Mineral separation and enrichment method suitable for associated scheelite in molybdenite floatation tailings

A technology for flotation tailings and scheelite, which is applied in chemical instruments and methods, wet separation, recycling technology, etc., can solve problems such as low recovery rate, low grade, and poor flotation effect of scheelite, and achieve Improve the total recovery rate, increase the recovery rate of gravity separation, and improve the effect of monomer dissociation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Sulfide ore flotation tailings contain WO 3 The grade is 0.082%, and the strong magnetic minerals are removed through the magnetic separation of drum-shaped wet weak magnetic separator (field strength 1000Oe), and the weak magnetic minerals, strong magnetic minerals and weak magnetic Minerals are merged into magnetic tailings with a yield of 66.73%, WO 3 The grade is 0.023%; the yield of the remaining non-magnetic minerals is 33.27%, WO 3 Grade 0.20%, WO 3 The operating recovery rate is 81.26%, and scheelite is pre-enriched in non-magnetic minerals.

[0060] Sieve and classify the non-magnetic minerals into three grades of +0.074mm, -0.074mm+0.045mm, -0.045mm, and carry out shaking table gravity separation respectively to obtain concentrate, medium ore and tailings respectively; the medium ore is shaken again Bed gravity separation, divided into concentrate, middle ore and tailings. The concentrate, medium ore and tailings selected by each particle size are combined...

Embodiment 2

[0062] The sulfide ore flotation tailings are subjected to the same magnetic separation operation as in Example 1, and the obtained strong magnetic minerals and weak magnetic minerals are combined into magnetic tailings, with a yield of 66.73%, WO 3 The grade is 0.023%; the yield of the remaining non-magnetic minerals is 33.27%, WO 3 Grade 0.20%, WO 3 The job recovery rate is 81.26%.

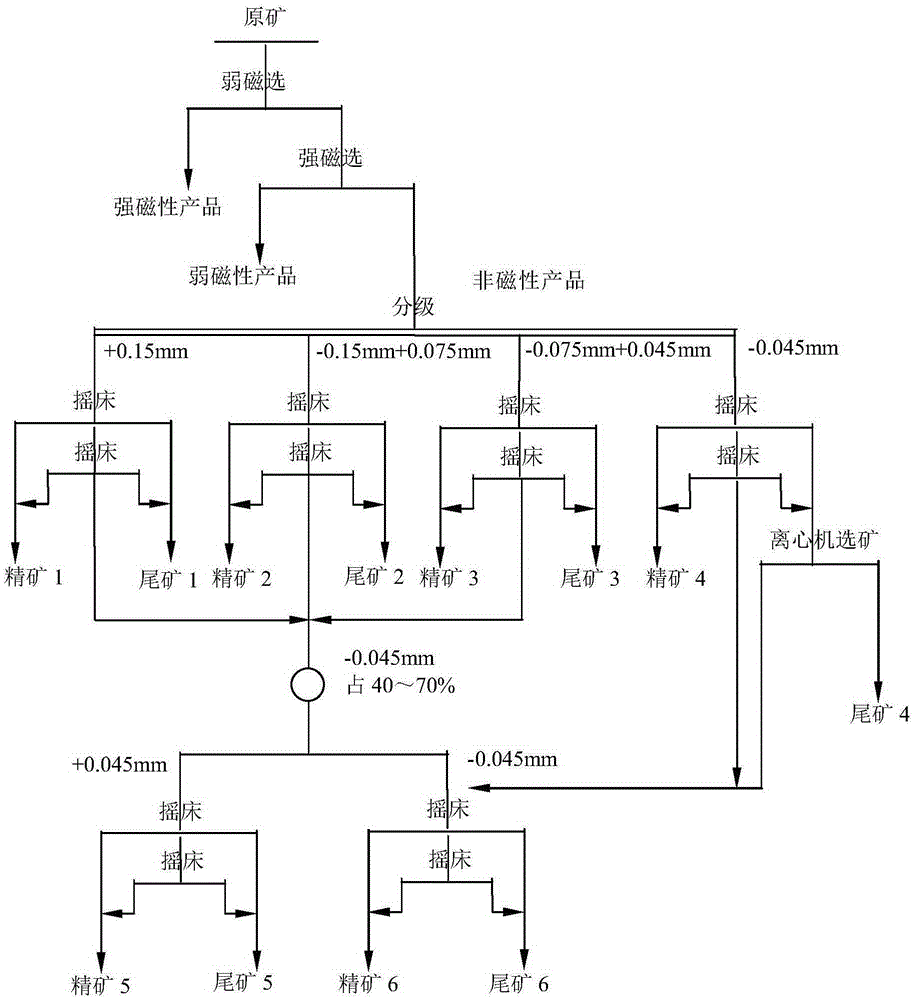

[0063] Sieve and classify non-magnetic minerals into four grades of +0.15mm, -0.15mm+0.074mm, -0.074mm+0.045mm, -0.045mm, and carry out shaker gravity separation respectively to obtain concentrate, medium ore and tailings ore; the middle ore of the first shaking table is re-selected by the second shaking table, and is also divided into concentrate, middle ore and tailings. The concentrates, middlings and tailings selected from each particle size are combined separately to obtain concentrate products 1, 2, 3, 4 and tailings 1, 2, 3, 4 of different particle sizes.

[0064] Merge three parts of ...

Embodiment 3

[0069] The sulfide ore flotation tailings are subjected to the same magnetic separation operation as in Example 1, and the obtained strong magnetic minerals and weak magnetic minerals are combined into magnetic tailings, with a yield of 66.73%, WO 3 The grade is 0.023%; the yield of the remaining non-magnetic minerals is 33.27%, WO 3 Grade 0.20%, WO 3 The job recovery rate is 81.26%.

[0070] Sieve and classify non-magnetic minerals into four grades of +0.15mm, -0.15mm+0.074mm, -0.074mm+0.045mm, -0.045mm, and carry out shaker gravity separation respectively to obtain concentrate, medium ore and tailings ore; the middle ore of the first shaking table is re-selected by the second shaking table, and is also divided into concentrate, middle ore and tailings. The concentrated ore, medium ore and tailings selected from each particle size are respectively combined to obtain concentrate products 1, 2, 3, 4 and tailings 1, 2, 3, 4 of different particle sizes.

[0071] The tailings 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com