Process for extracting nickel and cobalt from laterite-nickel ore

A technology of lateritic nickel ore and nickel-cobalt, applied in the direction of improving process efficiency, etc., can solve the problems of insufficient environmental protection, complicated treatment process, low recovery rate, etc., and achieve the effect of environmental protection process, simple process and fast leaching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

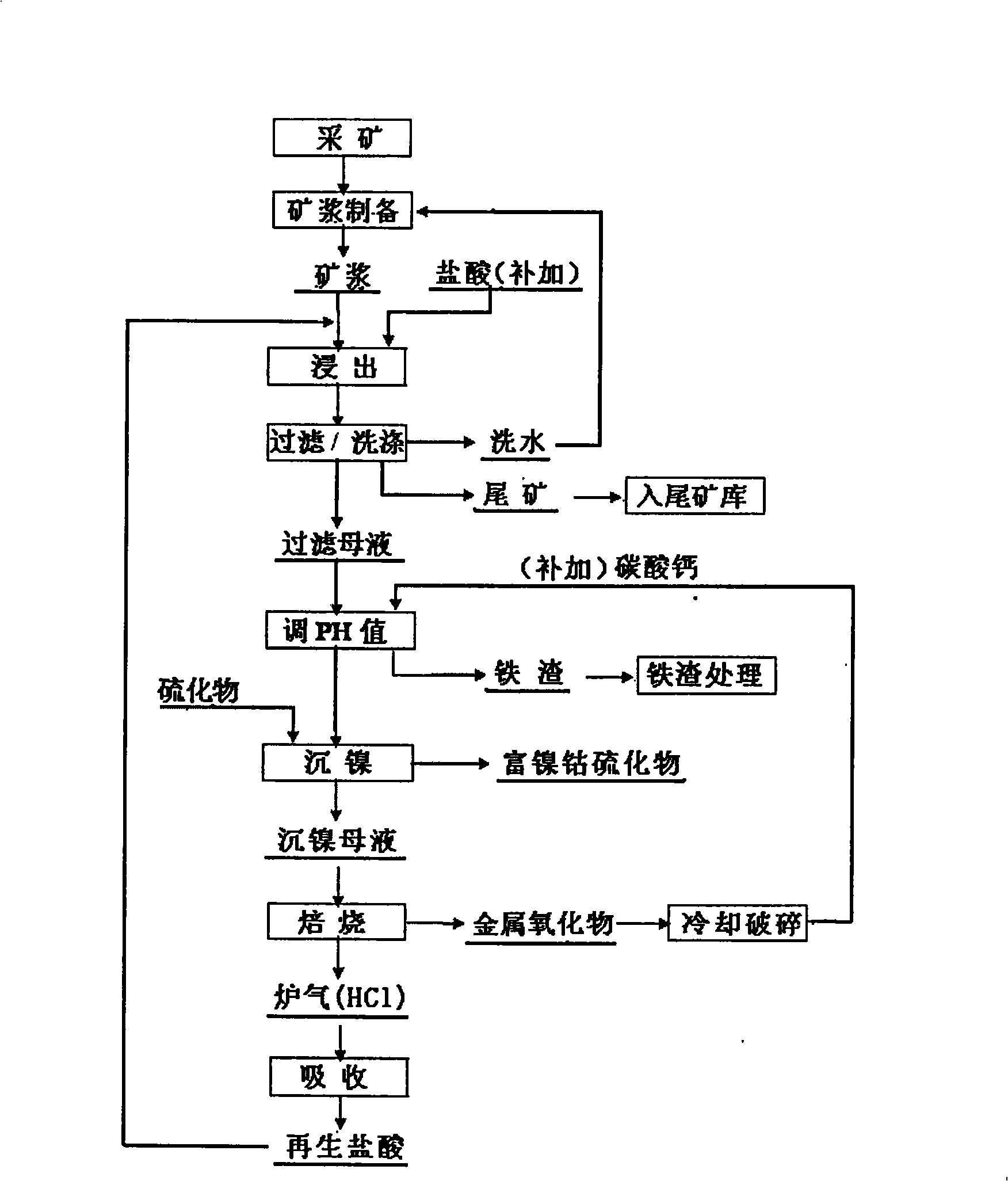

Method used

Image

Examples

Embodiment 1

[0025] Add water according to the ratio of material to water 1: 1 (wt) to ball mill the laterite nickel ore and pass through a 100 mesh sieve, get the -100 mesh slurry, add water and hydrochloric acid (hydrochloric acid) respectively according to the solid-liquid ratio of 3.5: 1 and the HCl / material ratio of 1.0 Mass percentage concentration more than 35%), stirring.

[0026] Leach according to the following procedure: stirring and leaching at room temperature for 1 hour; then raising the temperature to 40°C, stirring and leaching for 1 hour; and so on, leaching at 60°C, 80°C, and 90°C for 1 hour respectively, and the total leaching time is controlled for 5 hours.

[0027] Filter while hot, wash the residue, and analyze the mother liquor after constant volume. The results confirmed that the comprehensive leaching rate of nickel and cobalt was 92.7%.

Embodiment 2

[0029] Add water according to the ratio of material to water 1: 2 (wt) and the laterite nickel ore is ball-milled and passed through a 100-mesh sieve to get the -100-mesh slurry, and add water and hydrochloric acid (hydrochloric acid) respectively according to the solid-to-liquid ratio of 5: 1 and the HCl / material ratio of 1.4 Mass percentage concentration more than 35%), stirring.

[0030] Leach according to the following procedure: raise the temperature to 40°C for 1 hour with stirring and leaching; then raise the temperature to 80°C for 1 hour with stirring and leaching; then raise the temperature to 90°C for 1 hour with stirring and leaching, and control the total leaching time for 3 hours.

[0031] Filter while hot, wash the residue, and analyze the mother liquor after constant volume. The results confirmed that the comprehensive leaching rate of nickel and cobalt was 91.3%.

[0032] After leaching laterite nickel ore with hydrochloric acid, the contents of nickel and co...

Embodiment 3

[0034] Take the leachate, heat it to 90°C, stir; add 100g of industrial calcium carbonate per 1000ml of leachate to carry out the first neutralization operation on the leachate, neutralize for 1 hour, filter, and wash slightly; similarly, at 90°C Add 100g of industrial calcium carbonate to the filtrate to perform a second neutralization operation on the first neutralization solution, neutralize for 1 hour, filter, and wash slightly; then perform a third neutralization operation on the second neutralization solution at 90°C And, the amount of calcium carbonate added is based on the pH of the neutral solution at 3.0 to 4.0 as the end point, and the adjustment time is controlled for 1 hour, filtered and washed to obtain a neutralizing solution; the neutralizing solution composition (g / L) Ni 2.14; Co 0.17, pH3. 41.

[0035] Heat the neutralizing solution to 90°C and stir; add sodium sulfide (Na 2 S·9H 2 (0) 20.0g, slowly add sodium sulfide to the neutralization solution, the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com