Catalyst for preparing methyl isobutyl carbinol and preparation method thereof

A technology of methyl isobutyl ketone and methyl isobutyl is applied to the catalyst for preparing methyl isobutyl methanol and the field of preparation thereof, and can solve the problems of low yield of methyl isobutyl methanol, difficulty in meeting industrial demands and the like , to achieve the effect of saving investment cost, simple preparation method and mild reaction process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

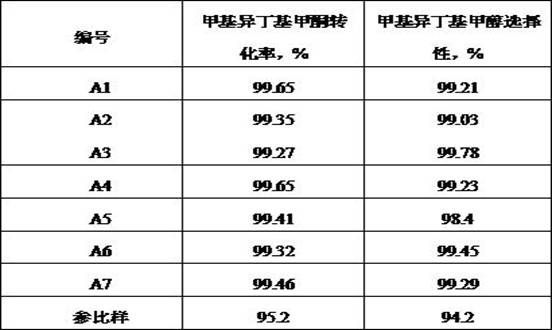

Examples

Embodiment 1

[0024] Select silicon balls (mainly composed of SiO 2 ) as a catalyst carrier with a diameter of 3~4mm. Put 78g of silicon balls into the reaction kettle, add deionized water, cover the silicon balls, seal, start stirring, raise the temperature to 180°C, keep warm and pressurized for two hours, then unload it and put it in a constant temperature blast drying oven. For the first drying, the temperature of the drying oven is 90°C, and the drying time is 6 hours. Weigh 28.58 grams of ammonium molybdate and prepare a 78ml solution for use. Put the dry carrier into a rotating sugar coating machine, and spray the ammonium molybdate evenly on the carrier After spraying, let it stand for 30 minutes. Put the impregnated catalyst into a constant temperature blast drying oven for secondary drying, the oven temperature is 90°C, the drying time is 2 hours, and then put into a muffle furnace for roasting, the roasting temperature is 450°C, and the roasting time is 2 hours hour, then the s...

Embodiment 2

[0026] Select silicon balls (mainly composed of SiO 2 ) as a catalyst carrier with a diameter of 3~4mm. Put 85g of silicon balls into the reaction kettle, add deionized water, cover the silicon balls, seal, start stirring, heat up to 180°C, keep warm and pressurized and expand the holes for two hours, then unload it, and put it in a constant temperature blast drying oven For the first drying, the temperature of the drying oven is 90°C, the drying time is 6 hours, and the water absorption rate of the carrier after reaming is 100%. Weigh 10.20 grams of ammonium molybdate to make 85ml solution for later use, and put the dry carrier into the rotary sugar coating machine In the process, the ammonium molybdate is evenly sprayed onto the carrier, and after the spraying is completed, it is left to stand for 30 minutes. Put the impregnated catalyst into a constant temperature blast drying oven for secondary drying, the oven temperature is 90°C, the drying time is 2 hours, and then put...

Embodiment 3

[0028] Select silicon balls (mainly composed of SiO 2 ) as a catalyst carrier with a diameter of 3~4mm. Put 84g of silicon balls into the reaction kettle, add deionized water, cover the silicon balls, seal, start stirring, heat up to 180°C, keep warm and pressurized and expand the holes for two hours, then unload it, and put it in a constant temperature blast drying oven For the first drying, the temperature of the drying oven is 90°C, and the drying time is 6 hours. The water absorption rate of the carrier after the expansion is 100%. Weigh 8.17 grams of ammonium molybdate to make 84 solution for later use, and put the dry carrier into the rotating sugar coating machine In the process, the ammonium molybdate is evenly sprayed onto the carrier, and after the spraying is completed, it is left to stand for 30 minutes. Put the impregnated catalyst into a constant temperature blast drying oven for secondary drying, the oven temperature is 90°C, the drying time is 2 hours, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com