Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

240 results about "Magnetic impurity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A magnetic impurity is an impurity in a host metal that has a magnetic moment. The magnetic impurity can then interact with the conduction electrons of the metal, leading to interesting physics such as the Kondo effect, and heavy fermion behaviour. Some examples of magnetic impurities that metals can be doped with are iron and nickel. Such an impurity will contribute a Curie-Weiss term to the magnetic susceptibility, χᵢₘₚ=C/(T+θ).

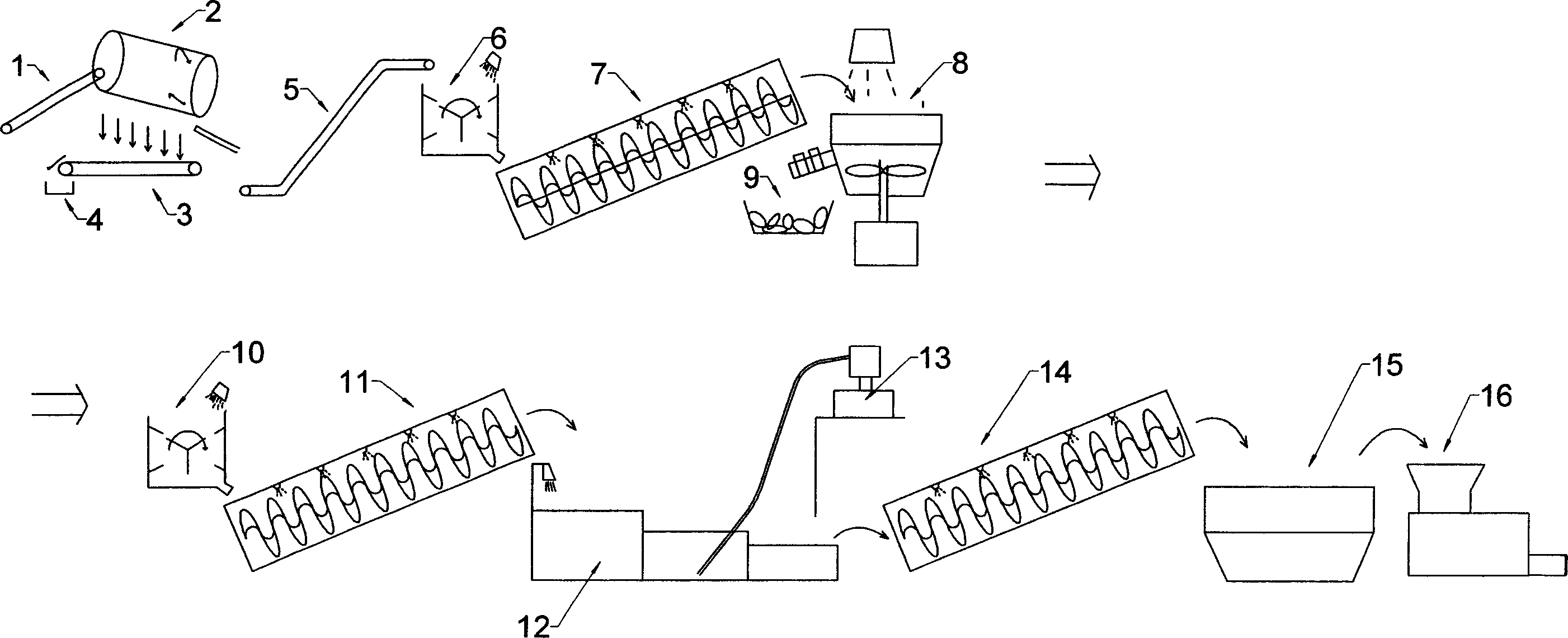

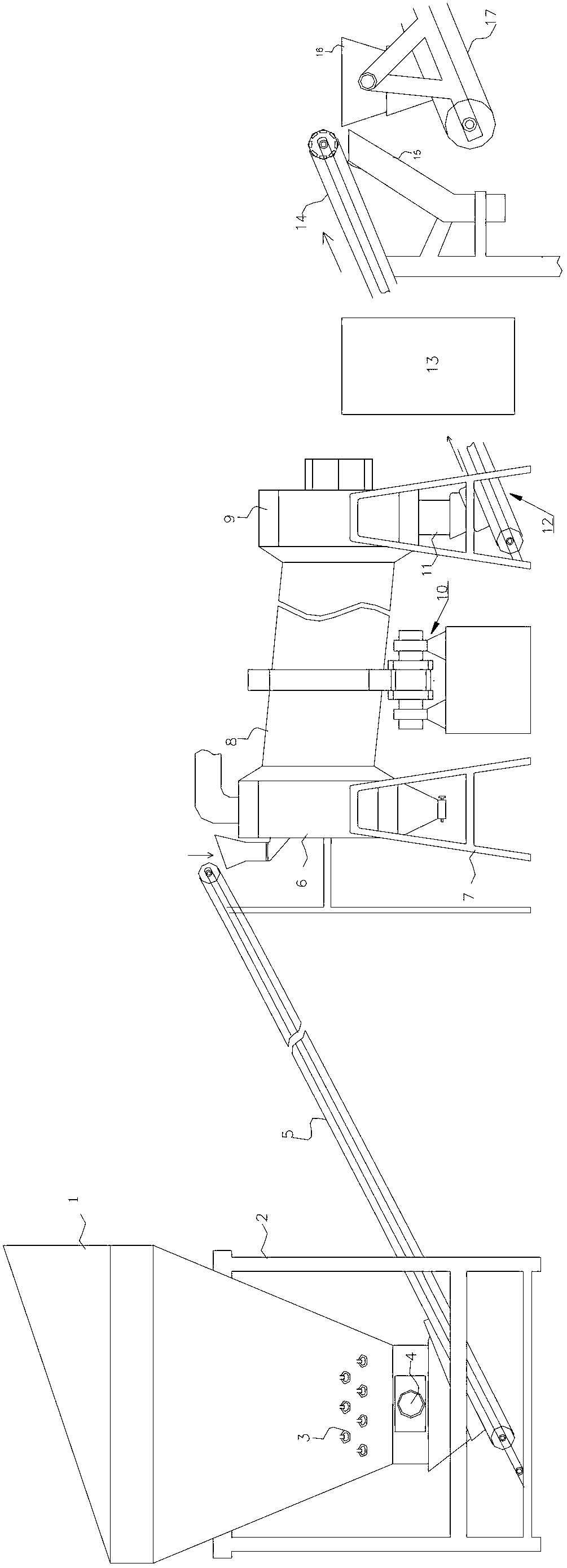

Separating method and system for waste paper and waste plastic mixture

InactiveCN1834340AReduce energy consumptionReduce loadGas current separationWashing/displacing pulp-treating liquorsFiberSingle stage

A method for separating out waste paper and waste plastic form their mixture including preliminary selecting, using magnetic separator to select out magnetic impurities, using hand to pick up large impurity block without plastic, using fan to blow impurities with different gravities into different grooves at different distance, using mechanical rubbing machine to separate paper fiber from plastic, using single stage floating tank to beat floating matters for releasing paper fiber off, storing floated out plastic and palletizing them for reutilization.

Owner:曾碚凯

Rutile beneficiation method comprising magnetic separation, tailing discarding reselection. desliming and fine particle floatation

InactiveCN103586124AReduce the amount of incoming flotationReduce the cost of beneficiationWet separationConcentration ratioNon magnetic

The invention relates to a rutile beneficiation method comprising magnetic separation, tailing discarding reselection, desliming and fine particle floatation. According to the method, raw rutile is crushed and screened to have a certain feed size of ore grinding; obtained rutile particles are ground to a certain particle size through an ore grinding machine to obtain ore pulp with a certain concentration through preparation; the ore pulp is led to an intensity magnetic separator for separation to obtain magnetic minerals and non-magnetic minerals; the non-magnetic minerals are subjected to the reselection for desliming to obtain ore concentrate, and then the ore concentrate is dewatered to a certain concentration; the dewatered ore concentrate is subjected to the floatation operation, gangue mineral inhibitors, rutile activators, collectors and foaming agents are added in the dewatered ore concentrate, the rutile is subjected to the flotation, and after rough separation, 1-2 times of fine separation and scavenging are carried out in sequence, rough concentrate of the flotation rutile is obtained; the rough concentrate of the flotation rutile is subjected to the magnetic separation to eliminate magnetic impurities and then eliminate sulphur and phosphorus impurities through roasting and acid pickling, and finally high-grade rutile concentrate is obtained. The method has the advantages that the process procedure is simple, beneficiation cost is low, the recovery rate is high, and the concentration ratio is high.

Owner:CENT SOUTH UNIV +1

Method for efficiently preparing feldspar glazes for ceramics

The invention discloses a method for efficiently preparing feldspar glazes for ceramics. The method comprises the following specific steps: after raw feldspar ores are crushed, grinding the raw feldspar ores by a high-alumina ball grinding mill, classifying the raw feldspar ores in a spiral manner by a spiral classifier, and screening the raw feldspar ores by a high-frequency classifying screen, so that the sufficient dissociation of feldspar mines and the controlling the granularity can be ensured, the feeding granularity of the fed feldspar mines can be ensured, and conditions for the following magnetic separation and the classifying processes of a cyclone are created; separating and effectively removing magnetic impurities of the raw feldspar ores by the magnetic separation with various intensity in a classifying and multi-section manner of the granularity, increasing the kinds of products, and increasing the recovery of resources. Through the use of the technologies, such as the classification of the cyclone, the permanent magnet iron removal of a drum magnetic separator, the iron removal of a vertical ring pulsating high-gradient strong magnetic separator and the like, the adaptability and the reliability are greatly improved, the quality of the concentrates is effectively ensured and stabilized, the risk due to fluctuation of the impurity content is reduced, the separating efficiency and the comprehensive utilization of resources are improved, and the efficiently comprehensive utilization of the feldspar resources is realized.

Owner:赣州金环磁选科技装备股份有限公司

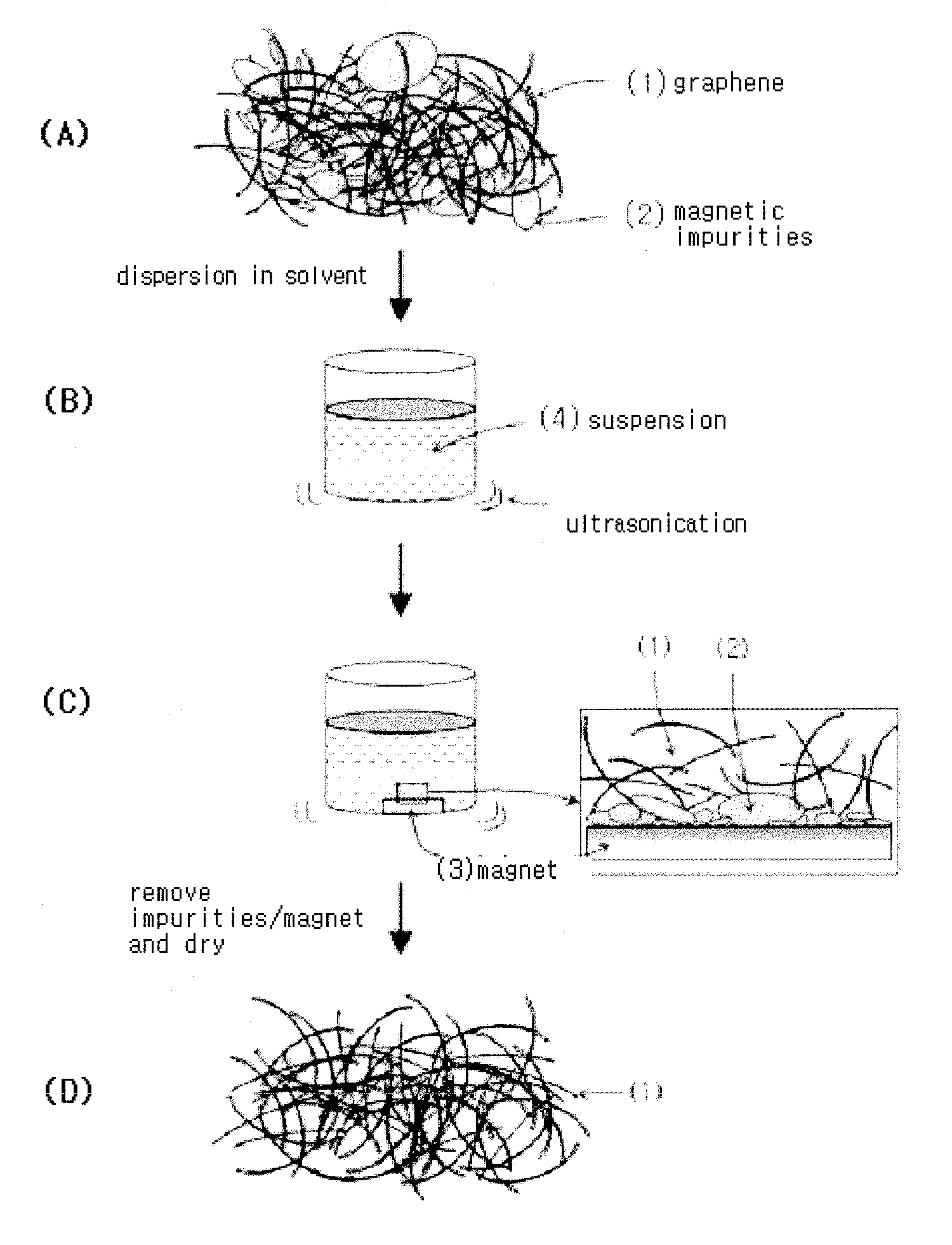

Method for purifying graphene powder

ActiveUS20120043402A1The process is simple and effectiveMaterial nanotechnologyCarbon compoundsGraphiteSolvent

An easy and effective method for purifying graphene powder by removing magnetic impurities, wherein magnetic impurities are incorporated during the process of fabricating the graphene powder, is provided. The method for purifying graphene powder, the method including: (1) ball-milling a graphite material to form graphene powder; (2) dispersing the graphene powder in a solvent to form a suspension; and (3) separating magnetic impurities during stirring the suspension, by using a magnet, Wherein the magnetic impurities were incorporated into the graphene powder during ball-milling from the balls and dispersed in the suspension.

Owner:KOREA INST OF SCI & TECH

Method for recovering tantalum-niobium, lepidolite and feldspar powder by utilizing difficult-to-treat mine solid waste

InactiveCN108525843AValue cost enhancementGreat benefitWet separationMechanical material recoveryNiobiumSlag

The invention discloses a method for recovering tantalum-niobium, lepidolite and feldspar powder by utilizing difficult-to-treat mine solid waste. The method is characterized in that the difficult-to-treat mine solid waste is taken as a raw material, wherein the difficult-to-treat mine solid waste is a valuable component material containing a trace of (Ta, Nb)2O5, lepidolite and feldspar, and themethod comprises the step of recovering the tantalum-niobium concentrate, the feldspar powder and the lepidolite, recovering of the tantalum-niobium concentrate is achieved though the following steps,the series-connection technology of weak magnetism, medium magnetism and strong magnetism is carried out on the difficult-to-treat mine solid waste raw material for separation of iron slag, magneticminerals and non-magnetic mineral so that the influence of iron minerals on the reselection of the tantalum-niobium ore can be eliminated, a tantalum-niobium ore waste stone raw material is obtained,the tantalum-niobium ore waste stone raw material undergoes classification by adopting a stage grinding-stage separation process method, coarse grains enter a ball mill for ore grinding, a high-frequency vibration fine sieve is adopted for carrying out intensifying classification on the fine fraction, and then the tantalum-niobium concentrate and the feldspar-lepidolite mixture with tailings beingiron-tantalum-niobium contained weak-magnetic impurities are prepared. The method has the advantages that the technology is simple, the efficiency is high, the economic and technical benefits are obvious, and the recovery rate of the tantalum-niobium and other mineral resource products is high.

Owner:江西金辉再生资源股份有限公司

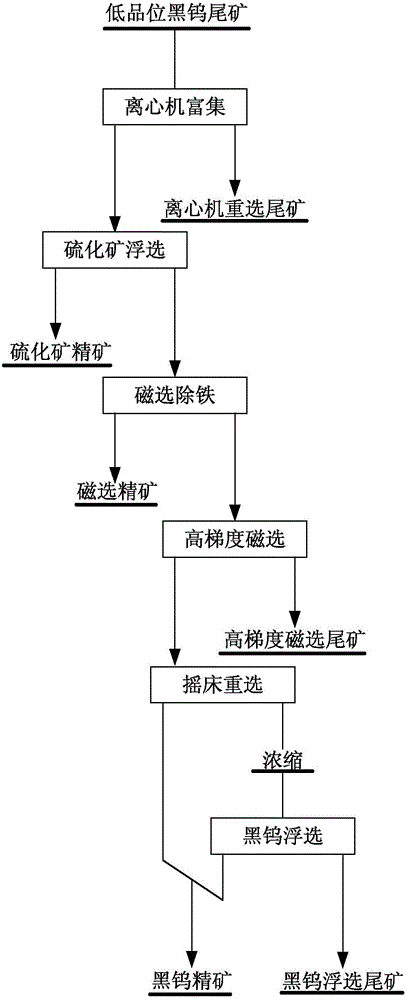

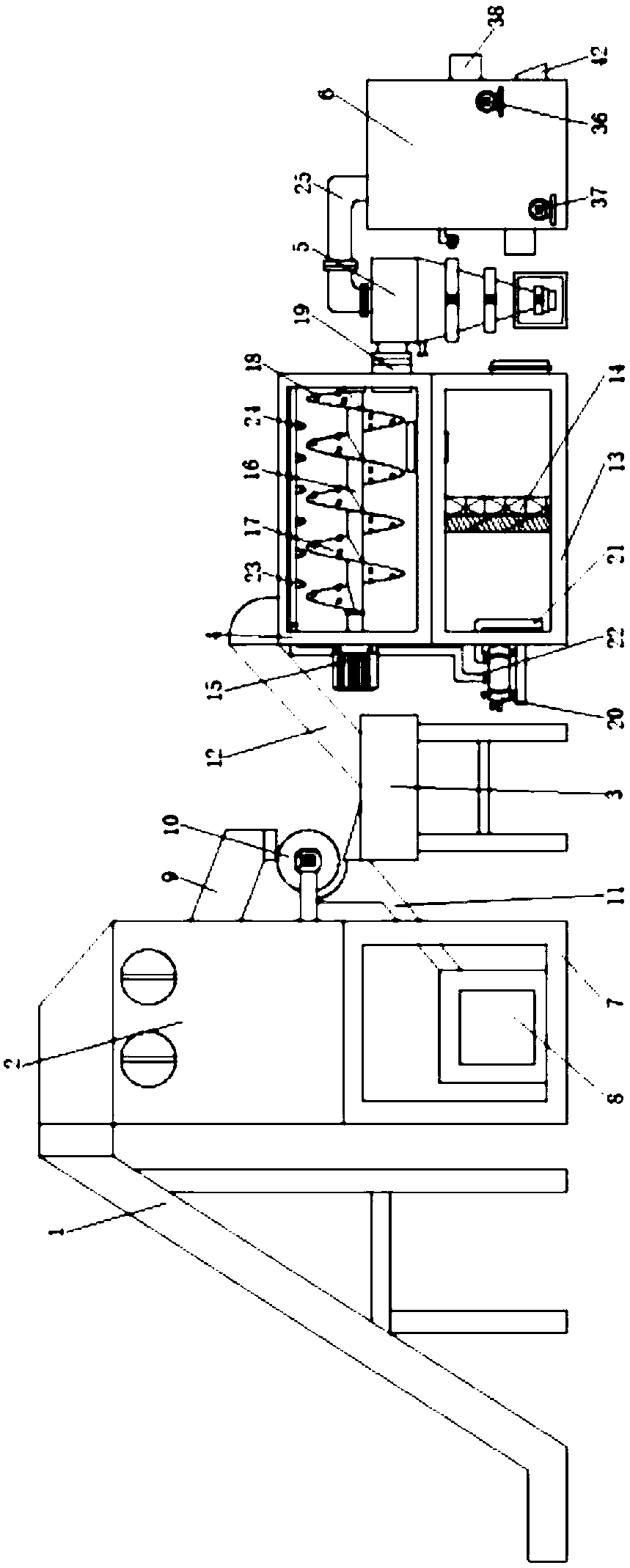

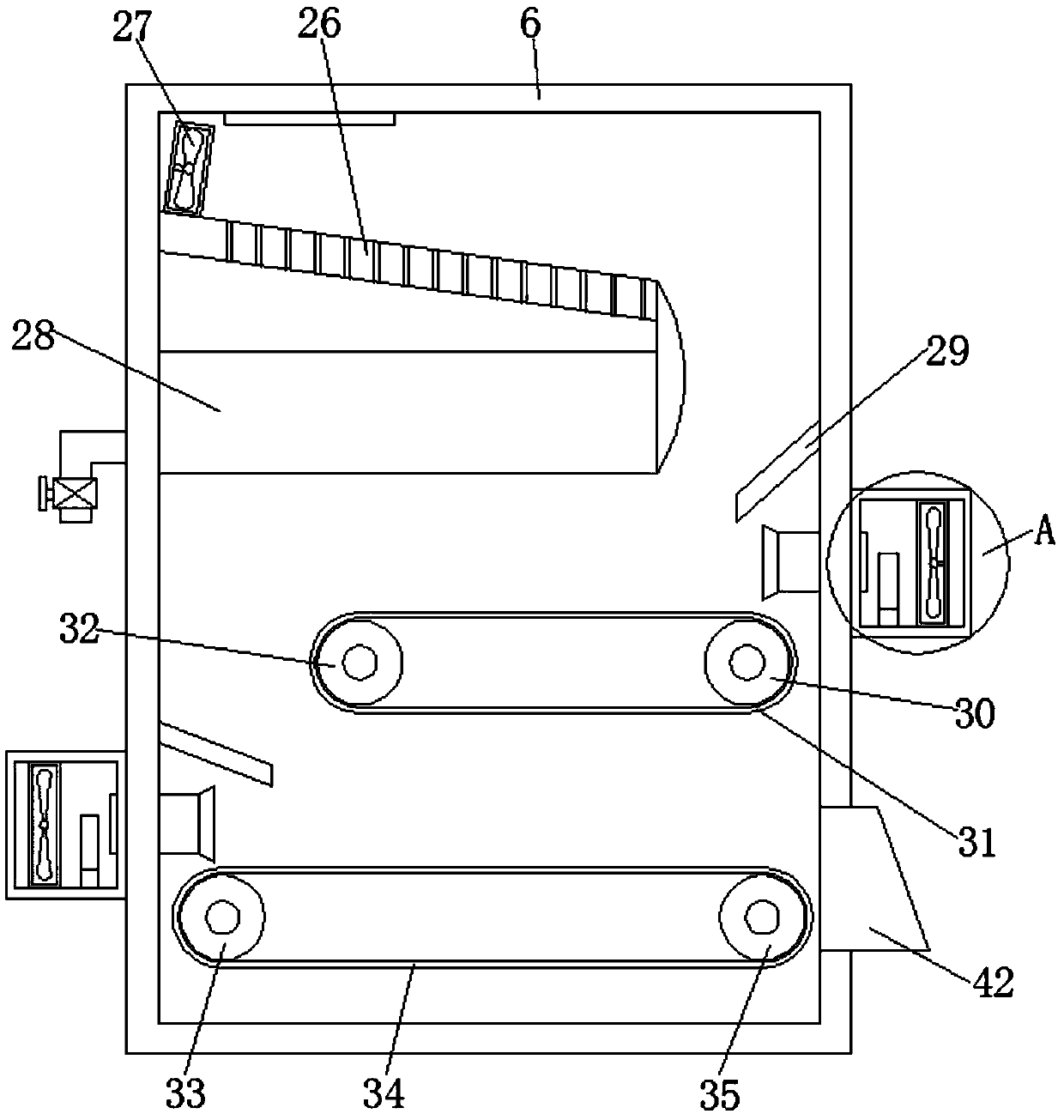

Mineral separation method for recycling wolframite from tailing

ActiveCN106669964AImprove the quality of selectionReduce the amount of oreSolid separationMechanical material recoveryGravity separationMagnetic separation

The invention discloses a mineral separation method for recycling wolframite from a tailing. The mineral separation method comprises the following steps that (1) gravity separation of a centrifugal machine is conducted for tailing discarding and preenrichment; (2) sulphide ore flotation is conducted; (3) magnetic separation is conducted and magnetic impurities are removed; (4) high-gradient magnetic separation is conducted for wolframite enrichment; (5) tabling gravity separation is conducted to obtain coarse grained wolframite; and (6) flotation is conducted to obtain fine grained wolframite. By means of centrifugation gravity separation preenrichment, the separation grade of the wolframite is improved, the ore feeding quantity and the mud content of wolframite separation are reduced, and flotation reagent dosage is saved. By means of the sulphide ore flotation and magnetic separation iron removal, the disturbance of sulphide minerals and magnetic minerals on wolframite separation is reduced. According to the mineral separation characteristics of the wolframite, the separation index of the wolframite is improved by adopting the high-gradient magnetic separation and the coarse grained and fine grained wolframite grading and separation process. Efficient recycling of the wolframite in low-grade wolframite tailing resources is achieved, and the mineral separation method is environmentally friendly, efficient and energy saving, and suitable for application and popularization.

Owner:JIANGXI UNIV OF SCI & TECH

Method for separating brown rice peel layer

InactiveCN103506176AGentle rubbingImprove integrityGrain huskingGrain polishingWater vaporWhite rice

The invention relates to a method for separating a brown rice peel layer. The method comprises the first step of cleaning the rice, namely, large, small and light impurities and the like easy to clean are cleaned from unprocessed grain, the magnetic impurity in the rice is removed, rice particles are separated from barnyard grass particles, and the rice is separated from stones; the second step of rice hulling, namely, rice hulls are removed through a rice huller, the rice hulls are separated out from the rice processed by the rice huller, and brown rice and the rice are sorted from the brown rice mixture through a brown rice screen sieve; the third step of dampening, namely, the content of the moisture of the brown rice is adjusted into 14%-15% of the total weight through the water mist or the water vapor, and the dampening time duration ranges from 6 minutes to 18 minutes; the fourth step of rice milling, namely, an emery roll rice husking machine is used for removing outer bran layers of the rice particles and an iron roll air blast rice husking machine is used for removing the brown rice peel layer; the fifth step of brown rice peel layer collecting, the grinded white rice is separated from the brown rice peel layer, and the brown rice peel layer is collected. The accurate dampening moisture part and dampening time control are carried out on hulled clean brown rice through a water atomizing method, the emery roll rice husking machine arranged in the middle of a first rice machine and the iron roll air blast rice husking machine arranged in a tail rice machine are selected in a combined mode to be connected in series for grinding, the brown rice is subjected to soft grinding force, the integrity of the peel layer is kept high, the effect of high peel producing ratio is achieved when the brown rice peel layer is separated, and the technique is simple and easy to control.

Owner:HUNAN AGRICULTURAL UNIV

Method for removing magnetic impurities from tantalum-niobium waste ores by utilizing combined magnetic separation

InactiveCN106378254AHigh recovery rateHigh demagnetization impurity rateHigh gradient magnetic separatorsWet separationNiobiumGravity separation

The invention provides a method for removing magnetic impurities from tantalum-niobium waste ores by utilizing combined magnetic separation. The method comprises the following steps: by taking the tantalum-niobium waste ores or tailings as raw materials and adopting a magnetic separation method, grinding and screening the tantalum-niobium tailings and / or the tantalum-niobium waste ores; removing iron and impurities in advance by adopting wet type low-intensity permanent magnetic separation to obtain a tantalum-niobium gravity-separated ore material; separating a magnetic ore material from a nonmagnetic ore material of the tantalum-niobium gravity-separated ore material by adopting a combined magnetic separation method; subsequently extracting tantalum-niobium ore resource products by adopting a magnetic separation, gravity separation and floatation separation combined process, wherein the resource products include lithium feldspar powder, lithionite concentrate powder and tantalum-niobium concentrate powder; the combined magnetic separation respectively includes three stages of magnetic separation processes, including permanent magnetic separation, medium-intensity magnetic separation and high-intensity magnetic separation in sequence. The method provided by the invention is obvious in economic benefits and technical benefits, small in treatment of three wastes and high in recovery rate of tantalum-niobium ore resource products. The invention provides a combined magnetic separation method, which is simple in process and quite high in efficiency, for removing magnetic impurities in tantalum-niobium waste ores. The combined magnetic separation method is obvious in economic benefits and technical benefits, small in treatment of three wastes and high in recovery rate of tantalum-niobium ore resource products.

Owner:江西领辉科技有限公司

Cleaning method of glass substrate and device for implementing method

ActiveCN103341405AEfficient removalOvercome the defect of poor removal abilitySuction cleanersDirt cleaningCleaning methodsElectrical and Electronics engineering

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Method for cleansing glass substrate and device for performing the method

ActiveUS20150027490A1Efficient removalCleansing a glass substrateSuction cleanersElectrostatic cleaningEngineeringElectrical and Electronics engineering

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Method of recovering metal and/or oxide thereof in a slurry and tailings obtained from said method

Owner:CABOT SPECIALTY FLUIDS

Detection method for sulfur-containing inclusions in steel

ActiveCN107084870AExpressiveAccurate shapePreparing sample for investigationAcid dissolutionThree dimensional shape

The invention relates to the technical field of quality detection of continuous casting production in ferrous metallurgy and particularly relates to a detection method for sulfur-containing inclusions in steel. According to the detection method, magnetic impurities in mixed liquid are removed in a magnetic separation manner, non-magnetic iron-containing compounds are converted into iron particles or magnetic iron-containing compounds, and the iron particles or the magnetic iron-containing compounds are removed in a magnetic separation manner, so that the influences caused by the non-magnetic iron-containing compounds to the detection of a target sulfur-containing inclusion are reduced, and a detection result is relatively accurate. Besides, finally obtained inclusion powder is placed on a conductive carrier so as to be subjected to SEM detection or EDS detection, so that a three-dimensional shape characteristic map of the inclusion can be obtained, the shape of the target sulfur-containing inclusion can be comprehensively and accurately expressed, and therefore, the reliable and accurate basis is provided for subsequent researches. Besides, the sulfur-containing inclusions are not separated from a steel sample by virtue of an acid dissolution method, so that the detection method is applicable to the sulfur-containing inclusions dissolvable in acid.

Owner:NORTHEASTERN UNIV

Material smashing device with screening and filtering functions

InactiveCN107199090AEnter the box again to realize the crushing of the material againReduce filtration efficiencyGrain treatmentsHelical bladeFiltration

The invention discloses a material crushing device with screening and filtering functions, which comprises a crushing motor, a screening plate, a conveying motor, a vibrating motor, a permanent magnet and an air cylinder. The crushing motor rotates to drive the crushing blades on the crushing shaft to rotate the materials. For crushing, the screening plate is used to screen the crushed materials, and the conveying motor is used to rotate to drive the screw blades on the conveying shaft to rotate and then convey the materials to the discharge port of the material conveying device, and the vibrating motor is used to vibrate to drive the filtration The vibration of the plate improves the efficiency of the filter plate in filtering the material in the buffer filter chamber. The permanent magnet is used to absorb the magnetic impurities in the material in the material buffer chamber, and the cylinder is used to push the push plate to move in the discharge chamber, and then the material in the discharge chamber is removed from the first discharge chamber. The second outlet is pushed out, which is convenient and quick, and improves the practicability of the equipment.

Owner:盘海秀

Method for removing impurities from natural quartz sand

InactiveCN108654829AEfficient removalImprove qualitySilicaFlotationNon magneticUltimate tensile strength

The invention discloses a method for removing impurities from natural quartz sand and relates to the technical field of removing impurities from the quartz sand. The method for removing the impuritiescomprises the specific steps that quartz sand particles with the fineness of 60-100 meshes are subjected to magnetic separation by a dry type magnetic separation machine, and the magnetic field strength of the dry type magnetic separation machine ranges from 120 mT to 600 mT; first-stage flotation and second-stage flotation are carried out, the dewatered quartz sand is conveyed to a scrubber, anda catalyst and oxalic acid liquid with the concentration of 3%-18% are cyclically added to the scrubber, the addition of the catalyst and oxalic acid is 0.5%-3% of the mass of the quartz sand entering the scrubber, and then the pickled quartz sand is filtered out; and acid removing and drying and packaging are carried out. According to the process, flotation and magnetic separation methods are adopted, and non-magnetic associated impurities and magnetic impurities such as feldspar and mica of the quartz sand can be effectively removed, so that the acid-pickled quartz sand is purer and higherin quality, the process is simple, the impurity removal effect is good, and the purity of the quartz sand can reach more than 99.9% by adopting the impurity removal method.

Owner:奈曼旗忠義砂产业有限公司

Method for regenerating rare earth trichromatic fluorescent powder for lamp

ActiveCN101942298ALow cost regenerationGood regeneration performanceRecycling and recovery technologiesLuminescent compositionsRare earthReducing atmosphere

The invention discloses a method for regenerating rare earth trichromatic fluorescent powder for a lamp. The method comprises the following steps of: cleaning sieved and magnetic impurity-removed reclaimed fluorescent powder with cleaning solution; performing ball-milling on the cleaned fluorescent powder, sieving and drying; reducing dry fluorescent powder under a reducing atmosphere; sieving and calcining the reduced fluorescent powder; and sieving the calcined fluorescent powder to obtain regenerated fluorescent powder. The method realizes the low cost regeneration of fluorescent powder for the lamp. The regenerated fluorescent powder has only 5 to 15 percent of light efficiency difference at a similar color temperature and good regeneration effect and can be directly applied to the manufacturing of the lamp. The reclamation method has low cost, realizes the low cost reutilization of rare earth fluorescent powder and effectively recycles precious rare earth resources.

Owner:JIANGMEN KANHOO IND

Lithium ion battery cathode material and preparation method thereof, and application thereof

ActiveCN109728262AInhibitionGood body consistencyCell electrodesSecondary cellsManganeseLithium-ion battery

The invention relates to a lithium ion battery cathode material and a preparation method thereof and application thereof. The cathode material has a chemical formula of LixNiaCobRcMdO2, R is selectedfrom manganese or aluminum, M is a doping element, 0.95<x<1.15, 0.60<a<0.95, 0.0<b<0.2, 0.98<=a+b+c<=1.00, 0<=d<0.1, 0.0<c<0.3; in the cathode material, the magnetic substance content is not larger than 100ppb. A surface-rich lithium-type ternary cathode material in the preparation and synthesis stage is generated to effectively suppress the generation of the magnetic impurities, the prepared lithium ion battery cathode material is good in consistency, consistent in the surface smoothness topography and easy for powder processing, the magnetic material of the finished product is with 100ppb, is high in safety and can be widely applied in the fields of 3C and xEV, and ESS.

Owner:贵州高点科技有限公司 +1

Method and system for detection of biomaterials using magnetic marker

InactiveUS20080284413A1Reduce the impactEfficient use ofMagnetic property measurementsBiological testingMagnetic markerSpecimen containers

Accurate measurement cannot be performed due to magnetic signals from magnetic impurities included in a specimen container. By finding a difference between two measurement signals obtained by applying an external magnetic field for orientation to respective normal and reverse directions, the magnetic signals from the magnetic impurities included in the specimen container which are not dependent on the external magnetic field for orientation can be cancelled. The influence of the magnetic impurities included in the specimen container is reduced, and the signal of the intended bound magnetic marker can be measured with high sensitivity.

Owner:HITACHI LTD

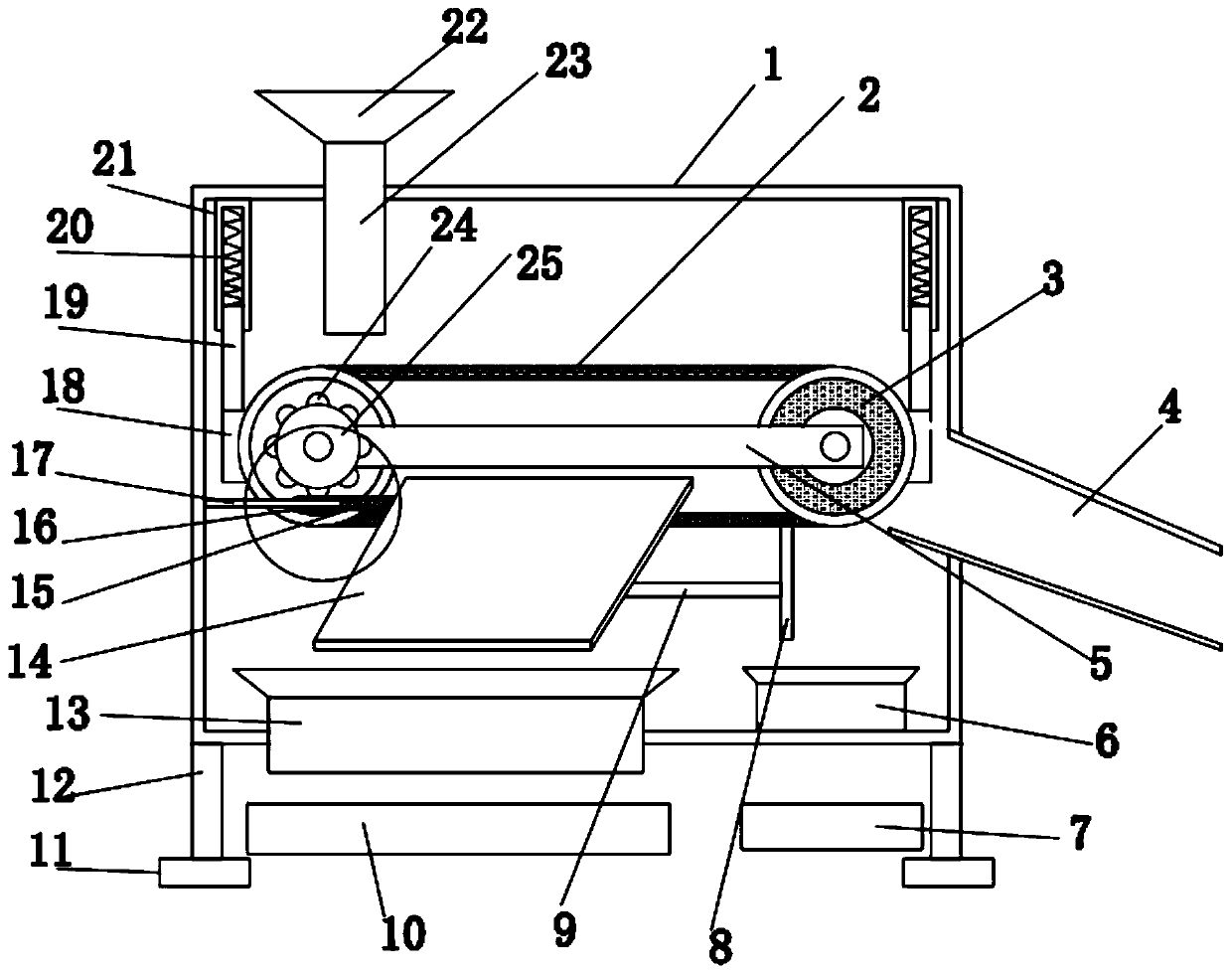

Swirling flow type waste plastic crushing sorting cleaning system

InactiveCN109551664AQuality improvementReduce metal magnetic impuritiesPlastic recyclingMechanical material recoveryWater resourcesPlastic recycling

The invention provides a swirling flow type waste plastic crushing sorting cleaning system. The swirling flow type waste plastic crushing sorting cleaning system includes a first transfer machine, a crushing machine, a transfer box, a cleaning device, a swirler, a box body and a fixing frame, and the top of the fixing frame is fixed to the bottom of the crushing machine. According to the swirlingflow type waste plastic crushing sorting cleaning system, metal magnetic impurities in waste plastic are reduced, the quality of waste plastic recycling is improved, meanwhile, the waste metal magnetic impurities are collected, post-processing and production of processing are convenient, multi-angle cleaning is realized, cleaning is more even, the efficiency and quality of cleaning are ensured, thus the recycling efficiency of the waste plastic is improved, reuse of water resources is improved, the cleanliness degree of the cleaning process is increased, thus the recycling quality of the wasteplastic is ensured, the water content of waste plastic recycling is decreased, and the quality of production is ensured, so that secondary processing is avoided.

Owner:开平市源成达塑胶制品有限公司

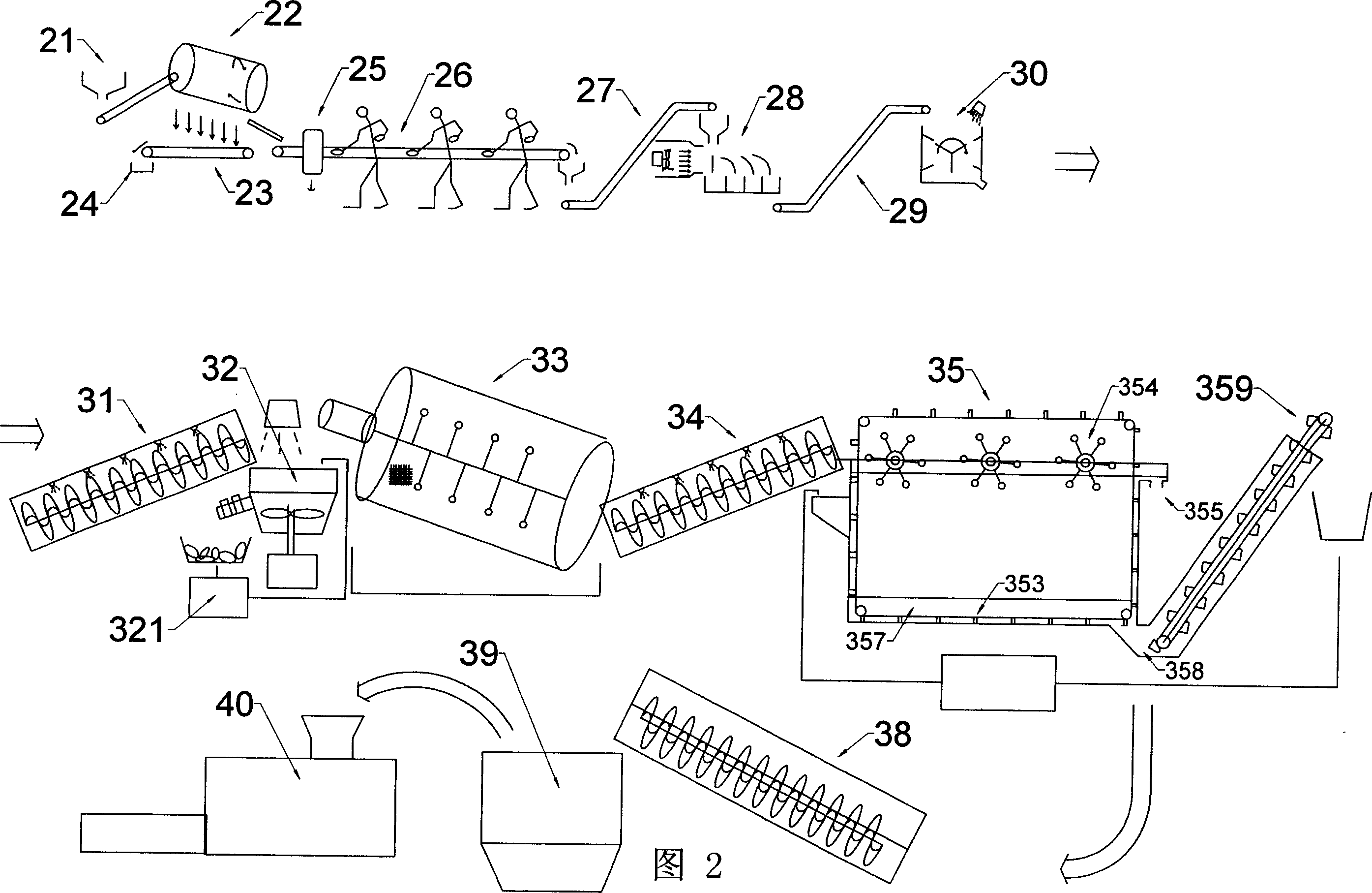

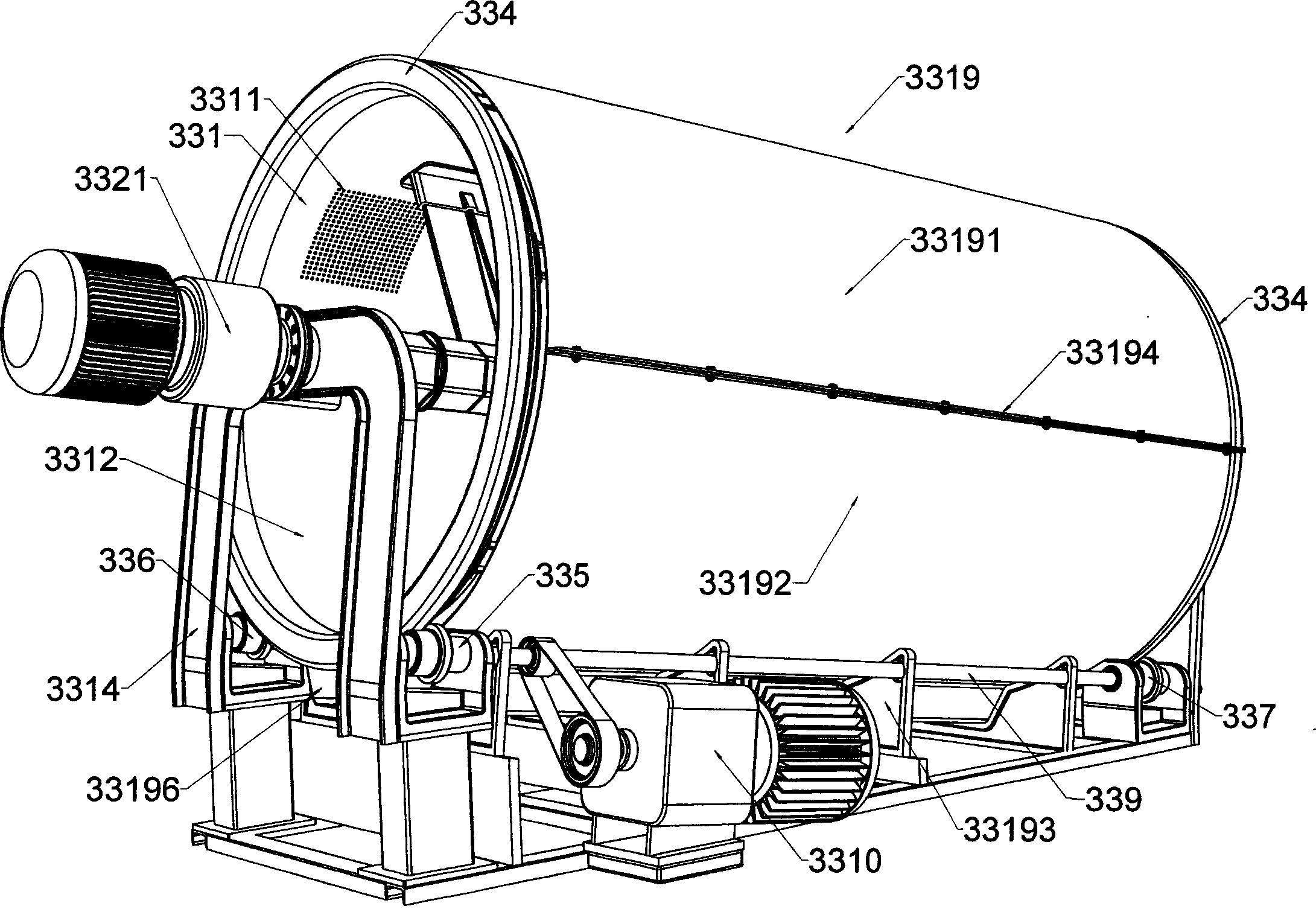

Foam glass production system

The invention provides a foam glass production system. The foam glass production system comprises a raw material cleaning system, a raw material ball milling system, a heating system and an annealing system which are used for processing the raw materials in sequence, wherein the raw material cleaning system comprises a feeding device, a drying and dust removing device, a crushing device, a magnetic impurity removing device and a storage bin which are used for correspondingly treating the raw materials of the foam glass in sequence; the raw material ball milling system comprises a ball mill, a raw material conveying device and a storing and transporting distributing device; the heating system comprises a heating furnace, a first rail, a die box transfer trolley, a foam glass transfer trolley, a transfer rail, and a finished product raw material bin above the transfer rail; and the annealing system comprises an annealing furnace, a kin vehicle, a second rail, a skin vehicle traction device, a third rail abutted with the first rail, a fourth rail which connects the second rail with the third rail, and a skin car transfer truck. The foam glass production system is reasonable in structural design and high in production efficiency, and can provide guarantee to the high quality of the foam glass.

Owner:江苏德和绝热科技有限公司

Organic waste treatment system

PendingCN108636583AReduce labor intensityImprove work efficiencySolid waste disposalMagnetic separationThree stageEngineering

The invention discloses an organic waste treatment system. The organic waste treatment system comprises a machine frame, a lifting mechanism, a feeding trolley, a winding roller lifting mechanism, a magnetic impurity removing device, an impurity removal discharging mechanism, a crushing mechanism, a dewatering mechanism, a biological fermentation mechanism and a spiral conveying mechanism, whereinthe winding roller lifting mechanism drives the lifting mechanism to move along feeding turnover rails through a traction rope, the feeding trolley cooperates with the lifting mechanism, the magneticimpurity removing device is arranged on the right side of the machine frame, a first crushing assembly is arranged in the crushing mechanism, two crushing rollers are arranged below the first crushing assembly, a discharging hole of the crushing mechanism communicates with the dewatering mechanism, and a stirring mechanism is arranged in the biological fermentation mechanism. According to the organic waste treatment system, the automatic feeding work is realized through the lifting turnover of the feeding trolley, three-stage crushing is adopted so that crushing can be guaranteed to be thorough, crushed and dewatered materials are conveyed into the biological fermentation mechanism through the spiral conveying mechanism, and the stirring mechanism can be used for mixing the materials, sothat the fermentation efficiency is improved.

Owner:ZHEJIANG MINGJIA ENVIRONMENTAL PROTECTION TECH CO LTD

Method for purifying graphene powder

ActiveUS8672246B2The process is simple and effectiveMaterial nanotechnologyCarbon compoundsGraphiteSolvent

An easy and effective method for purifying graphene powder by removing magnetic impurities, wherein magnetic impurities are incorporated during the process of fabricating the graphene powder, is provided. The method for purifying graphene powder, the method including: (1) ball-milling a graphite material to form graphene powder; (2) dispersing the graphene powder in a solvent to form a suspension; and (3) separating magnetic impurities during stirring the suspension, by using a magnet, Wherein the magnetic impurities were incorporated into the graphene powder during ball-milling from the balls and dispersed in the suspension.

Owner:KOREA INST OF SCI & TECH

Comprehensive utilization method for gold tailings containing gold, iron and feldspar

ActiveCN109894259AEfficient removalImprove recycling ratesSolid separationMechanical material recoveryMagnetiteSulfide minerals

The invention discloses a comprehensive utilization method for gold tailings containing gold, iron and feldspar. The comprehensive utilization method comprises the following steps: graded desliming ofthe tailings; separation of magnetite and gold-containing minerals; strong magnetic separation to reduce impurities; dehydration of concentrate; and concentration and dry discharge of the impurities.By means of the graded desliming, coarse particle raw tailings and fine particle oxide impurities which affect the quality of feldspar are removed, and the product granularity is controlled effectively. By means of a spiral chute, a drum magnetic separator and a table and by combining reselection and magnetic separation, magnetite and gold-containing sulfide mineral with value are separated effectively, and conditions are created for a follow-up strong magnetic separation impurity-reducing flow; and by means of three strong magnetic separation impurity-reducing operations with different magnetic field intensity, it is sufficiently ensured that magnetic impurities in the feldspar are separated and removed effectively. The magnetite and gold-containing sulfide mineral with value are also recovered while the high-quality feldspar is obtained. Plus sieve coarse grain sand is returned to a concentration plant to be subjected to grinding and gold selection again, and fine grain mud and themagnetic impurities serve as cement or building material raw materials, so that zero discharge of the tailings is achieved.

Owner:SHANDONG HUATE MAGNET TECH

Integrated sorting and recycling device for construction wastes

ActiveCN110369130AOptimize iron removal methodSolve the disadvantages of poor sorting effectSievingScreeningIron removalTransmission belt

The invention discloses an integrated sorting and recycling device for construction wastes, which comprises a box body and supporting legs arranged at four corners of the lower end of the box body, wherein the lower end of each supporting leg is provided with a supporting block for increasing the supporting area, a feeding hopper for feeding is arranged above the box body, a lower port of the feeding hopper is communicated with a feeding port of the box body through a discharging pipe, and the box body is internally provided with a sorting mechanism for sorting the wastes. According to the invention, an improvement is made in view of disadvantages of the existing device, and the iron removal mode is optimized; iron impurities are attracted to the surface of a transmission belt by using thestrong magnetic property of a magnetic ring, the iron impurities are separated from other impurities close to a blanking pipe under the action of gravity along with the rotation of the transmission belt, the magnetic force received by the magnetic impurities is smaller and smaller, and finally the magnetic impurities drop from the transmission belt, so that the separation of the iron impurities is completed, and thus the drawback of poor sorting effect of the existing device is overcome.

Owner:NEIJIANG NORMAL UNIV

Permanent magnetic expansion cylinder magnetic extractor

The invention discloses a permanent magnetic expansion cylinder magnetic extractor in the field of a feed processing device. The permanent magnetic expansion cylinder magnetic extractor comprises a storehouse body, wherein a material inlet is arranged above the storehouse body, a material outlet is arranged under the storehouse body, an expansion cylinder is installed under the material inlet in the storehouse body by a bearing, the expansion cylinder is internally provided with a fixed magnetic group, the magnetic group is fan-shaped, an exhaust opening is further arranged above the storehouse body, an impurity outlet is further arranged under the storehouse body, the material inlet is further provided with a material homogenizing door, and the outer surface of the expansion cylinder is further provided with a plurality of material baffle strips. According to the permanent magnetic expansion cylinder magnetic extractor, the material baffle strips can be impacted due to the action of gravity when materials fall off, the expansion cylinder can be driven to rotate, and the process of magnetic impurity removal in the materials can be completed, so that the impurity can be removed by the means that the expansion cylinder is driven to rotate without a power source, therefore, the energy sources can be saved, the structure can be simplified, the cost can be reduced, and the permanent magnetic pulley magnetic extractor can be used for the impurity removing process in the process of feed processing.

Owner:陶仁

Method for checking magnetic impurities in powder material

InactiveCN102507654AShort timeLow costMaterial analysis by electric/magnetic meansMagnetic separationScreening effectGram

The invention discloses a method for checking magnetic impurities in a powder material. The method comprises the following steps of: (1) weighing a sample, namely weighing 300 grams of the powder material to be tested; (2) dissolving, namely fully mixing 1,500 milliliters of pure water and the powder material sample; (3) stirring, namely packaging a small plastic sample bag outside a magnetic bar of which the strength is more than 2,000 Gaussian, putting into the sample and pure water mixed solution, and fully contacting and stirring; (4) washing, namely simultaneously taking out the magnetic bar and the small plastic sample bag, washing in a large beaker with 1,000 milliliters of pure water twice, then putting into a beaker with 500 milliliters of water, independently taking out the magnetic bar, washing substances adsorbed on the surface of the small plastic sample bag in the beaker, and taking out the small plastic sample bag; and (5) judging the content of magnetic substances, namely moving the magnetic bar at the bottom of the beaker with 500 milliliters of water to observe the number, the sizes and the shapes of the magnetic substances in the beaker. The method has the advantages that: the whole detection process is low in time consumption, and low in cost; the operation is simple and feasible; and a detection and screening effect is intuitive.

Owner:ZHUHAI CAIZHU IND

Substance separating sieve

InactiveCN103056027ASolve the removal problemImprove grading effectSievingScreeningButt jointEngineering

The invention relates to equipment for removing iron magnetic impurities in materials and sieving the materials. A substance separating sieve is characterized by comprising a magnetic system, a rotary drum, a cylindrical sieve, a chute, a chute frame and an engine base, wherein the rotary drum is made of a non-magnetism-conducting stainless steel material; the rotary drum and the cylindrical sieve are cylindrical drum bodies with openings at two ends; one end of the rotary drum is fixed at an ore discharging opening of a mill by a flange and the other end of the rotary drum is in butt joint with one end of the cylindrical sieve through a flange; the magnetic system is arranged at the outer side of the rotary drum and the magnetic system is fixed on the engine base; the upper end of the chute penetrates through the cylindrical sieve and is located in the rotary drum; the lower end of the chute is located outside the cylindrical sieve and the chute is supported and fixed by the chute frame; the upper end of the chute is provided with a chute inlet and the lower end of the chute is provided with a chute outlet; and a washing water pipe is arranged at the chute inlet of the chute, and a water outlet end of the washing water pipe appoints to the upper part of the inner side of the rotary drum provided with the magnetic system. According to the substance separating sieve disclosed by the invention, crushed steel ball iron magnetic substances in ore discharged by the mill can be removed; and ore slurry of the ore discharged by the mill can be pre-graded and rough-grin materials are separated in advance.

Owner:WUHAN UNIV OF TECH

Magnetic filter

The invention relates to a magnetic filter, comprising a housing, a magnetic assembly and a filter cartridge, wherein the housing is provided with a fluid inlet for allowing fluid to enter the housing and a fluid outlet for allowing fluid to exit the housing; the magnetic The assembly is detachably arranged on the outer wall of the housing, and the magnetic assembly is used to adsorb impurities in the fluid on the inner wall of the housing; the filter cartridge has a U-shaped cross section and is detachably arranged in the housing. The outer wall of the filter cartridge is used to intercept impurities in the fluid outside the filter cartridge; the fluid inlet leads to the outside of the filter cartridge, and the inside of the filter cartridge communicates with the fluid outlet. The invention provides a magnetic filter capable of removing magnetic impurities and non-magnetic impurities in a fluid. The magnetic filter not only has a simple structure, but also has a good effect of removing impurities, prolongs the service life of the filter screen, and reduces the number of times to replace the filter screen. , and the cleaning of adsorbed impurities is also very convenient.

Owner:云威能源科技(上海)有限公司

Method for efficiently sorting scheelite containing weakly magnetic impurities

The invention discloses a method for efficiently sorting scheelite containing weakly magnetic impurities. The method comprises the following steps of: crushing crude ore of scheelite, performing a process of stage grinding, high-frequency screening and high-gradient magnetic separation, fully dissociating minerals before a conventional flotation process, and removing the weakly magnetic impurities in advance, wherein the grade of wolframine in the scheelite during flotation is improved; and performing an original multi-stage flotation to obtain high-grade wolframine concentrate, so that high-quality powdered iron can be produced, and tailings are removed through magnetic separation and scavenging only in the selection process. The method has the advantages of obviously performing pre-concentration and in-advance tailing removal on the scheelite containing weakly magnetic impurities and effectively and stably stabilizing the quality of the flotation ore; and meanwhile, the method also has the advantages of reducing risk brought by fluctuation of the mineral quality, improving the mineral separation efficiency, improving the flotation operation efficiency, saving lots of agents and flotation management cost, improving the comprehensive utilization rate of wolframine resources and the like.

Owner:赣州金环磁选科技装备股份有限公司

Multifunctional filter unit

ActiveCN110002660ASimple structureFlexible adjustmentTreatment involving filtrationMultistage water/sewage treatmentBlowoff valveBiochemical engineering

The invention relates to a filter unit, specifically to a filter unit for separating magnetic impurities, particle impurities and gases from a fluid. The filter unit is especially applicable to heating pipelines or air-conditioning systems. A multifunctional filter unit comprises a main body, a water inlet cover, and a locking cap which is clamped on the water inlet cover and tightens up the mainbody. A blind hole cavity used for planting a magnetic strip is arranged at the lower end of the main body. A blowoff valve is arranged at the lateral side of the bottom of the cavity of the main body. A fixed through hole is arranged at the opposite side of the blowoff valve. The upper end of the water inlet cover is equipped with a first fixed hole, a second fixed hole and a third fixed hole. The first fixed hole and the third fixed hole are horizontally and coaxially arranged. In the cavity of the main body, one end of a bend channel is connected with the first fixed hole, and the other endof the bend channel is connected with a cylindrical filter screen. The filter unit of the invention can meet access requirement of pipelines from multi-directions and multi-angles. The filter unit ofthe invention has a simple structure, is flexible to adjust, has high adaptability, and has market competitiveness.

Owner:TAIZHOU BANCHENG HVAC TECH CO LTD

Dry-type superfine powder magnetic separator

The invention relates to a dry-type superfine powder magnetic separator. The separator is characterized by consisting of a magnetic separation bin (1), a cloth screen (2) and a draught fan (3) which are connected in turn through pipelines, wherein the side wall of the magnetic separation bin is provided with a feed inlet (101), while the bottom is provided with a scarp outlet (104); the bottom of the magnetic separation bin is provided with a group of compressed air nozzles (105); the middle part of the magnetic separation bin is provided with three layers of stainless steel cylinders (102a); and a ferromagnetic bar (103) is arranged in each stainless steel cylinder (102a). When the magnetic separator is used, compressed air is sprayed into the magnetic separation bin through the nozzles; superfine powder is transpired under the action of the compressed air, and is evenly dispersed to form fluidized mist superfine powder; the mist superfine powder flows to the cloth screen under negative pressure; ferromagnetic substances are adsorbed to the stainless steel cylinders which are inserted with the ferromagnetic bars; and magnetic impurities can be cleared and discharged from the scarp outlet by pulling the ferromagnetic bars out. The magnetic separator has the advantages of evenly dispersing the superfine powder and effectively removing the ferromagnetic impurities in the powder, and is applicable to superfine powder (the median particle diameter is less than 5 mu meters, and the maximum particle diameter is less than 10 mu meters).

Owner:BENGBU ZHONGHENG NEW MATERIALS SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com