Lead zinc ore flotation method adopting novel combined inhibitor

A combination of inhibitor and lead-zinc ore technology, applied in flotation, solid separation, etc., can solve the problems of oxidation failure and time-dependent inhibition, and achieve the effect of reducing zinc content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

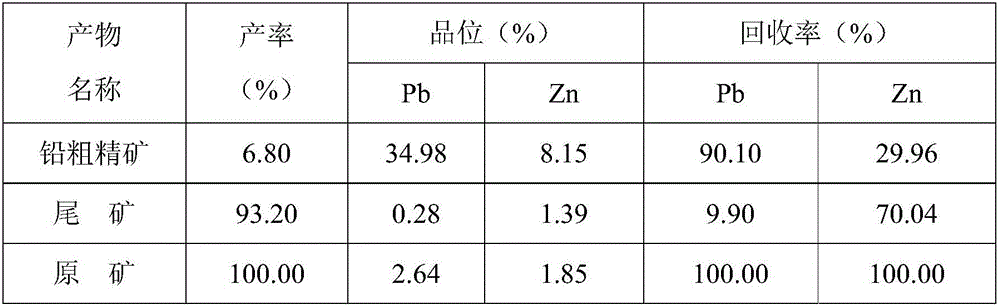

Embodiment 1

[0043] Include the following steps:

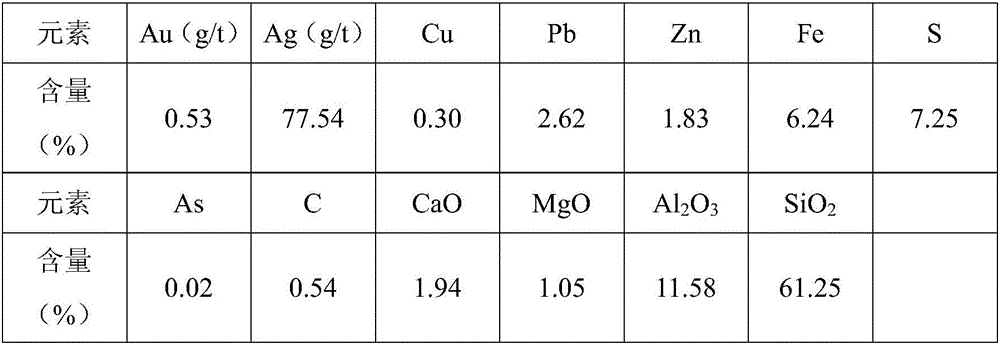

[0044] (1) Grinding and classifying operations: grinding the lead-zinc polymetallic ore to a fineness of -200 mesh, and the content accounts for 70%;

[0045] (2) Flotation operation:

[0046] (1) Rough separation operation: add calcium oxide to adjust the pulp, stirring time is 5 minutes, pH value is 10.5, then add inhibitor 2400g / t, the inhibitor is Na 2 CO 3 : ZnSO 4 The weight ratio is 1:1, the stirring time is 5 minutes, the collector is ethyl disulfide, the dosage is 40g / t, the stirring time is 3 minutes, and finally the foaming agent methyl isobutyl carbinol is added, the dosage is 20g / t, The stirring time is 2 minutes, and the flotation time is 4 minutes to obtain the coarse ore concentrate;

[0047] (2) Sweeping I operation: keep the pH value of the ore pulp at 10.5, the dosage of other chemicals is 1 / 2 of the dosage of roughing agents, and the flotation time is 4 minutes to obtain middle ore 1;

[0048] (3) Sweeping II opera...

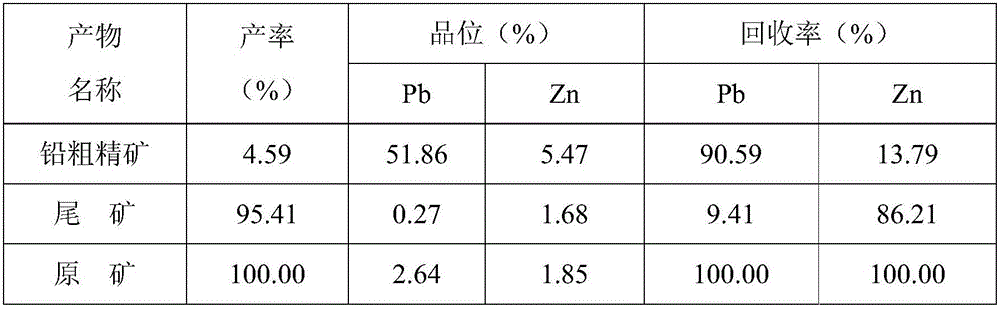

Embodiment 2

[0051] Include the following steps:

[0052] (1) Grinding and classifying operations: grinding the lead-zinc polymetallic ore to a fineness of -200 mesh, and the content accounts for 80%;

[0053] (2) Flotation operation:

[0054] (1) Rough separation operation: add calcium oxide to adjust the pulp, stirring time is 8 minutes, pH value is 11.0, and then add inhibitor 3600g / t, the inhibitor is Na 2 CO 3 : ZnSO 4 The weight ratio is 1:2, the stirring time is 8 minutes, the collector is ethyl disulfide, the dosage is 45g / t, the stirring time is 4 minutes, and finally the foaming agent methyl isobutyl carbinol is added, the dosage is 25g / t, The stirring time is 2.5 minutes, and the flotation time is 5 minutes to obtain the coarse ore concentrate;

[0055] (2) Sweeping I operation: keep the pH value of the ore pulp at 11.0, the dosage of other agents is 1 / 2 of the dosage of roughing agents, and the flotation time is 4.5 minutes to obtain middle ore 1;

[0056] (3) Sweeping II ...

Embodiment 3

[0059] Include the following steps:

[0060] (1) Grinding and classifying operations: grinding the lead-zinc polymetallic ore to a fineness of -200 mesh, and the content accounts for 90%;

[0061] (2) Flotation operation:

[0062] (1) Rough separation operation: adding calcium oxide to adjust the pulp, stirring time for 10 minutes, pH value 11.5, then adding inhibitor 4800g / t, the inhibitor is Na 2 CO 3 : ZnSO 4 The weight ratio is 1:3, the stirring time is 10 minutes, the collector is ethylsulfide nitrogen, the dosage is 50g / t, the stirring time is 5 minutes, and finally the foaming agent methyl isobutyl carbinol is added, the dosage is 30g / t, The stirring time is 3 minutes, and the flotation time is 6 minutes to obtain the coarse ore concentrate;

[0063] (2) Sweeping I operation: keep the pH value of the ore pulp at 11.5, the dosage of other chemicals is 1 / 2 of the dosage of roughing agents, and the flotation time is 5 minutes to obtain middle ore 1;

[0064] (3) Sweep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com