Dephosphorization method for molten iron

A technology of molten iron and lime, which is applied in the field of dephosphorization of molten iron using a large top-bottom combined blowing converter, can solve the problems of high equipment maintenance requirements, difficulty in popularization and application, and increase of injection equipment, so as to reduce erosion and environmental pollution, improve Dephosphorization efficiency, erosion reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

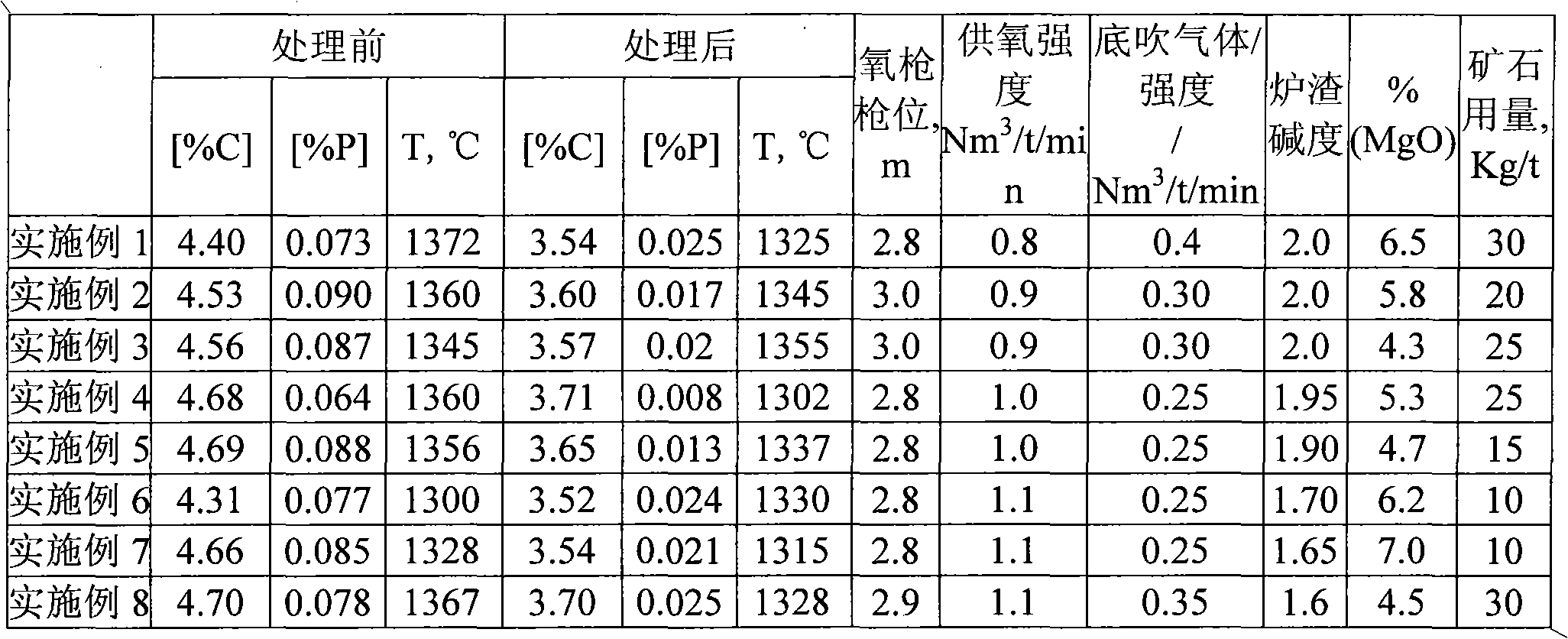

[0026] In order to clearly illustrate the main points of smelting of the present invention and its implementation effect, the embodiment and implementation effect of 210-ton converter smelting are provided.

[0027] According to the method for dephosphorizing hot metal in a large-scale top-bottom combined blowing converter provided by the present invention, scrap steel and molten iron are loaded into a 210-ton top-bottom combined blowing converter. , the position of the oxygen lance in blowing is 2.8-3.0m, and the oxygen supply intensity is 0.8-1.1Nm 3 / t / min, the specific oxygen lance position and oxygen supply intensity changes are shown in Table 1. After the oxygen lance is blown, put lime and light-burned dolomite into the converter at one time, and add pellets in four batches within 15%, 30%, 45%, and 60% of the total oxygen supply. Nitrogen is used as the bottom blowing gas in the blowing process, and the gas supply intensity is shown in Table 1. When blowing reaches t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com