Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

114results about How to "Fast slag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

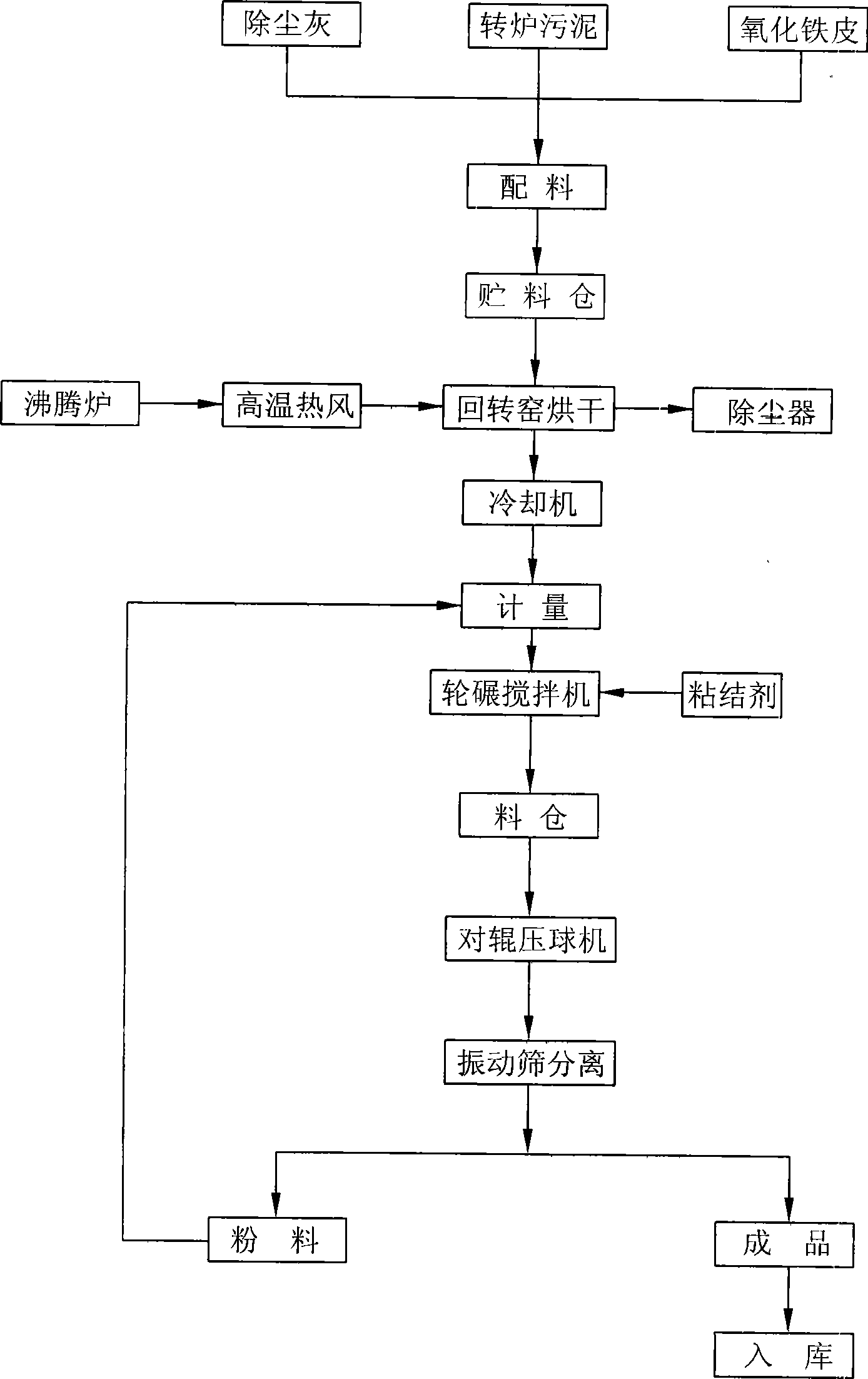

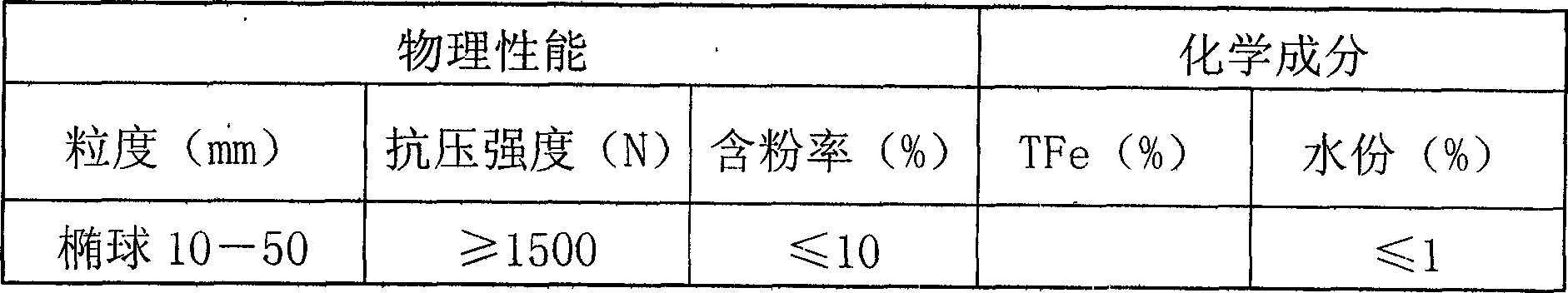

Method for utilizing iron containing metallurgical dust

The invention relates to a method for utilizing iron containing metallurgical dust, which comprises that: steel-making sludge, metallurgical dust-removing powder and iron scale are mixed; the mixed raw materials are sent into a rotary kiln and dried, and the drying temperature is determined according to moisture content of the raw materials and controlled to be between 300 and 500 DEG C; the dried materials are cooled by a cooler, the cooled materials are added with 5 to 10 percent of caking agent by weight, and the material and the caking agent are fully stirred evenly by a wheel-rolling mixer; and finally, the mixture is pressed into cooled agglomerated pellet products by a twin-roller machine, the pressure of the twin-roller machine is more than or equal to 500 Kg / cm<2>, and the cooled agglomerated pellet products are prepared into finished products after separation by a vibration sieve. The method has the advantages of low production energy consumption, high product strength, low moisture content and good quality, and can realize full effective utilization of resources; and the finished products of cooled agglomerated pellets can be directly used as a cooling agent and a slag former in steel making, can improve smelting effect and achieve functions of cooling and slag forming, and can be also used for blast furnace process.

Owner:SHAOGUAN QUJIANG SHENGDA EQUIP & MATERIALS

Ladle refining slag modifier, preparation method and slag modifying method

InactiveCN101519712AStrong fluxing effectImprove flux effectProcess efficiency improvementSteelmakingImpurity

The invention belongs to the technical field of steelmaking and refining, and discloses a ladle refining slag modifier, a preparation method and a slag modifying method. The slag modifier comprises the following chemical components in percentage by mass: 30 to 60 percent of CaO, 30 to 60 percent of Al2O3, 2 to 10 percent of MgO2, 2 to 10 percent of B2O3, and less than 8 percent of impurities. The slag modifying method using the slag modifier comprises that: the slag modifier is hoisted to the front of a refining furnace after a steelmaking furnace discharges steels, and then is directly fed into ladles, or the slag modifier can also be fed into the furnace along with other slags at a refining station; the components of modifying slag are determined according to the ladle residue amount and components, desulfuration amount and steel deoxidation product amount; and the modifying slag for controlling the ladle slag comprises the following components according to the adding amount: 48 to 54 percent of CaO, 26 to 32 percent of Al2O3, 6 to 8 percent of MgO, 2 to 4 percent of B2O3, and 0 to 8 percent of SiO2, wherein the modifying slag is better if the content of the SiO2 is lower. The slag modifier has the capabilities of quickly manufacturing the slag, improving desulfuration and deoxidation of the refining slag and accommodating and absorbing deoxidation products, and is simple to prepare and convenient to store, transport and use.

Owner:JIANGSU UNIV

Aluminum industrial red mud-based dephosphorizing agent for converter steelmaking and preparation method thereof

InactiveCN103725825AMeet general requirementsReduce phosphorus contentManufacturing convertersSteelmakingRed mud

The invention discloses an aluminum industrial red mud-based dephosphorizing agent for converter steelmaking and a preparation method thereof, belonging to the field of converter steelmaking. The dephosphorizing agent is mainly prepared from the following raw materials by mass percent: 50-70% of dried red mud, 5-15% of lime, 15-30% of iron ore concentrate or iron sheet ball, 2-10% of light roasting dolomite, and 0.5% of binding agent. The dephosphorizing agent is prepared by the following steps of crushing the raw materials, mixing uniformly, pressing into chunks, roasting for 2-4 hours at 300-500 DEG C, cooling down, and then crushing into the dephosphorizing agent with grain size of 15-30mm. The dephosphorizing agent is added in dephosphorizing step in steelmaking by the converter, can be used for processing molten iron with middle or low content of phosphorus, and can remove more than 90% of phosphorus. By utilizing large amount of CaO and Fe2O3 in the red mud, the dephosphorizing agent not only has good dephosphorizing effect, but also solves the problem of red mud pollution, thus recycling the red mud and lowering the cost for steelmaking.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

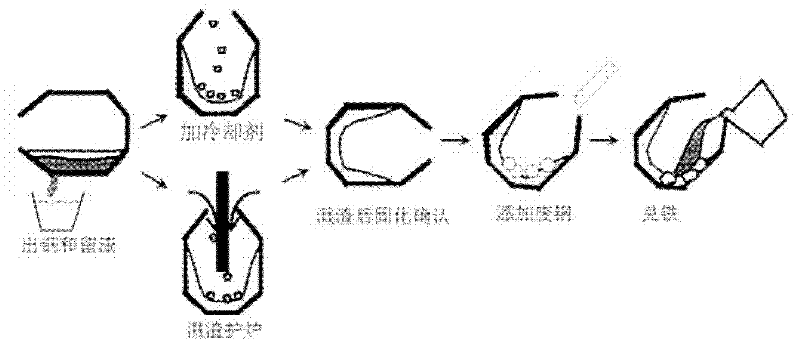

Cooling solidification recycling method for high-temperature liquid-state slag in steelmaking furnace

InactiveCN102337372AExtended reaction timeGood reaction kineticsManufacturing convertersProcess efficiency improvementSteelmakingLiquid state

The invention discloses a cooling solidification recycling method for a high-temperature liquid-state slag in a steelmaking furnace. The method comprises the following steps of: remaining slag, namely performing slag remaining operation after tapping, wherein the slag remaining amount in a converter is 5 to 40t; adding a coolant into residual slag according to the content of end point carbon in the converter and the slag remaining amount after the tapping, wherein the coolant comprises 1 to 3.0t of lime, 0 to 3.0t of magnesium carbon ball and 0.2 to 3.0t of dolomite; splashing the slag, namely splashing the slag and jetting N2 by using a gun under the pressure of between 1.2 and 1.5MPa at the temperature of between 25 and 35 DEG C for 3 to 7min, wherein the flow is 30,000 to 50,000Nm<3> / h; after the slag splashing is finished, lifting the gun, shaking the furnace to observe a slag splashing effect that whether the slag is solidified or not, and adding scrap steel together with iron after the high-temperature liquid-state slag in the furnace is cooled and solidified; and otherwise, adding 0 to 3.0t of coolant into the converter, wherein the coolant is lime. In the method, a tapping and slag remaining process, a slag splashing and furnace protecting process and a coolant adding process are combined, and the high-temperature liquid-state slag is recycled; and the slag is simply and effectively recycled, so that a good steel slag reaction condition is provided for subsequent smelting of the converter.

Owner:UNIV OF SCI & TECH BEIJING

Slag adhesion preventing fluorine-free slag modifier for ladle refining, preparation method and using method

InactiveCN101519713AIncrease contentIncrease surface tensionProcess efficiency improvementSteelmakingPhosphor

The invention belongs to the field of steelmaking, and particularly discloses a fluorine-free slag modifier for preventing a ladle refining device from adhering slag, a preparation method and a using method. The slag modifier consists of active lime, bauxite and boric anhydride; and the slag modifier comprises the following chemical components in percentage by mass: 75 to 85 percent of CaO, 10 to 20 percent of Al2O3, 5 to 15 percent of B2O3, 0 to 8 percent of MgO, and the balance of impurities, wherein SiO2 is less than 7.0 percent, H2O is less than 0.05 percent, and the total amount of sulfur and phosphor is less than 0.01 percent. During use, in order to prevent a ladle from adhering the slag, the slag modifier is fed into the ladle in the later period of discharging steel from a steelmaking furnace, and in order to prevent an RH dip pipe or a CAS-OB dip cover and the like from dipping into the ladle device to adhere slag, the slag modifier is fed at a refining station. The slag modifier can effectively control the refining device from slag adhesion and improve the service life of a fireproof material, is favorable for reducing the contents of the sulfur, oxygen and impurities in the steel, and is simple to prepare and convenient to store, transport and use.

Owner:JIANGSU UNIV

Method for producing high carbon steel by high-catching carbon method

ActiveCN101333578AReduce oxidationReduce erosionManufacturing convertersProcess efficiency improvementHigh carbonSmelting process

The invention provides a method for producing high-carbon steel by a high-carbon-withdrawal method, in particular to a smelting process of high-carbon-withdrawal tapping when a converter adopts a single slag process to produce high-carbon steel. The process comprises the following steps of: (1) putting molten iron and scrap steel into the converter according to the requirements on tapping temperature and a certain hot metal ratio; (2) air refining with the oxygen supply strength of 3.1 to 3.4Nm<3> / min / t in the converter; (3) adding active lime and an ore slagging element into the converter; (4) adopting an oxygen supply system of different lance positions under constant flow, adopting rather high lance positions in the whole course of air refining of the converter, and adopting a lance position system in which lance positions get lower piecewise from the beginning to the end of air refining; (5) adding ore and fluorite in small amount by a plurality of batches when the total air refining oxygen consumption is within 70 percent to 85 percent; (6) finishing the air refining of the converter, deslagging by turning down the converter, temperature measurement and sampling; and (7) converter tapping. The smelting process has advantages of short time of air refining of the converter and active slag, and can meet the dephosphorization effect under the high-carbon-withdrawal condition of molten steel, and realize the high-carbon-withdrawal tapping.

Owner:SHOUGANG CORPORATION

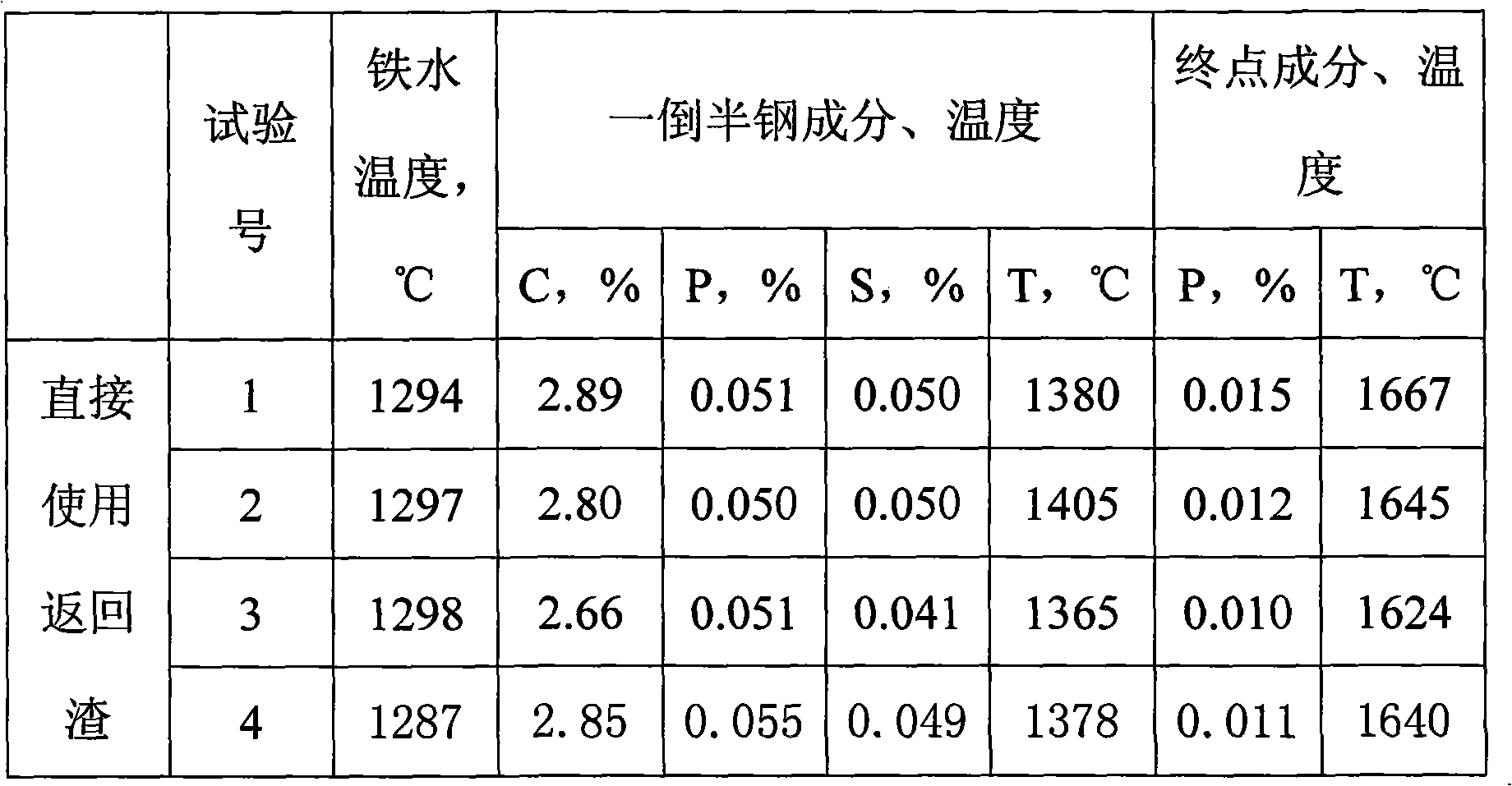

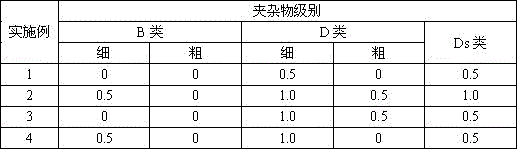

Compound dephosphorization agent with converter slag as raw material and preparing method thereof

The invention discloses a molten iron pretreatment compound dephosphorization agent with converter slag as the raw material, and the compound dephosphorization agent contains the following raw materials by weight: 45 to 55 percent of converter slag, 3 to 5 percent of quartz sand, 22 to 34 percent of steel-rolling iron sheet, 3 to 6 percent of bauxite, 10 to 14 percent of soda and 0 to 5 percent of fluorite; the raw materials meeting the ingredient demands are evenly mixed according to the proportions after being crushed, and then the product with the diameter being 20 to 50mm is produced after ball-milling, screen separation, palletizing and drying. The compound dephosphorization agent realizes cyclic utilization of the converter slag which accounts for 45 to 55 percent, thus reducing the produced slag amount in the steel-making process and the environmental load; the converter slag contains plenty of CaO and FeO, which can reduce consumption of lime to a certain degree, thus increasing the metal yield rate and reducing the steel-making cost; the compound dephosphorization agent has low melting point, slag can be formed fast, the liquidity is good, thus shortening the treatment time, the dephosphorizing efficiency is high, and the dephosphorized final slag has low alkalinity and low melting point.

Owner:CHONGQING UNIV

Slagging constituent for semisteel converter steelmaking and manufacturing method thereof

ActiveCN102912068AFast slagEfficient productionManufacturing convertersProcess efficiency improvementSteelmakingSludge

The invention discloses a slagging constituent for semisteel converter steelmaking and a preparation method thereof, wherein the slagging constituent for semisteel converter steelmaking comprises the following compounds in percentage by weight: 45-55% of SiO2, 2-8% of CaO, 5-15% of Al2O3, 2-8% of MnO, 5-15% of MgO, 5-10% of FeO and 10-20% of Fe2O3; the manufacturing method thereof comprises the following steps: scattering quartz sand, manganese ore, corundum slag and converter sludge and grinding till the granularity is below 1mm; and mixing with a bonding agent to obtain a mixture, wherein the mixture is pressed for palletizing and then baked for manufacturing the slagging constituent. The slagging constituent disclosed by the invention has the advantages of being quick in slagging speed, relatively low to control converter gun position integrally, easier to control in sladding process, low in melting point of converter final slag, relatively low for TFe in the slag, high in dephosphorization efficiency, and the like; the efficient production of semisteel converter steelmaking can be ensured; the solid waste of corundum slag is further utilized so that the corundum slag becomes a secondary resource for steelmaking and the cyclic utilization of waste resource is realized; therefore, the slagging constituent for semisteel converter steelmaking and the manufacturing method thereof have better economic value and social value.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Ladle top slag deoxidation modifier for ultralow carbon steel, and use method thereof

The invention relates to a ladle top slag deoxidation modifier for ultralow carbon steel, and a use method thereof. The technical problems of complex preparation process, high production cost and easyenvironment pollution during use of existing ladle top slag modifiers for ultralow carbon steel are mainly solved. The ladle top slag deoxidation modifier for ultralow carbon steel comprises 18-28 wt% of Al, 20-30 wt% of CaCO3, 3-7 wt% of CaO, 5-10 wt% of Al2O3, 5-9 wt% of CaF2, 5-8 wt% of MgO, 6 wt% or less of Na2CO3, and the balance of inevitable impurities; and the particle size of all components in the ladle top slag deoxidation modifier is less than or equal to 1 mm. The modifier can significantly improve the slag crusting problem of the ladle and improve the fluidity of molten steel.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

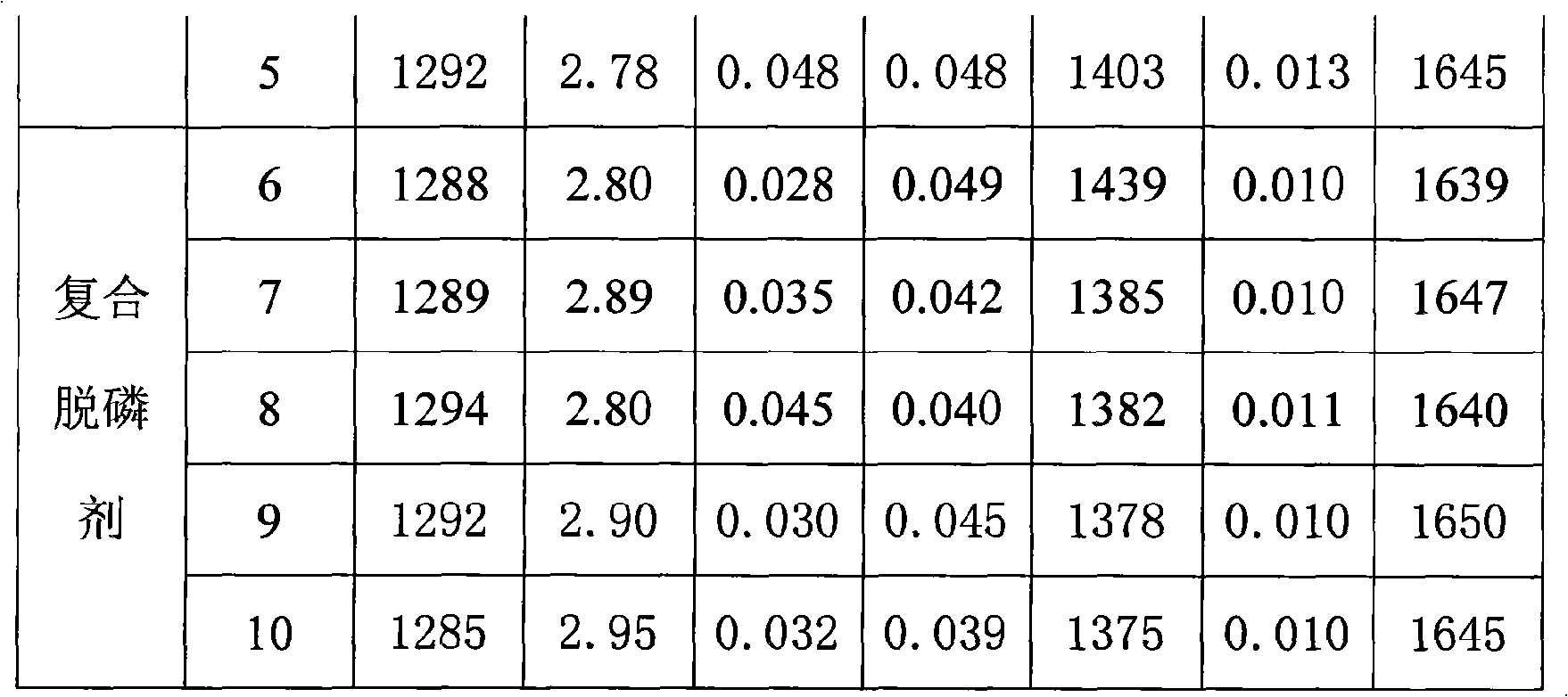

Refining method for controlling brittle inclusions in bearing steel

The invention discloses a refining method for controlling brittle inclusions in bearing steel, comprising an LF refining procedure and an RH refining procedure; the LF refining procedure comprises a process from steel tapping and alloying to pre-deoxidation slag formation on an LF treatment position and an LF treatment process; the process from steel tapping and alloying to pre-deoxidation slag formation on the LF treatment position comprises the steps of controlling the molten steel temperature at a converter smelting end point at 1600-1650 DEG C; adding 7-10kg / t of refining slag at the later stage of steel tapping, wherein the refining slag has high alkalinity and a low melting point; controlling the flow of argon blown to a steel ladle in the steel tapping process at 2.5-3.5NL / min.t<-1>; carrying out slag stopping operation at the last stage of steel tapping, and adding 20-40kg of aluminum particles; and controlling the flow of argon blown to the steel ladle at 0.15-0.35L / min.t<-1> in the process from steel tapping ending to LF refining; and the LF treatment process comprises the steps of controlling the flow of argon blown to the steel ladle at 2.5-5.0L / min.t<-1> in the LF treatment process; adding 30-50kg of aluminum particles at the earlier stage of LF smelting; and in the middle stage of LF smelting, adding 30-50kg of quartz and 200-400kg of lime, and adopting refining slag with medium-lower alkalinity. By using the method, the brittle inclusions in the steel can be effectively prevented and removed.

Owner:XINGTAI IRON & STEEL

Exothermic agent for converter molten iron with low heating value

InactiveCN101988137AAdjust alkalinityPlay the role of supplementing molten iron [Si]Manufacturing convertersSlagSilicon

The invention discloses an exothermic agent for converter molten iron with a low heating value, which comprises the following components in percentage by weight: 31-44 percent of carbonaceous material, 35-48 percent of siliceous material, 6-14 percent of bauxite, 4-10 percent of iron granules or scrap iron and 4-8 percent of binder, and the bulk specific weight of the exothermic agent is 2.2-3.5ton / m<3>. The exothermic agent for the converter molten iron with the low heating value has the characteristic of raising the temperature obviously and promoting slagging for low-silicon and low-temperature molten iron, and can improve the dephosphorizing capability of converter slag.

Owner:BAOSHAN IRON & STEEL CO LTD

Composite molten steel refining additive

This invention provides a molten steel composite refining additive. The said additive by wt.% includes aluminium ash 10-50% (aluminium content at least being 15% of ash wt.), metallurgical furnace slag 10-60%, carbide 5-65%, limestone 1-10% and witherite 1-10%. This additive is used for the oxidable slag tapping process of steel smelting furnace such as electric furnace, converter, etc. and for refining furnace to make the oxidable molten steel proceed polybasic composite oxygen removal, sulphur removal and quick deoxidated impurity inclusion removal, and at the same time, it enhances quick dissolution of added slagging material and quick slag forming.

Owner:重庆工业高等专科学校

Converter dephosphorization complex slag former and slagging technology

InactiveCN101532071AUniform compositionImprove performanceManufacturing convertersSlagHigh phosphorus

The present invention discloses a converter dephosphorization complex slag former that includes constituents with percentages by weight below: 30 to 40% of active lime; 30 to 40% of rolled steel sheet iron; 13 to 18% of quartz sand; 11 to 13% of soda; and 0 to 6% of fluorite; said raw materials are smashed into powder, mixed uniformly, sieved and palletized to obtain the complex slag former. The complex slag former is advanced with low melting point, fast slag forming, uniform constituent, stable property, big phosphorus capacity and high dephophorization efficiency of a dephosphorizer, for application in converter dephosphorization with hot metal with higher phosphorus content; the complex slag former is provided with good slagging situation, low alkalinity of final slag after dephosphorization, low content of free calcium oxide; the complex slag former has low content of fluorite, to thereby reduce lining refractory material erosion; the fluorine-free high phosphorus slag can be used as a steel slag phosphate fertilizer when smelting high phosphorus liquid iron.

Owner:CHONGQING UNIV

Deep desulfurization method using premelted slag in RH vacuum furnace

The invention relates to a pre-melted slag deep desulphurization method in a RH vacuum furnace, belonging to the vacuum steelmaking technical field. 300-800Kg / t of pre-melted desulphurized slag is added by an alloy feeding chute during the vacuum treatment of the RH furnace to realize the molten steel deep desulphurization. The pre-melted desulphurized slag comprises the following components by weight percentage of 55-60% of CaO, 15-25% of Al2O3, 2-8% of SiO2, 0-5% of MgO, 0-0.06% of S, 0-0.5% of water and 0-1.89% of impurities. The pre-melted slag deep desulphurization method has the advantages of simple equipment, no powder injection desulphurization top lance and low operating cost. Compared with a powder injection desulphurization mode, the pre-melted slag deep desulphurization method has larger added pre-melted slag amount and is beneficial for improving the desulphurization rate of molten steel.

Owner:QINHUANGDAO SHOUQIN METAL MATERIAL +1

Process of tron melt adding ore revolving furnace for steelmaking

The invention provides a new process of molten iron plus ore converter steelmaking. The technical feature of the invention is that the converter steelmaking is to add ore with molten iron, and to replace all scrap steel and iron lumps with iron ore. Roast and sieve to ensure that the ore is dry and the particle size is uniform. Start the oxygen blowing smelting gun position. Oxygen blowing will be added in proportion to the ore blowing for a certain period of time. After the ore is added within a short time, the present invention has the advantages of rapid slagging during the smelting process, basically no back-drying phenomenon in the middle and late stages, good removal effect of P and S harmful elements, and shortened smelting cycle. At the same time, the ore resources are abundant and the cost is low, and the oxygen consumption is greatly reduce.

Owner:SHANDONG IRON & STEEL CO LTD

Aluminium-calcareous premelted refining slag for low-cost steel-making and method for preparing same

InactiveCN102787213AReduce manufacturing costLow melting pointProcess efficiency improvementSteelmakingCalcium in biology

The invention relates to aluminium-calcareous premelted refining slag for low-cost steel-making and a method for preparing the same. The refining slag mainly uses industrial waste rich in calcium oxide and alumina as raw materials of production. The method comprises powdering the industrial waste, mixing the powder according to a certain proportion, putting the mixed powder into a high-temperature kiln to smelt at a temperature of 1600 to 1750 DEG C, cooling crystallization after smelting and tapping, and crushing to prepare the blocky premelted refining slag which has a low melting point and a granularity of 0 to 70 mm, and is rich in CaO and Al2O3. The refining slag is low in melting point and quick in melting rate, and can be added during the steel-making process to promote slagging and shorten smelting time. Meanwhile, the refining slag is high in sulfur capacity and can be used for refining desulphurization of molten steel during the process of tapping or the process of refining the molten steel by an LF furnace. Moreover, the refining slag is prepared from high temperature smelting and thus has advantages of stable performance and low fluorine, and is without deterioration, pulverization and water-absorption, thereby not only facilitating storage and transport but also benefiting environmental protection and pollution reduction. In addition, the refining slag uses industrial waste as raw materials and the used amount of the refining slag is fewer than that of other types of refining slag, and thus the cost of production of the steel can be reduced.

Owner:辽宁中汇环保科技有限公司

Environmental-protecting and energy-saving premelting refining slag conditioning agent

The invention proposes an environmental-protecting and energy-saving premelting refining slag conditioning agent. The environmental-protecting and energy-saving premelting refining slag conditioning agent comprises the following chemical components in percentage by weight: 20-28% of Al, 29-37% of CaO, 33-41% of Al2O3, MgO not more than 2.5%, SiO2 not more than 2.5%, FeO+MnO not more than 0.7%, S not more than 0.2%, P not more than 0.2%, TiO not more than 0.30%, and H2O not more than 0.7%. The refining slag conditioning agent is premolten beforehand, wherein CaO and Al2O3 are combined to generate a lot of low-melting-point 12CaO-7Al2O3; the melting point of the refining slag conditioning agent is lowered; the slag can be quickly molten at the earlier stage of LF furnace refining; the power supply time is shortened; and the energy is saved; and as aluminum is uniformly distributed in the slag conditioning agent, the earlier deoxidation speed is quicker, and the deoxidation effect is excellent. The refining slag conditioning agent is lower in content of TiO, balances the [Ti] element in molten steel, and has a certain capacity of absorbing the [Ti] element in the molten steel.

Owner:QINGDAO SPECIAL STEEL CO LTD

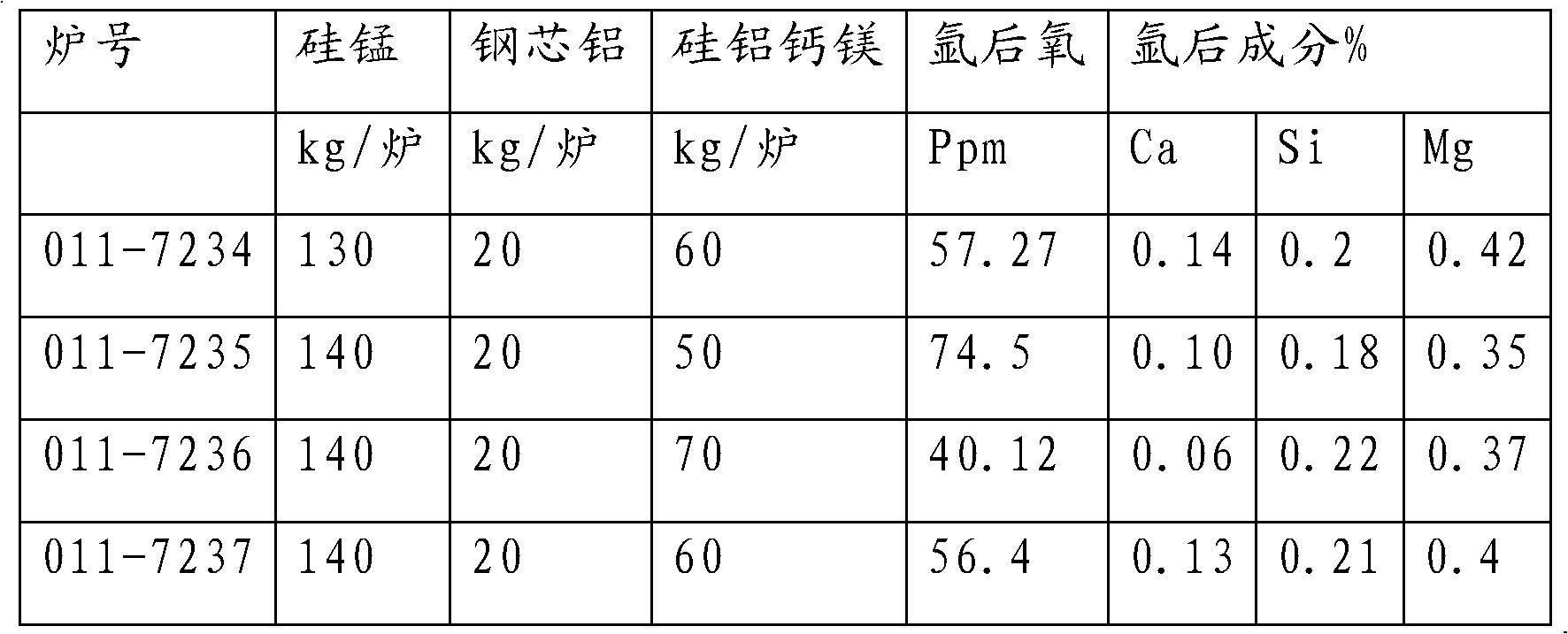

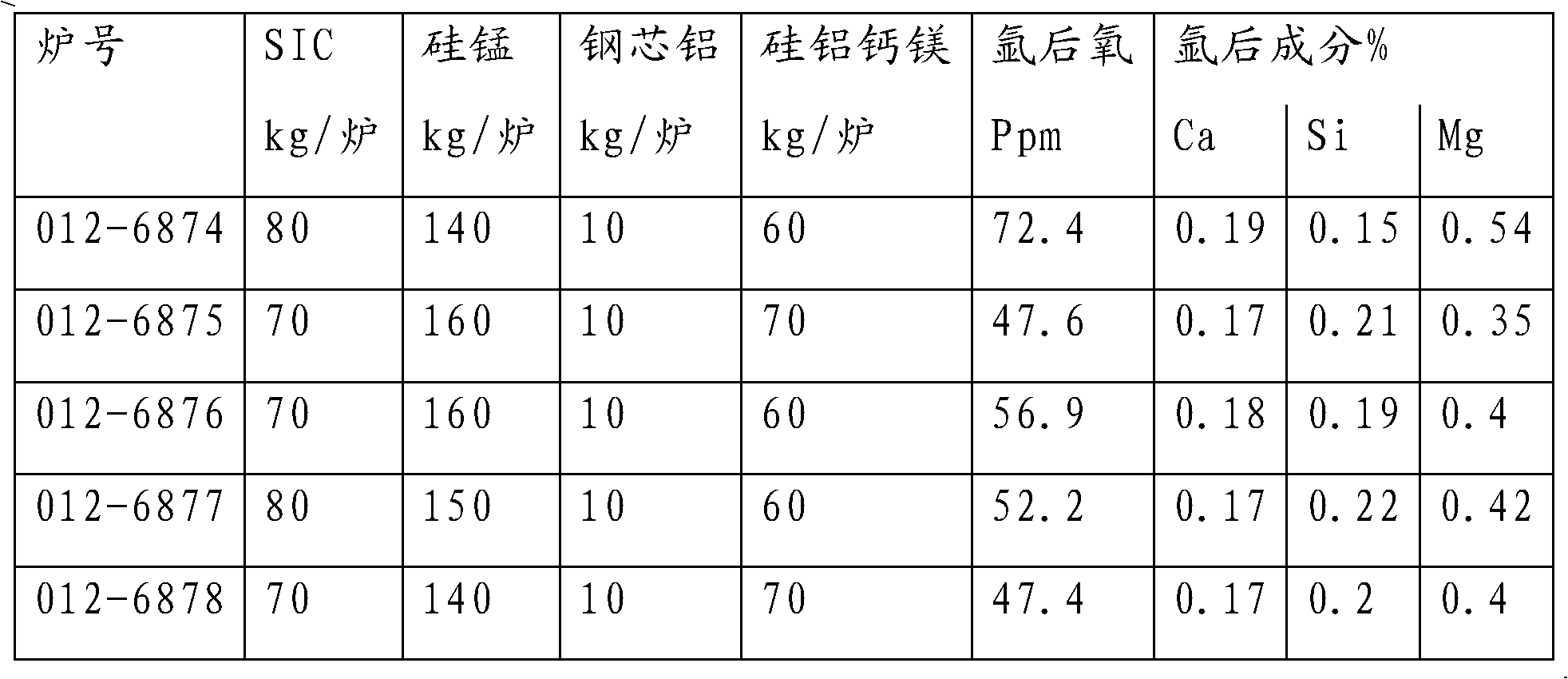

Silicon-aluminum-calcium-magnesium alloy as well as preparation method and application thereof

The invention provides a silicon-aluminum-calcium-magnesium alloy for steelmaking deoxidization. The alloy consists of the following components in percentage by weight: 10-30 percent of silicon (Si), 5-25 percent of aluminum (Al), 5-25 percent of calcium (Ca), 3-15 percent of magnesium (Mg), 5-20 percent of silicon carbide (SiC) and the balance of iron and inevitable impurities. When the alloy is applied to steelmaking deoxidization, smog is not produced, plugging and dross are avoided, the deoxidization speed is remarkably increased and the alloy recovery rate is high, so that energy consumption is lowered, environmental pollution is avoided, the quality of a steel product is enhanced and steelmaking cost is lowered. The invention also provides a preparation method and application of the silicon-aluminum-calcium-magnesium alloy.

Owner:刘治国

Method for preparing low-silicon-titanium-type vanadium slag from vanadium-containing molten iron

ActiveCN107312910AHigh silicon and titanium impurity contentHigh silicon and titanium impurity content, low vanadium contentProcess efficiency improvementSocial benefitsSlag

The invention relates to a method for preparing low-silicon-titanium-type vanadium slag from vanadium-containing molten iron. The method solves the problem that the vanadium slag which is melted by blowing from the vanadium-containing molten iron in an existing technology is high in silicon content and low in vanadium content. According to the method, a weak oxidizing gas is blown to the high-silicon low-vanadium molten iron as a weak oxidizing agent for removing the silicon, the silicon in the vanadium-containing molten iron is slightly oxidized into a silicon oxide gas to be removed, the vanadium in optimized molten iron is hardly oxidized, and the obtained optimized molten iron is high in vanadium content and low in silicon content; and then oxygen is used as a strong oxidizing agent to deeply oxidize the high-vanadium low-silicon purified molten iron, and the high-quality high-vanadium low-silicon vanadium slag is obtained. The method has the advantages of being reasonable in technological process design, simple, convenient, safe and stable in operation and free of environmental pollution and waste discharge. The vanadium slag prepared by the method is excellent in quality, low in silicon impurity content and titanium impurity content, and high in vanadium content. When the high-quality vanadium slag is used, the quality of vanadium pentoxide in the subsequent preparation and the quality of metal vanadium and vanadium series alloys prepared by the vanadium pentoxide can be remarkably improved, the technical process of subsequent preparation is simplified, and the economic and social benefits are improved.

Owner:隋智通

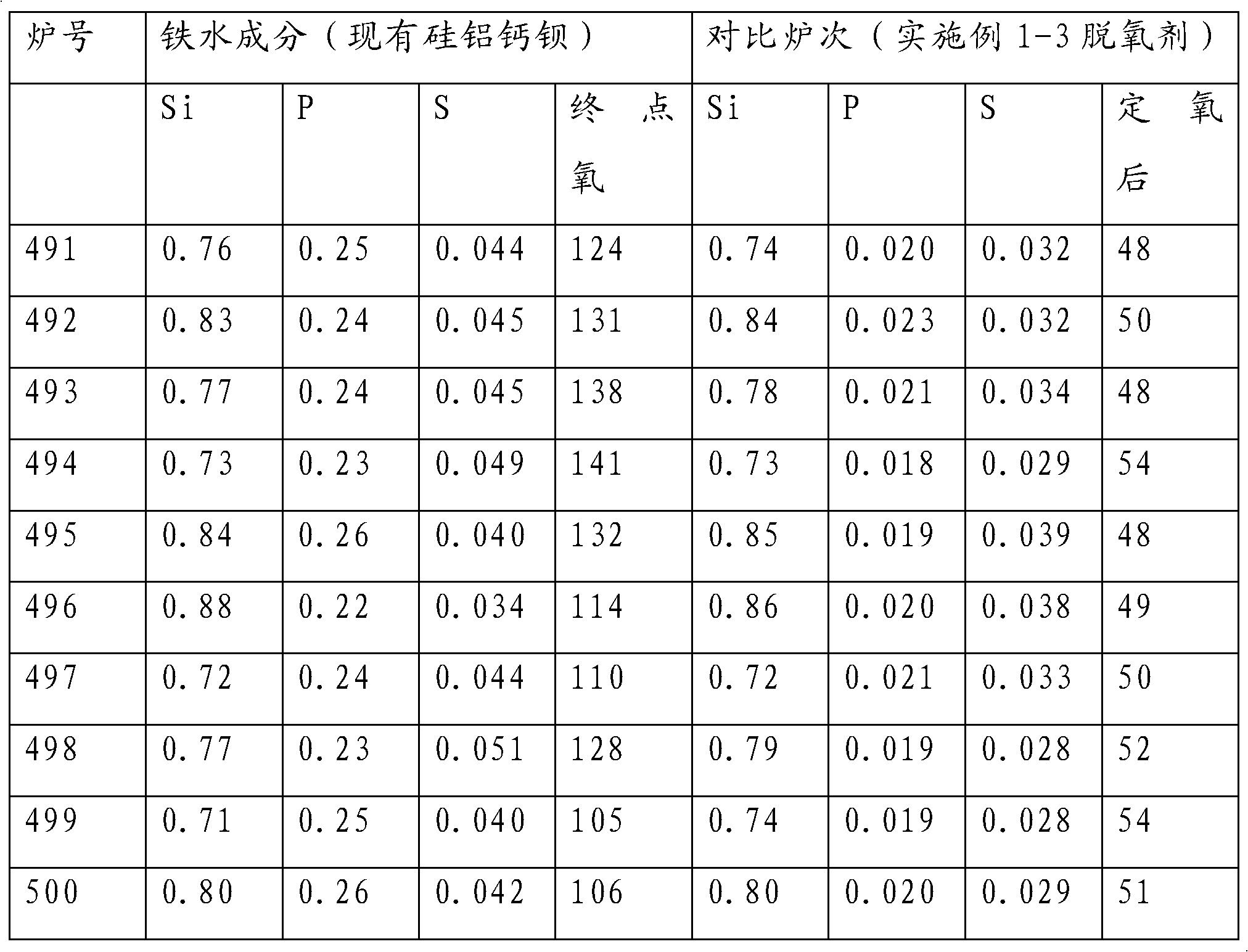

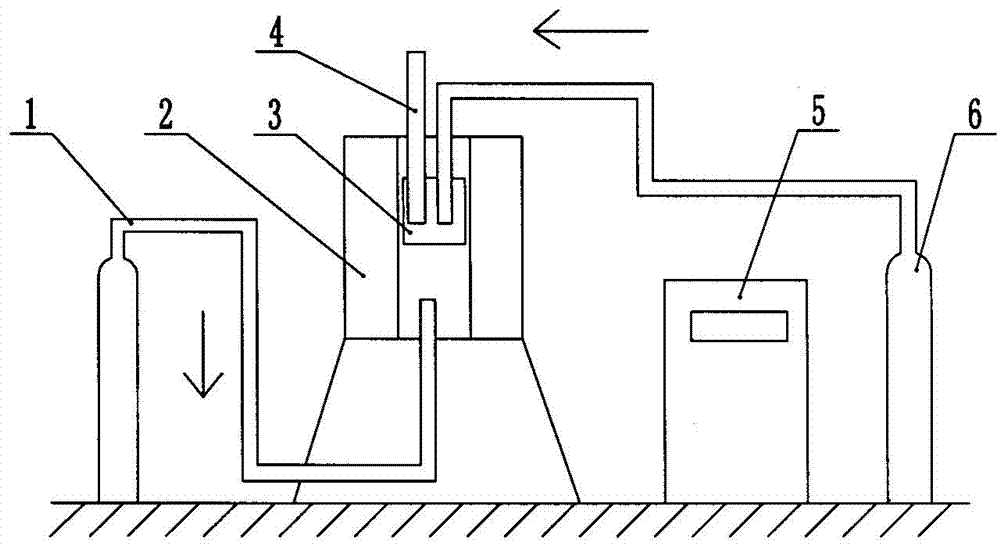

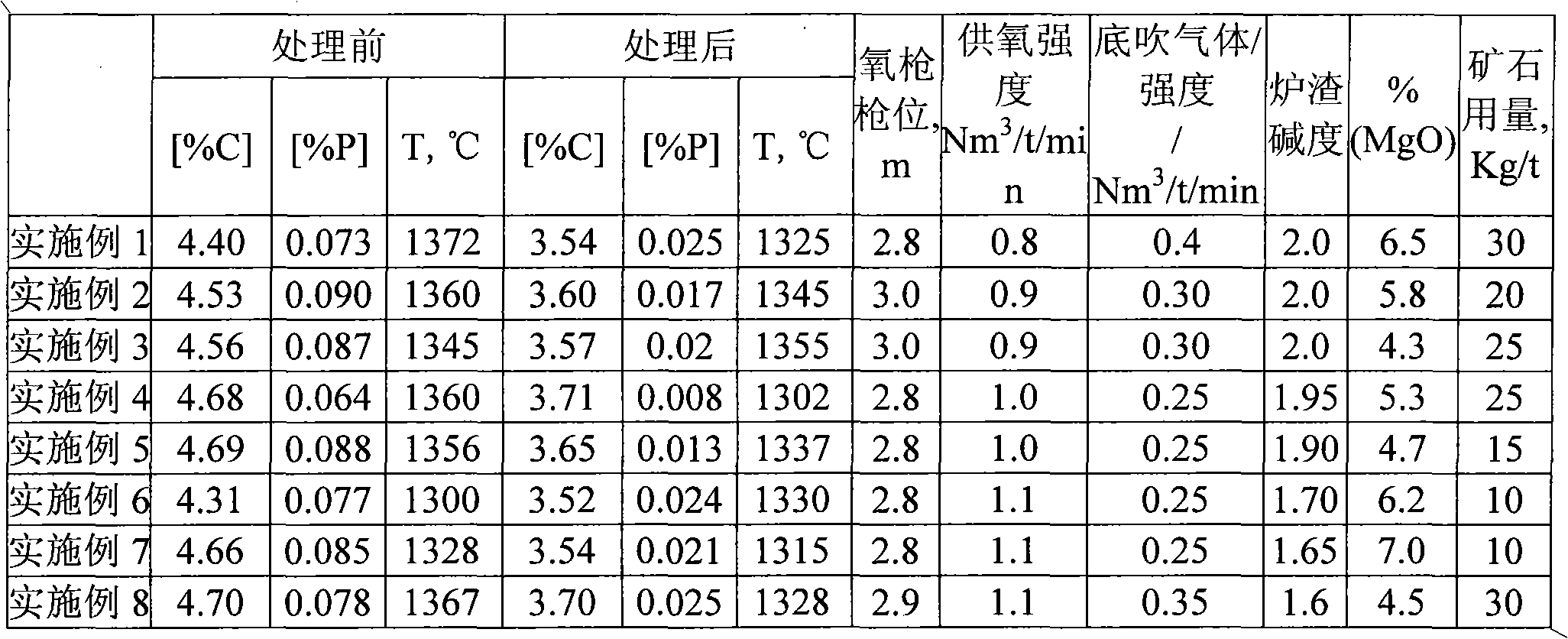

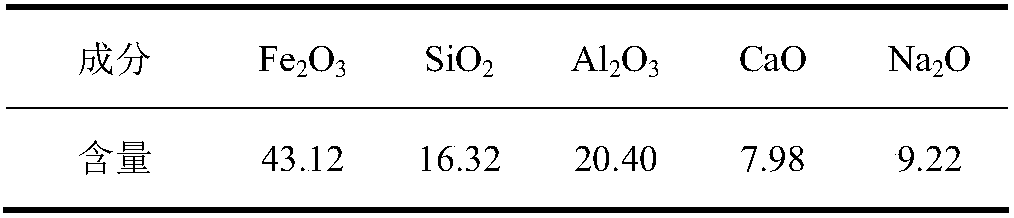

Dephosphorization method for molten iron

The invention provides a dephosphorization method for molten iron, which mainly aims at the dephosphorization of the molten iron of a large converter. The method comprises the following steps of: (1) supplying oxygen to the surface of the molten iron from the top through an oxygen lance, wherein the oxygen supply strength is changed in a range of 0.8 to 1.1 Nm<3> / t / min; (2) adding slag forming materials mainly comprising lime, light burned dolomite and ore into the molten iron through a hopper arranged above the converter to perform slag formation, wherein the binary alkalinity (CaO / SiO2) of the formed slag is 1.6 to 2.0; and (3) supplying stirring gas to the interior of the molten iron through a gas supply system at the bottom of the converter, wherein the gas supply strength is 0.25 to 0.40Nm<3> / t / min. The method promotes slag formation and oxygen supply by using low melting point of the low-alkalinity slag, easy slag forming property due to low temperature of the molten iron and large amount of the ore, prolongs the blowing time by using low oxygen supply strength, realizes full mix between slag and metal by using high bottom blowing strength, realizes dephosphorization, and has the advantages of good dephosphorization effect, low lime using amount, low consumption of accessories for dephosphorization and little slag discharge.

Owner:SHOUGANG CORPORATION

Ladle slag activator and application thereof

The invention relates to a ladle slag activator which comprises the following components in percentage by weight: 40-45% of active lime, 40-45% of pre-melted slag, 5-10% of fluorite, 5-7% of fused magnesia and 3-5% of aluminum particles, wherein the main component of the active lime is CaO, and the main components of the pre-melted slag are CaO and Al2O3. The invention also provides an application of the ladle slag activator. The invention has reasonable component selection and uniform component distribution and can ensure stable use in steel making; when the ladle slag activator of the invention is used on site, the slag melting speed is high, the fluidity of slag is good, and the corrosion on a ladle liner is small; and impurities in the molten steel are few, thereby reducing the pollution of other slag systems on the molten steel and improving the purity of the molten steel.

Owner:宝钢集团上海梅山有限公司 +1

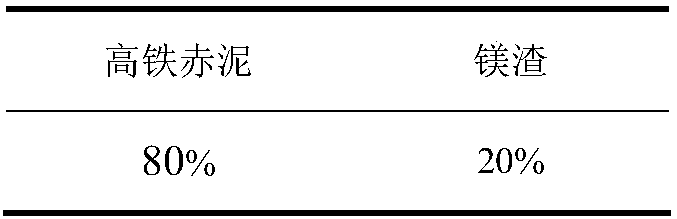

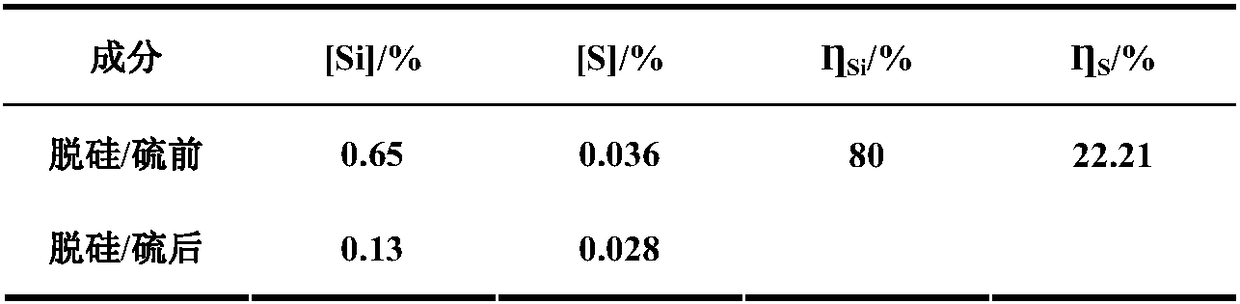

Molten iron desiliconization agent with high-ferric red mud as matrix and application method thereof

InactiveCN108220521ADesilication reaction time is sufficientImprove desiliconization efficiencySlagRed mud

The invention discloses a molten iron desiliconization agent with high-ferric red mud as a matrix and an application method thereof. The molten iron desiliconization agent comprises, by mass percent,70%-90% of high-ferric red mud and 10%-25% of magnesium slag. The binary basicity of the desiliconization agent is controlled within 0.6-1.2. The high-ferric red mud comprises 35-55% of Fe2O3, 10-20%of Al2O3, 5-15% of Na2O, and the balance SiO2, TiO2, CaO and impurities. The magnesium slag contains calcium oxide greater than or equal to 55%, magnesium oxide greater than or equal to 6% and silicondioxide less than or equal to 35%. Before or when blast-furnace tapping, the dry molten iron desiliconization agent is added into a hot metal ladle at 20-40 kg per ton of molten iron.

Owner:ANGANG STEEL CO LTD

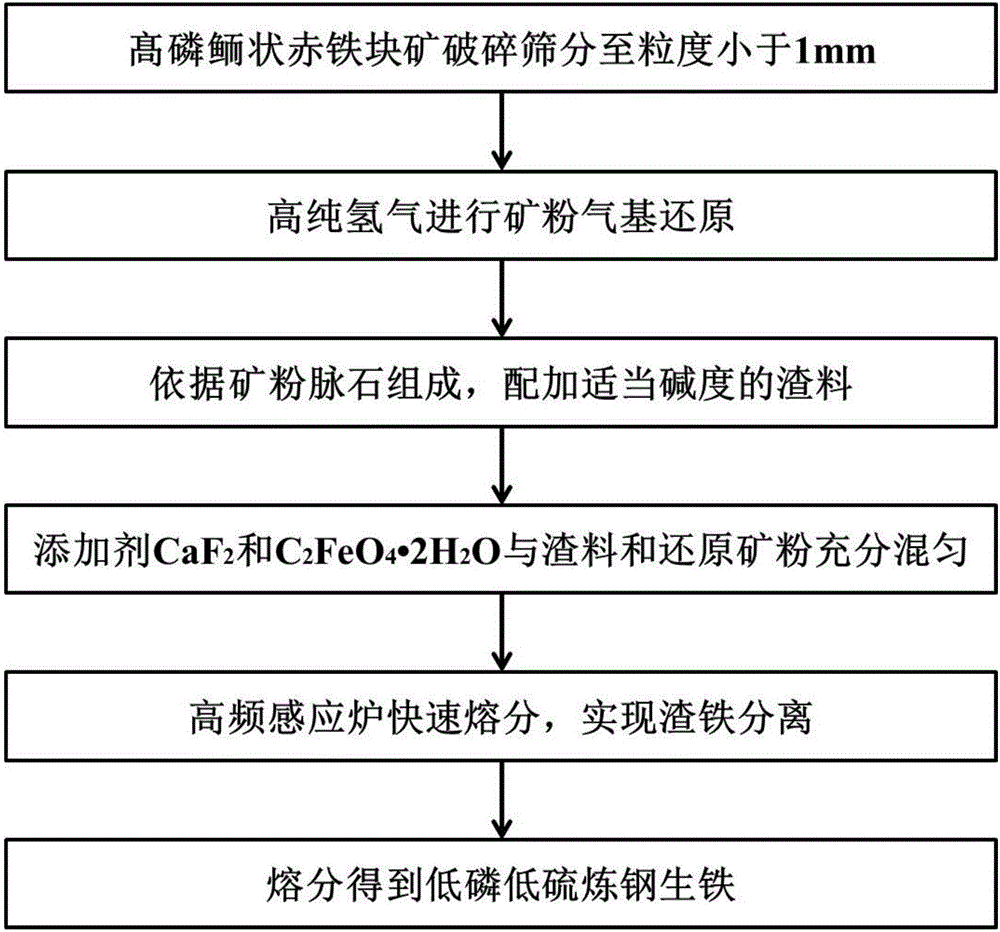

Method for preparing steel-making pig iron from high-phosphorus oolitic hematite based on high-frequency induction furnace

The invention relates to a method for preparing steel-making pig iron from high-phosphorus oolitic hematite based on a high-frequency induction furnace and belongs to the field of ferrous metallurgy and resource recycling. The method adopts high-purity H2 to perform gas-based reduction on raw mineral powder, facilitates improving the metallization ratio and the porosity of the mineral powder, and the metallization ratio of the mineral powder subjected to reduction reaches 85% or above. Through adding of favorably pre-molten CaO-SiO2 binary basicity slag charge and a little of powdery additives CaF2 and C2FeO4.2H2O, quick slag-iron deslagging and separation can be realized. The advantages that the high-frequency induction furnace is high in heating speed and melting efficiency are utilized to realize slag-iron separation within a short period of time. Meanwhile, as the induction furnace has a certain electromagnetic mixing effect, slag and iron are in full contact, and the system dephosphorization and desulfuration effects are improved. The steel-making pig iron prepared under the process condition has the phosphorus content of less than 0.3%, the sulfate content of less than 0.02%, the silicone content of less than 0.5% and the iron recovery rate more than 85%.

Owner:WUHAN UNIV OF SCI & TECH

Slagging agent used in converter steelmaking, and preparation method thereof

ActiveCN103131818AGood molding effectEasy to processManufacturing convertersProcess efficiency improvementSteelmakingSludge

The invention discloses a slagging agent used in converter steelmaking, and a preparation method thereof. The slagging agent is composed of, by mass, 50-55% of converter sludge, 35-45% of steel rolling oxide scale, and 5-10% of an adhesive. The preparation method comprises the steps that: (1) the converter sludge is bake-dried by using a rotary drying kiln, wherein a baking temperature is 750-850 DEG C; the rotary drying kiln also has a crushing and grinding function, and sludge particle size is lower than 3mm; (2) the raw materials are weighed according to the following mass percentages and are mixed in a mixing chamber: converter sludge 50-55%, steel rolling oxide scale 35-45%, and adhesive 5-10%; the mixed raw material is delivered to a stirring machine, and is well mixed with water; (4) the well mixed raw material is manufactured into pellets with a specification of 28*38mm by using a pellet pressing machine, such that the converter steelmaking slagging agent provided by the invention is prepared.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Method for producing premelting-type calcium aluminate from electrolytic aluminum waste residue

InactiveCN103966453AQuality improvementExtended service lifeChemical industryProcess efficiency improvementAluminateMelting tank

The invention discloses a method for producing premelting-type calcium aluminate from electrolytic aluminum waste residue. The method comprises the following steps of 1, purifying electrolytic aluminum waste residue, 2, mixing the purified electrolytic aluminum waste residue and lime, 3, putting the raw material into a melting furnace and carrying out melting, 4, discharging the melt product into a high temperature-resistant melting tank and carrying out cooling, and 5, crushing the cooled premelting-type calcium aluminate, carrying out screening and carrying out packaging. The method utilizes electrolytic aluminum waste residue and limestone to prepare the premelting-type calcium aluminate, realizes recycle of waste, is environmentally friendly, saves energy, prevents aluminum resource loss, reduces a calcium aluminate cost and reduces environmental pollution. The calcium aluminate produced by the method has the characteristics of less impurity and uniform and stable components, can be used for the refining process of LF, SKF and VHP and can greatly improve molten steel quality and a ladle service life.

Owner:ZHENGZHOU WHALE SPECIAL MATERIALS

Short process method of recycling LF liquid refining slag in thermal-state steel ladle

InactiveCN105969943AReduce consumptionFast slagProcess efficiency improvementElectricityThermal state

The invention provides a short process method of recycling LF liquid refining slag in a thermal-state steel ladle. After molten steel is refined through new slag manufactured for the first time, the sulphur distribution coefficient of the slag and steel is far lower than a theoretical balance value, and the slag can be reused. After the molten steel is poured completely, through hoisting with a crown block, the liquid refining slag is mixed with the molten steel to be refined with the LF, and then the mixed molten steel is hoisted to the LF to be subjected to refining operation. Consumption of lime and fluorite can be reduced, rapid slagging is realized through the physical heat of the slag, electricity consumption is lowered, the cost can be reduced by 5 yuan per ton of steel, and residual molten steel obtained after pouring with a casting machine can be recycled.

Owner:SHANDONG IRON & STEEL CO LTD

Submerged arc refining slag and preparation method thereof

InactiveCN102220456AImprove ingredient stabilityHigh yieldProcess efficiency improvementSlagHigh carbon

The invention discloses submerged arc refining slag, which is prepared from the following raw materials in part by weight: 35 to 40 parts of sintered bauxite, 1 to 2 parts of metal aluminum powder, 8 to 12 parts of silicon carbide, 2 to 4 parts of high carbon powder, 40 to 45 parts of limestone, 1 to 3 parts of blast furnace grain slag and 2 to 4 parts of lignin. In the invention, deoxygenation, submerged arc foaming and refining are integrated, production process is simplified, working environment is improved, the stability of ingredients of molten steel is improved, smelting cost is lowered, refining time is reduced, yield of expensive metal is increased, secondary oxidization of molten steel is relieved, the recovery rate of molten steel is increased, arc and noise pollution are reduced and the service life of refractory materials is prolonged.

Owner:ZHENGZHOU DONGSHENG METALLURGY NEW MATERIAL

Method for producing ultra-low phosphoretic steel by molten steel dephosphorising outside furnace

The invention provides a method to produce ultra low phosphorus steel by out-of-furnace dephosphorization, in particular to a controlling method to control phosphorus in steel during ultra low phosphorus steel production process. The invention is done according to the following steps: (1) when converter tapping, the weight percent of end phosphorus content is less than 0.013 percent and dephosphorization flux is added along with steel flow stream to ladle at the same time; (2) slag-stopping and non-deoxidation tapping is adopted; (3) after tapping, remove dephosphorization flux in the ladle; (4) after flux removal, refining treatment such as heating, deoxidation alloying and desulphurization; (5) continuous casting is done. The invention is convenient for operation, high efficiency of dephosphorization, short time consumption, and stable dephosphorization effect which can satisfy dephosphorization requirement of different content ultra low phosphorus molten steel by dephosphorization during the tapping without increase treatment time.

Owner:SHOUGANG CORPORATION

Start powder for stainless steel continuous casting and application thereof

ActiveCN113290216AImprove thermal conditionsImproving the Comprehensive Yield of Continuous CastingSteelmakingFerrosilicon

The invention discloses start powder for stainless steel continuous casting and an application thereof, and belongs to the technical field of steelmaking auxiliary materials. The start powder is prepared from the following raw materials of, in parts by weight, 20-30 parts of fluorite, 15-30 parts of cement clinker, 15-22 parts of glass powder, 9-20 parts of bentonite, 2-7 parts of white alkali, 3-6 parts of sodium nitrate and 10-20 parts of a heating material, and the heating material comprises a mixture of scrap iron and ferrosilicon alloy and does not contain coke or coke powder. The start powder for stainless steel continuous casting effectively avoids the problem of recarburization inevitably existing when common start powder uses coke or coke powder as a heating material, the start powder provided can meet the production requirements of stainless steel continuous casting, and on the premise of ensuring the quality of a first billet, the quality defects such as slag inclusion and recarburization of the first billet are reduced, and the stainless steel continuous casting comprehensive yield is improved.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Hot metal pretreatment dephosphorization agent and preparation method thereof

The invention discloses a hot metal pretreatment dephosphorization agent and a preparation method thereof. In mass percent, a formula of the dephosphorization agent comprises: 30-70% of drying sintering nose electric precipitation ash, 10-30% of lime CaCO3 and 10-40% of iron oxide; binary basicity CaO / SiO2 of the hot metal pretreatment dephosphorization agent is 3-4, and alkali chloride content is 5-15%; in mass percent, the total content of four substances, namely CaO, Fe, KCl and NaCl, in the dry sintering nose electric precipitation ash is not less than 60%, wherein the content of alkali chlorides is not less than 10%; and the iron oxide is one or more of sintered ore, iron ore powder, converter dust, electric furnace dust and oxidized scale. Ingredients of the formula of the dephosphorization agent are dried and treated and then are ground until particle size is below 1mm, and uniform mixing is carried out.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com