A kind of beneficiation method of copper oxide ore containing magnetic impurities

A mineral processing method, copper oxide ore technology, applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of low mineral processing index, complicated mineral processing process, high mineral processing cost, etc. The process is simple and the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

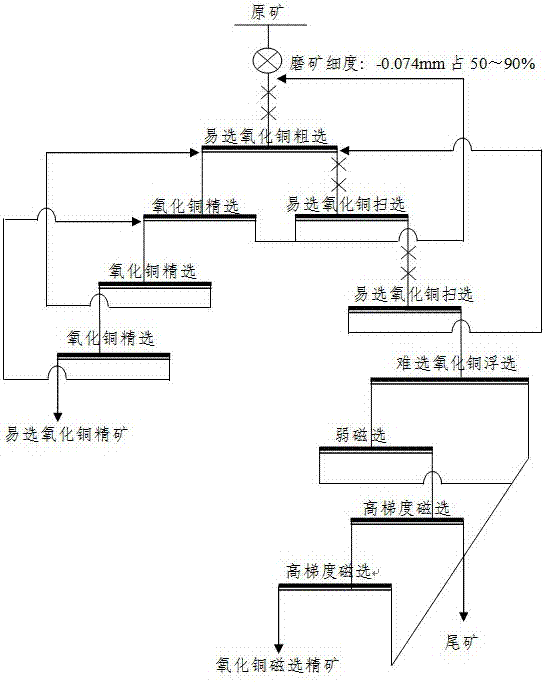

Method used

Image

Examples

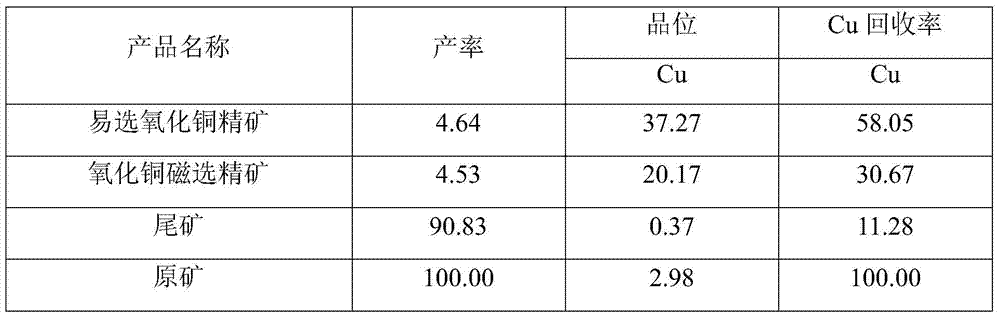

Embodiment 1

[0022] The raw ore is selected from a certain foreign copper oxide ore, containing 2.98% copper, 5.17% iron, and a copper oxidation rate of more than 95%. Azurite, etc., some copper minerals are adsorbed or mechanically mixed with iron and manganese impurities.

[0023] The ore beneficiation includes the following steps:

[0024] (1) Grinding: Raw ore is ground to a fineness of -0.074mm, accounting for 75%;

[0025] (2) Rough separation of easy-to-select copper oxide ore: according to the ore feed per ton, the amount of sodium sulfide is 1600g, stirred for 2 minutes, 120g of pentaxanthate, 20g of polyether alcohol, stirred for 1 minute, and the flotation time is 3 minutes; Copper oxide roughing concentrate and easy-to-select copper oxide roughing tailings;

[0026] (3) Easy-to-select copper oxide roughing tailings are obtained through two sweeps to obtain easy-to-select copper oxide sweep tailings, calculated per ton of ore feed, wherein in the sweeping process, the amount o...

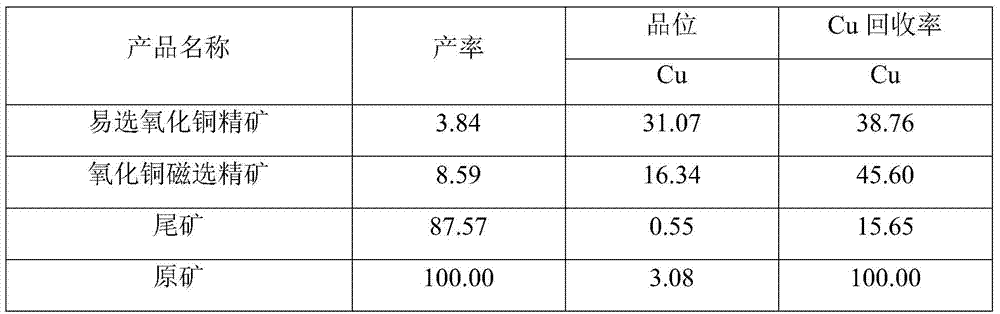

Embodiment 2

[0035] The raw ore is selected from a copper oxide ore with high iron content and large slime content in a certain place in Tibet. The ore contains 3.08% copper, 17.85% iron, and a copper oxidation rate of about 97%. The copper minerals are mainly malachite and blue copper. Iron ore, copper-iron ore, chrysocolla, copper-iron-silicon-oxygen complex, etc., a large number of copper minerals are mixed with iron by adsorption or mechanically.

[0036] The ore beneficiation includes the following steps:

[0037] (1) Grinding: Raw ore is ground to a fineness of -0.074mm, accounting for 80%;

[0038] (2) Rough separation of easy-to-select copper oxide ore: according to the ore feed per ton, the amount of sodium sulfide is 2400g, stirred for 2 minutes, pentaxanthate 160g, polyether alcohol 30g, stirred for 1 minute, and the flotation time is 4 minutes; Copper oxide roughing concentrate and easy-to-select copper oxide roughing tailings;

[0039] (3) The easy-to-select copper oxide rou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com