Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66 results about "Methyl isobutyl carbinol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

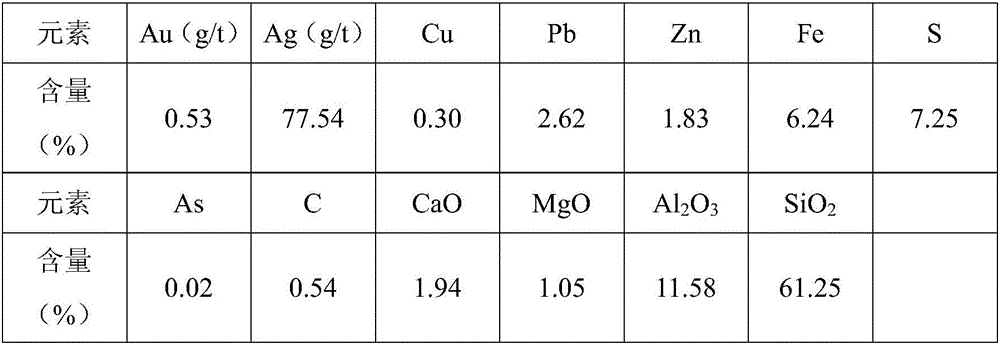

4-Methyl-2-pentanol (IUPAC name: 4-methylpentan-2-ol) or methyl isobutyl carbinol (MIBC) is an organic chemical compound used primarily as a frother in mineral flotation. It is also used as a solvent, in organic synthesis, and in the manufacture of brake fluid and as a precursor to some plasticizers.

Method for high-efficiency floatation and separation of molybdenum and nickel and recovery of molybdenum and nickel from high carbon nickel-molybdenum ore to obtain molybdenum concentrate and nickel-molybdenum bulk concentrate

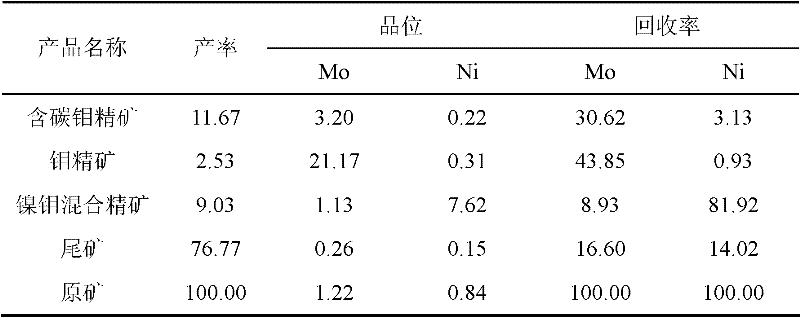

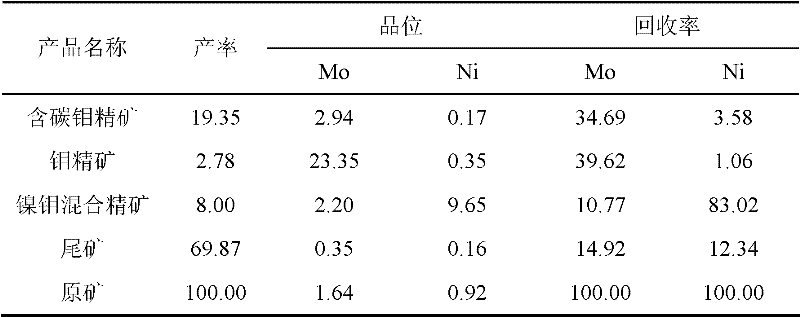

The invention discloses a method for high-efficiency floatation and separation of molybdenum and nickel and recovery of molybdenum and nickel from high carbon nickel-molybdenum ore to obtain molybdenum concentrate and nickel-molybdenum bulk concentrate. The method comprises the following steps of: selecting raw ore; grinding the ore; performing floatation to remove carbon; performing floatation of molybdenum preferably; and performing nickel-molybdenum bulk floatation, wherein in the step of performing carbon removal floatation, an ore dressing reagent of methyl isobutyl carbinol (MIBC) is used as a carbon substance foaming agent and collector, and water glass and lime are used as a dispersing agent and an ore pulp regulator; in the step of performing floatation of molybdenum preferably, emulsified kerosene is used as a collector for molybdenum mineral, terpenic oil is used as a foaming agent, carboxy methylated cellulose (CMC) is used as an inhibitor for carbonic matters and gangue, and Na2SO3 and lime are used as an inhibitor for nickel mineral and pentlandite; and in the step of performing nickel-molybdenum bulk floatation, ore dressing reagents of butyl xanthate and diethyldithiocarbamate are used as a collector for nickel-molybdenum mineral, terpenic oil is used as a foaming agent, CuSO4 is used to activate the nickel mineral, and sulfuric acid is used as a regulator to regulate the pH value of the ore pulp so as to induce the floatation of the nickel and the molybdenum. In the method, the metallic mineral separating effect is good, the recovery rates of metals are high, and the process flow is easy to control and has high repeatability.

Owner:HUNAN RES INST FOR NONFERROUS METALS

A high-efficiency beneficiation and impurity removal process and combined agent for complex and refractory potassium albite ore

ActiveCN102284352AImprove qualityGood workmanshipFlotationWet separationWater useMethyl isobutyl carbinol

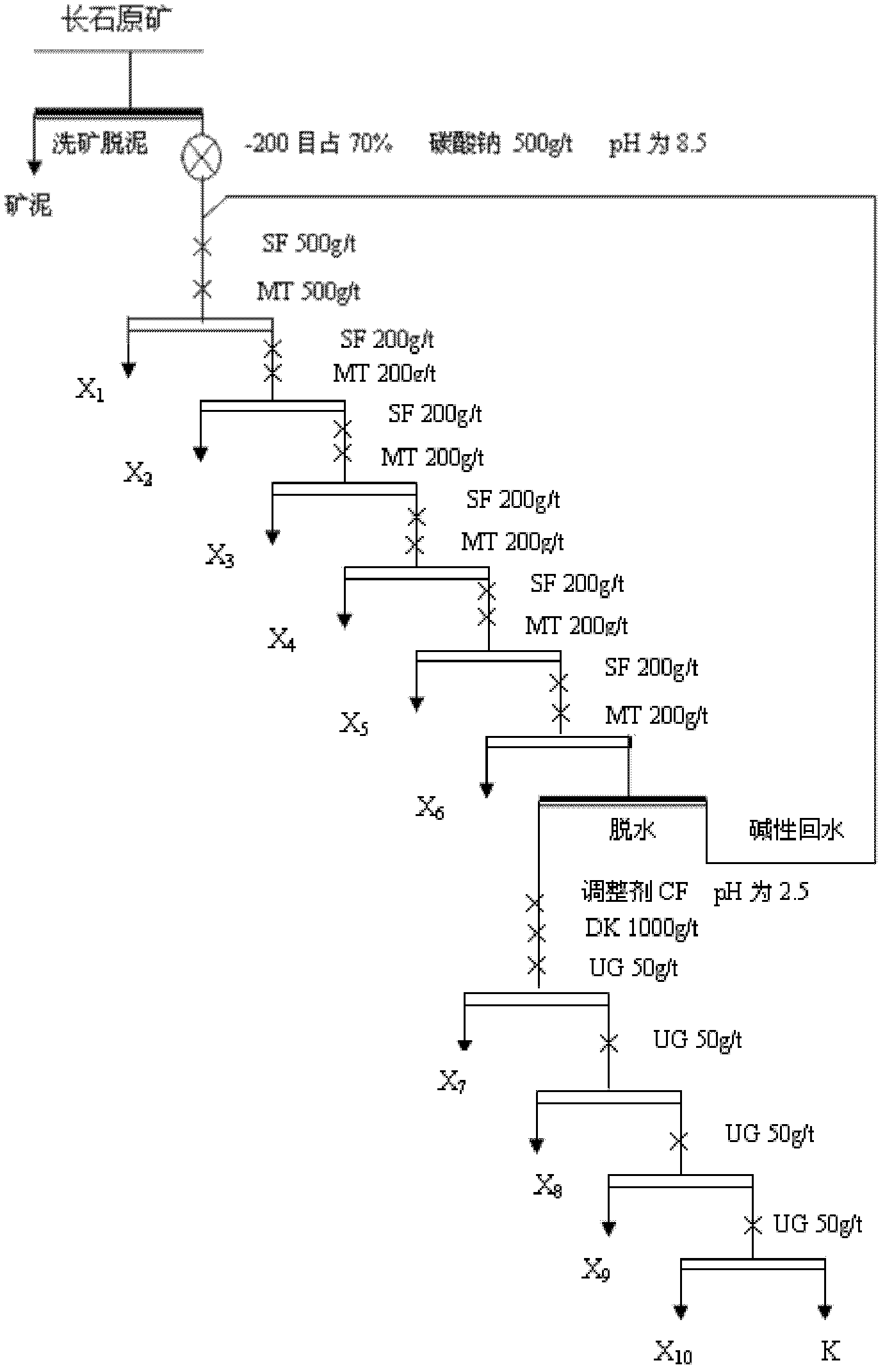

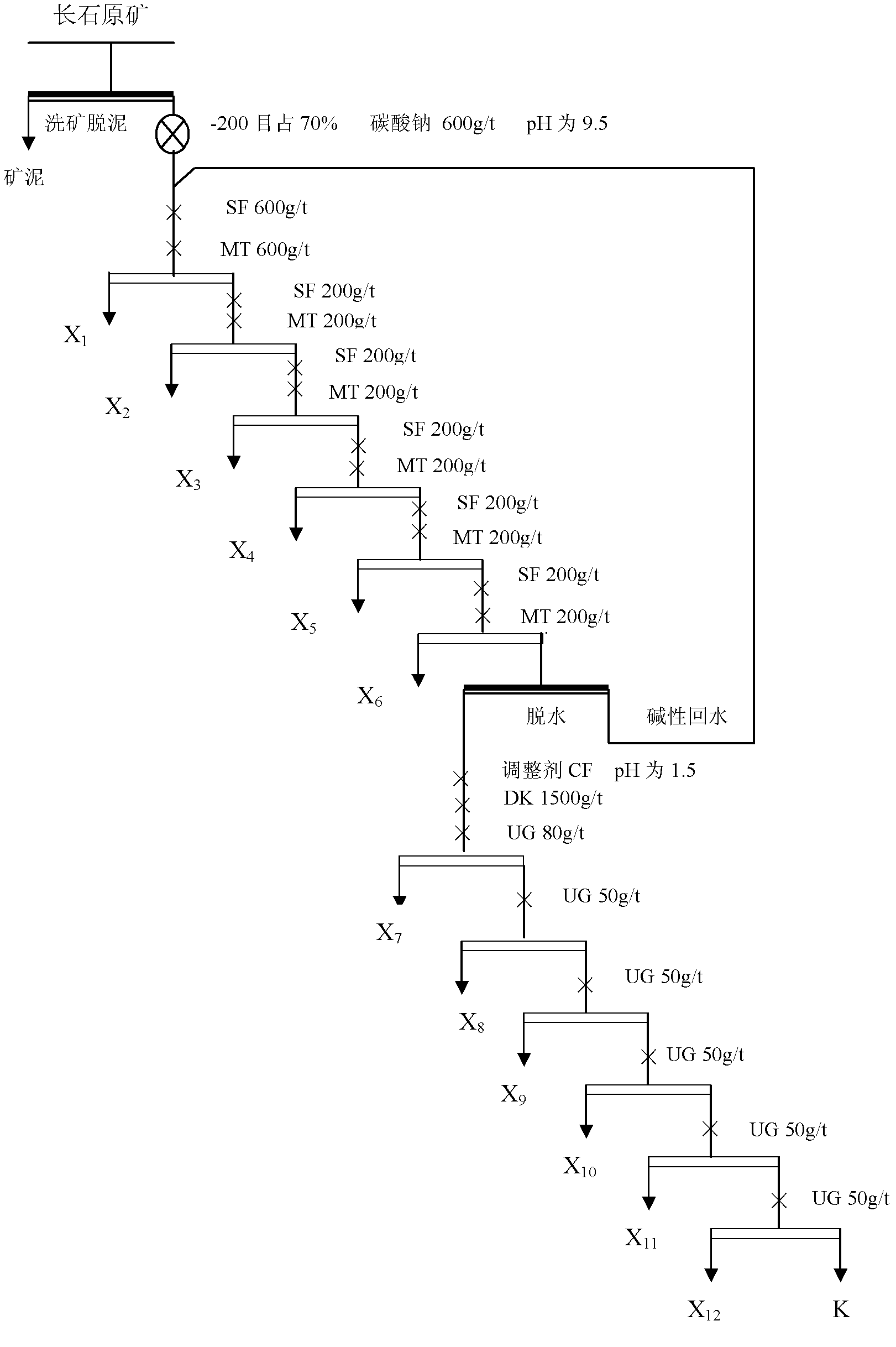

The invention relates to an efficient ore dressing and impurity removal process for potassium and sodium feldspar ores which are complex and difficult to process and a combined medicament thereof. The process comprises the following steps of: desliming and regulating the pH value of ore pulp to 8 to 10 in the phases of desliming by ore washing and grading by ore grinding; adding 1,000 to 2,000 g / t of saponification oleic acid and 1,000 to 2,000 g / t of benzohydroxamic acid in the alkaline flotation phase of reverse flotation impurity removal to perform collection and floatation on iron and titanium minerals by anions, wherein in the saponification oleic acid, a mass ratio of the oleic acid to sodium carbonate is 1:(0.3-0.5); and after dehydrating, regulating the pH value of the ore pulp to2 to 3 in the acidic floatation phase, adding 800 to 1,500 g / t of sodium chloride and 800 to 1,500 g / t of potassium chloride to inhibit potassium and sodium feldspar, and adding 200 to 400 g / t of dodecanaminium and 200 to 400 g / t of methyl isobutyl carbinol (MIBC) which serve as emulsified cation collecting agents to perform the floatation impurities with colors. By the process, feldspar concentrates in which the content of Fe2O3 and TiO2 is below 0.1 percent, and the content of Na2O and K2O is over 14 percent can be obtained, and the whiteness of the directly-sintered feldspar concentrates can reach over 55, so the feldspar concentrates can be used as super high-quality ceramic raw materials, and other products can be used for firing bricks. In addition, return water used in the process in the moisture phase is recycled, namely water dehydrated after alkaline flotation and return water of acidic tailings can return to the process to be recycled, so the process is high in comprehensive recovery efficiency, economic, practical, energy-saving and environment-friendly.

Owner:CENT SOUTH UNIV

Brown coal reverse-flotation medicament combination use method

InactiveCN102773168AImproved floating speedImprove settlement performanceFlotationMineral flotationSlurry

A brown coal reverse-flotation medicament combination use method belongs to a fine particle coal separate method. The method comprises the following steps of: mixing brown coal which is finely ground so that the monomer granularity achieves basic dissociation into ore slurry with preference concentration; firstly adding soluble salt (sodium chloride) to stir; adding an inhibiting agent (causticizing corn starch) to stir; then adding a collecting agent (dodecyl amine-hydrochloride) to stir; and finally adding a foaming agent (methyl isobutyl carbinol) to stir; and the brown coal reverse-flotation medicament combination use method is characterized in that the soluble salt is added in the brown coal reverse-flotation, and four medicaments are combined for use. The brown coal reverse-flotation medicament combination use method has the advantages that the conventional floating agent is used, and the flotation of thin brown coal granules without modification is realized by using a reverse-flotation method through the combination of medicaments, namely, mineral granules with high ash float out from foams as a goal object; and simultaneously, according to the method, the flotation rate of mineral is increased, the separating effect is improved, the sedimentation rate of ore slurry is quickened, and the sedimentation of separated ore slurry is facilitated. Compared with the direct flotation, the stronger the hydrophilicity of the surface of brown coal is, the better the reverse-flotation effect is; and therefore, the disadvantages are changed into the advantages.

Owner:CHINA UNIV OF MINING & TECH

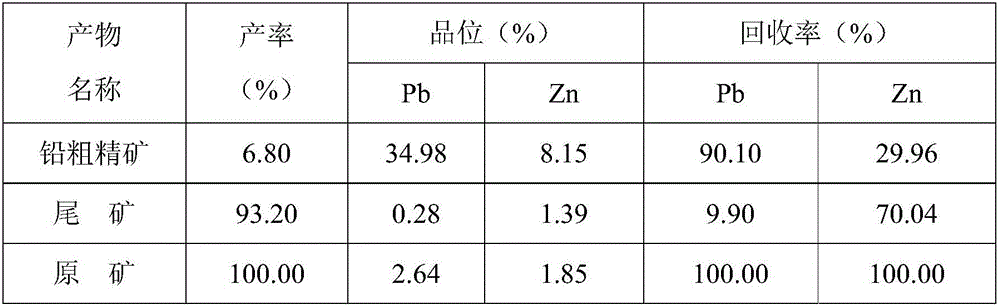

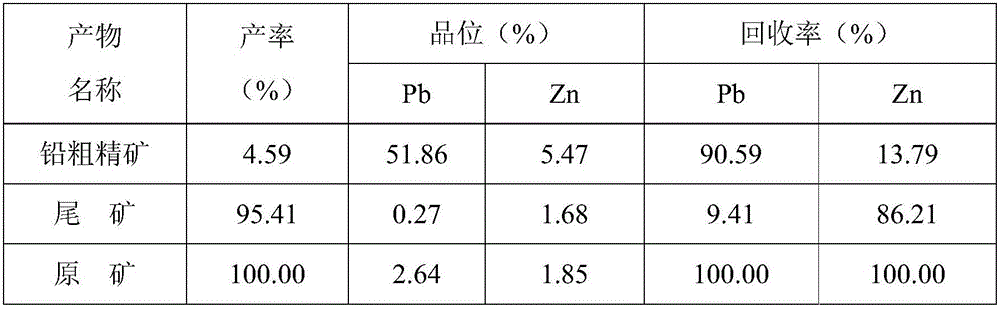

Lead zinc ore flotation method adopting novel combined inhibitor

The invention relates to a lead zinc ore flotation method adopting a novel combined inhibitor, and belongs to lead zinc ore flotation methods adopting inhibitors. The method comprises the steps of ore grinding grading operation, wherein lead and zinc polymetallic ore is subjected to ore grinding till the fineness of 200 mesh is achieved, and the content ranges from 70% to 90%; roughing operation, wherein calcium oxide is added to carry out size mixing on ore pulp, the inhibitor Na2CO3:ZnSO4 and a collector and foaming agent methyl isobutyl carbinol are added, and rough concentrate is obtained; scavenging I operation; scavenging II operation; concentrating operation and inhibitor adding. The method has the advantages that after the novel combined inhibitor Na2CO3+ZnSO4 is used in the lead and zinc flotation process, zinc in lead concentrate can be effectively inhibited, the zinc content in the lead concentrate is obviously reduced, and the qualified lead concentrate product can be obtained.

Owner:CHANGCHUN GOLD RES INST

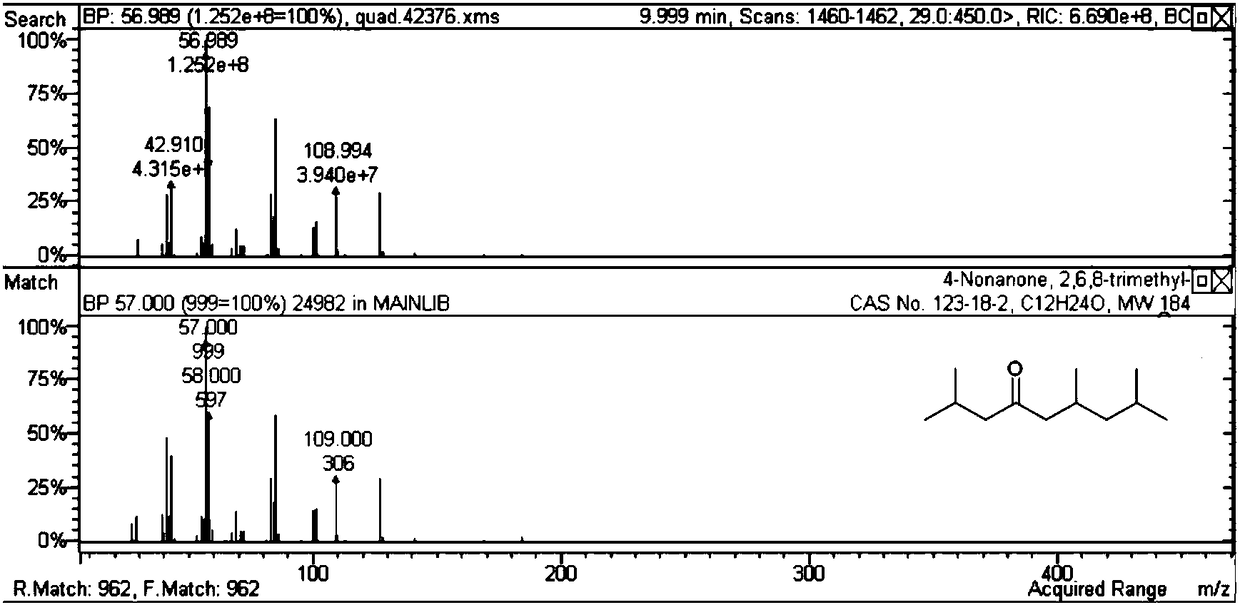

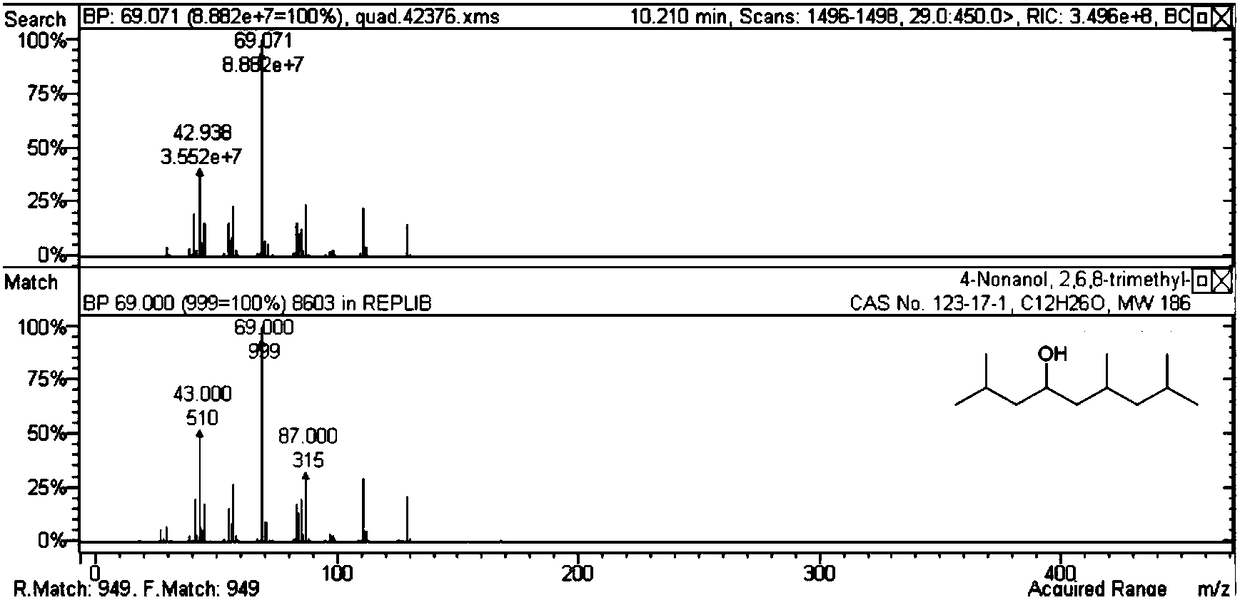

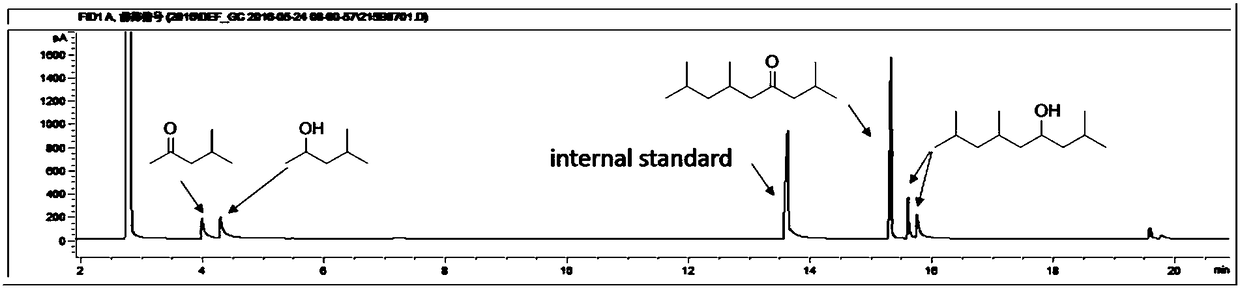

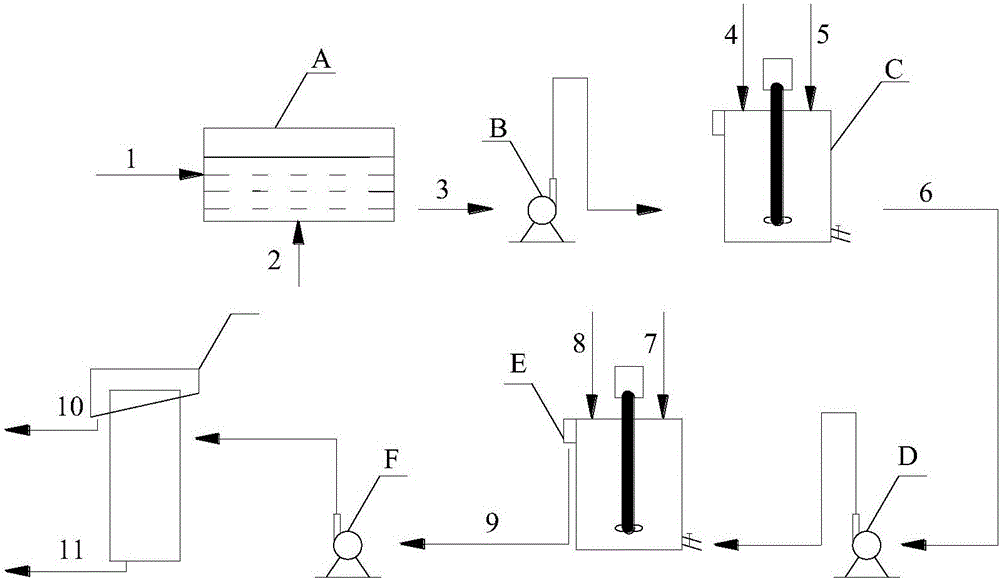

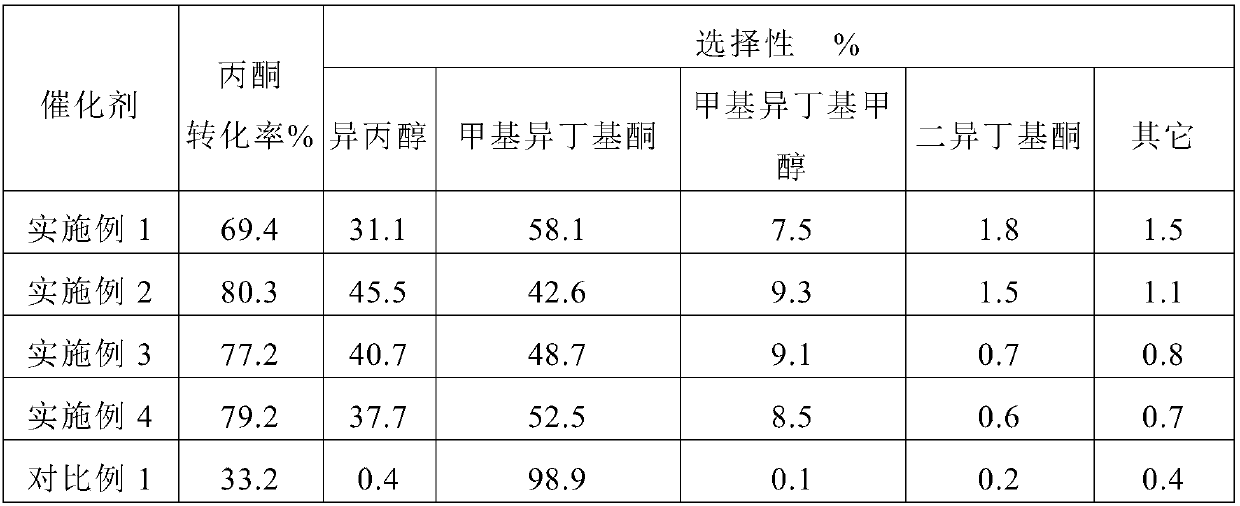

Method for coproduction of methyl isobutyl ketone and methyl isobutyl carbinol

ActiveCN103420786ALow costImprove stabilityOxygen-containing compound preparationOrganic compound preparationChemical industryReaction temperature

The invention relates to a method for coproduction of methyl isobutyl ketone and methyl isobutyl carbinol, and particularly to the production method for simultaneously coproducing methyl isobutyl ketone and methyl isobutyl carbinol with acetone and hydrogen as raw materials, employing a non-pure noble metal catalyst especially employing a catalyst with a brand number of BC-A-61 and produced by Beijing Research Institute of Chemical Industry, and under reaction conditions of the reaction temperature of 170-230 DEG C, the reaction pressure of 1.0-6.0 MPa, the acetone liquid phase airspeed of 0.5-3.0 h<-1> and the hydrogen and ketone molar ratio of 0.3-1. The method of the invention has the advantages of relatively low catalyst cost, reasonable and simple technological process and low energy consumption, simultaneously coproduces two kinds of products which are methyl isobutyl ketone and methyl isobutyl carbinol and have supply and demand gaps existing in markets, and has few by-product heavy components.

Owner:ZHEJIANG XINHUA CHEM +1

Preparation method of reproducible dodecanol and branched paraffin in range of aviation kerosene

ActiveCN108102683AHigh selectivityOrganic compound preparationHydroxy compound preparationKeroseneSolid acid

The invention relates to a preparation method of biomass-based dodecanol and branched paraffin in a range of aviation kerosene. The preparation method comprises two parts: 1), mesityl oxide, diacetonealcohol and methyl isobutyl carbinol or a mixture of two or more of the compounds is subjected to a condensation reaction on a first catalyst bed layer of a fixed bed continuous reactor under catalysis of an acid catalyst, a base catalyst, a metal doped solid acid catalyst or a metal doped solid base catalyst, and an oxygen-containing organic compound with carbon chain length being 12 is obtained; 2), a condensation product produced on the first catalyst bed layer and unreacted hydrogen are subjected to a hydrogenation reaction on a second catalyst bed layer of the fixed bed continuous reactor at lower reaction temperature under the acceleration of a metal catalyst, and dodecanol is obtained.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Sorting method of oxidized coal slurry

ActiveCN106669977ASolution to high drug consumptionResolve recovery rateFlotationEngineeringPolypropylene

The invention discloses a sorting method for oxidized coal slurry. The sorting method comprises the following three parts of the preparation of a CO2 saturated water solution, treatment of oxidized coal slurry ore pulp and sorting of the oxidized coal slurry. The sorting method comprises the following steps of adding a floatation reagent and a foaming agent to the ore pulp; injecting the mixed ore pulp in a flotation column for flotation operation by a pump, wherein the floatation reagent comprises 20-40% of a hydroxyl compound, 1-2% of alkyl phenol polyoxyethylene ether, 1-2% of methyl isobutyl carbinol, 1-2% of xylene, 1-2% of polypropylene ethanediol, 1-2% of sodium silicate, and the balance of hydrocarbon type oil; and enabling coal particles to enter the foam cleaned coal along with the floating of bubbles. According to the sorting method disclosed by the invention, the selection of the technology and the floating agent is optimized, and the recovery rate of the oxidized coal is greatly increased.

Owner:CHINA UNIV OF MINING & TECH

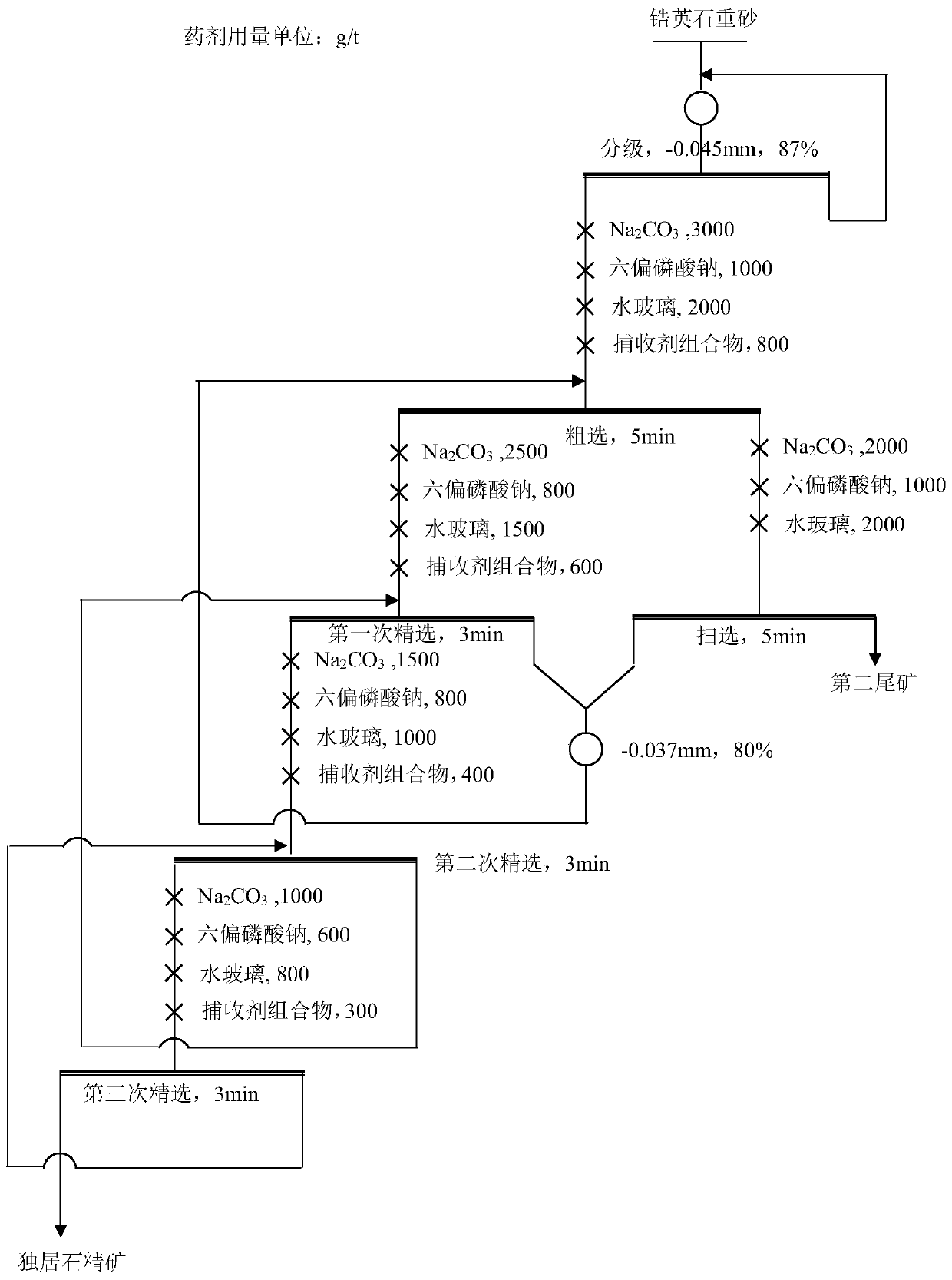

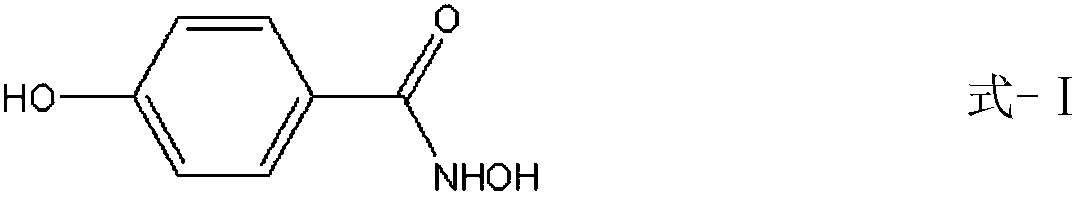

Collecting agent composition for flotation recovery of monazite from zirconite heavy sand

The invention provides a collecting agent composition for flotation recovery of monazite from zirconite heavy sand, wherein the collecting agent composition comprises, by weight, 35-50 parts of an agent A, 10-30 parts of an agent B, 20-40 parts of sodium p-ethylmandelate and 1-2 parts of methyl isobutyl carbinol. According to the invention, the collecting agent composition is high in selectivity and good in collecting capacity, and can effectively recover monazite in zirconite heavy sand; and compared with the traditional flotation agent, the collecting agent composition of the invention can improve the grade and the recovery rate of rare earth oxides in monazite concentrate by more than 1% and more than 3% respectively, improve the grade of zirconite heavy sand by more than 2%, and reducethe flotation temperature by 10-15 DEG C.

Owner:SHANGLUO UNIV

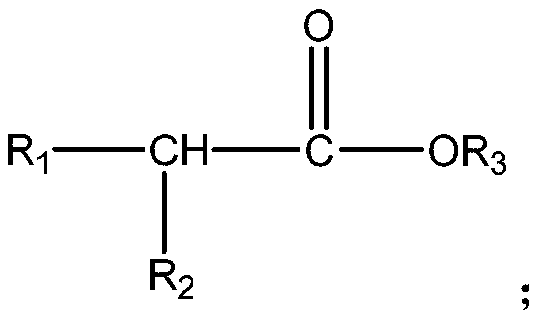

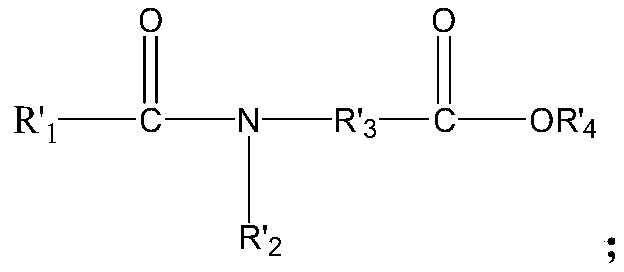

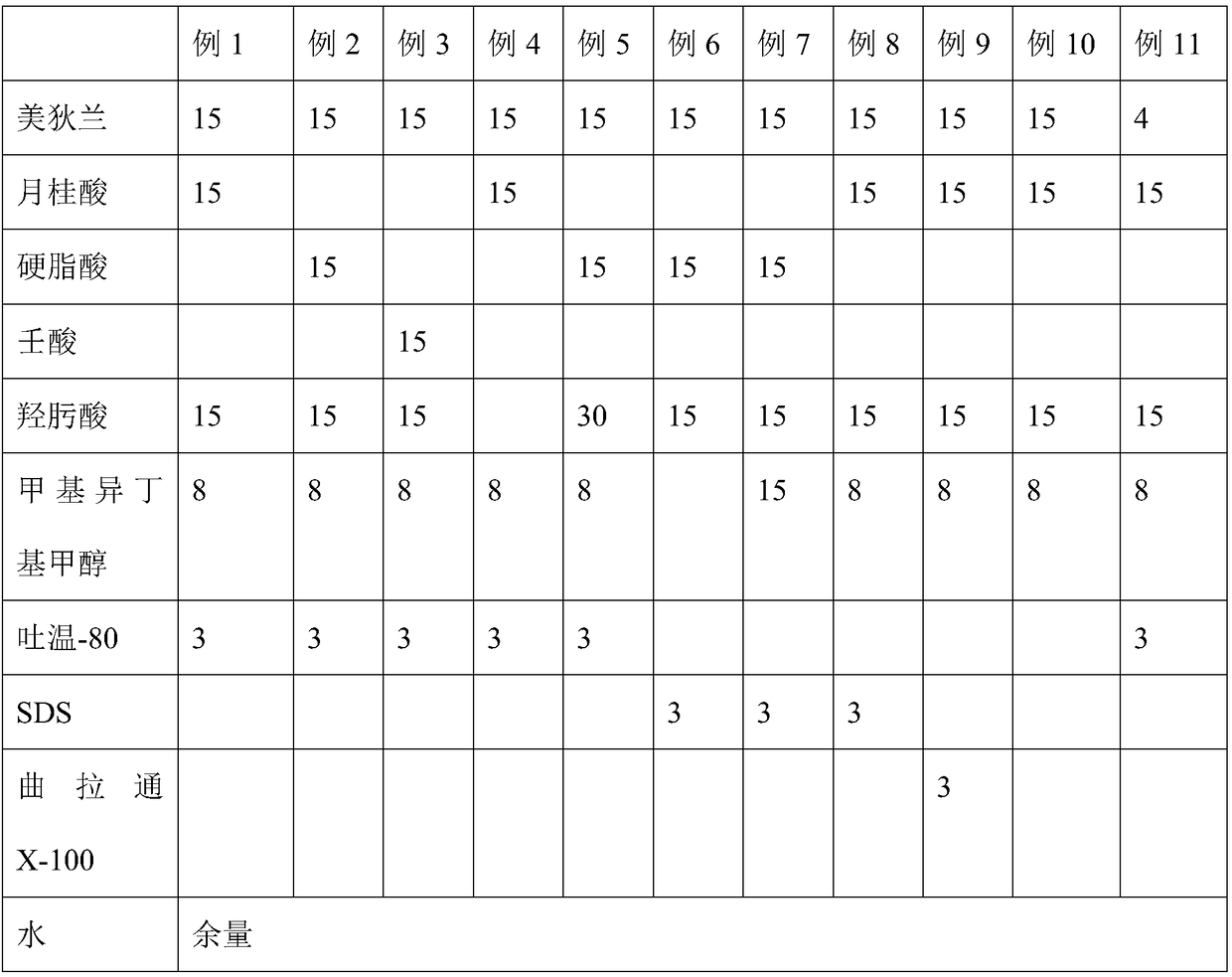

Mineral collecting agent for collecting oxidized ores such as fluorite and preparation method thereof

The invention provides a mineral collecting agent for collecting oxidized ores such as fluorite and a preparation method thereof, and belongs to the technical field of a mineral flotation collecting agent. The mineral flotation collecting agent for the oxidized ores such as fluorite is obtained by mixing Medialen, specific carbon atom fatty acid, hydroximic acid, methyl isobutyl carbinol, a surface active agent and the like, and then is used. The mineral flotation collecting agent has the characteristics of good water solubility, good dispersibility and strong preferential adsorption capacityof a target mineral, and is mainly used for flotation separation of useful minerals in the oxidized ores such as the fluorite, calcite, barite and ilmenite. A preparation method of the mineral flotation collecting agent for the oxidized ores has simple process and is easy in control of operation; and the prepared collecting agent has the advantages of strong selectivity, good dispersibility, lessdosage of chemicals, high overall efficiency of beneficiation and the like, and is of great significance for promoting the beneficiation of the minerals such as the oxidized ores.

Owner:河南天鸿选矿科技有限公司

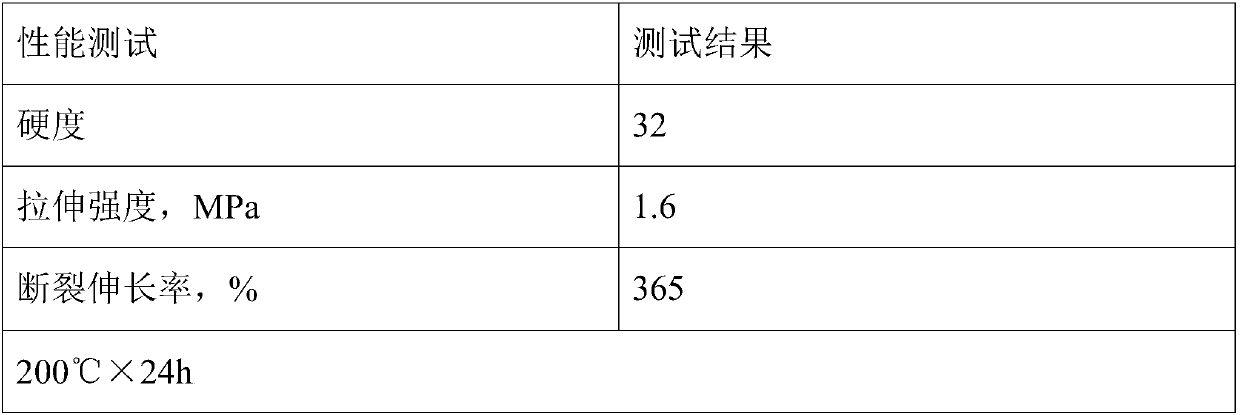

Colorful quick-drying nitrocellulose paint

Colorful quick-drying nitrocellulose paint comprises raw materials in parts by weight as follows: 100 parts of nitrocellulose, 5-15 parts of ethylene glycol monoethyl ether, 10-20 parts of methoxy methylpentanone, 20-30 parts of rutile type titanium dioxide, 1-10 parts of ethylene glycol monobutyl ether, 5-25 parts of polysiloxane, 80-90 parts of deionized water, 15-25 parts of hydroxyethyl methylacrylate, 10-20 parts of pigment, 15-35 parts of isobutyl acetate, 25-35 parts of methyl isobutyl carbinol, 10-30 parts of methyl amylketone, 5-10 parts of a plasticizer, 35-45 parts of cellulose acetate butyrate, 20-40 parts of naphtha and 20-30 parts of benzophenone; the pH value of a product is 7-9, and surface dry is performed for 30-60 minutes; the adhesive force is 100%, and the paint doesn't bubble and come off after soaked in water for 10-20 days; hard dry is performed for 6-10 hours, and the loss is 0.004-0.006g / cm<2> after the paint is tested by a reciprocating tester for 1,000 times; and the paint can be washed for 300-500 times, can be widely produced and can continuously replace a conventional material.

Owner:盐城市盐龙水务有限公司

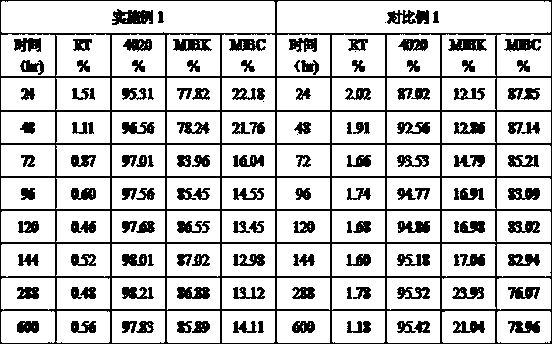

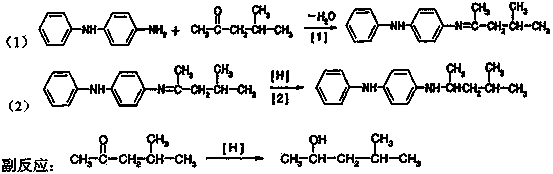

Method for increasing ketone-alcohol ratio in hydrogenation reaction of anti-aging agent 4020 by modification-catalysis

ActiveCN104276958AHigh selectivityImprove ketone-to-alcohol ratioOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystOrganic synthesis

The invention belongs to the technical field of organic synthesis and specifically relates to a method for increasing the ketone-alcohol ratio in hydrogenation reaction of an anti-aging agent 4020 by modification-catalysis. The method is characterized by preparing raw materials, namely 4-aminodiphenylamine, methyl isobutyl ketone (MIBK) and an ionic liquid into a raw material solution, loading a copper-based catalyst into a fixed bed reactor, and putting the raw material solution into the fixed bed reactor in a continuous feeding and discharging way for preparing the anti-aging agent 4020 by catalytic hydrogenation, wherein the ketone-alcohol ratio after the hydrogenation reaction is significantly increased. The method provided by the invention is simple, convenient to operate, high in yield and good in selectivity, the MIBK becomes methyl isobutyl carbinol (MIBC) by hydrogenation, and side effects are obviously inhibited, so that the method is conductive to increasing the ketone-alcohol ratio after catalytic hydrogenation in industrial production, reducing the consumption of the MIBK and greatly reducing the production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Zinc oxide composite floating agent and preparation method and application thereof

The invention discloses a zinc oxide composite floating agent and a preparation method and application thereof. The floating agent is prepared from the following components of, by mass, 30-40 parts ofoctadecylamine acetate, 15-20 parts of dodecylamine, 15-20 parts of primary amine, 30-40 parts of methyl isobutyl carbinol, 7-15 parts of copper sulfate and 3-5 parts of an emulgator. The preparationmethod comprises the steps that the octadecylamine acetate, the dodecylamine, the primary amine and the solid copper sulfate are put into a container, then, the methyl isobutyl carbinol and the emulgator are added into the container, stirring is uniformly conducted at the temperature of 30-40 DEG C to obtain a mixed solution, the mixed solution is subjected to emulsification treatment, and the zinc oxide composite floating agent is obtained. When the composite floating agent is used for processing low-grade high-slime zinc oxide ore, raw ore does not need to be subjected to desliming treatment, and floating is directly conducted. The technical process is simple, and the zinc oxide composite floating agent is free of environment pollution and environmental friendly and has broad application prospects.

Owner:KUNMING UNIV OF SCI & TECH

A Flotation Technology of Large Scale Crystalline Graphite Ore

The invention relates to a large-scale crystalline graphite ore flotation fast selecting agent and a flotation technology. The agent comprises following components including, by weight, 50% to 65% of methyl isobutyl carbinol, 20% to 30% of petroleum ether and 10% to 25% of acetone. The graphite ore flotation fast selecting agent can rapidly select high-quality large-scale graphite ore from neutral pulp, and high-grade large-scale crystalline graphite concentrate can be obtained through the short selection technology free of regrinding; compared with a traditional large-scale crystalline graphite ore flotation technology, graphite scales can be effectively protected, meanwhile, the consumption amount of the floatation agent can be reduced, and the production cost is reduced.

Owner:金建工程设计有限公司

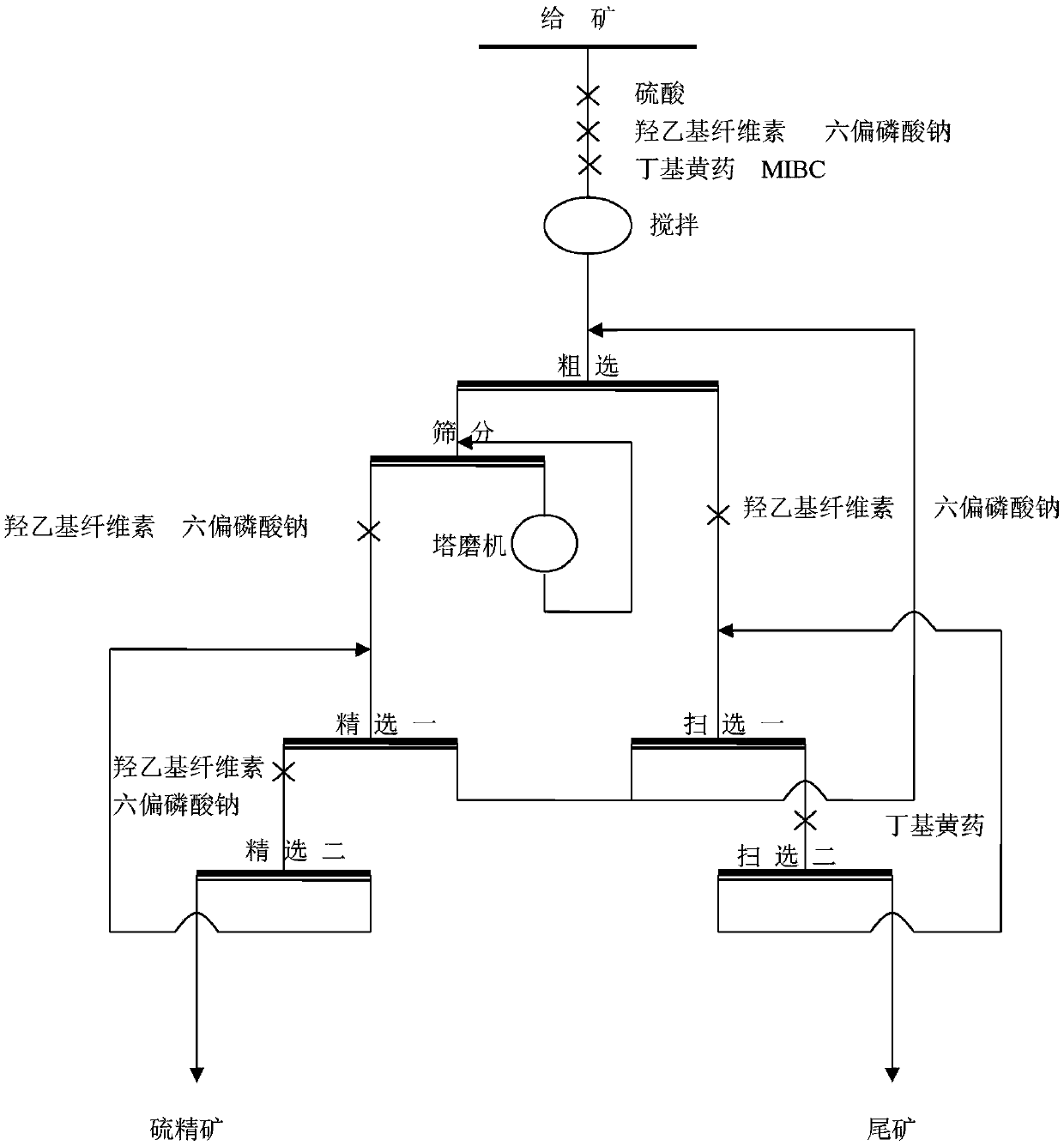

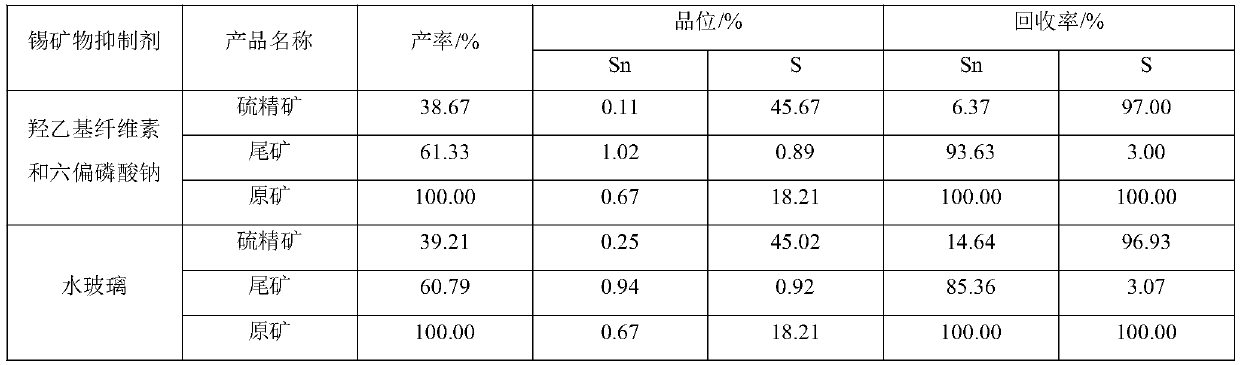

Flotation method for reducing tin content of pyrite

InactiveCN109604071ALow tin contentEasy to useFlotationGrain treatmentsCycloneMethyl isobutyl carbinol

The invention discloses a flotation method for reducing a tin content of a sulfur ore concentrate. The method comprises the following steps: performing ore pulp adjustment on preferential-flotation lead-zinc tailings, adding sulfuric acid into a stirring device, maintaining the pH value at 5-6, adding collecting agent butyl xanthate and foaming agent methyl isobutyl carbinol, adding cassiterite inhibitor hydroxyethyl cellulose and sodium hexametaphosphate according to a mass ratio of 1:1, performing rough selection for one time, performing scavenging for two times, performing re-grinding on arough ore concentrate product by a tower mill, performing classification by a cyclone to obtain a qualified product, and performing concentration for two times to obtain a pyrite product with a low tin content. The method provided by the invention has a simple production process, and the tin content of the sulfur ore concentrate is less than 0.12%, and the method facilitates recovery of tin minerals.

Owner:广东省资源综合利用研究所

Preparation method of adsorbent special for heparin sodium

ActiveCN105289546AHigh selectivityImprove adsorption capacityOther chemical processesFoaming agentVinyl pyridine

The invention discloses a preparation method of an adsorbent special for heparin sodium. In polymerization, slight FPMMA and 0.1-0.5 part of 4-vinyl pyridine are introduced to be used as comonomers, and methyl isobutyl carbinol is used as a pore-foaming agent, so as to improve the mechanical strength of the adsorbent.

Owner:JIANGSU WANBANG BIOPHARMLS +1

Flotation process of ilmenite or bastnaesite

ActiveCN108452949AImprove adsorption capacityStrong harvesting abilityFlotationFoaming agentGranularity

The invention relates to the technology of flotation, and particularly relates to a flotation process of ilmenite or bastnaesite. According to the process disclosed by the invention, a using amount ofa nipagin hydroximic acid collecting agent is more than or equal to 15g / t, and the granularity of ores is minus 0.074mm, occupying 60 percent to 100 percent; lime, sodium hydroxide or sodium carbonate is added to regulate pH of ore pulp to reach 4 to 12; water glass is an inhibitor, and a using amount of the inhibitor is 200g / t to 2000g / t; and MIBC (Methyl Isobutyl Carbinol) is a foaming agent, ausing amount of the MIBC is 10mg / L to 20mg / L, and the acting time is about 1 minute. The process disclosed by the invention is applied to flotation and refractory of fine-particle oxidized ores, andcan improve the flotation effect and mineral processing indexes. According to the process disclosed by the invention, medicament is reduced, and the mineral processing cost is reduced.

Owner:JIANGXI UNIV OF SCI & TECH

Catalyst for co-producing 4-methyl-2-pentanone and 4-methyl-2-pentanol through one-step method

ActiveCN107930640ALow costEasy to operateOrganic compound preparationHeterogenous catalyst chemical elementsAlkaline earth metalPalladium catalyst

The invention relates to a catalyst, and belongs to the technical field of applications and development of acetone downstream products, wherein copper, an alkaline earth metal, cerium and chromium areused as loading components, aluminum oxide, silicon oxide or an aluminum oxide-silicon oxide composite carrier with rich pH value is selected to promote a reaction, the catalyst is used under a mildreaction condition, the yield of 4-methyl-2-pentanone in the application of the catalyst of the present invention is higher than the yield of 4-methyl-2-pentanone in the application of the palladium / resin catalyst used in the current industrial apparatus, and 4-methyl-2-pentanol is economically by-produced. According to the present invention, the obtained catalyst has the ideal stability, has thecost significantly lower than the cost of the existing palladium catalyst, and has good economic benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

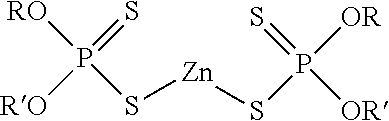

Lubricant compositions for improved engine performance

The disclosure provides a lubricant composition for lubricating an engine, a method for operating an engine and an additive concentrate. The lubricant composition includes a base oil of lubricating viscosity; one or more metal dialkyldithiophosphates having more than 75 mole percent of alkyl groups derived from 4-methyl-2-pentanol, and from about 0.1 to about 2.0 percent by weight of detergent derived from an alkyl phenol or sulfurized alkyl phenol based on a total weight of the lubricant composition. An amount of the one or more metal dialkyldithiophosphate in the lubricant composition ranges from about 0.01 to about 0.10 percent by weight phosphorus based on a total weight of the lubricant composition. The lubricant composition has a total a total base number (TBN) of about 5.0 to about 10.0.

Owner:AFTON CHEMICAL

Preparation method of mold release agent durable in storage

ActiveCN106955968AImprove heat resistanceImprove stabilityFoundry mouldsFoundry coresHydroxypropylmethylcellulose phthalateTert-Butyloxycarbonyl protecting group

The invention provides a preparation method of a mold release agent durable in storage. A mold release agent product is obtained by adding (heptadecafluoro-1,1,2,2-tetradecyl)trimethoxysilane, poly(ethylene glycol) methyl ether meth-acrylate, poly-4-methyl-1-amylene, methyl isobutyl carbinol, hydroxypropyl methylcellulose phthalate, 5,7-difluoro-2,3-dihydrobenzofuran and N-(tert-butoxycarbonyl)-1-[(4-methylphenyl)sulfonyl]-L-histidine in an agitated vessel to be stirred and diffused.

Owner:江苏康姆罗拉特种陶瓷有限公司

Positive ion type foaming agent for mineral separation

ActiveCN107138289AEfficient mineralizationHigh recovery rateFlotationCucurbitacin IMethyl isobutyl carbinol

The invention discloses a positive ion type foaming agent for mineral separation. Cucurbitacin, cetyl trimethyl ammonium bromide, methyl isobutyl carbinol and an emulgator serve as raw materials, and by means of high-strength stirring, an appropriate matching ratio, ultrasonic treatment and other operation, the novel ion type foaming agent is obtained. The positive ion type foaming agent is especially suitable for flotation of micro-fine grained metal, in the flotation process, the novel foaming agent is scattered into ore pulp, after inflation is carried out, micro-foam with surface provided with positive charges is produced, the surfaces of metal mineral grains are provided with negative charges, the grains and the foam collide with each other through the intensifying action of electrostatic attraction, chitosan-sepiolite is added, finally, very efficient mineralization is achieved through the foam, and the recycling rate is greatly increased.

Owner:乌拉特前旗西沙德盖钼业有限责任公司

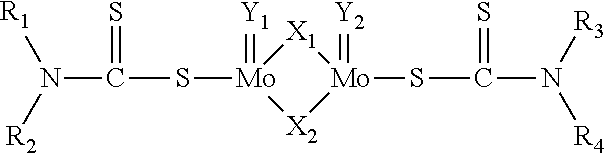

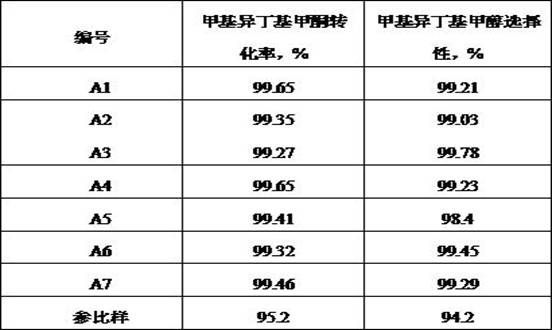

Catalyst for preparing methyl isobutyl carbinol and preparation method thereof

ActiveCN112536041AEasy to prepareLow priceOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystCombinatorial chemistry

The invention provides a catalyst for preparing methyl isobutyl carbinol and a preparation method thereof, and belongs to the technical field of catalysts. The catalyst contains 10%-25% of active components Cu and Mo, 70%-85% of a carrier silicon dioxide and the balance of auxiliaries. The mass ratio of copper to molybdenum in the active components is 0.5-9. The catalyst is prepared by adopting astep-by-step impregnation method. The catalyst has the advantages of high methyl isobutyl methanol conversion rate, good selectivity, mild reaction conditions and the like, and is easy to popularize and apply.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-cost flame-retardant photovoltaic cable with good thermal stability

InactiveCN107674405AEffective dispersionEffective in promoting dispersionRubber insulatorsPolyethylene glycolEngineering

The invention discloses a low-cost flame-retardant photovoltaic cable with good thermal stability. The cable comprises a cable core and a sheath layer coating the outer side of the cable core, whereinthe sheath layer is prepared from the raw materials in parts by weight: 110-130 parts of substrate, 0.1-0.18 part of maleic anhydride, 0.4-1 part of tin dibutyl dilaurate, 1.5-2.5 parts of cross-linker, 1-2 parts of glycerine, 0.2-0.8 part of 4-methyl-2-pentanol, 1-2 parts of pentaerythritol, 30-50 parts of modified bamboo powder, 28-40 parts of micro-capsulated red phosphorus, 15-18 parts of magnesium hydroxide, 2-4 parts of zinc borate, 3-8 parts of talcum powder and 3-6 parts of maifanite powder. The modified bamboo powder is prepared through the following processes: subjecting sodium methylate, polyethylene glycol 200 and methyl palmitate to heating and vacuum stirring, adding bamboo powder and water into the mixture, carrying out stirring, carrying out filtering, carrying out washing, adding titanium sulfate, urea and water, carrying out uniform mixing, feeding the mixture into a hydrothermal reactor, carrying out sealing, carrying out heating, carrying out a hydrothermal reaction, carrying out cooling, carrying out filtering, carrying out washing, and carrying out drying.

Owner:安徽伙伴电气有限公司

Method for machining pyrrhotite containing nickel ore

InactiveCN107670843ADeactivationReduce contentFlotationGrain treatmentsMethyl isobutyl carbinolButylxanthate

The invention discloses a method for machining pyrrhotite containing nickel ore. The method comprises the steps that (1) the pyrrhotite containing nickel ore is subjected to smashing treatment so thatsmashed ore can be obtained; (2) the smashed ore is subjected to wet grinding treatment through a ball grinder so that ore pulp can be obtained, wherein a lining plate and balls of the ball grinder are all made of stainless steel; and (3) the ore pulp, sodium n-butylxanthate and methyl isobutyl carbinol are mixed and stirred and then subjected to floatation treatment so that nickel concentrate and pyrrhotite can be obtained separately. According to the method, no inhibitor needs to be added, the environment-friendly effect is achieved, moreover, the cost is low, operation is convenient, the grade and the recovery rate of the nickel concentrate are remarkably improved, and remarkable economical benefits are achieved.

Owner:CHINA ENFI ENGINEERING CORPORATION

Packaging thin film material for electronic commerce logistics transportation

InactiveCN105907075AExcellent flame retardantGood acid and alkali resistanceBenzoic acidDecabromobiphenyl ether

The invention relates to a packaging thin film material for electronic commerce logistics transportation. The packaging thin film material is prepared from the following components: epichlorohydrin rubber, chloroprene rubber adhesive, neoprene, deca-brominated diphenyl ether, titanium tetrabutoxide, sodium stannate, barium stearate, parachlormetaxylenol, garlic extract, beta-bromo-beta-nitrotrimethyleneglycol, 2-mercaptobenzothiazole, garlic oil, sodium dihydrogen phosphate, lead oxide powder, lead iodate powder, vermiculite powder, camellia pollen, modified attapulgite powder, pearl powder, amyl acetate, sesame oil, methyl isobutyl carbinol, trimethyl borate, N-nitro sodimethylamine, arabinogalactan, amino propyl trimethoxy silane, a barium-zinc stabilizer, benzotriazole, benzoic acid and ricinoleic acid polyoxyethylene allyl ester. The packaging thin film material has relatively excellent flame resistance, acid and alkali resistance and mildew and mold resistance; and the product performance is improved.

Owner:王根夫

A kind of preparation method of modified phosphorus nitrogen type flame retardant

The invention provides a method for preparing a modified phosphorus-nitrogen flame-retardant agent. In a reaction kettle, phosphoric acid, ethylene glycol, melamine and methyl isobutyl carbinol are added by weight, an esterification reaction and a salt forming reaction are conducted to obtain an intermediate product, and then a modification reaction is conducted to obtain the product.

Owner:HUAIAN SHUANGYANG CHEM

A flotation method for recovering carbon and electrolyte from waste cathode carbon blocks of aluminum electrolytic cell

Owner:CENT SOUTH UNIV

3D printing flame-retardant antibacterial composite material

InactiveCN106009503AExcellent flame retardantGood acid and alkali resistanceAdditive manufacturing apparatusMethyl benzoateMethyl isobutyl carbinol

The invention relates to a 3D printing flame-retardant and antibacterial composite material, which is composed of the following components: urea-formaldehyde resin, perchloroethylene resin, fluorosilicone rubber, N-methylpyrrolidone, diethylene glycol monoethyl ether, soybean oil, methyl Isobutyl carbinol, methyl benzoate, antimicrobial peptide, p-chloro-m-xylenol, eucalyptus oil, biguanide trioctylbenzene sulfonate, sodium hydrosulfide, porcelain powder, titanium nitride powder, sodium dihydrogen phosphate , barium sulfate powder, molybdenum disulfide powder, lead iodate powder, praseodymium oxide powder, diethyl ethyl phosphonate, nano-zinc oxide, hexabromobenzene, acrylonitrile, sodium dodecylsulfonate, hydrogen sulfite Sodium, isophorone, cumene, sodium carboxymethylcellulose, polyoxyethylene oleate. The product of the invention has relatively superior flame retardancy, acid and alkali resistance, anti-mildew and antibacterial properties, and improves product performance.

Owner:李云海

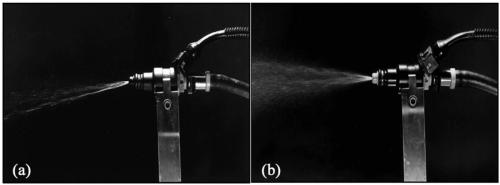

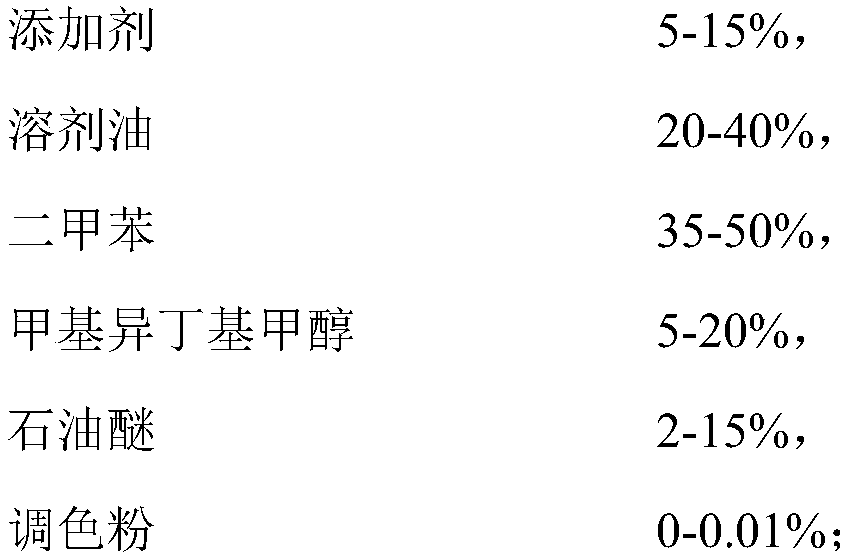

Oil nozzle cleaning agent and preparation method thereof

InactiveCN109294641AImprove poor atomizationImprove vehicle power shortageLiquid carbonaceous fuelsFuel additivesSolventCleansing Agents

The invention discloses an oil nozzle cleaning agent and a preparation method thereof. The oil nozzle cleaning agent is prepared from, by mass, 5-15% of an additive, 20-40% of solvent oil, 35-50% of xylene, 5-20% of methyl isobutyl carbinol, 2-15% of petroleum ether and 0-0.01% of color mixing powder. The additive is prepared from, by mass, 20-30% of polyether amine, 15-30% of heavy solvent naphtha, 1-10% of light solvent naphtha, 10-30% of polyether glycol, 1-10% of 2-ethylhexanol, 1-10% of trimethylbenzene, 0.5-5% of naphthalene, 0.5-5% of n-propyl benzene, 0.5-5% of polypropylene glycol, 0.05-3% of cumene and 0.01-5% of triethanolamine. The oil nozzle cleaning agent is capable of clearing carbon deposit in oil nozzles to improve oil atomizing effects, and oil consumption reduction, power recovery and improvement of difficulty in cold starting are realized.

Owner:GUANGDONG YUEFU AUTOMOTIVE SUPPLIES

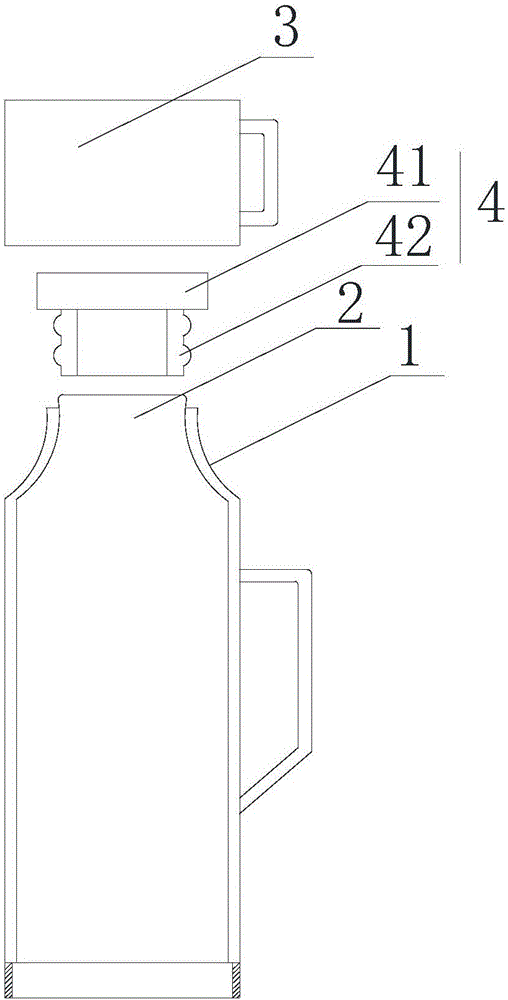

Safe eco-friendly vacuum flask and preparation method of seal cartridge of safe eco-friendly vacuum flask

InactiveCN105153709AGood high and low temperature resistanceImprove aging resistanceNon-pressured vesselsThermal insulationSilanes

Owner:蚌埠市耀得保温容器有限公司

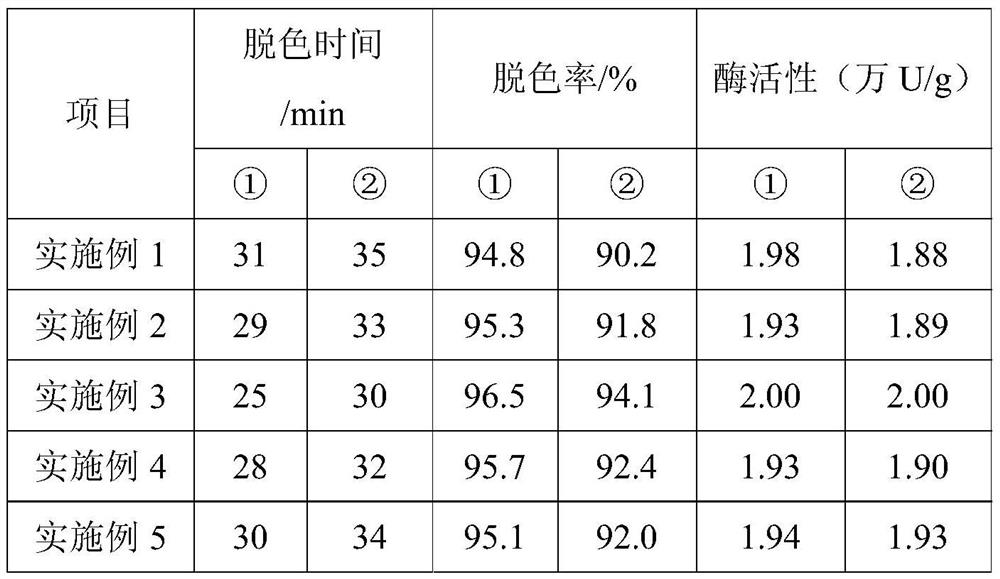

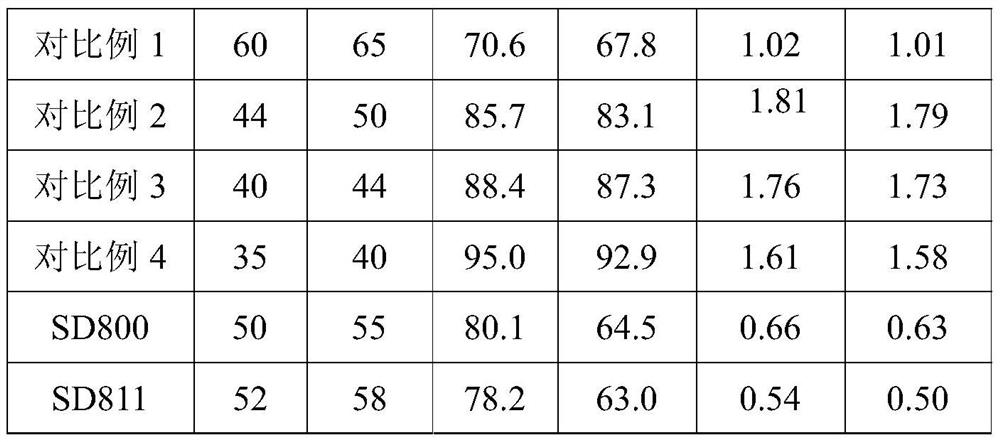

Decolorizing resin for lactase and preparation method of decolorizing resin

The invention discloses a decolorizing resin for lactase. The decolorizing resin comprises styrene, divinylbenzene, gelatin, juncus roemerianus, methyl isobutyl carbinol, hydroxyethyl methylacrylate, triallyl cyanurate, N-phenylmaleimide, chitosan, vitamin C magnesium phosphate, benzoyl peroxide, polyvinyl alcohol, tributyl phosphate, salicylic acid, hydroxyethyl methyl cellulose and a pore-foaming agent. The invention also discloses a preparation method of the decolorizing resin. The preparation method comprises the following steps of: mixing gelatin, chitosan, hydroxyethyl methyl cellulose, polyvinyl alcohol and salicylic acid to prepare a liquid phase; mixing styrene, divinylbenzene, methyl isobutyl carbinol, hydroxyethyl methylacrylate, triallyl cyanurate, N-phenylmaleimide, benzoyl peroxide, tributyl phosphate and a pore-foaming agent to prepare an oil phase; mixing the juncus roemerianus fiber with vitamin C magnesium phosphate to prepare a solid phase; and mixing the three phases to prepare the polymer. The decolorizing resin is high in decoloration efficiency, short in time and small in lactase activity loss after decoloration.

Owner:广西叁万生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com