Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

391 results about "Magnetic minerals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

These are some of the more common minerals that demonstrate magnetic properties: Babingtonite (weakly) Chromite (weakly) Columbite (weakly) Ferberite (weakly) Franklinite (weakly) Ilmenite (weakly, always when heated) Iron-nickel (attracted to magnets)

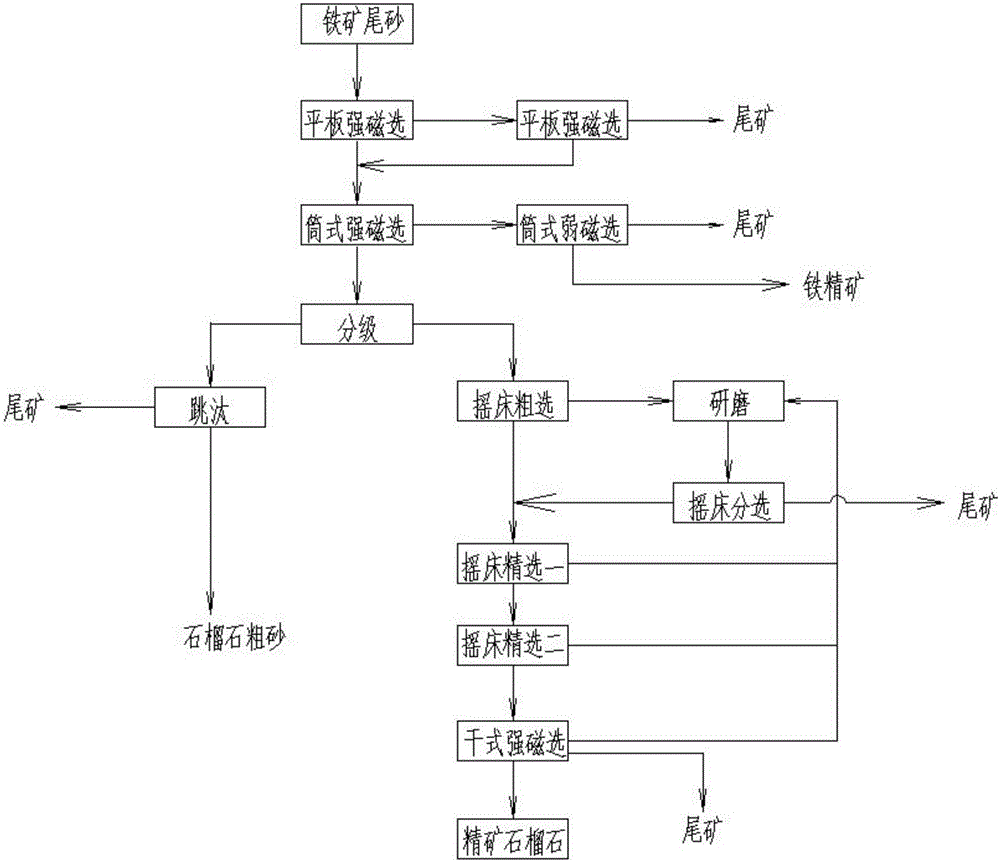

Technique for separating mineral from weak magnetic separation iron tail sand

InactiveCN101219412AProduction process specificationLow costElectrostatic separationFlotationApatiteNon magnetic

The invention relates to a method used for separating minerals from weak magnetic iron tails, which is divided into six stages: primary sorting of strong magnetic minerals, separation of strong magnetic minerals, separation of weak magnetic minerals, separation of non-magnetic minerals, treatment of ore pulp water during the ore dressing process and treatment of finish tail sand. According to the magnetic susceptibility differences, specific gravitydifferences and floating differeces between minerals, magnetite, vanadium titano-magnetite, mixed ore of apatite and xenotime and hematite feldspar concentrate can be separated from the weak magnetic iron by using techniques of crude separation with a strong magnetic separator, refine separation with a weak magnetic separator, gravity separation, floatation, electric separation, etc. The method has advantages of standard production technique, low cost for industrialized production, great variety of separated minerals, stable quality and high separating efficiency, thereby having significant social and economic benefits.

Owner:冯云善

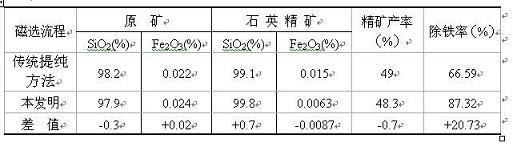

Efficient magnetic separation method for quartz sand

InactiveCN102626668AIncrease production capacityReduce unit energy consumptionWet separationPurification methodsNo production

The invention discloses an efficient purification method for quartz sand. In the method, two-section smashing (rough smashing and fine smashing) and ore milling with a rod mill are adopted, so that the production capacity is increased greatly, unit energy consumption is lowered, and the method is suitable for large-scale production. A method for removing weakly-magnetic minerals and intergrowth quartz with high iron content from quartz sand through advanced ore washing and weakly magnetic-high gradient strongly magnetic combined magnetic separation before ore milling is adopted, so that the purity of quartz sand is increased greatly. The method has the advantages of simple process flow, easiness for operating, low cost, high purification efficiency, stable performance and environmental friendliness of a produced product, no use of any chemical substance in an entire production process, no production of any waste water, waste residues and waste gas, true realization of zero emission, no production of waste and prevention of pollution. The method is not limited by the production scale, various quartz sand products of low, medium and high grades can be produced, the enterprise profit can be maximized, and the method has a wide application prospect on the aspect of purification of quartz sand.

Owner:赣州金环磁选科技装备股份有限公司

Ore dressing process of oolitic high phosphorus hematite

The ore dressing process of oolitic high phosphorus hematite includes the following steps: roasting crushed oolitic high phosphorus hematite in 80-99 wt% with coal powder as reductant in 1-20 wt% inside a shaft furnace or rotary kiln at 700-1050 deg.c for 0.5-2.5 hr and sealed cooling to room temperature; crushing the roasted hematite, grinding and weak magnetic separation; regulating pH value of the coarse concentrate to 8-12, adding iron ore inhibitor sulfonated starch in 0.5-3.0 kg / ton, activator in 0.2-2.0kg / ton and collecting agent in 0.2-3.0kg / ton and final reverse floatation. The process converts the weak magnetic hematite into strong magnetic mineral, concentrates iron mineral via weak magnetic separation and eliminate P, Si and other impurities in reverse floatation, and can obtain iron concentrate with iron grade higher than 63 %, P content less than 0.15 %, and iron recovering rate over 75 %.

Owner:WUHAN UNIV OF SCI & TECH

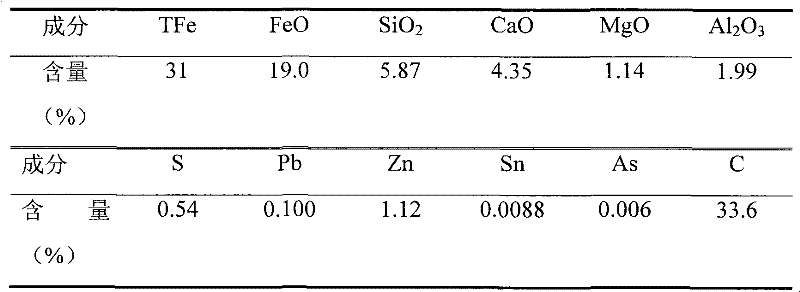

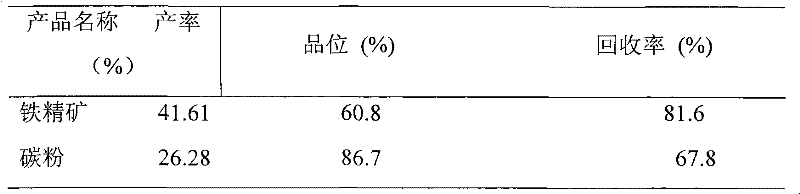

Technology for recovering iron ore concentrate and coke powder from blast furnace gas dust or gas sludge

InactiveCN102392125AHigh recovery rateThe process is simple and continuousFlotationProcess efficiency improvementSludgeMagnetization

The invention relates to a technology for recovering iron ore concentrate and coke powder from blast furnace gas dust or gas sludge, characterized by using coke carried by the gas dust (sludge) as a reducing agent, carrying out magnetization roasting on the gas dust (sludge), converting the weak magnetic iron ore in the gas dust (sludge) into strongly magnetic mineral, then recovering through magnetic separation, and recovering excess carbon powder through flotation. The technology comprises the following main steps: 1) sending the dried gas dust (sludge) in a furnace, and carrying out reduction magnetization roasting; 2) carrying out wet grinding and weak magnetic separation on the roasted gas dust (sludge) to obtain the iron ore concentrate; and 3) carrying out flotation on the magnetically selected tailings to obtain the coke powder. The technology has the advantages of simple and continuous process, low energy consumption, and high recovery rate of iron and carbon, and realizes the comprehensive utilization of the gas dust (sludge).

Owner:INNER MONGOLIA UNIV OF SCI & TECH

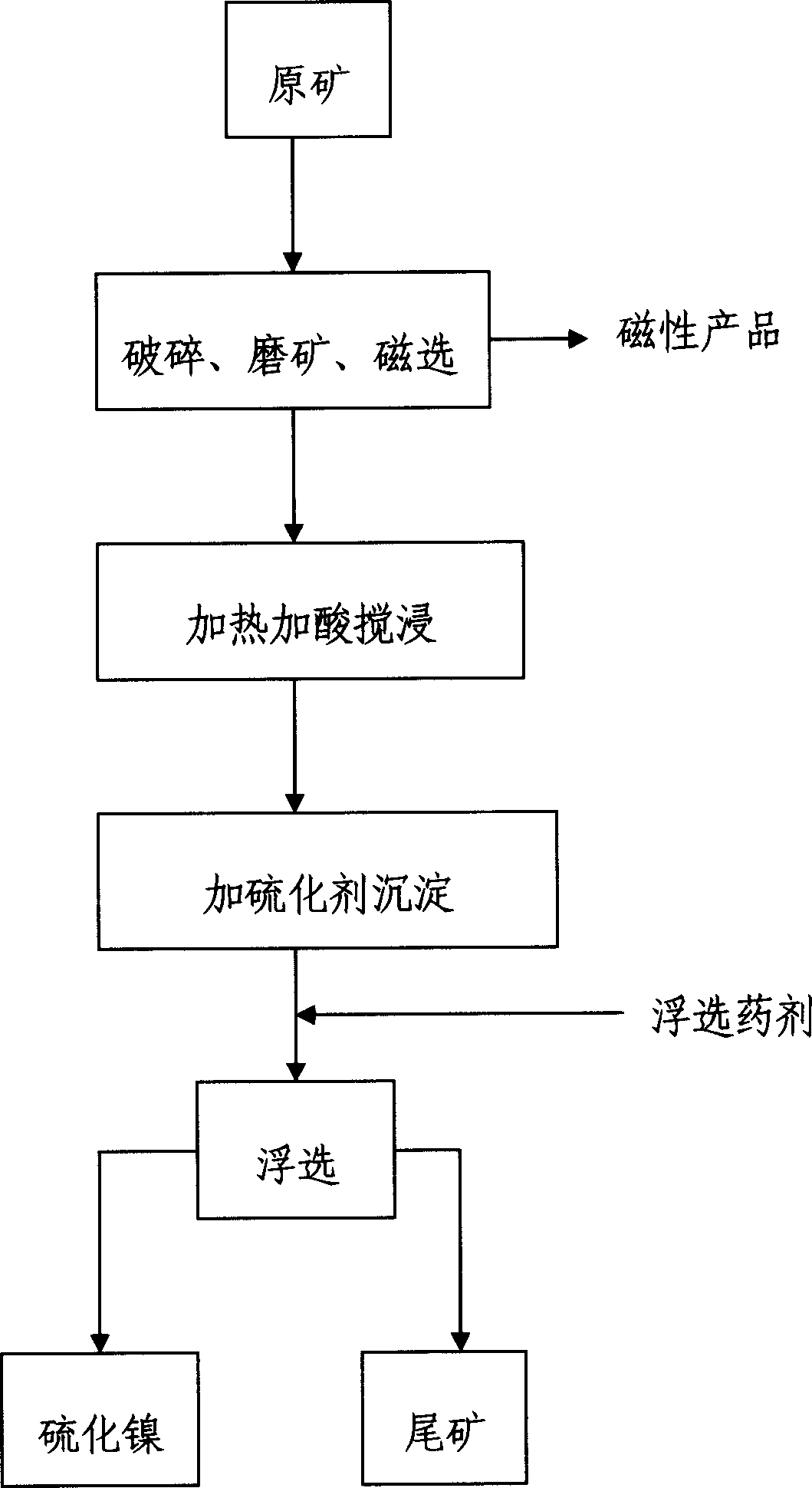

New treating method for nickel oxide ore

InactiveCN1858274AEfficient use ofHigh recovery rateFlotationProcess efficiency improvementChemical reactionNickel sulfide

The new nickel oxide ore treating process has synthesized chemical metallurgy and ore dressing technology. The technological process includes crushing ore, grinding ore into ore pulp, magnetically separating out strong magnetic mineral, heating ore pulp and leaching out with concentrated sulfuric acid, adding sulfurizing agent for chemical reaction to produce nickel sulfide precipitate, and floating out nickel sulfide concentrate. The technological process is simple, low in production cost, high in nickel oxide leaching rate, effective utilization of resource and environment friendship.

Owner:YUNNAN TIN GROUP HLDG

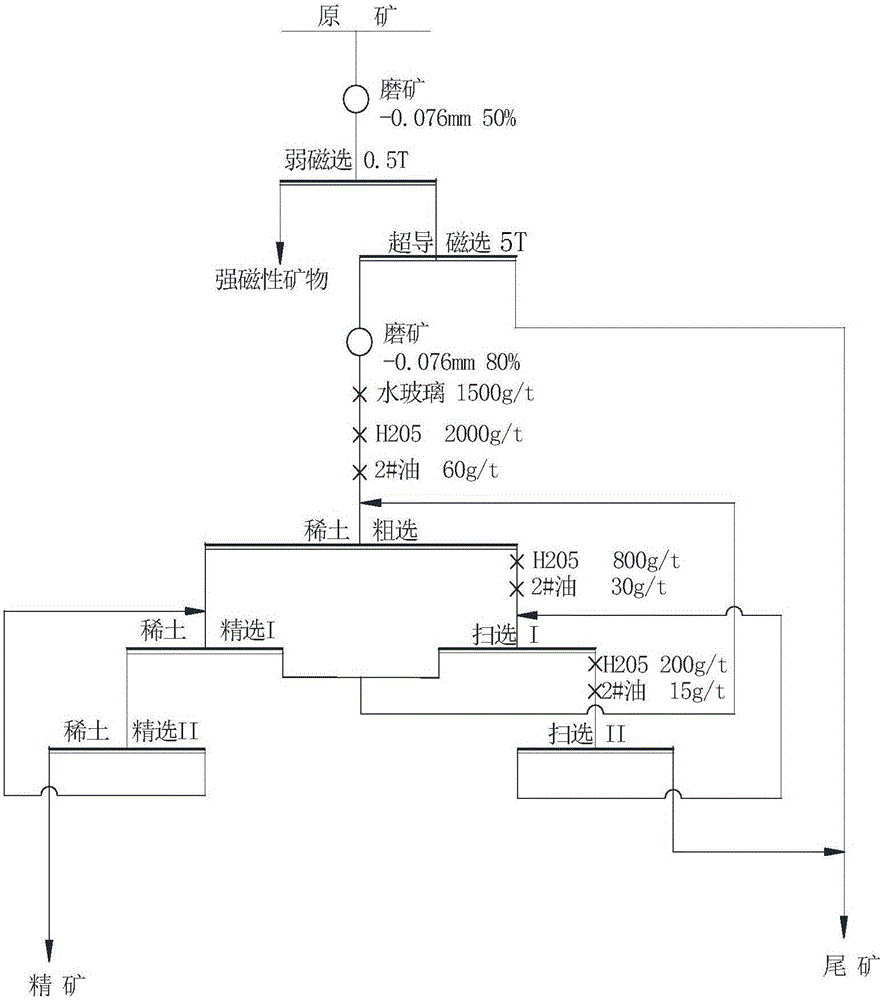

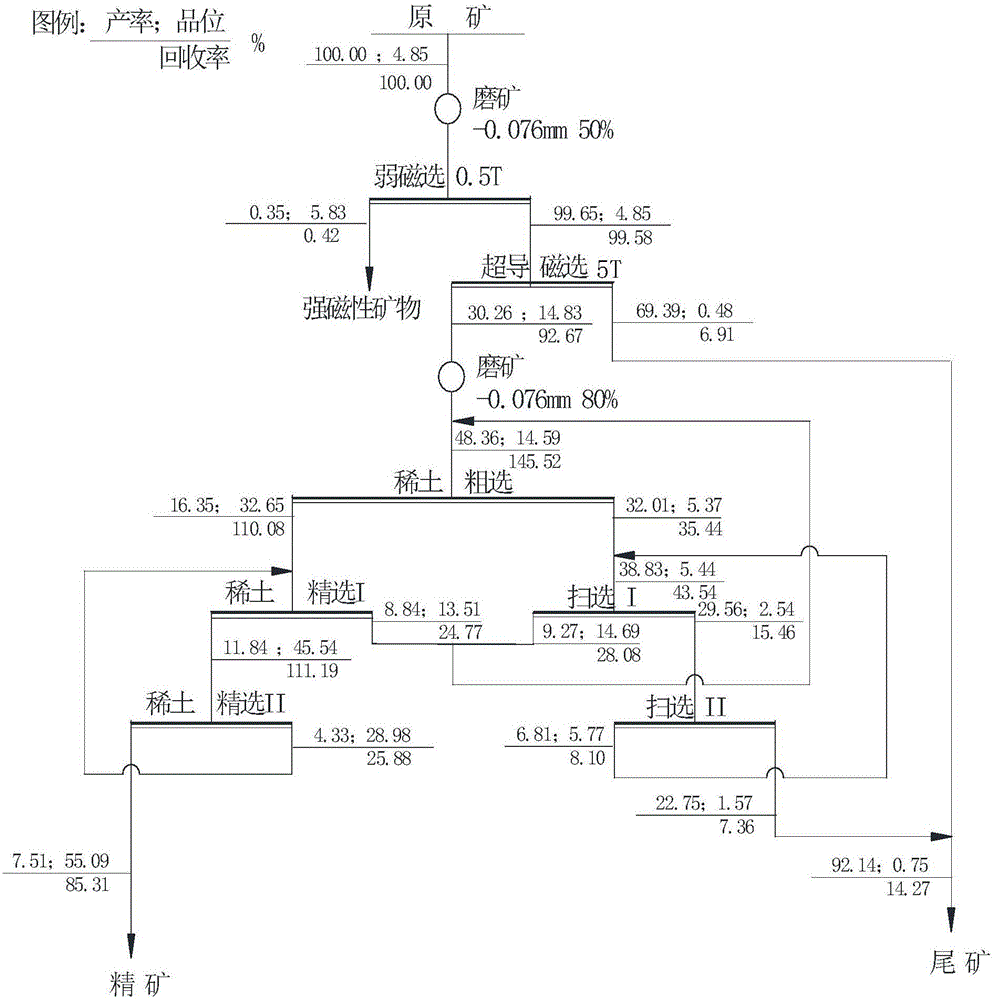

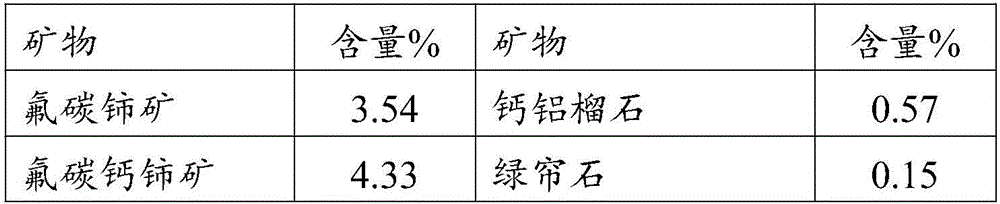

Beneficiation method of rare earth ore

ActiveCN106799300AReduce the amount requiredQuality assuranceWet separationRare earthUltimate tensile strength

The invention discloses a beneficiation method of rare earth ore. The beneficiation method comprises the steps that crude ore is subjected to crushing and ore grinding till the crude ore with the fineness being -0.076 mm accounting for 50% or above, low intensity magnetic separation is carried out to remove strongly magnetic minerals, then superconducting magnetic separation rougher flotation is carried out to obtain rare earth rough concentrates, the rare earth rough concentrates are ground till the rare earth rough concentrates with the fineness being -0.076 mm accounting for 80% or above, conventional flotation work is carried out, and final rare earth ore concentrates are obtained; conventional flotation work includes the processes of one-section rougher flotation, two-section concentration and two-section scavenging; according to low intensity magnetic separation, the magnetic field intensity ranges from 0.1 T to 0.5 T, and the magnetic field force is (3-15)*10<5>kA<2> / m<2>; and according to superconducting magnetic separation, the magnetic field intensity is larger than 0.5 T, and the magnetic field force is larger than 3*10<7>kA<2> / m<2>. According to the method, the high-grade rare earth rough concentrates can be obtained through superconducting magnetic separation, a large quantity of tailings can be thrown out, the grading efficiency is high, the two-section ball grinding ore feeding quantity is greatly reduced, grinding and selecting energy consumption is reduced, the rare earth grade of the obtained rare earth ore concentrates is improved, and the recovery rate is high.

Owner:江苏旌凯中科超导高技术有限公司

Method for recovering valuable metal mineral in zinc tailing

ActiveCN101797531AImprove sorting efficiencyEffective development and utilizationMagnetic separationWet separationMaterials scienceTin

The invention relates to a method for comprehensively recovering a valuable metal in a zinc tailing and belongs to the technical field of metal beneficiation. The process procedure comprises the following steps: roughing the prepared zinc tailing under the magnetic field strength of 8,000 to 12,000 OE by taking an attractive mineral in the zinc tailing as a carrier; performing ore grinding on the magnetic material until the magnetic material which can pass through 200 meshes screen accounts for 60 to 70 percent for dissociating lead-zinc combination; selecting the ground magnetic mineral under the magnetic field strength of 2,500 to 4,000 OE to obtain an iron ore concentrate finished product with the grade of iron over 60 percent; and sorting a nonmagnetic material through a multi-section table to obtain a tin-rich middling product with the grade of tin over 3 percent. The method has the advantages of increasing recovery rate of a tin metal, recovering ferrous metal and manganese metal in the zinc tailing, and effectively utilizing the tailing resource, along with simple beneficiation process flow, low production cost, environmental-friendliness and good application and popularizing prospect; and the fruit can be spread and applied to the development and exploiting of high-ferric and low-tin resources.

Owner:YUNNAN TIN GROUP HLDG

Rutile beneficiation method comprising magnetic separation, tailing discarding reselection. desliming and fine particle floatation

InactiveCN103586124AReduce the amount of incoming flotationReduce the cost of beneficiationWet separationConcentration ratioNon magnetic

The invention relates to a rutile beneficiation method comprising magnetic separation, tailing discarding reselection, desliming and fine particle floatation. According to the method, raw rutile is crushed and screened to have a certain feed size of ore grinding; obtained rutile particles are ground to a certain particle size through an ore grinding machine to obtain ore pulp with a certain concentration through preparation; the ore pulp is led to an intensity magnetic separator for separation to obtain magnetic minerals and non-magnetic minerals; the non-magnetic minerals are subjected to the reselection for desliming to obtain ore concentrate, and then the ore concentrate is dewatered to a certain concentration; the dewatered ore concentrate is subjected to the floatation operation, gangue mineral inhibitors, rutile activators, collectors and foaming agents are added in the dewatered ore concentrate, the rutile is subjected to the flotation, and after rough separation, 1-2 times of fine separation and scavenging are carried out in sequence, rough concentrate of the flotation rutile is obtained; the rough concentrate of the flotation rutile is subjected to the magnetic separation to eliminate magnetic impurities and then eliminate sulphur and phosphorus impurities through roasting and acid pickling, and finally high-grade rutile concentrate is obtained. The method has the advantages that the process procedure is simple, beneficiation cost is low, the recovery rate is high, and the concentration ratio is high.

Owner:CENT SOUTH UNIV +1

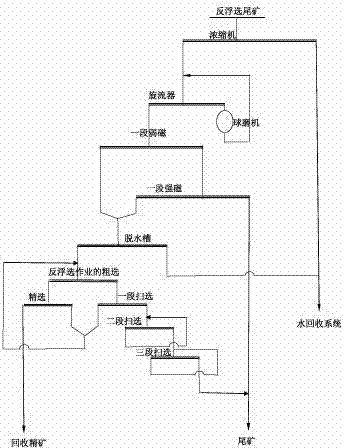

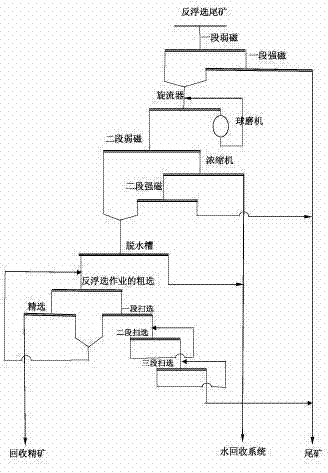

Hematite reverse flotation tailings re-election process

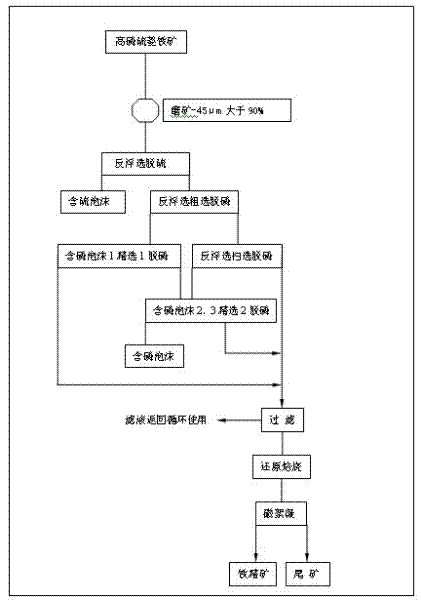

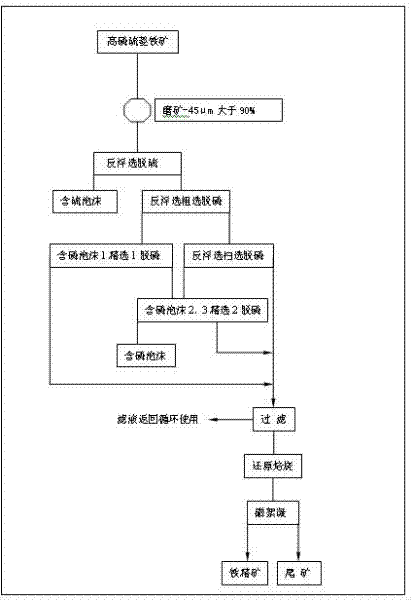

The invention relates to the technical field of hematite reverse flotation tailings, in particular to a hematite reverse flotation tailings re-election process, which is characterized in that the stage grinding of lean hematite, magnetic separation-gravity separation-anion reverse The reverse flotation tailings in the flotation combined process are re-selected, that is, the reverse flotation tailings are concentrated, then ground to a particle size of -320 mesh with a content of more than 90%, and then subjected to weak magnetic separation, strong magnetic separation-reverse flotation Operation, recovery of magnetic minerals in the reverse flotation tailings, the advantages of the present invention: firstly, the reverse flotation tailings are concentrated and defoamed to reduce the foam in the pulp, which is beneficial to the subsequent sorting operation. The reverse flotation tailings after concentration and defoaming undergo regrinding, weak magnetic, strong magnetic, reverse flotation operations of roughing, selection and three-stage sweeping to decompose the coarse-grained intergrowth monomers in the reverse flotation tailings Separation, separation and recovery of metals in reverse flotation tailings, reducing metal loss and lowering the final tailings grade. The process is simple, the number of equipment is small, and the occupied area is small.

Owner:ANSTEEL GRP MINING CO LTD

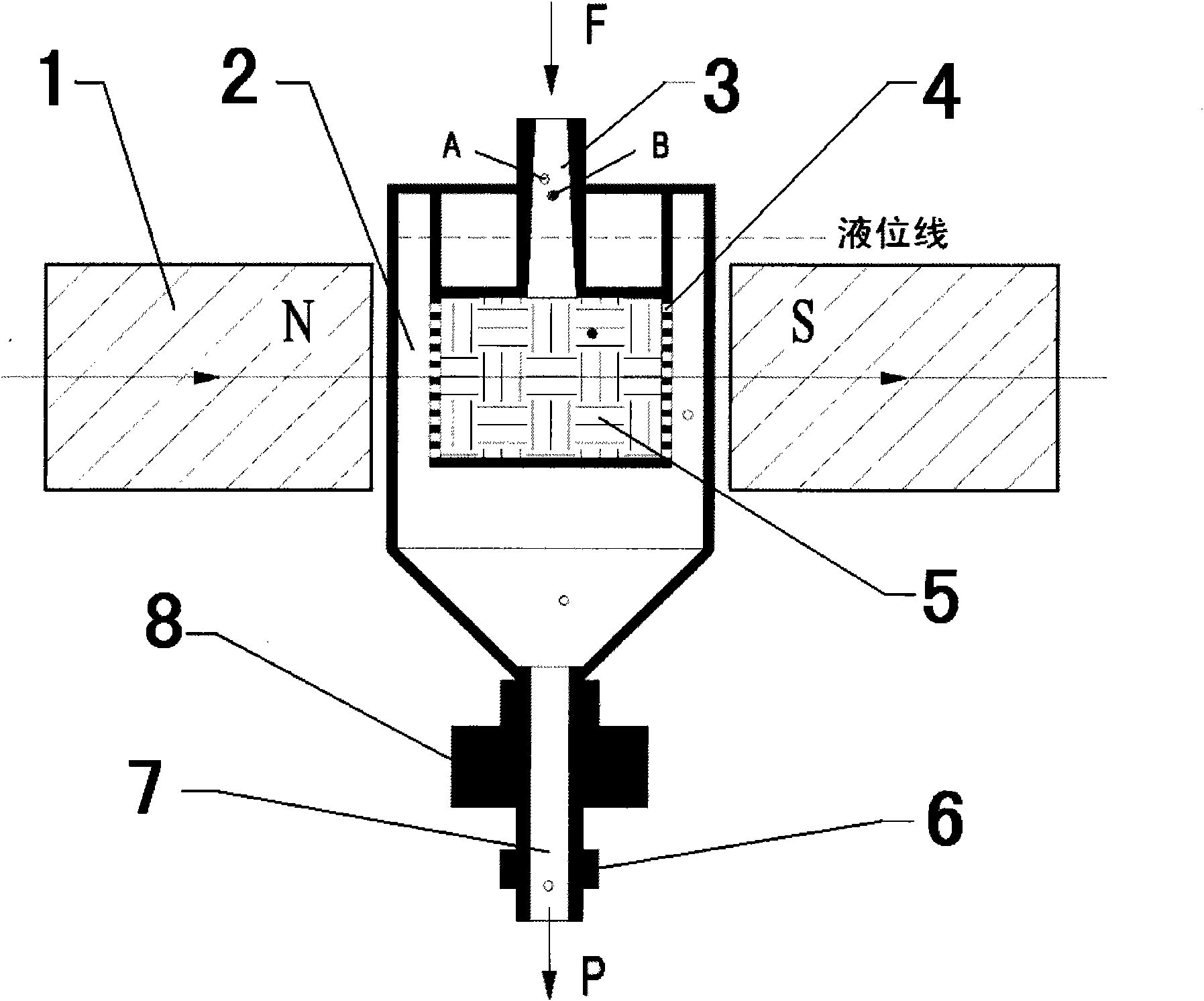

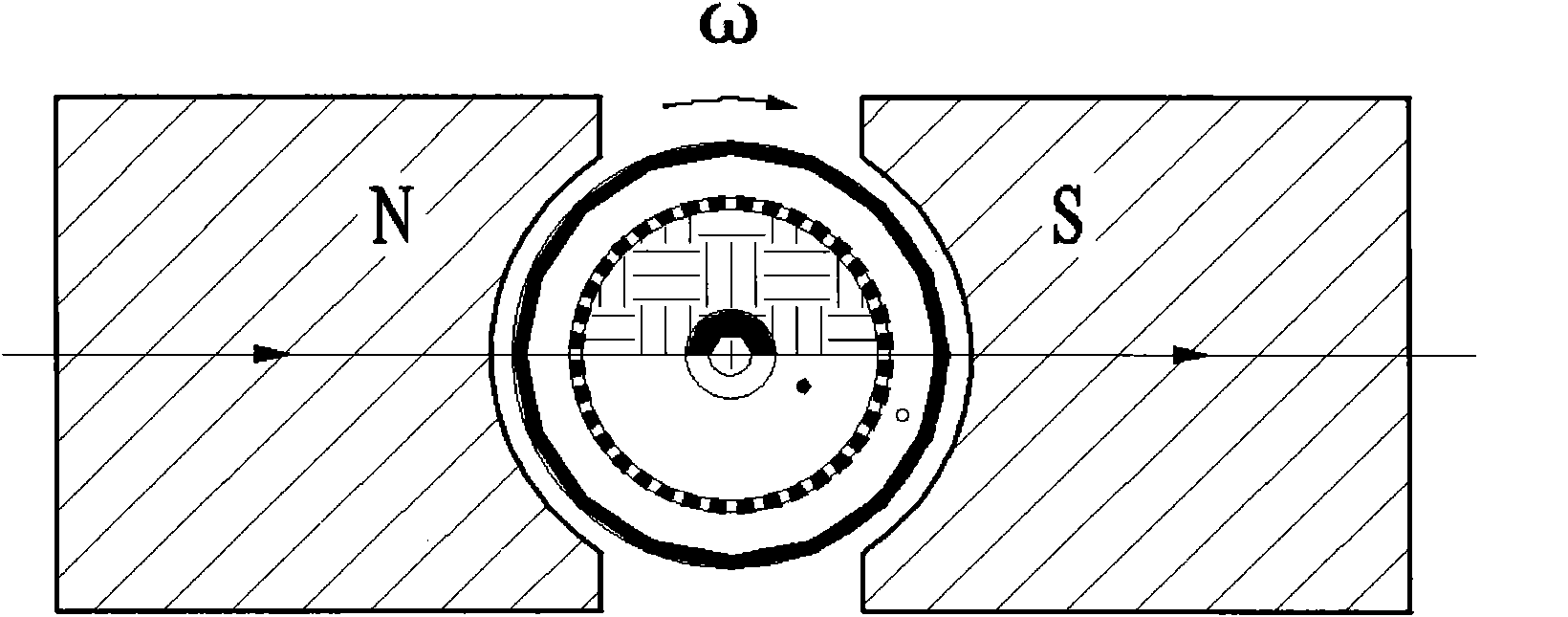

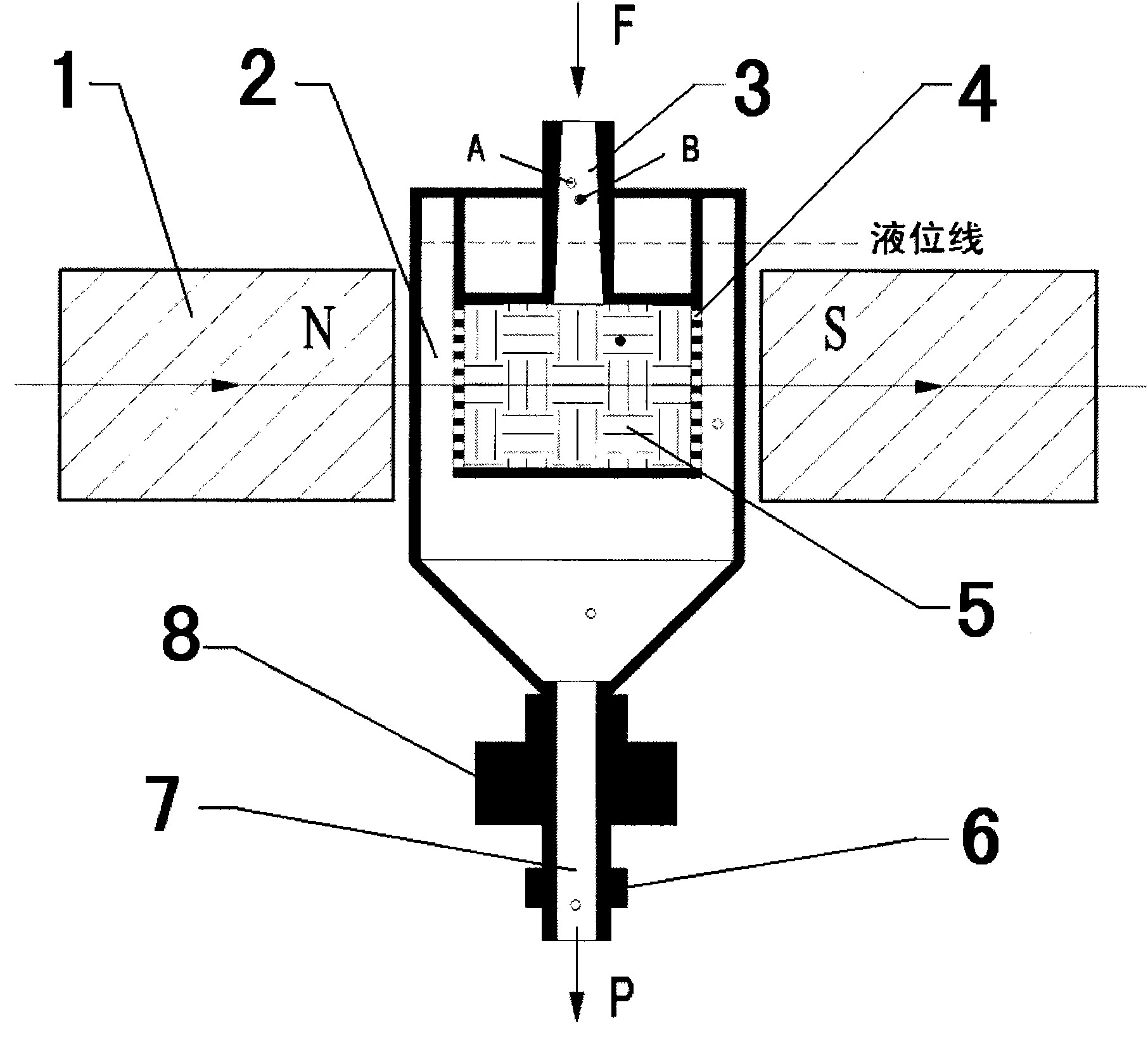

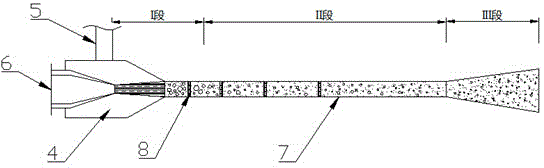

Centrifugal high-gradient magnetic method

InactiveCN101862702AImprove qualityChange magnetic forceMagnetic separationMagnetic tension forceMagnetic media

The invention provides a centrifugal high-gradient magnetic method, which comprises the following steps: a magnetic medium cylinder with magnetic medium is fixed in the middle of a separating cylinder and rotates along with the separating cylinder in magnetic field to form a comprehensive force-field by the competition of high-gradient magnetic field and centrifugal force filed in the magnetic medium. A pulp self-feeding ore taper pipe enters into the magnetic medium cylinder to carry out separation; because magnetic force of magnetic minerals is greater than the centrifugal force, the magnetic medium can capture the magnetic minerals; because the magnetic force of poor intergrowth and gangue is less than the centrifugal force, the poor intergrowth and gangue can pass through the magnetic medium, flow out of a through-hole on a magnetic medium cylinder wall, enter into the separating cylinder and finally flow out of an ore discharging pipe at the bottom. When the magnetic minerals of captured by the magnetic medium is in saturation state, ore-feeding is ceased, the magnetic field is cut and clean water is injected, so that the magnetic minerals are washed out under the action of centrifugal force; the obtained magnetic minerals enter into the separating cylinder and then flow out of the ore-discharging pipe. The method can separate the poor intergrowth and the gangues, can be used for separating various weakly magnetic minerals, in particular being applied to producing high-quality magnetic concentrates from selected fine weakly magnetic ores, is capable of separating fine medium magnetic minerals and has stronger adaptability.

Owner:KUNMING UNIV OF SCI & TECH

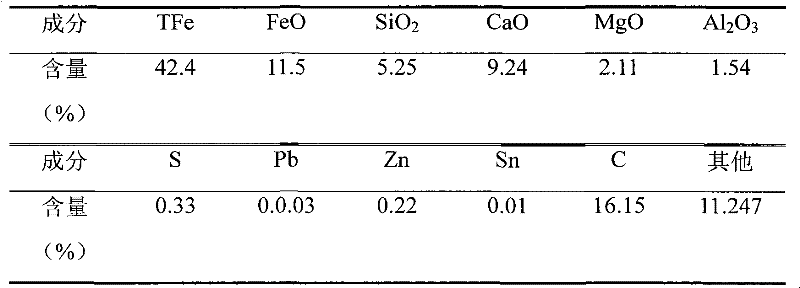

Separation-smelting combined method for producing iron ore concentrate from oolitic lean hematite

InactiveCN101862703ASimple processGood technical and economic indicatorsMagnetic separationCombined methodSlurry

The invention relates to a separation-smelting combined method for producing iron ore concentrate from oolitic lean hematite. The technical scheme first comminutes oolitic lean hematite containing 30 to 40 percent of iron, the comminuted mineral slurry enters a high-intensity magnetic separator and preseparated, weak-magnetic mineral is turned into strong-magnetic concentrate, and tailings are removed in advance; the strong-magnetic concentrate is mixed with pulverized coal, the weight of which accounts for 10 to 30 percent of the weight of the concentrate, and the mixture is heated to 900 DEG C to 1100 DEG C in a muffle furnace, and is magnetically roasted as the temperature is kept for 1 to 3 hours; after being cooled, the magnetically roasted mineral sample is wet-milled, and is then fed into a low-intensity magnetic separator and separated under low-intensity magnetism, magnetic mineral is turned into weak-magnetic concentrate, and thereby high-quality iron concentrate is produced. The grade of the obtained iron concentrate is higher than 64 percent, the phosphor content is less than 0.15 percent, and the sulfur content is less than 0.10 percent. The invention is characterized by simple process flow, good technical and economic indexes and high product quality.

Owner:KUNMING UNIV OF SCI & TECH

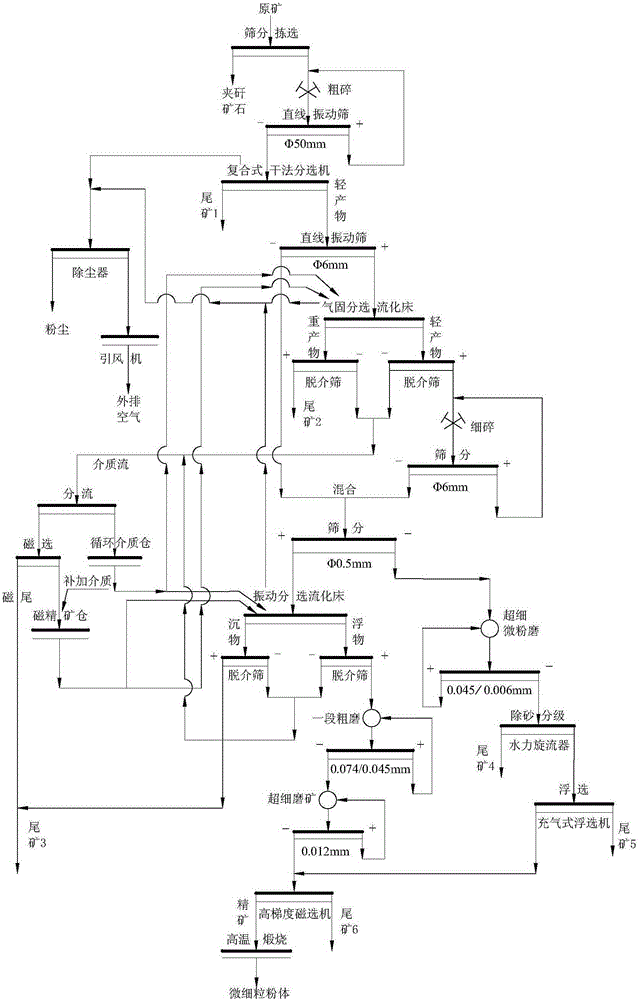

Wide-particle-size coal series kaolinite upgrading process based on fluidization sorting

The invention discloses a wide-particle-size coal series kaolinite upgrading process based on fluidization sorting, and belongs to coal series kaolinite upgrading processes. The process comprises the steps that coal series kaolinite raw ore is firstly subjected to mechanical sorting, coarse crushing, screening and drying, the raw ore of -50 mm enters a composite dry method sorting machine to be pre-sorted, and light products are screened by a vibration screen of 6 mm; the ore of 6 mm to 50 mm passes through a dense gas-solid fluidized bed sorting machine to obtain coarse-grained concentrate and tailings, the concentrate is subjected to medium removal and then finely ground to obtain ore of -6 mm, and the ore of -6 mm and the original ore of -6 mm are evenly mixed and screened by a classifying screen of 0.5 mm; the ore of 0.5 mm to 6 mm passes through a vibrated fluidized bed sorting machine to obtain fine-grained concentrate and tailings; the ore of -0. 5 mm is subjected to ore grinding, sand removal and classification and then passes through a flotation machine to obtain flotation concentrate and tailings; the concentrate of 0.5 mm to 6 mm is ground after being subjected to medium removal, and is mixed with the flotation concentrate, and then titanium and iron-containing high-magnetic mineral is removed through magnetic separation. Medium solids are separated through a medium removal screen and are subjected to dry type magnetic separation and recycled as circulating media. According to the process, efficient sorting of the wide-particle-size coal series kaolinite raw ore is achieved, and great significance for development and utilization of coal series kaolinite resources in our country is achieved.

Owner:CHINA UNIV OF MINING & TECH

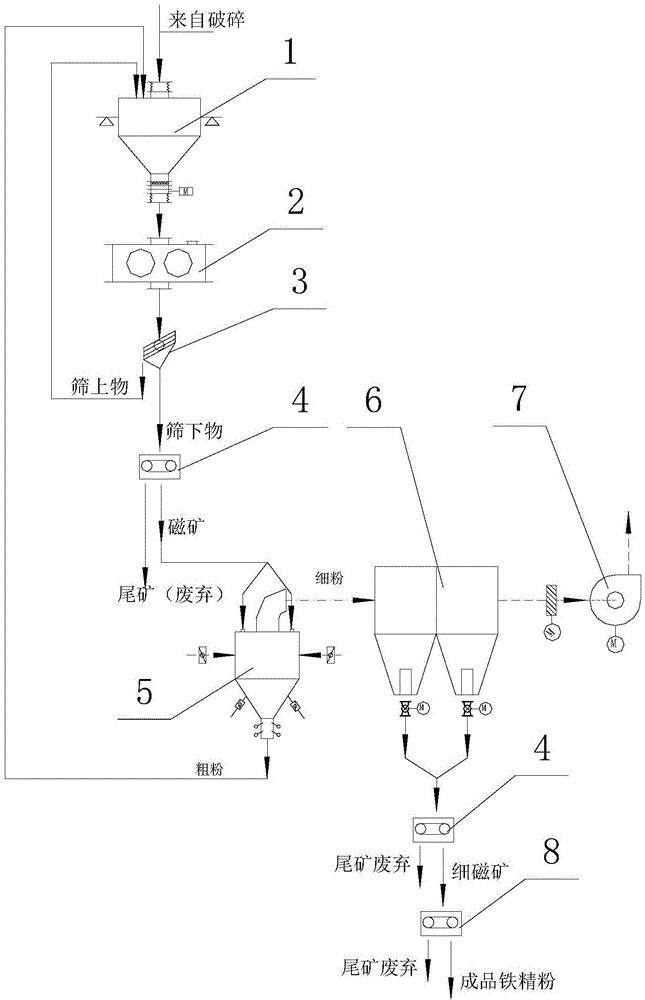

Magnetite dry grinding and dry separation method and device

ActiveCN104815739AReach granularity requirementsReduce power consumptionMagnetic separationGrain treatmentsHigh pressureMechanical screening

The invention discloses a magnetite dry grinding and dry separation method and a magnetite dry grinding and dry separation device, and belongs to the technical field of iron ore selection and grinding. The method comprises the steps of mixing secondarily crushed ore with particle size less than 80mm and coarse-grain return scrap to obtain a mixture I, extruding the mixture I by virtue of a high pressure roller, and mechanically screening the mixture I, wherein the screening granularity is 3mm; returning an oversize product adopted as the coarse-grain return scrap to the high pressure roller to be continuously extruded, separating screen underflow in a dry-type magnetic separator, grading rough concentrate separated by the dry-type magnetic separator by virtue of a wind power powder separation machine, returning coarse powder graded by the wind power powder separation machine and adopted as coarse-grain return scrap to the high pressure roller to be continuously extruded, collecting fine powder meeting the fineness requirement of iron fine powder after the grading of the wind power powder separation machine, separating the fine powder by virtue of the dry-type magnetic separator, and finally carrying out the wet-type magnetic separation for fine magnetic minerals meeting the fineness requirement of the iron fine powder after the separation of the dry-type magnetic separator. By adopting the magnetite dry grinding and dry separation method, the crushing grinding and the magnetic separation of the ore are reasonably matched, so that the system energy consumption is reduced, consumption of steel and water is reduced, and the environmental pollution is alleviated.

Owner:成都建筑材料工业设计研究院有限公司

Separation of plastic and elastomers for food and pharmaceutical products

InactiveUS20070205529A1Considerable effectEliminate riskElectrostatic separationControl devices for conveyorsElastomerBiochemical engineering

Contaminants in food or pharmaceuticals derived from the handling equipment are detected by known detection devices in product flow by the method of detecting particulate magnetic mineral dispersed in the handling equipment or the film used to wrap the food. The minerals magnetic field is detected and the signal generated thereby causes rejection of the product which contains the contamination. A method of making moulded parts of the handling equipment and wrapping film by incorporation of ferrimagnetic ceramic fillers is disclosed. Compositions for moulding and film extrusion with 10-50% of magnetite and other magnetic fillers with a size range of 0.5-20μ are disclosed.

Owner:MAY DONALD BRUCE +1

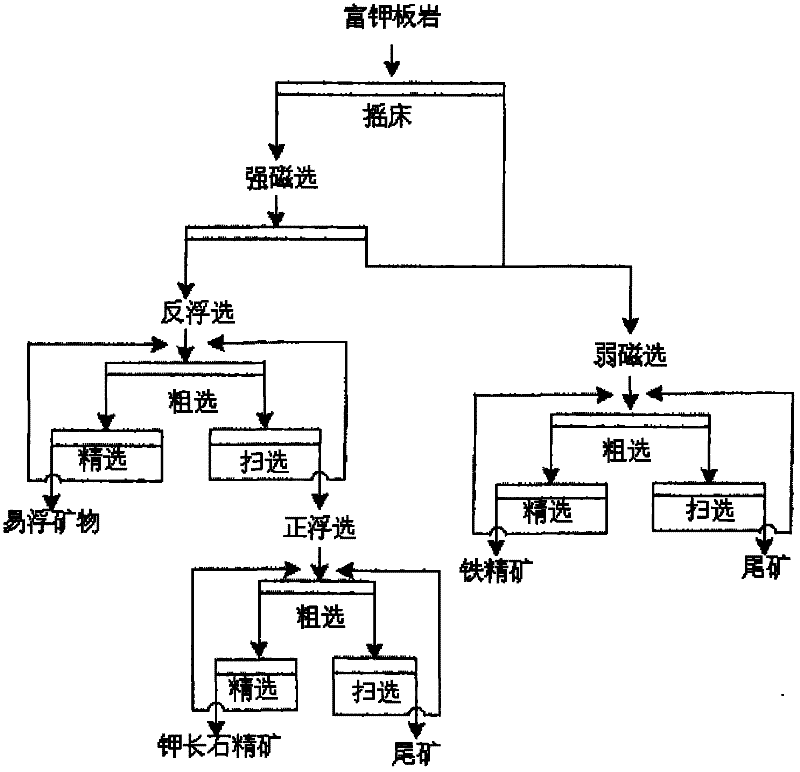

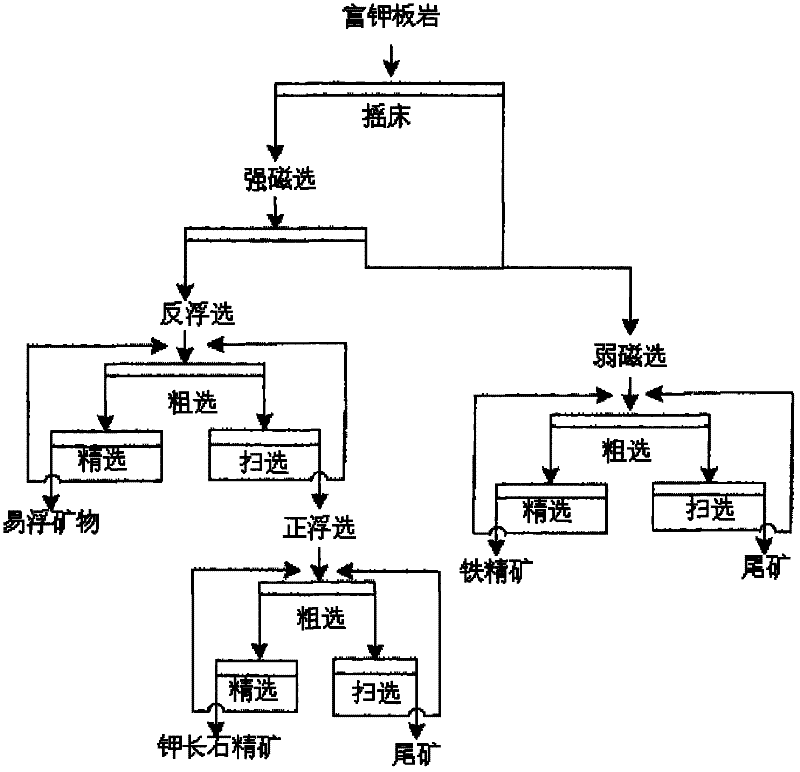

Method for separating potassium feldspar ore concentrate and iron ore concentrate from Baiyunebo potassium rich slate

The invention relates to a method for separating potassium feldspar ore concentrate and iron ore concentrate from Baiyunebo potassium rich slate, and belongs to the field of ore dressing. The method comprises the following steps of: reselection: performing table reselection on the potassium rich slate, over 90 percent of which has the granularity of 200 meshes, and separating out heavy minerals and light minerals; strong magnetic separation: performing strong magnetic separation on the light minerals obtained by reselection to obtain magnetic minerals and nonmagnetic minerals; weak magnetic separation: merging the heavy minerals obtained by reselection and the magnetic minerals obtained by strong magnetic separation, performing weak magnetic separation to obtain the iron ore concentrate; and flotation: performing reverse flotation and positive flotation to obtain the potassium feldspar ore concentrate. The method is scientific and reasonable, and the potassium feldspar ore concentratewith the purity of 95 percent and the yield of 85 percent and the iron ore concentrate with the full iron grade of over 65 percent and the yield of more than 95 percent can be obtained.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

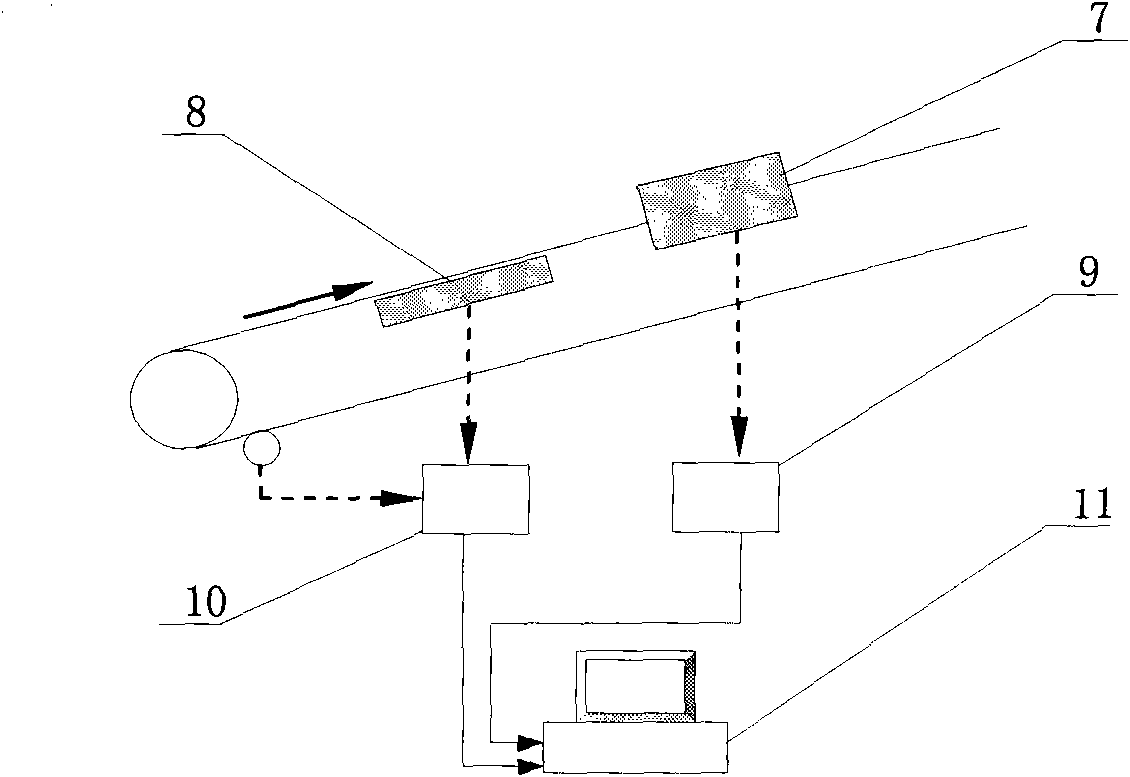

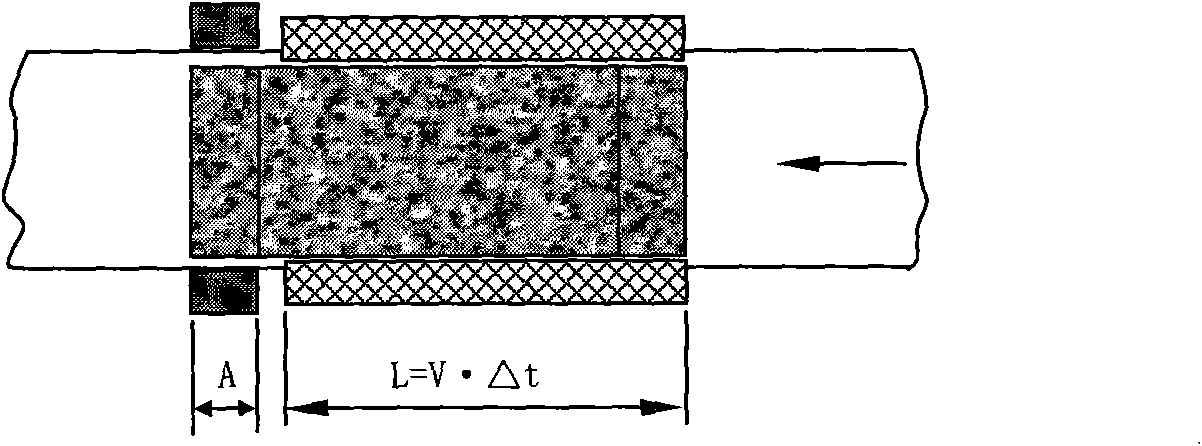

Device and method for dynamically detecting magnetic iron content in iron ores

InactiveCN101614699ASimple structureEasy to use in industrial fieldMaterial weighingMaterial magnetic variablesIntegratorMathematical model

The invention relates to a device for detecting magnetic iron content in iron ores in mineral dressing industry, in particular to a device and a method for dynamically detecting the magnetic iron content in the iron ores. The device for detecting comprises an induction coil, an electric induction or magnetic induction current detecting instrument, an electromagnetic coil arranged around a conveying belt, a paramagnetic material frame, a detecting instrument connected with the induction coil, an electronic balance in the conveying belt, an interface module, a digital integrator and a computer, wherein the detecting instrument is either an electric induction current detecting instrument or a magnetic induction current detecting instrument; the interface module is an analog-digital conversion module; and the computer is an industrial control computer. The method for detecting comprises the following steps: dynamically detecting the electric induction or magnetic induction current of the induction coil, and measuring the weight of iron-containing magnetic minerals synchronously; establishing a corresponding relation curve set of the magnetic iron content and the detected electric induction or magnetic induction current of the iron ores; scheduling a detection cycle; and determining the magnetic iron content in the iron ores by the computer according to a mathematical model. The device for dynamically detecting utilizes electromagnetic induction principle, has simple structure and is easy to use in industrial fields.

Owner:ANSTEEL GRP MINING CO LTD

Magnetic ore separation equipment and method

InactiveCN103056028AReduce the number of units usedSmall footprintFlotationMagnetic separationMining engineeringMagnetic separator

The invention discloses magnetic ore separation equipment. According to the technical point, an underflow ore discharge pipe of a magnetic separation column is connected with a feed port of a first agitating vessel, and an overflow groove ore discharge pipe of the magnetic separation column is connected with an overflow groove of a two-section magnetism flotation column; the ore discharge pipe of the first agitating vessel is connected with the feed port of a second agitating vessel, the ore discharge pipe of the second agitating vessel is connected with a feed hopper with a one-section magnetism flotation column, the one-section magnetism flotation column is connected with a scavenging device, and the overflow groove ore discharge pipe of the one-section magnetism flotation column is connected with the feeding end of the scavenging device; the two-section magnetism flotation column or a magnetic separator is used as the scavenging device, and the underflow ore discharge pipe of the two-section magnetism flotation column is connected with the feed hopper of the one-section magnetism flotation column; and the overflow groove ore discharge pipe of the two-section magnetism flotation column or a tailings discharge pipe of the magnetic separator is connected with a tailings recovery system. The invention simultaneously provides a separation method for using the equipment. Problems in the prior art that magnetic inclusion generates in the core separation of magnetite, the separation method is complicated, the floor area is large, the separation flow path is low and the separation cost is high and the like are solved.

Owner:沈阳华大科技有限公司

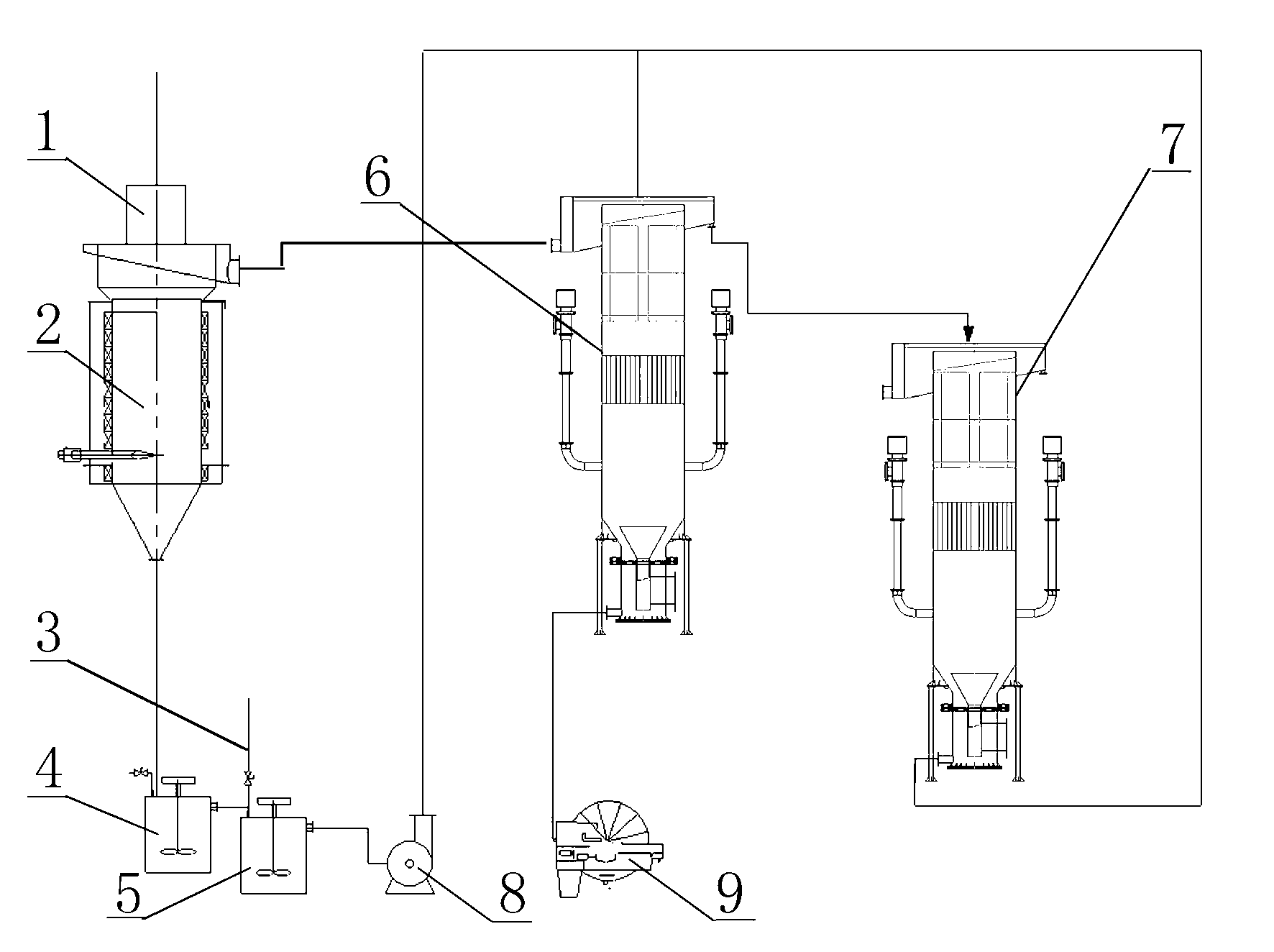

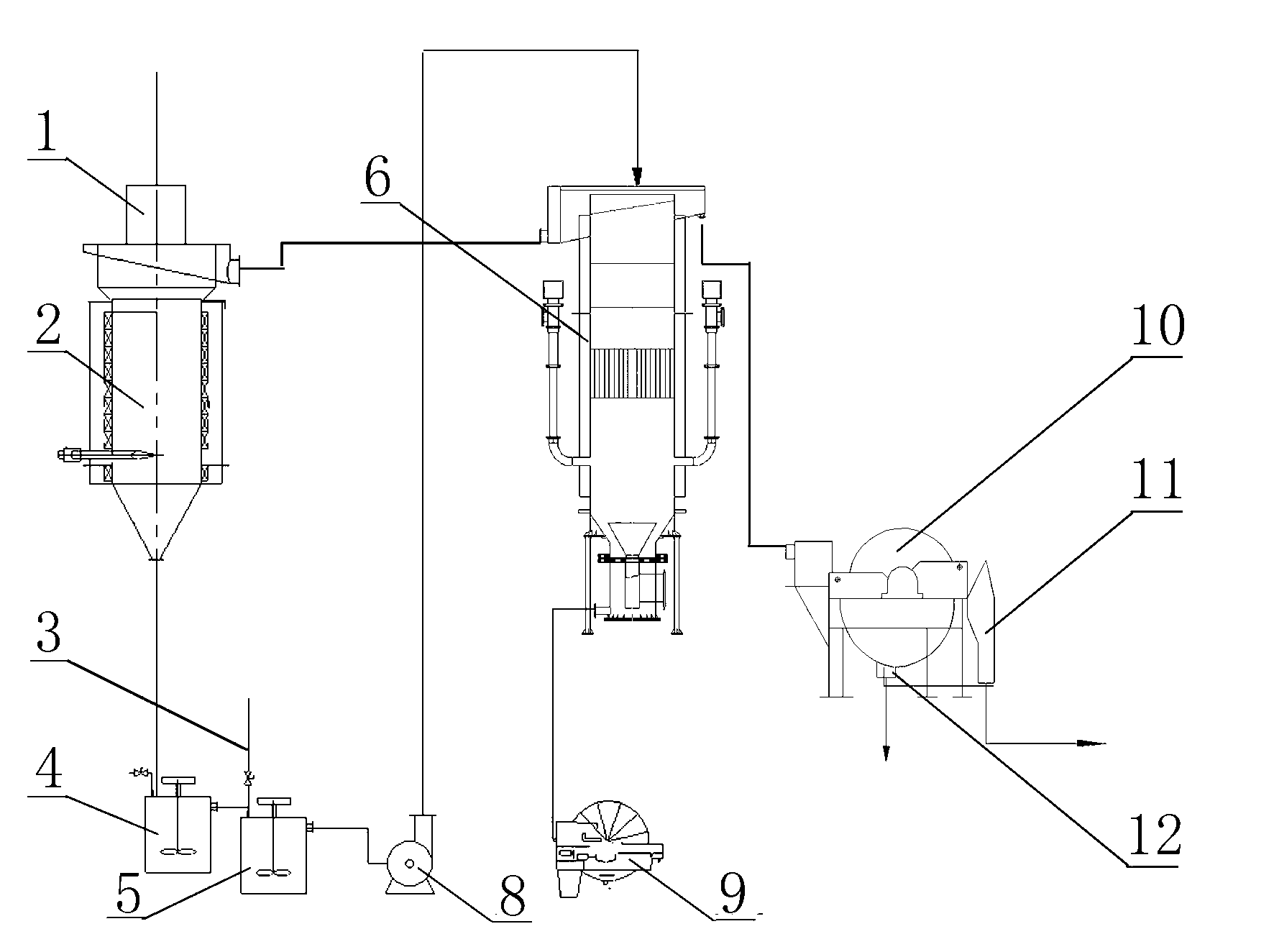

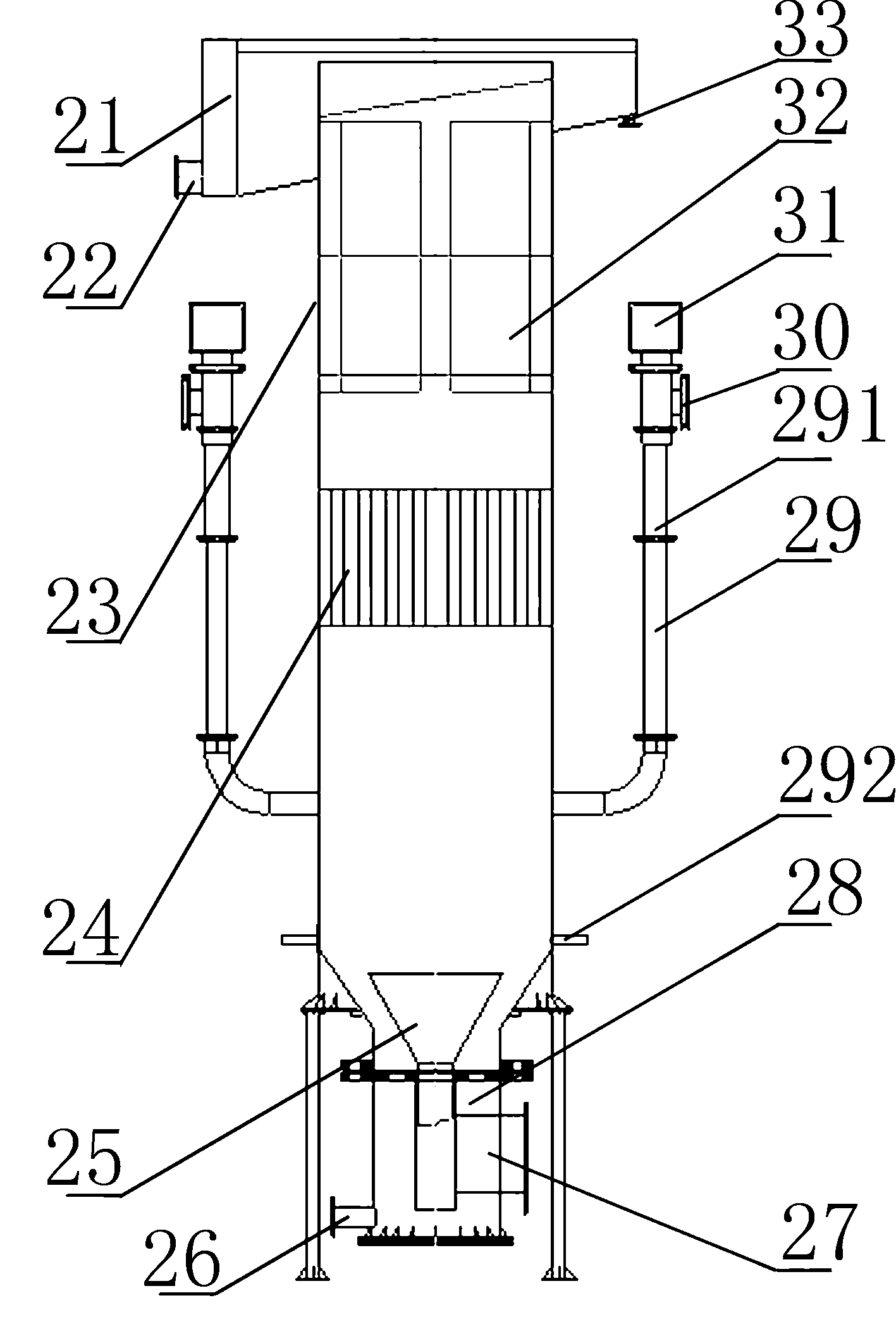

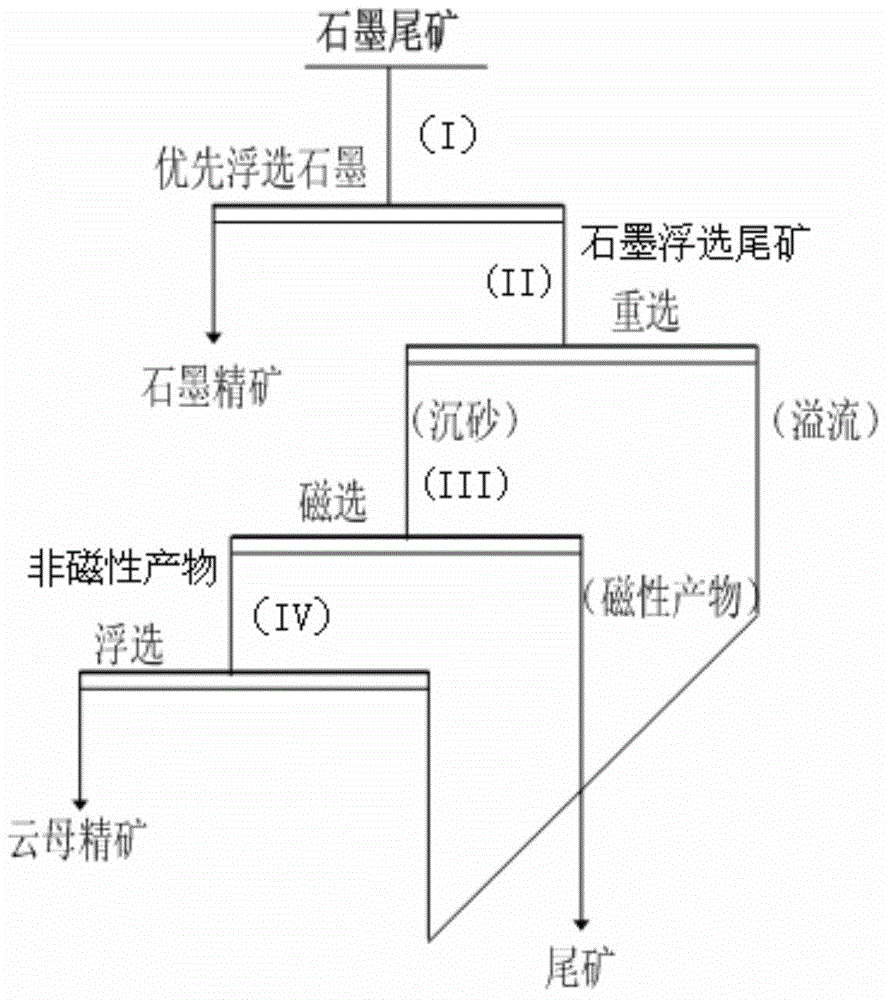

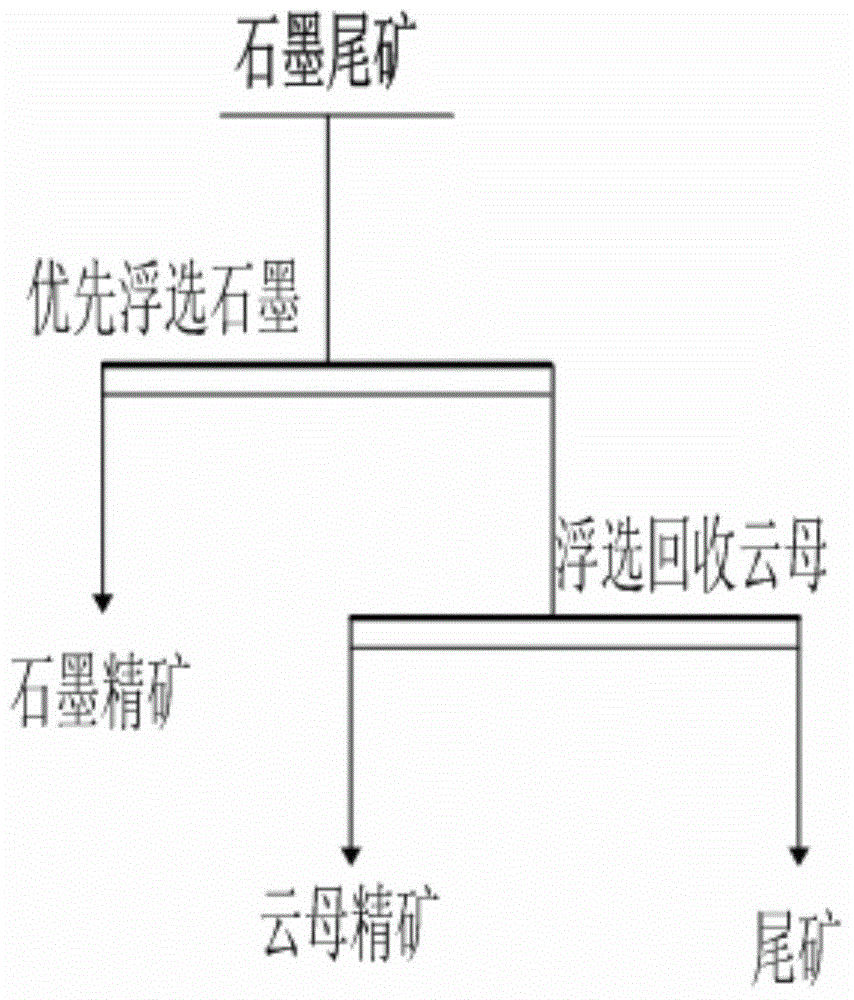

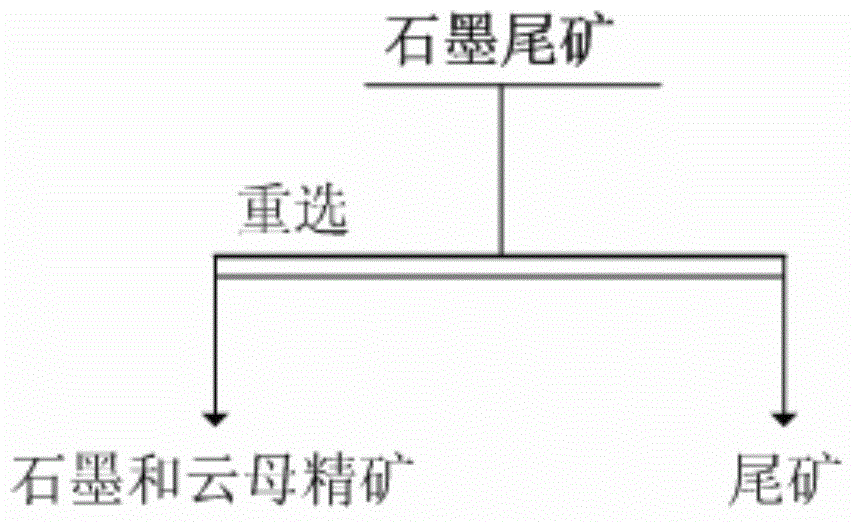

Mineral separation technology for recycling graphite and mica in graphite tailings

InactiveCN105268539AHigh recovery rateImprove resource utilizationWet separationSeparation technologyGraphite

A mineral separation technology for recycling graphite and mica in graphite tailings includes the following steps that I, graphite flotation is conducted on the graphite tailings, and graphite concentrate and graphite flotation tailings are obtained; II, re-flotation is conducted on the graphite flotation tailings obtained in the step I, sink sand is obtained, and the sink sand is enriched with the mica; III, magnetic separation is conducted on the sink sand obtained in the step II, and magnetic minerals and non-magnetic minerals are obtained; and IV, mica flotation is conducted on the non-magnetic minerals obtained in the step III, and mica concentrate is obtained. By means of the mineral separation technology, the concentrate grade and the recycling rate of the graphite and the mica recycled from the graphite tailings are increased.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

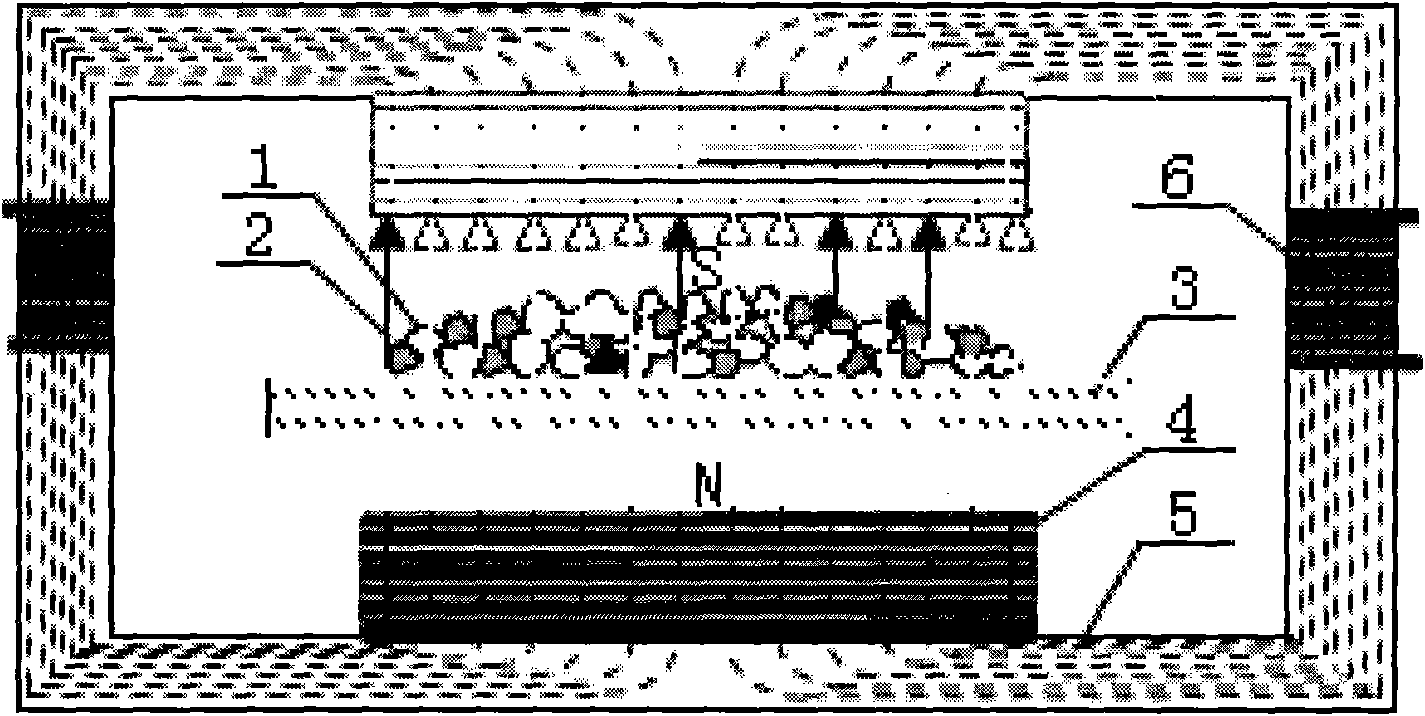

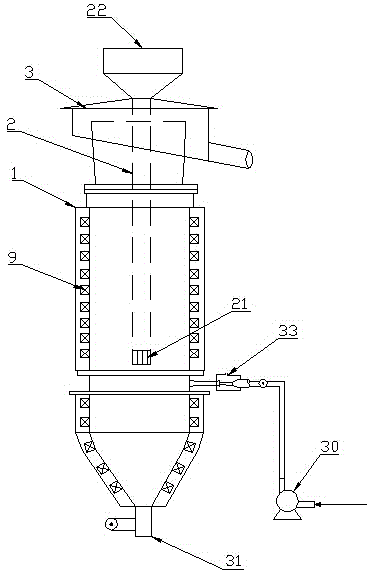

Floating agglomeration electromagnetic concentrating equipment

InactiveCN104815753AEfficient removalAvoid the phenomenon of running blackMagnetic separationEngineeringNon magnetic

The invention provides floating agglomeration electromagnetic concentrating equipment. The lower end of a cylinder is provided with a concentrate discharging port or connected with a concentrate discharging pipe, a discharging port of a feeding pipe extends into the cylinder and is positioned on the middle upper portion in the cylinder, an output port of a micronano bubble generating device is communicated with an inner cavity of the cylinder tangentially and corresponds to the discharging port of the feeding pipe in position, an alternating magnetic field generator is positioned on the periphery of the cylinder and provides a nonuniform alternating magnetic field, and an overflow tank is positioned above the cylinder and communicated with the upper end of the cylinder. The equipment can generate a lot of micronano bubbles, especially nano bubbles, and the micronano bubbles and the alternating pulse electromagnetic field jointly act to enable magnetic or strongly-magnetic minerals and nonmagnetic or weakly-magnetic gangue minerals in material ore pulp to be in dispersion, agglomeration, re-dispersion and selective agglomeration respectively so as to enable the nonmagnetic or weakly-magnetic gangue minerals to thoroughly break away from a magnetic chain finally, so that escape of tailings is avoided effectively, and high-grade magnetic iron concentrate or titanomagnetite concentrate is obtained finally.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

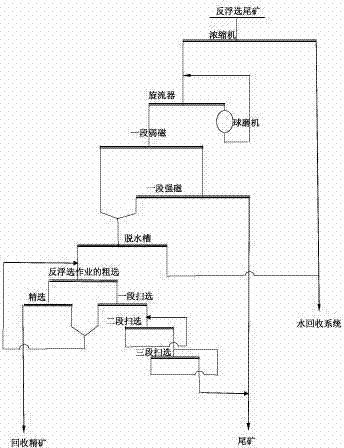

Method for iron concentrate in ore grinding, coarse and fine separation, gravity-magnetic-flotation process tailings in recovery stage

InactiveCN102259059AReduce processingImprove the quality of selectionFlotationMagnetic separationReverse flotationRecovery stage

The invention relates to the technical field of re-election of lean hematite tailings, in particular to a method for iron concentrate in tailings in the recovery stage of grinding, coarse and fine separation, and gravity-magnetic-flotation process, which is characterized in that the lean hematite stage The comprehensive tailings in the combined process of ore grinding, coarse and fine classification, gravity separation-magnetic separation-flotation are obtained by gravity separation and weak magnetic sweeping. Roughing, beneficiation and three-stage scavenging of weak magnetic and strong magnetic-reverse flotation operations to recover magnetic ore in tailings. In the present invention, the comprehensive tailings are sorted by gravity separation and weak magnetic sweeping, and the rough concentrate with a grade of 27% to 31% is recovered, which reduces the processing capacity of subsequent grinding and sorting operations and improves the selection of subsequent operations Grade; regrind the coarse concentrate to dissociate the intergrowth in the coarse concentrate; use weak magnetic, strong magnetic-reverse flotation to sort the regrind coarse concentrate, and obtain the final grade of more than 66%. Concentrate, to reduce the comprehensive tailings grade by 1%, to achieve the effective use of resources.

Owner:ANSTEEL GRP MINING CO LTD

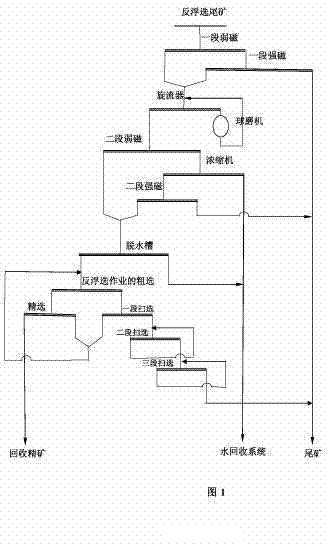

Method for recovering iron resources in reverse flotation tailings

The invention relates to the technical field of recovering reverse flotation tailings of hematite, in particular to a method for recovering iron resources in reverse flotation tailings. It is characterized in that the rough concentrate obtained from the reverse flotation tailings in the stage grinding of lean hematite and the combined process of magnetic separation-gravity separation-anion reverse flotation is separated by one stage of weak magnetic and one stage of strong magnetic separation, and then ground to After the particle size-320 mesh content reaches more than 91%, the magnetic ore in the reverse flotation tailings is recovered through the second-stage weak magnetic separation, the second-stage strong magnetic separation-reverse flotation operation, roughing, selection and three-stage scavenging. In the present invention, reverse flotation tailings are sorted by one section of weak magnetic field and one section of strong magnetic field, throwing away part of the tailings, regrinding a section of weak magnetic concentrate, and a section of strong magnetic concentrate. light. After regrinding, through the second-stage weak magnetic field, the second-stage strong magnetic field, the roughing, selection and three-stage sweeping of the reverse flotation operation, the coarse-grained intergrowth monomers in the reverse flotation tailings are dissociated, and the reverse flotation process is recovered. Flotate the metals in the tailings to reduce the loss of metals and reduce the grade of tailings.

Owner:ANSTEEL GRP MINING CO LTD

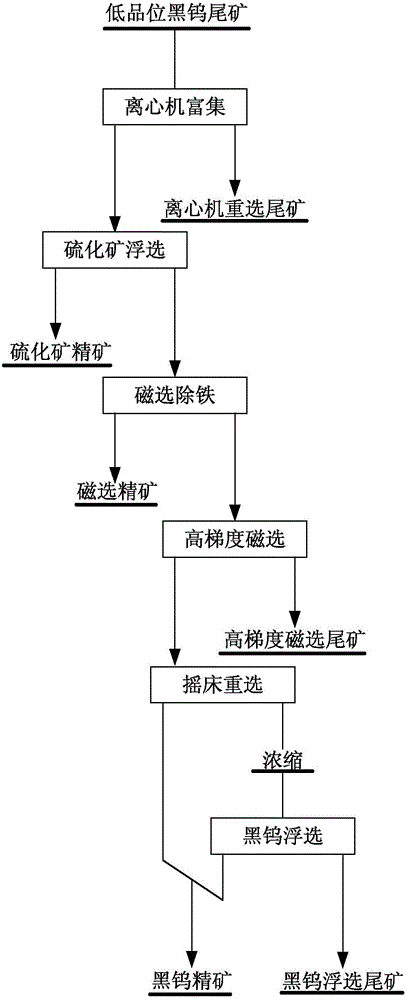

Mineral separation method for recycling wolframite from tailing

ActiveCN106669964AImprove the quality of selectionReduce the amount of oreSolid separationMechanical material recoveryGravity separationMagnetic separation

The invention discloses a mineral separation method for recycling wolframite from a tailing. The mineral separation method comprises the following steps that (1) gravity separation of a centrifugal machine is conducted for tailing discarding and preenrichment; (2) sulphide ore flotation is conducted; (3) magnetic separation is conducted and magnetic impurities are removed; (4) high-gradient magnetic separation is conducted for wolframite enrichment; (5) tabling gravity separation is conducted to obtain coarse grained wolframite; and (6) flotation is conducted to obtain fine grained wolframite. By means of centrifugation gravity separation preenrichment, the separation grade of the wolframite is improved, the ore feeding quantity and the mud content of wolframite separation are reduced, and flotation reagent dosage is saved. By means of the sulphide ore flotation and magnetic separation iron removal, the disturbance of sulphide minerals and magnetic minerals on wolframite separation is reduced. According to the mineral separation characteristics of the wolframite, the separation index of the wolframite is improved by adopting the high-gradient magnetic separation and the coarse grained and fine grained wolframite grading and separation process. Efficient recycling of the wolframite in low-grade wolframite tailing resources is achieved, and the mineral separation method is environmentally friendly, efficient and energy saving, and suitable for application and popularization.

Owner:JIANGXI UNIV OF SCI & TECH

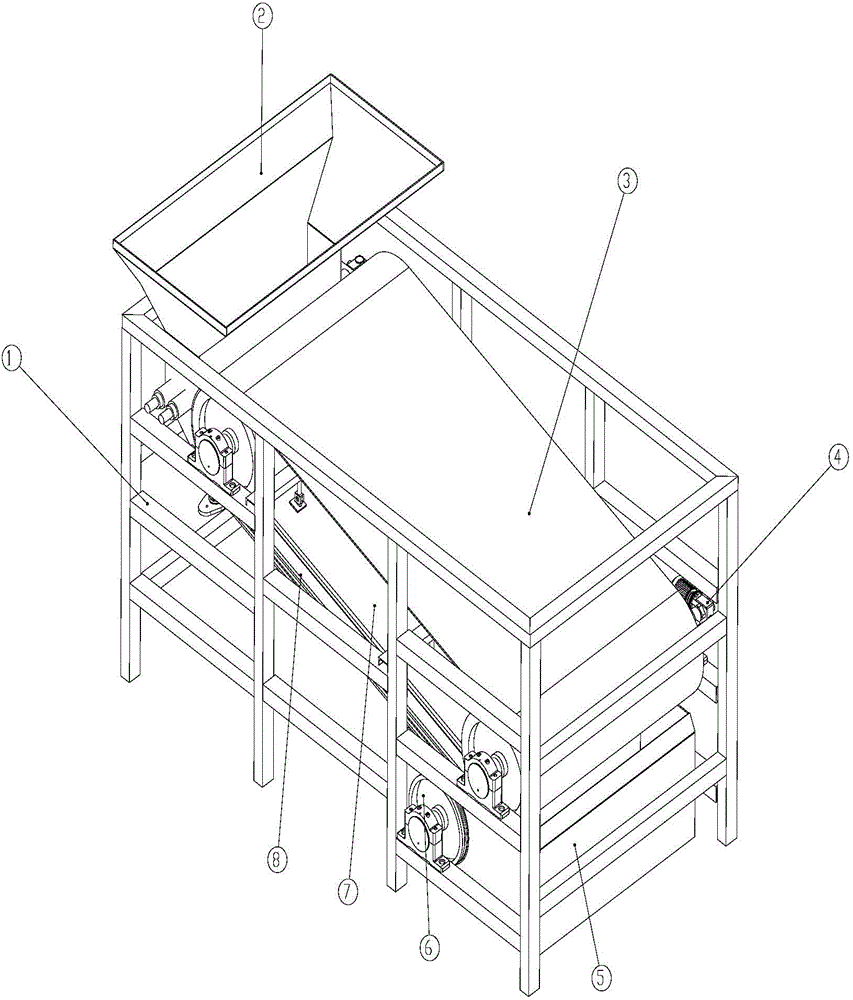

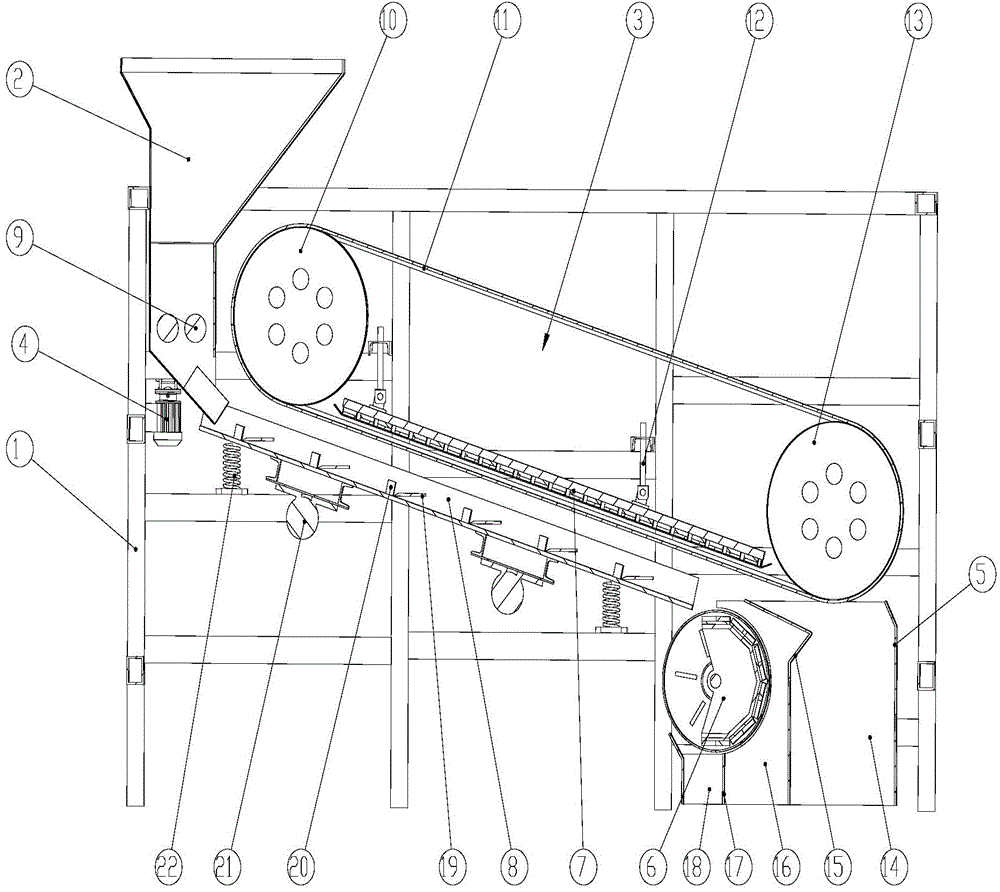

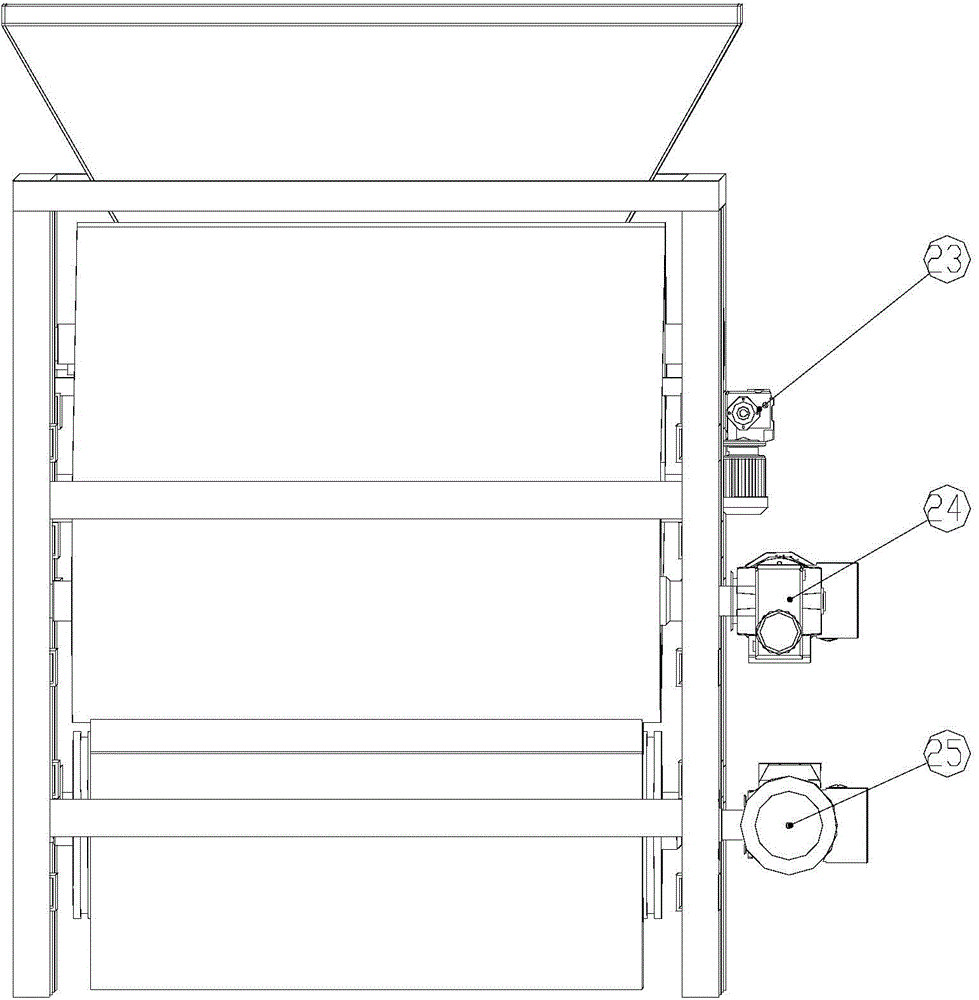

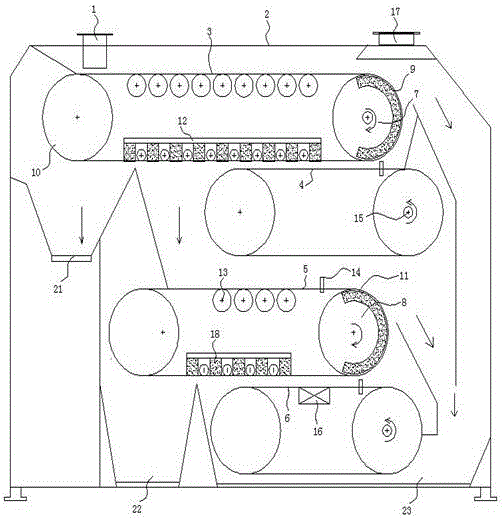

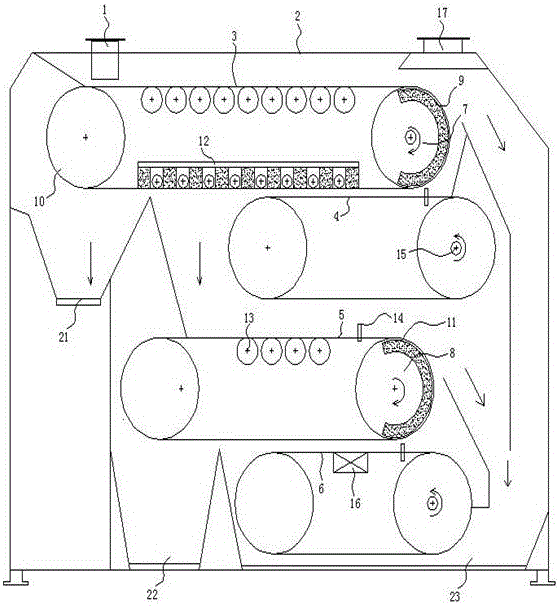

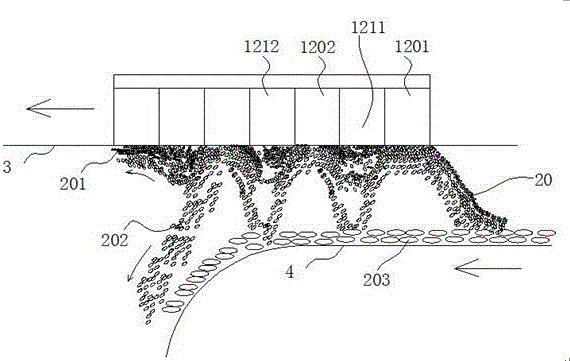

Asynchronous dry magnetic separator

ActiveCN104888950ARaise the gradeGuaranteed tailings indicatorsMagnetic separationMagnetic separatorMagnetic minerals

The invention discloses an asynchronous dry magnetic separator comprising a support frame. A feed hopper is disposed at the left upper end of the support frame; a roughing conveyer belt, an adjustable flat plate system and a vibrational conveyer are obliquely arranged on the support frame from the upper left end to the lower right end; the adjustable flat-plate magnetic system and the vibrational conveyer are disposed above and below a lower branch of the roughing conveyer belt; a lower outlet of the feed hopper is aligned to the front end of the vibrational conveyer; a scavenging magnetic roller is mounted on the support frame below a tail outlet of the vibrational conveyer; a receiving hopper is mounted below and on the right of the scavenging magnetic roller. The roughing conveyer belt suspends and sucks up strong magnetic mineral monomers or rich aggregates in material conveyed on the vibrational conveyer; during forward conveying, alternating poles and transient magnetic fields of the flat plate system help roll and drop gangues or lean aggregate inclusions, and thus high quality of rough concentrate is achieved. The scavenging magnetic roller helps scavenge and recover the lean aggregates of the weak magnetic minerals or strong magnetic minerals, thus ensuring the index of tailings.

Owner:BGRIMM MACHINERY & AUTOMATION TECH CO LTD

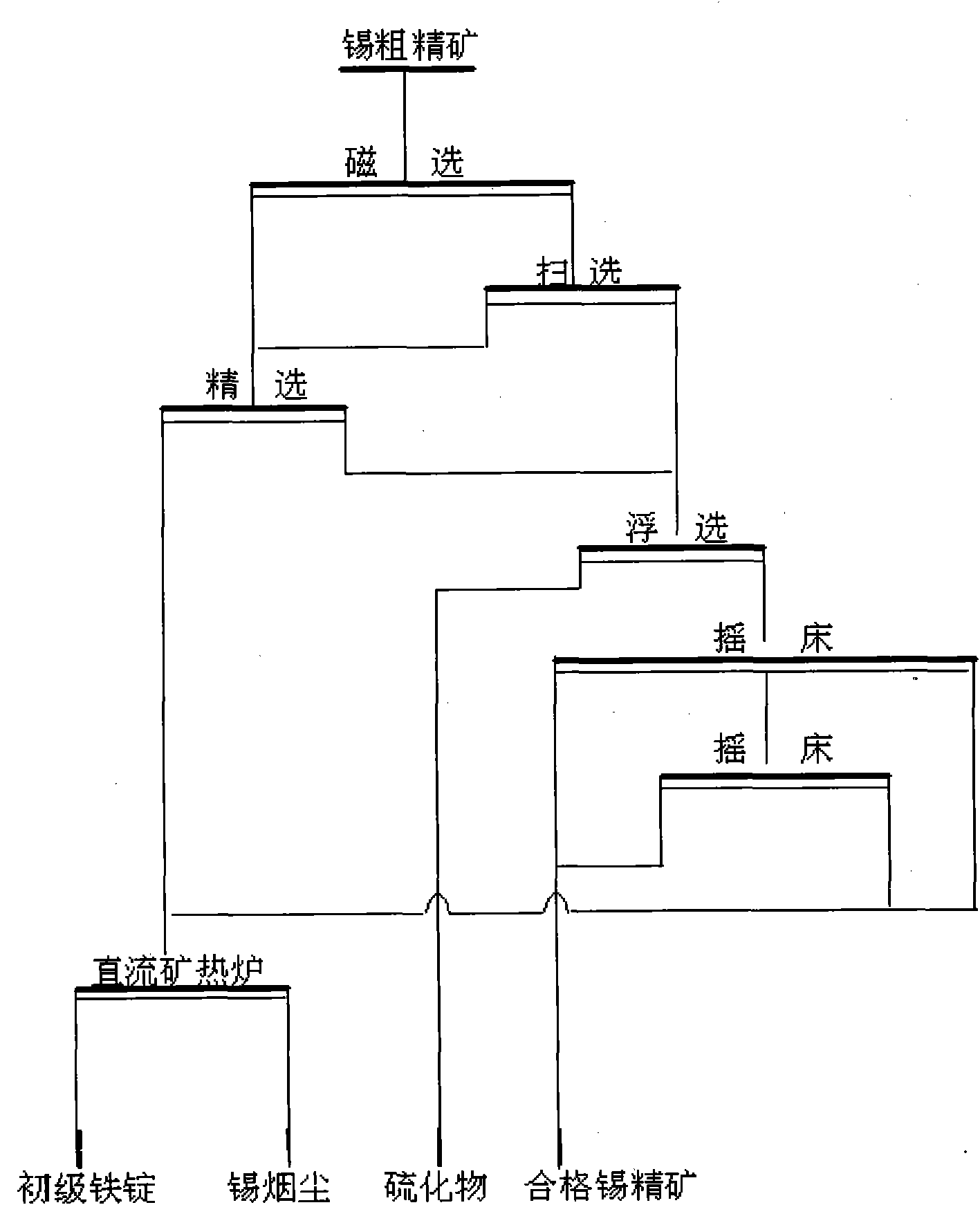

Combined flow treatment method of tin rough concentrate

ActiveCN101792867AHigh recovery rateImprove recovery indicatorsFlotationMagnetic separationTin dioxideResource utilization

The invention relates to a combined flow treatment method of tin rough concentrate, belonging to the technical field of non-ferrous metal ore-dressing and metallurgy. The process flow comprises the following steps: preparing pulp containing the tin rough concentrate; feeding the tin rough concentrate subjected to the pulp preparation into a magnetic separator for dressing magnetic minerals; making sulfide minerals float out of non magnetic ore by a floating operation; sorting by using a table concentrator to obtain qualified tin rough concentrate and a lean middling ore product; combining a magnetic mineral and lean middling ore obtained by magnetic separation; and treating a mixture by a direct current submerged arc furnace to obtain tin dioxide soot and primary iron ingot. By adopting an ore-dressing and metallurgy combined process flow, the method greatly simplifies the ore-dressing and concentrating process flow. Iron products are treated by the direct current submerged arc furnace, so that not only tin metals of the iron products can be recovered, but also the primary iron ingot can be obtained and iron metals can be recycled while improving the tin recovery rate; and the invention improves the resource utilization rate and has favorable application and popularization prospect.

Owner:YUNNAN TIN GROUP HLDG

Feldspar concentrates separated from vanadium titano-magnetite tailings and separation method thereof

ActiveCN107470013ARealize resourcesAchieve reductionMagnetic separationWet separationSulfideMaterials science

The invention relates to feldspar concentrates separated from vanadium titano-magnetite tailings and a separation method thereof. The vanadium titano-magnetite tailings are used as raw materials; firstly, impurities in the vanadium titano-magnetite tailings are separated; then, sulfides in the tailings are removed through flotation; strongly magnetic minerals in the tailings are removed through low-intensity magnetic separation; weakly magnetic minerals in the tailings are removed through high-intensity magnetic separation; and finally, the feldspar concentrates can be obtained through classification or reverse flotation. The core problems of high quantity, limited transportation radius and low economical value of the vanadium titano-magnetite tailings are overcome; and the environmental pollution and the safety problem caused by long-time accumulation of the tailings are solved.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Method for recycling high-phosphorus/sulfur siderite resource

The invention discloses a method for recycling high-phosphorus / sulfur siderite resources. The method comprises the following steps: finely grinding the raw ore, and removing phosphorus and sulfur by asynchronous reverse flotation, to obtain low-phosphorus / sulfur crude concentrate; subjecting the crude concentrate to reduction roasting in a roasting furnace while adding sodium carbonate, to obtain reduced roasted ore; and performing magnetic flocculation-enhanced separation. The process can not only increase the concentrate grade but also effectively improve recovery of magnetic minerals at fine-particle level and micro-fine-particle level and achieve advanced removal of phosphorus and sulfur from the roasted ore, greatly increases the recycling rate of a great amount of refractory high-phosphorus / sulfur siderite resources, and produces iron concentrate having iron grade of more than 65%, iron recovery rate of more than 65%, phosphorus content of less than 0.20% and sulfur content of less than 0.3%.

Owner:KUNMING UNIV OF SCI & TECH

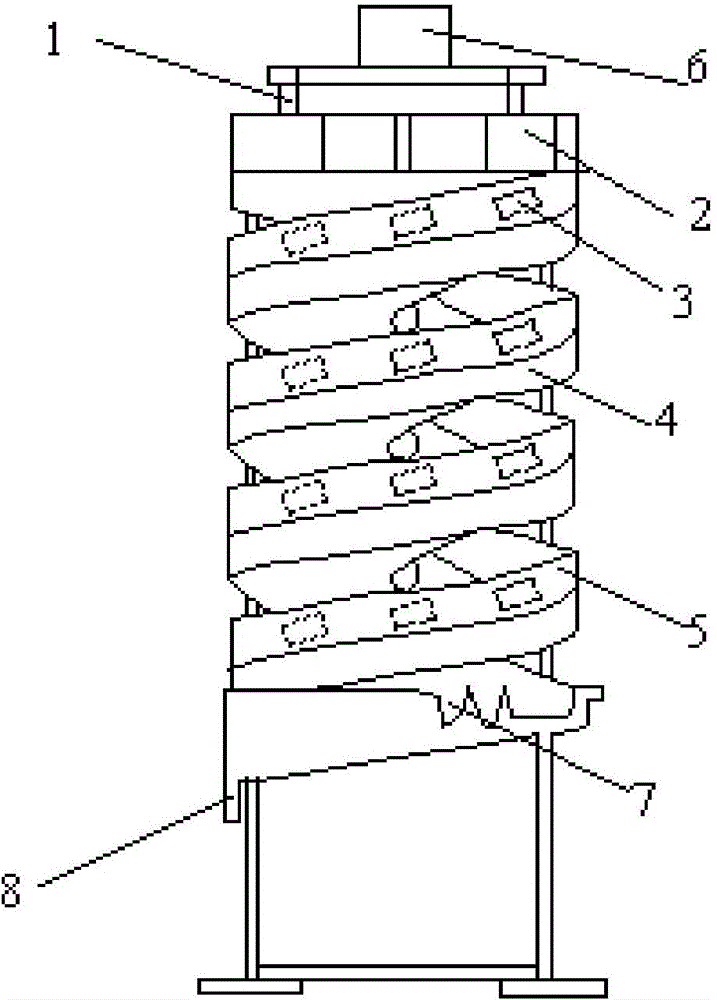

Complex force field spiral chute for ore dressing

The present invention discloses a complex force field spiral chute for ore dressing, and fine particles can be effectively prevented from entering into a tailing zone. The spiral chute comprises a channel steel support, an ore-feeding device, magnetic poles, a pulsating pressure water tank, a spiral blade, an ore dividing bucket, an ore intercepting bucket and an ore receiving bucket. The permanent magnetic fixed magnetic poles are installed at an external portion of a spiral blade of an existing spiral chute, so that magnetic fine particles in magnetic mineral can be forced by an inward-radial magnetic retentive force to enter into a concentrate zone under the function of an applied magnetic field. The pulsating water tank is installed at the bottom of a spiral surface, ore particles are prevented from rubbing with the spiral surface, so that the ore particles can be well layered and separated conveniently, and equipment abrasion can be eliminated conveniently. Concentrate grades can be improved, concentration ratio can be increased, mineral recovery rates can be improved, an existing spiral ore dressing technology can be simplified, and equipment maintenance rates and equipment power consumption can be reduced.

Owner:UNIV OF SCI & TECH LIAONING

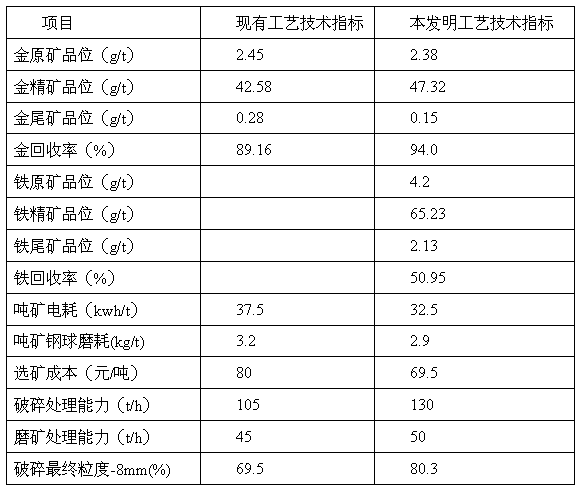

Beneficiation method and device for quartz vein type gold deposit

ActiveCN103464275AReduce wearIncreased crushing capacity efficiencyWet separationSteel ballNon magnetic

The invention discloses a beneficiation method for quartz vein type gold deposit. The beneficiation method for the quartz vein type gold deposit includes the steps of using a jaw crusher to crush raw ore, sending crushed mineral material into a double layer circular vibrating screen to be sieved, putting sieved and qualified mineral material into a grid type ball mill for single stage grinding, returning unqualified mineral material after two stage crushing back to the double layer circular vibrating screen, separating magnetic and non-magnetic minerals after discharging material from single stage grinding passing a magnetic arc, making magnetic minerals for magnetic separation to obtain iron ore concentrate and putting the non-magnetic minerals separated through the magnetic arc into a sorting system after twice classification. Compared with the prior art, with beneficiation method for quartz vein type gold deposit, the content of fine particles of a crushed final product is mostly of 80.3%, crushing efficiency is improved, wear rate of a steel ball is decreased by 9%, ferrous metals can be recycled, synchronous improvement of ore dressing recovery percentage and concentrate grade is realized with the recovery percentage increased by 4.2% and the concentrate grade increased by 3.5 grams per ton, power consumption rate is reduced by 13.86%, and cost is reduced by 15.0%.

Owner:阿勒泰正元国际矿业有限公司

Separation and purification method for garnets of iron ore tailings and product of method

ActiveCN106000627AReduce the difficulty of separation and purificationLong-term retention of characteristicsSievingScreeningPurification methodsMagnetization

Owner:河源紫金天宏科技有限公司

Series grading magnetic separator

ActiveCN105728185AAdjust the size of the forcePromote stratificationMagnetic separationMagnetic separatorEngineering

The invention discloses a series grading magnetic separator. The series grading magnetic separator comprises a rack which is internally provided with a first-grade separation belt, a first-grade conveying belt, a second-grade separation belt and a second-grade conveying belt from top to bottom in sequence; the first-grade separation belt is located below a feeding opening, a first tailing throwing mechanism is arranged at the unloading end of the first-grade separation belt, and a first separation magnetic system is arranged on the inner side of a lower belt of the first-grade separation belt; the unloading end of the first-grade conveying belt is covered with the first separation magnetic system; and the unloading end of the first-grade conveying belt is covered with the feeding end of the second-grade separation belt, a second tailing throwing mechanism is arranged at the unloading end of the second-grade separation belt, and the unloading scope of the second tailing throwing mechanism is covered with the feeding end of the second-grade conveying belt. The series grading magnetic separator is simple in structure, wide in application scope, capable of guaranteeing the grade of the finished product mine, capable of improving the recovery rate and suitable for separating magnetic mineral ground by grinding equipment in the industry of metallurgy, mines, chemical engineering and the like.

Owner:CHENGDU LEEJUN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com