Low zinc rubber composition

A rubber composition, zinc hydroxide technology, applied in tire parts, transportation and packaging, special tires, etc., can solve the problems of low zinc content, zinc pollution, low rolling resistance, etc., achieve low zinc content, improve environmental performance , the effect of optimizing tire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

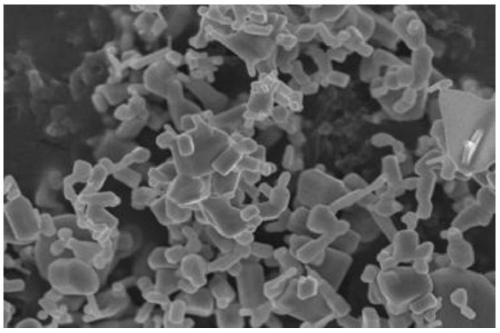

[0067] The indirect method of zinc oxide meets the requirements of the national standard GB / T3185-2016, and the content of zinc oxide is ≥99.7%, such as figure 1 As shown, it can be seen that the indirect method of zinc oxide is mostly rock sugar-like irregular square.

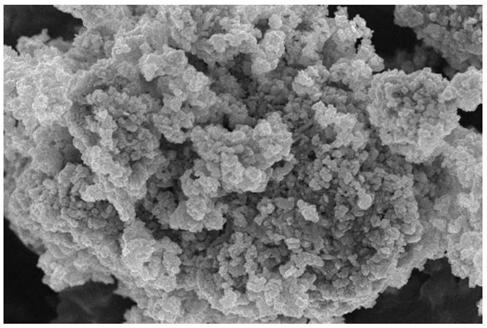

[0068] Ordinary nano zinc oxide A: meet the requirements of GB / T 19589-2004, the content of zinc oxide is ≥99.0%, and the specific surface area is 45m 2 / g, such as figure 2 Agglomeration is evident.

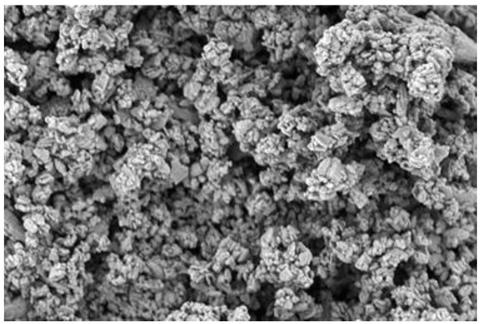

[0069] Nano-zinc oxide B: Nano-zinc oxide with zinc hydroxide as the carrier, the specific surface area is 45m 2 / g, wherein the mass fraction of zinc oxide is 80.2%, and the mass fraction of zinc hydroxide is 19.5%, that is, the present invention uses nano-zinc oxide, such as image 3 shown.

[0070] formula:

[0071]

[0072]

[0073] performance:

[0074]

[0075]In addition to acting as a vulcanization activator in the rubber vulcanization, crosslinking and aging process, zinc oxide can also...

Embodiment 2

[0080] Nano zinc oxide B in embodiment 2: take zinc hydroxide as the nano zinc oxide of carrier, specific surface area is 45m 2 / g, wherein the mass fraction of zinc oxide is 80.2%, and the mass fraction of zinc hydroxide is 19.5%, that is, the present invention uses nano-zinc oxide, such as image 3 shown.

[0081] The indirect method zinc oxide used in the comparison formula 2-1 meets the requirements of the national standard GB / T3185-2016, and the zinc oxide content is ≥99.7%, such as figure 1 As shown, it can be seen that the indirect method of zinc oxide is mostly rock sugar-like irregular square.

[0082] The nano-zinc oxide C used in the comparative formula 2-2 is: the above-mentioned nano-zinc oxide B with zinc hydroxide as a carrier is heat-treated at 150° C. for 2 hours, so that the zinc hydroxide is completely decomposed into zinc oxide, and the nano-zinc oxide C is obtained. .

[0083] formula:

[0084] Formula Components

Comparative formula 2-1

...

Embodiment 3-5

[0091] The indirect method zinc oxide used in the comparative formula 3 meets the requirements of the national standard GB / T3185-2016, and the zinc oxide content is ≥99.7%, such as figure 1 As shown, it can be seen that the indirect method of zinc oxide is mostly rock sugar-like irregular square.

[0092] Nano zinc oxide B in embodiment 3,4,5: take zinc hydroxide as the nano zinc oxide of carrier, specific surface area is 45m 2 / g, wherein the mass fraction of zinc oxide is 80.2%, and the mass fraction of zinc hydroxide is 19.5%, that is, the present invention uses nano-zinc oxide, such as image 3 .

[0093] formula:

[0094] Formula Components

Comparing formula 3

Example 3

Example 4

Example 5

bromobutyl rubber

80.0

80.0

90.0

70.0

20.0

20.0

10.0

30.0

N660 carbon black

64.0

58.0

55.0

45.0

N550 carbon black

8.0

13.0

20.0

leveling agent

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com