Method for recovering valuable metal mineral in zinc tailing

A technology for valuable metals and tailings, applied in chemical instruments and methods, wet separation, magnetic separation, etc., can solve the problems of ineffective utilization of tailings resources, complex process flow, and high production costs, and achieve good results. The effect of application and promotion prospects, simple process flow and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

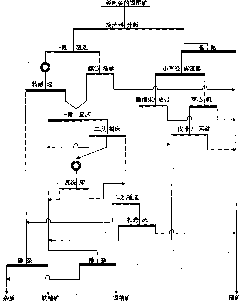

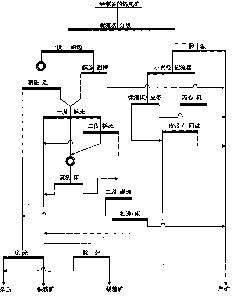

Image

Examples

Embodiment 1

[0022] Tin tailings contain Sn0.18%, Fe9.74%, S0.3%, As0.15%, grading by cyclone with a diameter of 300mm, rough magnetic separation (magnetic field strength 10000 Oersted), 70.53% tin metal , 81.3% of iron metal is enriched in magnetic products, after grinding (-200 mesh accounts for 61%), magnetic separation and concentration (magnetic field strength 4000 Oersted), the output iron grade is 59.51%, and the iron recovery rate is 32.47% Iron products; non-magnetic products are separated by three-stage shaking table to obtain tin-rich middle ore with a tin content of 3.6% and a tin recovery rate of 38.23%; two-stage magnetic separation (magnetic field strength 5000 Oersted), the output iron grade is 58.58 %, the iron product with an iron recovery rate of 28.89%; the fine mud part is deslimed, classified by a small diameter cyclone, sorted by a direct-current belt chute for sand settling, and sorted by a centrifugal concentrator-belt chute for overflow, and the obtained tin conten...

Embodiment 2

[0024] Tin tailings contain Sn0.21%, Fe18.6%, S0.6%, As0.49%, grading by 300mm diameter cyclone, magnetic separation roughing (magnetic field strength 9000 Oersted), 72.32% tin metal , 89.1% of iron metal is enriched in magnetic products, after grinding (-200 mesh accounts for 65%), magnetic separation and concentration (magnetic field strength 3500 Oersted), the output iron grade is 59.78%, and the iron recovery rate is 40.34% Iron products; non-magnetic products are sorted by three-stage shaking table to obtain tin middle ore with 3.58% tin content and 39.12% tin recovery rate; two-stage magnetic separation (magnetic field strength 4000 Oersted), the output iron grade is 59.68% , Iron products with an iron recovery rate of 26.17%; the fine mud part is deslimed and classified by a small-diameter cyclone, the sand is separated by a fine mud shaker, and the overflow is separated by a centrifugal concentrator-disc concentrator. Tin medium ore with 3.36% tin and 15.22% tin recove...

Embodiment 3

[0026] Tin tailings contain Sn0.29%, Fe20.76%, S0.5%, As0.36%, after grading by 300mm diameter cyclone, magnetic separation roughing (magnetic field strength 10000 Oersted), 71.19% tin metal , 82.2% of iron metal is enriched in magnetic products, after grinding (-200 mesh accounts for 65%), magnetic separation and concentration (magnetic field strength 4000 Oersted), the output iron grade is 60.21%, and the iron recovery rate is 38.67% Iron products; non-magnetic products are sorted by a three-stage shaker to obtain tin ore with a tin content of 3.58% and a tin recovery rate of 43.44%; two-stage magnetic separation (magnetic field strength 5000 Oersted), the output iron grade is 59.89% , Iron products with an iron recovery rate of 30.33%; the fine mud part is deslimed, classified by a small diameter cyclone, sorted by a fine mud shaker for sand settling, and a centrifugal concentrator for overflow - a disc concentrator, to obtain a tin content of 3.42 %, tin recovery rate of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com