Smelting method for improving phosphorus removal rate of converter

A converter dephosphorization rate and smelting method technology, applied in the manufacture of converters, etc., can solve problems such as poor fluidity of slag, limited dephosphorization efficiency, troublesome production organization, etc., to prevent foamy splashing, improve dephosphorization efficiency, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

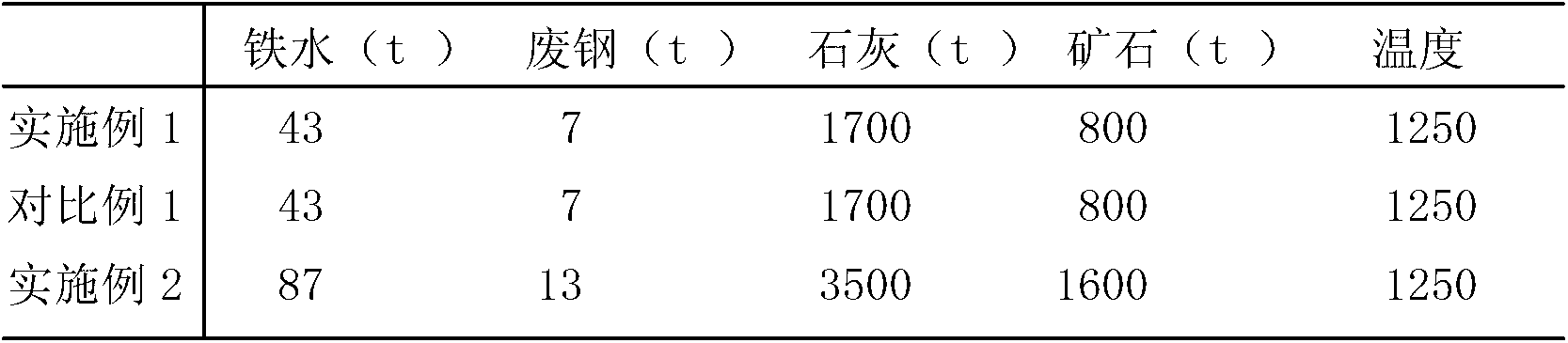

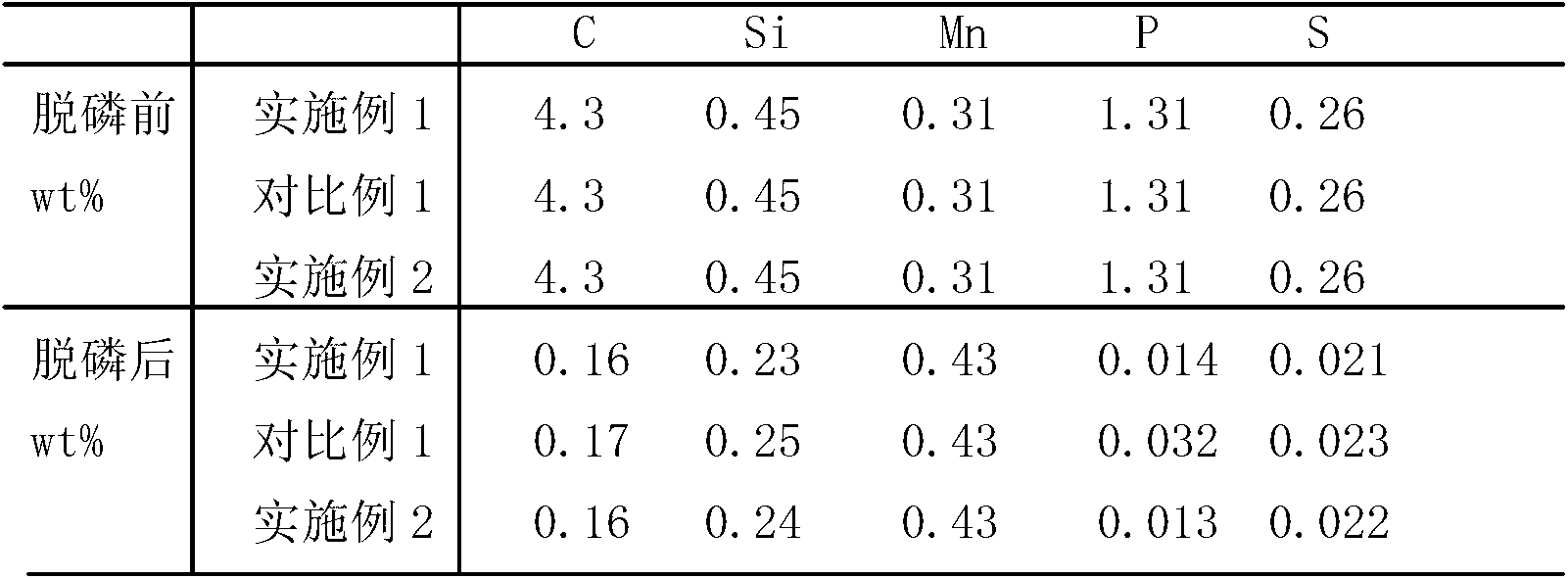

[0042] Example 1. A 50-ton oxygen top-blown converter is used, and the amount of feed is the amount per furnace.

[0043] A smelting method for improving the dephosphorization rate of the converter, the steps are as follows:

[0044] a. After the converter tapping is completed, the slag splashing is required to protect the furnace. The slag splashing is required. 600kg of lime is weighed during the slag splashing process. When the slag splashing process is about to be completed, add it into the furnace and use medium pressure nitrogen to stir for 15 seconds. Lift the gun, and then add scrap steel and add molten iron. The medium pressure nitrogen flow is controlled at 220±10Nm 3 / min.

[0045] According to the silicon content of the molten iron, the theoretical lime addition amount is calculated to be 1700kg, minus the 600kg preheated lime used in step a, and then set aside 200kg lime for 2 batches and 3 batches, and the remaining amount is 900 kg for a batch of raw lime Dosage

[00...

Embodiment 2

[0054] Example 2: Using 100 tons of oxygen top blowing converter

[0055] A smelting method for improving the dephosphorization rate of the converter, the steps are as follows:

[0056] a After the converter is tapped, the slag splashing protection operation is carried out. The slag splashing is required. During the slag splashing process, weigh 1200kg of lime, and add it to the furnace when the slag splashing is about to complete. Use medium pressure nitrogen to stir and lift the gun. Carry out the operation of adding scrap steel and adding molten iron.

[0057] According to the silicon content of the molten iron, the theoretical lime addition amount is calculated to be 3500kg, subtract the 1200kg preheated lime used in step a, and then set aside 500kg lime for 2 batches and 3 batches, and the remaining amount 1800kg is a batch of raw lime Dosage

[0058] b After the molten iron is added, the furnace is erected, the blowing lance is 1300mm (the oxygen lance is from the metal surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com