Silicon-aluminum-calcium-magnesium alloy as well as preparation method and application thereof

A calcium-magnesium alloy and alloy technology, applied in the field of metallurgy, can solve problems such as product quality decline, low alloy recovery rate, and inability to desulfurize molten steel, so as to improve the mechanical properties of steel, improve the fluidity of molten steel, and increase the alloy recovery rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take silica (SiO 2 >98%) 300kg, silicon carbide (SiC>88%) 300kg, high-purity magnesia (MgO>95%) 120kg, bauxite (Al 2 o 3 >85%) 300kg, limestone (CaCO 3 >85%) 220kg, 20kg of steel shavings, mixed evenly, put into an intermediate frequency electric furnace to smelt the chemical material for 40-70 minutes, smelt at 1700°C for 110 minutes, remove the slag and get out of the furnace.

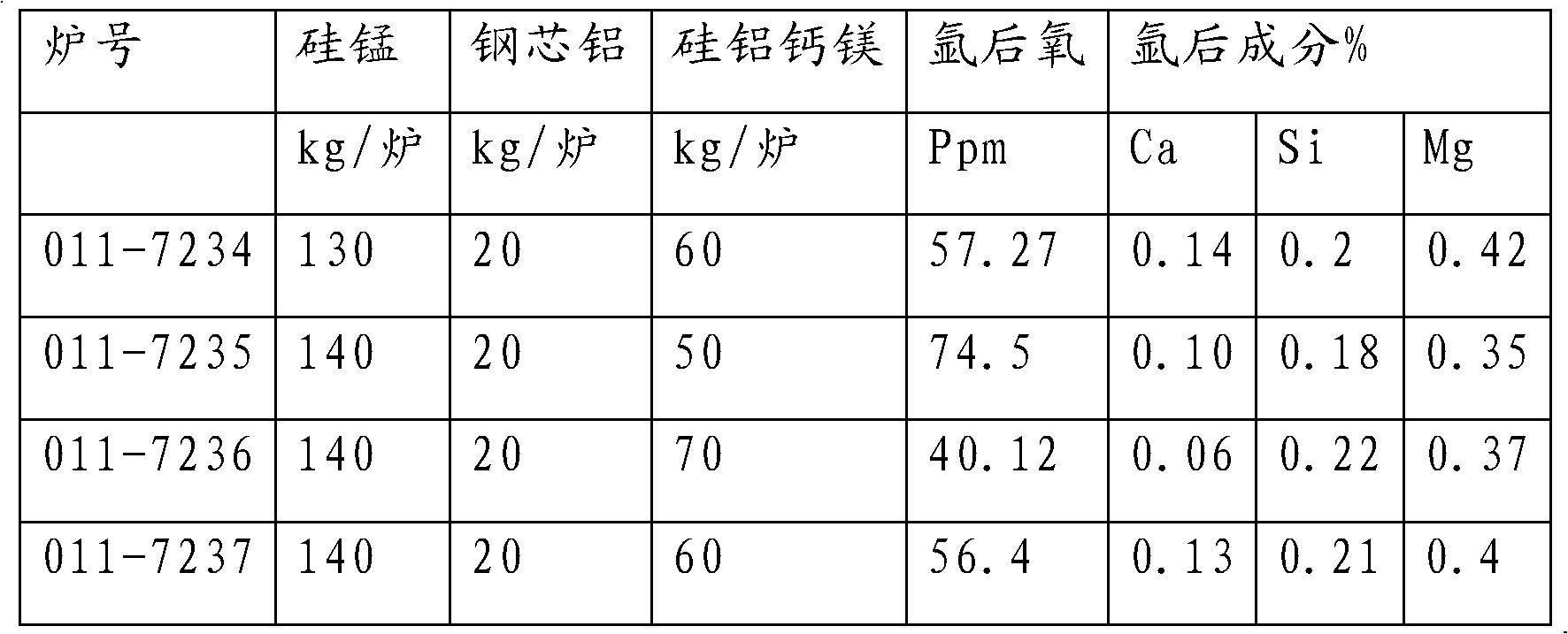

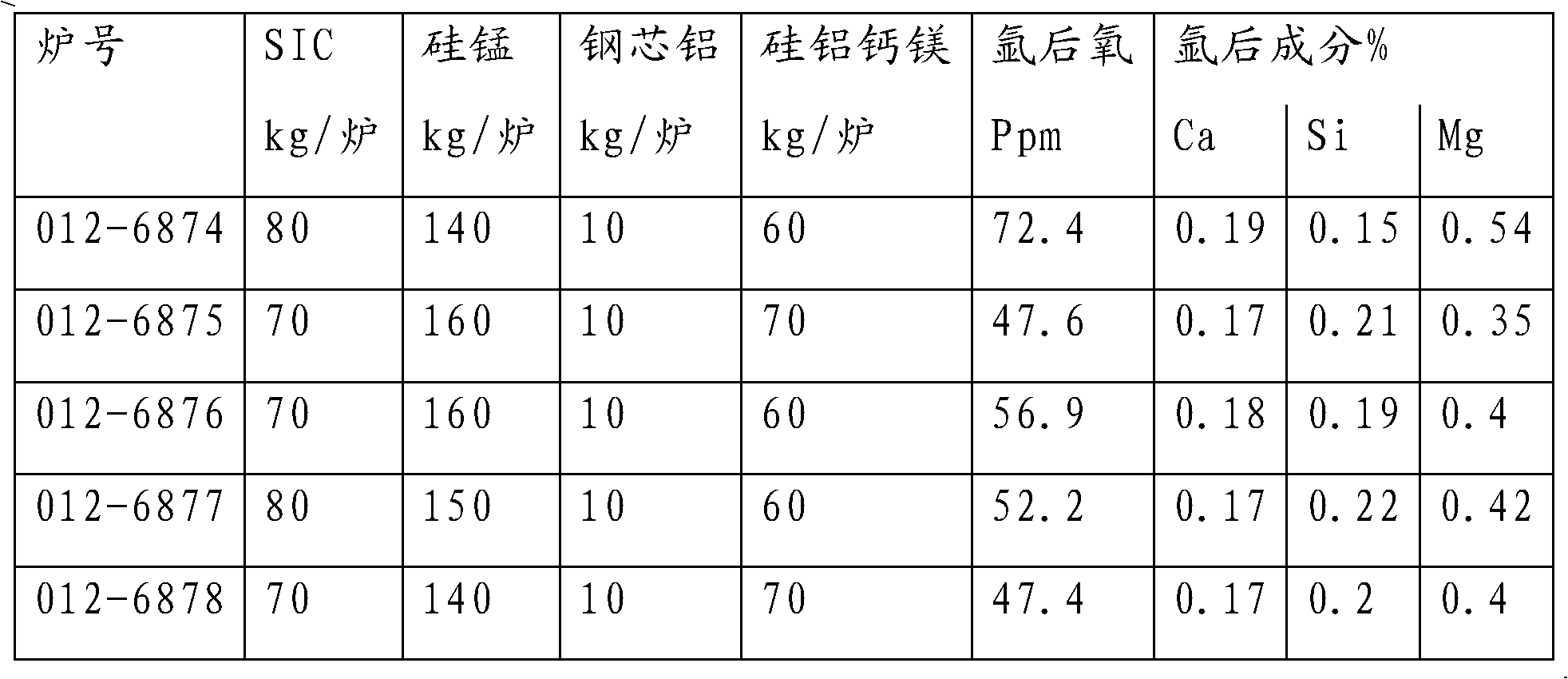

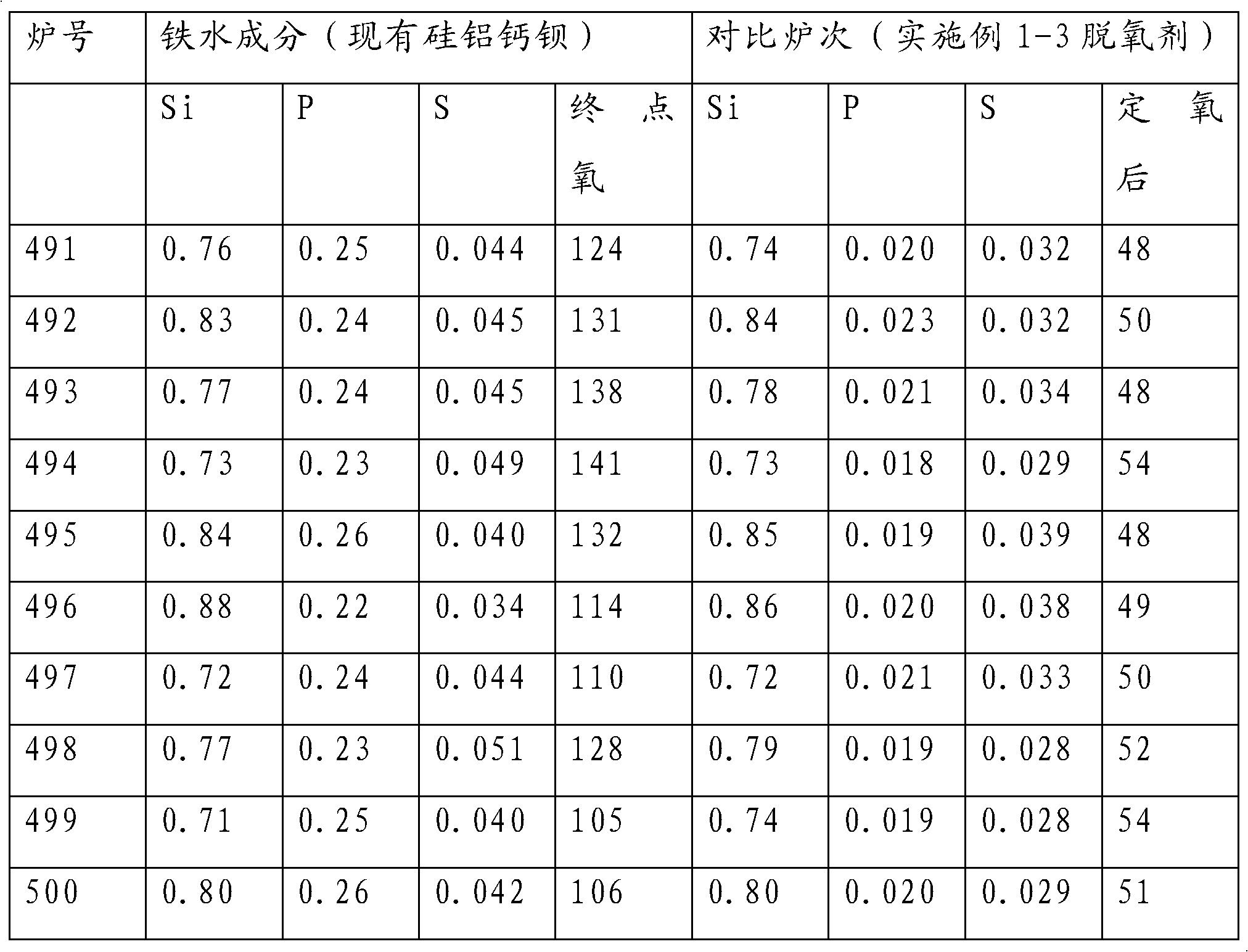

[0025] The obtained products were tested by the Rock and Mineral Testing Center of the First Institute of Geological Exploration of Henan Provincial Bureau of Geology and Mineral Resources, as shown in Table 1

[0026] Table 1

[0027] Test items and parameters

[0028] The percentage content of each component is: silicon (Si) 24%, aluminum (Al) 8%, calcium (Ca) 14%, magnesium (Mg) 5%, silicon carbide (SiC) 7%, sulfur (S) 0.06%, phosphorus (P) 0.025%, and the balance is iron. Melting point≤1320°C, melting rate (1600°C)≤50S, viscosity (1500°C)≤1pa.s.

Embodiment 2

[0030] Take silica (SiO 2 >98%) 280kg, silicon carbide (SiC>88%) 280kg, high-purity magnesia (MgO>95%) 100kg, bauxite (Al 2 o 3 >85%) 350kg, limestone (CaCO 3 >85%) 250kg, 20kg of steel shavings, mixed evenly, put into an intermediate frequency electric furnace to smelt the chemical material for 40-70 minutes, smelt at 1700°C for 110 minutes, and remove the slag to get it out of the furnace.

[0031] The resulting product is detected by the Rock and Mineral Testing Center of the First Academy of Geological Exploration of the Bureau of Geology and Mineral Resources of Henan Province, the same as in Example 1. The percentage content of each component is: silicon (Si) 22%, aluminum (Al) 12%, calcium (Ca) 18%, magnesium (Mg) 4%, silicon carbide (SiC) 6%, sulfur (S) 0.07%, phosphorus (P) 0.025%, and the balance is iron. Melting point≤1320°C, melting rate (1600°C)≤50S, viscosity (1500°C)≤1pa.s.

Embodiment 3

[0033] Take silica (SiO 2 >98%) 330kg, silicon carbide (SiC>88%) 330kg, high-purity magnesia (MgO>95%) 150kg, bauxite (Al 2 o 3 >85%) 250kg, limestone (CaCO 3 >85%) 200kg, 20kg of steel shavings, mixed evenly, put into an intermediate frequency electric furnace to smelt the chemical material for 40-70 minutes, smelt at 1700°C for 110 minutes, remove the slag and get out of the furnace.

[0034] Gained product is detected by the Rock and Mineral Testing Center of the First Institute of Geological Exploration of Henan Bureau of Geology and Mineral Resources, and the percentage composition of its components is as in Example 1: silicon (Si) 28%, aluminum (Al) 7%, calcium (Ca ) 12%, magnesium (Mg) 8%, silicon carbide (SiC) 10%, sulfur (S) 0.07%, phosphorus (P) 0.025%, and the balance is iron. Melting point≤1320°C, melting rate (1600°C)≤50S, viscosity (1500°C)≤1pa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com