Beneficiation activating agent for sphalerite and marmatite and method for reducing zinc in iron ore concentrate through flotation

A technology for sphalerite and sphalerite, which is applied in flotation, solid separation and other directions, can solve the problems of difficulty in realizing deep zinc reduction of iron concentrate, insignificant activation effect, and unsuitability for iron concentrate, etc. The effect of buoyancy, outstanding ability, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

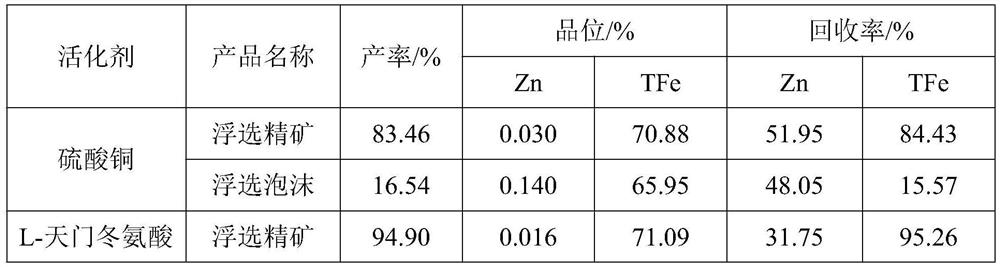

[0033] For a zinc-bearing iron ore, the zinc content in the weak magnetic separation iron concentrate is 0.048%, of which the zinc content in sphalerite is 0.022%, the zinc content in sphalerite is 0.021%, and the zinc iron spinel The zinc content is 0.005%, and the zinc content exceeds the user's quality requirement of 0.02%.

[0034] Dezincification treatment is carried out by adopting sphalerite and sphalerite beneficiation activator and iron concentrate flotation zinc reduction method of the present invention, specifically comprising the following steps:

[0035](1) Add L-aspartic acid solution (ie L-aspartic acid The amount of acid added is 6kg / t), stirred for 3min, and the pH value of the pulp is adjusted to 4.5; the L-aspartic acid solution is prepared by adding sulfuric acid (the mass fraction of sulfuric acid is 30%) to L-aspartic acid. into, the mass fraction of L-aspartic acid in the solution is 10%.

[0036] (2) Add pentyl xanthate collector to the pulp obtained ...

Embodiment 2

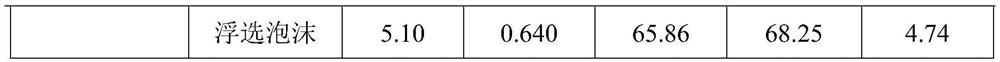

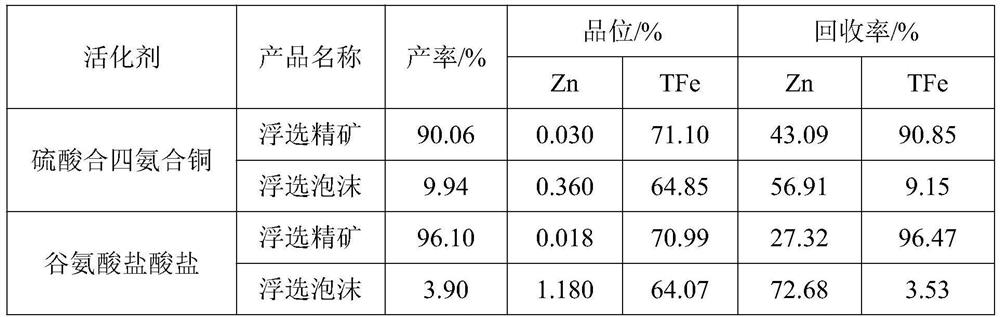

[0044] A zinc-bearing iron ore, the zinc content in the weak magnetic separation iron concentrate is 0.063%, the zinc content in the sphalerite is 0.031%, the zinc content in the sphalerite is 0.024%, and the zinc iron spinel The zinc content is 0.008%, and the zinc content exceeds the user's quality requirement of 0.02%.

[0045] Dezincification treatment is carried out by adopting sphalerite and sphalerite beneficiation activator and iron concentrate flotation zinc reduction method of the present invention, specifically comprising the following steps:

[0046] (1) Add glutamic acid hydrochloride solution (i.e. glutamic acid hydrochloric acid) in an effective amount of 4kg / t in the weak magnetic separation iron concentrate with a feeding concentration of 40% and a feeding particle size of -0.045mm accounting for 70%. The amount of salt added is 4kg / t), stirred for 3min, and the pH value of the slurry was adjusted to 5.1; the glutamic acid hydrochloride solution was prepared b...

Embodiment 3

[0054] For a zinc-bearing iron ore, the zinc content in the weak magnetic separation iron concentrate is 0.075%, of which the zinc content in sphalerite is 0.038%, the zinc content in sphalerite is 0.031%, and the zinc content in zinc oxide It is 0.006%, and the zinc content exceeds the user's quality requirement of 0.02%.

[0055] Adopt the sphalerite and sphalerite mineral processing activator of the present invention and the method for iron ore concentrate flotation zinc reduction to carry out dezincification treatment, the specific method is the same as embodiment 2, the difference is: in step (1), in the weak magnetic Add glutamic acid solution to the iron ore concentrate, the glutamic acid solution is a solution prepared by adding sulfuric acid (the mass fraction of sulfuric acid is 30%) to glutamic acid, and the mass fraction of glutamic acid in the solution is 10%.

[0056] The flotation comparison test results of the glutamic acid activator in this example and the cop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com