New treating method for nickel oxide ore

A technology of nickel oxide ore and a new method, applied in the direction of process efficiency improvement, solid separation, flotation, etc., can solve the problems of undesired heap leaching, low leaching rate, waste of resources, etc., to save and protect the environment, nickel The effect of less loss and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

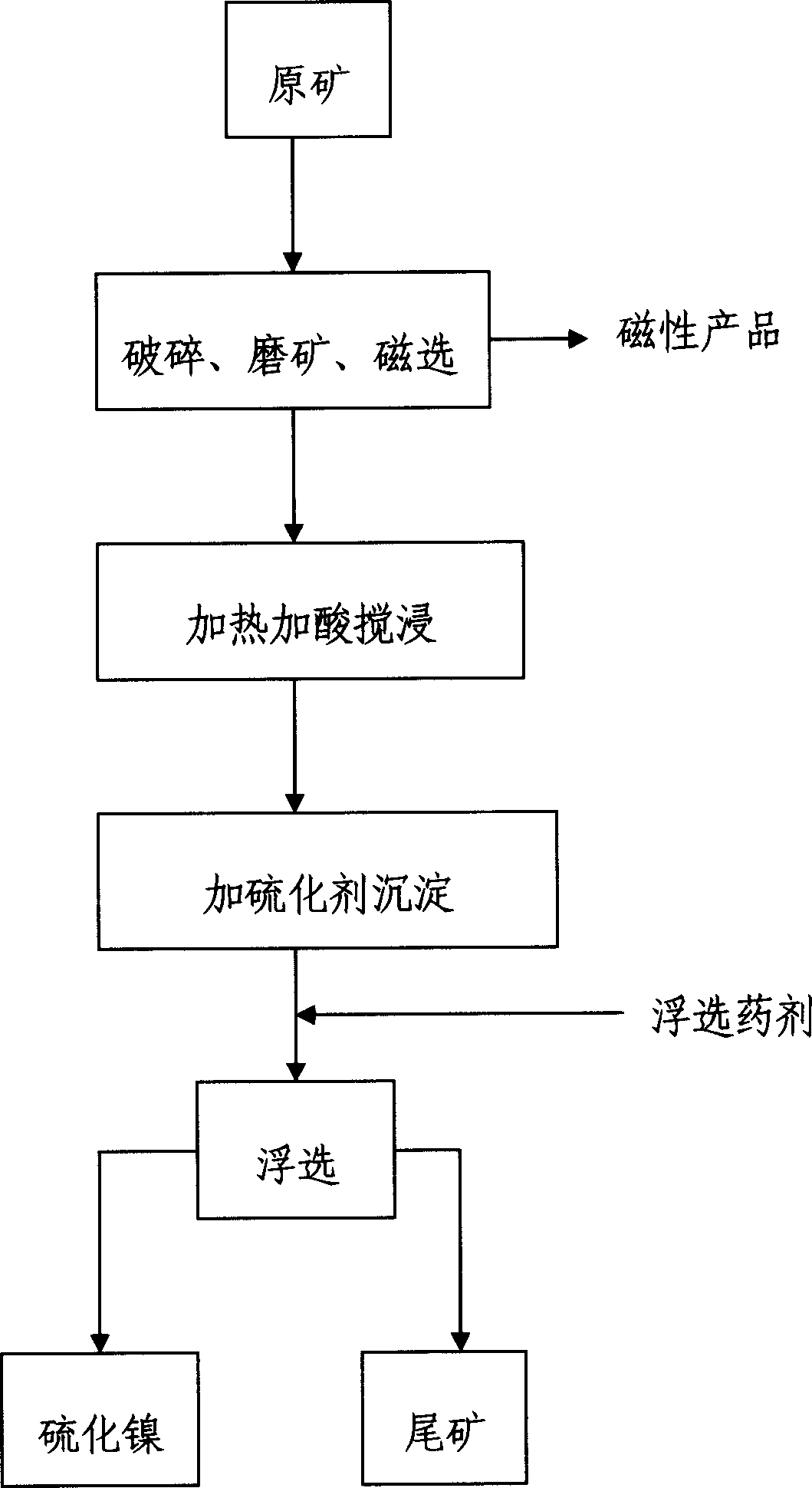

Method used

Image

Examples

Embodiment 1

[0022] Get 2 kilograms of laterite nickel ore (ferro-magnesian mixed ore) in Yuanjiang, Yunnan, and through crushing and grinding, the slurry particle size is less than 150 mesh, accounting for 85%, and the liquid-solid ratio of the slurry is 2.5. The material is charged into the reactor, heated to 80 ° C, and Concentrated sulfuric acid was stirred for 1 hour, and the pH value at the end point was controlled to reach 2, and the vulcanizing agent sodium sulfide was added to carry out a chemical reaction. After the reaction, the pH value was 3, and precipitated nickel sulfide was produced. Then send all the reactants in the reactor to the mixing tank, add the flotation agent butyl xanthate into the mixing tank for stirring, and then put the pulp into the flotation column to float the nickel sulfide concentrate. The nickel grade of the ore is 1.19%, the nickel grade of the concentrate is 24-25%, and the nickel recovery rate is 66-70%.

Embodiment 2

[0024] Take 100 kg of laterite nickel ore (ferro-magnesian mixed ore) in Yuanjiang, Yunnan, and after crushing and grinding, the slurry particle size is less than 150 mesh, accounting for 80%, and the liquid-solid ratio of the slurry is 2.8. In the reaction kettle, heat to 90°C, add concentrated sulfuric acid and forcefully stir for 100 minutes, control the end point pH value to 1.5, add sulfide agent hydrogen sulfide to carry out chemical reaction, the pH value after the reaction is 3.5, and produce precipitated nickel sulfide. Then send all the reactants in the reaction kettle to the mixing tank, add the flotation agent ethaxanthate into the mixing tank for stirring, and then put the pulp into the flotation machine to float the nickel sulfide concentrate. The nickel grade of the ore is 1.25%, the nickel grade of the concentrate is 24-25%, and the nickel recovery rate is 63-66%.

Embodiment 3

[0026] Take 400 kg of laterite nickel ore (ferro-magnesian mixed ore) in Yuanjiang, Yunnan, and after crushing and grinding, the slurry particle size is less than 150 mesh, accounting for 86%, and the liquid-solid ratio of the slurry is 3. In the reaction kettle, heat to 95°C, add concentrated sulfuric acid and forcefully stir for 120 minutes, control the end point pH value to 1.8, add the vulcanizing agent potassium sulfide to carry out chemical reaction, the pH value after the reaction is 4, and precipitated nickel sulfide is produced. Then send all the reactants in the reactor to the mixing tank, add the flotation agent pine oil into the mixing tank for stirring, and then put the pulp into the flotation tank to float the nickel sulfide concentrate. The nickel grade of the ore is 1.22%, the nickel grade of the concentrate is 24-25%, and the nickel recovery rate is 64-67%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com