Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "The beneficiation process is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

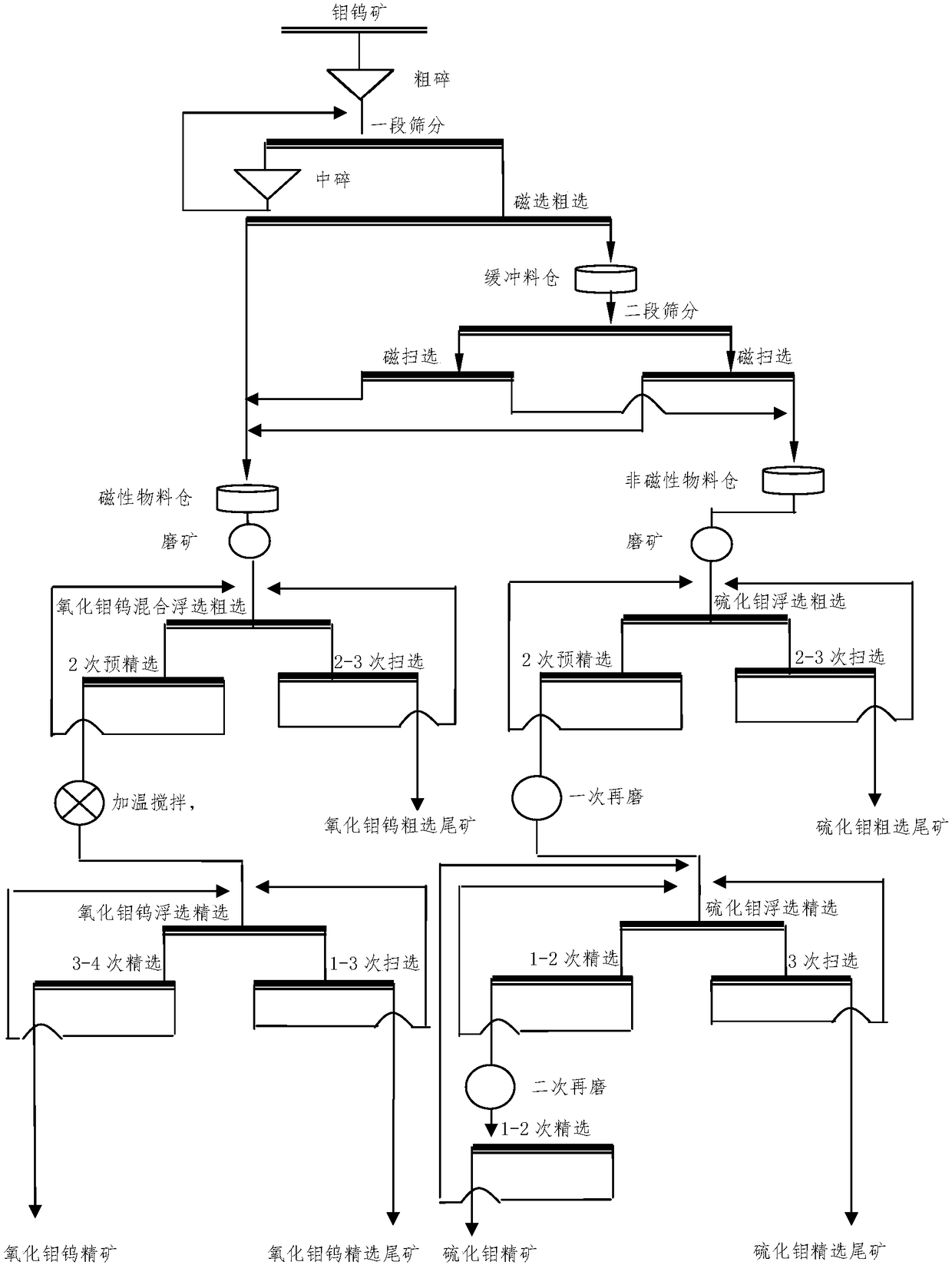

Beneficiation method for separating molybdenum-tungsten oxide ore and molybdenum sulfide ore from molybdenum tungsten ore

InactiveCN106076590AEliminate the need for deslimingThe beneficiation process is simpleFlotationMagnetic separationNon magneticMagnetic characteristic

The invention relates to a beneficiation method for separating molybdenum-tungsten oxide ore and molybdenum sulfide ore from molybdenum tungsten ore. The beneficiation method comprises the steps that magnetic separation is conducted on raw separation molybdenum sulfide ore at least twice, so that the raw separation molybdenum sulfide ore subjected to magnetic separation is divided into magnetic ore containing molybdenum-tungsten oxide and non-magnetic ore containing molybdenum sulfide; and a molybdenum-tungsten oxide flotation process is conducted on the magnetic ore, and a molybdenum sulfide flotation process is conducted on the non-magnetic ore, so that molybdenum-tungsten oxide concentrate and molybdenum sulfide concentrate are obtained. According to the beneficiation method for separating the molybdenum-tungsten oxide ore and the molybdenum sulfide ore from the molybdenum tungsten ore, the magnetic ore containing molybdenum-tungsten oxide and the non-magnetic ore containing molybdenum sulfide are separated out before ore grinding by means of the magnetic characteristic of iron-bearing ore in skarn in a magnetic separation and flotation combined way, so that the floatability of the ore is improved, the beneficiation feed grades of the molybdenum sulfide ore and the and molybdenum-tungsten oxide ore subjected to flotation are increased, and a subsequent flotation technological process is simplified; and in addition, grading index fluctuation caused by the change of the characteristics of the ore is reduced, and the mine production cost can be reduced easily.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

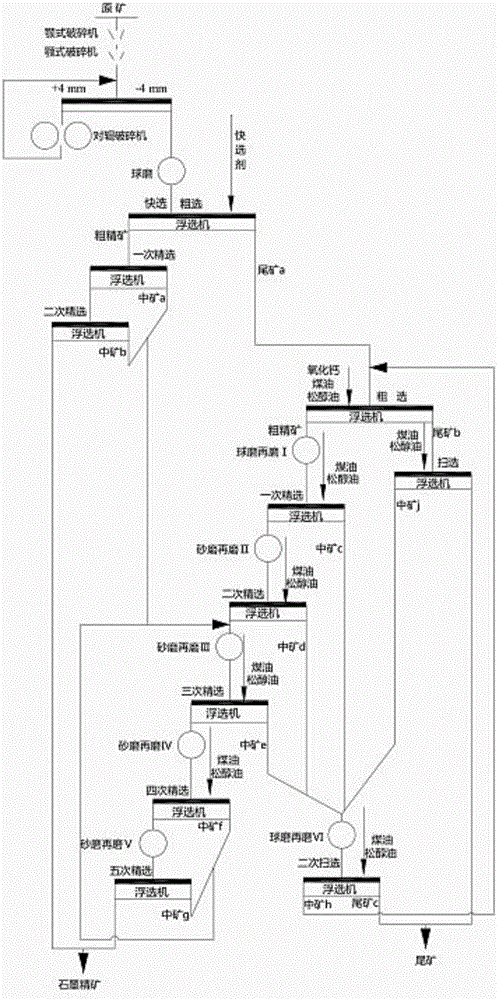

Large-scale crystalline graphite ore flotation fast selecting agent and flotation technology

ActiveCN106513164AReduce consumptionReduce manufacturing costFlotationWet separationMethanolGraphite

The invention relates to a large-scale crystalline graphite ore flotation fast selecting agent and a flotation technology. The agent comprises following components including, by weight, 50% to 65% of methyl isobutyl carbinol, 20% to 30% of petroleum ether and 10% to 25% of acetone. The graphite ore flotation fast selecting agent can rapidly select high-quality large-scale graphite ore from neutral pulp, and high-grade large-scale crystalline graphite concentrate can be obtained through the short selection technology free of regrinding; compared with a traditional large-scale crystalline graphite ore flotation technology, graphite scales can be effectively protected, meanwhile, the consumption amount of the floatation agent can be reduced, and the production cost is reduced.

Owner:金建工程设计有限公司

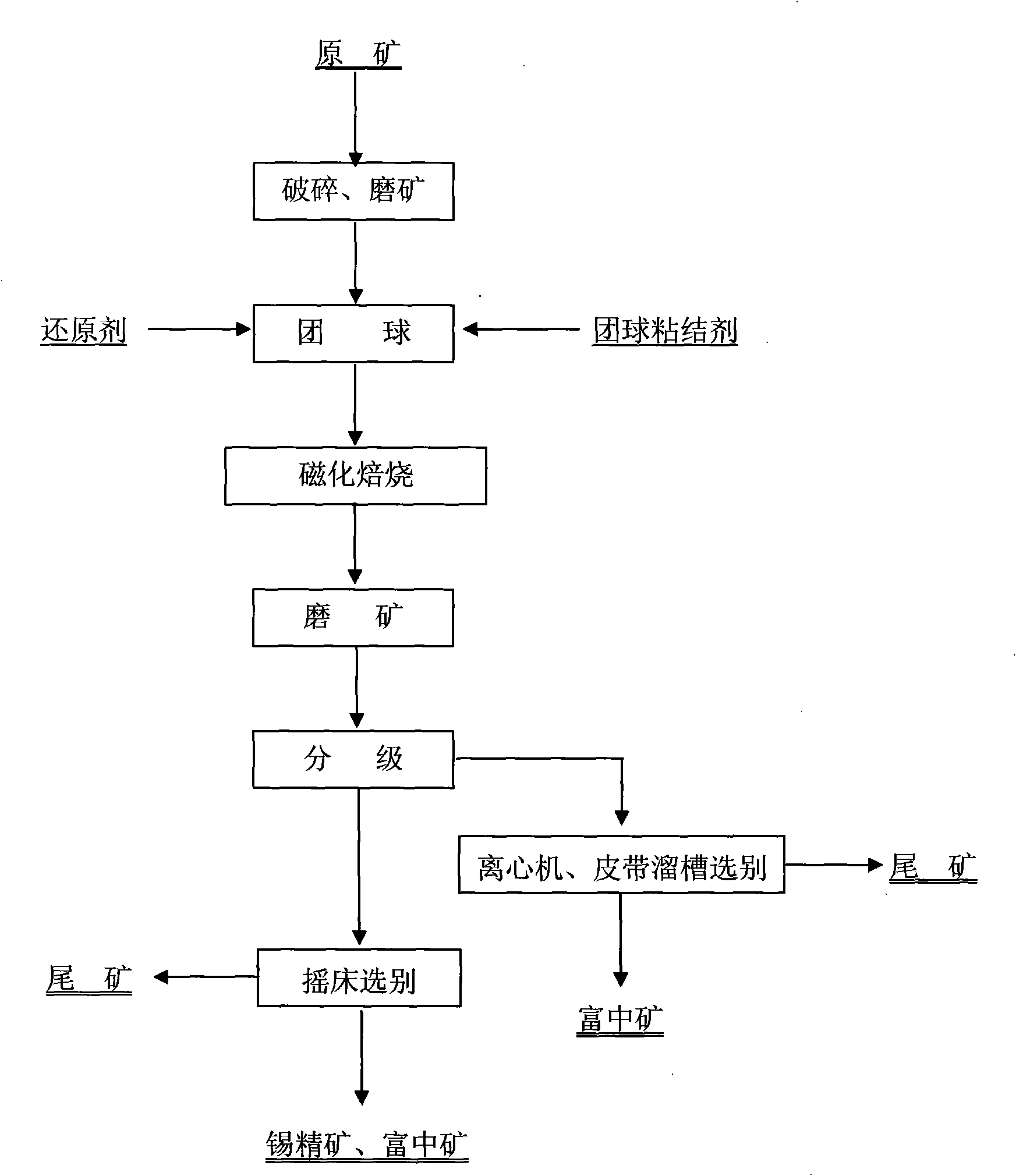

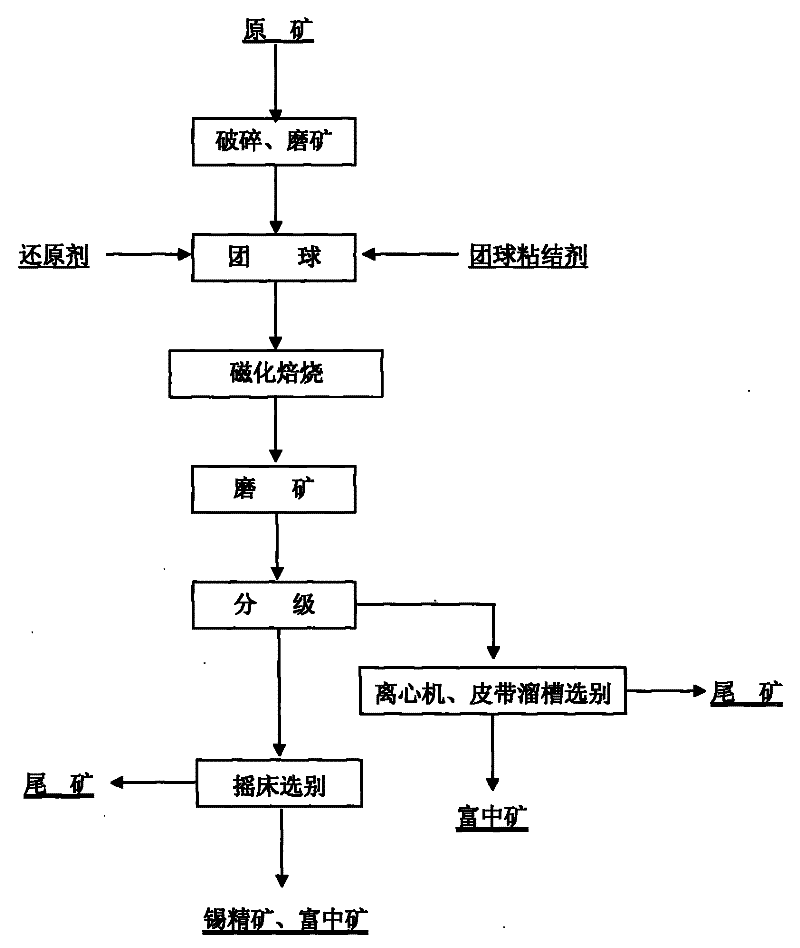

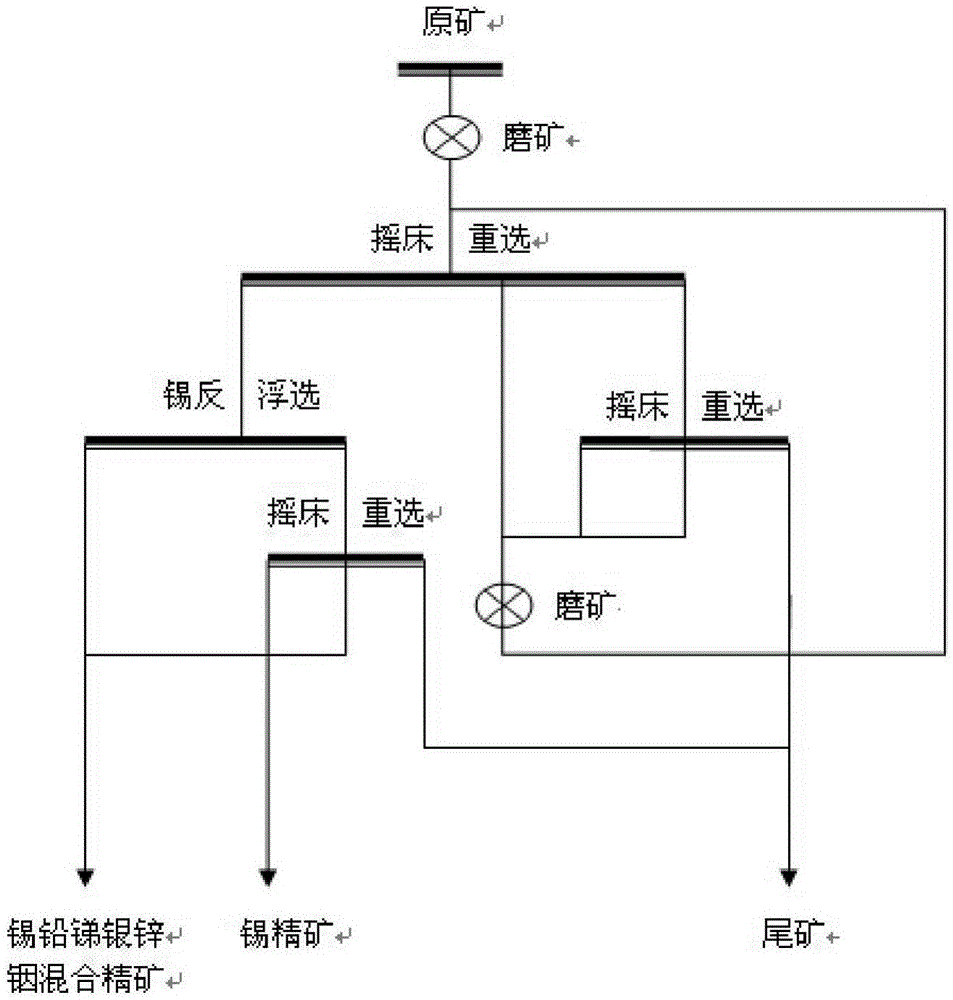

Combined process flow processing method of high-iron low-tin oxidized ore

The invention relates to a processing method of refractory high-iron low-tin oxidized ore, belonging to the technical field of nonferrous metallurgy and mineral separation. The technological process of the method comprises: crushing and finely grinding ore, adding reducing agent and binding agent into the ore, preparing the obtained ore into pellets, drying, roasting and recrushing the pellets, and then carrying out wet-type ore grinding; adopting a magnetic ore separator to select out magnetic mineral iron ore concentrate, and obtaining the iron ore concentrate product containing more than 60% of iron; sorting non-magnetic mineral by cavity separation equipment such as a jerking table and the like, and obtaining qualified tin ore concentrate containing less than 40% of tin and tin-rich mineral products containing more than 4% of tin; furthermore, the total yield of tin reaches 65-75%. By adopting the process flow combining metallurgy and mineral separation, the method can greatly improve the recovery rate of the tin, simultaneously obtains an iron ore concentrate product, simplifies the process flow of the mineral separation, is short in the process flow, low in production cost and environment-friendly, can greatly improve the recovery rate of the tin and iron, effectively utilizes limited resources, and has good application and popularization prospects.

Owner:YUNNAN TIN GROUP HLDG

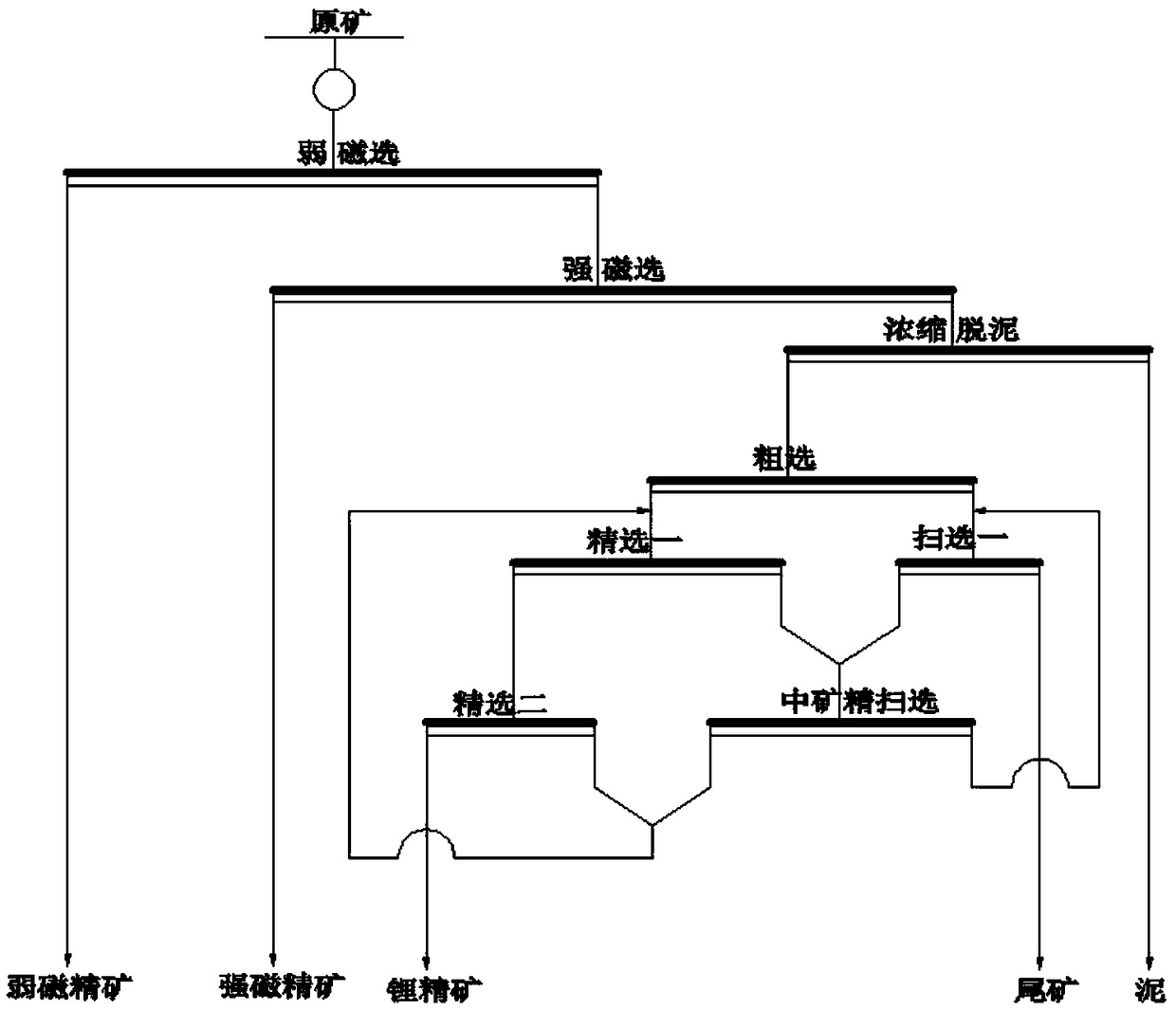

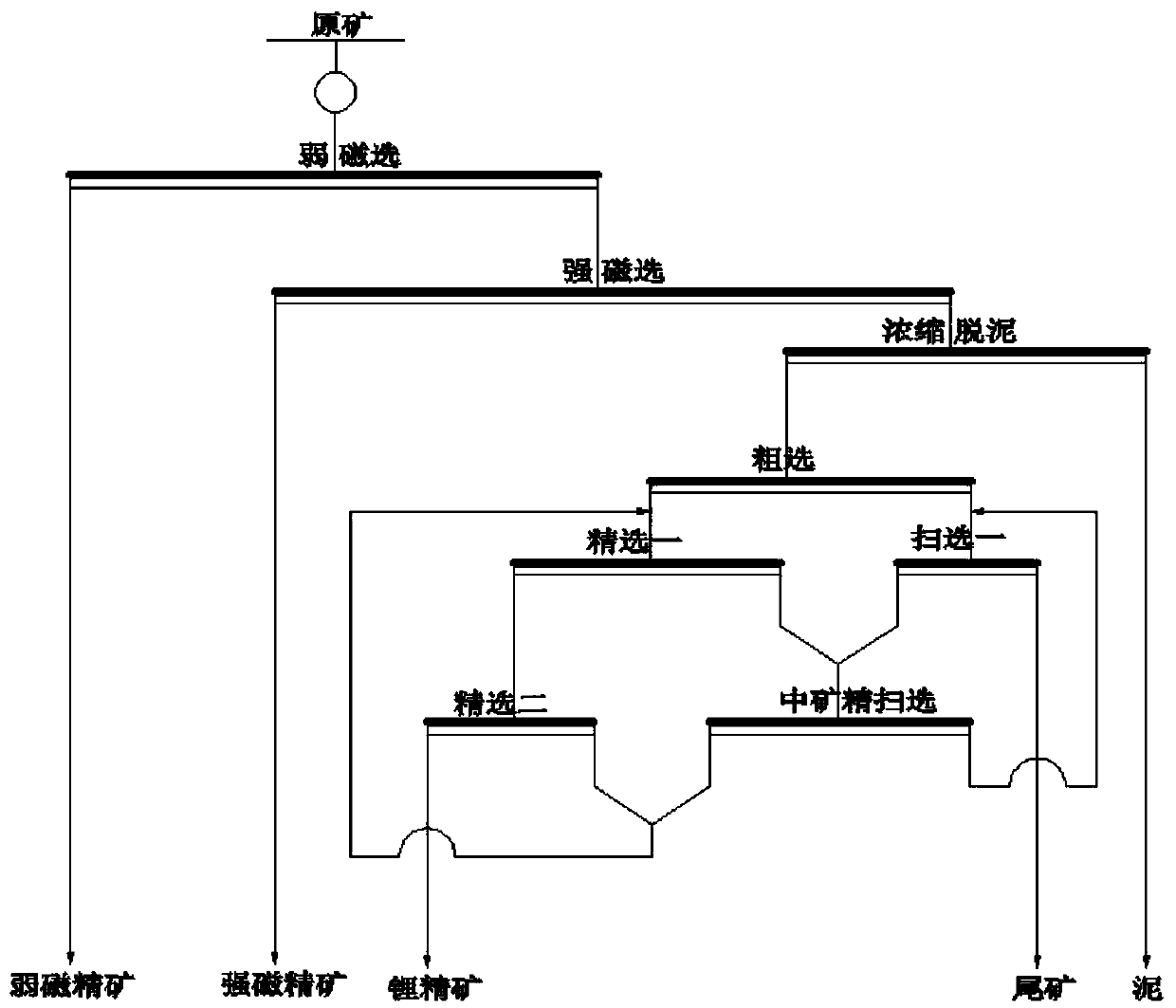

Magnet-flotation combined beneficiation technology of spodumene

ActiveCN109107754AThe flotation process is stableGood beneficiation indexWet separationOleic Acid TriglycerideMagnetic separation

The invention discloses a magnet-flotation combined beneficiation technology of spodumene. Spodumene ore is subjected to smashing and grinding. Ore pulp after grinding is sequentially subjected to lowintensity magnetic separation and high intensity magnetic separation to respectively obtain low intensity magnetic concentrated ore and high intensity magnetic concentrated ore. The discharged high intensity magnetic tailing ore is subjected to concentration and desliming, and is provided for flotation operation. Procedures of the flotation operation comprises one time of roughing, two times of scavenging and two times of concentrating. A collecting agent adopts compound of Fatty calcium, hydroxylamine compound and oleic acid, wherein the ratio is (6-7):(2.0-2.5):(1.0-1.5). The Li2O grade inthe final lithium concentrate is as high as 5.8-6.4%, and the recycling rate is 79.0-88%. The beneficiation technology is simple, stable and reliable, applicability is high, the laboratory index and the industrial application index are in agreement with each other, and the disadvantage of a big gap between the industrial application index and the laboratory index in the spodumene beneficiation technology is overcome. The collecting agent is excellent in selectivity, high in collecting performance, and is environmentally friendly.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

Beneficiation method for spodumene ore

ActiveCN109127117AThe flotation process is stableGood beneficiation indexWet separationDecompositionEngineering

The invention discloses a beneficiation method for spodumene ore. The spodumene ore is crushed and ground, ore pulp obtained after ore grinding is sequentially subjected to low-intensity magnetic separation and high-intensity magnetic separation, and weak-magnetism concentrates and strong-magnetism concentrates are obtained; discharged strong-magnetism tailings are fed to the flotation operation after being subjected to concentration and desliming, and the flotation operation process includes primary roughing, secondary scavenging and secondary fine selecting; calcium fatty acid prepared through the double decomposition reaction of a sodium fatty acid soap solution and a calcium chloride water solution is adopted as a collecting agent, the Li2O grade in the finally-obtained lithium concentrate reaches up to 5.7%-6.2%, and the recycling rate is 78%-88%. According to the beneficiation method, the beneficiation technology process is simple, stability and reliability are achieved, applicability is high, and the laboratory index highly conforms to the industry application index; and the defect that in the existing spodumene ore beneficiation technology, the difference between the industry application index and the laboratory index is large is overcome; and the adopted collecting agent has excellent properties that selectivity is good, the collecting capability is high, and environment friendliness is achieved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

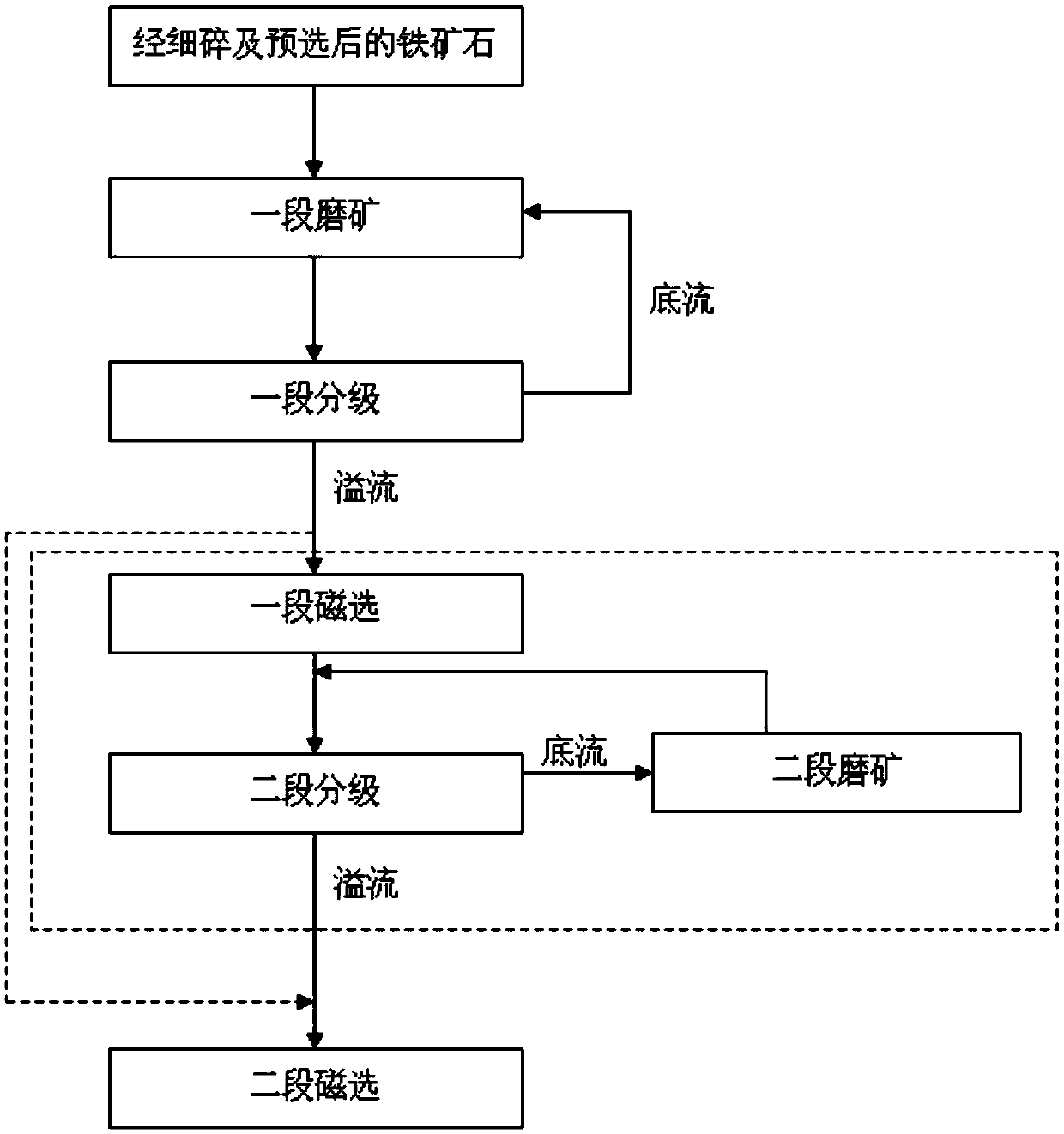

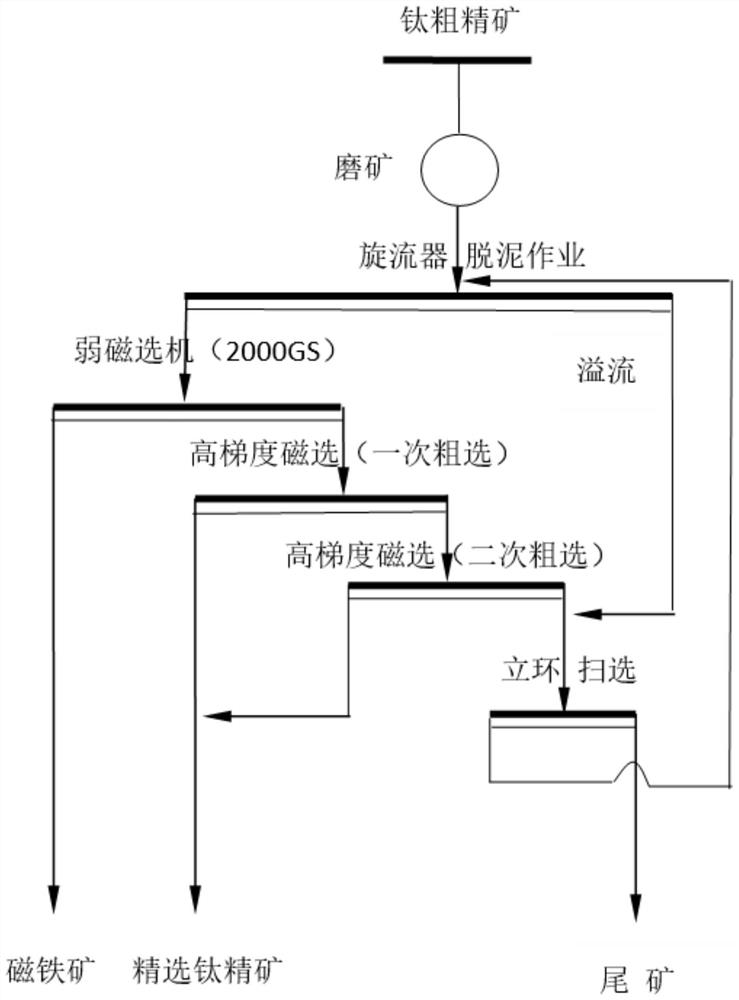

Method and system for producing refined sintered iron powder and refined pelletized iron powder simultaneously

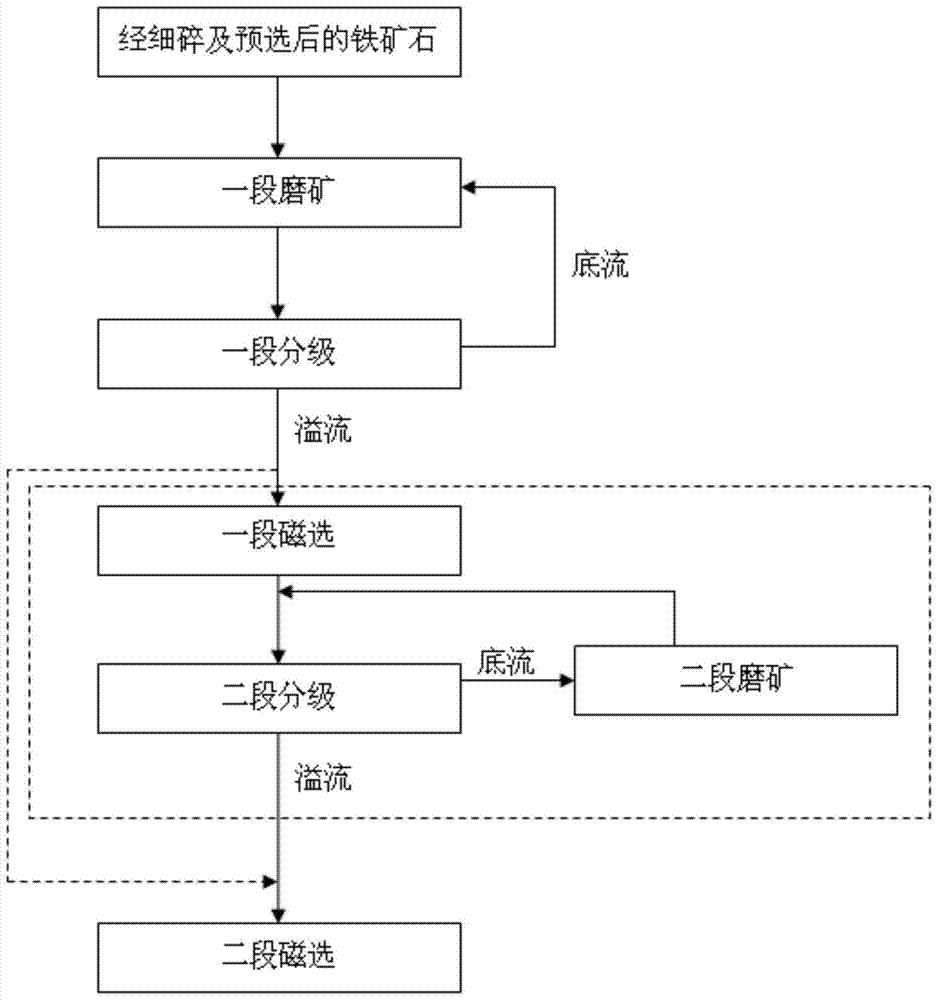

ActiveCN105498961AThe beneficiation process is simpleSave construction investmentVortex flow apparatusMagnetic separationIron powderBall mill

The invention discloses a method for producing refined sintered iron powder and refined pelletized iron powder simultaneously. The method comprises the following steps: carrying out primary grinding on finely-ground and pre-concentrated iron ores to obtain a primarily ground product; grading the primarily ground product to obtain a primary overflow ore product and a primary underflow ore product; carrying out secondary magnetic separation on the primary overflow ore product to obtain the refined sintered iron powder, and carrying out primary grinding on the primary underflow ore product in a ball grinding mill; or, carrying out primary magnetic separation and secondary grading on the primary overflow ore product, and then carrying out secondary magnetic separation to obtain the refined pelletized iron powder. The method and the system can be used for producing the refined sintered iron powder and the refined pelletized iron powder simultaneously, and thus the two products having different particle sizes can be produced in one process to meet different market requirements; and besides, the using efficacy of the equipment is improved, and the phenomenon that the utilization efficiency of the equipment is decreased due to change of the scheme of concentrate ore products but no change of ore dressing flow is avoided.

Owner:SHOUGANG CORPORATION

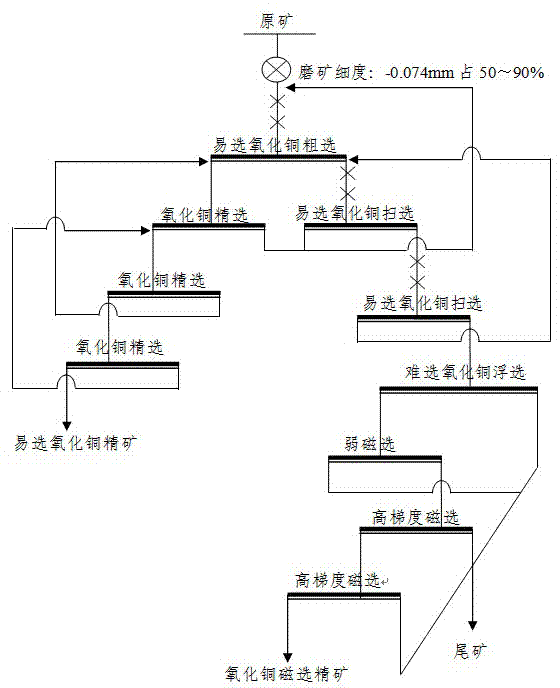

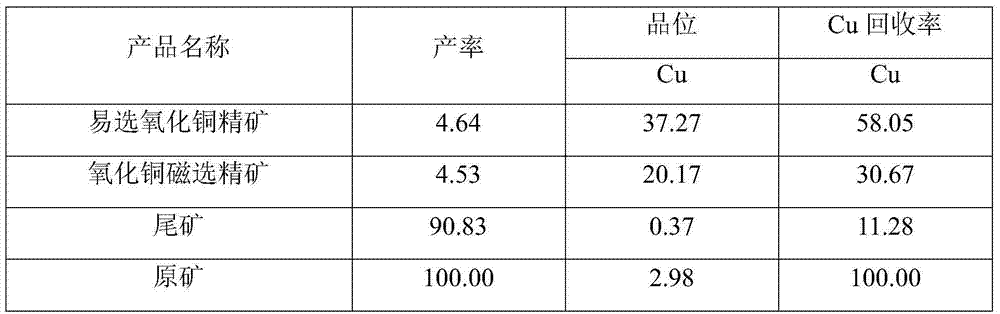

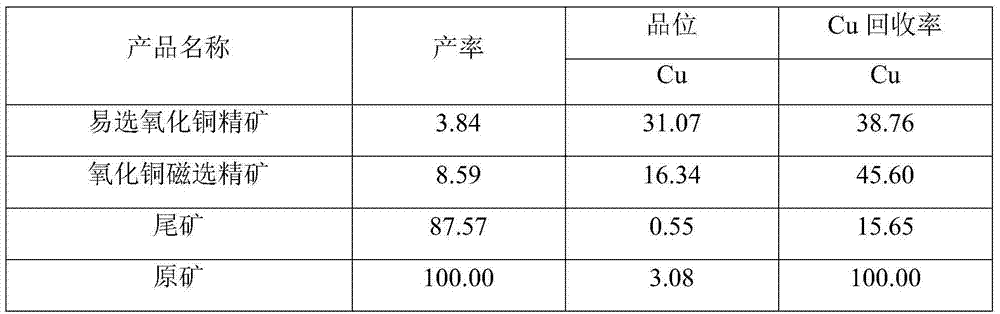

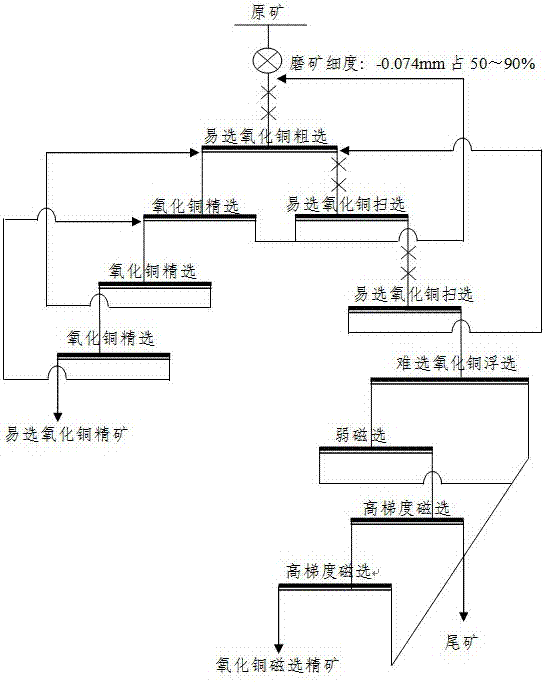

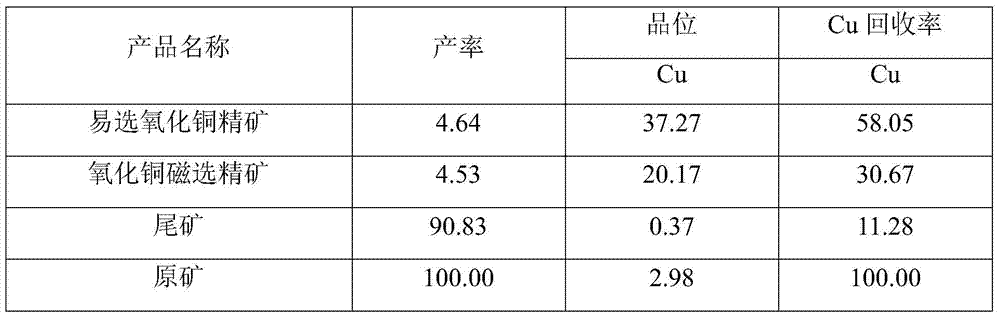

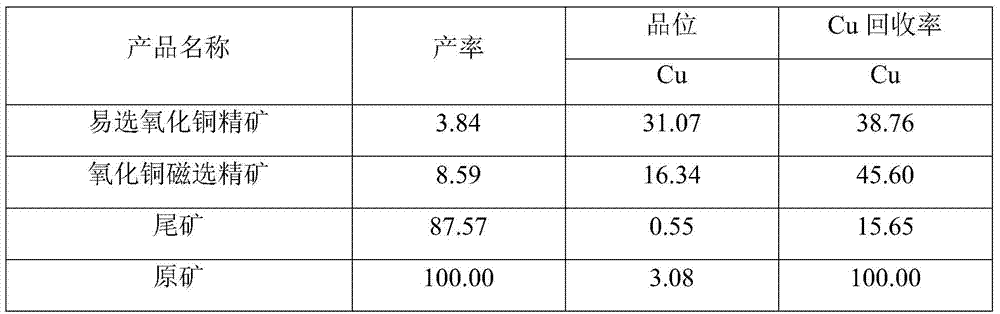

Method for separating copper oxide ores containing magnetic impurities

ActiveCN104759341AReduce manufacturing costThe beneficiation process is simpleFlotationWet separationSeparation processLower intensity

The invention relates to a method for separating copper oxide ores containing magnetic impurities. The copper oxide ores firstly goes through easily separable copper oxide flotation to obtain easily separable copper oxide concentrate and easily separable copper oxide tailings, and then difficultly separable copper oxide floatation is performed on the easily separable copper oxide tailings to obtain difficultly separable copper oxide flotation concentrate; a collecting agent used for the difficultly separable copper oxide floatation is a combined collecting agent; the combined collecting agent is composed of an yellow catching agent and 4-sodium diphenylaminesulfonate; low intensity magnetic separation and high gradient magnetic separation are orderly performed on the difficultly separable copper oxide flotation concentrate to obtain copper magnetic separation concentrate; the magnetic field intensity of the low intensity magnetic separation is 0.2-0.5T; the background magnetic field intensity of the high gradient magnetic separation is 0.7-1.2T. The separation process of the copper oxide ores is simple in flow, low in production cost and prone to industrial implementation.

Owner:HUNAN RES INST FOR NONFERROUS METALS

A Flotation Technology of Large Scale Crystalline Graphite Ore

The invention relates to a large-scale crystalline graphite ore flotation fast selecting agent and a flotation technology. The agent comprises following components including, by weight, 50% to 65% of methyl isobutyl carbinol, 20% to 30% of petroleum ether and 10% to 25% of acetone. The graphite ore flotation fast selecting agent can rapidly select high-quality large-scale graphite ore from neutral pulp, and high-grade large-scale crystalline graphite concentrate can be obtained through the short selection technology free of regrinding; compared with a traditional large-scale crystalline graphite ore flotation technology, graphite scales can be effectively protected, meanwhile, the consumption amount of the floatation agent can be reduced, and the production cost is reduced.

Owner:金建工程设计有限公司

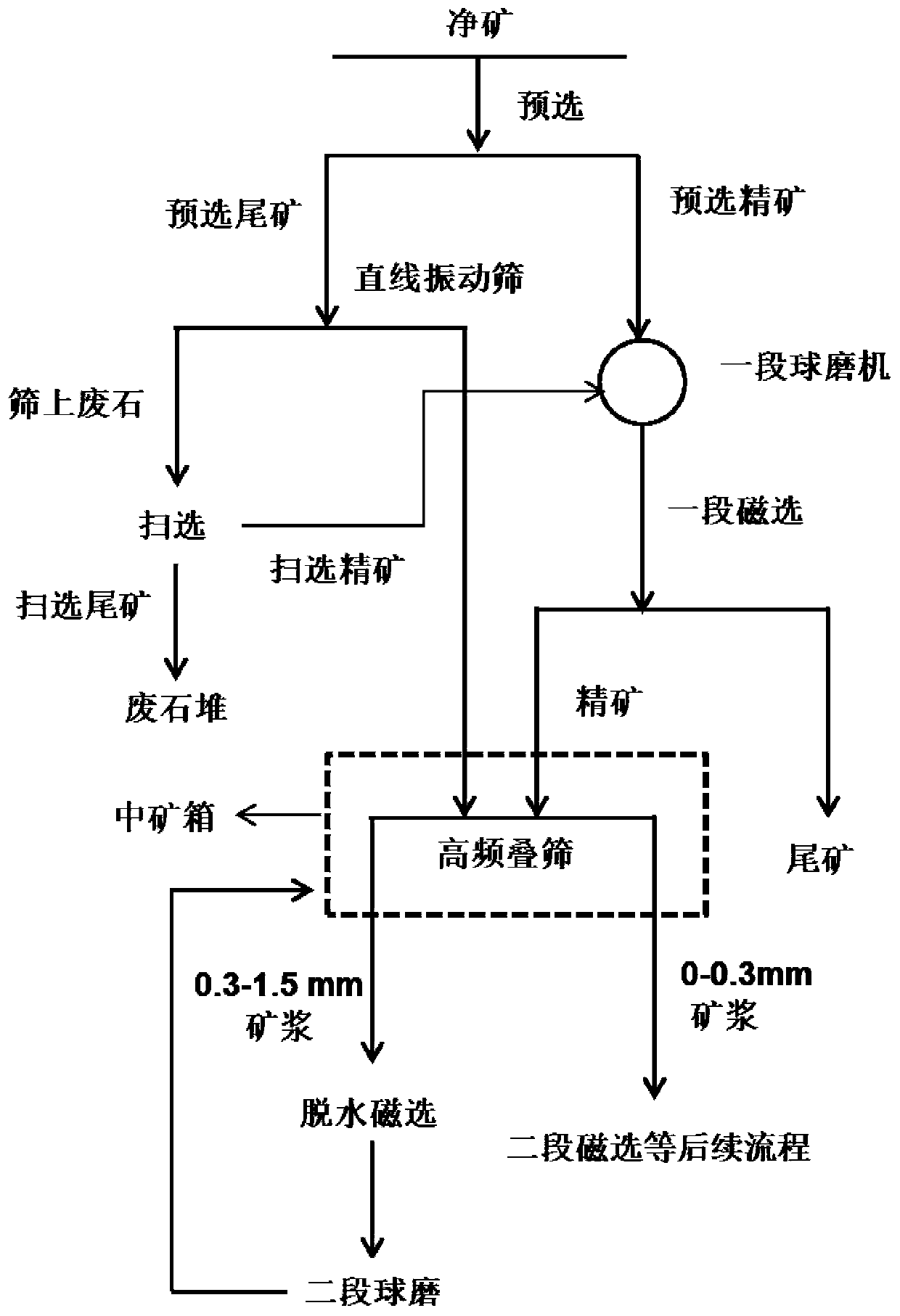

Ore dressing process for recycling lean magnetite

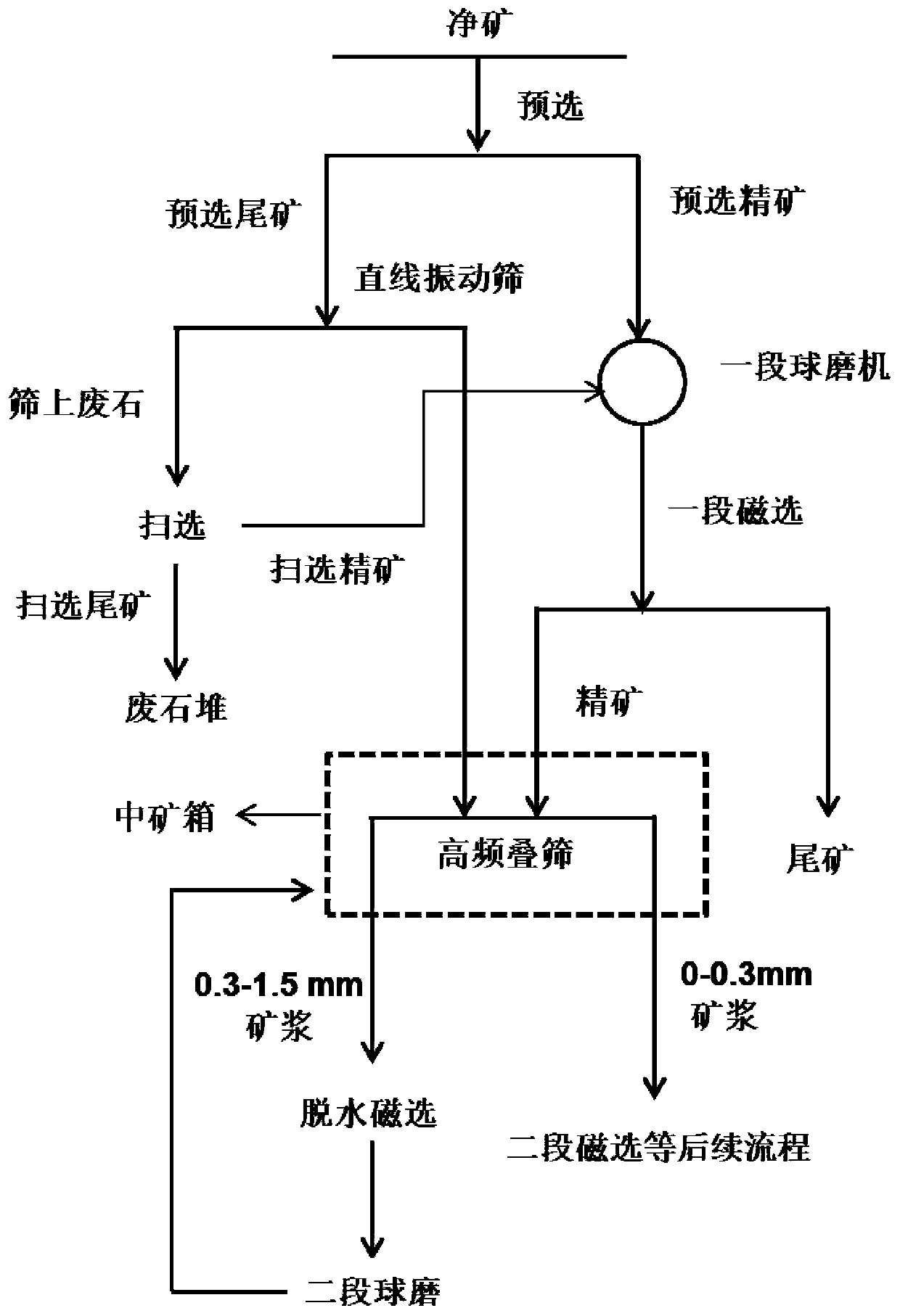

ActiveCN110064507AThe beneficiation process is simpleImprove initial taste and concentrate tasteWet separationBeneficiationMaterials science

The invention belongs to the field of ore dressing, and particularly relates to an ore dressing process for recycling lean magnetite. According to the process, the initial taste and the concentrate taste of ore are improved through the processes of pre-concentration before grinding, pre-concentrated concentrate treatment, pre-concentrated tailing classification, high-frequency cascade screening classification, waste ore recycling and the like, the beneficiation ratio is reduced, the production cost of a subsequent beneficiation process is reduced, and the ore dressing process is highly efficient.

Owner:DAZHONG MINING CO LTD INNER MONGOLIA

Collecting agent for sorting zinc oxide ore and preparation method thereof

The invention discloses a collecting agent for sorting zinc oxide ore. The collecting agent is mainly prepared by the following raw materials in parts by weight: 50 to 100 parts of isobutanol, 50 to 120 parts of sodium hydroxide, 60 to 120 parts of carbon disulfide, 10 to 200 parts of 1-amino-n-heptane, 50 to 100 parts of glycerol, 50 to 120 parts of salicylhydroxamic acid, 10 to 30 parts of sodium carbonate, 20 to 100 parts of sodium sulfide, 50 to 150 parts of water glass solution and 10 to 40 parts of kerosene. In addition, the invention also discloses a preparation method of the collecting agent. The collecting agent has collecting performance for both zinc sulfide and zinc oxide, the zinc sulfide and the zinc oxide can be simultaneously sorted, the process of sorting the zinc oxide after the zinc sulfide is sorted is not needed, the collecting agent is high in selectivity, the ore sorting process is simple in flow, the cost is low, the grade of the zinc concentrate obtained in a floatation manner is greater than 35%, and the grade and the recovery rate are obviously higher than those of conventional chemicals.

Owner:陕西省地质矿产实验研究所有限公司

Magnetic-flotation combined beneficiation process of spodumene

ActiveCN109107754BThe flotation process is stableGood beneficiation indexWet separationOleic Acid TriglycerideMagnetic separation

The invention discloses a magnet-flotation combined beneficiation technology of spodumene. Spodumene ore is subjected to smashing and grinding. Ore pulp after grinding is sequentially subjected to lowintensity magnetic separation and high intensity magnetic separation to respectively obtain low intensity magnetic concentrated ore and high intensity magnetic concentrated ore. The discharged high intensity magnetic tailing ore is subjected to concentration and desliming, and is provided for flotation operation. Procedures of the flotation operation comprises one time of roughing, two times of scavenging and two times of concentrating. A collecting agent adopts compound of Fatty calcium, hydroxylamine compound and oleic acid, wherein the ratio is (6-7):(2.0-2.5):(1.0-1.5). The Li2O grade inthe final lithium concentrate is as high as 5.8-6.4%, and the recycling rate is 79.0-88%. The beneficiation technology is simple, stable and reliable, applicability is high, the laboratory index and the industrial application index are in agreement with each other, and the disadvantage of a big gap between the industrial application index and the laboratory index in the spodumene beneficiation technology is overcome. The collecting agent is excellent in selectivity, high in collecting performance, and is environmentally friendly.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES CO LTD +1

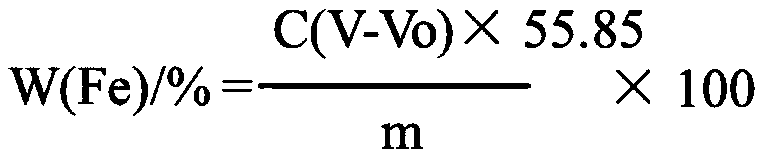

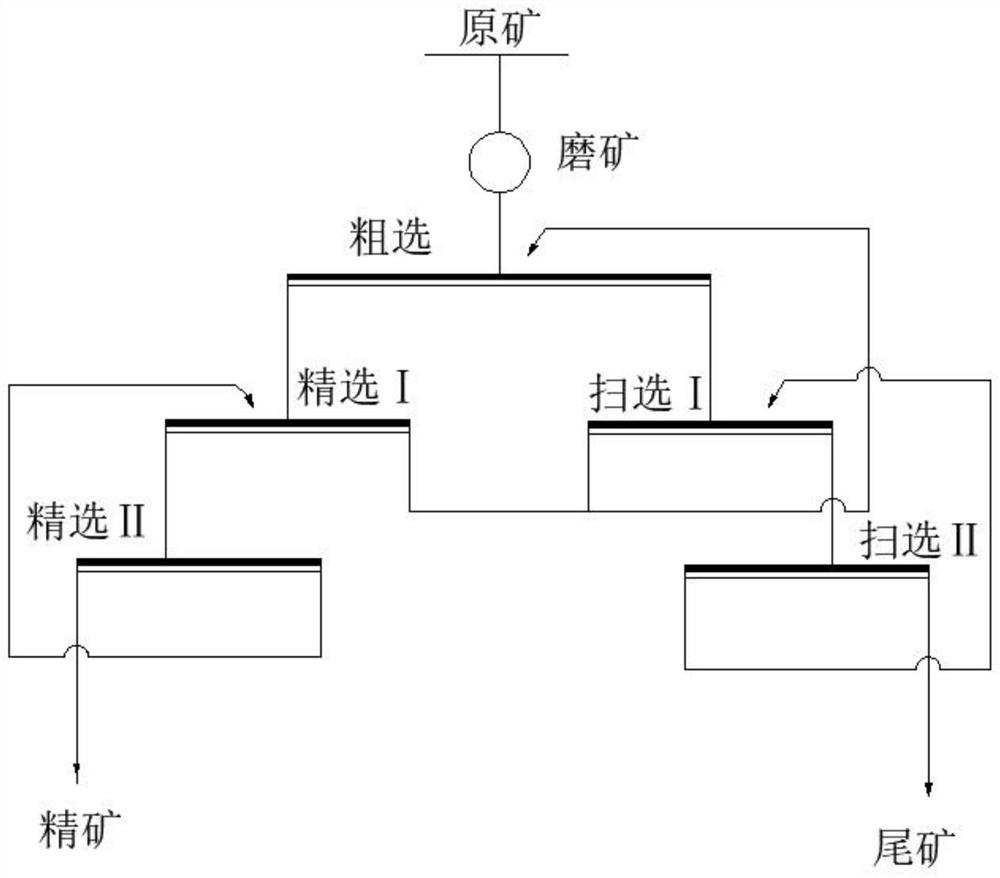

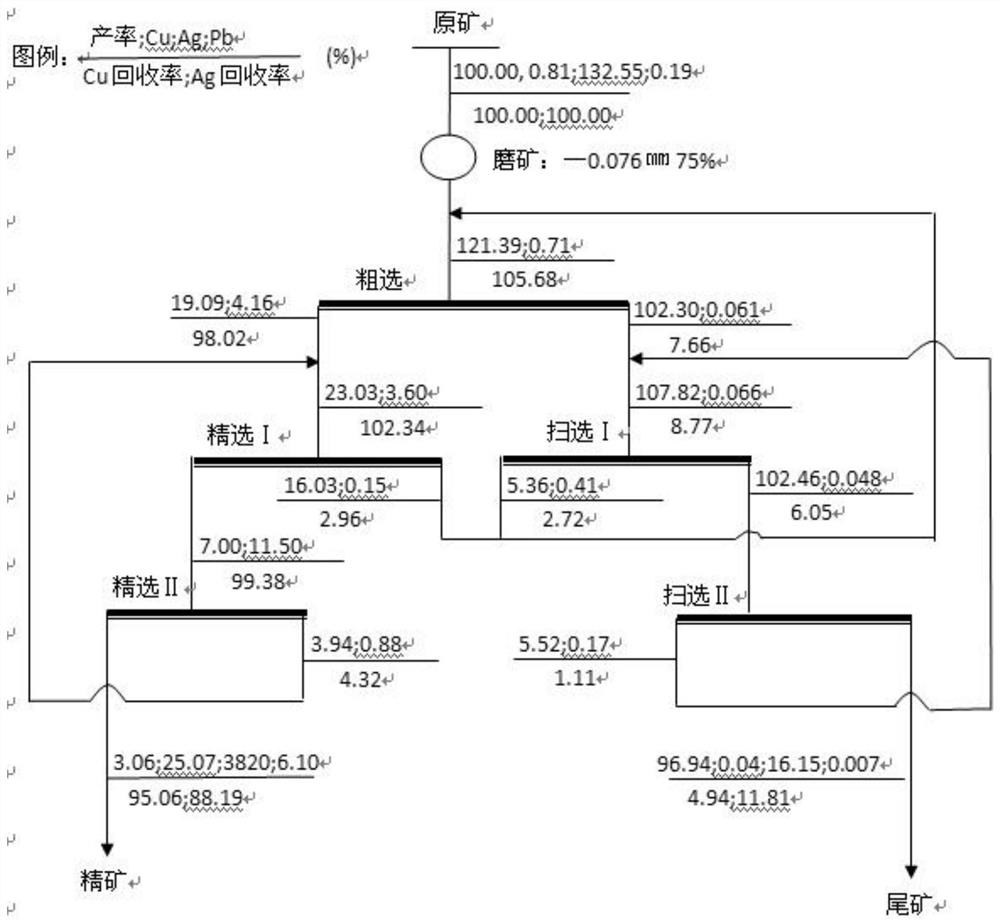

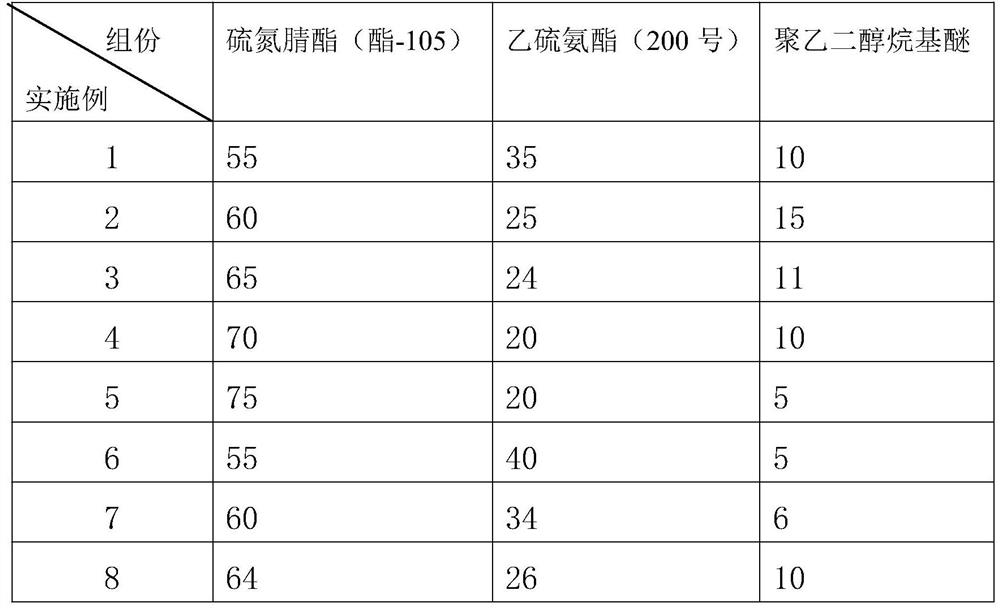

Collecting agent for flotation of complex and difficult-to-treat copper-silver sulfide ore

PendingCN114210462ANo pollutionSolve the technical problems of beneficiation that are difficult to use efficientlyFlotationFoaming agentCopper sulfide

The invention discloses a collecting agent for flotation of complex and difficult-to-treat copper sulfide silver ore, which is prepared by mixing the following components in percentage by mass: 55 to 75 percent of sulfur nitrogen nitrile ester, 20 to 40 percent of ethionine ester and 5 to 15 percent of polyethylene glycol alkyl ether. The collecting agent disclosed by the invention not only has very strong collecting performance, but also has foamability, so that the cost of a foaming agent can be saved in production; due to the fact that the collecting agent MT-23 is high in capacity, the total consumption of the agent per ton of ore is extremely low; the flotation cost is saved by more than 25% compared with that of an existing agent; the collecting agent is non-toxic, odorless and easy to degrade, belongs to a green and environment-friendly mineral separation collecting agent, and has a wide popularization prospect. By the adoption of the method, the recovery rate of copper and silver can be remarkably increased on the premise that the quality of copper-silver concentrate products is guaranteed, and the method has the advantages of being simple in technological process, stable, reliable, high in applicability, simple in reagent system, small in reagent dosage, convenient to add and the like.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

Mineral processing method for efficiently recycling iron blast furnace ash

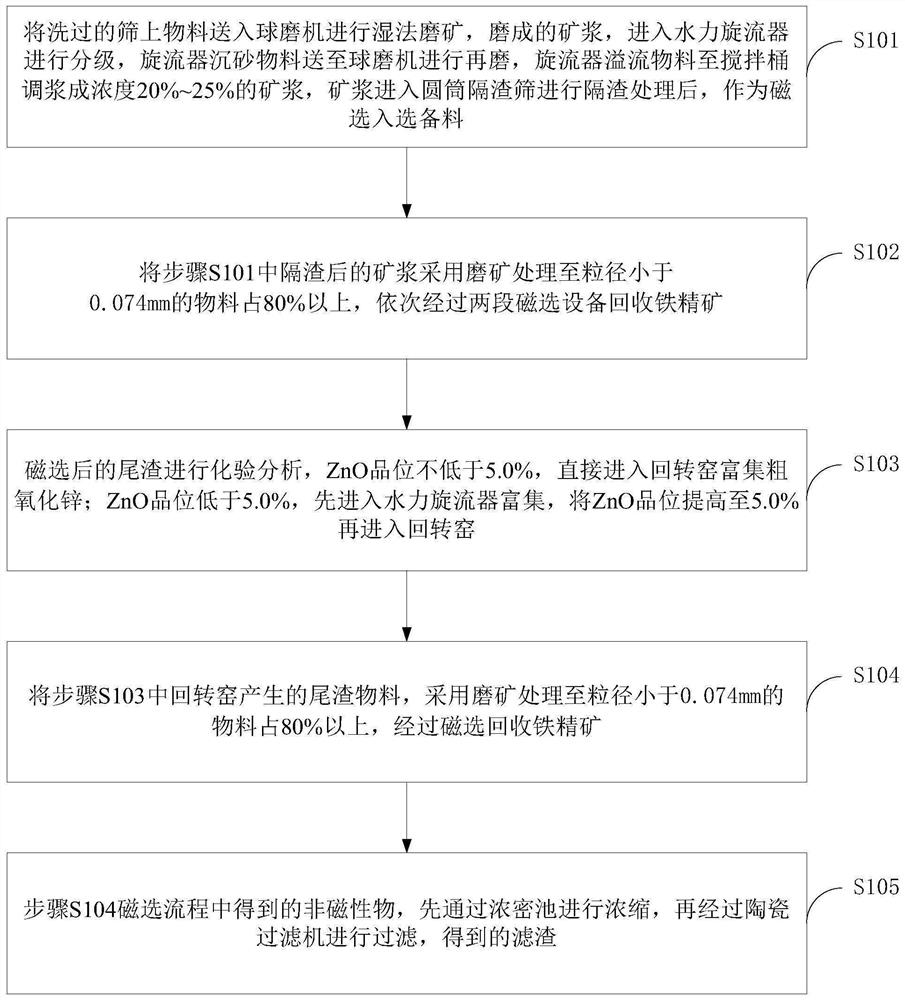

InactiveCN112458295AAchieve recyclingSolve the problem of stacking wasteRotary drum furnacesHigh gradient magnetic separatorsSlagMagnetic separation

The invention discloses a mineral processing method for efficiently recycling iron blast furnace ash. The method comprises the steps of ball milling, grading, size mixing, rotary kiln enrichment and the like, a two-section vertical ring pulsating high-gradient magnetic separator is adopted for magnetic separation so that the purity of iron-containing valuable metal elements in magnetic materials is greatly improved, zinc elements are enriched, carbon resources play a role of fuel in a rotary kiln, reasonable utilization of the carbon resources is guaranteed, tailings produced by the rotary kiln are subjected to magnetic separation and recovery again to obtain qualified iron ore concentrate, and slag obtained after magnetic separation is dehydrated and then serves as a building material. The mineral processing technological process is simple, the resource recycling rate is high, the mineral processing environment is good, economic benefits are high, tailings are avoided in the whole harmless production process, economic benefits are increased for the iron and steel industry, and the environmental protection pressure is reduced.

Owner:赣州金环磁选科技装备股份有限公司

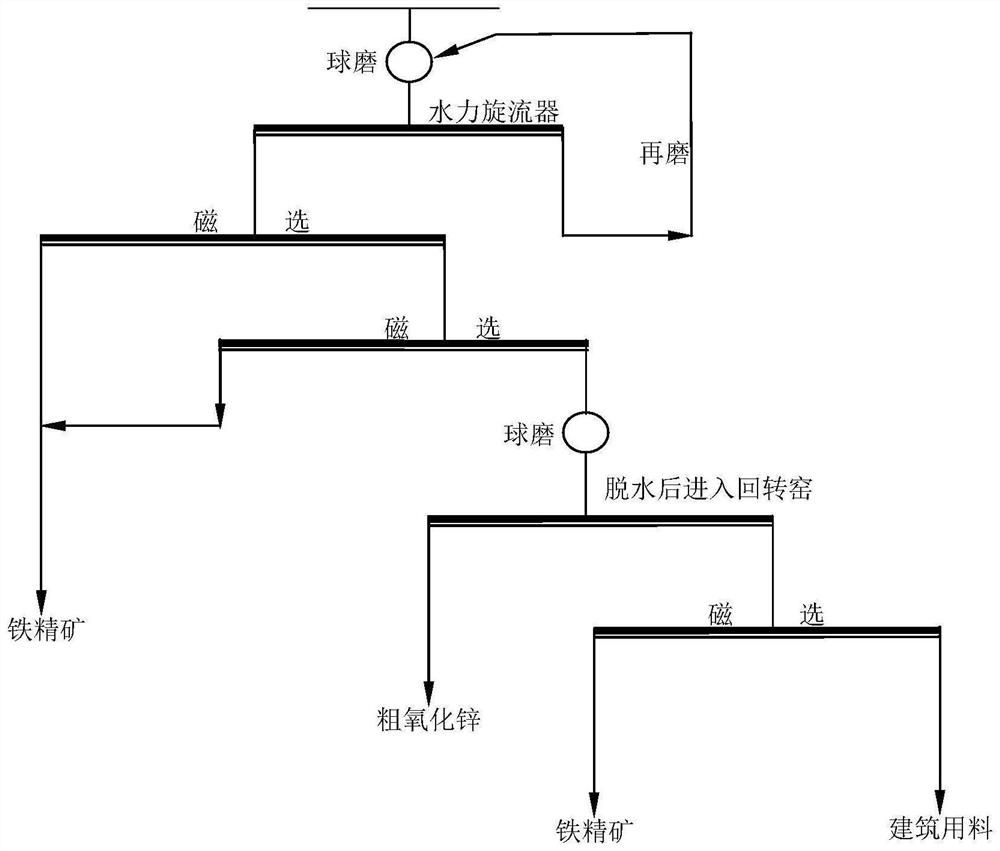

Method for recovering valuable metal mineral in zinc tailing

ActiveCN101797531BImprove sorting efficiencyEffective development and utilizationMagnetic separationWet separationUltimate tensile strengthMaterials science

The invention relates to a method for comprehensively recovering a valuable metal in a zinc tailing and belongs to the technical field of metal beneficiation. The process procedure comprises the following steps: roughing the prepared zinc tailing under the magnetic field strength of 8,000 to 12,000 OE by taking an attractive mineral in the zinc tailing as a carrier; performing ore grinding on themagnetic material until the magnetic material which can pass through 200 meshes screen accounts for 60 to 70 percent for dissociating lead-zinc combination; selecting the ground magnetic mineral under the magnetic field strength of 2,500 to 4,000 OE to obtain an iron ore concentrate finished product with the grade of iron over 60 percent; and sorting a nonmagnetic material through a multi-sectiontable to obtain a tin-rich middling product with the grade of tin over 3 percent. The method has the advantages of increasing recovery rate of a tin metal, recovering ferrous metal and manganese metal in the zinc tailing, and effectively utilizing the tailing resource, along with simple beneficiation process flow, low production cost, environmental-friendliness and good application and popularizing prospect; and the fruit can be spread and applied to the development and exploiting of high-ferric and low-tin resources.

Owner:YUNNAN TIN GROUP HLDG

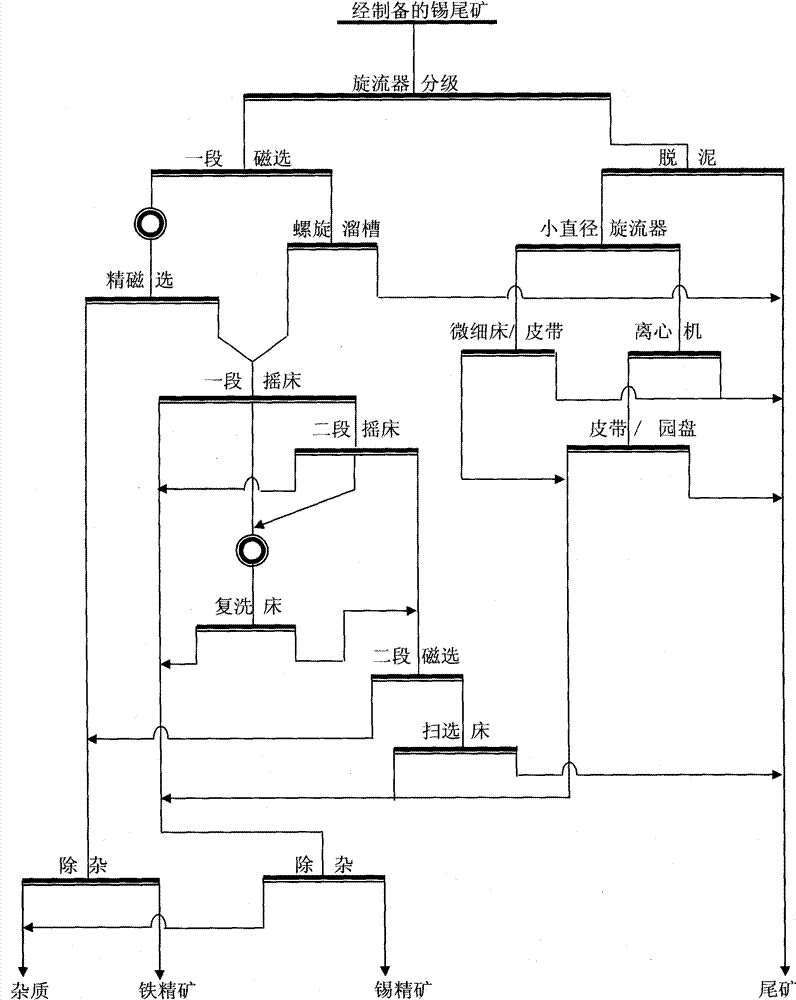

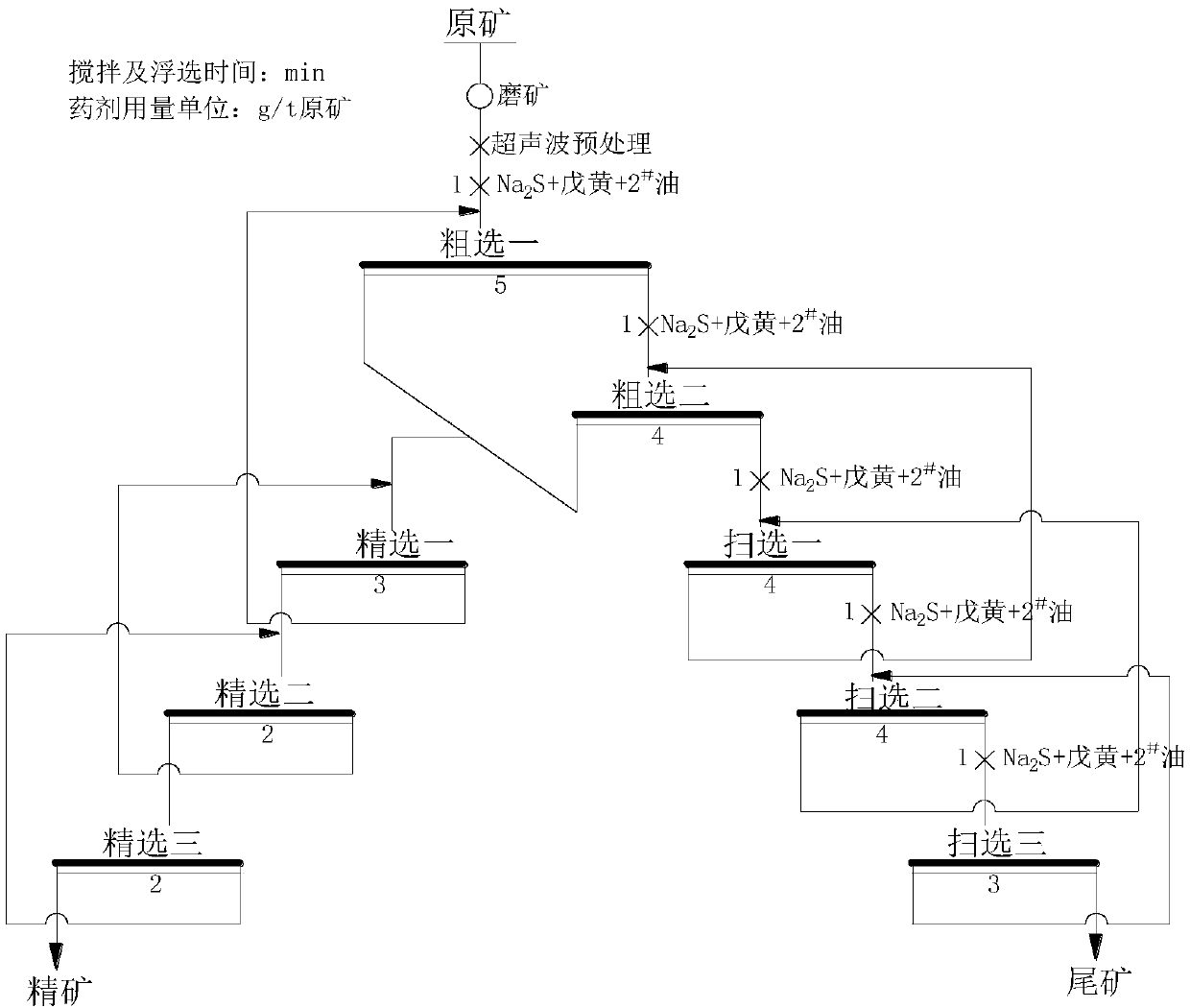

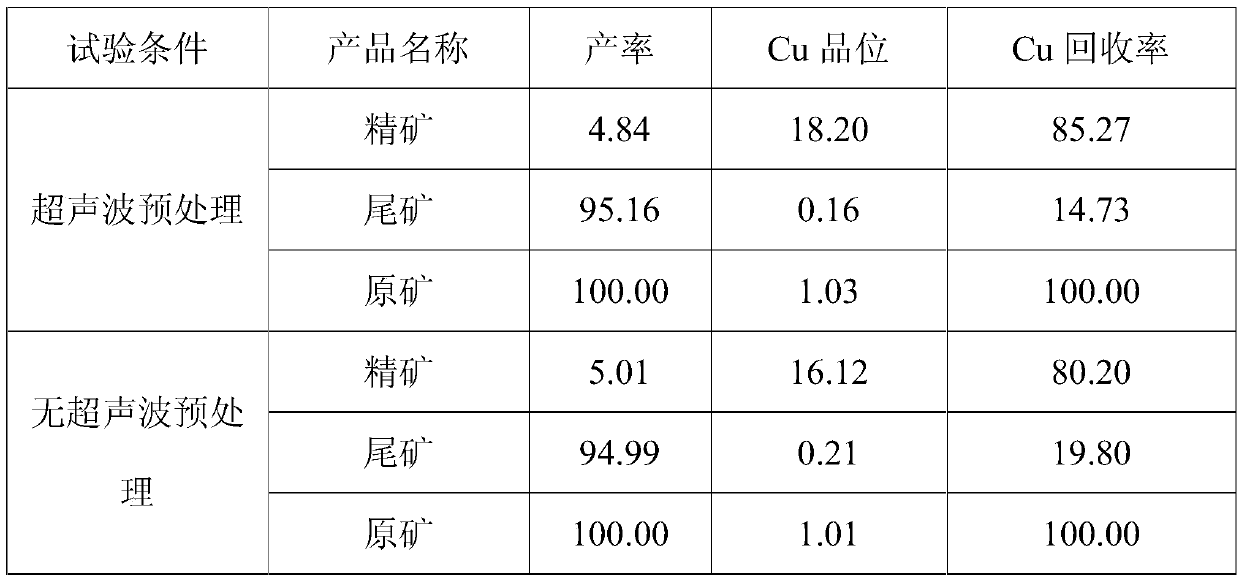

Method for improving high-shale-content copper oxide ore dressing indicators

InactiveCN107737667AHigh selectivityEnhanced harvesting capacityFlotationEnergy based chemical/physical/physico-chemical processesCopper oxideUltrasonic technology

The invention provides a method for improving high-shale-content copper oxide ore dressing indicators. The method comprises the following steps: ore grinding: grinding raw ore to achieve the finenessof negative 0.074 mm, the content of 85-95% and the ore pulp concentration of 18-30%; ultrasonic pretreatment: feeding obtained ore pulp into an ultrasonic stirring tank for the ultrasonic pretreatment, so as to obtain pretreated ore pulp; flotation: carrying out roughing on the pretreated ore pulp to obtain rougher concentrates and rougher tailings; carrying out concentration on the rougher concentrates to obtain a concentrate product; carrying out scavenging on the rougher tailings to obtain a tailing product; and adding a flotation reagent in the roughing and scavenging processes. Accordingto the method provided by the invention, a technological process that the ultrasonic pretreatment of the ore pulp and the floatation of copper oxide are combined is adopted, the problem about the covering effect of the ore pulp is solved, the target ore selectivity and capturing performance of the reagent are improved, and then the grade and the recovery rate of copper in the concentrate productare improved.

Owner:HUNAN RES INST FOR NONFERROUS METALS

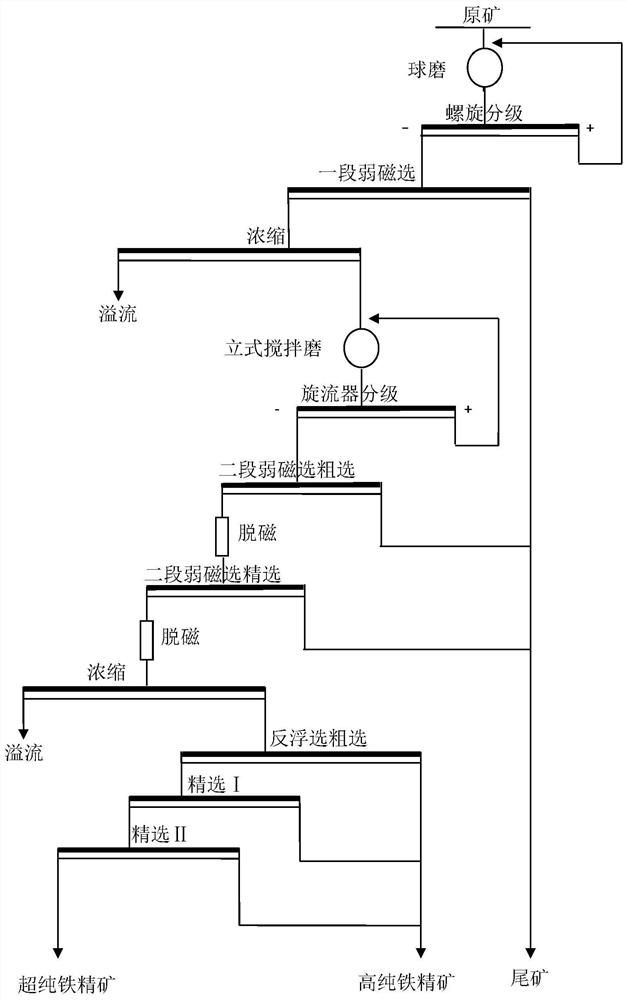

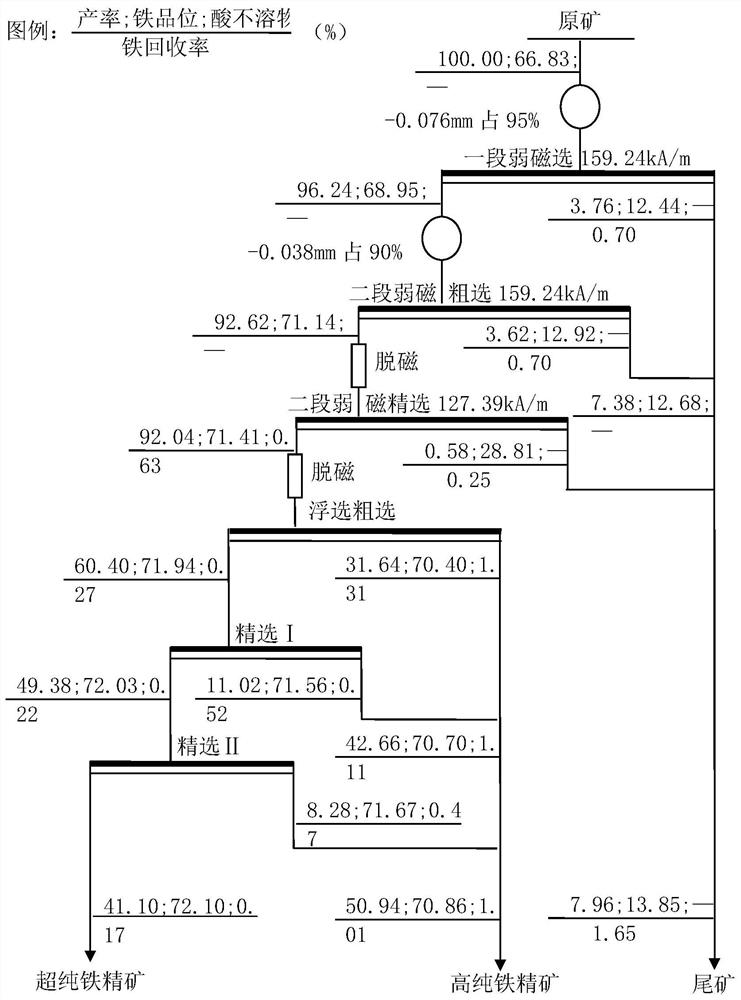

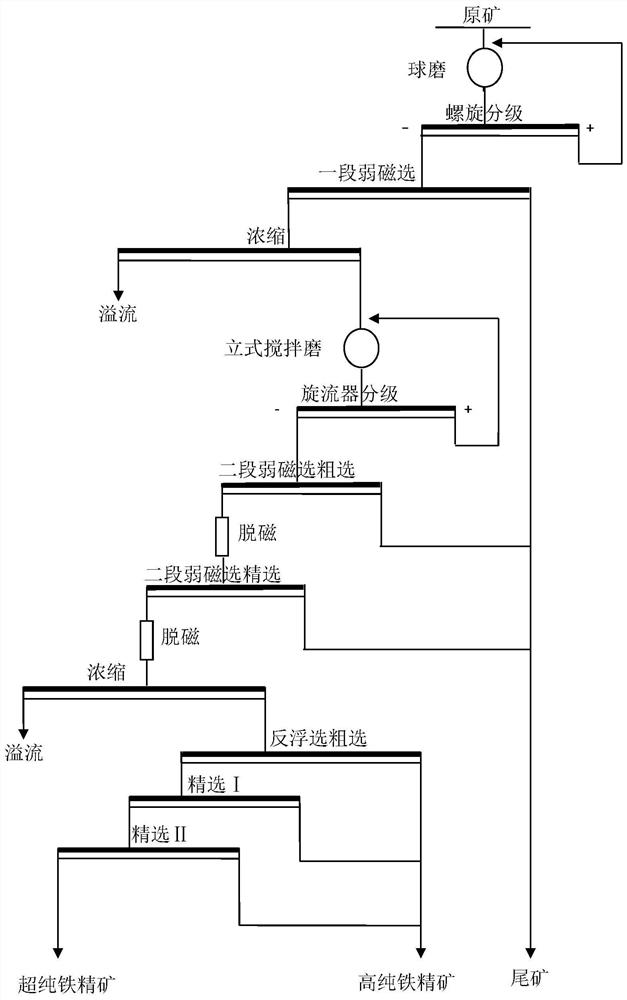

A method for preparing ultra-pure iron concentrate by deep processing of commercial grade magnetite concentrate

ActiveCN111905918BUniform particle sizeGrinding is flexible and variableFlotationWet separationAcetic acidMagnetite

The invention discloses a method for preparing ultra-pure iron ore concentrate through deep processing of commercial-grade magnetite concentrate, which adopts one-stage grinding-grading-one-stage weak magnetic separation, one-stage weak magnetic separation concentrate dehydration, and two-stage grinding- Classification, second-stage weak magnetic separation roughing-demagnetization-second-stage weak magnetic separation and concentration, second-stage weak magnetic separation concentrate demagnetization-concentration operation: demagnetize the second-stage weak magnetic separation concentrate , and then concentrated and reverse flotation operations, and finally obtained the grade of TFe in the ultra-pure iron concentrate 72.10% ~ 72.19%, SiO 2 Content 0.18% ~ 0.20%, acid insoluble matter 0.15% ~ 0.17%. At the same time, high-purity iron concentrates with a TFe grade of 70.86% to 71.12% can also be obtained. The collector for the reverse flotation operation of the present invention is a solution of dodecylamine and glacial acetic acid which is modified by heating according to the mass ratio of 4:1. The method of the invention has strong applicability, high efficiency and energy saving. The flotation reagent system is simple, the source is wide, the dosage is small, the selectivity is good, and it is very friendly to the environment and other excellent properties.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES CO LTD +1

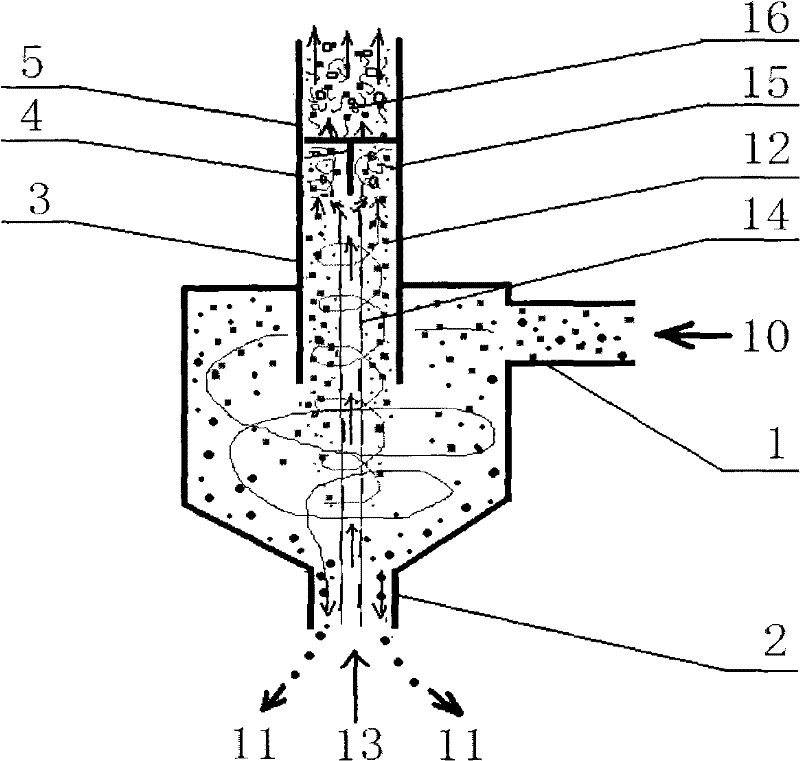

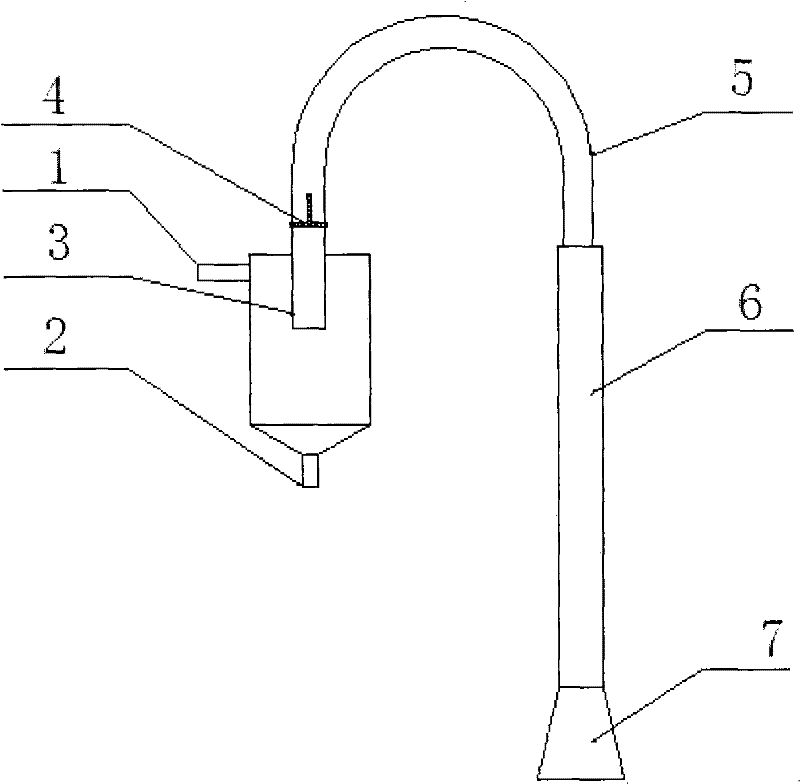

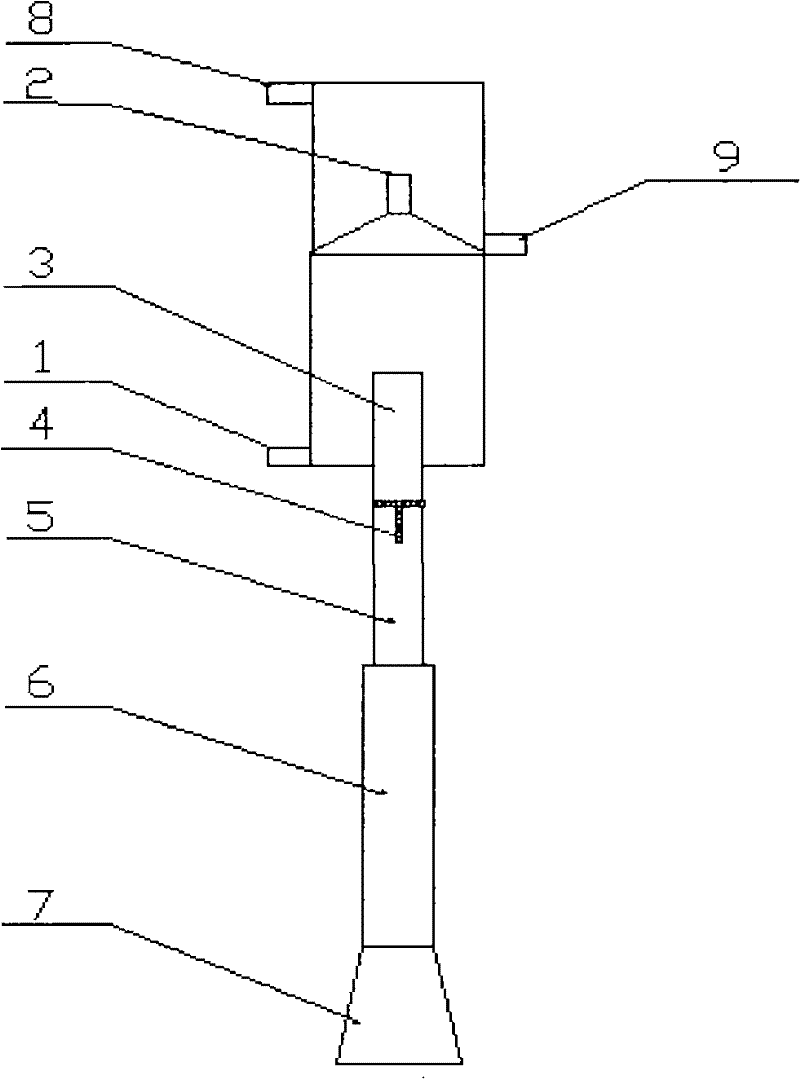

Rotational flow and jet flow inflating method and device thereof

ActiveCN101474599BSave jet kinetic energyImprove inflation efficiencyReversed direction vortexFlotationJet flowMixed flow

The invention provides an air inflation method and a device thereof for a flotation column. A whirlcone is combined with flotation air inflation, and by utilizing the characteristic that an air column exists inside the whirlcone during operation, the air column is guided out along with the overflow of the whirlcone and is thoroughly mixed with mine slurry; and then the dynamic power of the overflow of the whirlcone is utilized to jet currents, thereby realizing the air inflation of the flotation column and other kinds of equipment. The invention comprises a whirlcone, mixed vanes, a jet pipe,a hollow throat and a diverging pipe, wherein the mixed vanes are fixed at the outlet of an overflow pipe of the whirlcone, rotary mine slurry flowing out from the overflow pipe comes in contact withthe mixed vanes and are enforcedly divided into four strands of mine slurry flows, and air is involved in and intensively mixed with the mine slurry flows, thereby forming three-phase (air-liquid-solid) mixed flows; and the mixed flows carry great dynamic power to flow into the jet pipe, and then are sequentially led through the hollow throat and the diverging pipe, thereby completing the processes of air inflation and mineralization. The device has the function of grading or sorting, and can be combined with other kinds of sorting equipment to be used, thereby simplifying the mineral processing technology.

Owner:TAIYUAN UNIV OF TECH

A kind of beneficiation method of spodumene ore

ActiveCN109127117BThe flotation process is stableGood beneficiation indexWet separationFatty acidAqueous solution

Owner:SINOSTEEL MAANSHAN INST OF MINING RES CO LTD

A kind of beneficiation method of using magnetite concentrate to prepare ultra-pure iron concentrate

ActiveCN112090578BUniform particle sizeGrinding is flexible and variableFlotationGrain treatmentsMagnetiteAcetic acid solution

The invention discloses an ore dressing method for preparing ultra-pure iron concentrate by adopting magnetite concentrate, which adopts one-stage grinding-classification-one-stage weak magnetic separation, one-stage weak magnetic separation concentrate dehydration, and two-stage grinding-classification , Second-stage weak magnetic separation roughing-demagnetization-second-stage weak magnetic separation and concentration, second-stage weak magnetic separation concentrate demagnetization-concentration operation: demagnetize the obtained second-stage weak magnetic separation concentrate treatment, followed by concentration and reverse flotation operations to finally obtain TFe>72.0%, SiO 2 Ultra-pure iron concentrate with content ≤0.20%, acid insoluble matter ≤0.17%, and high-purity iron concentrate with TFe>70.7%. The collector for the reverse flotation operation of the present invention is a solution of dodecylamine and glacial acetic acid which is modified by heating according to the mass ratio of 4:1. The method of the invention has the advantages of flexible mineral processing process, stable and reliable, strong applicability, high efficiency and energy saving. The flotation reagent system is simple, the source is wide, the dosage is small, the selectivity is good, and it is very friendly to the environment and other excellent properties.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES CO LTD +1

A combined process treatment method for high-iron and low-tin oxide ore

Owner:YUNNAN TIN GROUP HLDG

A kind of beneficiation process for recycling lean magnetite

ActiveCN110064507BImprove annual processing capacityReduce manufacturing costWet separationMining engineeringMagnetite

The invention belongs to the field of ore dressing, and particularly relates to an ore dressing process for recycling lean magnetite. According to the process, the initial taste and the concentrate taste of ore are improved through the processes of pre-concentration before grinding, pre-concentrated concentrate treatment, pre-concentrated tailing classification, high-frequency cascade screening classification, waste ore recycling and the like, the beneficiation ratio is reduced, the production cost of a subsequent beneficiation process is reduced, and the ore dressing process is highly efficient.

Owner:DAZHONG MINING CO LTD INNER MONGOLIA

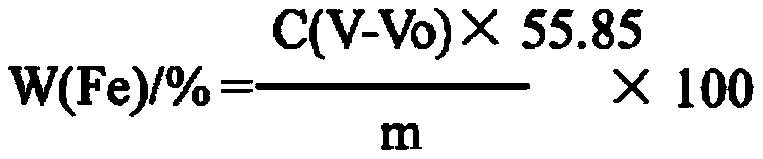

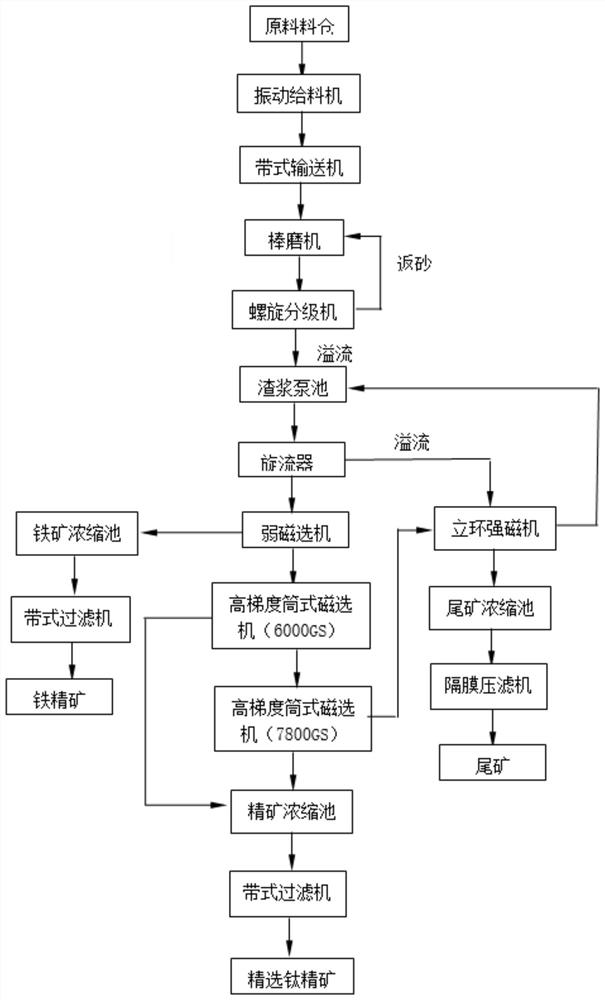

Titanium rough concentrate concentration method

The invention discloses a titanium rough concentrate concentration method, and belongs to the technical field of mineral separation. The problems that in the prior art, after concentration, titanium concentrate is low in grade, the content of impurity elements such as silicon and calcium is high, the yield of the titanium concentrate is low, and water and electricity energy consumption is low are solved. According to the titanium rough concentrate concentration method, a raw material bin, a conveying device, a rod mill, a slurry pump pool, a cyclone, a low-intensity magnetic separator, a high-gradient drum-type magnetic separator, a concentrate concentration pool and a belt filter which are sequentially connected are included, and the low-intensity magnetic separator is further sequentially connected with an iron ore concentration pool and the belt filter; and the high-gradient drum-type magnetic separator is sequentially connected with a vertical ring strong magnetic separator, a tailing concentration tank and a diaphragm filter press, an overflow port of the cyclone is connected with a feeding port of the vertical ring strong magnetic separator, and a discharging port of the vertical ring strong magnetic separator is further connected with the slurry pump tank. According to the titanium rough concentrate concentration method, after concentration, about 70% of impurity SiO2, 75% of impurity CaO and 16% of impurity magnesium in the titanium rough concentrate can be removed. The yield of the concentrate can be increased to 87.65%, and the tailing grade is reduced to 15.0%.

Owner:武定国钛金属有限公司

Method and system capable of simultaneously producing sintered iron fine powder and pelletized iron fine powder

ActiveCN105498961BThe beneficiation process is simpleSave construction investmentVortex flow apparatusMagnetic separationIron powderBall mill

The invention discloses a method for producing refined sintered iron powder and refined pelletized iron powder simultaneously. The method comprises the following steps: carrying out primary grinding on finely-ground and pre-concentrated iron ores to obtain a primarily ground product; grading the primarily ground product to obtain a primary overflow ore product and a primary underflow ore product; carrying out secondary magnetic separation on the primary overflow ore product to obtain the refined sintered iron powder, and carrying out primary grinding on the primary underflow ore product in a ball grinding mill; or, carrying out primary magnetic separation and secondary grading on the primary overflow ore product, and then carrying out secondary magnetic separation to obtain the refined pelletized iron powder. The method and the system can be used for producing the refined sintered iron powder and the refined pelletized iron powder simultaneously, and thus the two products having different particle sizes can be produced in one process to meet different market requirements; and besides, the using efficacy of the equipment is improved, and the phenomenon that the utilization efficiency of the equipment is decreased due to change of the scheme of concentrate ore products but no change of ore dressing flow is avoided.

Owner:SHOUGANG CORPORATION

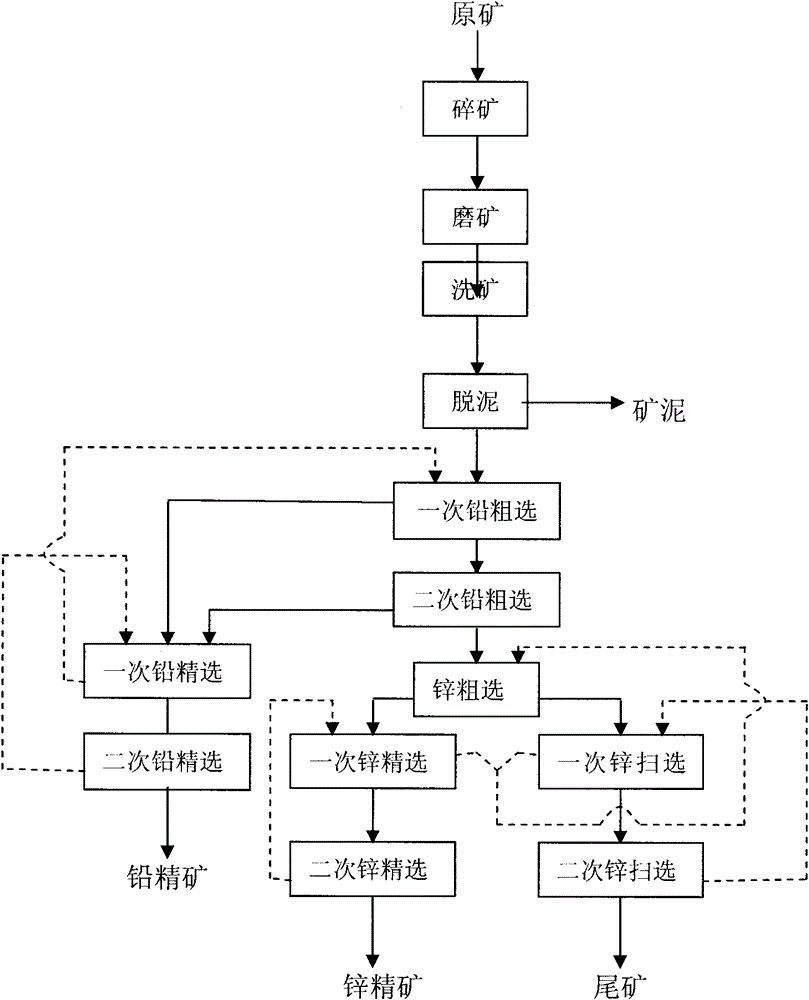

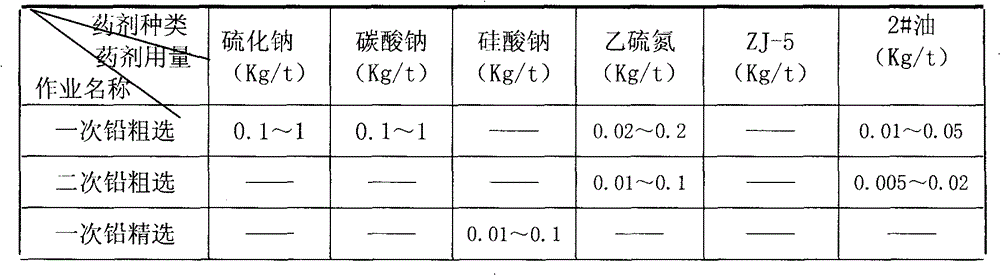

A mineral processing method for processing low-grade tin-lead-zinc polymetallic oxide ore

InactiveCN104148163BEfficient recyclingSimple processFlotationWet separationIndiumGravity separation

Owner:GUANGXI JINSHAN INDIUM & GERMANIUM METALLURGICAL CHEM

A collector for sorting zinc oxide ore and its preparation method

The invention discloses a collector for sorting zinc oxide ore, which is mainly made of the following raw materials in parts by weight: 50-100 parts of isobutanol, 50-120 parts of caustic soda, 60-120 parts of carbon disulfide, 1-amino 10-200 parts of heptane, 50-100 parts of glycerin, 50-120 parts of salicylic hydroxamic acid, 10-30 parts of sodium carbonate, 20-100 parts of sodium sulfide, 50-150 parts of water glass solution, 10-40 parts of kerosene . In addition, the invention also discloses a preparation method of the collector. The collector of the present invention has collecting performance for both zinc sulfide and zinc oxide, and can simultaneously select zinc sulfide and zinc oxide without first selecting zinc sulfide and then zinc oxide. The technological process is simple and the cost is low. The grade of the zinc concentrate obtained by flotation is greater than 35%, and the grade and recovery rate are obviously higher than those of conventional agents.

Owner:陕西省地质矿产实验研究所有限公司

A kind of beneficiation method for separating molybdenum tungsten oxide and molybdenum sulfide ore in molybdenum tungsten ore

InactiveCN106076590BRaise the gradeImprove beneficiation efficiencyFlotationMagnetic separationNon magneticMagnetic characteristic

The invention relates to a beneficiation method for separating molybdenum-tungsten oxide ore and molybdenum sulfide ore from molybdenum tungsten ore. The beneficiation method comprises the steps that magnetic separation is conducted on raw separation molybdenum sulfide ore at least twice, so that the raw separation molybdenum sulfide ore subjected to magnetic separation is divided into magnetic ore containing molybdenum-tungsten oxide and non-magnetic ore containing molybdenum sulfide; and a molybdenum-tungsten oxide flotation process is conducted on the magnetic ore, and a molybdenum sulfide flotation process is conducted on the non-magnetic ore, so that molybdenum-tungsten oxide concentrate and molybdenum sulfide concentrate are obtained. According to the beneficiation method for separating the molybdenum-tungsten oxide ore and the molybdenum sulfide ore from the molybdenum tungsten ore, the magnetic ore containing molybdenum-tungsten oxide and the non-magnetic ore containing molybdenum sulfide are separated out before ore grinding by means of the magnetic characteristic of iron-bearing ore in skarn in a magnetic separation and flotation combined way, so that the floatability of the ore is improved, the beneficiation feed grades of the molybdenum sulfide ore and the and molybdenum-tungsten oxide ore subjected to flotation are increased, and a subsequent flotation technological process is simplified; and in addition, grading index fluctuation caused by the change of the characteristics of the ore is reduced, and the mine production cost can be reduced easily.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

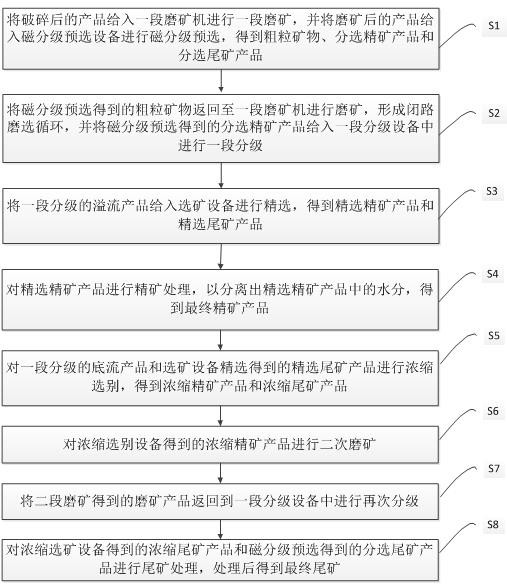

Ore separation method and ore separation system

PendingCN113560017AImprove sorting efficiencySimplify the sorting processMagnetic separationGrain treatmentsProcess engineeringSeparation system

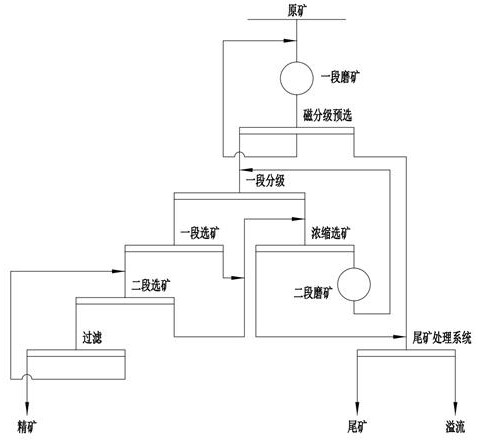

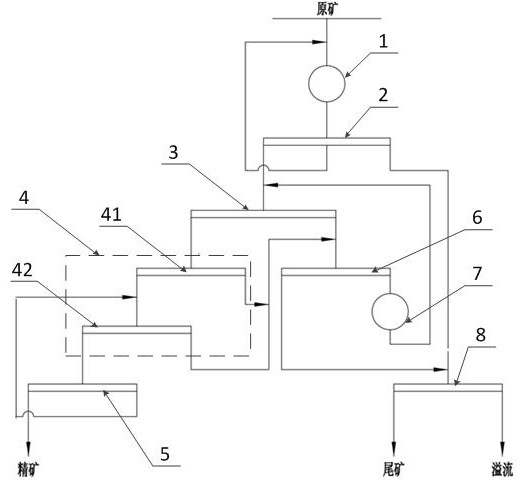

The invention provides an ore separation method and an ore separation system. The ore separation method comprises the steps that crushed products are fed into a primary ore grinding machine to be subjected to primary ore grinding, and the ground products are fed into magnetic classification pre-separation equipment to be subjected to magnetic classification pre-separation; separated concentrate products obtained through magnetic classification pre-separation are fed into primary classification equipment to be classified; overflow products subjected to primary classification are fed into ore separation equipment for concentration; and concentrate treatment is carried out on the concentrated concentrate products to separate moisture in the concentrated concentrate products to obtain final concentrate products. According to the method, the magnetic classification pre-separation equipment is selected to be connected with the primary ore grinding machine for use, the magnetic classification pre-separation equipment integrates classification and magnetic separation into a whole, and after the magnetic classification pre-separation equipment is directly used for the grinding machine, the ore grinding-classification-separation process in traditional primary ore treatment is optimized and upgraded to the ore grinding-separation process, the classification process is removed, the ore separation process is simplified, the number of devices in the process is reduced, the number of devices needing to be controlled is reduced, and the occupied area of mineral separation equipment is reduced.

Owner:LONGI MAGNET CO LTD

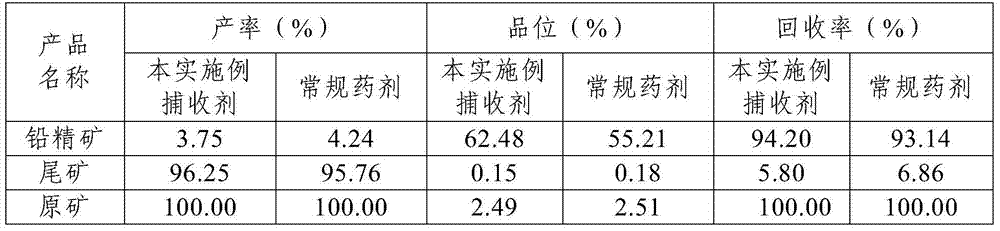

A kind of collector for sorting lead ore and preparation method thereof

The invention discloses a collector for sorting lead ores, which is prepared from the following raw materials in parts by weight: 50-120 parts of pentylenepentyl alcohol, 10-30 parts of carbon disulfide, 30-80 parts of monochloroacetic acid, and n-butylamine aqueous solution 50-80 parts, pentaerythritol 50-200 parts, terpineol oil 50-150 parts, caustic soda 20-60 parts, sodium sulfide 20-100 parts, water glass solution 50-150 parts, diesel oil 10-30 parts, active nickel catalyst 0-10 parts; the volume percent concentration of n-butylamine in the n-butylamine aqueous solution is 50%-70%. In addition, the invention also provides a preparation method of the collector. The collector of the present invention has collecting performance on lead sulfide and lead oxide, therefore, the collector can select lead sulfide and lead oxide at the same time, without first selecting lead sulfide and then lead oxide. The grade and recovery rate of lead concentrate obtained by collector flotation are significantly higher than those of conventional reagents.

Owner:陕西省地质矿产实验研究所有限公司

A kind of beneficiation method of copper oxide ore containing magnetic impurities

ActiveCN104759341BReduce manufacturing costThe beneficiation process is simpleFlotationWet separationCopper oxideSodium diphenylamine sulfonate

The invention relates to a method for separating copper oxide ores containing magnetic impurities. The copper oxide ores firstly goes through easily separable copper oxide flotation to obtain easily separable copper oxide concentrate and easily separable copper oxide tailings, and then difficultly separable copper oxide floatation is performed on the easily separable copper oxide tailings to obtain difficultly separable copper oxide flotation concentrate; a collecting agent used for the difficultly separable copper oxide floatation is a combined collecting agent; the combined collecting agent is composed of an yellow catching agent and 4-sodium diphenylaminesulfonate; low intensity magnetic separation and high gradient magnetic separation are orderly performed on the difficultly separable copper oxide flotation concentrate to obtain copper magnetic separation concentrate; the magnetic field intensity of the low intensity magnetic separation is 0.2-0.5T; the background magnetic field intensity of the high gradient magnetic separation is 0.7-1.2T. The separation process of the copper oxide ores is simple in flow, low in production cost and prone to industrial implementation.

Owner:HUNAN RES INST FOR NONFERROUS METALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com