Fluorin-free composite quick slag-forming constituents for convertor steelmaking and method of producing the same

A converter steel-making and slag-forming agent technology, which is applied in the manufacture of converters and other directions, can solve the problems of fluoride pollution, slow slagging, erosion of furnace lining, etc., and achieves a simple preparation method, reduces splashing, and improves slag-forming speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

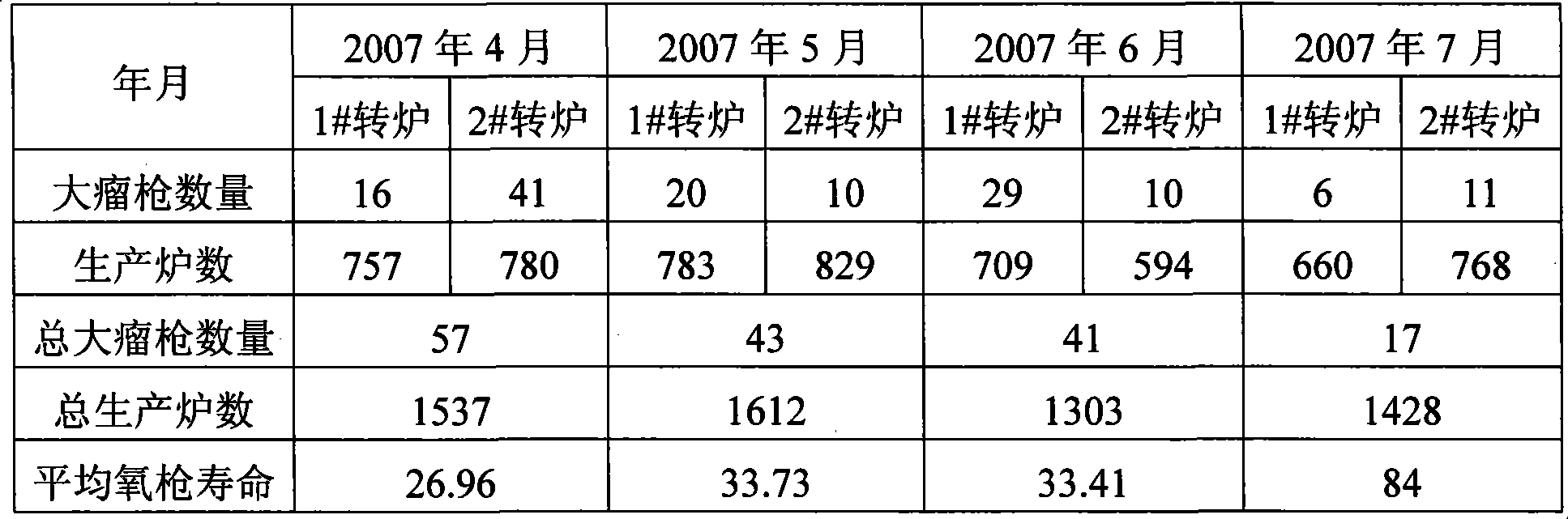

Image

Examples

Embodiment 1

[0025] A fluorine-free composite rapid slagging agent for converter steelmaking, which contains the following components in weight percentage: 40% of MnO, 16% of CaO, 25% of TFe, 13.5% of MgO, H 2 O 0.5%, Al 2 o 3 3%, polyvinyl alcohol 2%.

[0026] The preparation method is as follows:

[0027] (1) MnO, CaO, TFe, MgO and Al 2 o 3 Send it to the jaw crusher for mixing and coarse crushing;

[0028] (2) Carry out fine crushing again until the particle size of the material is less than or equal to 3mm;

[0029] (3) In the pulverized material, add the polyvinyl alcohol of formula quantity, add the water that weight is 1.5 times of polyvinyl alcohol weight again, mix evenly;

[0030] (4) Send it into the ball pressing machine again and press it into an ellipsoid;

[0031] (5) Send the pressed balls into a drying room for curing or drying in fine weather until the moisture content of the product reaches 0.5%.

Embodiment 2

[0033] A fluorine-free composite rapid slagging agent for converter steelmaking, which comprises the following components in weight percentage: 35% of MnO, 18% of CaO, 30% of TFe, 8.3% of MgO, H 2 O 0.7%, Al 2 o 3 5%, polyvinyl alcohol 3%.

[0034] The preparation method is as follows:

[0035] (1) MnO, CaO, TFe, MgO and Al 2 o 3 Send it to the jaw crusher for mixing and coarse crushing;

[0036] (2) Carry out fine crushing again until the particle size of the material is less than or equal to 3mm;

[0037] (3) In the pulverized material, add the polyvinyl alcohol of formula quantity, add the water that weight is 1.5 times of polyvinyl alcohol weight again, mix evenly;

[0038] (4) Send it into the ball pressing machine again and press it into an ellipsoid;

[0039] (5) Send the pressed balls into a drying room for curing or drying in fine weather until the moisture content of the product reaches 0.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com