Low-cost flame-retardant photovoltaic cable with good thermal stability

A thermal stability, photovoltaic cable technology, applied in rubber insulators, organic insulators, etc., can solve the problems of high cost, unsuitable for large-scale production and quantification, and achieve the effects of short time, excellent aging resistance, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

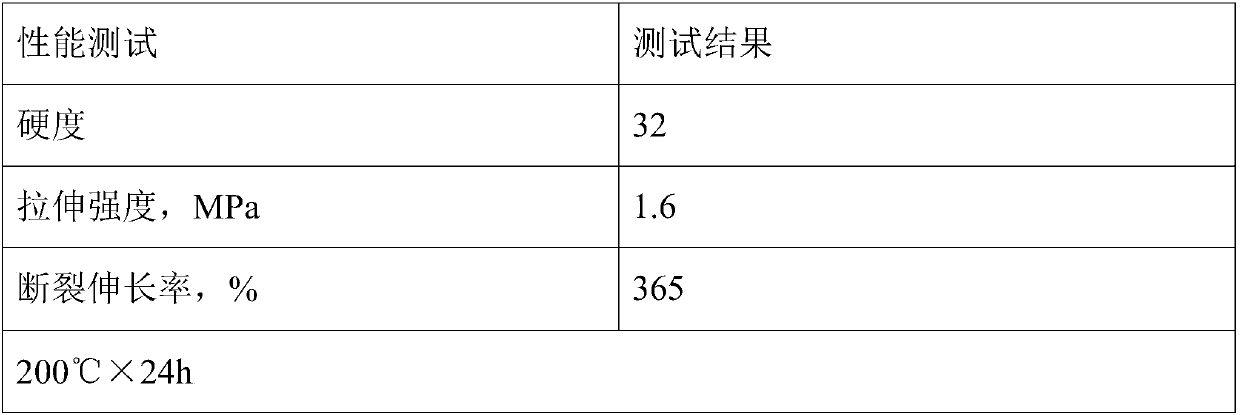

Examples

Embodiment 1

[0014] A low-cost, flame-retardant and thermally stable photovoltaic cable, including a cable core and a sheath layer coated on the outside of the cable core. The raw materials of the sheath layer include by weight: 110 parts of base material, 0.18 parts of maleic anhydride, two 0.4 parts of butyltin dilaurate, 2.5 parts of crosslinking agent, 1 part of glycerin, 0.8 parts of 4-methyl-2-pentanol, 1 part of pentaerythritol, 50 parts of modified bamboo powder, 28 parts of microencapsulated red phosphorus, 18 parts of magnesium hydroxide, 2 parts of zinc borate, 8 parts of talcum powder, and 3 parts of medical stone powder.

Embodiment 2

[0016] A low-cost, flame-retardant and thermally stable photovoltaic cable, including a cable core and a sheath layer coated on the outside of the cable core. The raw materials of the sheath layer include by weight: 130 parts of base material, 0.1 part of maleic anhydride, two 1 part of butyl tin dilaurate, 1.5 parts of crosslinking agent, 2 parts of glycerin, 0.2 parts of 4-methyl-2-pentanol, 2 parts of pentaerythritol, 30 parts of modified bamboo powder, 40 parts of microencapsulated red phosphorus, Magnesium hydroxide 15 parts, zinc borate 4 parts, talcum powder 3 parts, medical stone powder 6 parts.

[0017] The modified bamboo powder is prepared by the following process: sodium methoxide, polyethylene glycol 200, and methyl palmitate are heated up, stirred in a vacuum, added with bamboo powder and water, stirred, filtered, washed, added with titanium sulfate, urea, and water, and mixed evenly. Put it into a hydrothermal reaction kettle and seal it, heat up to carry out hy...

Embodiment 3

[0019] A low-cost, flame-retardant and thermally stable photovoltaic cable, including a cable core and a sheath layer coated on the outside of the cable core. The raw materials of the sheath layer include by weight: 115 parts of base material, 0.16 parts of maleic anhydride, di 0.6 parts of butyltin dilaurate, 2.2 parts of crosslinking agent, 1.2 parts of glycerin, 0.6 parts of 4-methyl-2-pentanol, 1.2 parts of pentaerythritol, 45 parts of modified bamboo powder, 30 parts of microencapsulated red phosphorus, Magnesium hydroxide 17 parts, zinc borate 2.5 parts, talcum powder 6 parts, medical stone powder 4 parts.

[0020] The base material includes by weight: 30 parts of nitrile silicone rubber, 40 parts of polyurethane rubber, and 15 parts of styrene-butadiene rubber. The crosslinking agent comprises by weight: 1 part of dibenzoyl peroxide, and 0.1 part of accelerator TMTD.

[0021] The modified bamboo powder is prepared by the following process: sodium methoxide, polyethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com