Composite desiliconization and dephosphorization agent for molten iron pretreatment and preparation method thereof

A technology of molten iron pretreatment and silicon dephosphorization agent, applied in the direction of improving process efficiency, etc., can solve the problems of dust environment and human health hazards, low utilization rate, and small amount of red mud utilization, so as to reduce the harm to the environment and human body , good economic and social benefits, and the effect of ensuring the effect of desiliconization and dephosphorization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

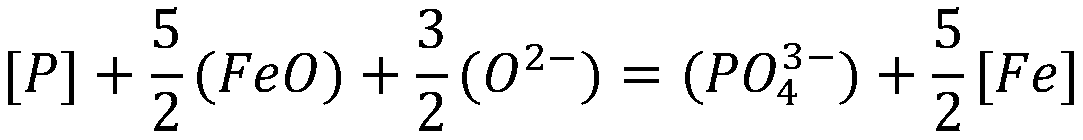

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a preparation method of molten iron pretreatment composite desiliconization and dephosphorization agent, which comprises the following steps:

[0041] Step S1, vanadium extraction tailings and active lime are sequentially crushed and screened to obtain vanadium extraction tailings and active lime with a particle size below 0.5 mm, and then dried.

[0042] Obtain vanadium extraction tailings and active lime with a particle size below 0.5mm to facilitate the transportation and loading of vanadium extraction tailings and active lime.

[0043] Step S2. Weigh the dried vanadium extraction tailings and active lime according to the amount of the vanadium extraction tailings and active lime in the composite desiliconization and dephosphorization agent, and mix them uniformly to obtain a composite desiliconization and dephosphorization agent.

[0044] The preparation method of the hot metal pretreatment composite desiliconization and dephospho...

Embodiment 1

[0047] In this embodiment, vanadium extraction tailings after sodium roasting and leaching of vanadium slag from a domestic steel plant were selected as raw materials.

[0048] Step S1, vanadium extraction tailings and active lime are sequentially crushed and screened to obtain vanadium extraction tailings and active lime with a particle size below 0.5 mm, and then dried.

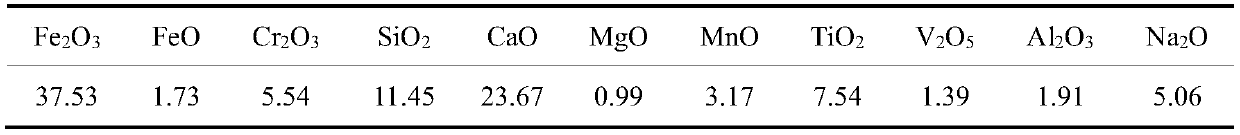

[0049] Step S2. Weigh the dried vanadium extraction tailings and active lime according to the mass ratio of 77:23, and mix them evenly to obtain a melting point of 1236.0°C and an alkalinity of CaO / SiO 2 2.1 Composite desiliconization and dephosphorization agent for molten iron pretreatment. Wherein, the melting point of the composite desiliconization and dephosphorization agent is measured according to the hemispherical method. The specific chemical composition of the hot metal pretreatment composite desiliconization and dephosphorization agent is shown in Table 1.

[0050] The chemical composition of mo...

Embodiment 2

[0054] In this embodiment, vanadium extraction tailings after sodium roasting and leaching of vanadium slag from a domestic steel plant were selected as raw materials.

[0055] Step S1, vanadium extraction tailings and active lime are sequentially crushed and screened to obtain vanadium extraction tailings and active lime with a particle size below 0.5 mm, and then dried.

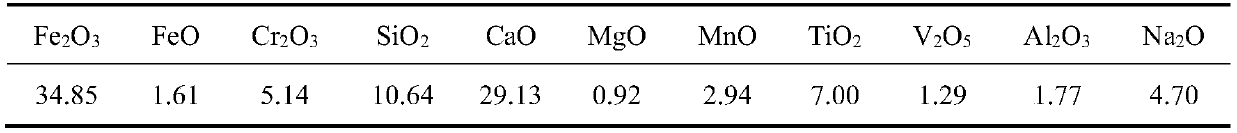

[0056] Step S2. Weigh the dried vanadium extraction tailings and active lime according to the mass ratio of 71:29, and mix them evenly to obtain a melting point of 1260.1°C and an alkalinity of CaO / SiO 2 It is a composite desiliconization and dephosphorization agent for hot metal pretreatment of 2.8. Wherein, the melting point of the composite desiliconization and dephosphorization agent is measured according to the hemispherical method. The specific chemical composition of the hot metal pretreatment composite desiliconization and dephosphorization agent is shown in Table 2.

[0057] The chemical composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com