Oil nozzle cleaning agent and preparation method thereof

A cleaning agent and fuel injector technology, which is applied in the field of gasoline additives, can solve problems such as shortening the service life of the three-way catalytic converter of the spark plug, difficulty in cold start, affecting the sealing performance and service life of the oil circuit, etc., so as to improve the difficult situation of cold start, The preparation method is simple and the effect of improving the atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better explain the present invention, it is further described in conjunction with the following specific examples, but the present invention is not limited to the specific examples.

[0035] Prepare fuel injector cleaning agent according to Table 1.

[0036] Table 1: Components (mass %) of the fuel injector cleaning agent of each embodiment.

[0037]

[0038] Prepare additives according to Table 2.

[0039] Table 2: Components (mass %) of additives in each example.

[0040]

[0041]

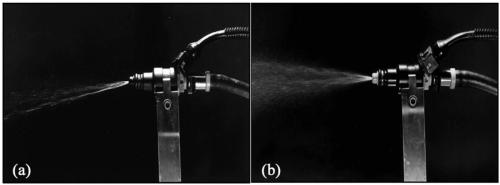

[0042] Use the fuel injector cleaning agent of the present invention to carry out the intake valve deposit (IVD) cleaning test, the measured benchmark IVD is 251mg, and the IVD after using the fuel injector cleaning agent of the present invention under the same conditions is 10mg, compared Below, the IVD using the injector cleaning agent of the present invention was reduced by 96%. figure 1 It is the effect diagram of fuel injection before and after using the fuel i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com