Method for increasing ketone-alcohol ratio in hydrogenation reaction of anti-aging agent 4020 by modification-catalysis

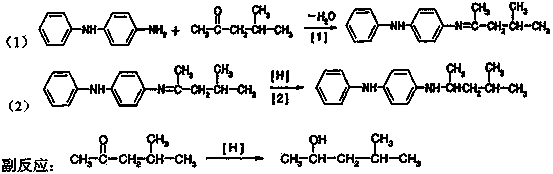

The technology of an antioxidant and modifier is applied in the field of modification and catalysis to improve the ratio of ketone to alcohol after the hydrogenation reaction of antioxidant 4020, which can solve the problems of reducing and increasing the production cost and increasing the consumption of raw material MIBK, so as to reduce side reactions, The effect of reducing consumption and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

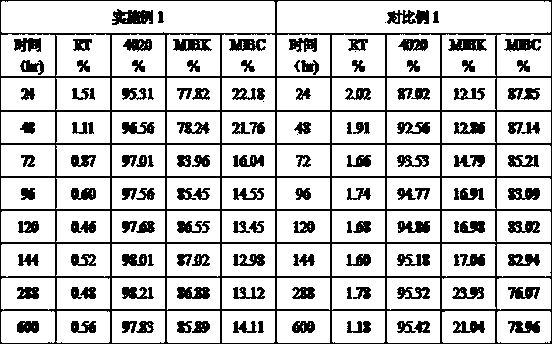

Examples

Embodiment 1

[0026] Add RT Bass, MIBK and [Bmim]BF to the ingredients tank 4 , stirred evenly to form a raw material solution, wherein the molar ratio of RT base to MIBK is 1:5.5, MIBK and [Bmim]BF 4 The volume ratio is 1000:2.5.

[0027] Install the granular C?207 copper-based catalyst in the fixed bed, pass in hydrogen, and adjust the pressure in the fixed bed to 4MPa, and then input MIBK solvent at a speed of 50ml / hour. After the solvent is mixed with hydrogen, after pre- The heater then enters the fixed bed reactor. Slowly increase the temperature of the preheater and the fixed bed, and when the temperature reaches 180°C, keep it for several hours until the solvent fills the fixed bed reactor. At this temperature, the system pressure was adjusted to 2.0MPa, the material was replaced with raw material solution, the feed rate was adjusted to 20ml / hour, and the reducing solution after the catalytic hydrogenation reaction overflowed from the top of the fixed-bed reactor. Move the reduci...

Embodiment 2

[0033] The specific operating conditions are the same as in Example 1, except that the copper-based catalyst is changed from C?207 to F04. The test results are shown in the comparison table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com