Method of vacuum pressure casting machine and device thereof

A vacuum pressure casting and vacuum technology, which is applied in the field of casting machines and vacuum pressure casting machines, can solve problems such as complex structures and inconspicuous effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

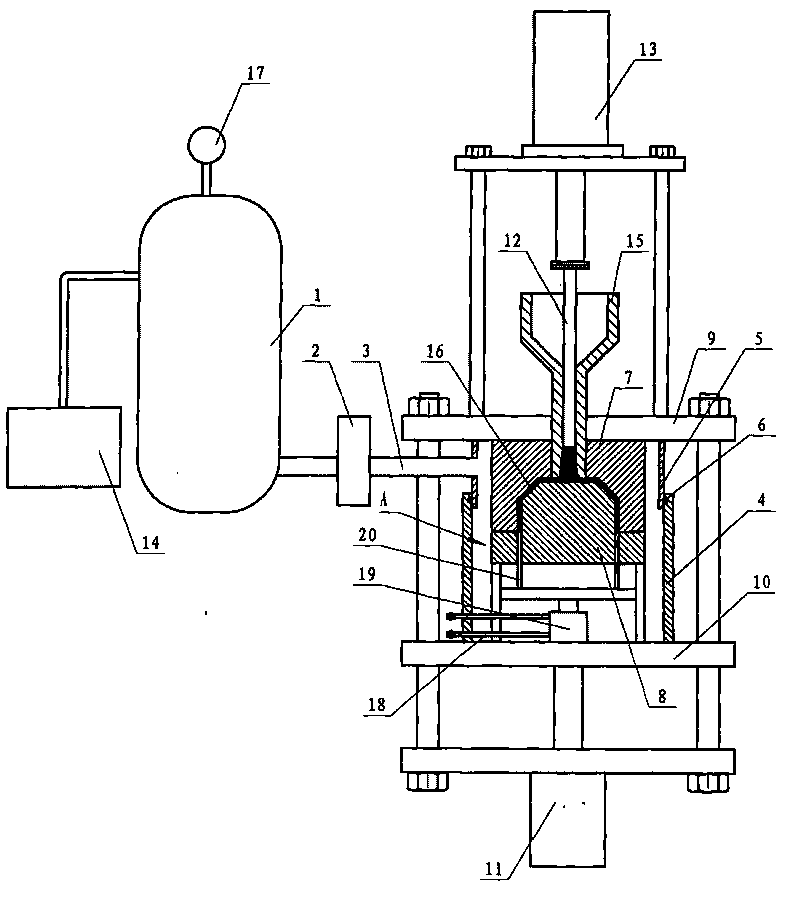

[0015] A vacuum pressure casting method, comprising mold making and sliding sealing cavity (A) making and pouring metal, placing the prepared mold in the sealing cavity (A) that can slide up and down, and the fixed mold of the mold (7 ) is fixed on the bottom plate (9) of the fixed housing (5), and the movable mold (8) is fixed on the slide plate (10) of the movable housing (4); after the slide plate (10) rises, the movable housing (4) It is sealed with the fixed housing (5) to form a sealed cavity (A), and the funnel-shaped barrel (15) is blocked by the injection piston (12); the air in the cavity is drawn out to keep it vacuum (negative pressure), and the funnel Add molten liquid to the mold barrel (15); after the injection piston (12) is lifted to allow the molten metal to flow into the cavity, the injection piston (12) immediately pressurizes the molten metal to make it solidify under normal pressure.

[0016] A vacuum pressure casting device, comprising a moving casing (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com