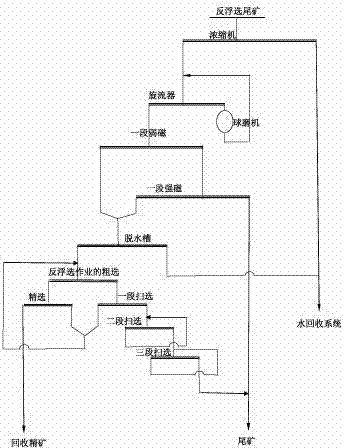

Hematite reverse flotation tailings re-election process

A technology of reverse flotation and hematite, which is applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., to achieve the effects of small footprint, reduced foam, and lower tailings grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] When the grade of the reverse flotation tailings is 25.32%, and the particle size of the cyclone overflow product reaches the requirement of -320 mesh content of more than 90%, the hematite reverse flotation tailings re-election process of the present invention can make the tailings The grade was reduced to 16.3%, while the recovered concentrate grade was 64.2%.

[0045] When the grade of the reverse flotation tailings is 15.30%, and the particle size of the cyclone overflow product reaches the requirement of -320 mesh content above 91%, the hematite reverse flotation tailings re-election process of the present invention can make the tailings The grade was reduced to 11.8%, while the recovered concentrate grade was 60.2%.

[0046] The beneficial effects of the present invention are: the reverse flotation tailings processed by concentration and defoaming are regrinded, and the reverse flotation tailings The coarse-grained intergrowth monomers in the process are dissocia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com