Method for microbiological leaching of uranium-molybdenum ore and enrichment and separation of uranium and molybdenum

A separation method and microbial technology, applied in the field of hydrometallurgy, can solve the problems of secondary pollution of organic matter, complicated extraction process and unsatisfactory effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. The microbial leaching method of uranium-molybdenum ore is as follows:

[0044] (1) Ore crushing: first crush the uranium-molybdenum ore, and the crushed ore requires more than 200 mesh to account for more than 50% of the total, and -30 mesh to account for no more than 10% of the total;

[0045] (2) Biological oxidant leaching: Under normal temperature conditions, put the crushed ore into the solution of acidophilic thiobacterium ferrooxidans containing biological ferric iron for leaching, and the crushed ore and acidophilic ferrous oxide sulfur containing biological The solid-liquid mass ratio of the bacillus solution: 1:2-4 or the mass ratio of iron in the solution of acidophilic Thiobacillus ferrooxidans to molybdenum in the crushed ore is Fe:Mo=12-15:1; the solution is divided into not less than 4 part, soaking with one part solution each time, each soaking time is 8-12 hours, and then soaking next time after each soaking and discharging the leachate; the high ir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

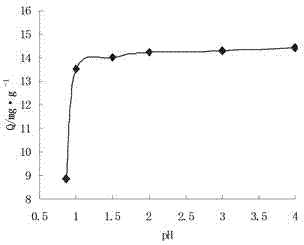

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com