Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Fast slag formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Premelting slag for RH vacuum treatment deep desulfurization of ultra low carbon steel

The RH vacuum treatment deep desulfurization premelting slag for ultra-low-carbon steel comprises: 48~56% CaO, 33~43% Al2O3, 0.2~5.0% MgO, 2.5~6.0% SiO2ú¼TiO2íœ1.9, Cíœ0.05 and impurity, and is prepared by electric melting the material of super 60-65% limestone and 35-40% Al2O3 powder (Al-content more than 96%). This invention improves desulfurization capacity, produces Ca(AlO2)2 convenient to preserving, and has little corrosion to RH groove.

Owner:BAOSHAN IRON & STEEL CO LTD

No-fluorine composite slag melting agent for converter steelmaking and its production process

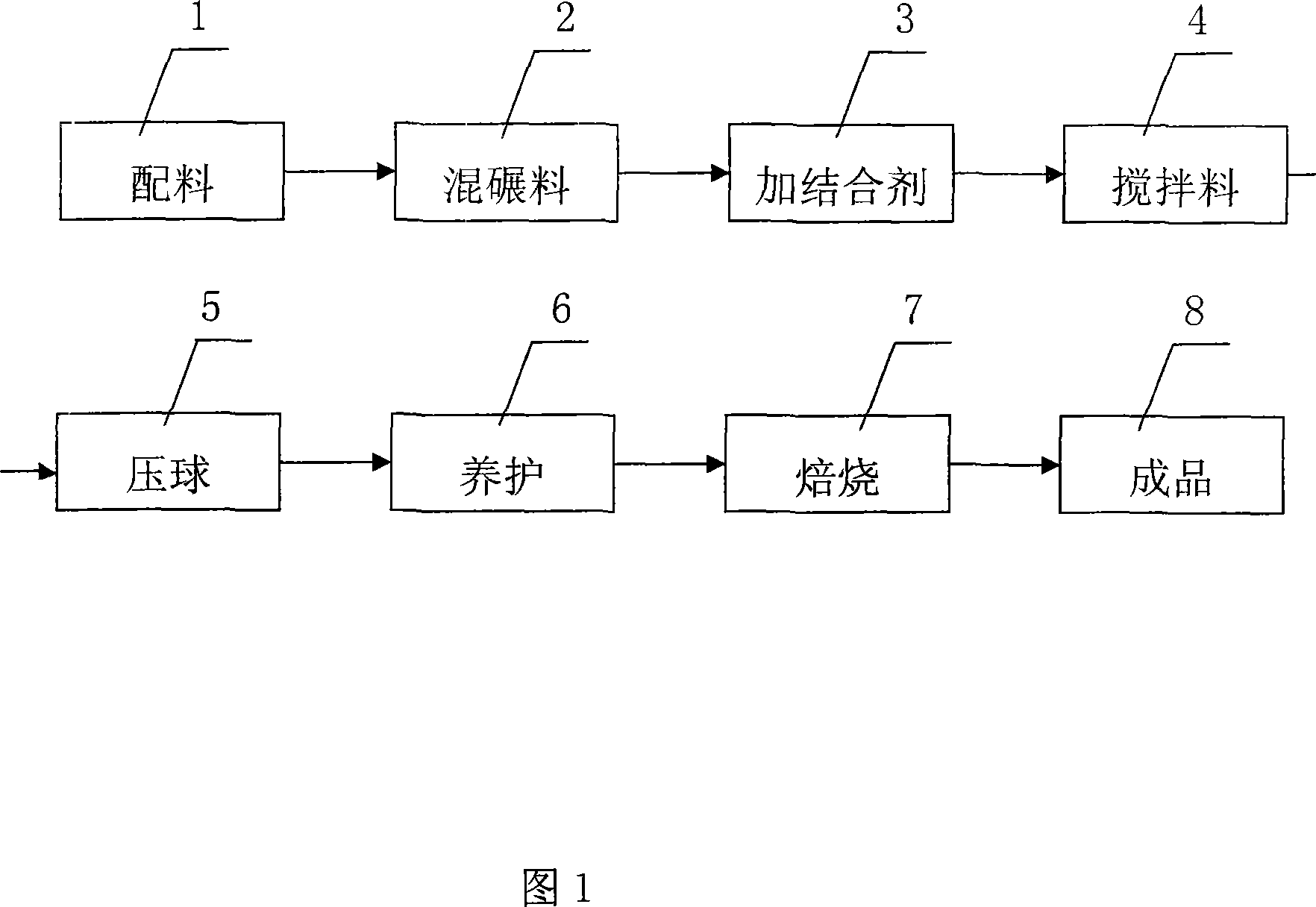

The present invention is one kind of no-fluorine composite slag melting agent for converter steelmaking and its production process. The no-fluorine composite slag melting agent as one kind of steelmaking supplementary material consists of FeO 40-50 wt%, CaO 10-20 wt%, MnO 12-45 wt%, H2O 0.5-1 wt%, MgO 1-8 wt%, Al2O3 and SiO2 1-10 wt%, and impurity for the rest. Its production process includes the steps of compounding, grinding, adding adhesive, stirring, pelletizing, curing and roasting. It is used in no-fluorine steelmaking with less invasion to converter lining, long converter service life, less environmental pollution, low production cost and other advantages.

Owner:郎雪 +1

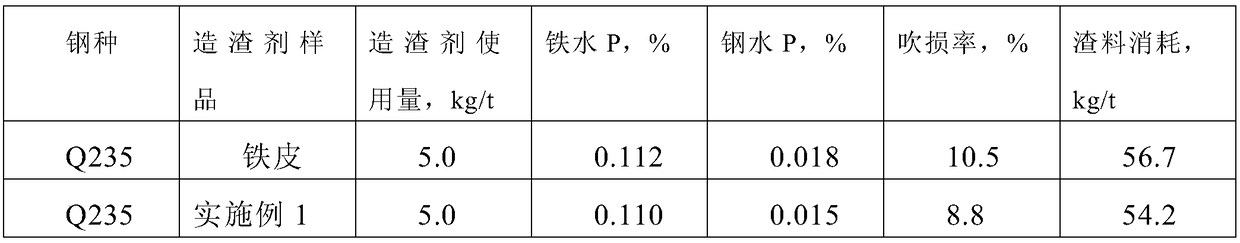

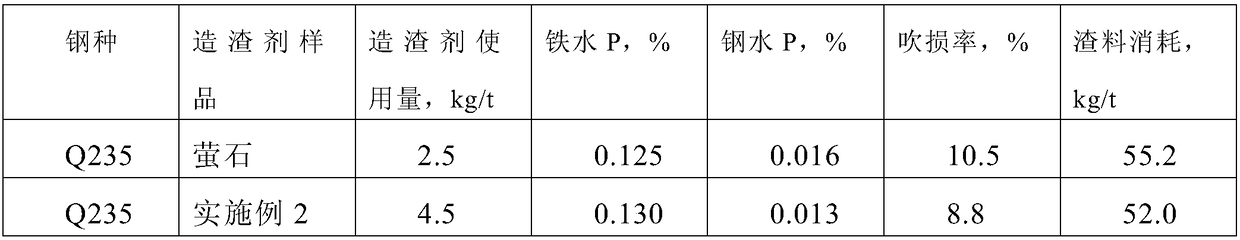

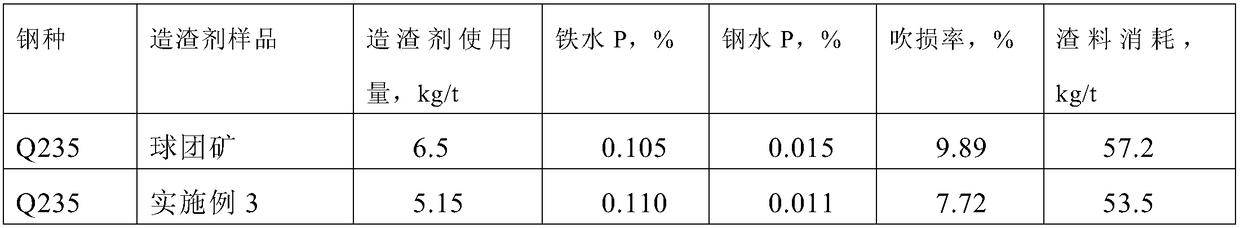

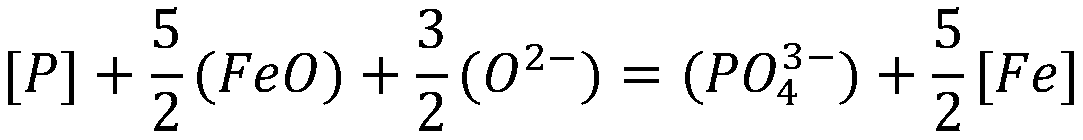

Dephosphorizing agent and application thereof

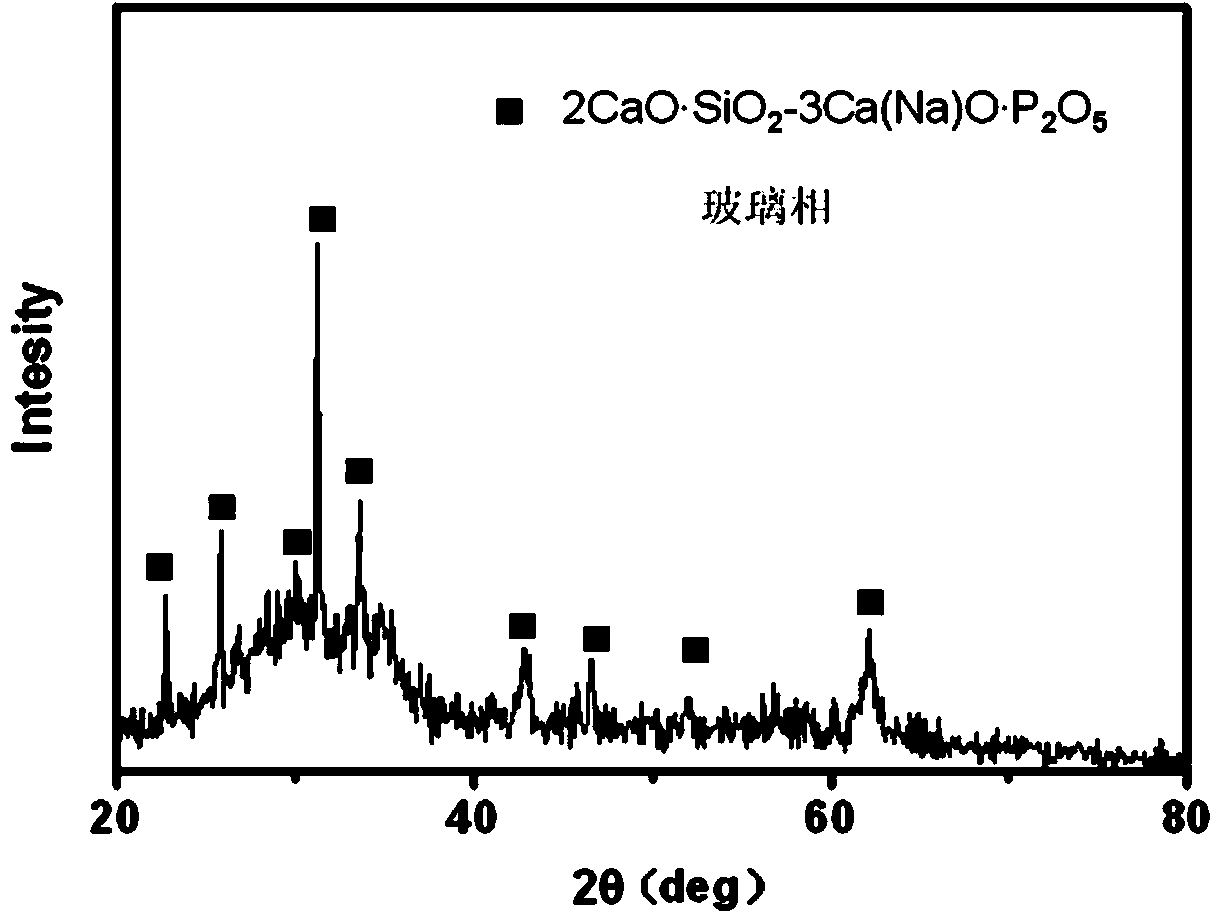

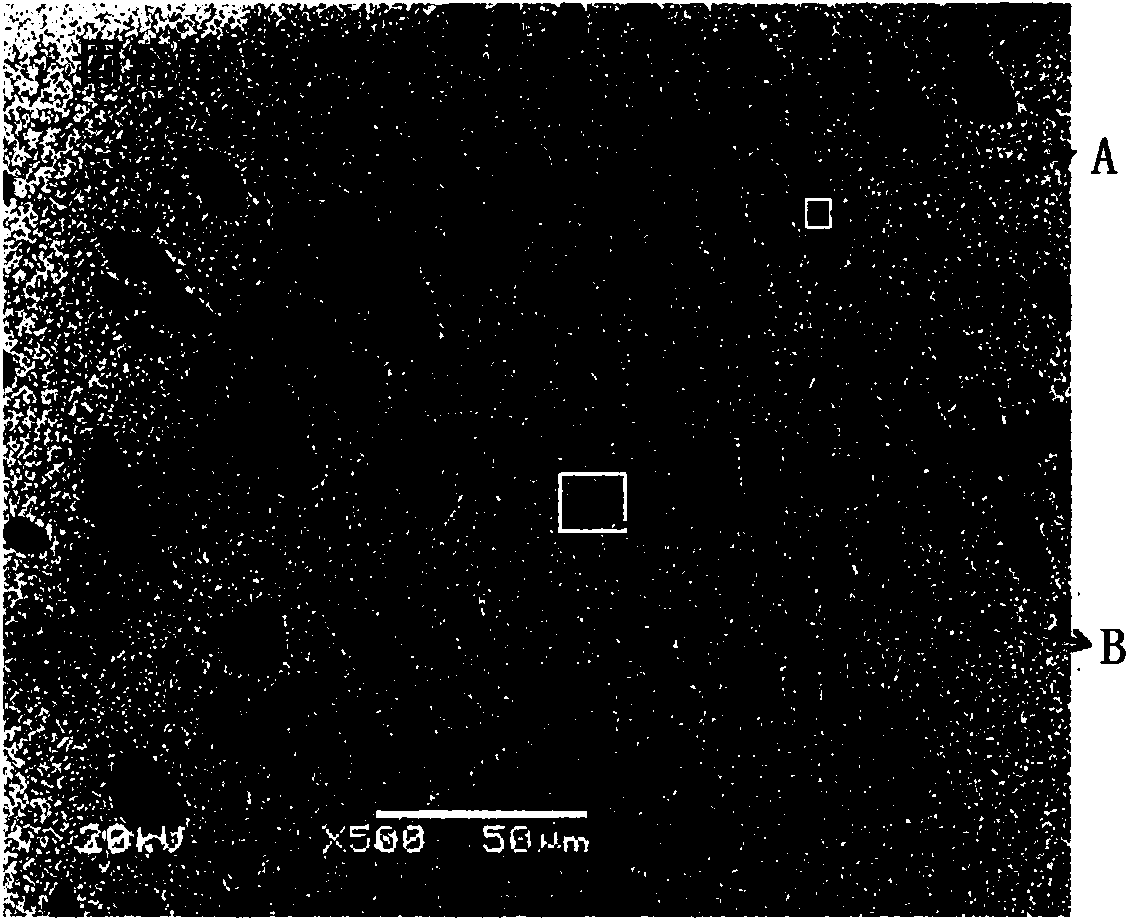

The invention relates to a dephosphorizing agent and application thereof, belonging to the technical field of ferrous metallurgy. The dephosphorizing agent solves the problems of low dephosphorizing efficiency, high residue consumption, environment pollution and difficulty in resource comprehensive utilization in the existing calcium-oxide-based molten iron pretreatment dephosphorizing agent. The dephosphorizing agent comprises the following components in percentage by mass: 25-50% of FeOt, 20-45% of CaO, 15-30% of SiO2, 2-10% of Na2O and 3-12% of Al2O3. After being molten, the molten iron dephosphorizing can form a solid-phase / liquid-phase coexistent multiphase residue system at 1300-1400 DEG C, wherein the solid phase is a 2CaO.SiO2 phase capable of providing a place for enriching oxidized phosphorus in molten iron, so that the dephosphorizing agent has the characteristics of favorable dephosphorizing effect, low slag consumption, no fluorine and small environmental pollution and is beneficial to comprehensive utilization of dephosphorizing slag.

Owner:CENT SOUTH UNIV

Molten iron dephosphorization agent manufactured by using converter dry-method dust-removal ash as raw material

InactiveCN102010933AIncrease alkalinityHigh CaO activityProcess efficiency improvementChemical compositionPre treatment

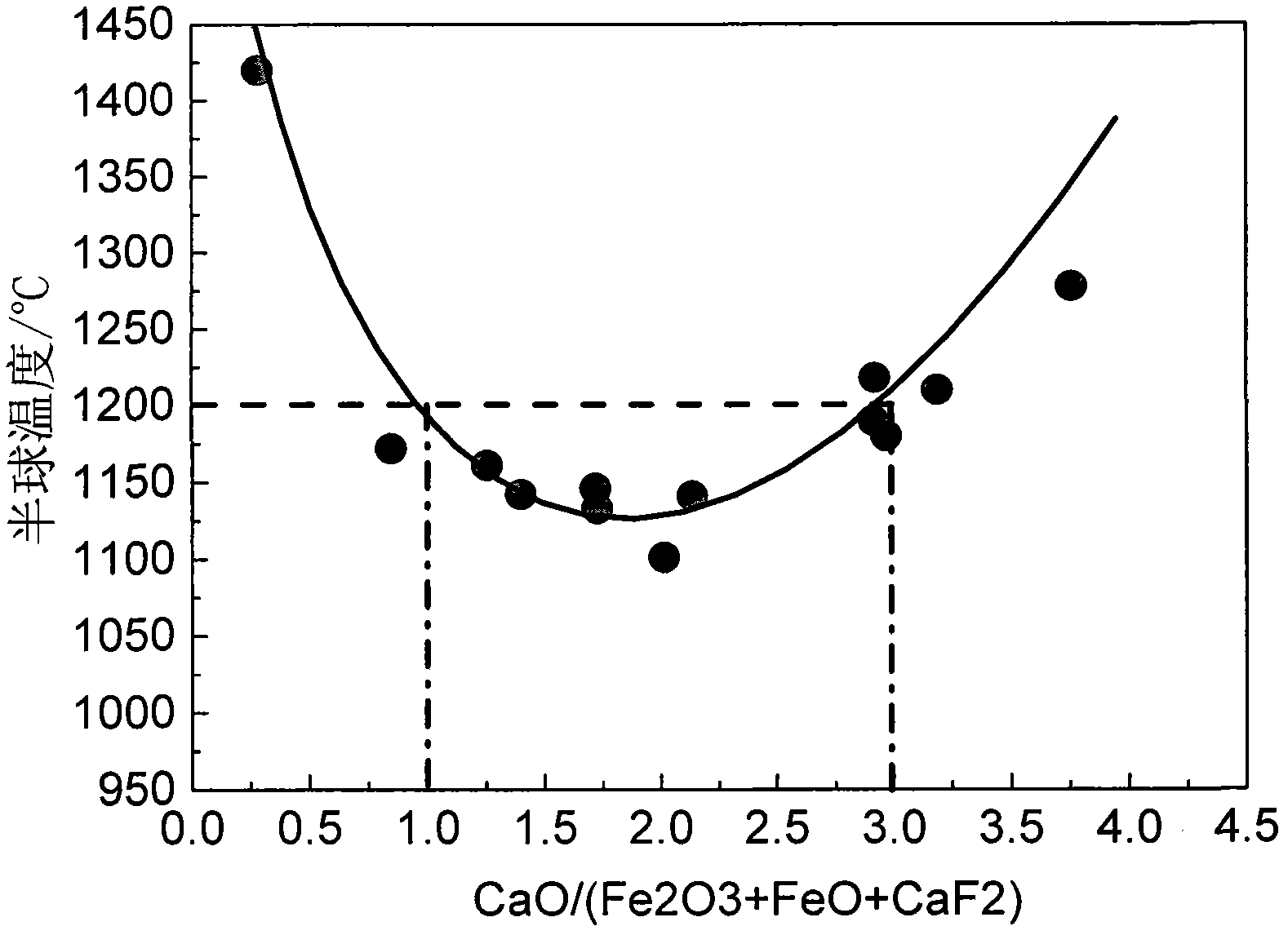

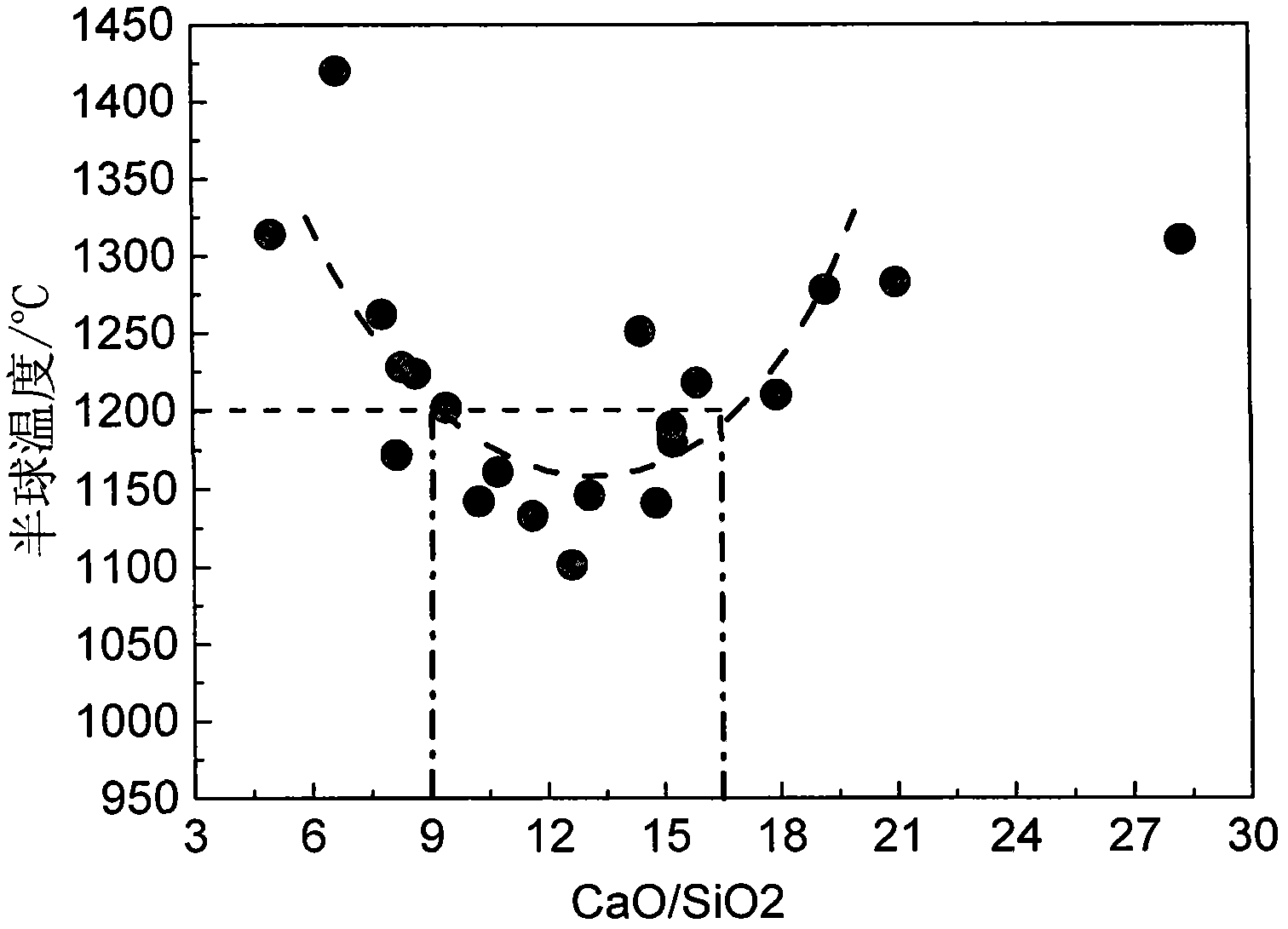

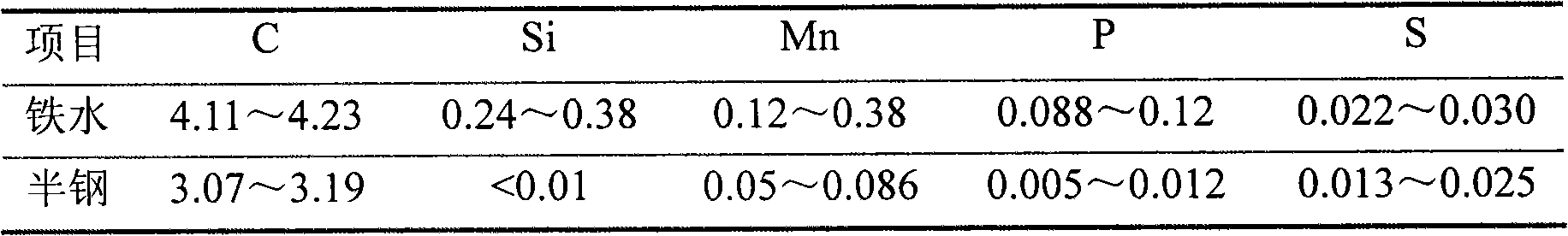

The invention discloses a molten iron dephosphorization agent manufactured by using converter dry-method dust-removal ash as a raw material, which belongs to the technical field of steel making and molten iron pretreatment and is applicable to converter molten iron dephosphorization treatment. The dephosphorization agent comprises the following chemical components in percentage by weight: 45 to 65 percent of CaO, 15 to 35 percent of iron oxides (Fe2O3+FeO), 5 to 15 percent of CaF2 and 2 to 6 percent of SiO2, wherein the ratio of CaO to Fe2O3+FeO+CaF2 ranges from 1.0 to 3.0, and the ratio of CaO to SiO2 ranges from 9 to 16; and the hemispherical fusion temperature of the dephosphorization agent is not more than 1,200 DEG C. The raw material of the dephosphorization agent comprises 20 to 60 percent of converter dry-method dust-removal ash, 20 to 60 percent of active lime powder and 5 to 20 percent of fluorite powder. The dephosphorization agent has the advantages that: after the converter molten iron dephosphorization pretreatment is performed by using the dephosphorization agent, the P content can be kept below 0.030 percent; the converter dry-method dust-removal ash is recycled in a steel making process; and the cost of the converter dephosphorization pretreatment is reduced considerably.

Owner:CENT IRON & STEEL RES INST

Method for heat application of low-alkalinity casting residue in steel-making

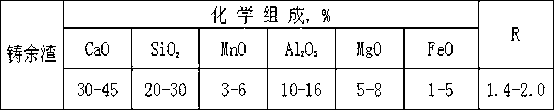

ActiveCN102994689ALow production costRealize full recyclingManufacturing convertersProcess efficiency improvementSteelmakingAlkalinity

The invention provides a method for heat application of low-alkalinity casting residue in steel-making. The method comprises the following steps that: 5 to 7kg / t of low-alkalinity casting reside of steel slag is added to a converter along with semi-steel under a hot steel state in order to fully utilize the heat of the molten casting residue, and the slag can be quickly generated by blowing for 2 minutes. By adopting the method, the complex slag forming constituent and heating agent requested in a conventional semi-steel smelting process are saved, and the production cost is reduced; the high-alkalinity slag can be quickly formed at low temperature in accordance with the slag formation system; the content of phosphorus of 0.35 to 0.80% in the molten ion can be quickly removed within the normal smelting period, and the final requirement of steel grade can be met; all casting residues in steel making are basically recycled, so that the pressure of residue discharge to the environment and the handling cost can be reduced, and remarkable environment protection benefit is brought. The method brings no change to original requirement, is high in dephosphorization efficiency, and little in influence on the converter melting furnace and the capacity, can expand the steel-making capacity, is high in storage capacity and low in cost, and can be used for expanding the application of phosphorite, and reducing the production cost.

Owner:WUKUN STEEL

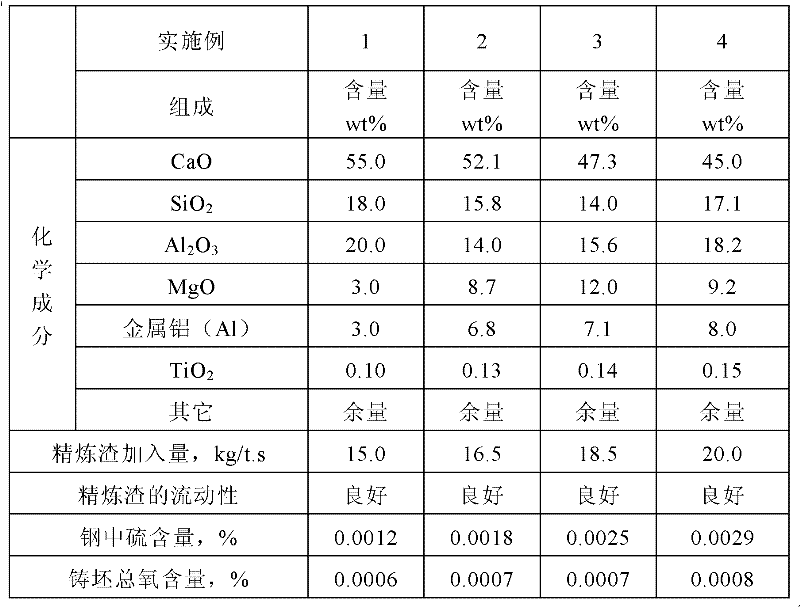

Refined slag used in steel-making process for bearing steel

The invention provides refined slag used in a steel-making process for bearing steel, which comprises the following raw materials by weight percentage: 45-55% of CaO, 14-20% of Al2O3, 14-18% of SiO2, 3-12% of MgO, 3-8% of metallic aluminum, less than or equal to 0.15% of Ti, less than or equal to 0.050% of P+S and the balance of impurities. The granularity of refined slag is 10-40mm. The CaO / SiO2 value can be controlled in the range of 2.7-3.5. The refined slag can effectively control the form, the composition, the size distribution and the like of the impurities in steel and has obvious effect for improving the quality of the bearing steel. The slag system has the advantages of fast slag forming speed, strong deoxidation and desulphurization capability, strong adsorption capability on impurities, controllable compositions and types of impurities in steel and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

Foamed dephosphorization pellet and preparation method thereof

InactiveCN101818229ALess slagSolve the problem of moisture brought into molten steelProcess efficiency improvementElectric furnaceAdhesiveSulfur

The invention provides a foamed dephosphorization pellet and a preparation method thereof. The pellet consists of the following components: 15 to 40 percent of calcium oxide (CaO), 15 to 40 percent of carbon (C), 20 to 30 percent of ferric oxide (Fe2O3), 1 to 3 percent of sodium oxide (Na2O) and 20 to 40 percent of caustic soda. The preparation method for the pellet comprises the following steps of: preparing limestone, low-sulfur coal powder, iron oxide red and soda ash according to the component content of the foamed dephosphorization pellet, mixing the materials uniformly by using a mixer, then adding a little amount of adhesive into the mixture, and pelleting the mixture by using a disc pelleting machine. The dephosphorization pellet of the invention does not produce pollution to the environment, so the pellet is favorable for environmental protection; the pellet has good dephosphorization effect and is favorable for improving the quality of the steel; and the pellet has little corrosion to a furnace lining, can reduce the using amount of lime fed into the furnace so as to simplify the operation in front of the furnace, and has obvious comprehensive economic benefit.

Owner:ANGANG STEEL CO LTD

Method for improving purity of molten steel in argon station

The invention discloses a method for improving purity of molten steel in an argon station, which comprises the following steps of: (1) adding 30 to 60kg of lime, 20 to 40kg of calcium carbide and 130 to 160kg of premelted refining slag into a steel ladle before argon blowing, and increasing argon quantity for strongly blowing argon, wherein the strong argon blow standard is that the sum of the diameters of blown open holes of the molten steel is controlled to be between 400 and 600mm; (2) after strongly blowing argon for 1 to 3 minutes, adding aluminum wires into the steel ladle; (3) after strongly blowing argon for 6 minutes together, reducing argon quantity for softly blowing argon, wherein the soft argon blow standard is that the sum of the diameters of blown open holes of the molten steel is controlled to be between 200 and 400mm, and the soft argon blow time is ensured to be more than or equal to 6 minutes; and (4) making the total argon blow time for the molten steel in the argon station more than or equal to 12 minutes, closing the argon when the temperature accords with the liquidus temperature of between 50 and 65 DEG C, and adding an alkaline covering agent and carbonized rice husks into the steel ladle. The premelted refining slag is added into the argon station, the process is easy to operate and the purity of the molten steel can be effectively improved.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Fluoride-free refining slag for 20 Cr structural alloy steel and preparation method thereof

InactiveCN103849712AEliminate pollutionMeet the requirements of green metallurgyRecovering materialsGranularitySlag

The invention discloses fluoride-free refining slag for 20 Cr structural alloy steel and a preparation method thereof. The granularity of the fluoride-free refining slag is 15-35mm, and the fluoride-free refining slag comprises the following components in percentage by weight: 55-60% of CaO, 10-16% of SiO2, 15-20% of Al2O3, 4-6% of MgO, 5-10% of B2O3, less than or equal to 1% of TFe and the balance of impurities. The preparation method of the fluoride-free refining slag comprises that mineral ore raw materials containing CaO, SiO2, Al2O3, MgO and B2O3 are crushed and blended and then moulding and crushing are carried out, so that the fluoride-free refining slag finished product is obtained. The preparation method of the fluoride-free refining slag is simple, and the prepared fluoride-free refining slag has the advantages of environmental friendliness, no fluoride, high slagging speed, strong slag inclusion removal capability, less furnace lining corrosion and strong desulphurization capability.

Owner:武钢集团有限公司

Premelting composite slugging agent for converter and preparation method thereof

InactiveCN109338027AConducive to smeltingResist drynessManufacturing convertersProcess efficiency improvementEnvironmental resistanceSlag

The invention relates to a premelting composite slugging agent for a converter and a preparation method thereof. The slugging agent comprises raw materials of lime, ferric oxide powder, activated aluminum oxide powder, low-sulfur cement, silica powder and an activating agent, wherein the raw materials comprise the following components in percentage by mass: 15-35% of CaO, 15-35% of Fe2O3, 5-15% ofAl2O3, 5-15% of MgO, and not greater than 15% of SiO; and the slugging agent contains not greater than 0.25% of impurity element S. According to the slugging agent, the raw materials are environmentally friendly; the melting point is low; the slagging speed is high; the breathability of slags can be obviously improved; the splashing in the converting process is reduced; and meanwhile, the slugging effect in the converting process can be effectively improved through the slugging agent, and the converting process is stable; the slugging agent avoids re-drying and gun adhering; in addition, theend point oxygen of a converter can be decreased after the converting slugging effect is improved, so that the oxidization of the slags can be reduced; the steel iron consumption is decreased; and theproduction cost is reduced.

Owner:武汉钢铁有限公司

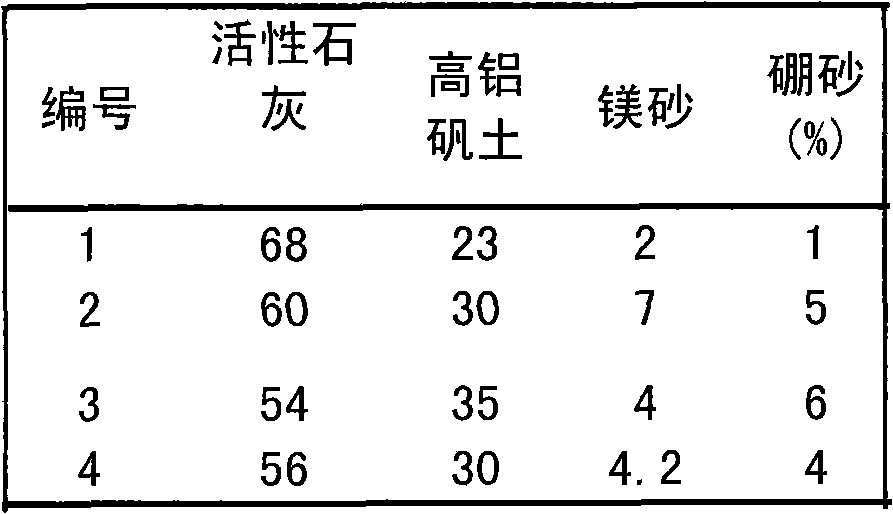

Pre-melted refining slag

InactiveCN102115805AShort refining timeFast slag formationProcess efficiency improvementLiquid steelAluminium

The invention discloses pre-melted refining slag comprising the following components in proportion by weight: 54-68 portions of active lime, 23-35 portions of high-alumina bauxite, 1-6 portions of borax and 2-7 portions of magnesite. The invention has the advantages of short refining time, high scorification speed, good desulfurization degree, no rephosphorization, low abrasion to a ladle liner, no caking of slags, complete smelting within two minuets after electrification and reduction of energy loss. Compared with a sintering shaft furnace, the electro-smelting has less sulphur and phosphorus-containing detrimental impurities, no pollution of liquid steel, large refining slag sulfur-washing capacity and more than 80 percent of desulfurization degree with the adoption of adequate lime; the sulfur content of an LF finished product can be controlled beneath 0.001 percent, the HR sulfur content can be controlled beneath 0.0005 percent, pulverization is avoided, and the shelf life is more than half year.

Owner:丹东泓辉科大高温材料有限公司

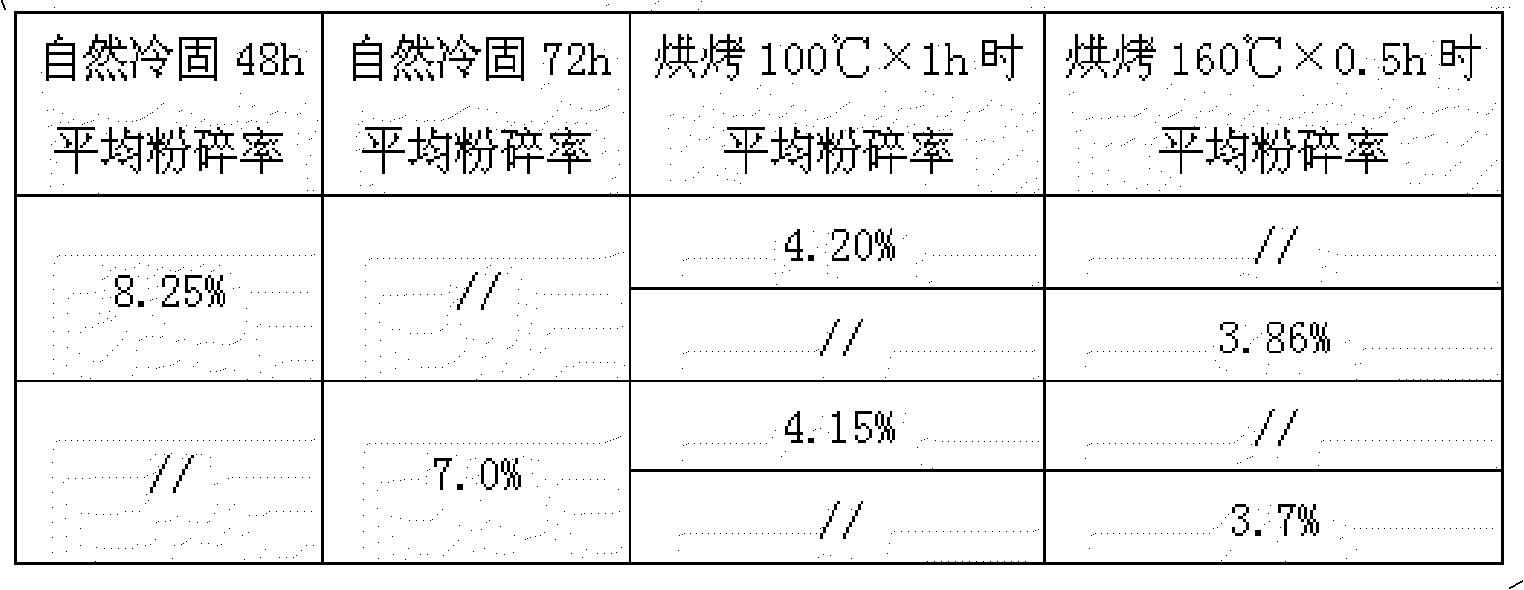

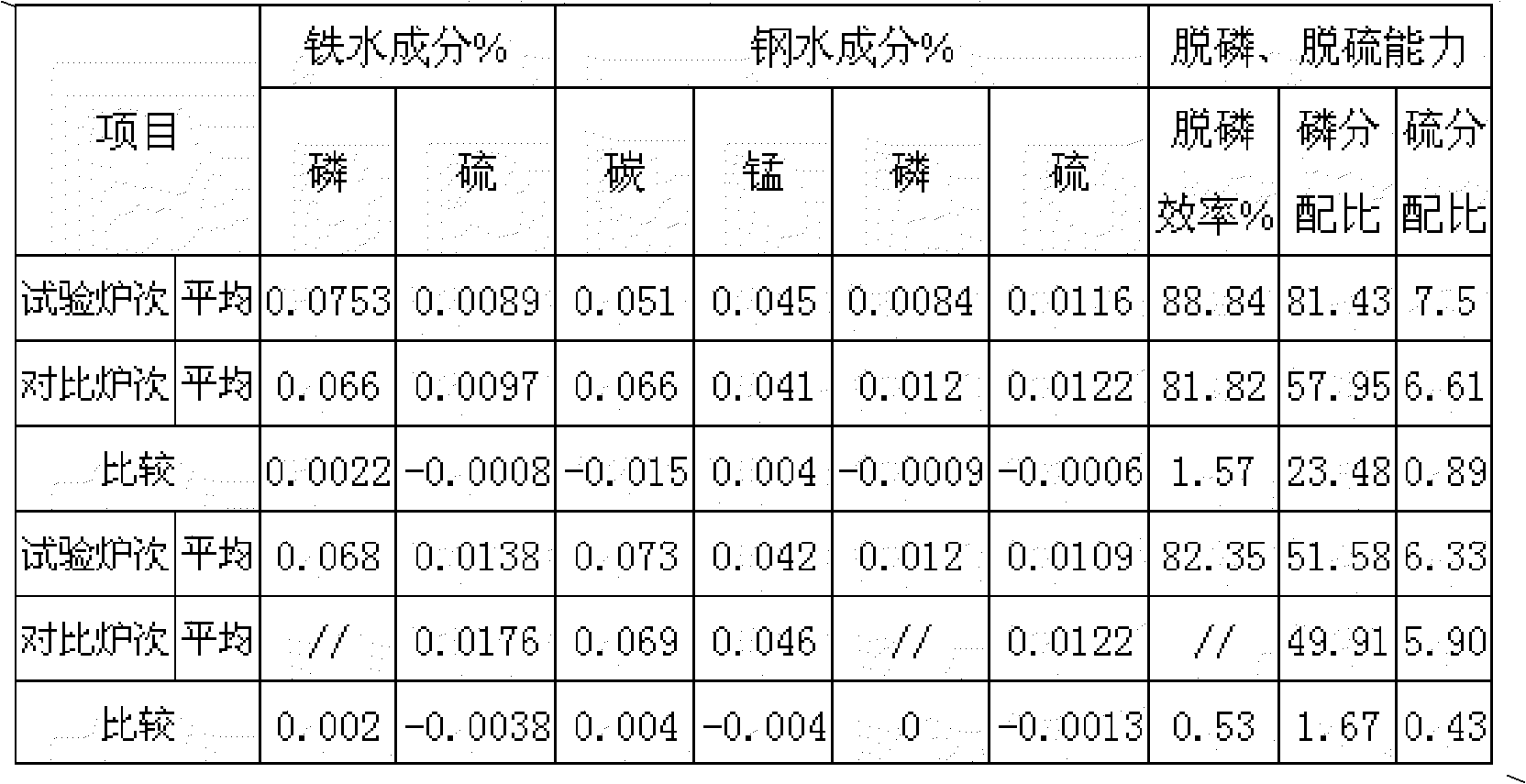

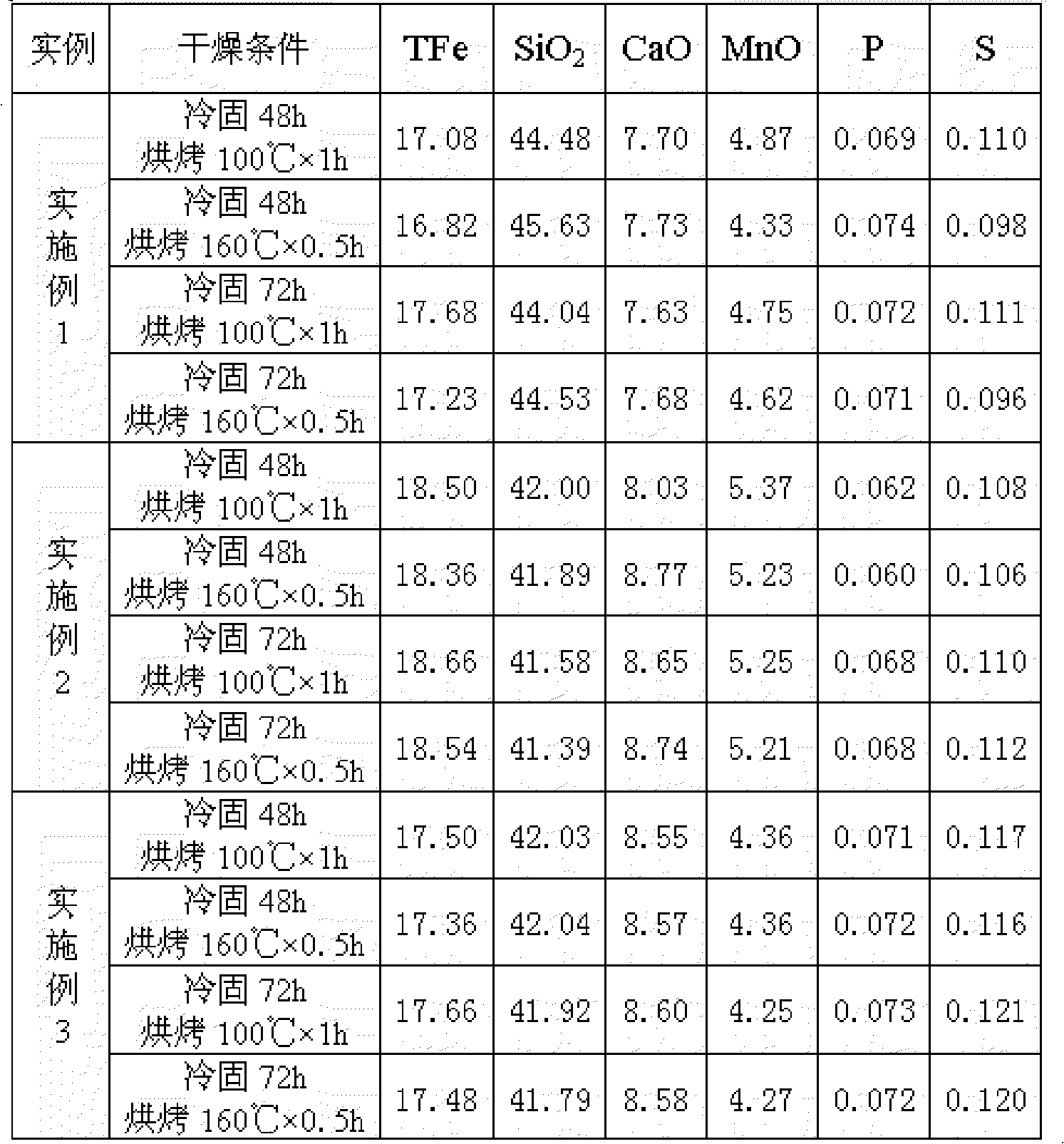

Method for refining high carbon molten steel by using low aluminum steel casting residue

The invention relates to comprehensive utilization of casting residue, in particular to a method for refining high carbon molten steel by using low aluminum steel casting residue with the Al content of less than or equal to 0.0040 percent. The method comprises the following steps of: 1, preparing refinery residue: collecting aluminum steel casting residue with the alkalinity of 2.0 to 4.5 and the Al content of less than or equal to 0.0040 percent; crushing the residue; grinding the residue; adding an inorganic adhesive agent or an organic adhesive agent; pelletizing; and baking residue; 2, adding the refinery residue prepared in step 1 within 30 seconds after the deoxidizing alloying of the molten steel; and 3, controlling the time from pouring to the refining completion within 15 to 30 minutes, and controlling basicity of the residue after the refining completion to be 2.1 to 2.8. The method has the advantageous of realizing the comprehensive cyclic utilization of the low aluminum high carbon steel casting residue, and reducing the environmental pollution and field occupation along with simple and feasible technology, low cost, good slag formation, high slag formation speed, and short slag formation time. Though the refining time is relatively prolonged, the quality of the molten steel is improved.

Owner:武汉钢铁有限公司

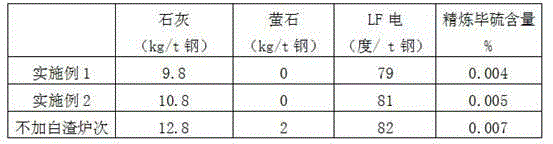

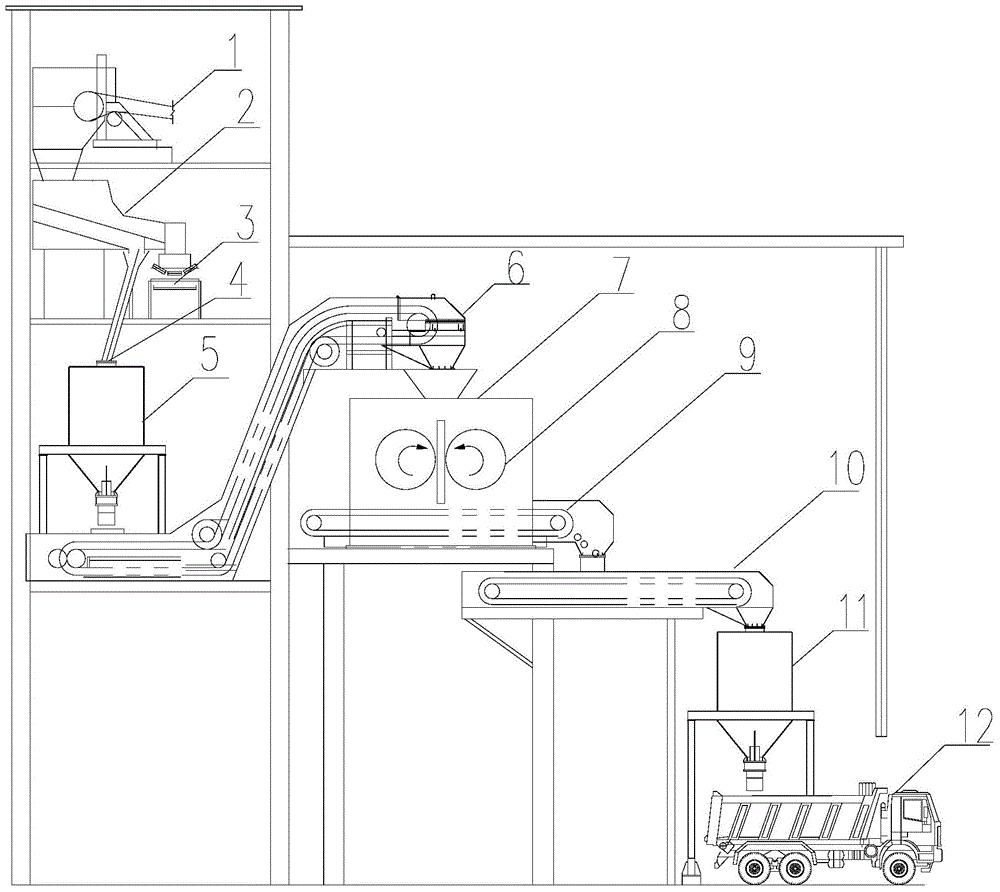

Fluorin-free composite quick slag-forming constituents for convertor steelmaking and method of producing the same

InactiveCN101368222AFast slag formationGood dephosphorization effectManufacturing convertersSteelmakingTO-18

The invention discloses a fluorine-free compounded fast slagging agent used for the steel-making of a converter, which comprises the components with the following weight percentage: 35 to 45 percent of MnO; 15 to 18 percent of CaO; 15 to 30 percent of TFe; 5 to 15 percent of MgO; 0.5 to 0.7 percent of H2O; 2 to 5 percent of Al2O3; 1 to 3 percent of organic bond. The invention also discloses a preparation method for the fluorine-free compounded fast slagging agent used for the steel-making of a converter. The fluorine-free compounded fast slagging agent used for the steel-making of a converter not only can be environmental friendly to prepare slag without fluorine, but also can increase the content of Mn at the end point of the molten steel, reduce the consumption of Mn alloy at the anaphase and reduce the cost. After the fluorine-free compounded fast slagging agent is used, the liquidity of the molten steel is good; the phenomena of spraying and dry returning of the molten steel can be reduced; besides, a lance-sticking phenomenon can be effectively reduced; the generating of a large lance knob is restrained; moreover, the sludging speed can be obviously improved and the dephosphorization effect can be improved to promote the dephosphorization of the convertor.

Owner:JIANGSU ZHENGDA FURNACE CHARGE

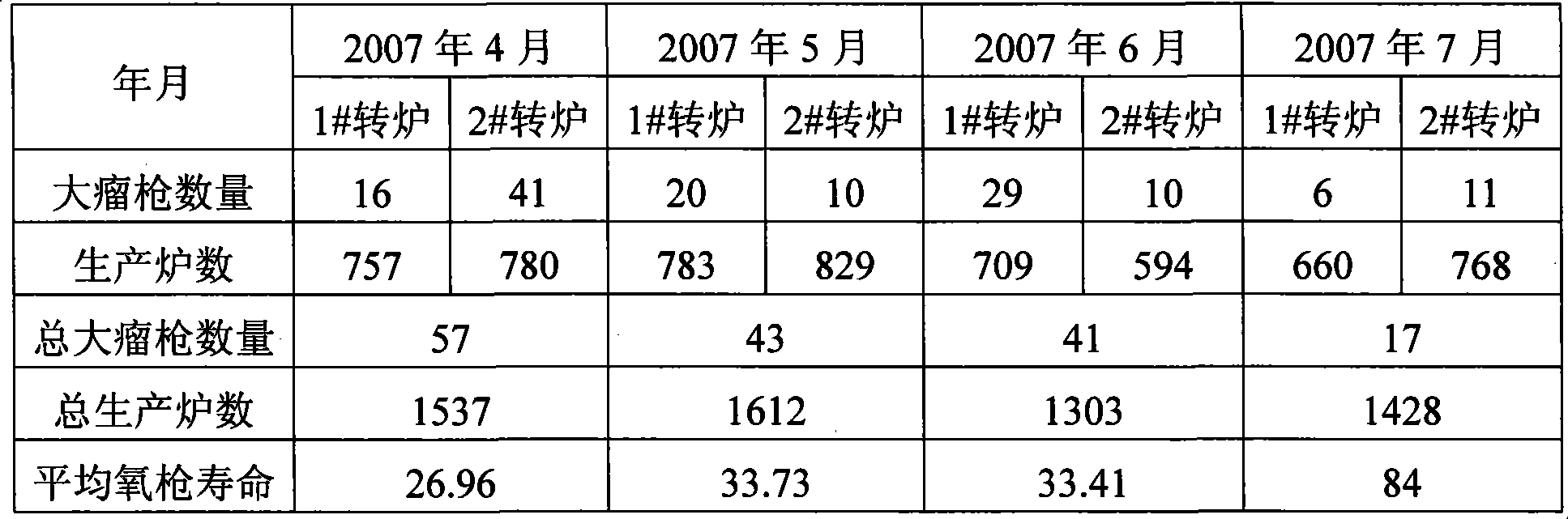

Recycling method of refining white slag

InactiveCN104404176ALow melting pointReduce consumptionRecycling and recovery technologiesProcess efficiency improvementElectricitySlag

The invention discloses a recycling method of refining white slag, the method is as follows: the white slag is added, before a slagging agent, into the molten steel which is refined or ready to refine; refined lime melting point is 2614DEG C, only after the addition of fluorite, aluminum bauxite and other slagging agent, the melting point can be reduced for slow slagging, the fluorite dosage is about 2kg per ton of steel, aluminum bauxite dosage is about 3kg per ton of steel; and after the recycled white slag is added, the part of the material can be completely or partially replaced. The method makes full use of the low melting point characteristic of the refining white slag, the rate of slag formation is improved, refining energy consumption is reduced, the problems of high treatment cost and large environmental pollution of the refining white slag can be effectively solved, refining electricity and refining lime and fluorite and other slagging agent consumption can be reduced, the molten steel quality is not reduced, at the same time, the method can reduce waste emissions, reduce air pollution, and effectively reduce the production cost, and has the characteristics of energy saving and environmental protection and low cost.

Owner:WUYANG IRON & STEEL

Special continuous casting crystallizer casting powder for ESP low carbon

The invention relates to special continuous casting crystallizer casting powder for ESP low carbon, and belongs to the field of metallurgy accessories. The casting powder comprises chemical componentsincluding, by weight, 28-33 parts of CaO, 22-29 parts of SiO2, 4.5-7.5 parts of MgO, 4.5-7 parts of Al2O3, 7-10 parts of Na2O, 8-11 parts of F, 0.3-1.5 parts of B2O3, 0.5-1 part of Li2O and 1-3.5 parts of C. The casting powder has the low melting temperature, low viscosity and high melting speed, the casting powder can be rapidly consumed when the continuous casting pulling rate is 5-7 m / min, andaccordingly heat transfer and lubricating performance between a continuous casting blank shell and a crystallizer copper plate are guaranteed.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Method for producing calcium ferrite from iron oxide

The invention discloses a method for producing calcium ferrite from iron oxide. The method utilizes an iron electrode to realize electric smelting, utilizes the iron electrode to produce calcium ferrite, prevents an additional component from entering into calcium ferrite, improves calcium ferrite purity and realizes better calcium ferrite actual use effects. In steel-making, through use of the calcium ferrite obtained by the method, a slagging rate is fast, dephosphorization efficiency is high, a lime use amount is reduced, fluorine-free steel-making is realized and environmental pollution is reduced.

Owner:ZHENGZHOU WHALE SPECIAL MATERIALS

Slag stopping material, slag stopping method and combined technology method of slag stopping and slag splashing protection

InactiveCN102943143ASolve the problem of slaggingReduce thicknessManufacturing convertersMaterial consumptionSlag

The invention relates to a slag stopping material, a slag stopping method and a combined technology method of slag stopping and slag splashing protection. The sum of mass percentages of CaO, MgO and C in the slag stopping material accounts for over 40% of the total mass of the slag stopping material, igloss is smaller than 47% of the total mass of the slag stopping material, and the mass percent of C is not more than 25% of the total mass of the slag stopping material. The slag stopping method comprises the step of putting a certain amount of slag stopping material on the liquid level area over a steel tapping hole in a converter. The slag stopping material, the slag stopping method and the combined technology method of slag stopping and slag splashing protection have the following beneficial effects: roughing slag amount is reduced, the thickness of the slag blanket in a ladle is thinned obviously, the tasks of deoxidation of molten steel in the ladle and modification of top slag are relieved, the consumption of deoxidizer is lessened, the phenomena of rephosphorization and silicon pick up in the refining process of the molten steel are reduced, the consumption of slag regulating materials is lowered, the time of molten steel refining is shortened and the smelting cost is decreased; and after steel tapping is finished, the slag stopping material can be directly used as a slag splashing protection material, the use amount of the slag splashing protection material is reduced, the time of slag splashing protection is shortened and the working efficiency of the converter is enhanced.

Owner:INST OF METALLURGICAL TECH DONGBEI UNIV SHENYANG

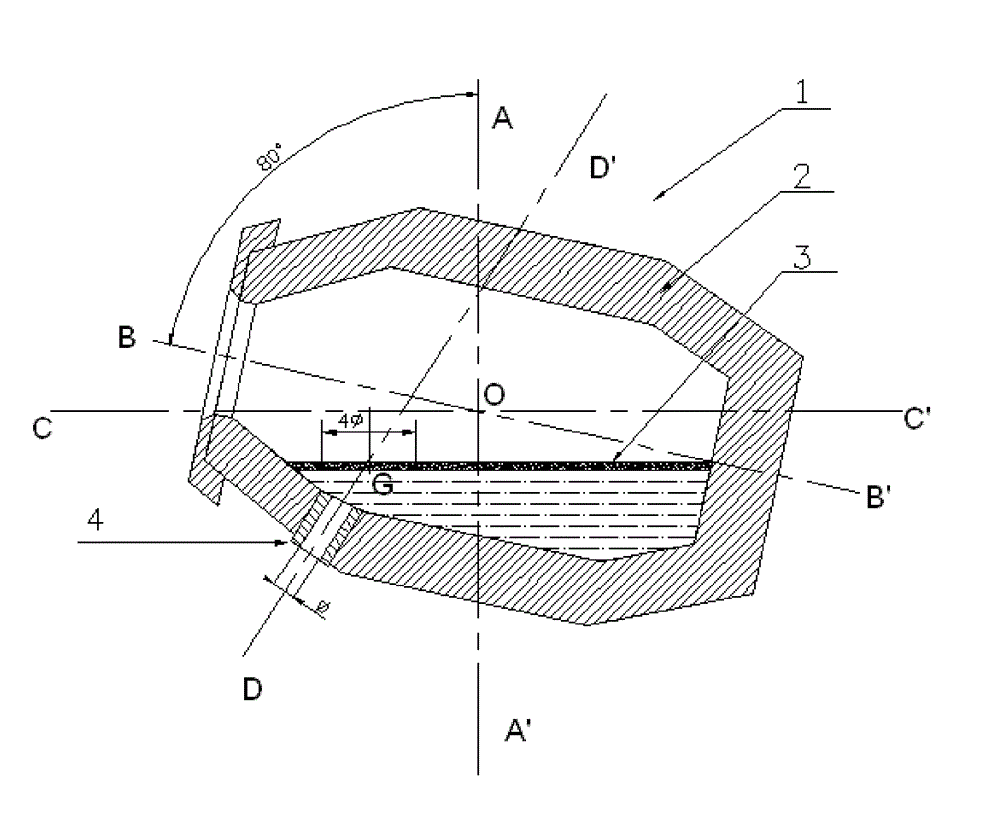

Metallurgy lime powder utilization system and technology method

InactiveCN104946853AControl granularityHigh activityProcess efficiency improvementMetallurgyMaterials science

The invention discloses a metallurgy lime powder utilization system and a technology method. The system and the technology method are mainly designed for effective recycling of lime powder in the metallurgy process. The metallurgy lime powder utilization system comprises a vibrating sieve, a lime powder ball press and a lime powder conveying unit, wherein the vibrating sieve is arranged on a lime raw material supply section and used for screening lime powder with the grain size smaller than 5 mm; the lime powder ball press is used for performing ball pressing on lime powder, and the lime powder conveying unit is used for communicating the vibrating sieve and the lime powder ball press. The lime powder conveying unit conveys the lime powder screened out by the vibrating sieve to the lime powder ball press, the lime powder ball press carries out ball pressing on the lime powder so that lime balls with the grain size being 20-40 mm and the special gravity being 1.9-2.2 t / m<3> can be obtained, and the lime balls are returned for steel making. The lime powder for metallurgy and with the grain size smaller than 50 mm is separated, recycled and used. Meanwhile, negative effects of the lime powder in the steel making and producing process are also avoided.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

Circulating dephosphorization steelmaking method in converter steel slag furnace

InactiveCN108676954AReduce consumptionAchieve recyclingManufacturing convertersProcess efficiency improvementSteelmakingPhosphorus

The invention relates to a circulating dephosphorization steelmaking method in a converter steel slag furnace and belongs to the technical field of metallurgy. The method comprises the steps of firstfurnace smelting, second furnace smelting, third furnace smelting, fourth furnace smelting, fifth furnace smelting, ......, and twentieth furnace smelting. In the first furnace smelting, semi-steel isblended in a furnace, oxygen is blown into the furnace, a first slagging material is added when blowing, the alkalinity of the slag at the end point is controlled to 3-4 to the end of the blowing, splashing of the slag after tapping is performed, and all the steel slag is retained. In the second furnace smelting, the amount of the first slagging material is halved, and the rest procedures are performed in the same way as the first furnace smelting. In the third furnace smelting, a double-slag retention method is adopted, no feeding is needed during the dephosphorization period, the alkalinityof the slag is adjusted to 1.5-2.5, dephosphorization at low temperature is performed, some of the phosphorus-rich slag is poured out, a second slagging material is added for secondary slagging, andall the steel slag is retained. In the fourth furnace smelting, the slagging smelting is performed again by a single slag method, half of the slag is poured out after the tapping, and the smokeless coal gasification dephosphorization is added when the slag is splashed; and the rest procedures are performed in the same way as the second furnace smelting. The procedures of the processes from the fifth furnace smelting to the twentieth furnace smelting are performed in the same way as the fourth furnace smelting. The method is simple, the slagging speed is high, the dephosphorization effect can be ensured under the condition of low auxiliary material consumption, and the steel slag recycling is realized.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

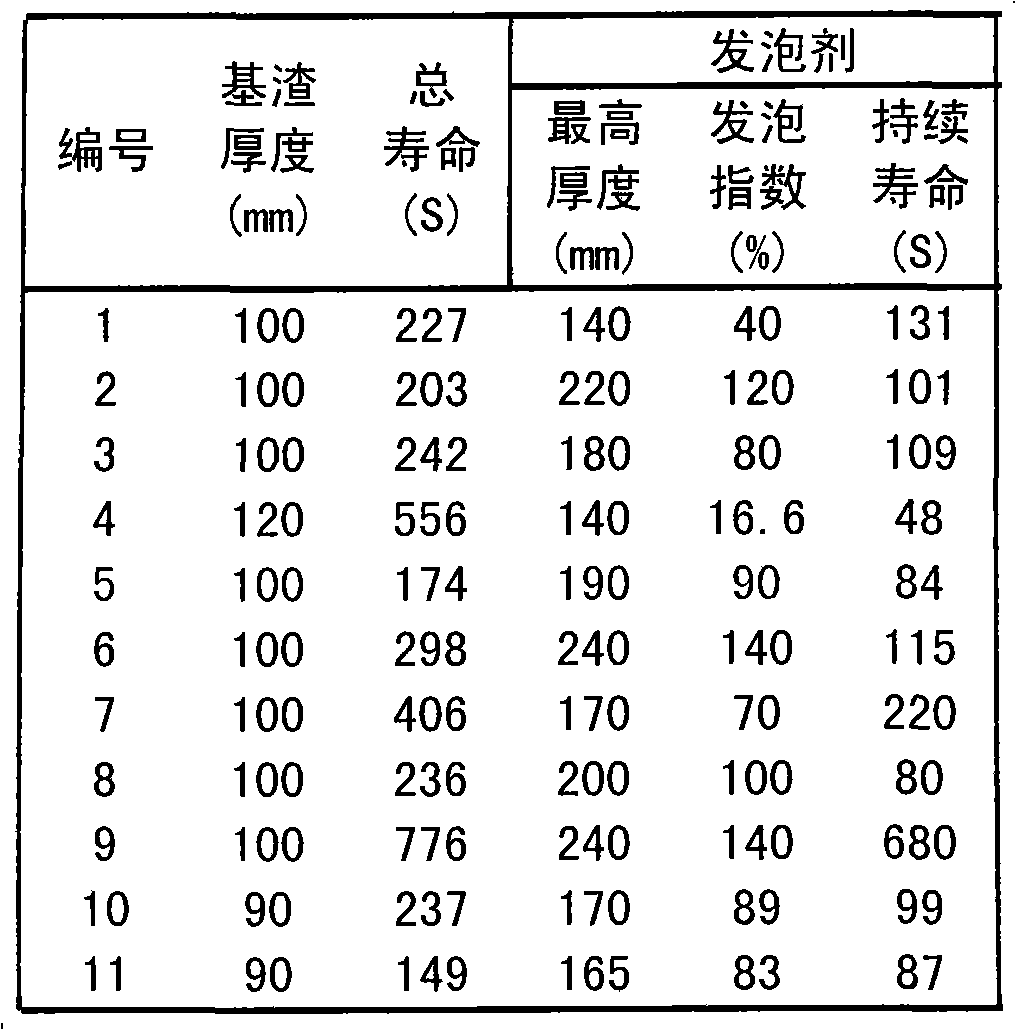

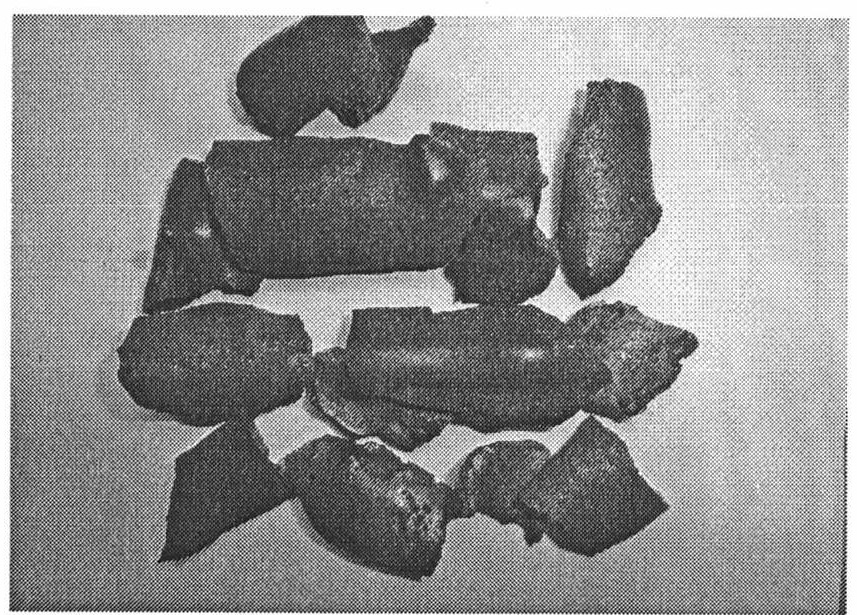

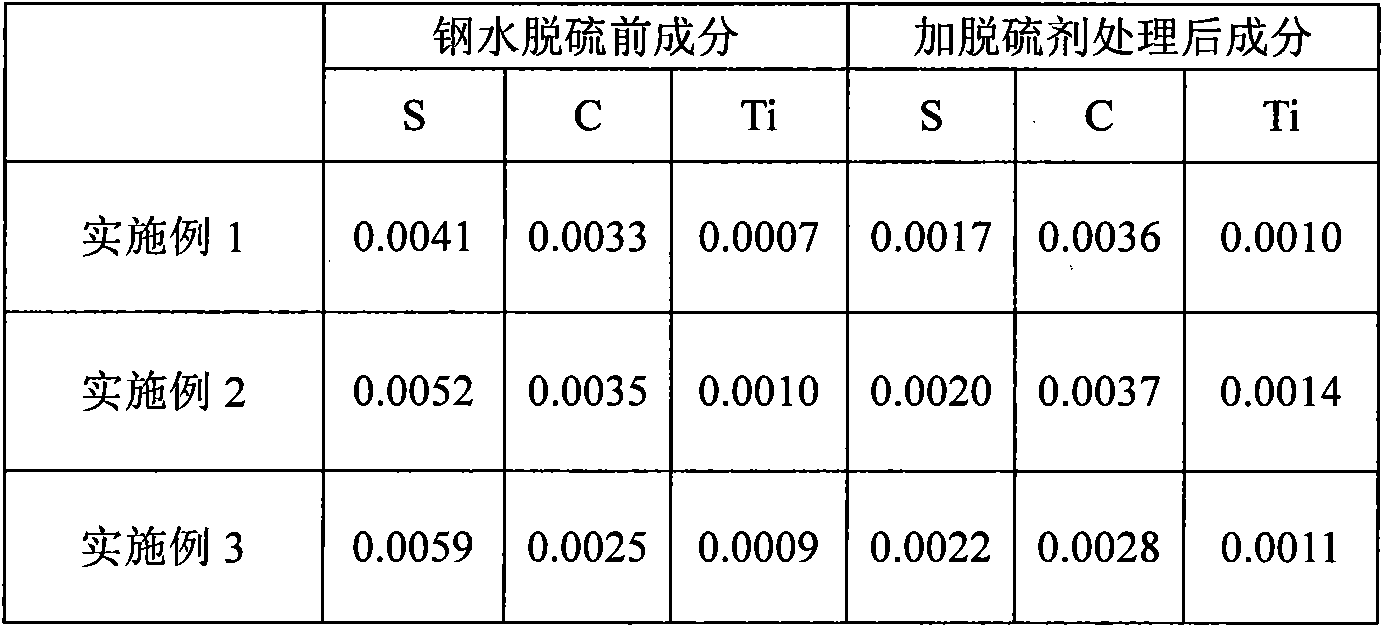

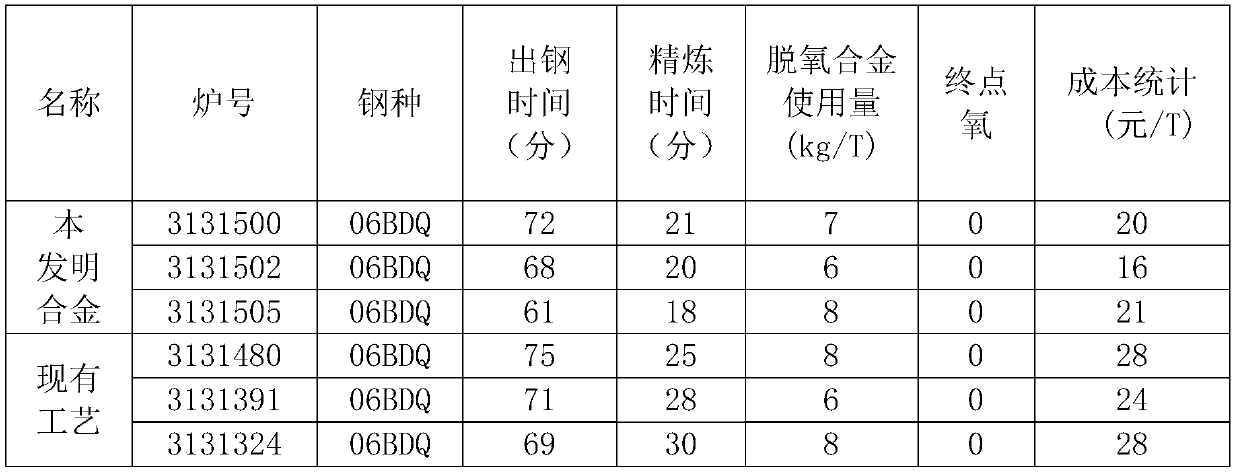

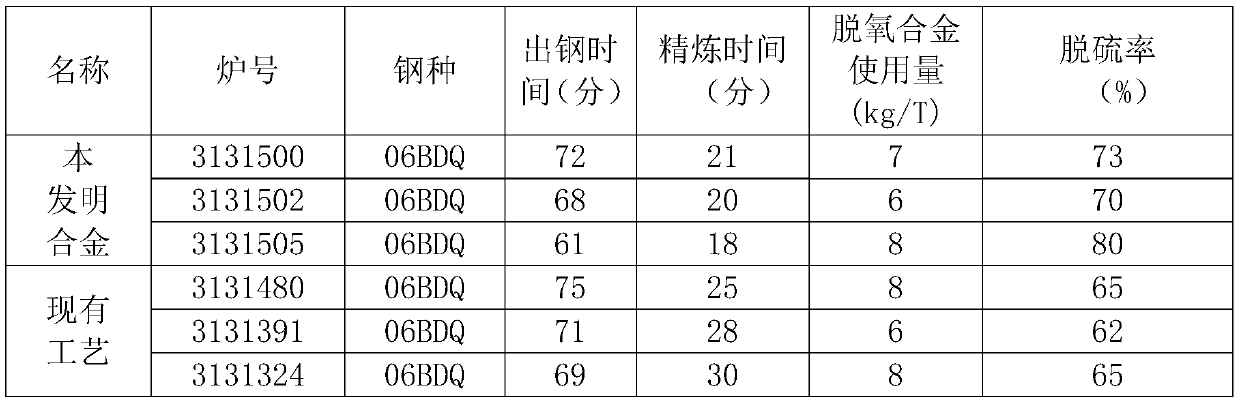

Calcium aluminate for desulfurization of ultralow titanium and carbon steel and preparation method thereof

The invention relates to calcium aluminate for desulfurization of ultralow titanium and carbon steel and a preparation method thereof. The calcium aluminate comprises more than or equal to 94% of Ca12Al14O33, less than or equal to 2% of Ca3Al2O6, less than or equal to 2% of Ca2SiO4, less than or equal to 1.5% of MgO, less than or equal to 0.01% of pure Ti and less than or equal to 0.02% of pure carbon. The preparation method comprises the following steps of: (1) preparing materials according to the following proportions: 60-65% of CaO and 35-40% of Al; (2) mixing the proportioned raw material particles in a material mixer; (3) adding the mixed materials into a smelting furnace, and blowing fuel to heat the furnace to make furnace temperature achieve 950-1050 DEG C; (4) blowing oxygen into the furnace, heating the furnace body to 1450-1500 DEG C; and (5) cooling and crushing premelted slag into 5-30 mm blocks. The desulfurizing agent provided by the invention has the advantages of low production cost, easy for storage, low melting point, high slag melting speed, high desulfurization effect and small corrosion to refractory materials, and the carbon increase amount and the titanium increase amount of liquid steel can be effectively controlled.

Owner:ANGANG STEEL CO LTD

Method for producing calcium ferrite by iron-electrode electric smelting of iron ore

InactiveCN103964510AFast slag formationIncrease contact surfaceIron compoundsFluorine freeActual use

The invention discloses a method for producing calcium ferrite from iron ore. The method utilizes an iron electrode to realize electric smelting, utilizes the iron electrode to produce calcium ferrite, prevents an additional component from entering into calcium ferrite, improves calcium ferrite purity and realizes better calcium ferrite actual use effects. In steel-making, through use of the calcium ferrite obtained by the method, a slagging rate is fast, dephosphorization efficiency is high, a lime use amount is reduced, fluorine-free steel-making is realized and environmental pollution is reduced.

Owner:ZHENGZHOU WHALE SPECIAL MATERIALS

RH furnace refining hydrogen oxygen control process

The invention discloses a RH furnace refining hydrogen oxygen control process. The RH furnace refining hydrogen oxygen control process is characterized by comprising the following steps that temperature measurement is carried out on molten steel; sampling and measuring N, C content are carried out; vacuumizing operation is carried out; high-pressure nitrogen gas and oxygen are adopted for mixing or argon gas and oxygen are used as lifting gas; the vacuum degree is kept at 3-4.5 kPa, and refining slag is added; then a decarbonization process is carried out; ferrochrome is added in the early stage of vacuum circulation degassing refining to perform chromium alloying; and steel liquid temperature measurement and oxygen measurement are carried out; deoxidation operation is carried out by adding low-carbon silicon iron, and alloying adjustment is carried out; dehydrogenation and tranquilizing treatment are carried out; the vacuum is broken, and argon blowing from the bottom and soft stirring is carried out on a steel ladle.

Owner:JINGYE STEEL CO LTD

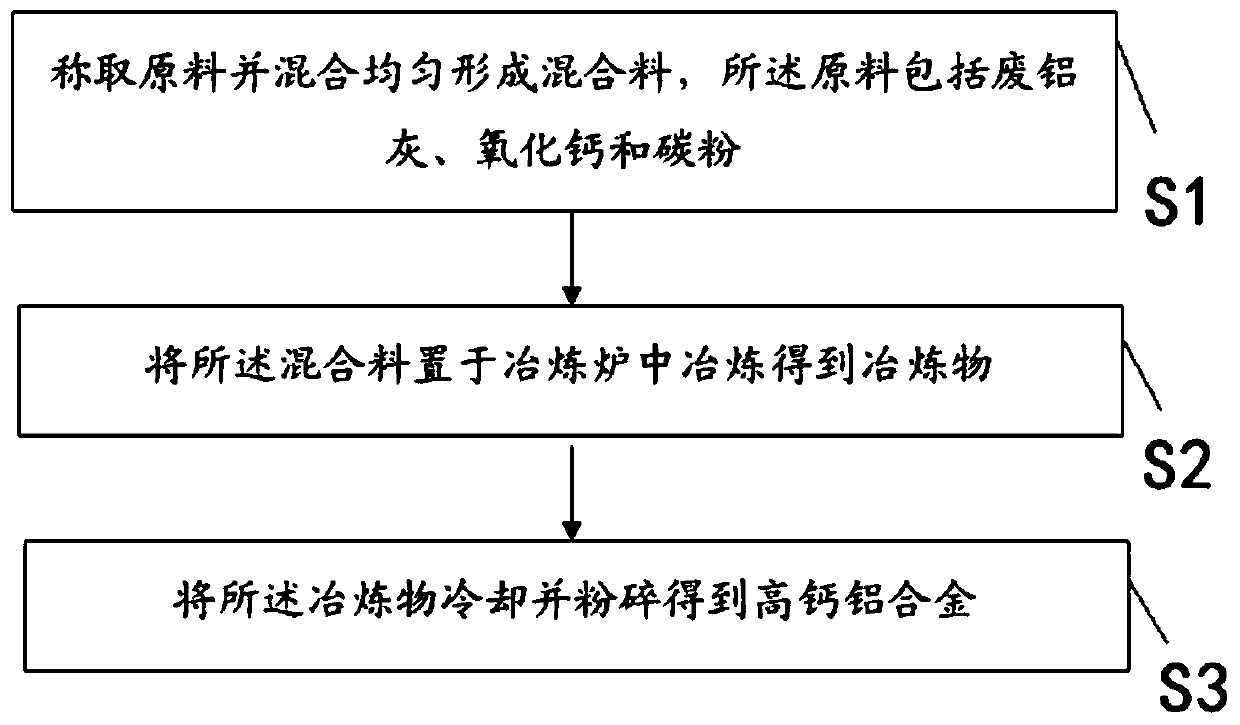

Preparation method for high calcium aluminium alloy, and high calcium aluminium alloy

The embodiment of the invention provides a preparation method for high calcium aluminium alloy, and the high calcium aluminium alloy. The preparation method comprises the steps of weighing and mixingraw materials uniformly to form mixtures, wherein the raw materials comprise aluminium scruff ash, calcium oxide and carbon powder; placing the mixtures in a smelting furnace for smelting to obtain smelting materials; and cooling and crushing the smelting materials to obtain the high calcium aluminium alloy. According to the high calcium aluminium alloy prepared with the above method, the aluminium scruff ash can be recycled, and the high calcium aluminium alloy is applied to the steel-making process; pollution can be reduced, and dust is not liable to produce at a production site; the slag forming speed is high, and the steel-making efficiency is improved; and subsequent desulfurization is not affected, and the cost is low.

Owner:肖卫学 +1

Converter slag forming process for rapid slagging

InactiveCN105603147AEliminate wasteFast slag formationManufacturing convertersProcess efficiency improvementSmelting processForming processes

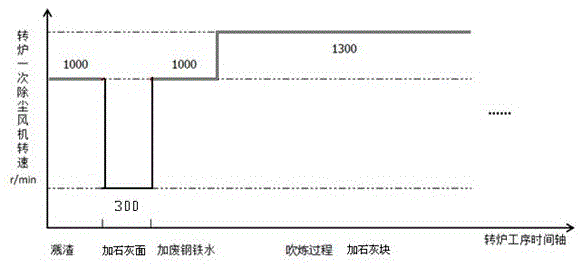

The invention discloses a converter slag forming process for rapid slagging and belongs to the technical field of converter processes for steel production. The converter slag forming process is used for rapid slagging of a converter. According to the technical scheme, in the converter slag forming process, the rotating speed of a fan is reduced before waste molten iron is added into the converter, lime powder of a small particle size is added in advance, and waste caused when lime powder of an extremely small particle size is sucked away by the fan is avoided; in addition, an initial slagging reaction is completed under the impact of the molten iron in the molten iron charging process, the rotating speed of the fan is increased to a normal value after lime powder is added, and lime blocks are added in the converting process. By means of the converter slag forming process, the slagging speed at the earlier smelting stage of the converter is effectively increased, and meanwhile waste caused when lime of an extremely small particle size is sucked away by the fan in the smelting process of the converter is reduced. The converter slag forming process is an innovation, solves the problem that the particle size of lime can not meet both sides, which brings trouble to slagging of the converter for a long term, effectively increases the slag forming speed in slagging of the converter, reduces the lime consumption in the slagging process, lowers production cost and improves the dust removing effect.

Owner:TANGSHAN IRON & STEEL GROUP

Slag-forming constituent and preparation thereof

ActiveCN101413042BFast slag formationReduce consumptionManufacturing convertersProcess efficiency improvementSteelmakingSludge

The invention belongs to the metallurgical field, and particularly relates to a slag former and a method for preparing the same. The technical problem solved by the invention is to provide a slag former with quick slagging by utilizing steelmaking sludge as a main material. The slag former consists of the following materials in weight percentage: 25 to 35 percent of steelmaking sludge, 25 percentof manganese ore with high silica, 34 to 45 percent of quartz sand and 5 percent of magnesium chloride. The average slag forming time of the slag former is 4.4 minutes, which is 1.5 minutes shorter than the prior slaggng method, and the average dephosphorizing efficiency is improved by 6.75 percent. Therefore the slag former maximally recovers iron in the sludge and lowers iron and steel consumption.

Owner:PANZHIHUA GANGCHENG GROUP

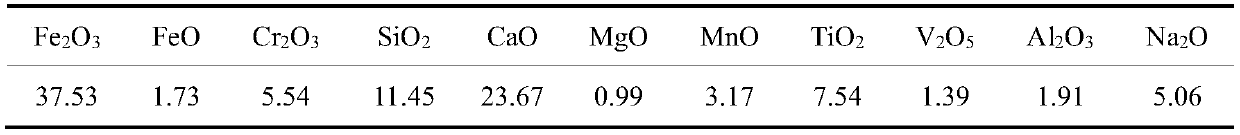

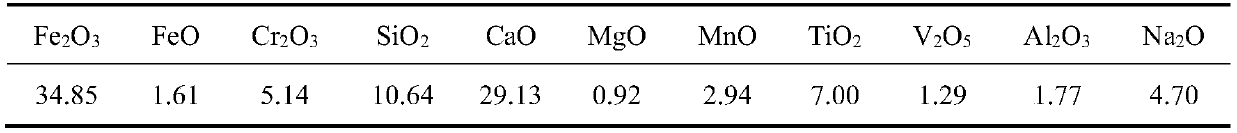

Composite desiliconization and dephosphorization agent for molten iron pretreatment and preparation method thereof

The invention provides a composite desiliconization and dephosphorization agent for molten iron pretreatment, which includes vanadium extraction tailings and active lime. The vanadium extraction tailings and active lime are evenly mixed. The weight percentage of the vanadium extraction tailings in the composite desiliconization and dephosphorization agent is 60 to 90%, and the weight percentage of active lime in the composite desiliconization and dephosphorization agent is 10 to 40%. It not only effectively utilizes the vanadium extraction tailings, but also effectively reduces the silicon and phosphorus content in the molten iron, providing high-quality molten iron for steelmaking. At the same time, the iron resources in the composite desiliconization and dephosphorization agent can be recovered during the molten iron pretreatment process. The invention also provides a method for preparing a composite desiliconization and dephosphorization agent for molten iron pretreatment, which includes: drying the vanadium extraction tailings and active lime; and then compounding the dried vanadium extraction tailings and active lime according to the above The amounts of vanadium extraction tailings and active lime in the desiliconization and dephosphorization agent are evenly mixed to obtain a composite desiliconization and dephosphorization agent. The ingredients are simple, the preparation is simple and the cost is low.

Owner:NORTHEASTERN UNIV LIAONING

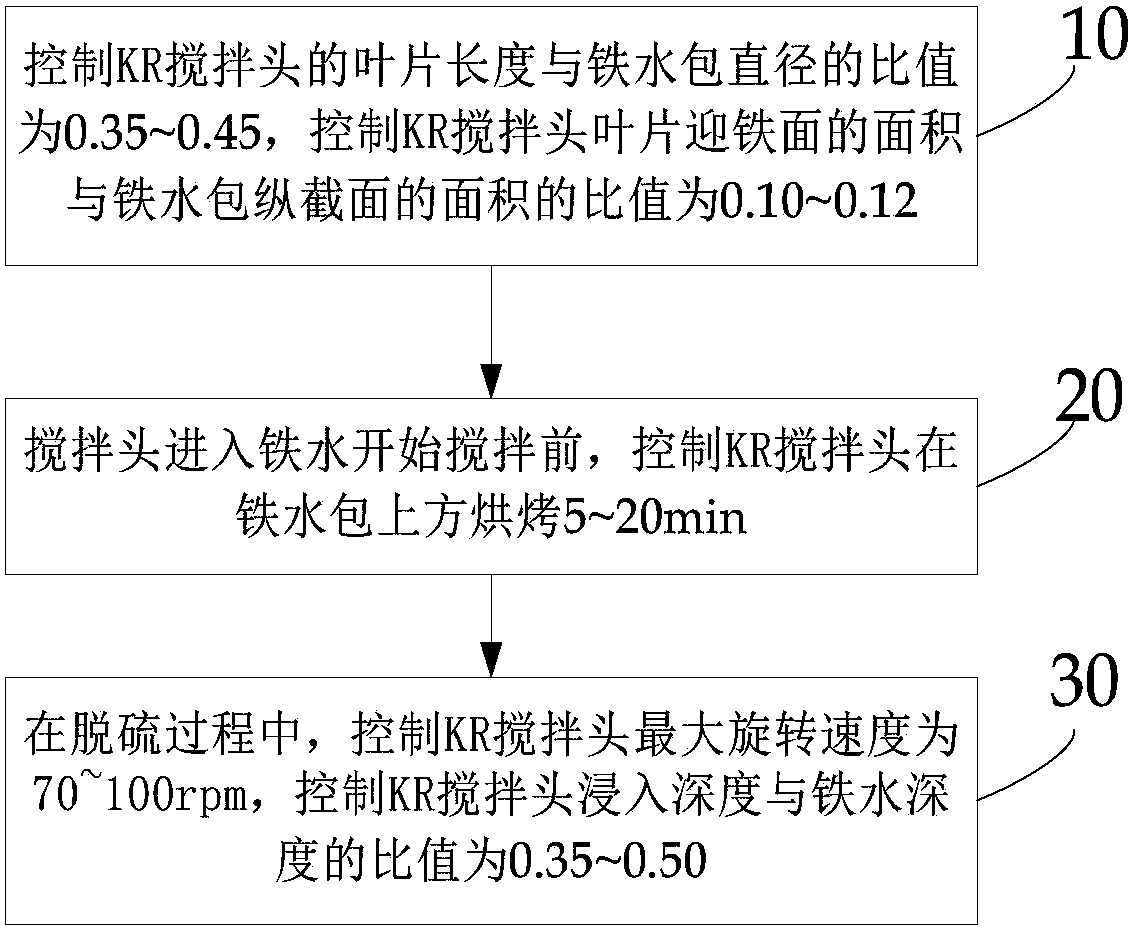

A method to improve the service life of kr stirring head

The invention relates to the technical field of metallurgy, in particular to a method for prolonging the service life of a KR stirring head. The method comprises the steps that 1, the ratio of the length of blades of the KR stirring head to the diameter of a hot metal ladle is controlled to be 0.35-0.45, and the ratio of the area of the surface facing iron of the blades of the KR stirring head to the area of the longitudinal section of the hot metal ladle is controlled to be 0.10-0.12; 2, before entering hot metal to be stirred, the KR stirring head is controlled to be baked for 5-20 min above the hot metal ladle; and 3, in the desulfurization process, the maximum rotating speed of the KR stirring head is controlled to be 70-100 rpm, and the ratio of the immersion depth of the KR stirring head to the depth of the hot metal is controlled to be 0.35-0.50. According to the method for prolonging the service life of the KR stirring head provided by the embodiment of the invention, the interior of the KR stirring head is prevented from producing cracks on the premise that efficient desulfurization is ensured, the shearing stress on the KR stirring head is reduced, and the service life of the KR stirring head is prolonged.

Owner:SHOUGANG CORPORATION

Method for heat application of low-alkalinity casting residue in steel-making

ActiveCN102994689BLow production costRealize full recyclingManufacturing convertersProcess efficiency improvementSteelmakingAlkalinity

Owner:WUKUN STEEL

A rh furnace refining hydrogen and oxygen control process

Owner:JINGYE STEEL CO LTD

Novel direct continuous casting slag washing mixed material and preparation process thereof

The invention relates to a novel direct continuous casting slag washing mixed material and a preparation process thereof, and belongs to the field of special-performance alloy and powder metallurgy novel material in metal materials of the novel materials. The novel heating slag washing mixed material comprises the following components in parts by weight: 30-65 parts of aluminum oxide powder, 30-50 parts of quick lime, 1-6 parts of magnesium oxide powder, 0-6 parts of fluorite and 5-6 parts of silicon dioxide powder. The preparation process of the novel heating slag washing mixed material comprises the following steps of: ball-milling the materials in a ball mill to obtain particle powder; press-moulding the ball-milled particle powder by a ball press, smelting in an electric-arc furnace; and adding 5-40 parts of aluminum powder to the molten liquid during a turning down process, and crushing the cooled material into particles. The novel direct continuous casting slag washing mixed material disclosed by the invention can be used for filtering deoxidized desulfurized molten steel very well, so that produced deoxidation products can be caught effectively and modification of impurities in the steel is promoted, so that the purpose of evolving the molten steel is reached.

Owner:涟源市飞达冶金炉料厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com