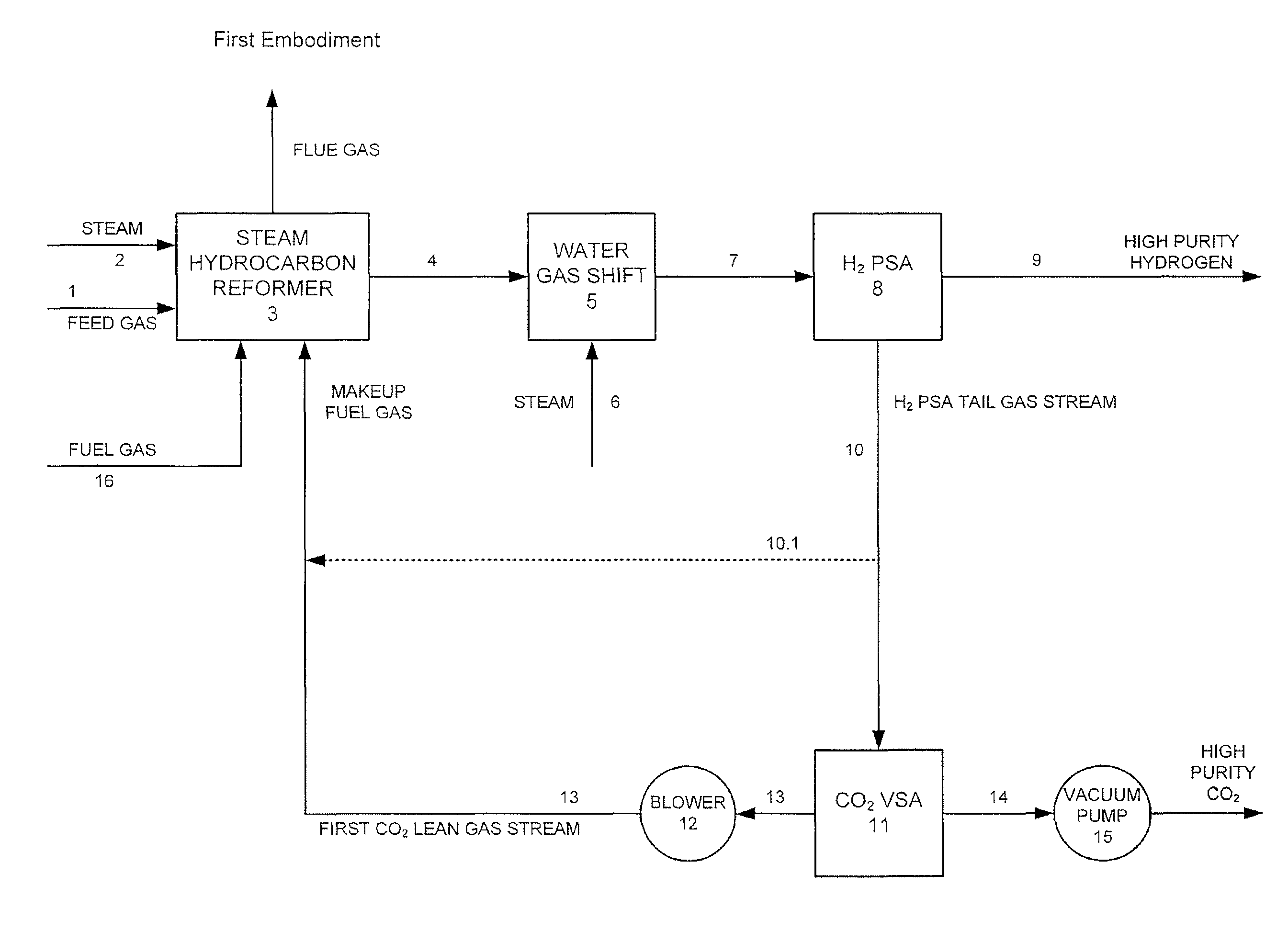

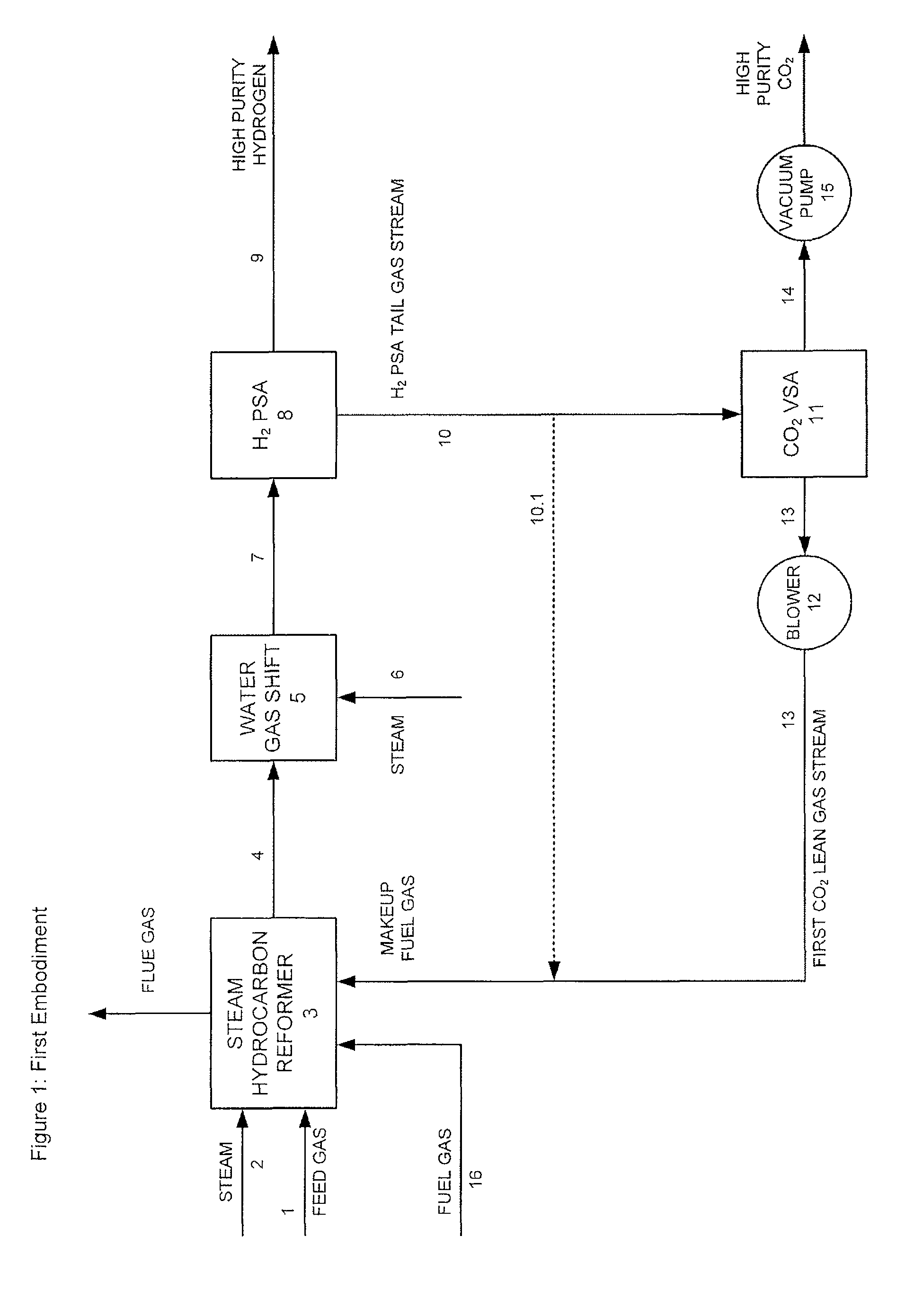

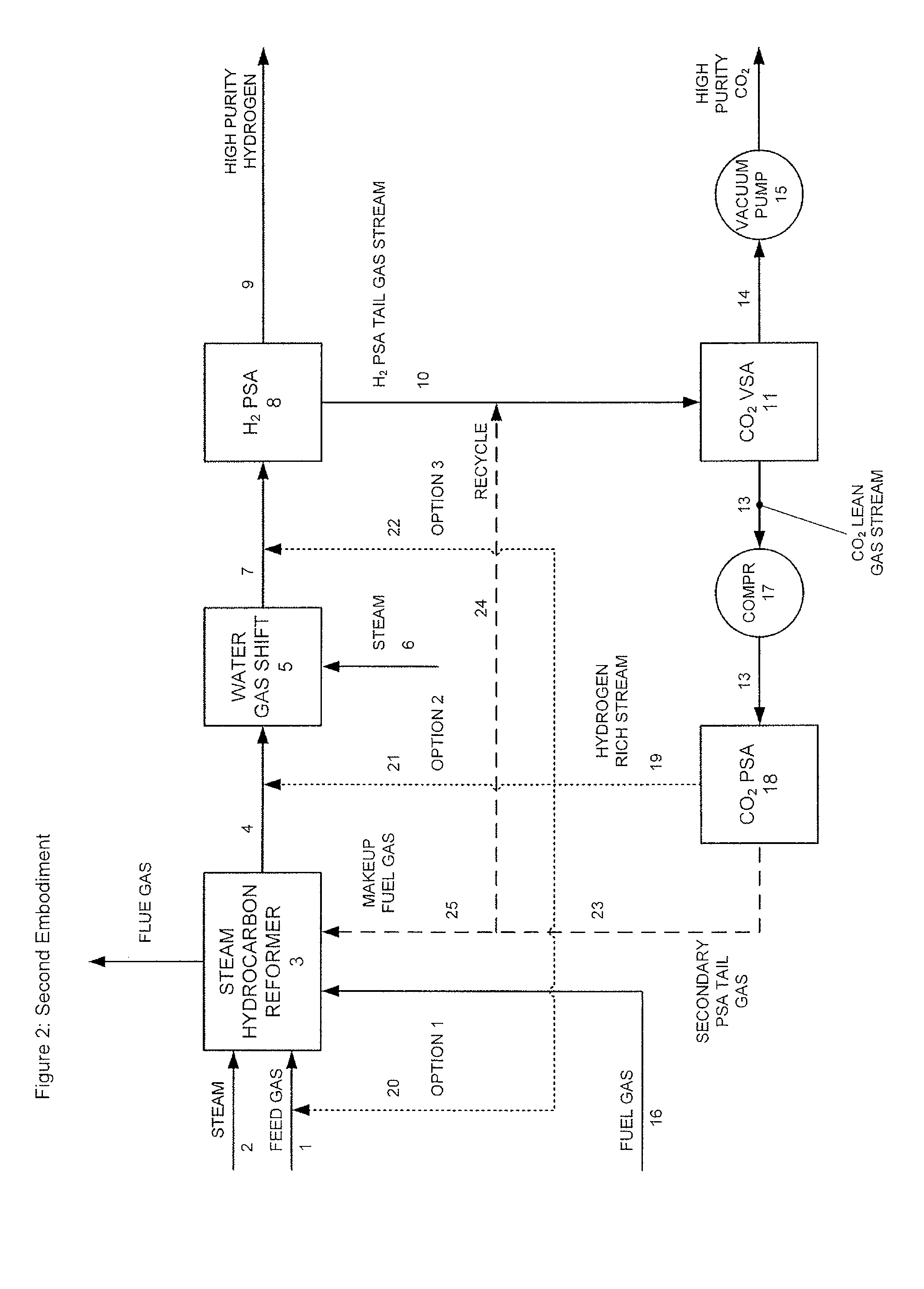

Processes For The Recovery Of High Purity Hydrogen And High Purity Carbon Dioxide

The present invention provides for various processes for recovering high purity gaseous hydrogen and high purity gaseous carbon dioxide from the gas stream produced using steam hydrocarbon reforming, especially steam methane reforming, utilizing a H2 pressure swing adsorption unit in combination with either a CO2 pressure swing adsorption unit in combination with a membrane separation unit or a CO2 pressure vacuum swing adsorption unit in combination with a membrane separation unit. The present invention further relates to a process for optimizing the recovery of carbon dioxide from waste gas streams produced during the hydrogen purification step of a steam hydrocarbon reforming / water gas shift reactor / H2 pressure swing adsorption unit utilizing either a CO2 pressure swing adsorption unit in combination with a membrane separation unit or a CO2 pressure vacuum swing adsorption unit in combination with a membrane separation unit. The present invention even further relates to the apparatus necessary to carry out the various processes of the present invention.

Owner:AIR LIQUIDE IND US LP +1

Process for gas purification

The present invention provides for a process for purifying carbon monoxide-containing gas streams that contain impurities such as hydrocarbons by using a cryogenic adsorption process. Preferably this process is a temperature swing adsorption process at cryogenic temperatures below −75° C. Alternatively, the carbon monoxide-containing gas streams may be purified using the cryogenic adsorption process with membrane separation units or vacuum swing adsorption units or cryogenic distillation.

Owner:JAIN RAVI +1

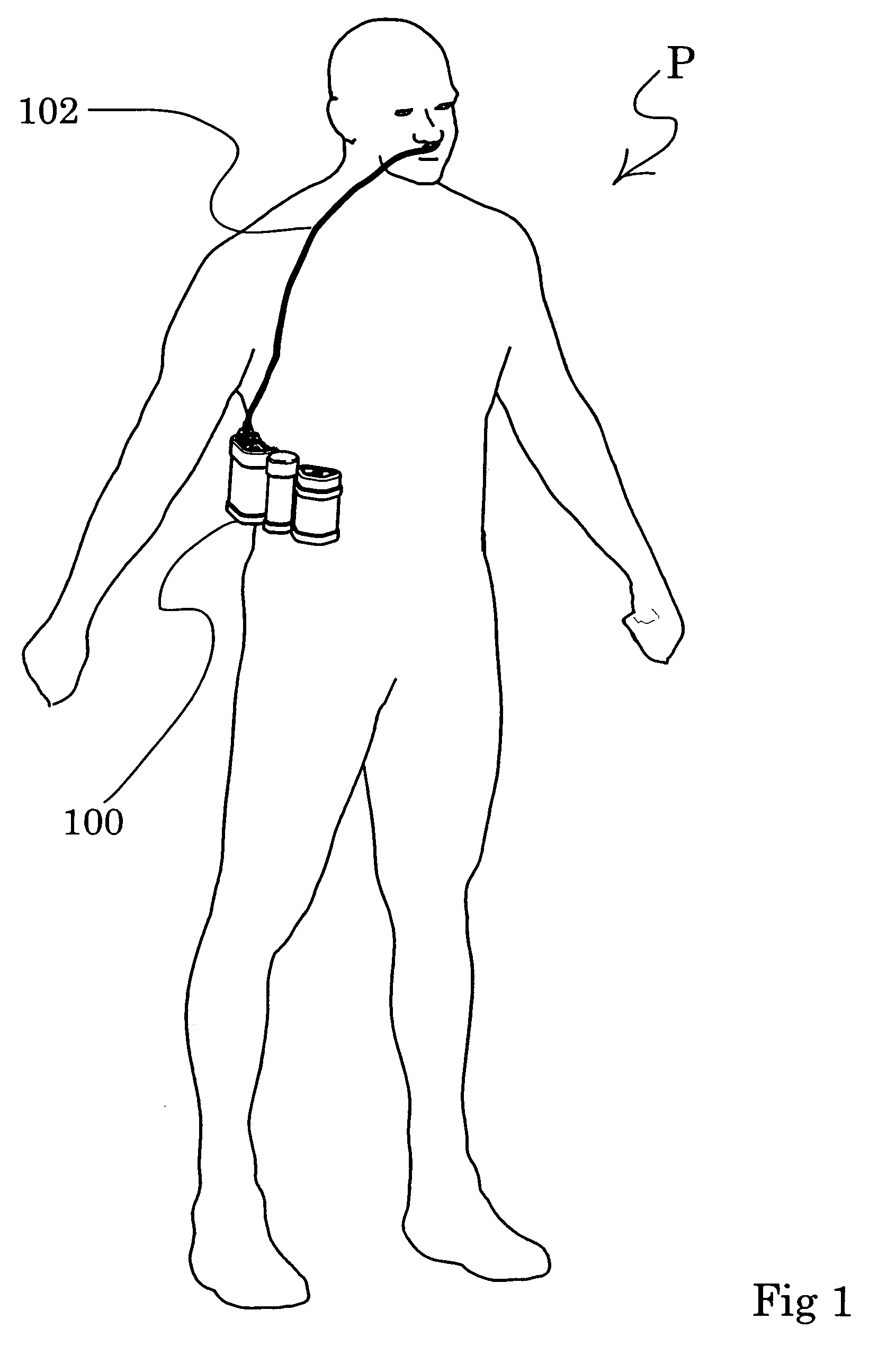

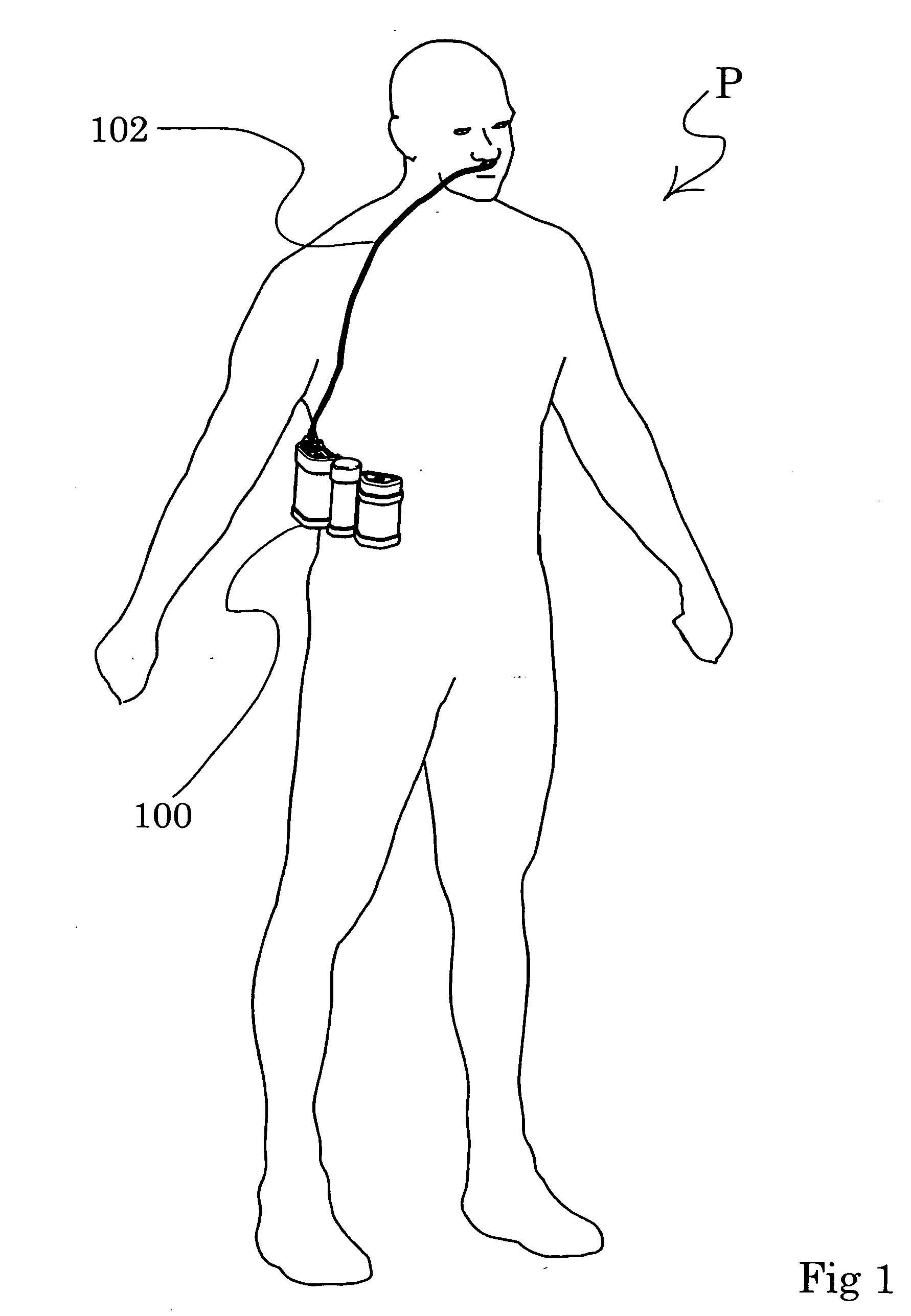

Personal oxygen concentrator

An oxygen separator for separating oxygen from ambient air utilizing a vacuum swing adsorption process has a mass of less than 2.3 kg. A carrier is mountable on a person to support the oxygen separator for ambulatory use.

Owner:VBOX

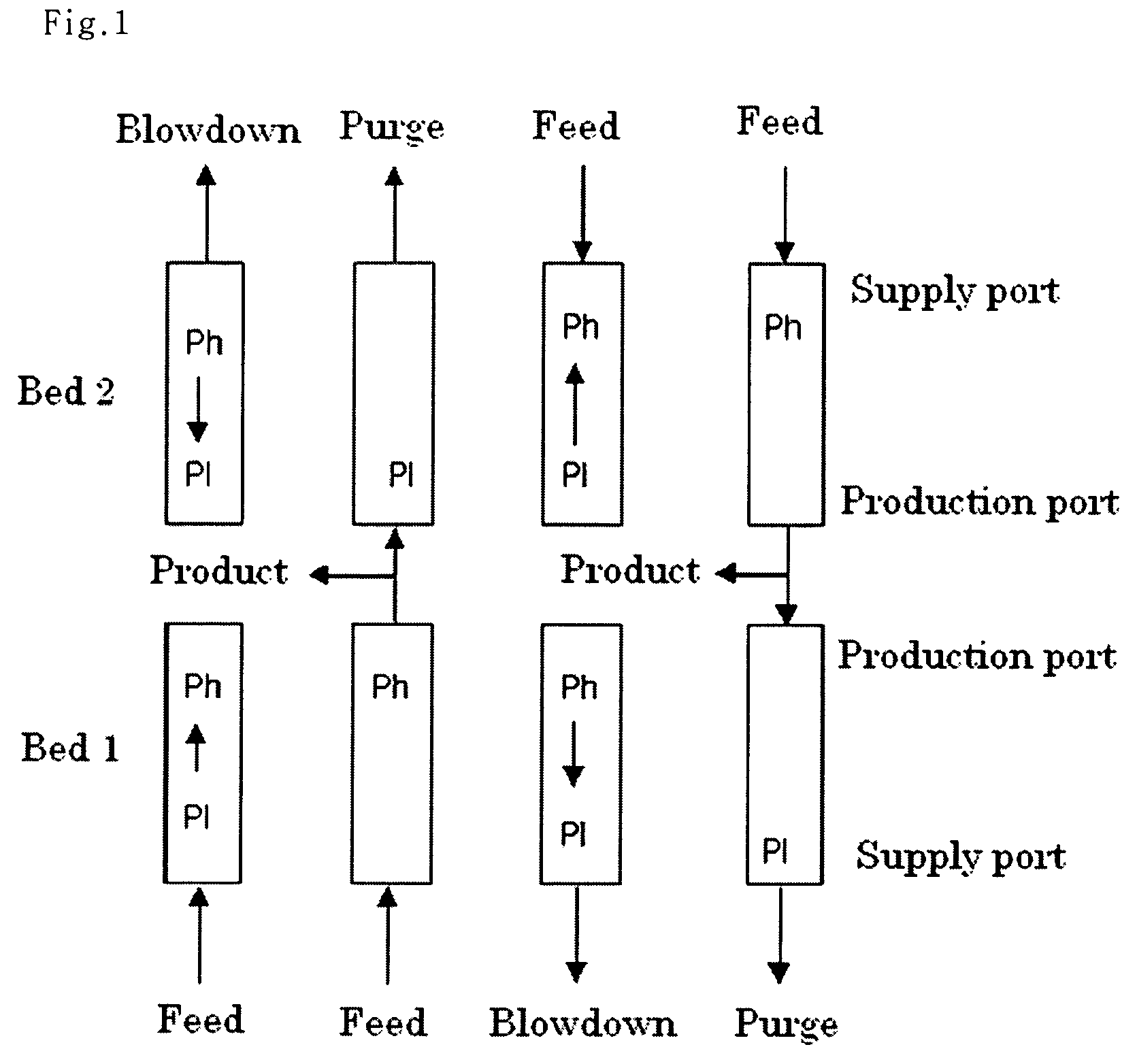

Nitrogen and oxygen separation using vacuum swing adsorption

A mixed gas is separated with collection of at least one constituent gas. An inlet leads to a blower or other gas compression element through a valve. This blower feeds a chamber which contains media which selectively adsorbs the constituent gas to be collected, such as nitrogen from air. An exhaust from the chamber leads to an exhaust through a check valve. The blower can be reversed after nitrogen has been adsorbed within the chamber to desorb nitrogen and deliver nitrogen back through the blower. The inlet valve is closed after blower reversing and a separate diversion pathway is opened so that nitrogen is delivered from the blower to a nitrogen collection region. A variant system also includes an oxygen collection region on a side of the chamber opposite the blower for collection of both nitrogen and oxygen separated from air simultaneously, or collection of other constituent gases.

Owner:PACIFIC CONSOL INDS

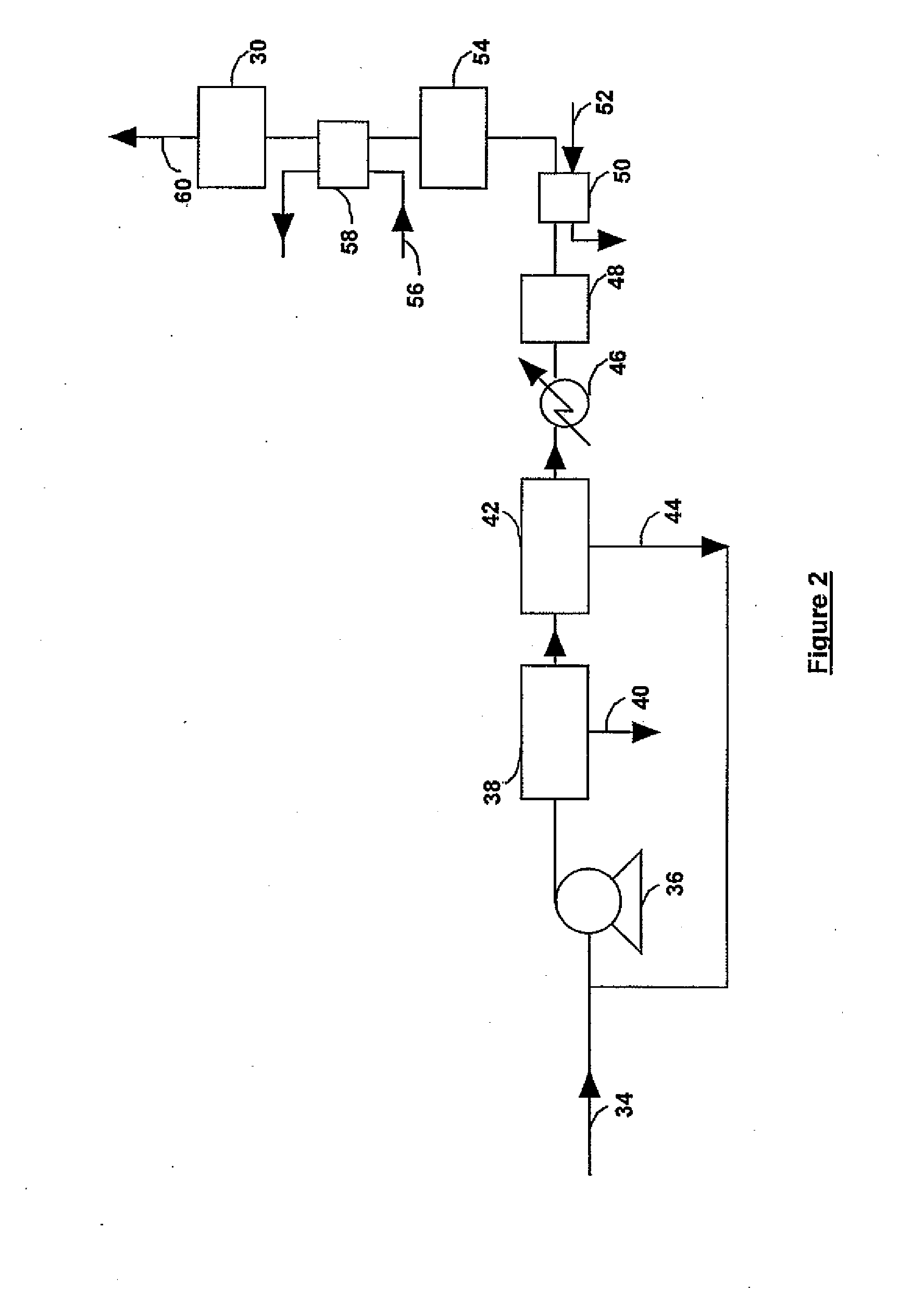

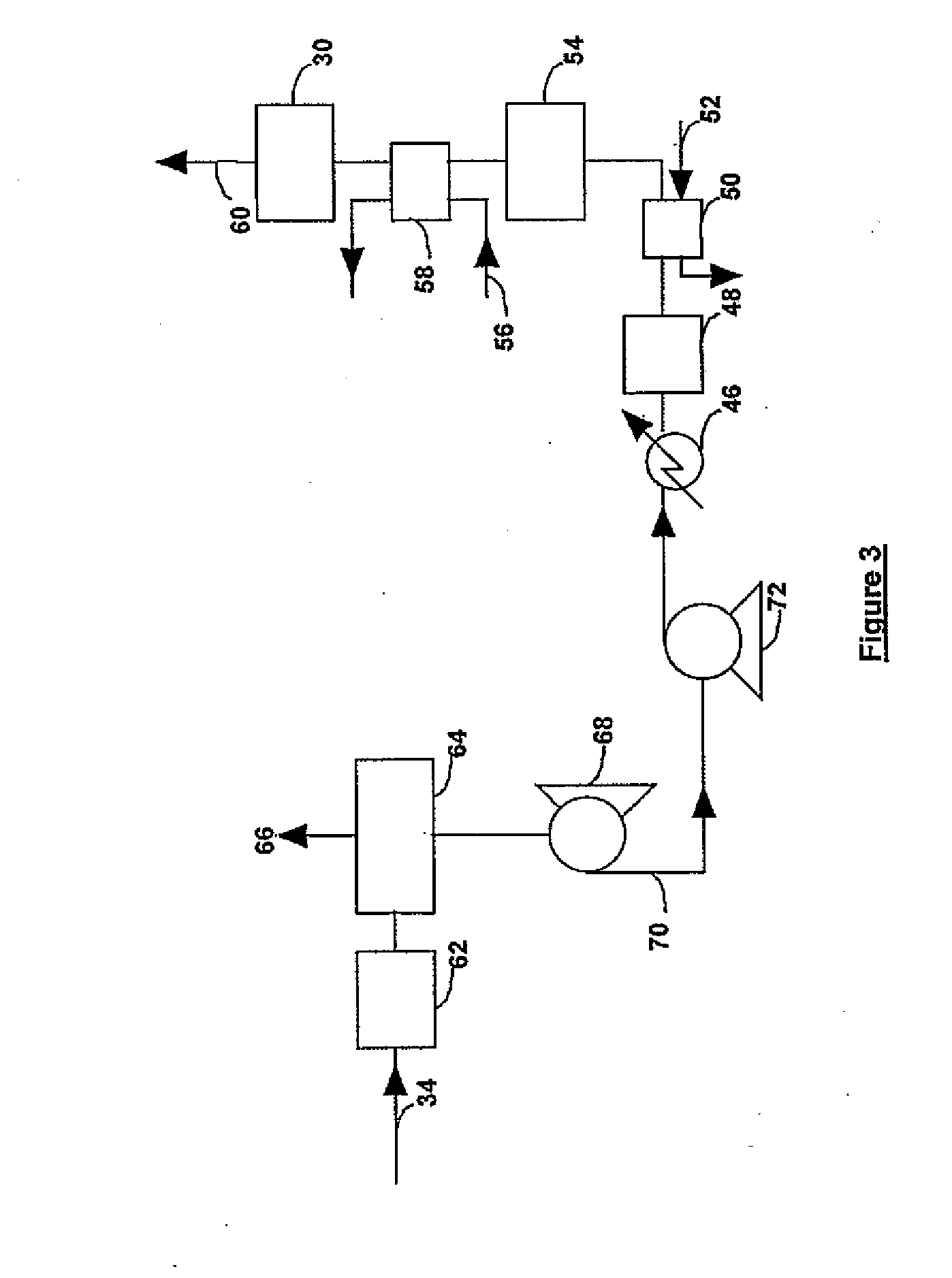

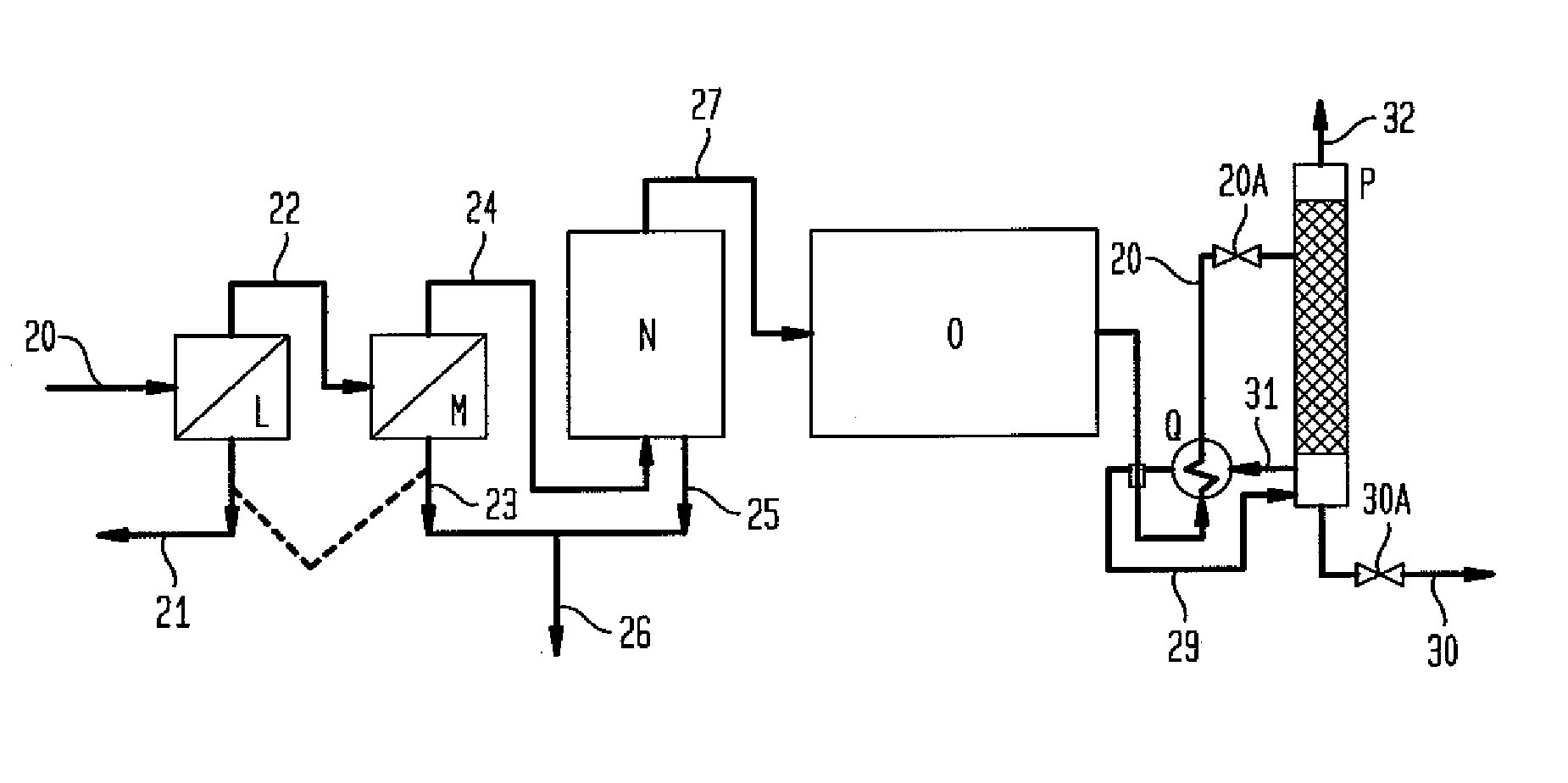

Processes For The Recovery Of High Purity Hydrogen And High Purity Carbon Dioxide

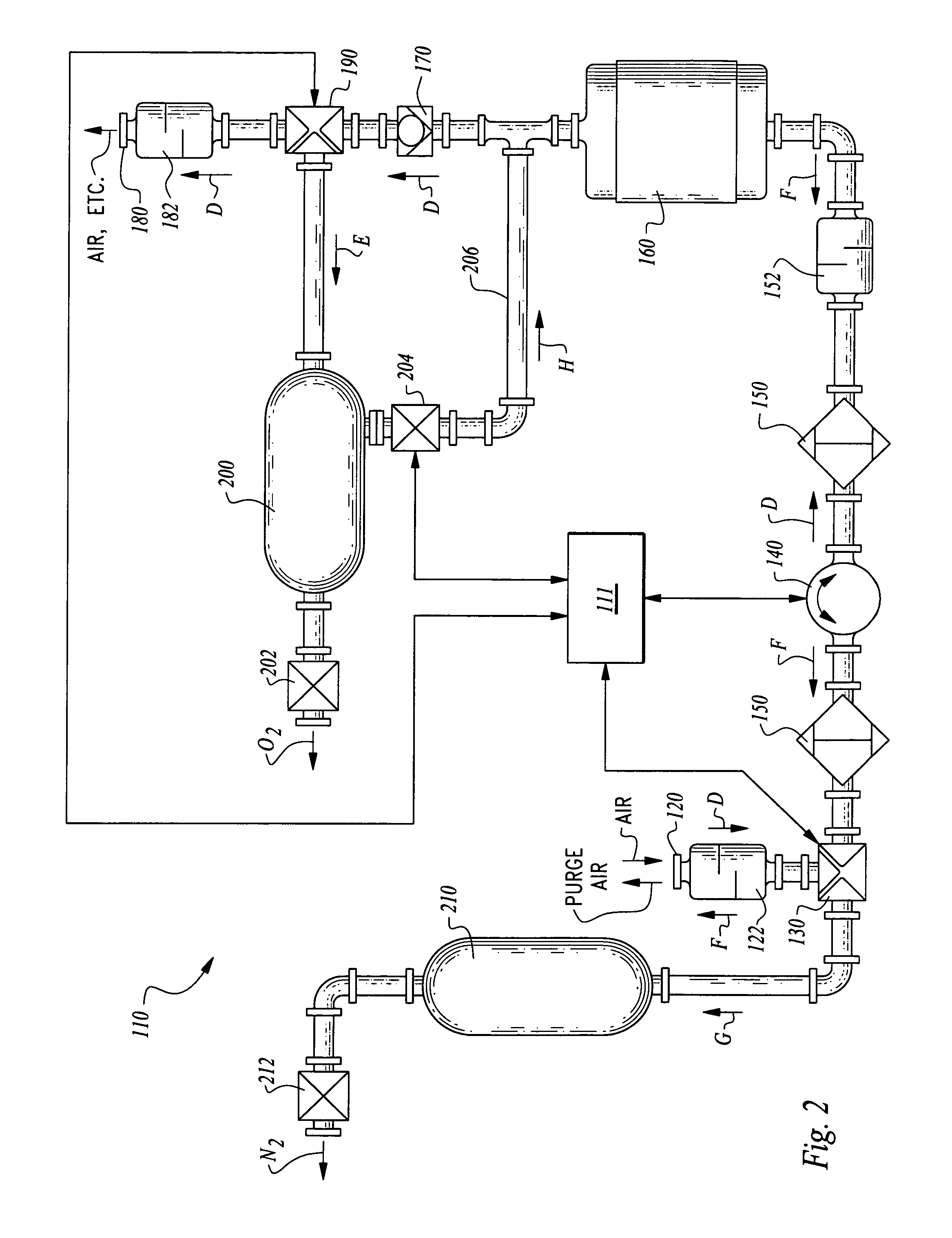

ActiveUS20100288123A1High purityCarbon compoundsHydrogen separation using solid contactGaseous hydrogenHydrocarbon

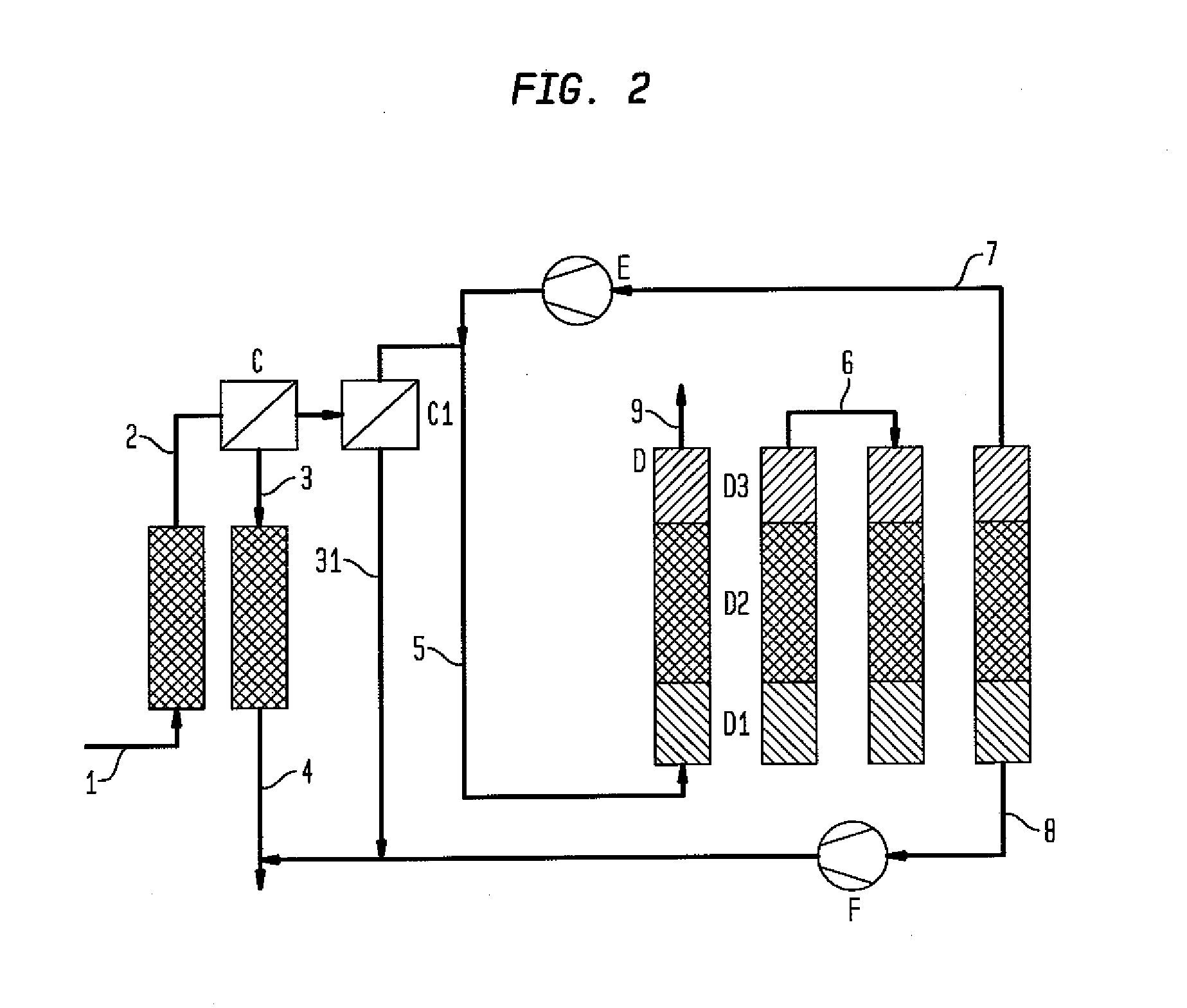

The present invention relates to various processes for recovering high purity gaseous hydrogen and high purity gaseous carbon dioxide from the gas stream produced using steam hydrocarbon reforming, especially steam methane reforming, utilizing a H2 pressure swing adsorption unit followed by either a CO2 vacuum swing adsorption unit or a CO2 vacuum swing adsorption unit in combination with an additional CO2 pressure swing adsorption unit. By using an uncoupled H2 PSA and CO2 VSA unit it is possible to produce high purity H2 and high purity CO2. The present invention further relates to a process for optimizing the recovery of CO2 from waste gas streams produced during the hydrogen purification step of a steam hydrocarbon reforming / H2 pressure swing adsorption unit utilizing either a CO2 vacuum swing adsorption unit or a CO2 vacuum swing adsorption unit in combination with a CO2 pressure swing adsorption unit. The present invention even further relates to the apparatus necessary to carry out the various processes of the present invention.

Owner:AIR LIQUIDE AMERICA INC +1

Production of carbon monoxide-free hydrogen and helium from a high-purity source

Owner:AIR PROD & CHEM INC

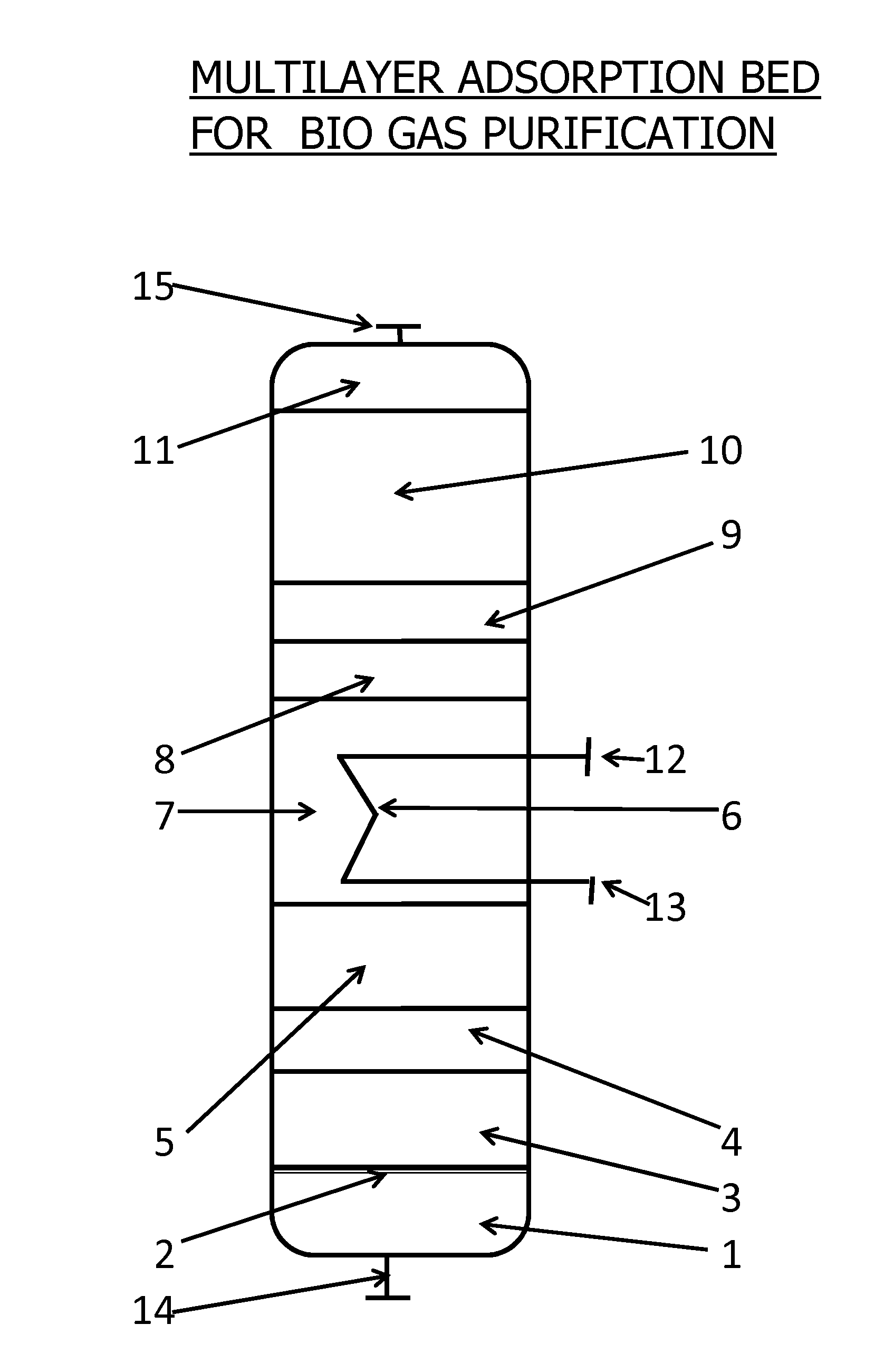

Method to clean impurities from bio-gas using adsorption

The present invention provides for a method to make a multiple layered adsorber bed to adsorb and remove water, siloxanes, hydrogen sulfide, mercaptans, and carbon-dioxide from Biogas sources such as landfill gas. This bed can be operated by a pressure swing or vacuum swing adsorption process.

Owner:ADSORPTECH

Gas concentration method and its apparatus

InactiveUS20050081713A1Improve productivitySimple equipmentGas treatmentIsotope separationProduction rateSorbent

The present invention relates a method for concentrating a gas by applying a pressure difference to an adsorbent and an apparatus therefor, and particularly, a method for producing an enriched gas in a large amount by introducing a continuous production into every step of the process focusing on productivity rather than concentration of the product gas and an apparatus therefor. The present invention relates to a method incorporating the vacuum swing adsorption method with the pressure swing adsorption method, particularly the rapid pressure swing adsorption method which can continuously produce a desired material in a depressurization step to improve recovery rate of the desired material and productivity and an apparatus therefor. The apparatus according to the present invention is advantageously applied in a small size machine rather than for industrial uses. Particularly, when applied in a small size oxygen concentrator, it can be used in electric home appliances, air conditioners and water purifier, as well as medical products.

Owner:JEJ +1

Personal oxygen concentrator

An oxygen separator for separating oxygen from ambient air utilizing a vacuum swing adsorption process has a mass of less than 2.3 kg. A carrier is mountable on a person to support the oxygen separator for ambulatory use.

Owner:VBOX

Methods for removing contaminants from natural gas

A method for removing contaminants from natural gas streams. The natural gas stream is fed to a dryer, then a membrane module and a multibed, multilayer vacuum swing adsorption process for removal of oxygen, nitrogen and carbon dioxide from the natural gas stream. Alternatively when carbon dioxide is in relatively low concentration in the natural gas stream, the membrane module step is not employed.

Owner:LINDE AG

Low power ambulatory oxygen concentrator

ActiveUS20060174878A1Reduce energy consumptionReduce quality problemsRespiratorsGas treatmentSorbentProduct gas

An oxygen concentrator comprises a vacuum swing adsorption (VSA) gas separation system which includes a cartridge containing a mass of adsorbent material for producing oxygen, a drive which activates the gas separation system, and a power source comprising a mass. A ratio of the mass of the power source to a flow rate of oxygen produced by the oxygen concentrator is between 0.047 and 0.29 kg / LPM·hr.

Owner:VBOX

Ambulatory oxygen concentrator containing a three phase vacuum separation system

An oxygen concentrator comprises an oxygen reservoir and adsorbent columns that each have an inlet, an outlet, and a bed of adsorbent material. The concentrator also comprises an air inlet, an exhaust outlet, and a vacuum pump for pumping nitrogen rich gas from one of the column inlets to the exhaust outlet. A product control pump pumps oxygen rich gas from one of the column outlets to the oxygen reservoir. A control valve controls flow in and out of the columns by selectively connecting the air inlet to one column inlet, connecting the vacuum pump to another column inlet, and connecting the product control pump to a column outlet. A motor drives the vacuum pump and control valve to produce vacuum swing adsorption (VSA) cycles in which oxygen-rich product gas is separated and accumulated in the reservoir.

Owner:VBOX

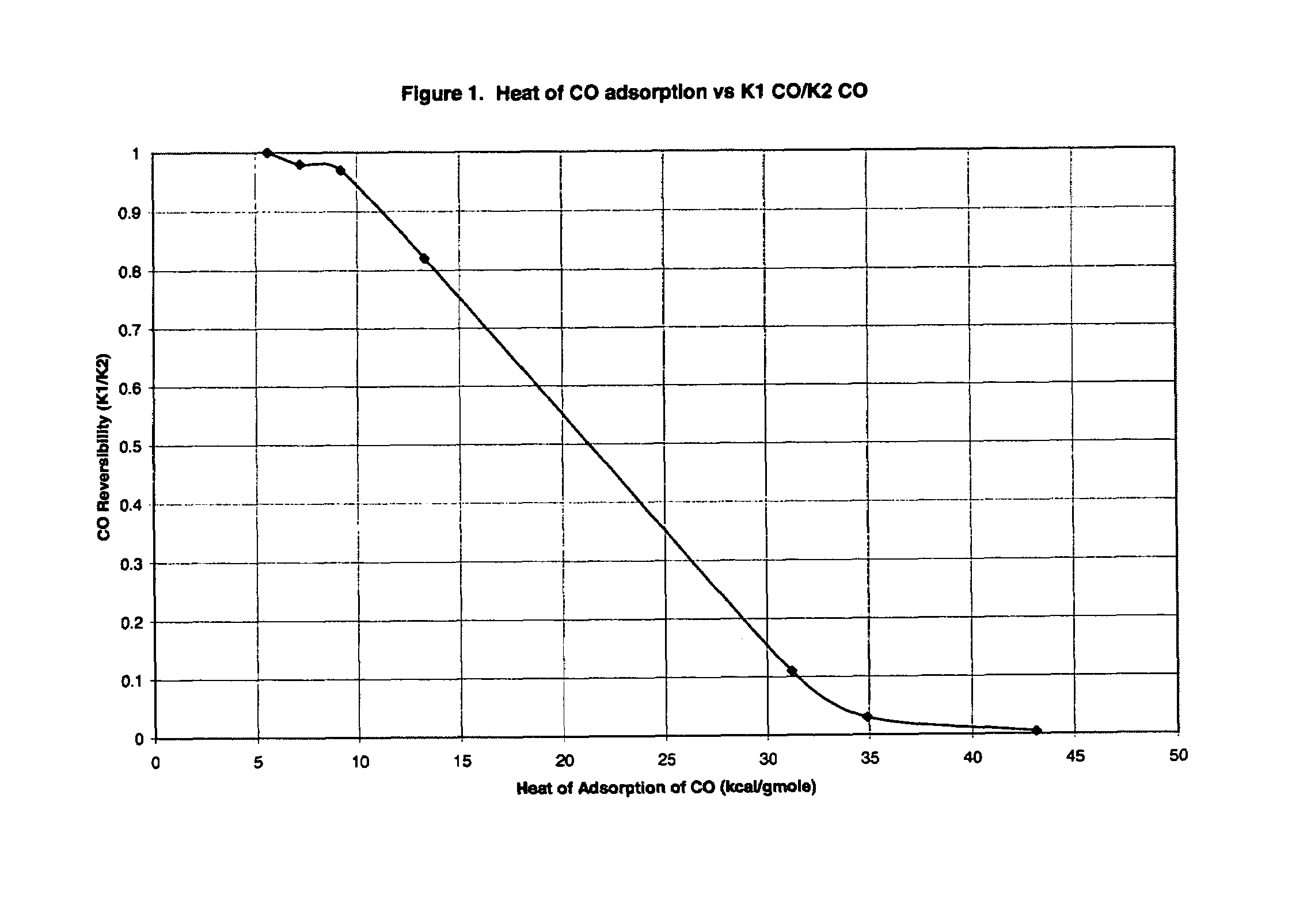

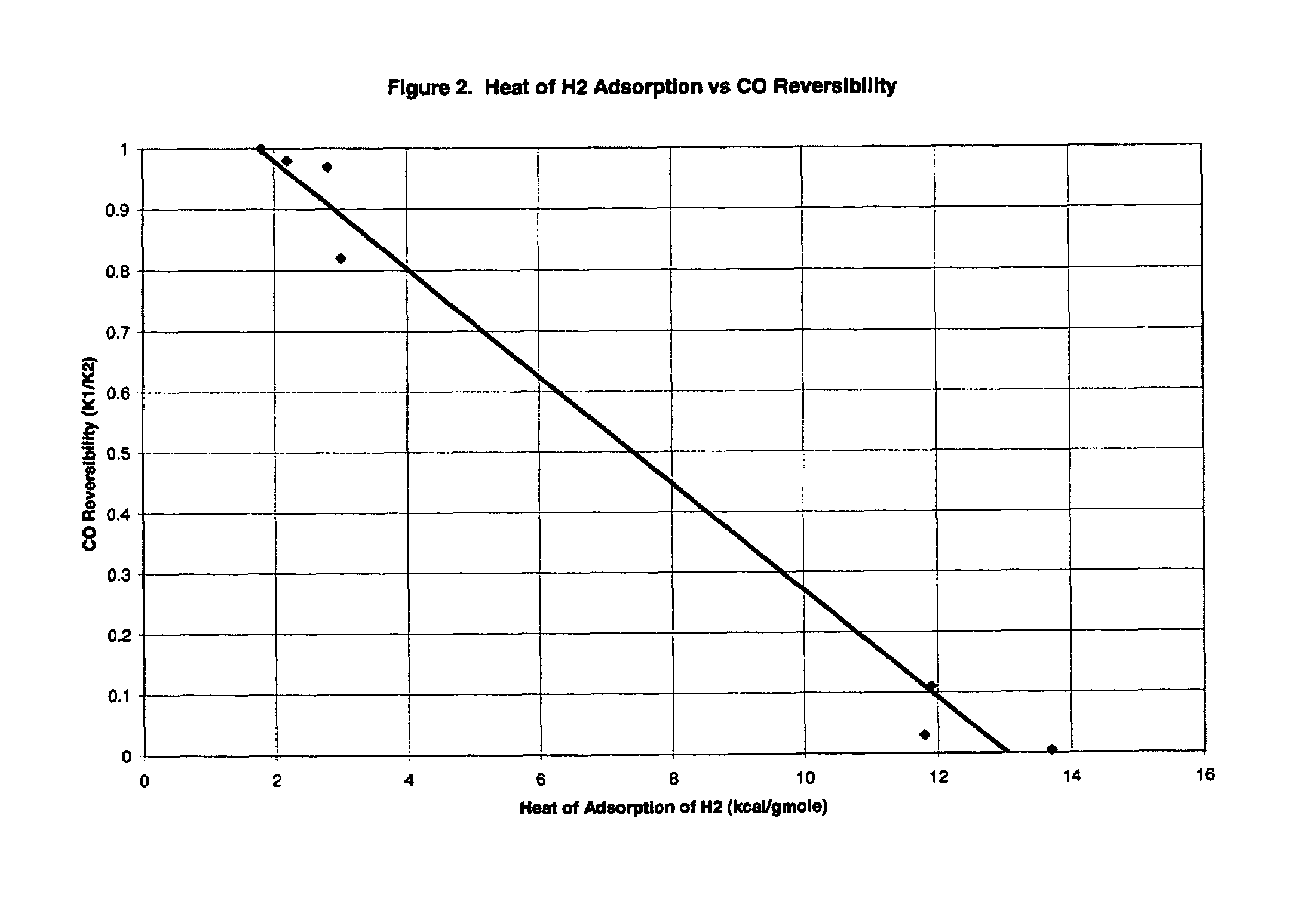

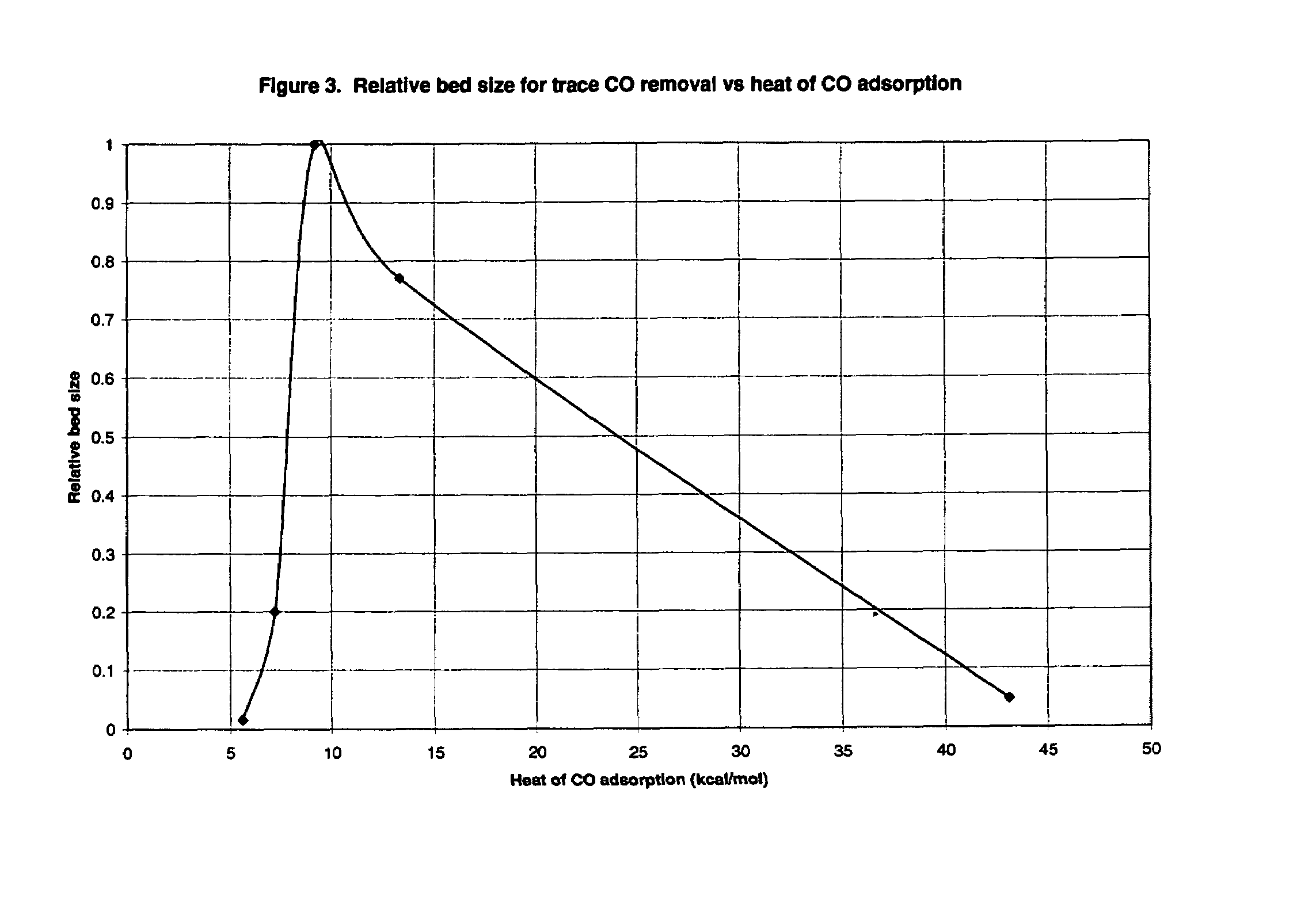

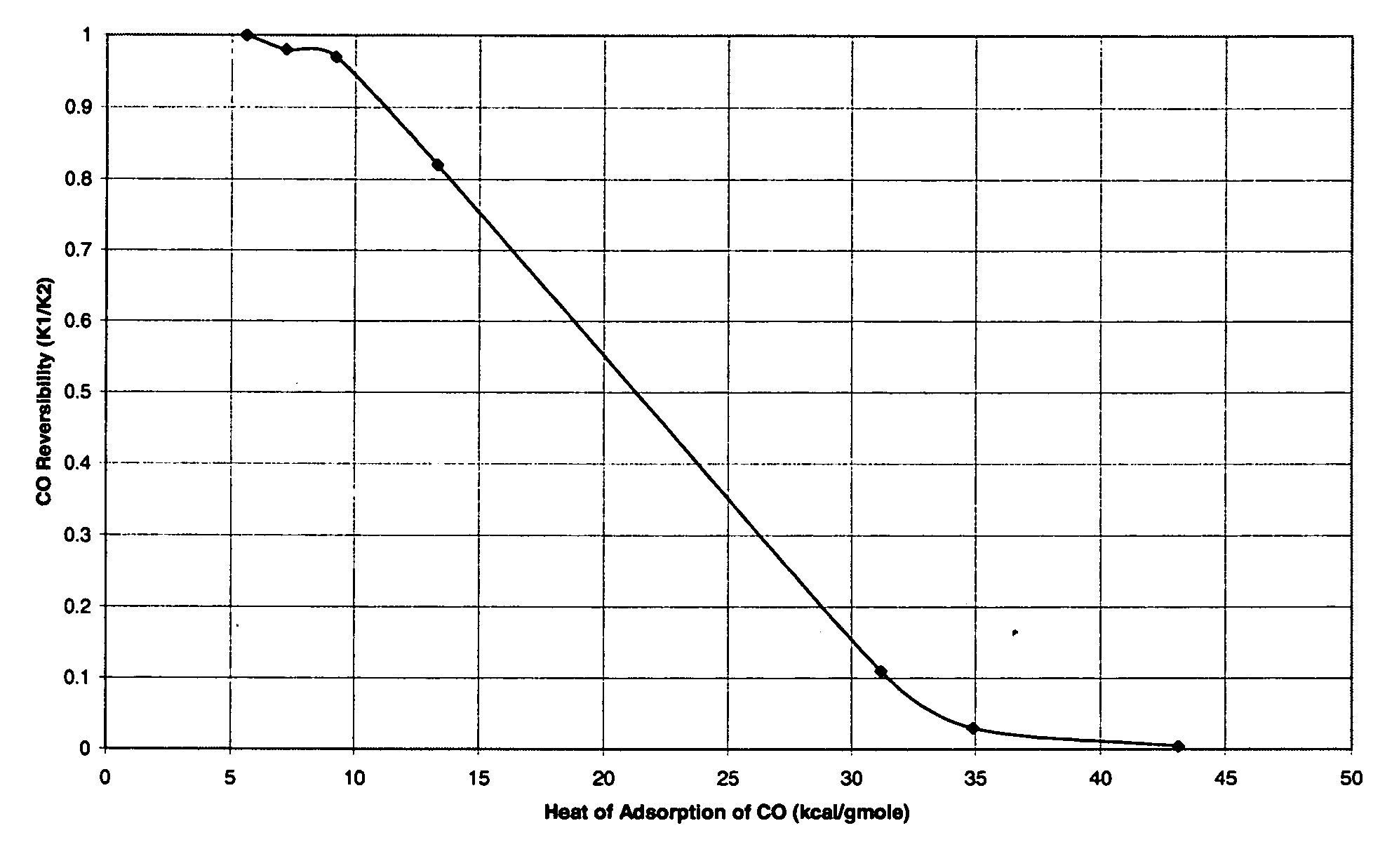

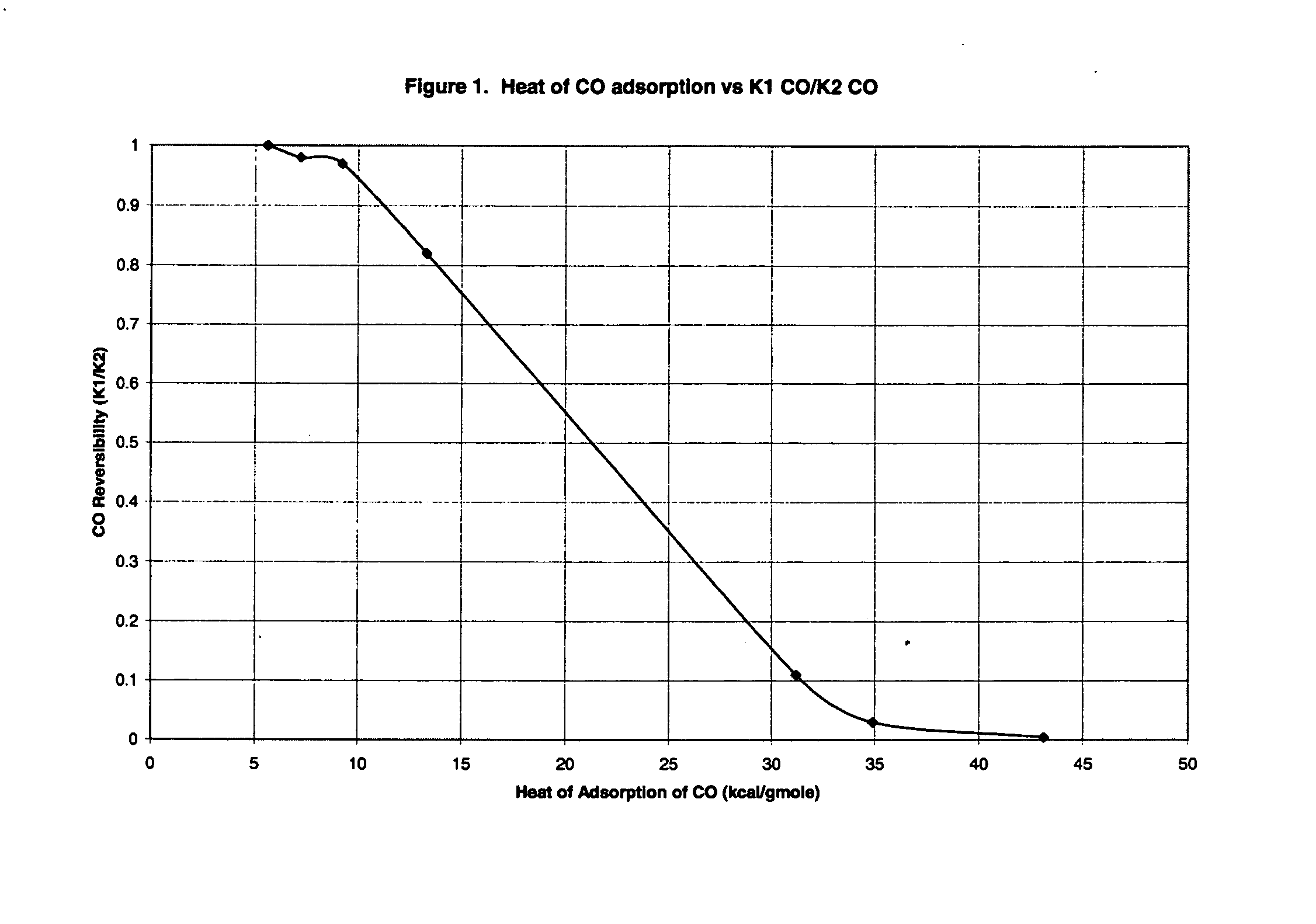

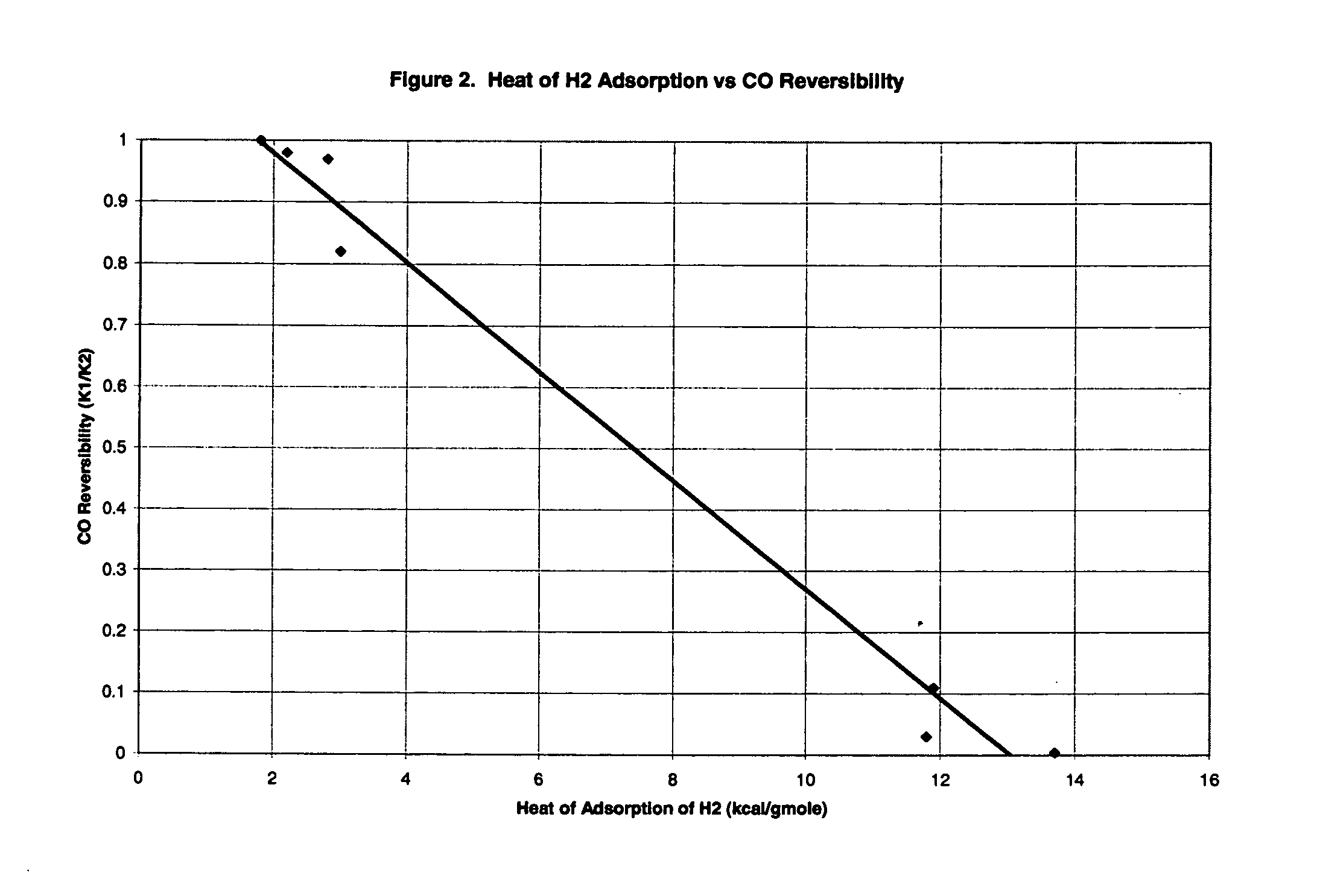

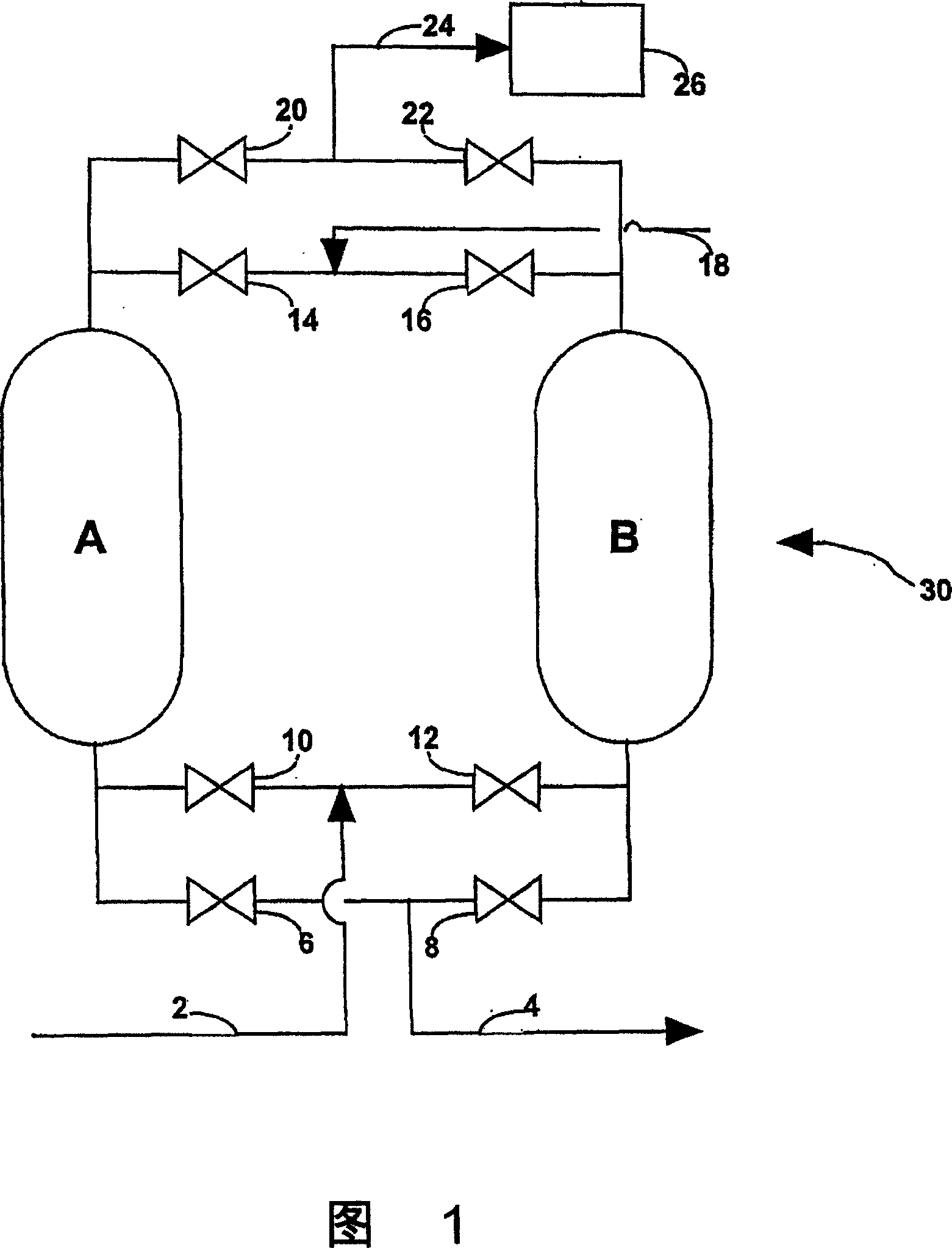

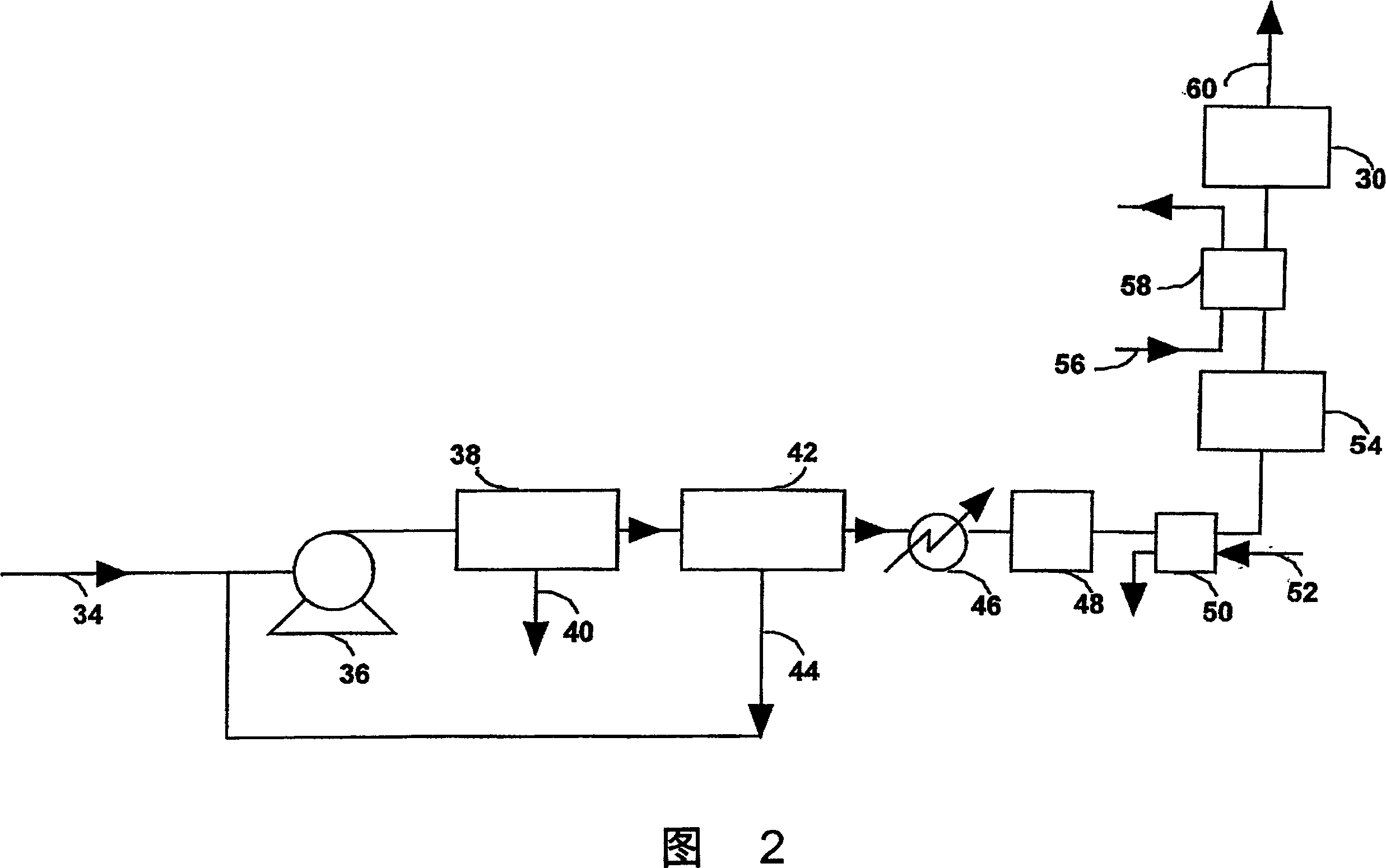

Production of carbon monoxide-free hydrogen and helium from a high-purity source

The invention provides vacuum swing adsorption processes that produce an essentially carbon monoxide-free hydrogen or helium gas stream from, respectively, a high-purity (e.g., pipeline grade) hydrogen or helium gas stream using one or two adsorber beds. By using physical adsorbents with high heats of nitrogen adsorption, intermediate heats of carbon monoxide adsorption, and low heats of hydrogen and helium adsorption, and by using vacuum purging and high feed stream pressures (e.g., pressures of as high as around 1,000 bar), pipeline grade hydrogen or helium can purified to produce essentially carbon monoxide -free hydrogen and helium, or carbon monoxide, nitrogen, and methane-free hydrogen and helium.

Owner:AIR PROD & CHEM INC

Gas purification method

The present invention provides for a method for purifying a carbon monoxide-containing gas stream that contains hydrocarbon impurities, such as methane, by using a cryogenic temperature swing adsorption method, at cryogenic temperatures below -75 DEG C. The carbon monoxide-containing gas stream may be pre-purified by membrane separation or vacuum swing adsorption or cryogenic distillation.

Owner:BOC GRP INC

Processes for the recovery of high purity hydrogen and high purity carbon dioxide

ActiveUS8303930B2Carbon compoundsHydrogen separation using solid contactThermodynamicsProcess engineering

The present invention relates to various processes for recovering high purity gaseous hydrogen and high purity gaseous carbon dioxide from the gas stream produced using steam hydrocarbon reforming, especially steam methane reforming, utilizing a H2 pressure swing adsorption unit followed by either a CO2 vacuum swing adsorption unit or a CO2 vacuum swing adsorption unit in combination with an additional CO2 pressure swing adsorption unit. By using an uncoupled H2 PSA and CO2 VSA unit it is possible to produce high purity H2 and high purity CO2. The present invention further relates to a process for optimizing the recovery of CO2 from waste gas streams produced during the hydrogen purification step of a steam hydrocarbon reforming / H2 pressure swing adsorption unit utilizing either a CO2 vacuum swing adsorption unit or a CO2 vacuum swing adsorption unit in combination with a CO2 pressure swing adsorption unit. The present invention even further relates to the apparatus necessary to carry out the various processes of the present invention.

Owner:AIR LIQUIDE AMERICA INC +1

Pressure and vacuum swing adsorption separation processes

A pressure or vacuum swing adsorption process for separating water from solvent utilizing molecular sieves and regenerating the molecular sieve by passing non-condensable recycled gas along the molecular sieve, capturing the recycled gas and using the recycled gas again to repeat regeneration of the molecular sieve.

Owner:WINTEK IND SYST INC

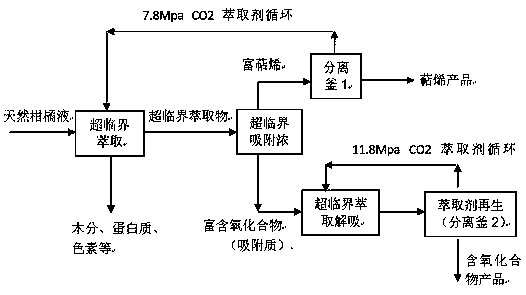

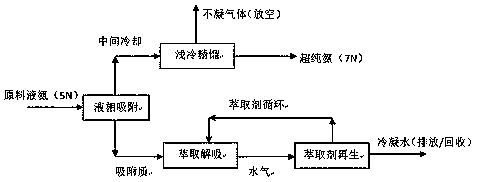

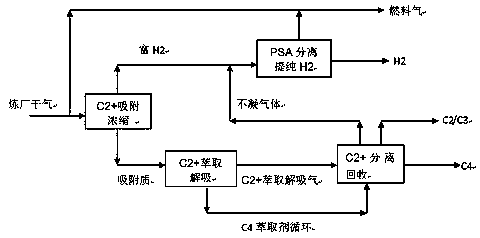

Adsorption extraction separation and purification method

InactiveCN107774092ASolve the bottleneck problem of easy adsorption-difficult desorptionImprove unityIon-exchange process apparatusGas treatmentPurification methodsDesorption

The invention discloses an adsorption extraction separation and purification method. According to the adsorption extraction separation and purification method, by virtue of difference in temperaturesand pressures of different raw material streams as well as selective adsorption capacities and selective dissolution capacities between an adsorbate component and a non-adsorbed phase component on anadsorbent and an extractant, adsorption concentration, extraction desorption, extractant regeneration, refining purification and other processes are performed; the extractant is used for dissolving out the adsorbate adsorbed by the adsorbent in the adsorption concentration process and the adsorbate remaining in a dead space inside an adsorption tower, and is recycled in the extractant regenerationprocess; a non-adsorbed phase fluid escaping out in the adsorption concentration process can be recycled through the refining purification process. By the adsorption extraction separation and purification method, simultaneous high-purity and high-yield separation, purification and recycling of the target adsorbate component and the target non-adsorbate component are achieved; cycle operation of isothermal and isobaric, isothermal and pressure-swing, temperature-swing and isobaric, and temperature-swing and pressure-swing adsorption and extraction desorption can be achieved, and a brand-new technical method is provided for adsorption separation and purification.

Owner:SICHUAN TECHAIRS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com