Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

200 results about "Lead Metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An element with atomic symbol Pb, atomic number 82, and atomic weight 207.2.

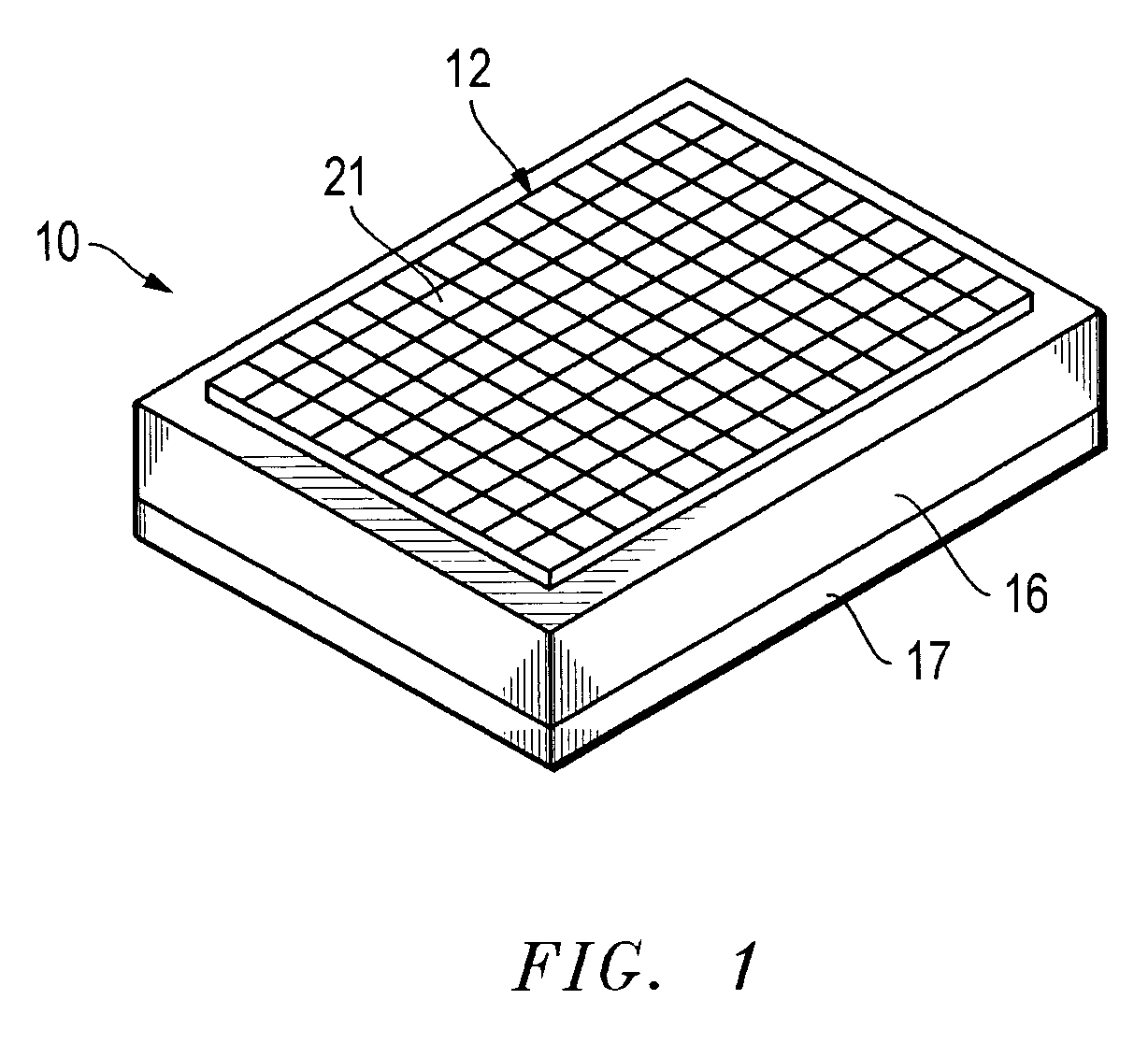

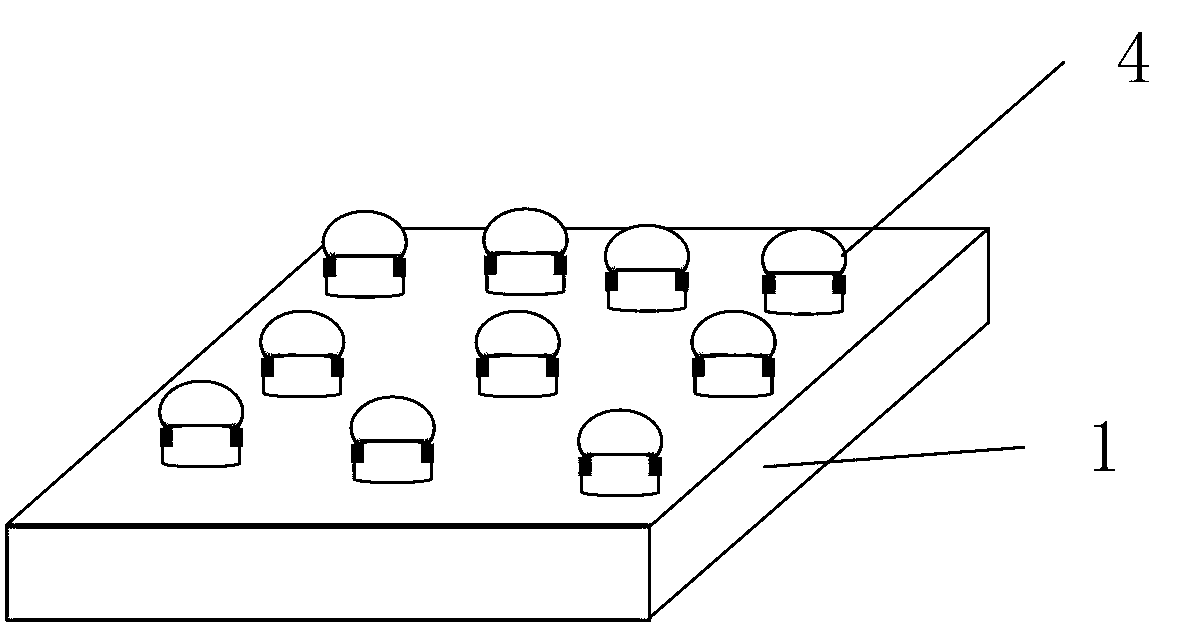

Replaceable light emitting diode module

ActiveUS6998650B1Easy to replaceEasy to liftBus-bar/wiring layoutsPoint-like light sourceCouplingEngineering

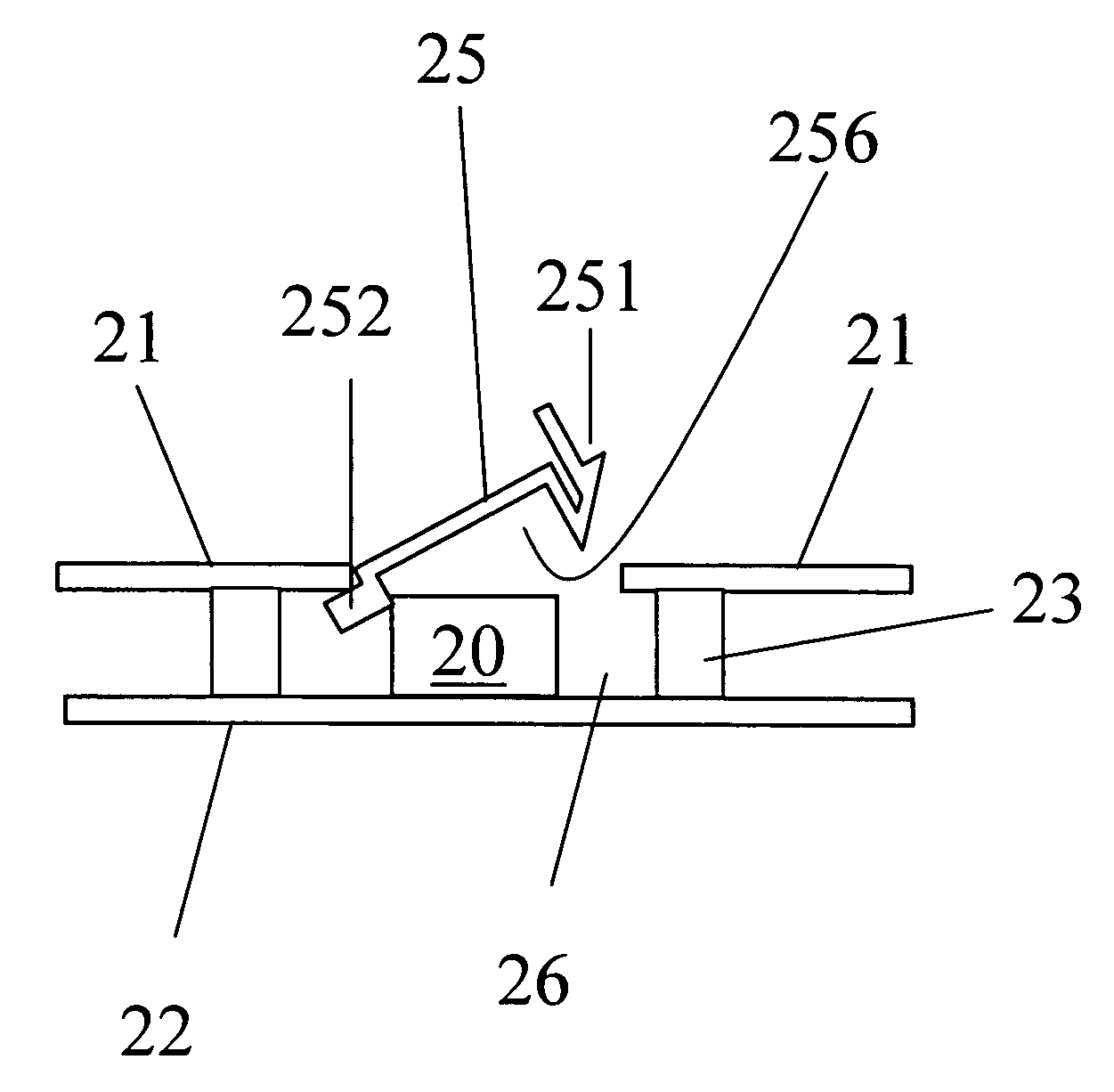

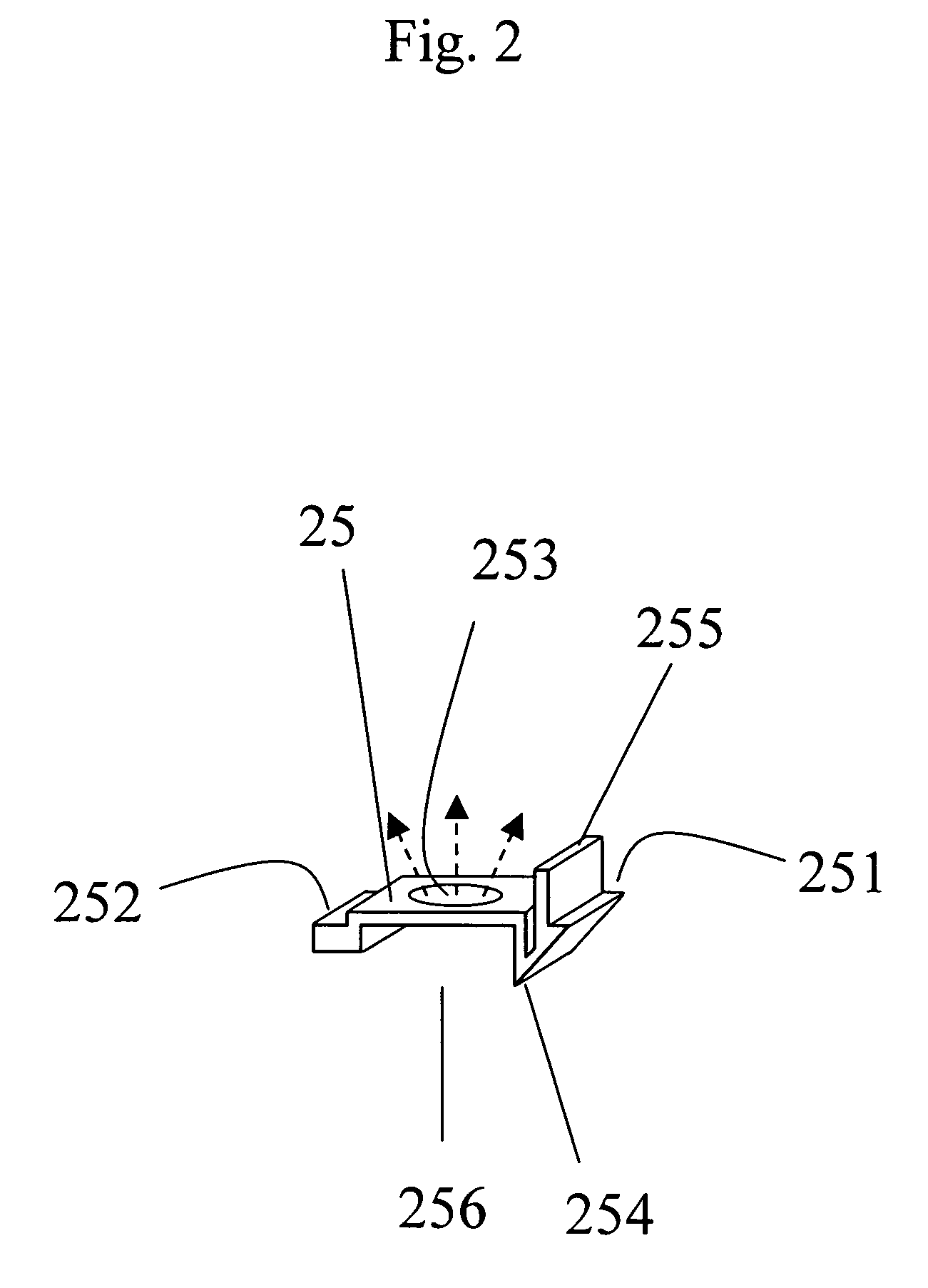

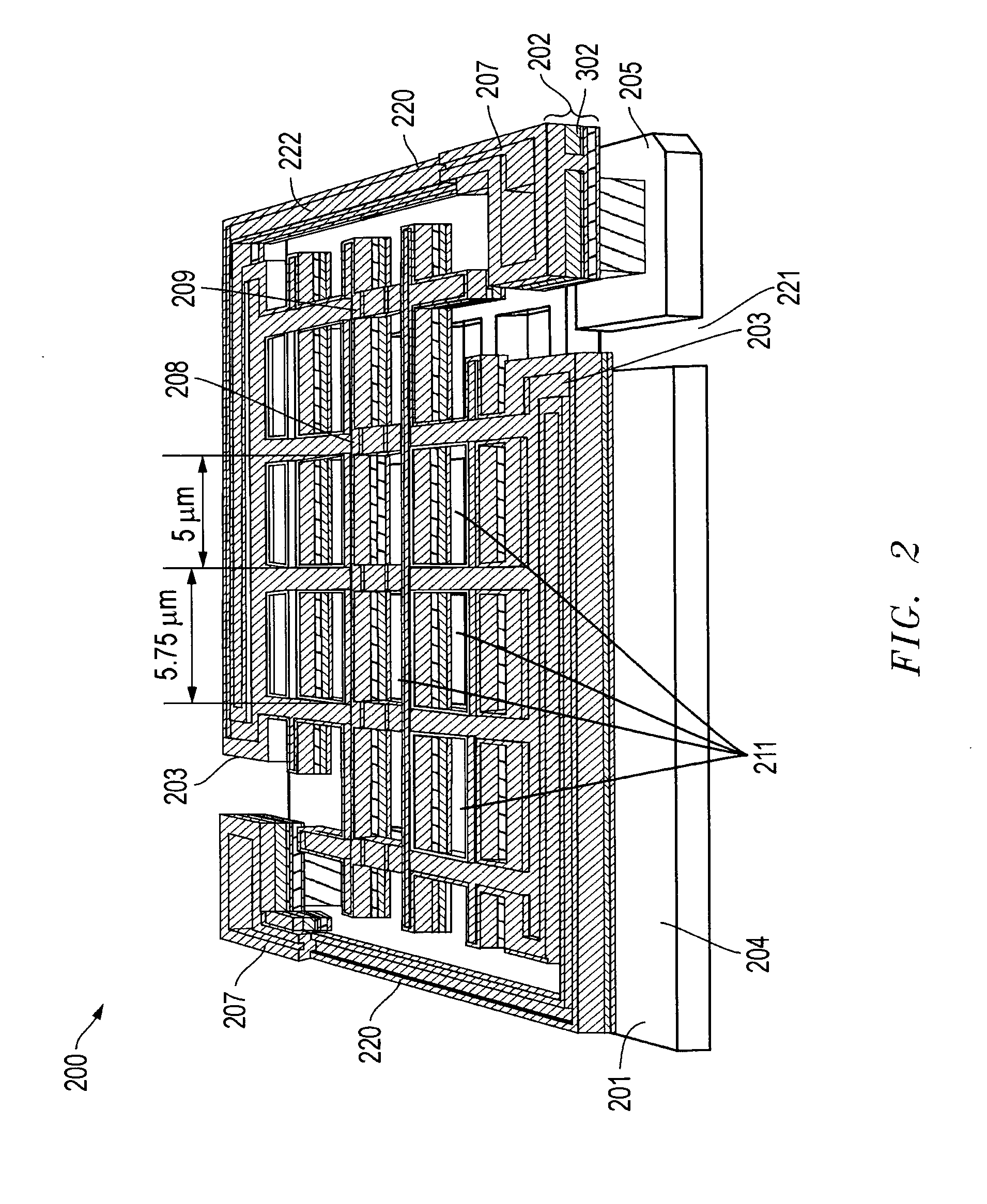

A clip is used to clamp a LED in place in a LED module. The clip has pliable conducting cover and can be latched to the upper lead metal of the LED module. The clip can be lifted for replacing a defective or color LED. A plurality of replaceable LEDs can be mounted a common metal substrate to form a display panel, and each LED can be clamped in position with clips straddling between parallel upper lead metal for electrical coupling to the top electrodes of the LED.

Owner:CHENG KUNG CAPITAL LLC

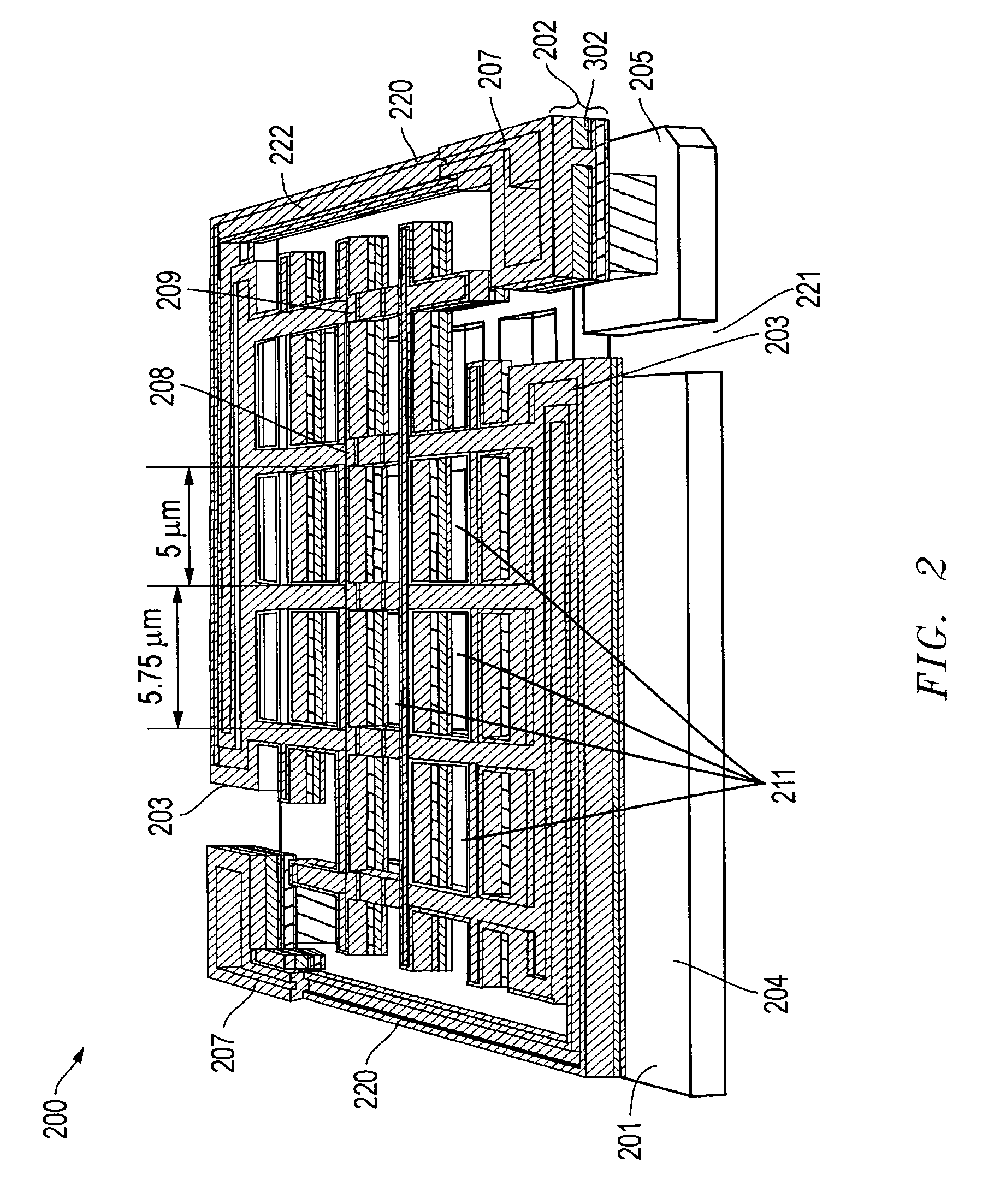

Infrared detector elements and methods of forming same

ActiveUS20070170363A1Shorten the timeHigh frame rate operationMaterial analysis by optical meansPyrometry using electric radation detectorsCMOSLead Metal

Owner:DRS NETWORK & IMAGING SYST

Method for waste lead-acid cell resourcization and lead-acid cell cyclic production

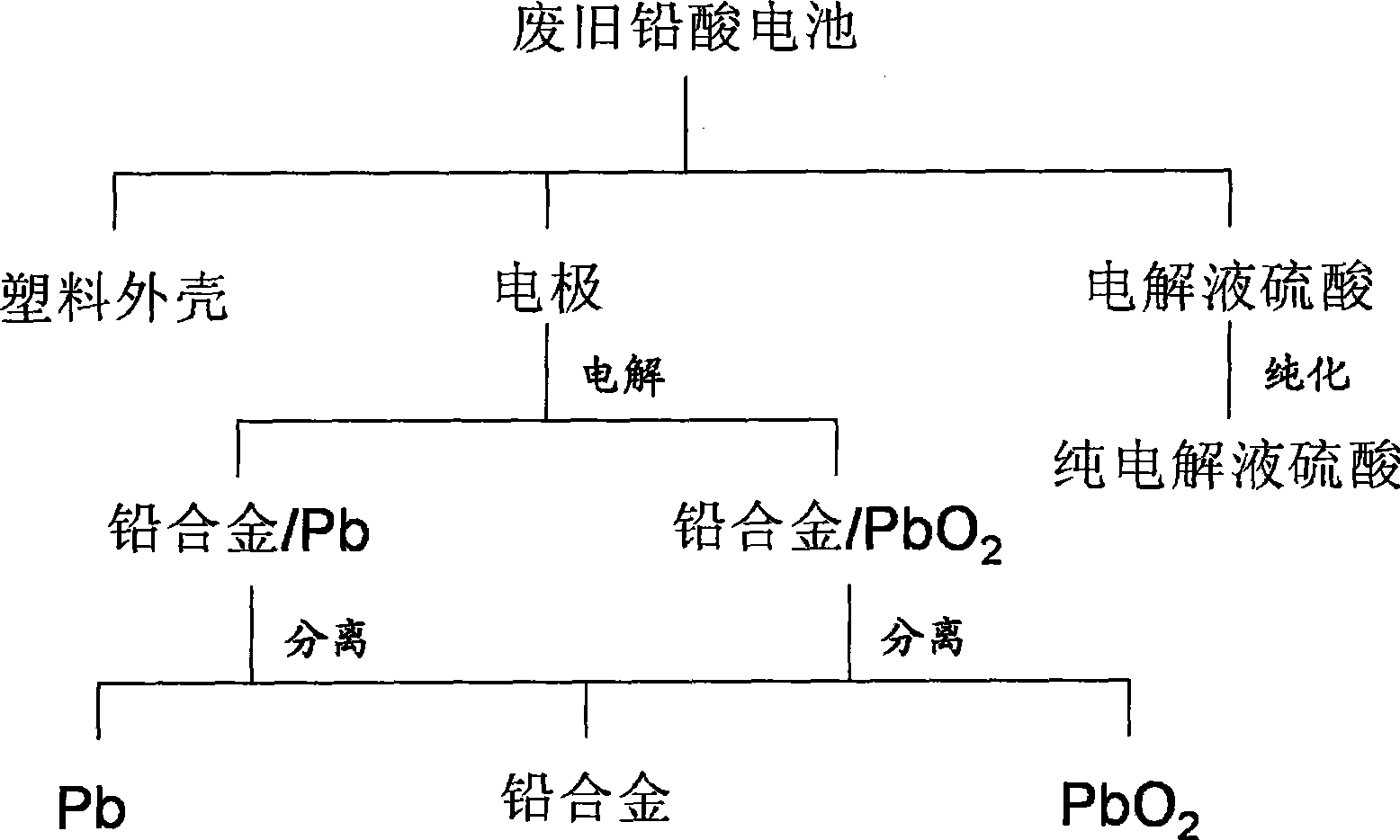

InactiveCN101488597AEliminate pollutionReserve availabilityWaste accumulators reclaimingBattery recyclingLead dioxideAlloy

The invention discloses a method for circularly producing lead acid batteries, aiming at thoroughly eliminating possible hazard of the lead acid battery on environment and leading the lead acid battery to be continuously useful in social life without causing negative effect. The method includes: the positive and negative plates of old and useless batteries are separated by a mechanical method, and then the positive and negative plates are subjected to electrochemical treatment, thus obtaining raw material for producing new lead acid battery and achieving the circular production of the lead acid battery including disassembly of the old and useless lead acid battery, purification of sulphuric acid electrolyte, the production of lead metal and lead dioxide by electrolyzing lead sulfate, the separation and regeneration of lead alloy as well as the production of new lead acid battery by the produced lead alloy, lead and lead dioxide. In theory, by the proposal, the raw material can be totally reused, thus achieving the aim of circularly producing the lead acid battery.

Owner:SOUTHEAST UNIV

Magnetic biological adsorption agent and preparation method thereof

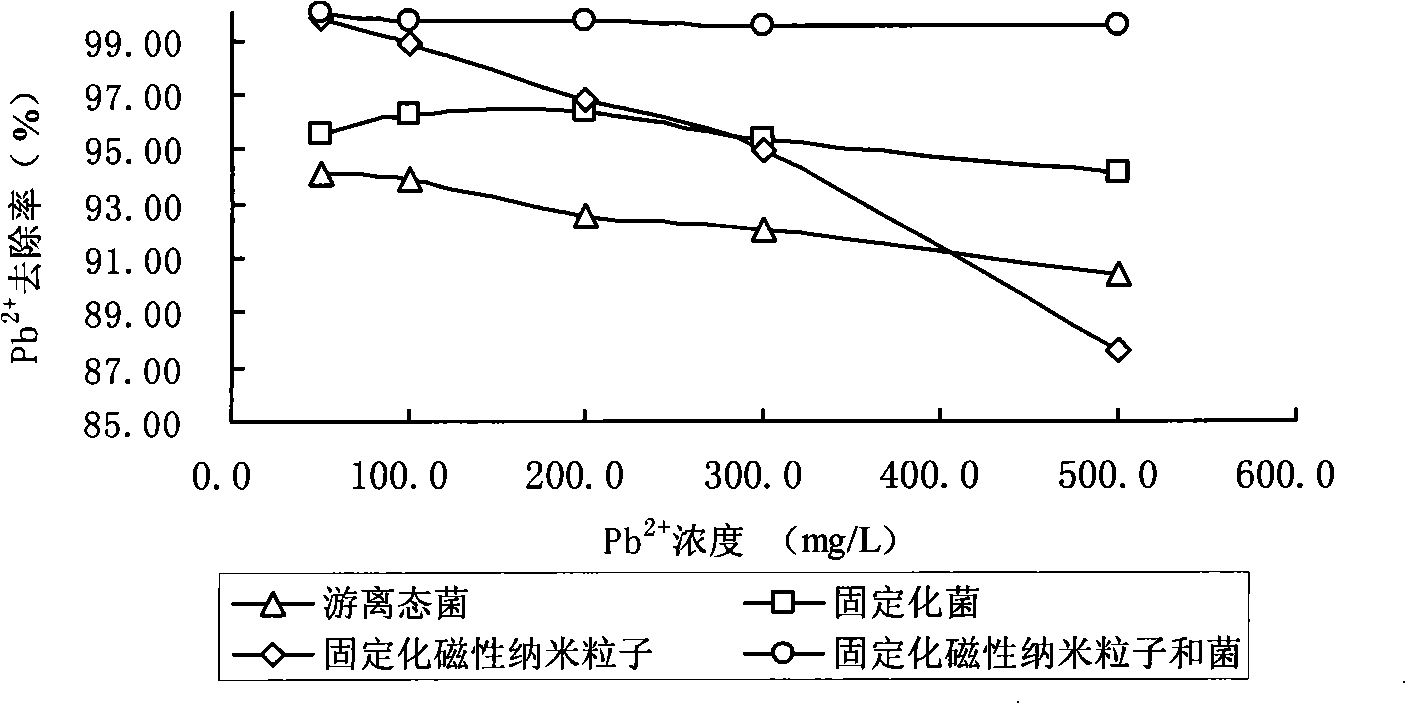

InactiveCN101314123APlay an auxiliary adsorption effectHigh removal rateOther chemical processesWater/sewage treatment by sorptionSorbentWastewater

The invention discloses a magnetic biological sorbent. The sorbent uses calcium alginate as a carrier, and is embedded with phanerochaete chrysosporium powder and magnetic nanometer particles, wherein, the mass ratio of the phanerochaete chrysosporium powder to the magnetic nanometer particles to the calcium alginate is 1 to (0.5-1.25) to (8-10). The invention also discloses a method for preparing the magnetic biological sorbent. The method comprises the following steps of: adding a mixture of the magnetic nanometer particles and the phanerochaete chrysosporium powder into a 1 to 2 mass concentration calcium alginate solution with 1 to 2 mass concentration, the dosage of the mixture in the solution being between 0.125 and 0.225g / mL, stirring evenly, and obtaining the magnetic biological sorbent through an immobilization process. The magnetic biological sorbent has the advantages of high adsorption efficiency, good selectivity, low cost, simple preparation process and treatment process and so on, and can be effectively applied to the treatment of lead metal in industrial wastewater.

Owner:HUNAN UNIV

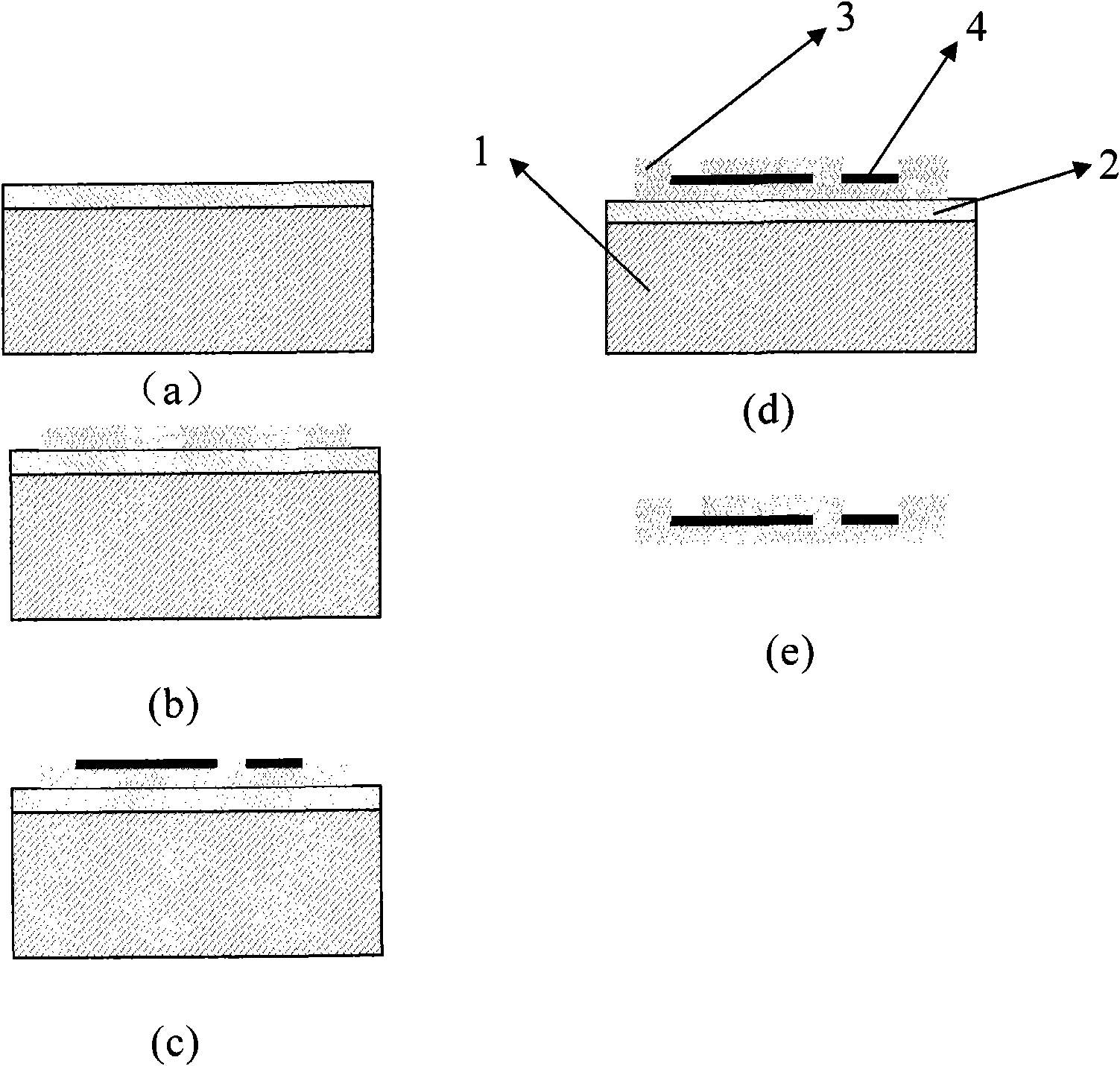

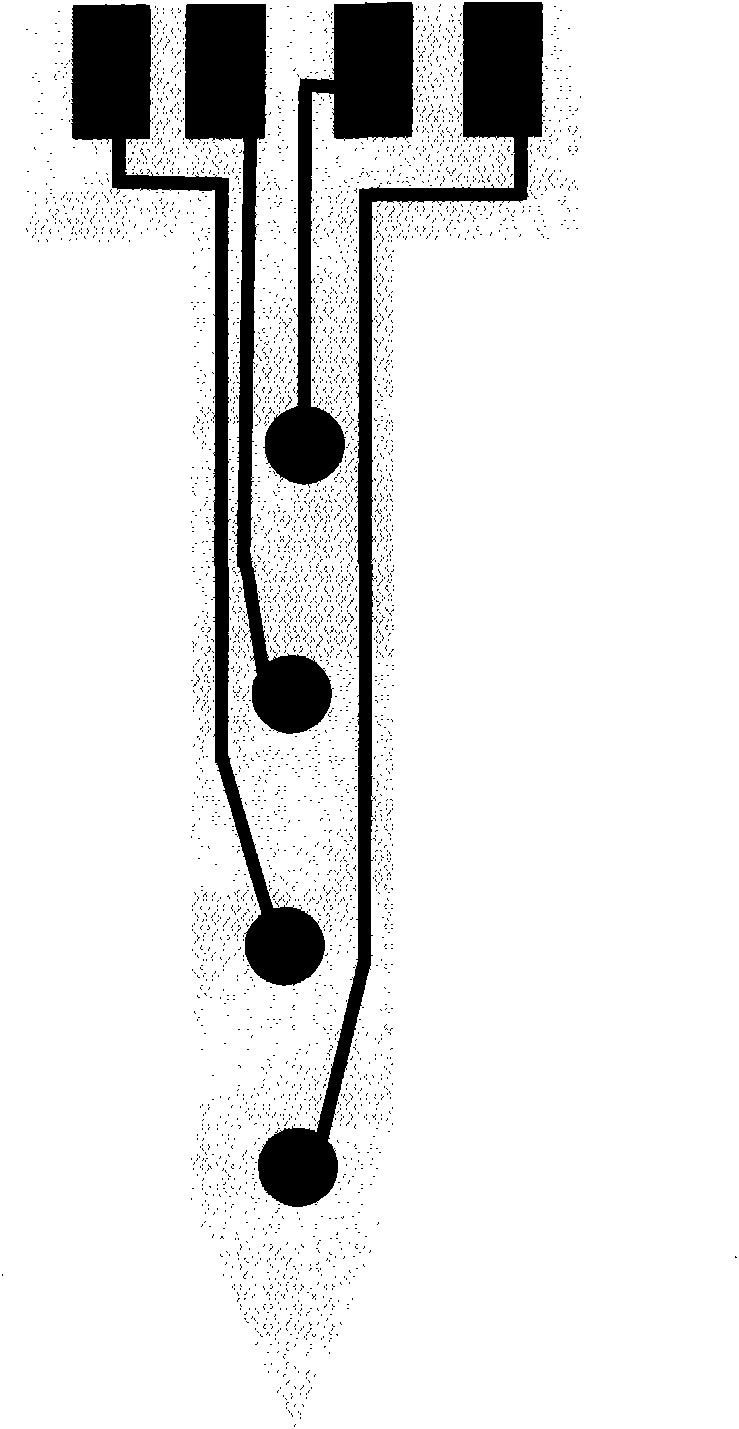

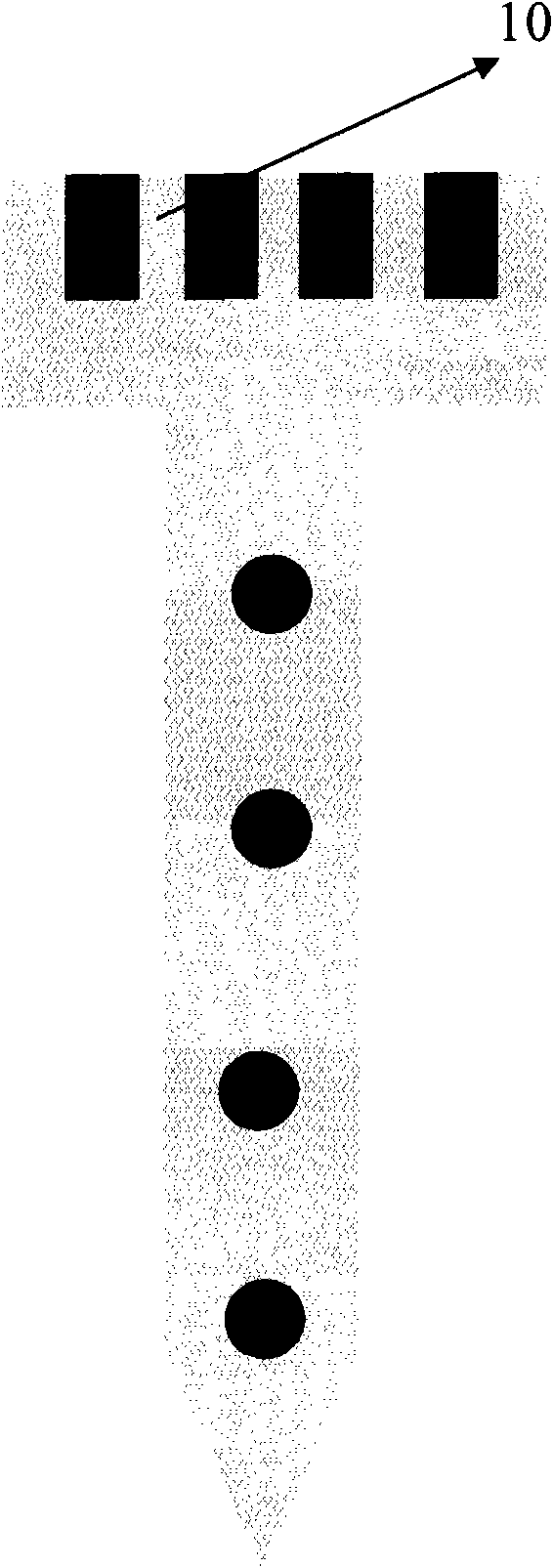

Flexible probe electrode used for recording electric signal of neural activity and implanting tool thereof

InactiveCN101884530AImprove permeabilityEasy to be pierced with precisionSurgeryDiagnostic recording/measuringBiocompatibility TestingHardness

The invention discloses a flexible probe electrode used for recording an electric signal of a neural activity. The flexible probe electrode comprises a flexible substrate, electrode sites, metal wires, lead welding spots and flexible insulating layers, wherein both the electrode sites and the metal wire are arranged on the flexible substrate; each electrode site is connected to a corresponding lead welding spot through led metal wires; and the flexible insulating layers are arranged on the surfaces of the metal wires instead of being arranged at the electrode sites and the metal welding spots. The invention also discloses an implanting tool for inserting the flexible probe electrode into tissues. Through the implanting tool, the electrode has a high flexibility and biocompatibility and the tissue damage is reduced, so that the long-term working stability of the electrode is ensured, the problem that the own hardness of the flexible electrode cannot satisfy an inserted hardness is solved and the defects that the conventional probe electrodes can damage the tissues easily and the electric signal is instable for the long-term recording of the electrode are overcome.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

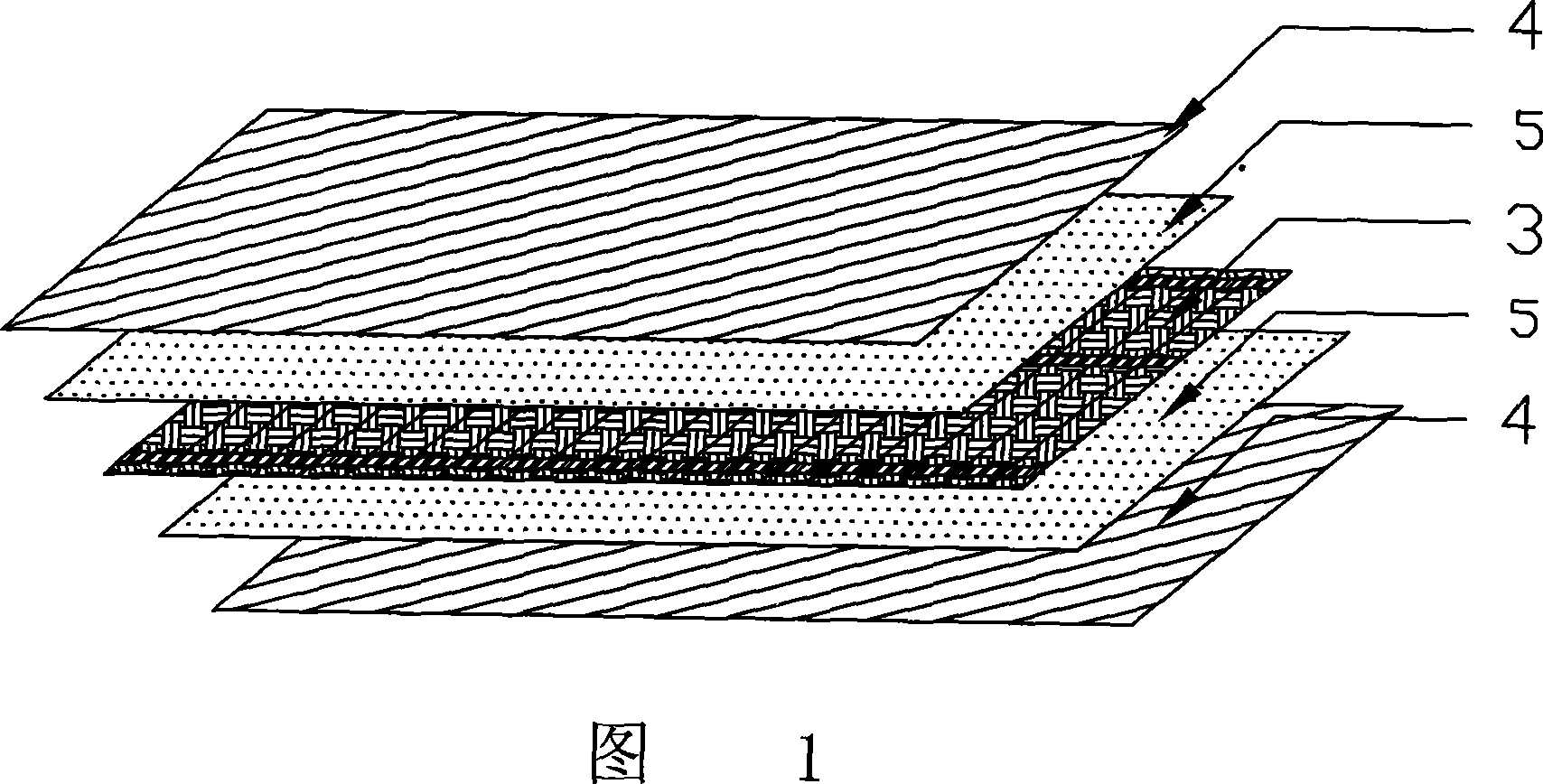

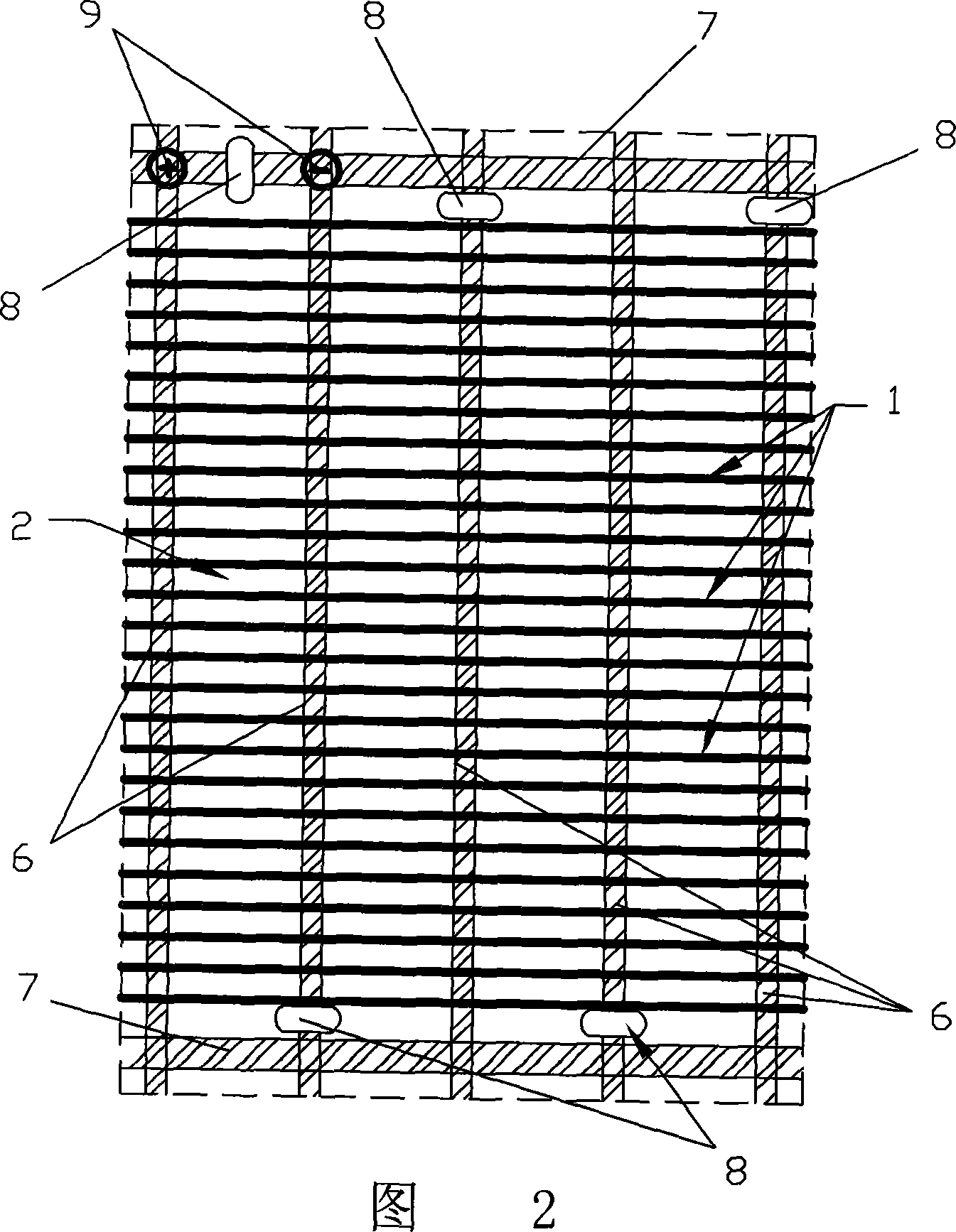

Radiation infrared electric heating cloth and its producing method and use

InactiveCN101052246ANo feeling of dryness and stuffinessWith electric heating characteristicsHeating element materialsFiberInfrared

The invention features a layer of textile fabric materials composed of non-metal heating wire, metal wire winding and textile fabrics; on the upper and bottom surfaces, respectively covering a protection layer; the non-metal heating wire is composed of the polypropylene and the carbon mixture; the metal wire winding is made by winding the metal wire on the textile fabric; on both edge of the textile fabric materials, respectively setting up a latitudinal direction metal wires band; in the longitude direction of the textile fabric materials, alternatively setting up several longitude-leading metal wire bands for connecting said latitudinal direction metal wires; the metal wire conducting band is composed of said metal wire windings and are set up with the cutting pierces and the negative and positive poles used for connecting the power; said protection layer is bound with the textile fabric materials with adhesives.

Owner:赵昭亮

Organic light-emitting diode encapsulation structure and manufacturing method thereof

InactiveCN102447077AAvoid accessExtend your lifeSolid-state devicesSemiconductor/solid-state device manufacturingPlastic materialsAluminum metal

Owner:CPTF VISUAL DISPLAY (FUZHOU) LTD +1

Low temperature process for making radiopac materials utilizing industrial/agricultural waste as raw material

ActiveUS20060066013A1Saving on accountConsiderable heat energyCeramic shaping apparatusNon-woven fabricsPyrophyllitePhosphate binder

Owner:COUNCIL OF SCI & IND RES

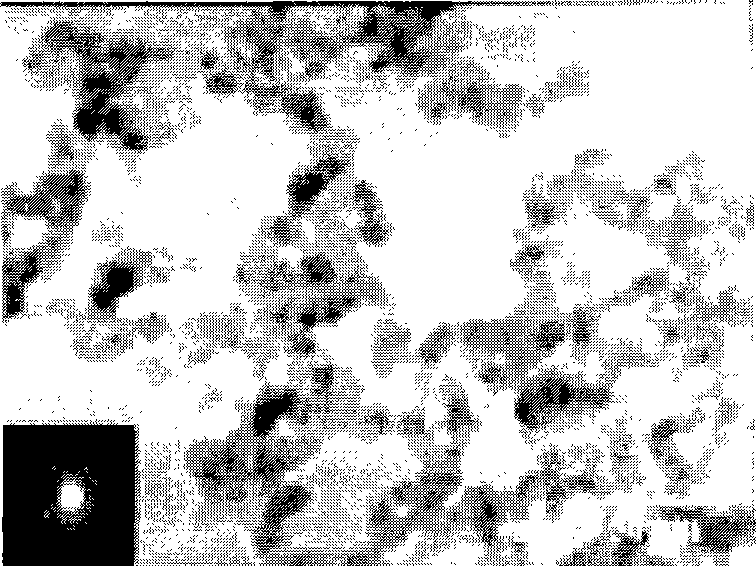

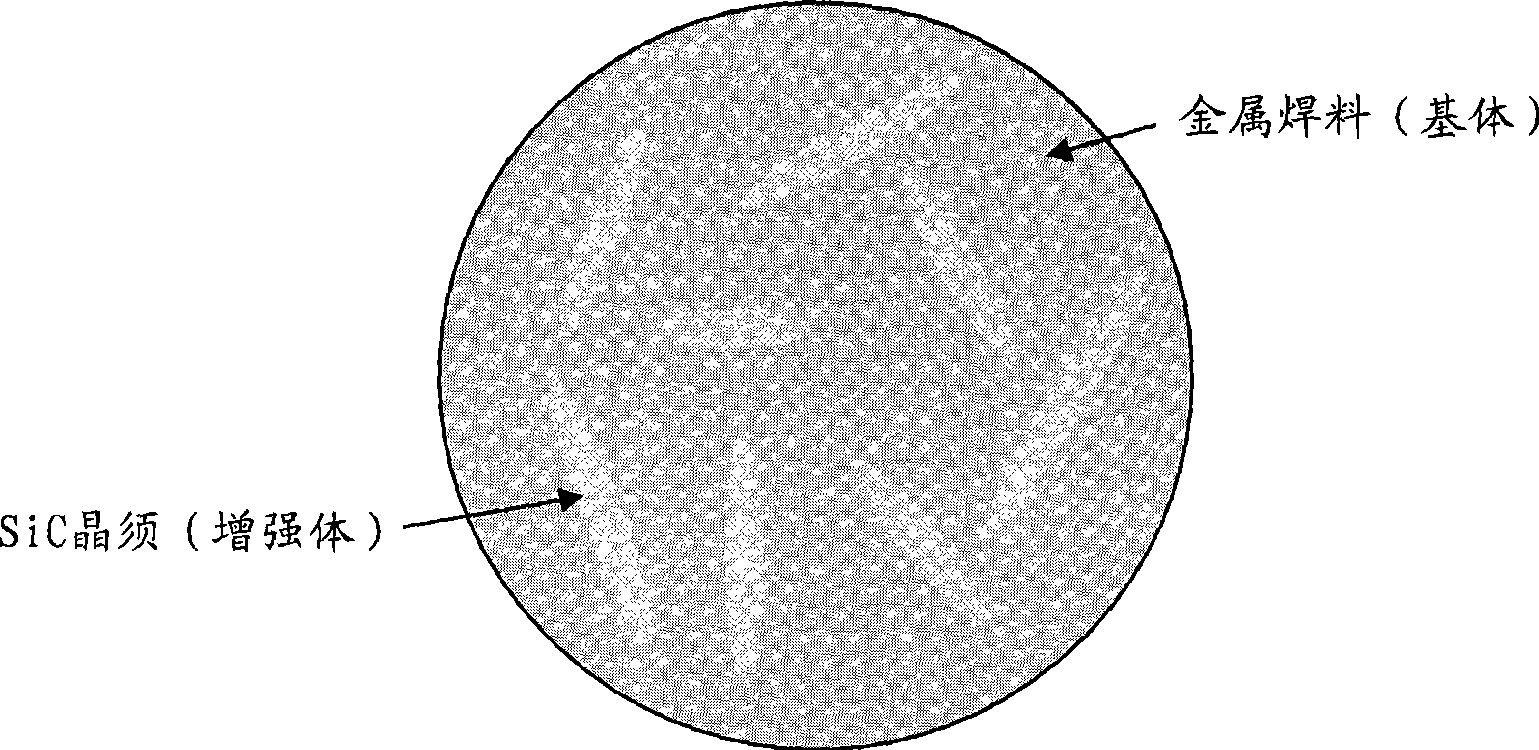

Solder with composite material and preparation method thereof

InactiveCN101480763AImprove the immunityImprove acceleration performanceWelding/cutting media/materialsSoldering mediaWhiskersComposite solder

The invention discloses a composite solder and a preparation method thereof. The composite solder comprises a metal solder as a substrate and SiC crystal whisker as a reinforcement, wherein the metal solder can be a lead metal solder or lead-free metal solder; the volume percent of the SiC crystal whisker can be 0.1-30 percent, the diameter can be 0.5-1 micron and the slenderness ratio can be 20:1 to 40:1. The composite solder has high ability of resisting creep deformation and crack extension.

Owner:SAMSUNG ELECTRONICS CO LTD +1

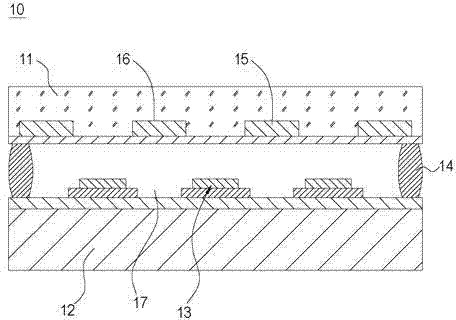

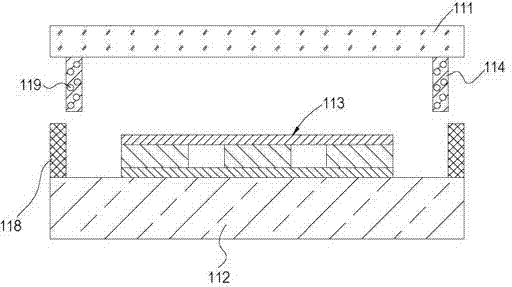

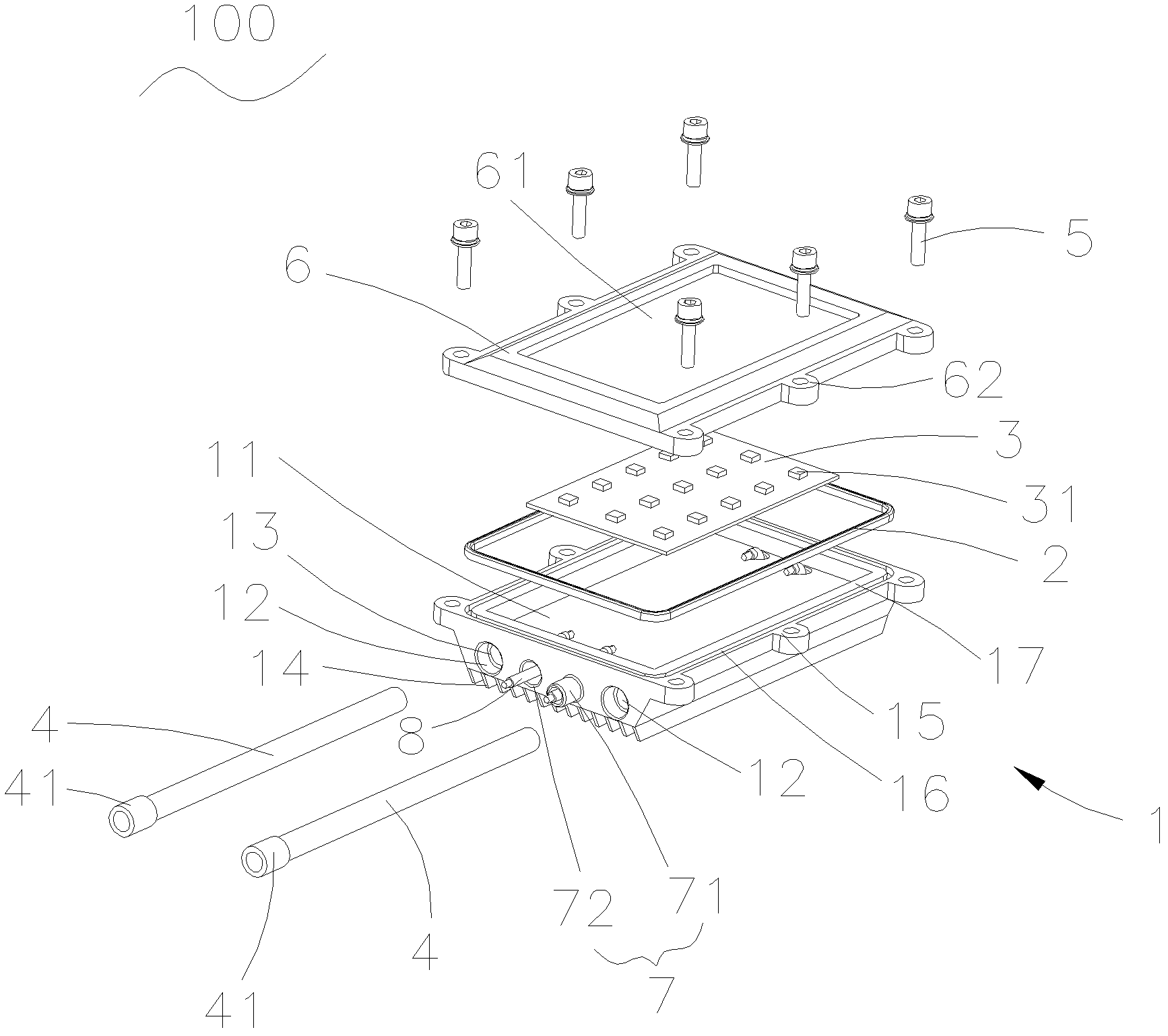

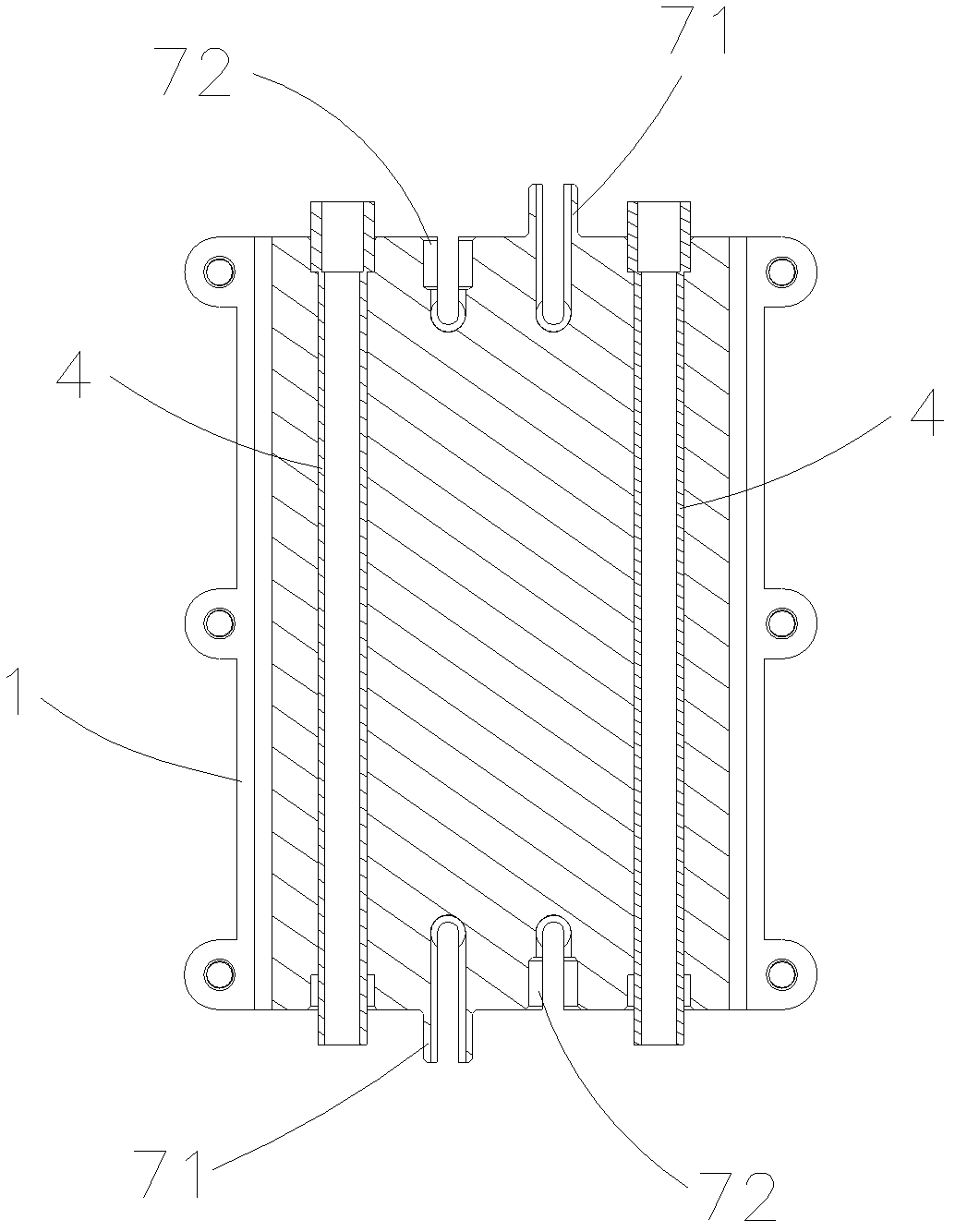

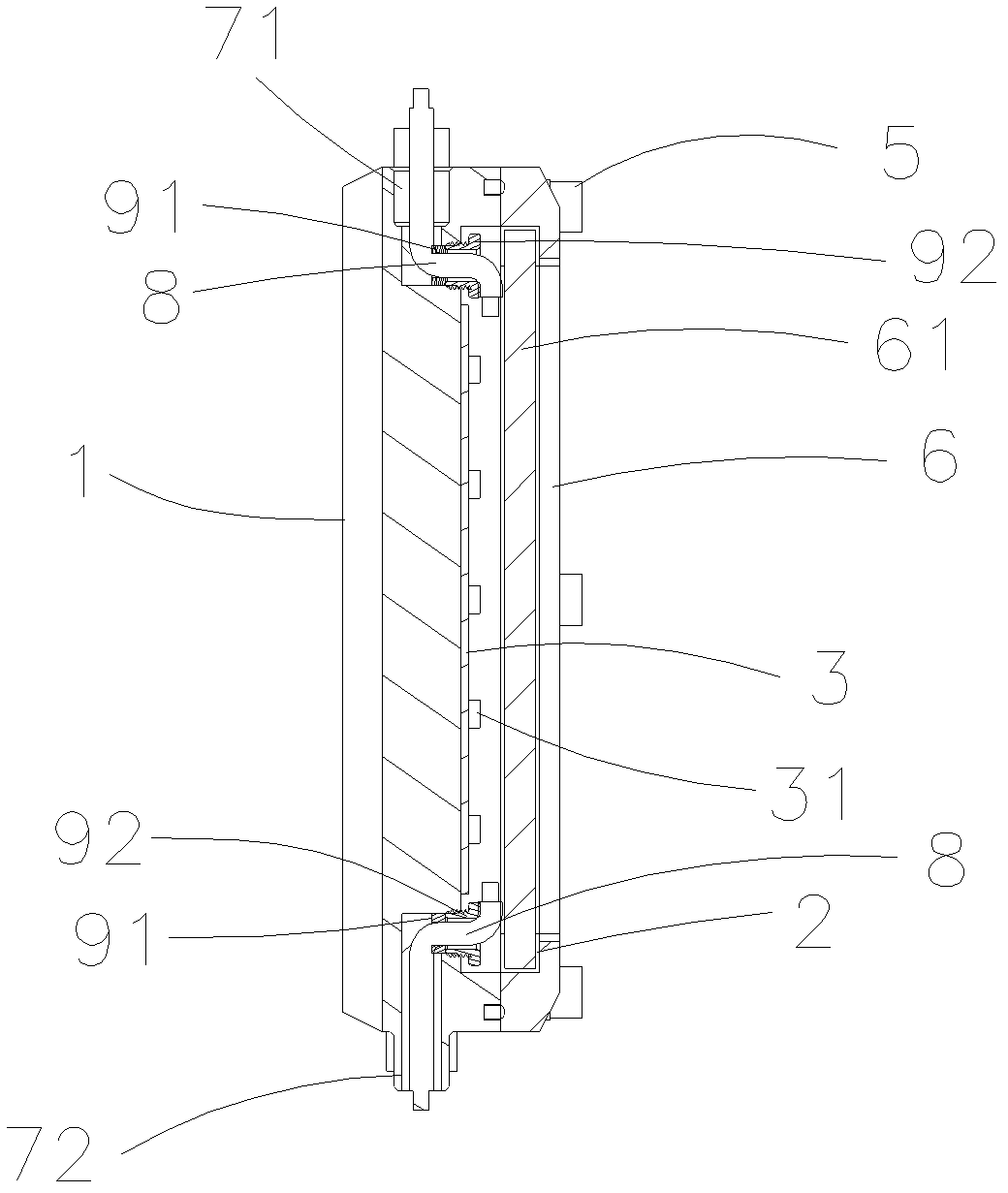

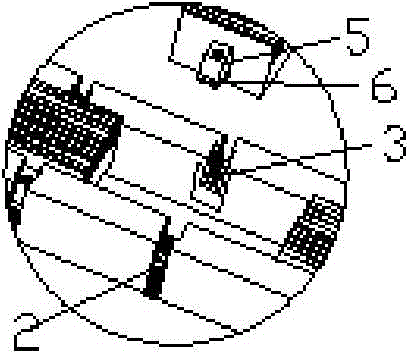

Explosion-proof LED (light emitting diode) lighting module and combination thereof

ActiveCN103032854AMeet lighting requirementsLow failure rateLighting applicationsPlanar light sourcesIlluminanceEffect light

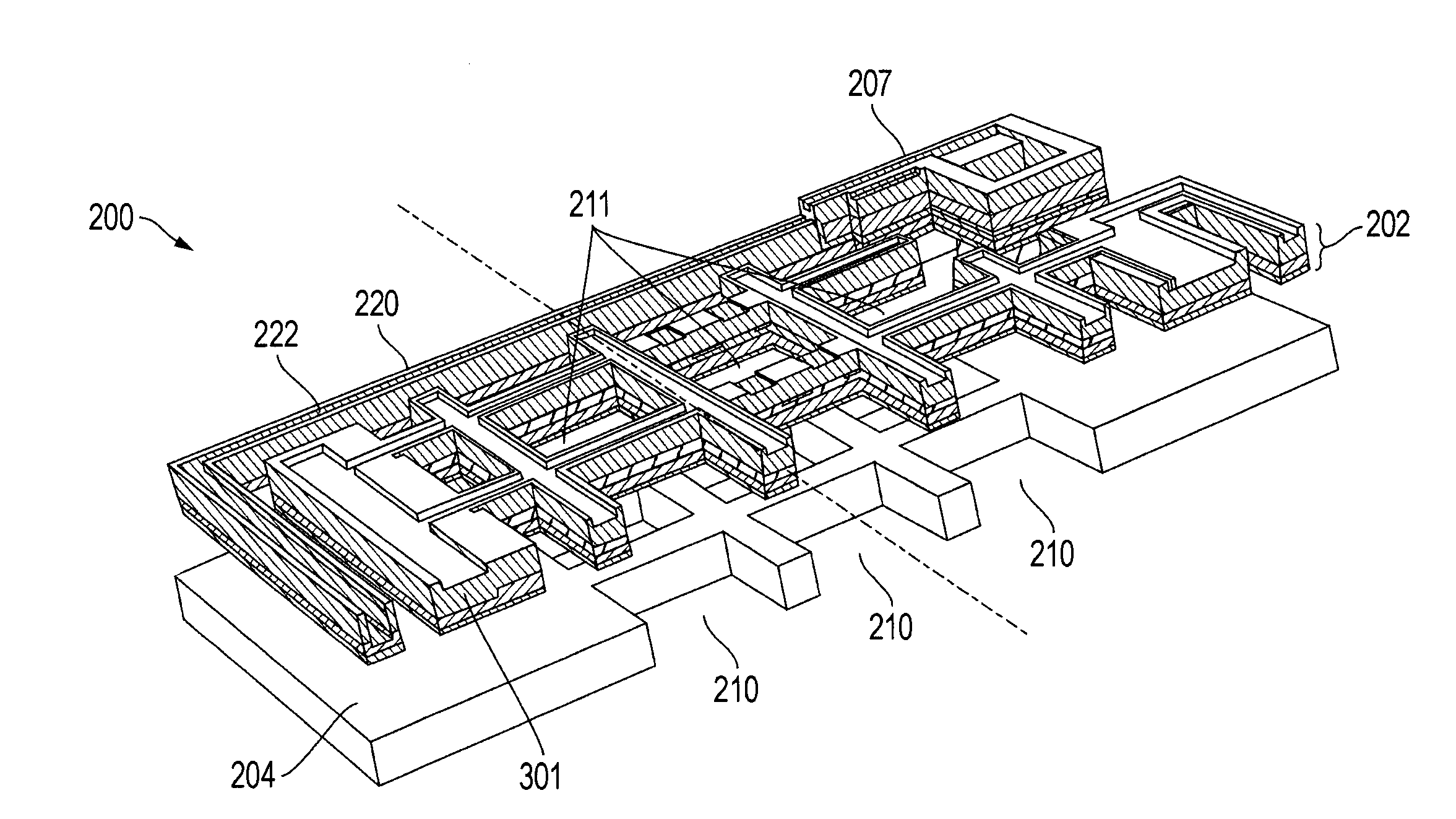

The invention provides an explosion-proof LED (light emitting diode) lighting module and combination thereof. The explosion-proof LED lighting module combination comprises at least two explosion-proof LED lighting modules which are mutually connected; each explosion-proof LED lighting module comprises a casing, a cover and an LED metal substrate, wherein the casing and the cover are mutually matched with each other, and the LED metal substrate is arranged in a sealing hollow cavity enclosed by the casing and the cover; an LED light source array formed by a plurality of LED lamps is arranged on each LED metal substrate; wire penetrating holes which are used for cables to pass through to electrically connect with an external power supply or other LED lighting modules are formed on two opposite sides of each casing; and butted components which are mechanically connected with other explosion-proof LED lighting modules are further arranged on the casings. The explosion-proof LED lighting module can be individually used or can be used in combination, and can satisfy lighting requirements of industrial scenes with different illuminations; the explosion-proof LED lighting module is independent in function, excellent in universality and compatibility, convenient to assemble and reconstruct, simple and easy to use, and low in installation, using and maintenance cost.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

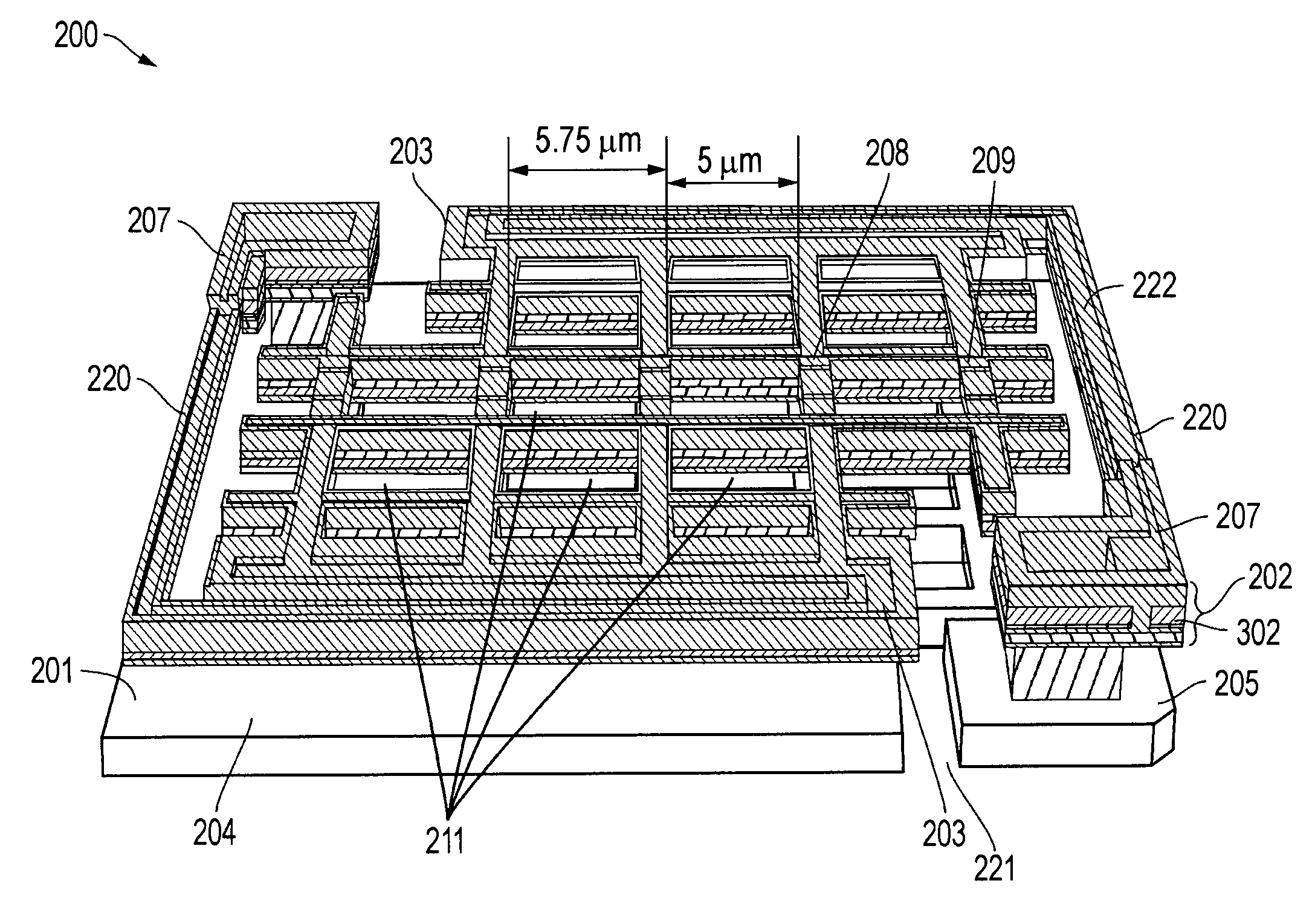

Infrared detector elements and methods of forming same

ActiveUS7655909B2Shorten the timeHigh frame rate operationMaterial analysis by optical meansPyrometry using electric radation detectorsCMOSLead Metal

Owner:DRS NETWORK & IMAGING SYST

Metal surface protective agent and production method

InactiveCN102702915ADoes not affect conductivityDoes not affect insulation propertiesAnti-corrosive paintsEpoxy resin coatingsVegetable oilSalt spray test

The invention discloses an environment-friendly metal surface protective agent with high salt fog resistance and a production method. The metal surface protective agent is characterized by being prepared by the steps of: weighing 10-25% of resin, 10-25% of vegetable oil, 45-75% of ethyl acetate, 1.8-5% of drying agent and 0.1-0.5% of benzotriazole based on 100% by weight, burdening and mixing. The metal surface protective agent is light-yellow clear solution or colorless clear solution, is nontoxic, odorless, non-volatile and non-deliquescent, and has the film-forming speed not more than 3min. The process is simple; the solvent is free of fluorine and chlorine elements; the product is environment-friendly, can undergo the neutral salt spray test for more than 96h, does not influence the conductivity, insulativity, high-frequency characteristic and weldability of a coated piece, and is suitable for surface treatment of metal products, in particular copper, aluminum, silver, tin and lead metal products.

Owner:YIYANG HUAXING MACHINERY TECH

Comprehensive method for separating stibium from materials containing stibium, tin and lead

InactiveCN101974765AEasy to separateEffective open circuitPhotography auxillary processesProcess efficiency improvementFiberHydrometallurgy

The invention provides a comprehensive method for separating stibium from materials containing the stibium, tin and lead, which is suitable for removing the stibium and recovering other valuable metals from tin lead materials containing stibium with high content. The invention puts an emphasis on that the comprehensive method comprises the following steps of: granulating the materials containing the stibium to manufacture irregular tin grains with the thicknesses of 2-5 mm and the grain diameters of 2-30 mm; then placing tin grain sheets into an anode frame lined with acid-resisting fibers to manufacture a tin grain anode; placing the fine tin lead materials as starting sheets into an electrolytic cell filled with silicofluoric acids to carry out electrolysis by electrifying DC, wherein tin and lead metals are electrolyzed and deposited on a cathode to obtain a cathode product with total tin and lead content more than 99.8 percent and stibium content less than 0.2 percent, and the valuable metals, i.e. the stibium, gold, silver, and the like, are gathered in anode mud; and finally recovering the valuable metals, i.e. the stibium, the gold and the silver, from the anode mud. A wet-process metallurgical process has advanced and reasonable process and can greatly enlarge the contact area of electrolyte and the anode, reduce the current density during the electrolysis and eliminate the anode passivation phenomena.

Owner:YUNNAN TIN GROUP HLDG

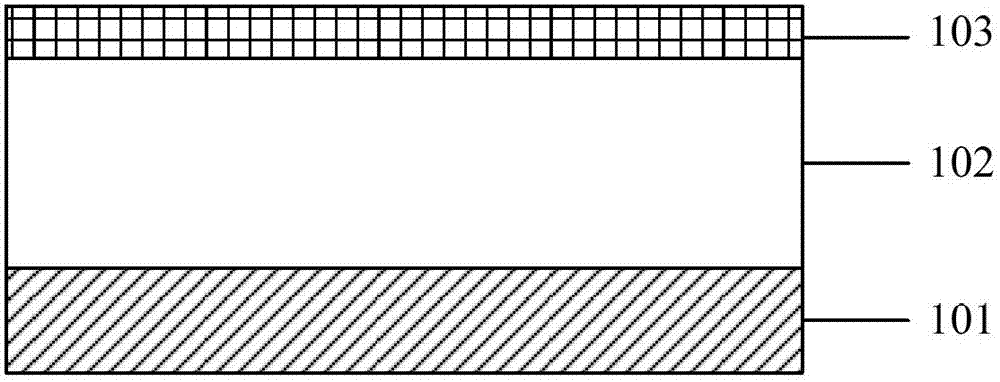

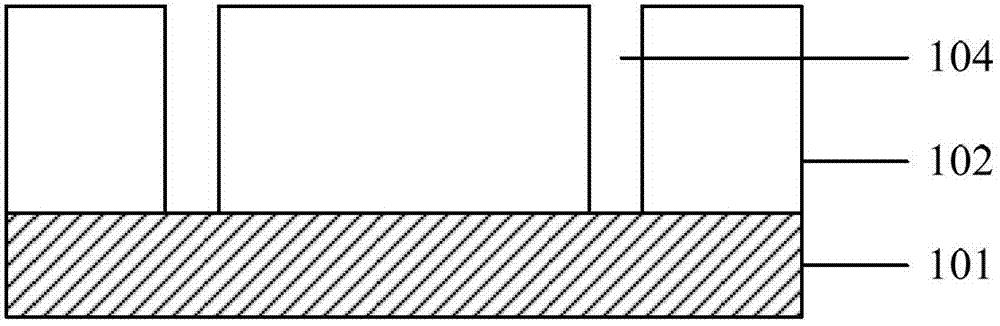

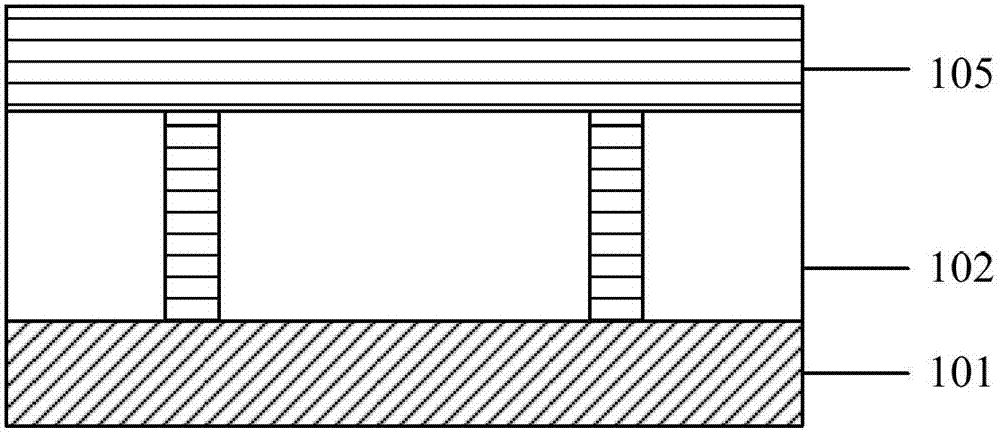

Self-assembling growth method of compound semiconductor film

ActiveCN102842490ALow densityPrecise size controlSemiconductor/solid-state device manufacturingThin layerLead Metal

The invention provides a self-assembling growth method of a compound semiconductor film, and the method comprises following steps of previously leading metal source reactant onto a substrate, and decomposing the metal source reactant to form a metal thin layer under high temperature; annealing the metal thin layer to form metal island particles; feeding III-group and V-group reactants, controlling the ratio of the V / III to be ranged from 50 to 200, controlling the temperature to be ranged between 800 to 1000 DEG C, utilizing the metal island particles as growth catalyst, and longitudinal growing nano columns along the metal island; and increasing the temperature to 1050 to 1100 DEG C, increasing the ratio of V / III to 1000 to 2000, accelerating the lateral growth of the top of the nano column, and forming a continuous semiconductor film.

Owner:EPITOP PHOTOELECTRIC TECH

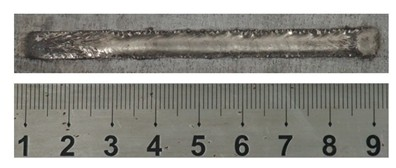

Method for separating indium and tin from In-Sn alloy by vacuum distillation

InactiveCN101660056AAchieve recyclingImprove direct yieldProcess efficiency improvementIndiumSmelting process

The invention relates to a method for separating indium and tin from In-Sn alloy by vacuum distillation. The method comprises the following steps: adding In-Sn alloy material which includes 40-99% ofIn and 1-60% of Sn into a vacuum furnace, controlling vacuum degree, temperature and distillation time in the furnace, and leading metal indium and tin to separate. The treated objects can be In-Sn alloy, In-Sn slag and the like generated during the non-ferrous smelting process. By vacuum distillation, the content of tin in metal indium is less than 0.5%, the content of indium in metal tin is lessthan 0.5%, and the total recovery efficiency of metal is more than 99%. During the process, any reagent does not need to be added, the technology is simple, the metal recovery efficiency is high, andthe electricity consumption is less than 10KW.h / kg.

Owner:KUNMING UNIV OF SCI & TECH +2

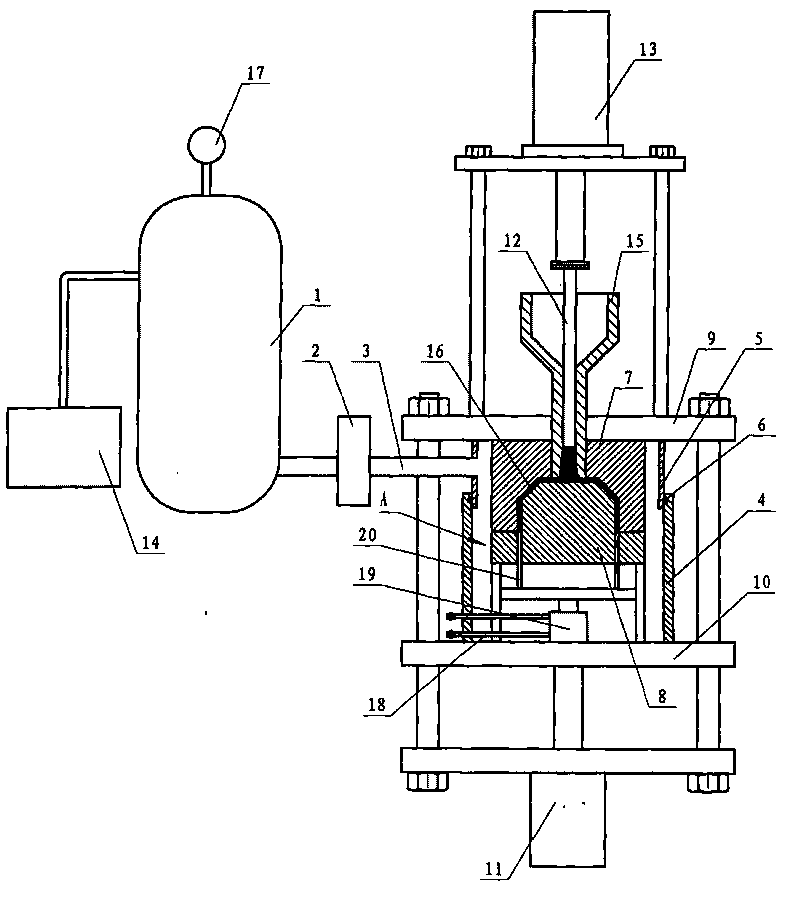

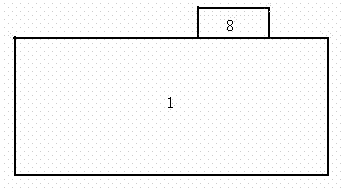

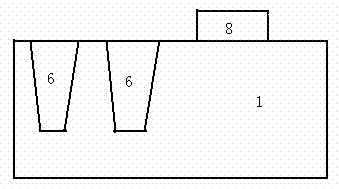

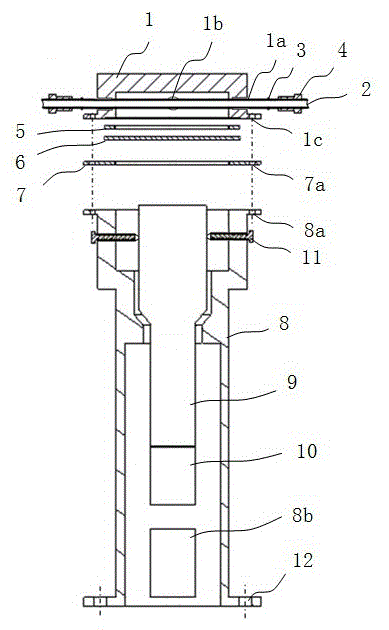

Method of vacuum pressure casting machine and device thereof

The invention relates to a method of a vacuum pressure casting machine and a device thereof, comprising a movable shell and a sliding plate, a fixed shell and a bottom plate, a sealing part, a vacuum pump, a pressure gauge, a vacuum energy storage tank and the like. After the sliding plate rises, the movable shell and the fixed shell are sealed to form a sealing cavity (A) which is connected with the vacuum energy storage tank and the vacuum pump by a pipeline and is provided with a valve; the bottom plate is provided with a material inlet which is connected with a funnel-shaped charging barrel that is internally provided with a pressure injection piston; a mould is arranged inside the sealing cavity (A); and when in work, an opening of the charging barrel is plugged by the pressure injection piston, melt liquid is added into the funnel-shaped charging barrel, the melt liquid is quickly sucked into a die cavity by vacuum when the pressure injection piston is lifted, and the pressure injection piston goes downwards to pressurize the melt liquid so as to lead metal liquid to be solidified under the pressure. After solidification, the sliding plate goes downwards, an ejection oil cylinder is used for pushing an ejector rob to eject a workpiece. The workpiece is charged and molded under the normal state of vacuum (negative pressure) and is solidified under the pressure, thus eliminating or reducing air holes inside castings and ensuring the workpiece to be well charged and molded.

Owner:吴为国

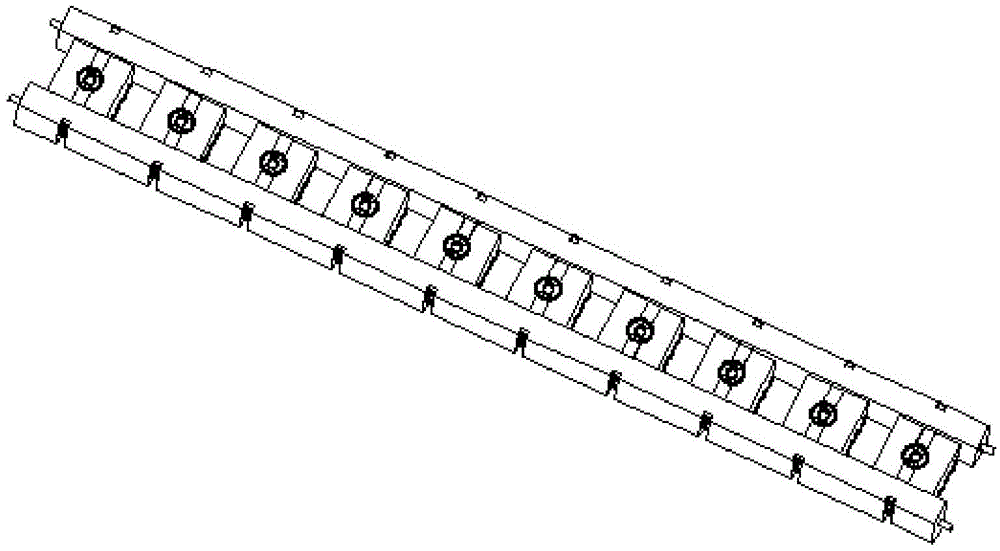

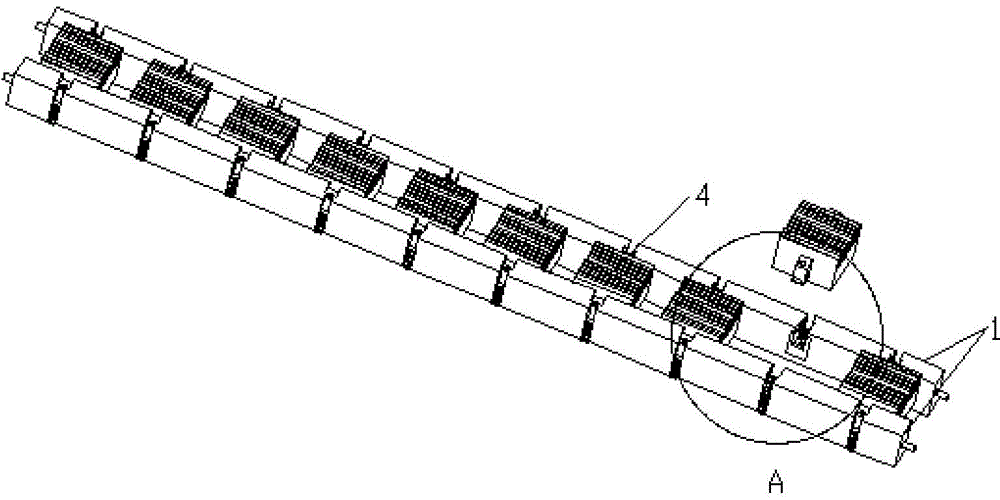

Bendable strip-shaped module lamp strip matched with pluggable LED (light emitting diode) metal lamp bulbs

ActiveCN104359037AWon't spring backEasy to plug and unplugPoint-like light sourceElongate light sourcesEngineeringLead Metal

The invention relates to the field of LED (light emitting diode) lamps, in particular to a bendable strip-shaped module lamp strip matched with pluggable LED metal lamp bulbs. The bendable strip-shaped module lamp strip comprises plastic lamp bulb strips and lamp bulbs, wherein the plastic lamp bulb strips and the lamp bulbs are plugged and fixed by a plugging assembly, and the plastic lamp bulb strips are connected by a connecting head to form a straight line shape, an L shape, a T shape and a cross shape. The bendable strip-shaped module lamp strip has the advantages that the strip-shaped module lamp strips can be bent into various shapes, the rebounding is avoided, the strip-shaped module lamp strip can be applied to structures with flat surfaces, annular surfaces, arc-shaped surfaces and spherical surfaces, and the plastic strips can also be cut into any length according to the structure of a lamp.

Owner:HUNAN YUEGANG MOOKRAY IND CO LTD

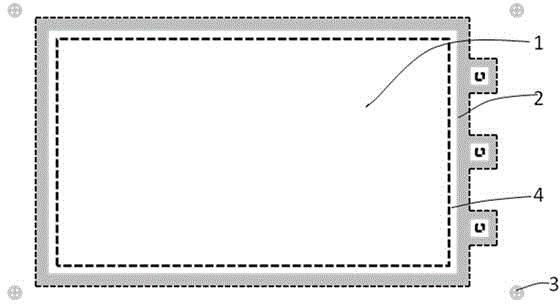

Manufacturing method for graphene touch screen sensor

InactiveCN104793786ASolve the problem of poor printing adhesionReliable electrical connectionInput/output processes for data processingGrapheneMetal electrodes

The invention discloses a manufacturing method for a graphene touch screen sensor. The method comprises the steps that a substrate transferred with graphene thin film serves as an object, the graphene thin film in an electrode printing area is removed in advance, a graphene overlapping area is only reserved, the overlapping area is the superposed area of the electrode printing area and the graphene thin film, the electrode printing area without the graphene thin film is printed with metal electrode paste, and the sensor is formed after patterning is conducted. According to the manufacturing method for the graphene touch screen sensor, the graphene thin film in the electrode printing area is removed in advance, the graphene overlapping area is only reserved, and then a lead metal electrode printing method is adopted, so that a printing electrode is only overlapped to graphene only on a minimal overlapping area, good electric connection or ohmic contact can be achieved, most of the metal electrode makes contact with the substrate, and the problem that the printing adhesive force of the metal paste on the graphene thin film is poor is solved.

Owner:WUXI GRAPHENE FILM

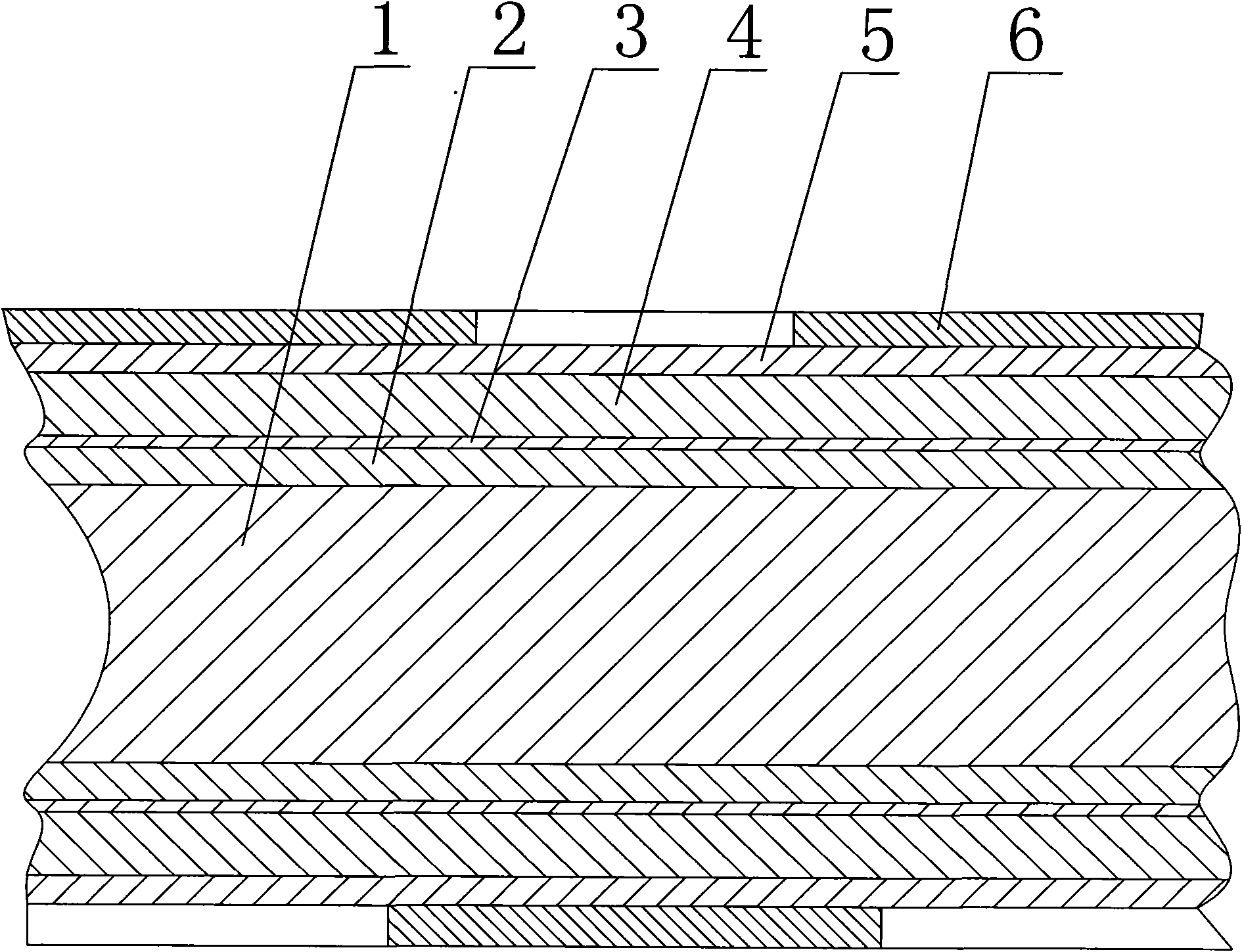

Metal baseplate provided with LED and manufacturing method thereof

InactiveCN101887942AImprove insulation performanceImprove thermal conductivitySemiconductor devicesCarbon filmDiamond-like carbon

The invention relates to a metal baseplate provided with an LED and a manufacturing method thereof, relating to the technical field of circuit board base materials, and in particular being applied to the technical field of production of a large-power LED metal baseplate. The manufacturing method comprises the following steps: successively plating a diamond-like carbon (DLC) coating on a metal plate; sputtering a metal layer capable of being carbonized on the outer surface of the diamond-like carbon coating; sputtering a thin copper layer outside the metal layer capable of being carbonized; and electroplating a thickened copper layer outside the thin copper layer and then carrying out circuit carving outside the thickened copper layer. The formed aluminium baseplate has excellent insulativity, and the adhesive strength of the diamond-like carbon coating and the baseplate is up to 20kg / cm<2>. The aluminum baseplate has the heat conductivity larger than 10W / mk which is more than twice of that of the traditional insulating layer containing glue, is particularly suitable for the application of the large power LED and can effectively reduce the optical attenuation speed.

Owner:江苏鑫钻新材料科技有限公司

Food-grade polypropylene composite material and preparation method and application thereof

The invention relates to a food-grade polypropylene composite material, a preparation method and an application thereof. The composite material is composed of the following components in mass percentage: 48-78wt% of polypropylene, 20-50wt% of food-grade additive calcium carbonate; 0.5-2wt% of food-grade processing aid and 0-1.0wt% of food-grade coloring agent, wherein the food-level standard is as follows: the content is 98.0-100% calculated by dry basis, the loss on drying is less than or equal to 2.0%, the content of acid insoluble matter is less than or equal to 0.2%, the content of fluoride is less than or equal to 0.005%, the content of alkali metals and magnesium salt is less than or equal to 1.0%, the content of arsenic metals is less than or equal to 3.0mg / kg, and the content of lead metals is less than or equal to 3.0mg / kg. The food-grade polypropylene composite material and the prepared tableware in the invention have favorable mechanical property and lower cost; and compared with the traditional tableware, the tableware filled with food-grade additive calcium carbonate are more in accordance with the hygienic standard and are easily degraded.

Owner:富岭科技股份有限公司

Method for removing zinc in renewable aluminum

InactiveCN101532093AReduce manufacturing costImprove economyProcess efficiency improvementAluminum canLate stage

The invention discloses a method for removing zinc in renewable aluminum, and the method comprises the following steps: a. renewable aluminum raw material is heated and melted to form a renewable aluminum melt; b. the vacuum distillation is carried out on the renewable aluminum melt in the step a to lead metal zinc therein to form steam to be discharged. The vacuum degree of the vacuum distillation is 10-50Pa, the temperature of the vacuum distillation is 650-800 DEG C, and the time of the vacuum distillation is 5-30 minutes. The method for removing the zinc in the renewable aluminum can effectively remove zinc impurities in the renewable aluminum, and the content of zinc element in the renewable aluminum melt after the vacuum distillation is not more than 0.5 percent, thereby having significant zinc removal effect, greatly reducing the using amount of primary aluminum in the late-stage component adjustment, facilitating the component adjustment of the follow-up production of the renewable aluminum, simultaneously increasing the using amount of the renewable aluminum raw material with high zinc content, greatly reducing the production cost of the renewable aluminum and improving the economy of the renewable aluminum raw material on the production and the use.

Owner:ALUMINUM CORP OF CHINA QINGDAO LIGHT METAL

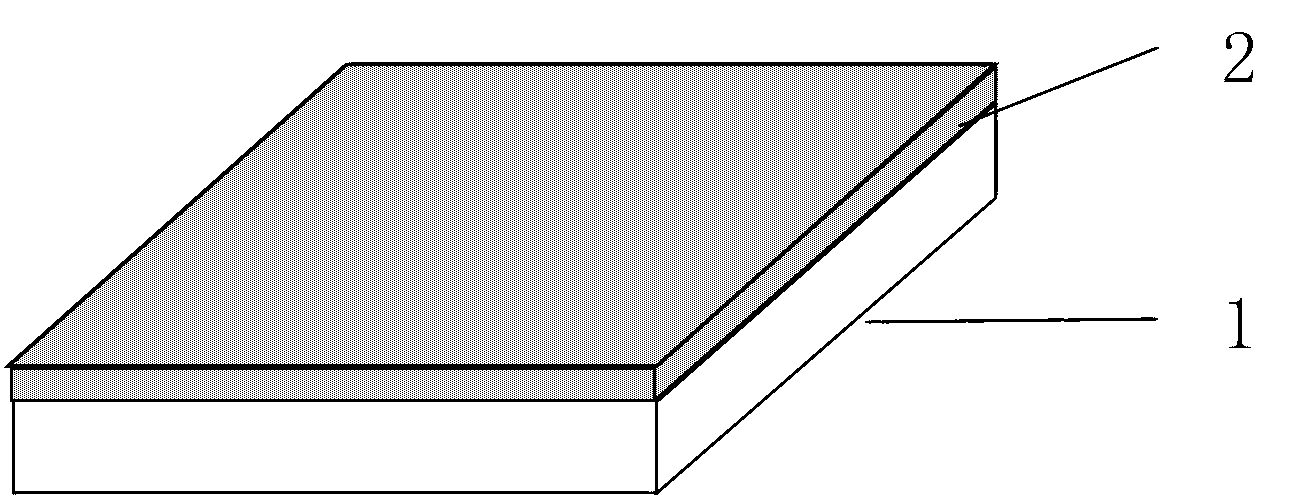

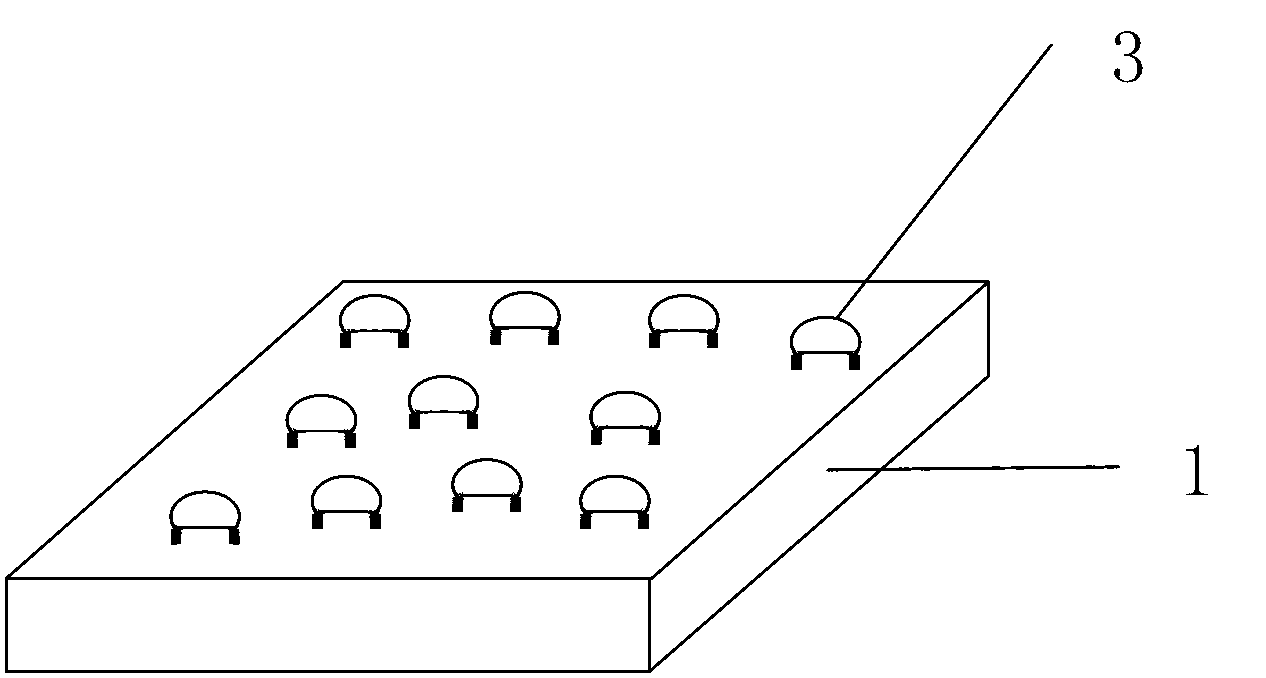

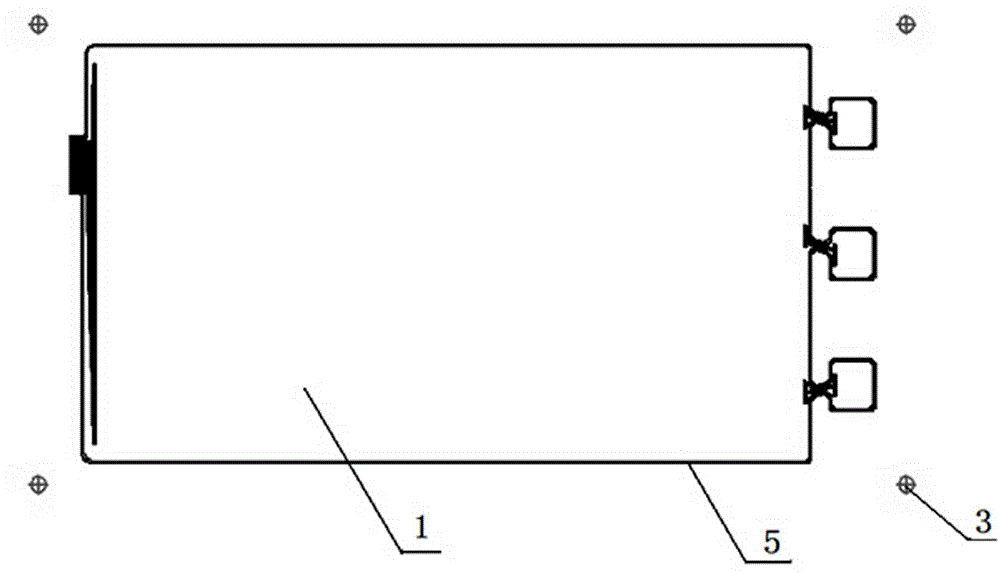

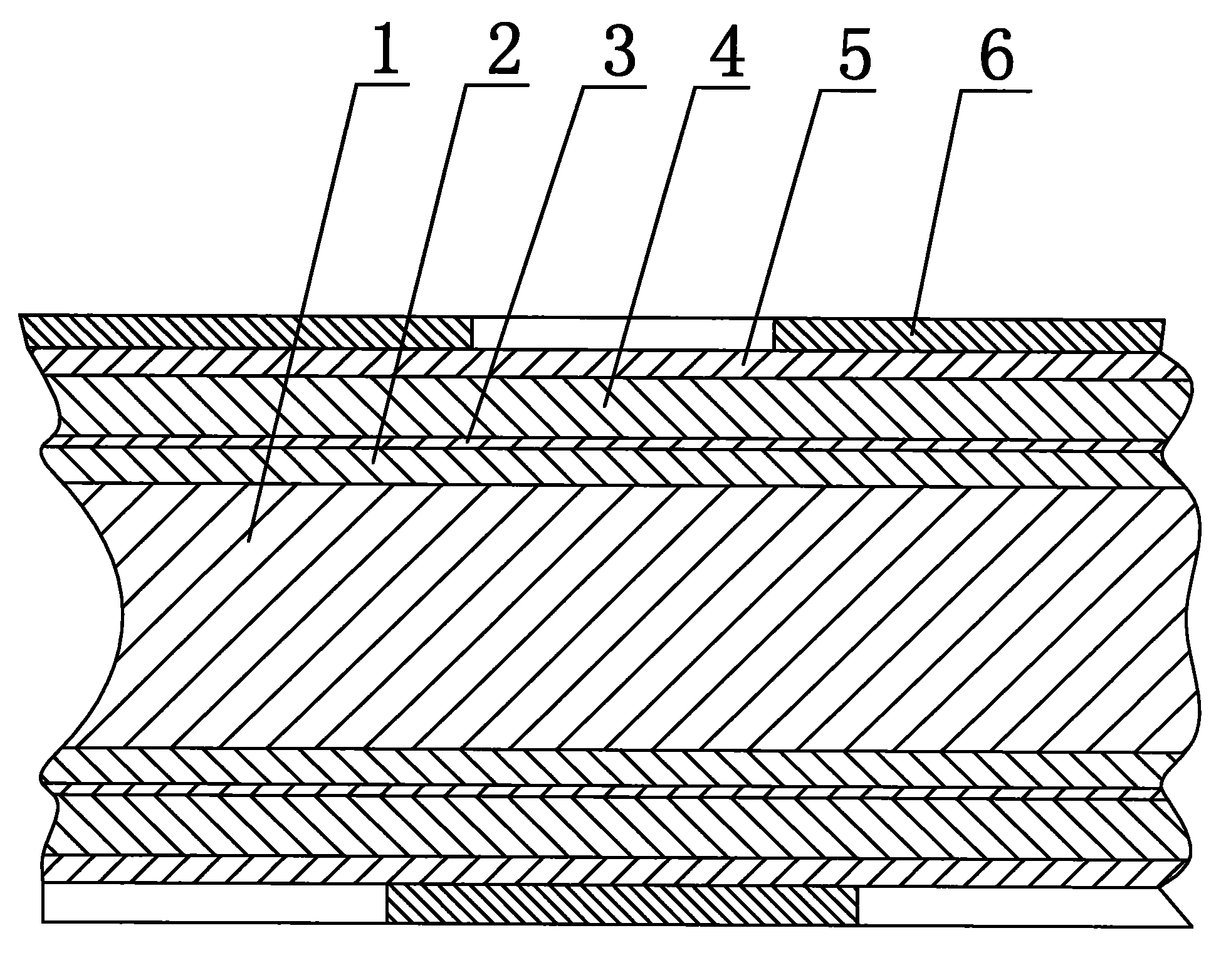

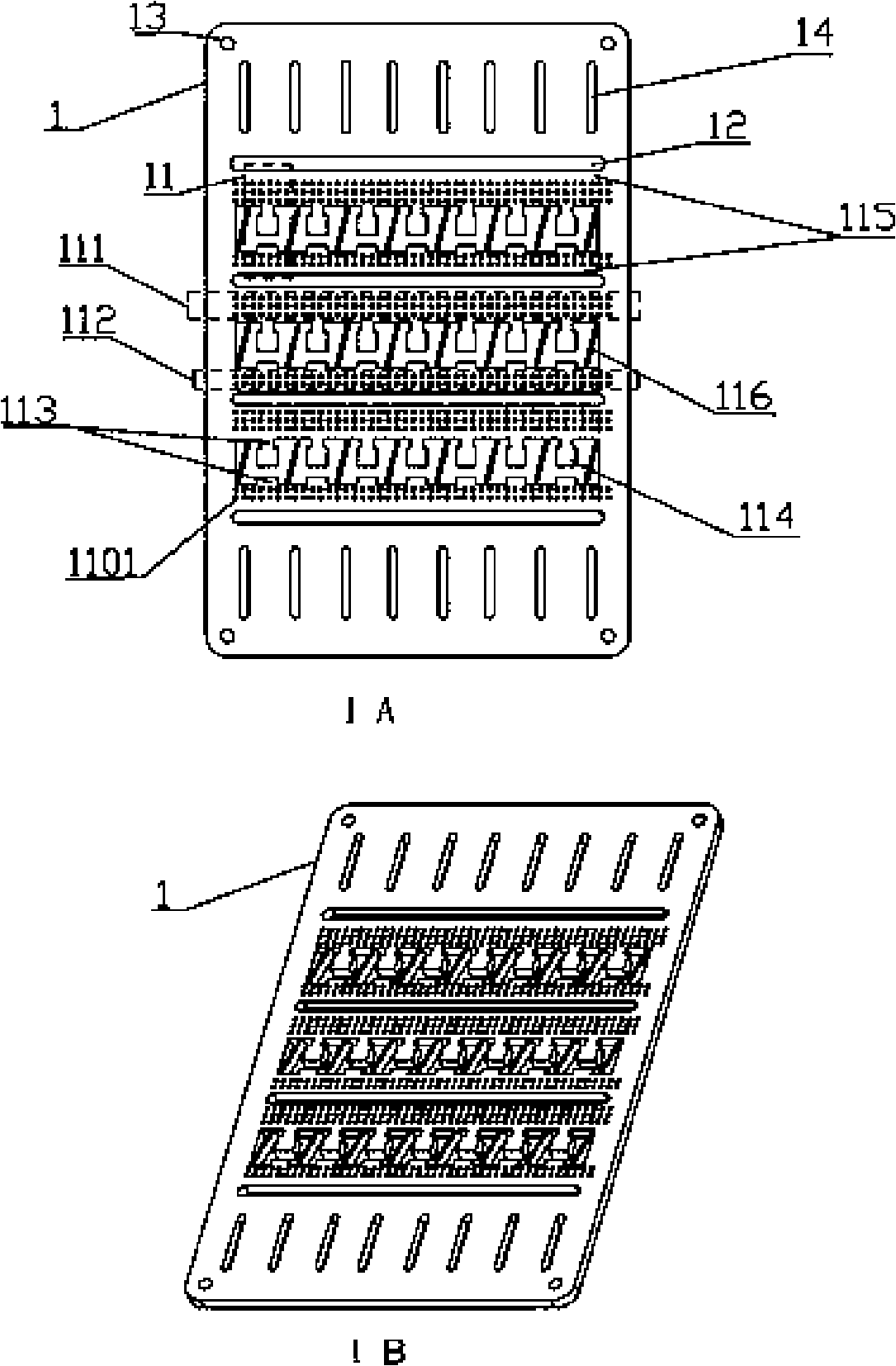

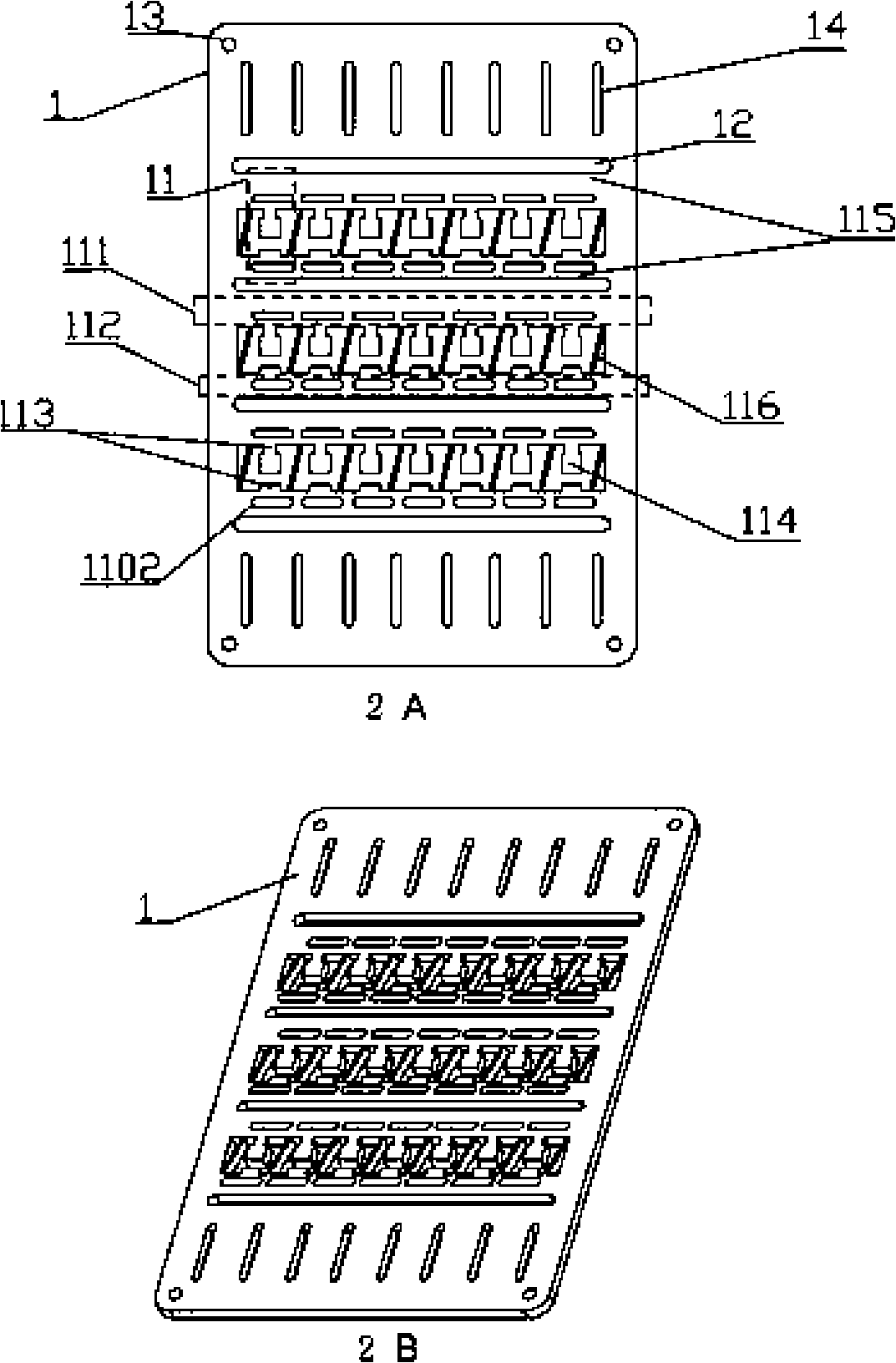

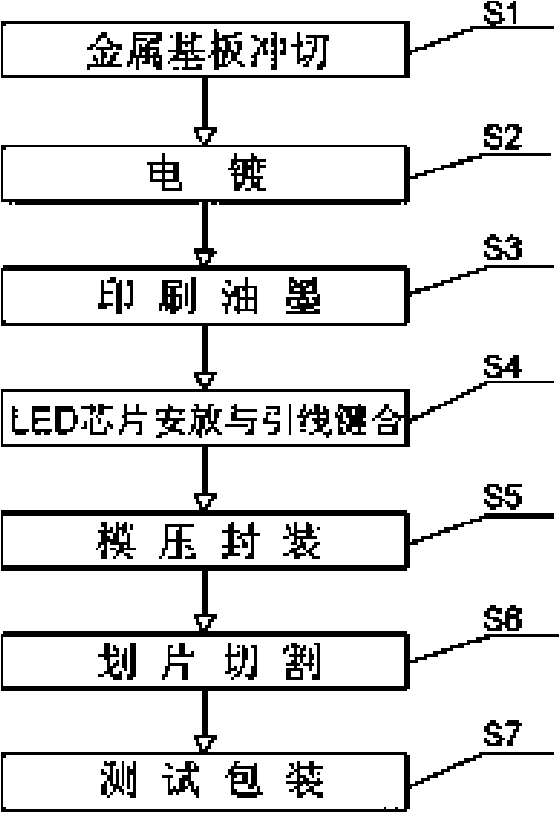

Platy LED metal substrate, platy LED light emitting device and manufacturing method thereof

ActiveCN101630716AImprove performanceImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingPrinting inkEngineering

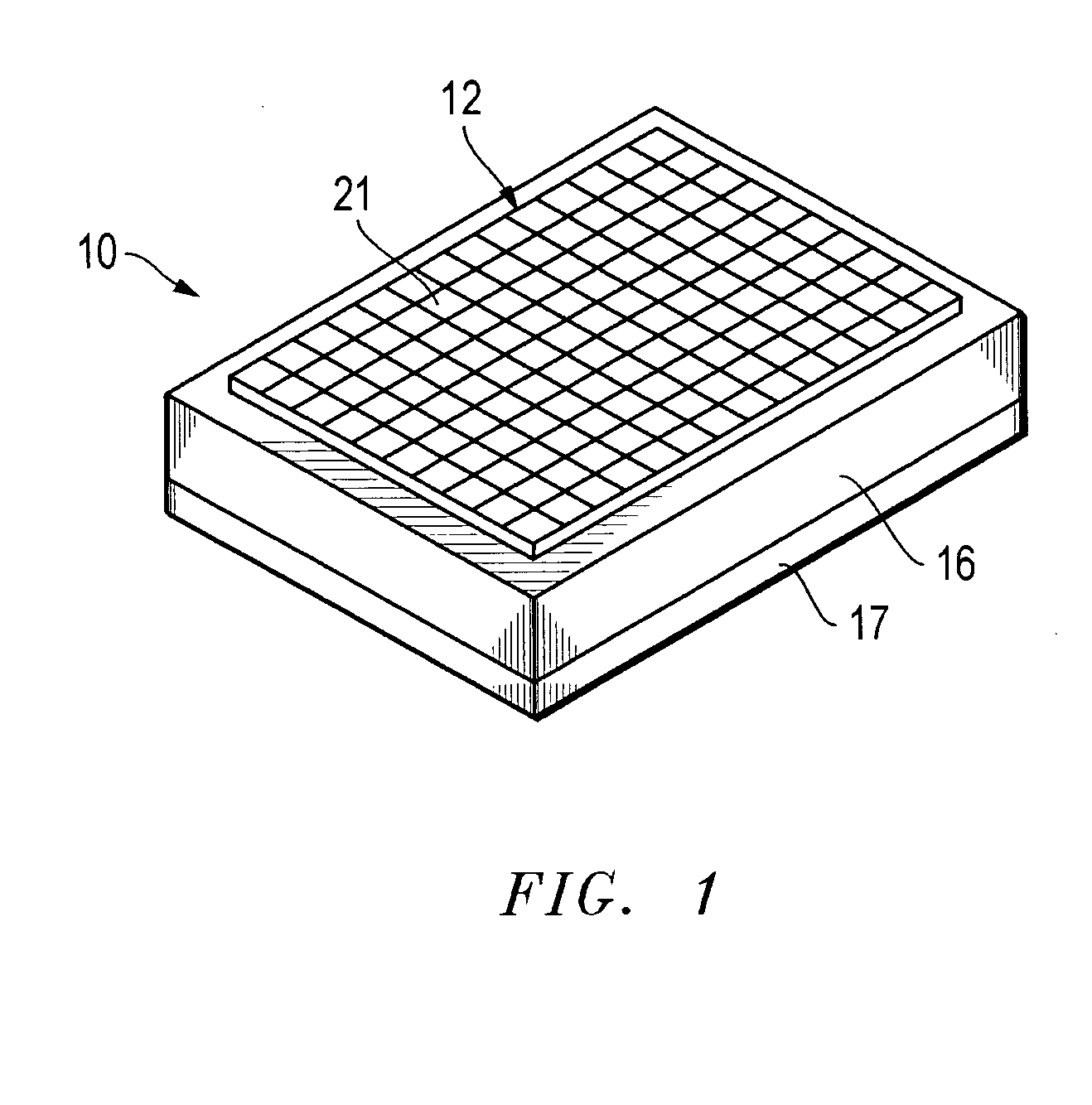

The invention relates to a platy LED metal substrate, a platy LED light emitting device and a manufacturing method thereof. The substrate is formed by elementary units which are provided with an upper hole part and a lower hole part opposite to each other, two lead connecting parts respectively connected with the inner sides of the upper hole part and the lower hole part, a chip placing part connected with the lead connecting part in connection with the upper hole part, two welding parts respectively connected with the outer sides of the upper hole part and the lower hole part, and two reinforcing ribs respectively located at two sides of the chip placing part and connected with the upper hole part and the lower hole part. The invention also relates to a method for manufacturing the platy LED light emitting device, comprising the steps of die cutting metal substrate, plating, printing ink, placing LED chip, bonding lead, packaging stamp, cutting wafer saw and testing package. The invention also relates to the metal substrate and a platy LED light emitting device manufactured by the method. The invention is simple in the process and improves the consistency and reliability of products; in addition, the manufactured platy LED light emitting device is featured by excellent performance and favorable consistency.

Owner:FOSHAN NATIONSTAR OPTOELECTRONICS CO LTD

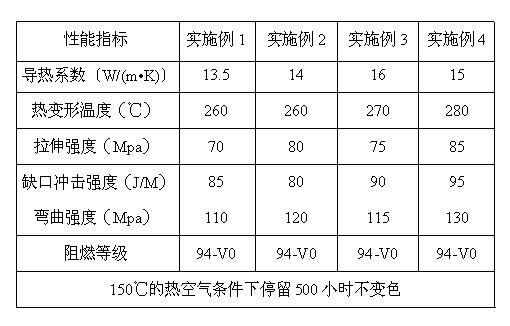

Heat conducting composite material and injection molding process for combining same and LED metal shell

InactiveCN102010694AImprove thermal conductivityImprove mechanical propertiesHeat-exchange elementsHeat conductingAntioxidant

The invention belongs to the technical field of heat conducting composite materials, and particularly relates to a heat conducting composite material and an injection molding process for combining the same and a light-emitting diode (LED) metal shell. The heat conducting composite material comprises the following raw materials in part by weight: 46 to 91 parts of polyhexamethylene adipamide, 5 to 25 parts of graphite, 2 to 10 parts of molybdenum disulfide, 0.5 to 2 parts of nano calcium carbonate, 2 to 15 parts of glass fiber, 0.5 to 5 parts of coupling agent, 1 to 2 parts of antioxidant and 0.5 to 2 parts of processing auxiliary agent. The heat conducting composite material has high heat conducting property and thermal physical and mechanical properties. The injection molding process for combining the heat conducting composite material and the LED metal shell comprises the following steps of: (a) raw material drying and granulation; (b) plasticizing; (c) injection molding and filling; (d) annealing treatment; and (e) humidifying treatment. The LED metal shell prepared by the injection molding process has the advantages of high heat dissipation efficiency and safe and reliable use.

Owner:湖北汉光光电股份有限公司

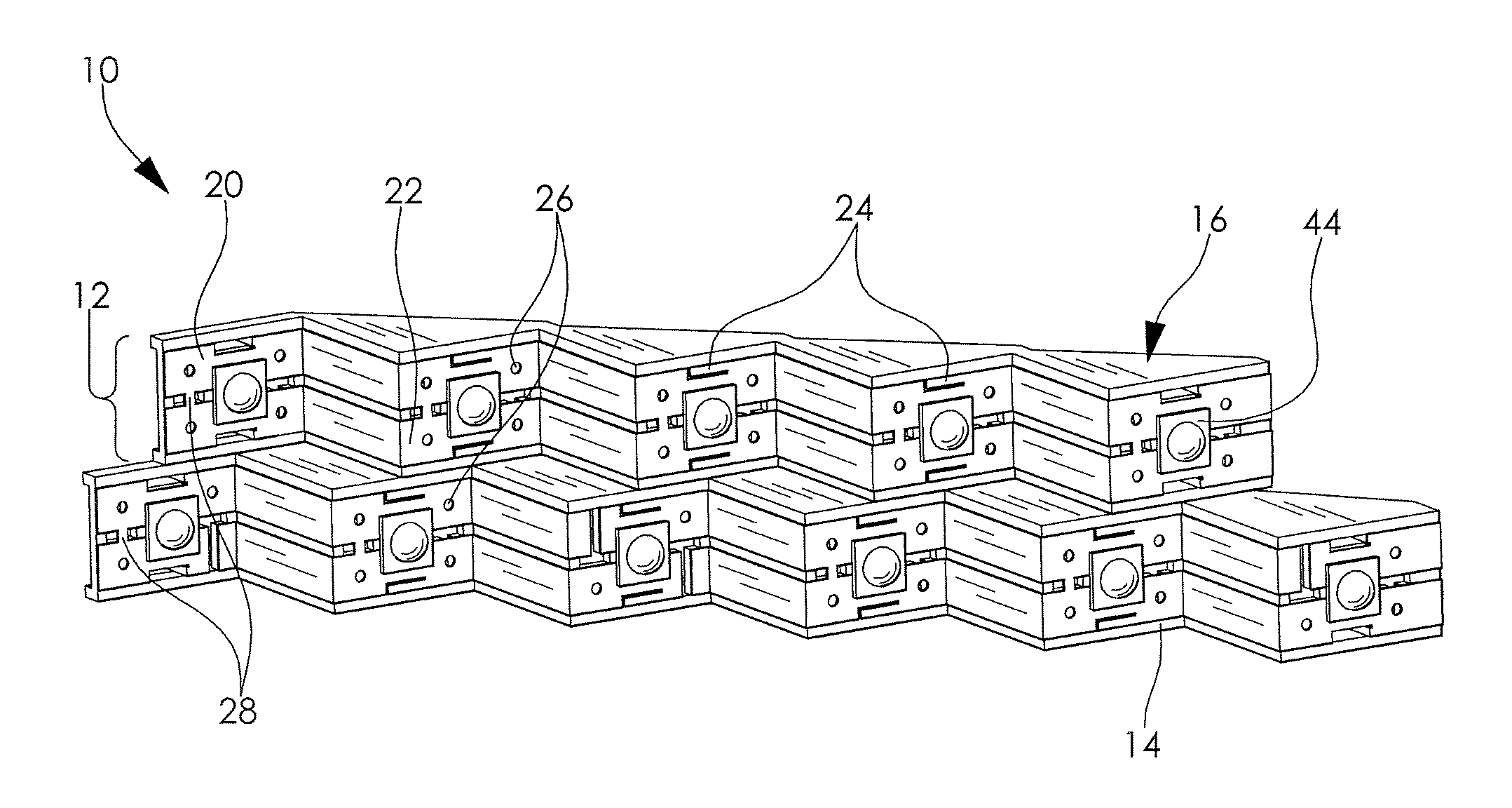

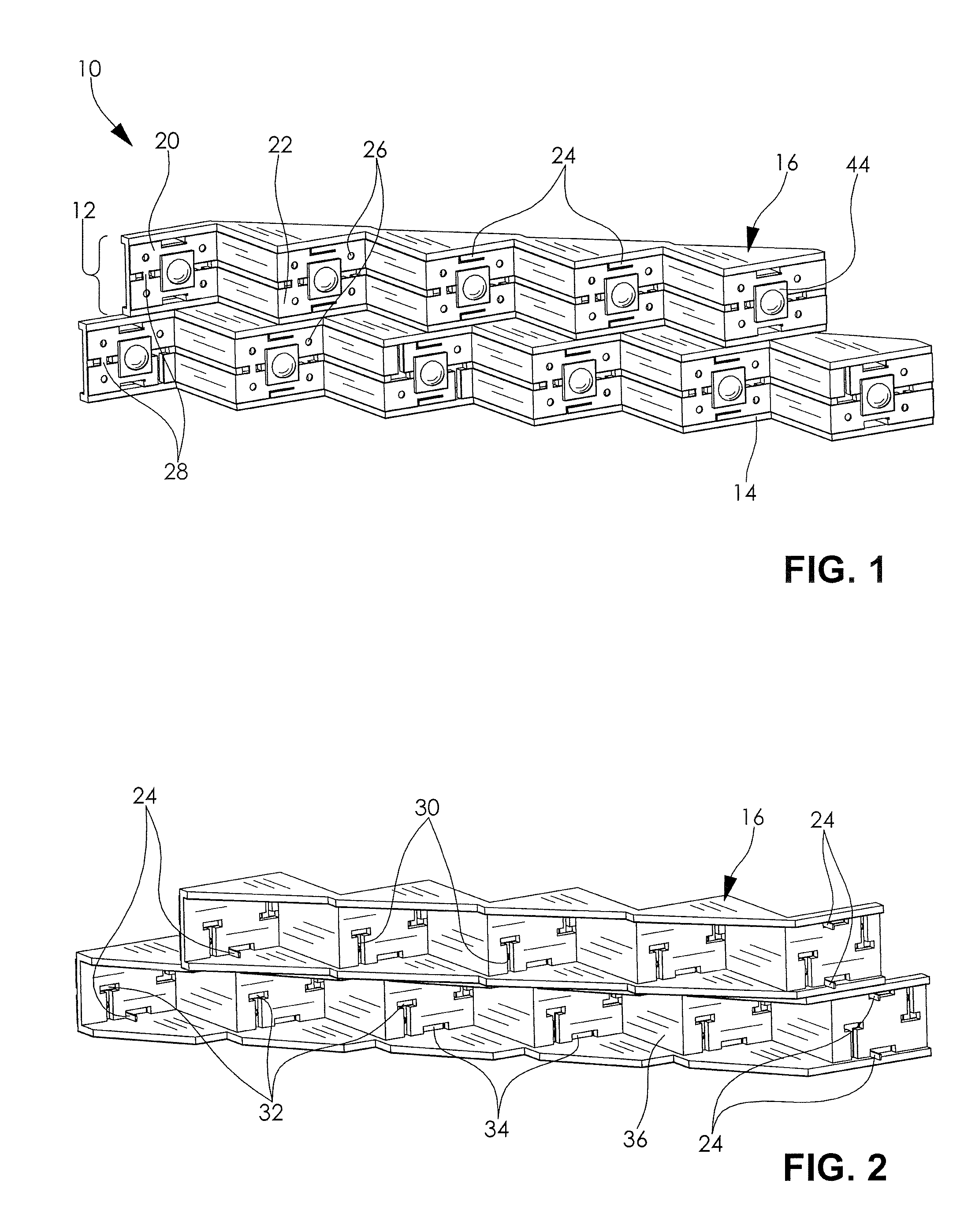

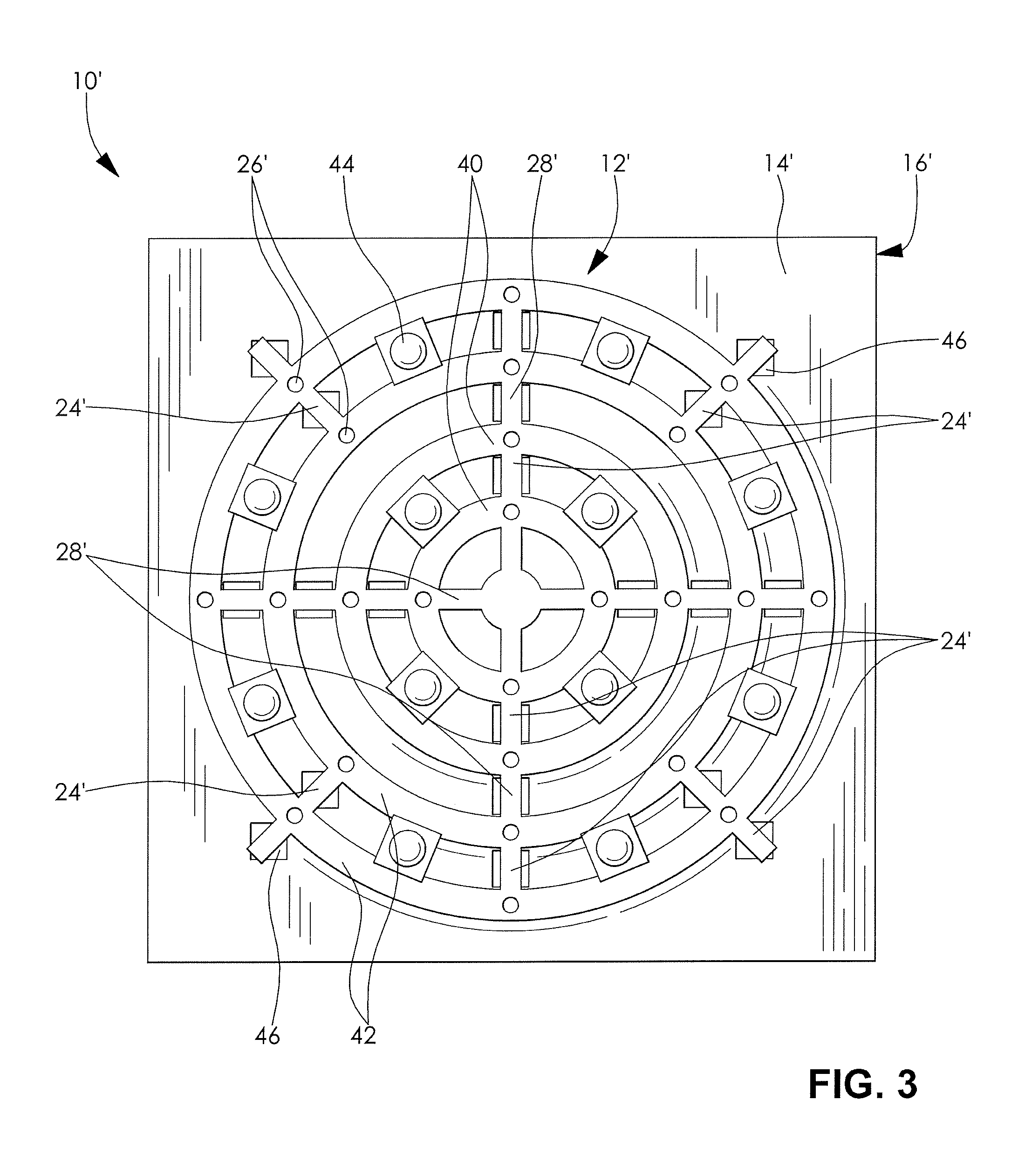

LED metal strip flexible interconnection

InactiveUS20090104804A1Simple, flexible and standardized3D rigid printed circuitsPoint-like light sourceMetal stripsLed array

An LED interconnection apparatus and a method of electrical connection for an array of LEDs are disclosed, the LED interconnection apparatus including a back plate substrate having a plurality of adaptable through-holes formed therein and a flexible conductive pattern disposed adjacent the back plate substrate, wherein the adaptable through-holes of the back plate substrate facilitate selective access to the flexible conductive pattern to provide a simple, adaptable, and standardized method of electrical communication for an array of LEDs.

Owner:VARROC LIGHTING SYST SRO

Through hole priority copper interconnection manufacturing method

InactiveCN102760696AFewer etch stepsReduce manufacturing costSemiconductor/solid-state device manufacturingInterconnectionCopper

The invention discloses a through hole priority copper interconnection manufacturing method, which comprises the following steps of: depositing a medium layer on a substrate, coating a first photoresist which can form a hard film on the medium layer, and forming a through hole structure in the first photoresist; coating a micro curing material on a first photoresist pattern for curing the through hole structure, heating for reacting the micro curing material with the surface of the first photoresist, and forming an isolating film on the surface of the first photoresist; coating a second photoresist on the cured first photoresist, and forming a channel structure positioned above the through hole structure in the second photoresist, wherein the isolating film is insoluble in the second photoresist; transferring the through hole structure and the channel structure into the medium layer; and continuing subsequent lead metal and through hole metal filling. In the method, the photoresist material which can form a hard film is used, so that an etching step is reduced, the manufacturing cost is lowered greatly, and the yield is increased effectively.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Manufacture process of removing redundant metal filling of metal layer

InactiveCN102446827AReduce or eliminate coupling capacitanceSemiconductor/solid-state device manufacturingCapacitanceCoupling

The invention provides a manufacture process of removing redundant metal filling of a metal layer. The manufacture process comprises the following steps of: 1, depositing a low k value dielectric layer; 2, forming a hard mask layer on the deposited low k value dielectric layer; 3, photoetching and etching the hard mask layer; 4, completing photoetching and etching to form a through hole; 5, carrying out filling of a lead metal, a through hole metal and a redundant metal for completing metal layer deposition; 6, carrying out chemically mechanical polishing on the metal layer; and 7, continuously chemically mechanical polishing of the low k value dielectric layer and a metal hybrid layer, and further removing redundant metal. Through a process of further removing the redundant metal by using chemically mechanical polishing in the manufacture process of single- damascene and dual- damascene metal interconnections, a coupling capacitance introduced in the metal layers and among the metal layers by the redundant metal filling can be effectively reduced or eliminated, thus the manufacture process is very practical.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

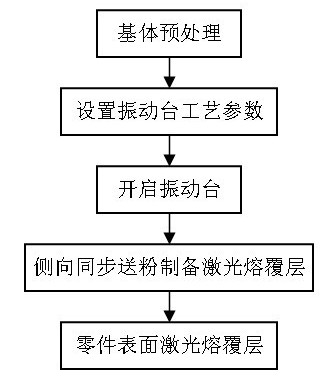

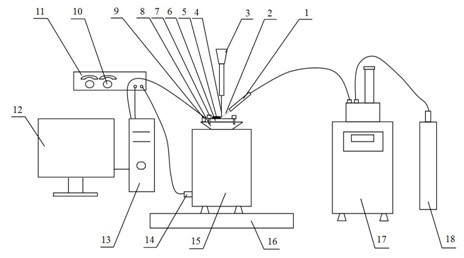

Method for controlling air holes of laser cladding layer by intermittent parking machine

InactiveCN102383124AImprove liquidityAvoid legacyMetallic material coating processesMelting tankEngineering

The invention relates to a method for controlling air holes of a laser cladding layer by an intermittent parking machine, belonging to the technical field of surface treatment. The method comprises the following steps of: fixing a cladding sample on a platform surface of an electromagnetic vibrating platform by a clamp device, adopting a lateral and synchronous powder feeding method, assisting low-amplitude and high-frequency intermittent parking vibration in the laser cladding process, leading metal liquid to be stressed by exciting force provided by mechanical vibration intermittently in the solidification process of a melting pool, and obtaining the high-quality cladding layer. In the method, the formation of a feeding channel can be enhanced, the intermittent vibration accelerates the escaping of residual gas in the cladding process, the residue of microscopic bubbles in the cladding layer is restrained, the macroscopic surface quality after the cladding layer is solidified is improved, the subsequent processing amount is reduced, and the comprehensive surface performance of the cladding layer is improved. The method is applicable to the fields such as strengthening and forming of laser cladding surfaces of metal parts and surface repairing of medium parts and the like, and can improve the quality of the cladding layer.

Owner:KUNMING UNIV OF SCI & TECH

Online measurement device for uranium concentration in solution

InactiveCN105115993AStrong radiation resistanceImprove sealingMaterial analysis using wave/particle radiationMeasurement deviceEngineering

The invention discloses an online measurement device for the uranium concentration in a solution. The online measurement device comprises an upper cover. First threaded holes allowing a pipeline to penetrate through are formed in the upper cover in the horizontal direction, and second threaded holes allowing circulating water to pass through are formed and are perpendicular to the first threaded holes in the horizontal direction. First O rings and hollow bolts penetrate through the pipeline and are screwed into the first threaded holes. A second O ring, a baffle and an intermediate plate are sequentially arranged at the lower portion of the upper cover. Bolts penetrate through first through holes in the bottom edge of the upper cover and second through holes in the edge of the intermediate plate and are connected with third through holes in the upper edge of a shielding bucket. A NaI crystal and a multi-channel energy disperse spectrometer are arranged inside the shielding bucket sequentially from top to bottom. Screws penetrate through threaded holes formed in the upper portion of the shielding bucket in the horizontal direction to fix the NaI crystal. A square hole allowing a power wire to penetrate through is formed in the lower portion of the shielding bucket. A base of the shielding bucket is provided with flange through holes used for fixing the base. The outer layer of the online measurement device is made of stainless steel, the inner layer of the online measurement deice is lead metal, and therefore the effect of uranium radiation resistance is good; the O rings and the threaded holes are used for fixing, so the online measurement device is simple in structure and good in sealing effect, and the testing cost is reduced.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

Cleaning technique of diode chip

InactiveCN101845638ARemove completelyEasy to useSemiconductor/solid-state device manufacturingInstabilityAmmonia

The invention provides a cleaning technique of a diode chip, and relates to an improvement of a cleaning liquid formula used in the cleaning technique, which can further reduce metal ions of the side surface of the chip, thus avoiding the chip from generating the phenomenon of creepage in working. The cleaning technique comprises the steps of mixed acid cleaning, double phosphorus cleaning and ammonia cleaning in sequence; when in ammonia cleaning, the cleaning liquid comprises ammonia water, water and hydrogen peroxide, the weight ratio of which is as follows: 1 part : 2-3.5 parts : 0.15-0.3 part. Compared with the original formula, the cleaning technique adds the hydrogen peroxide in ammonia cleaning liquid, feeds the obtained ammonia cleaning liquid downward onto an acid cleaning disc by an acid-feeding pipeline under the condition of being fully mixed; the acid liquid is over an upper nail head (equivalently to a clamping part of the upper end surface of the chip), thus leading the reaction to be full and further being capable of leading metal purities of the side surface of the chip to be removed more thoroughly; and the materials are more stable when being used under high temperature, thus reducing the instability of electric property of the materials due to larger surface leakage.

Owner:YANGZHOU YANGJIE ELECTRONIC TECH CO LTD

A kind of glass material for high temperature and high pressure sealing and preparation method thereof

The invention discloses a high temperature and high pressure resistant glass material for sealing and a preparation method thereof, which is prepared from the following components in parts by weight: SiO2: 9-12 parts; H3BO3: 25-27 parts; Al2O3: 4-6 parts; SrCO3 : 5 to 8 parts; Pb3O4: 50 to 53 parts; other impurity elements inevitably brought in: ≤1 part. The preparation method of the above-mentioned high temperature and high pressure resistant glass material comprises the following steps: a) batching; b) ball milling; c) pre-sintering; e) heat preservation and sintering; e) water quenching; f) ball milling; g) sieving; h )dry. The invention also provides a method for encapsulating the above-mentioned high-temperature and high-pressure-resistant sealing glass material with an alloy and a performance testing method. The sealing glass material of the present invention can be matched and sealed with Kovar alloy or other lead metals and stainless steel alloys of different grades, and has excellent sealing strength and quality; by controlling the packaging method, the sealing member can be used normally in high temperature, high pressure environment and destructive environment , with good stability and reliability.

Owner:湖南江麓仪器仪表有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com