Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

298results about How to "Improve dynamic conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for synthesizing metal matrix composition using metal reaction under the coupling action of magnetic field and ultrasonic field

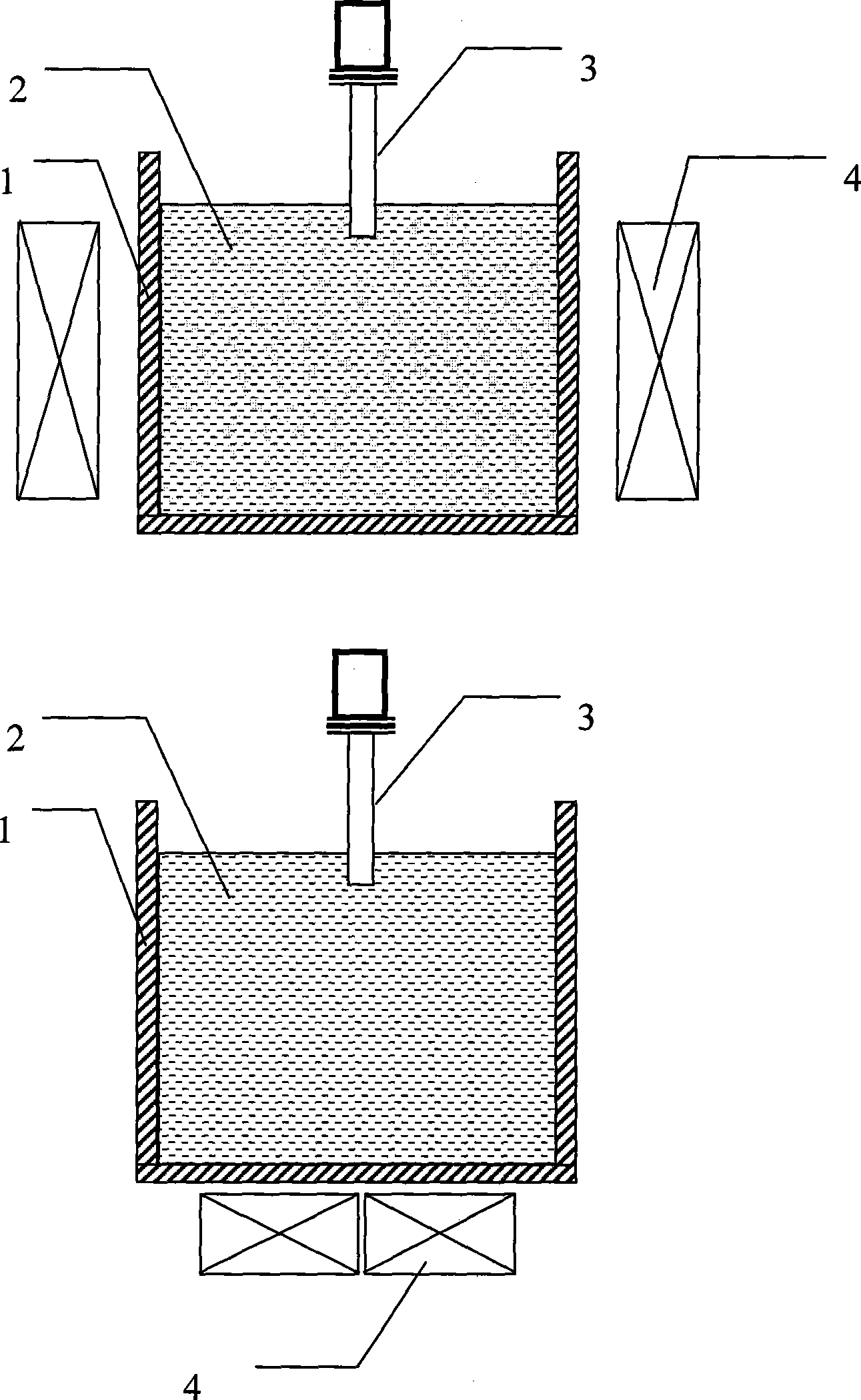

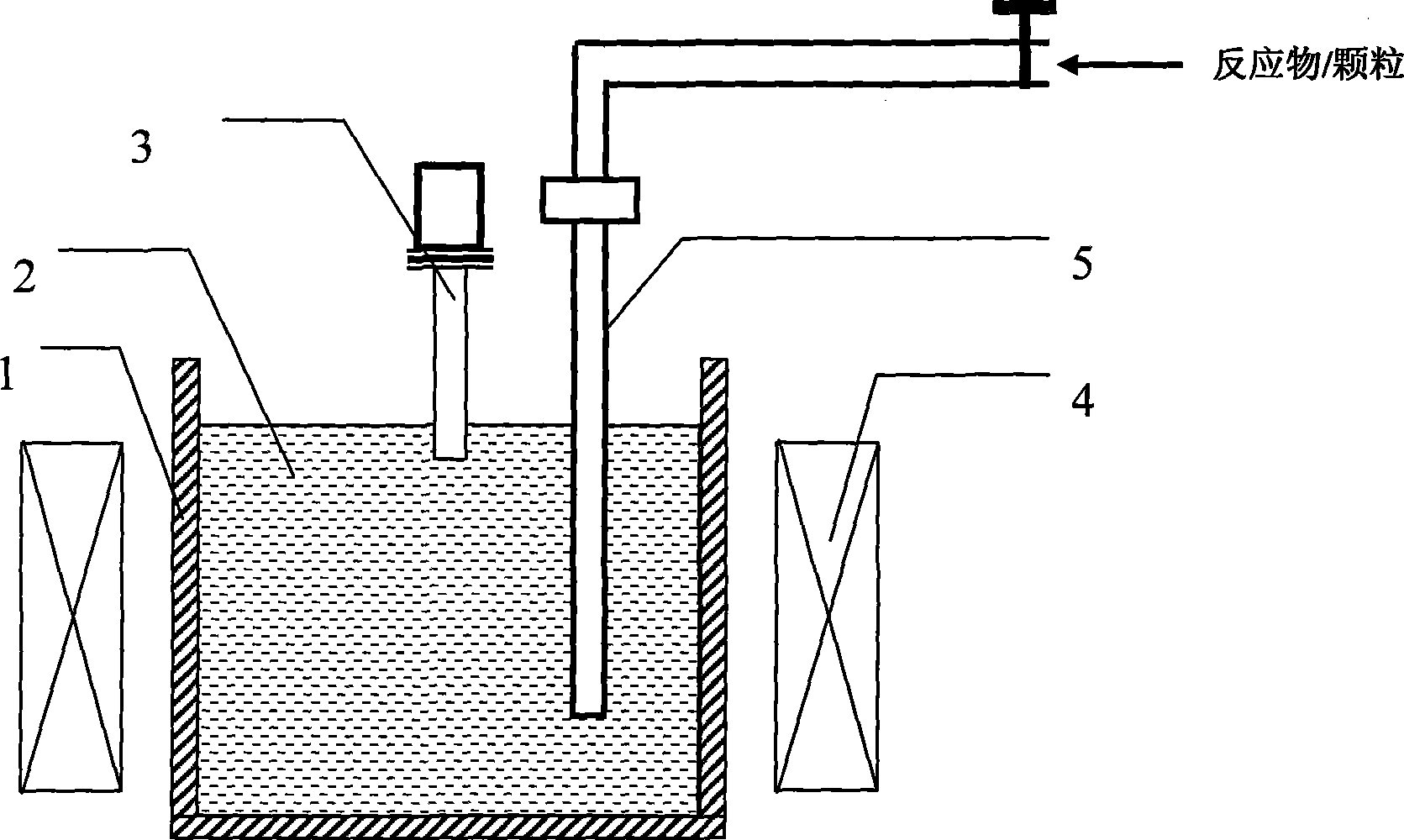

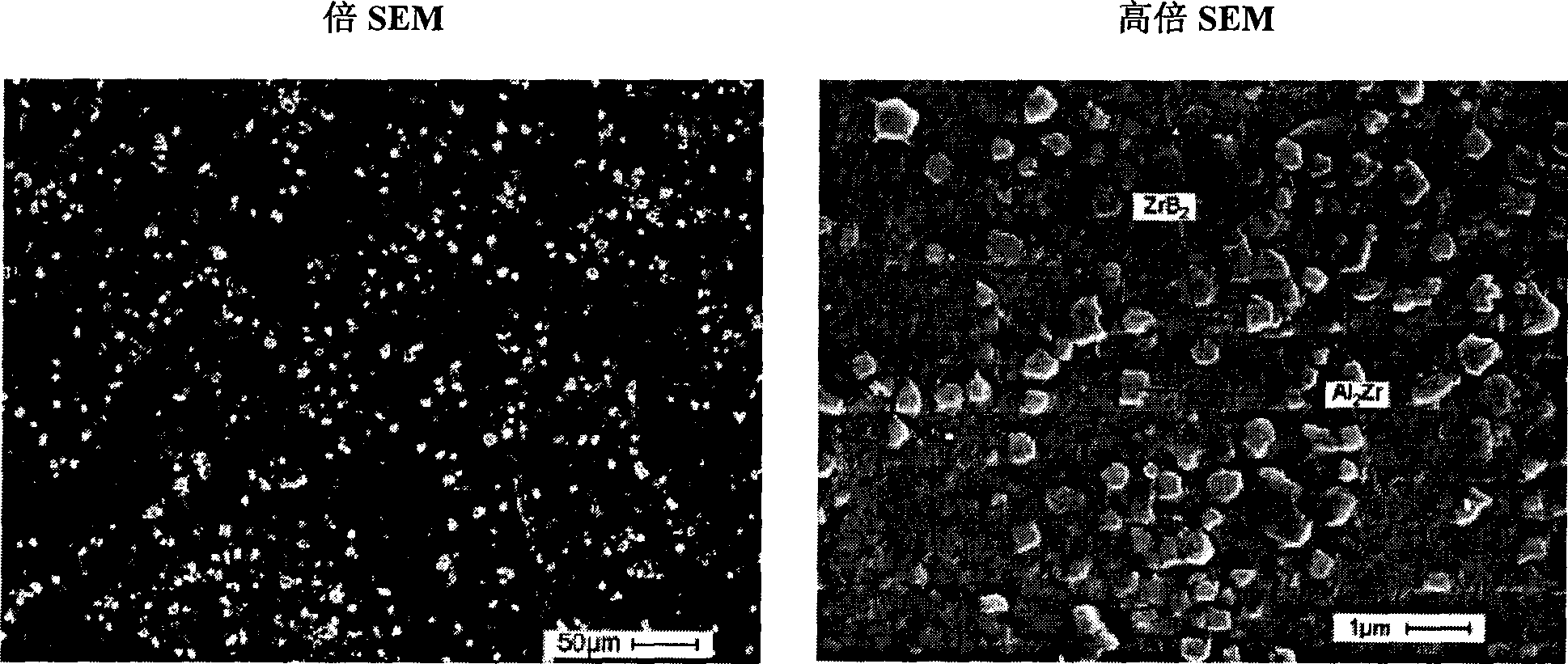

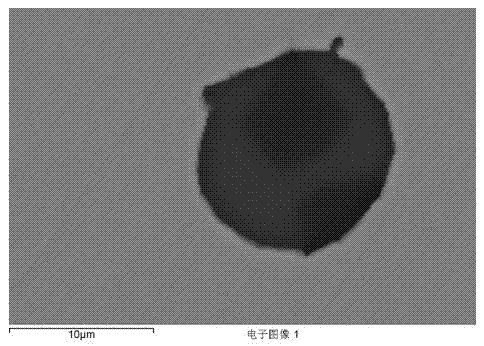

The invention relates to a method for preparing endogenetic particle reinforced metal matrix composites under the coupling effect of a magnetic field and supersonic waves. The method comprises: adjusting the temperature of a metal matrix fused mass to the reaction initial temperature after refining, adding a reactant which can generate a particle phase with the fused mass through the reaction in situ for implementing the synthesis reaction, standing the mixture after the reaction is over, and cooling the mixture to the pouring temperature for pouring; and the method is characterized in that: the magnetic field and the high-intensity ultrasonic field are simultaneously exerted in the reaction synthesis process to realize the synthesis of endogenetic particle reinforced metal matrix composites under the coupling effect of the magnetic field and the high-intensity ultrasonic field. The magnetic field can be an intense pulse magnetic field, a high frequency oscillation magnetic field or a low frequency alternating magnetic field. In the method, the coupling effect of the magnetic field and the ultrasonic field makes the particle sizes be thinned and dispersed evenly; the ultrasonic vibration agitation and electromagnetic stirring functions improve the composite dynamic condition, and the compounding of the particle phase and a base metal interface is better; and the co-action of magnetochemistry and sonochemistry improves the thermodynamic condition of the reaction in situ, as well as speeding up the reaction in situ and controlling the growth of the particle phase.

Owner:JIANGSU UNIV

Smelting method of HIC (Hydrogen Induced Crack)/SSCC (Sulfide Stress Corrosion Cracking)-preventing steel

ActiveCN103540833AImprove dynamic conditionsAchieve transformationManufacturing convertersProcess efficiency improvementOxygenStress corrosion cracking

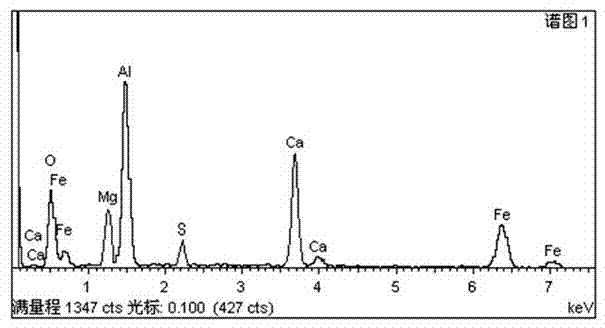

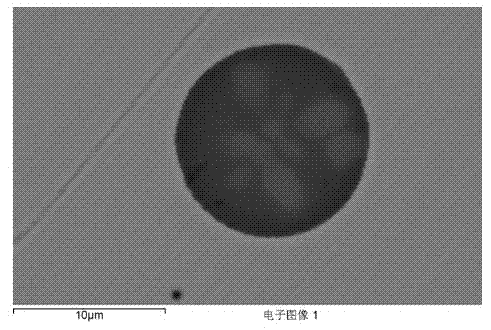

The invention discloses a converter smelting and external refining control method of HIC (Hydrogen Induced Crack) / SSCC (Sulfide Stress Corrosion Cracking)-preventing steel. A smelting process route of converter-CAS (Control Automatic System) station-LF (Low Frequency) refining-VD (Vacuum Distillation) / RH (Relative Humidity) vacuum-calcium treatment-soft blowing-continuous casting is adopted. Low-phosphor requirements of the HIC / SSCC-preventing steel are obtained through controlling the converter smelting process route; and meanwhile, part of deoxidation type inclusions are removed by carrying out strong deoxidation, alloying as well as residue washing in a converter steel-tapping process, and over 60% of sulfur in molten steel is removed by sufficient stirring of the residue washing. In the LF refining process, refining furnace slag which is high in alkalinity, high in Al2O3 and strong in reducibility is obtained by regulating components of the refining furnace slag, and the inclusions are transformed and removed towards a low melting point by virtue of balance of the furnace slag-molten steel-inclusions. Proper vacuum treatment time and vacuum degree are kept at a vacuum treatment furnace so as to remove part of gas and inclusions, excessive calcium line is fed into the molten steel after being broken in air, and then the molten steel is softly blown and stirred for over 20 minutes to obtain the molten steel with ultralow oxygen and ultralow sulfur.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

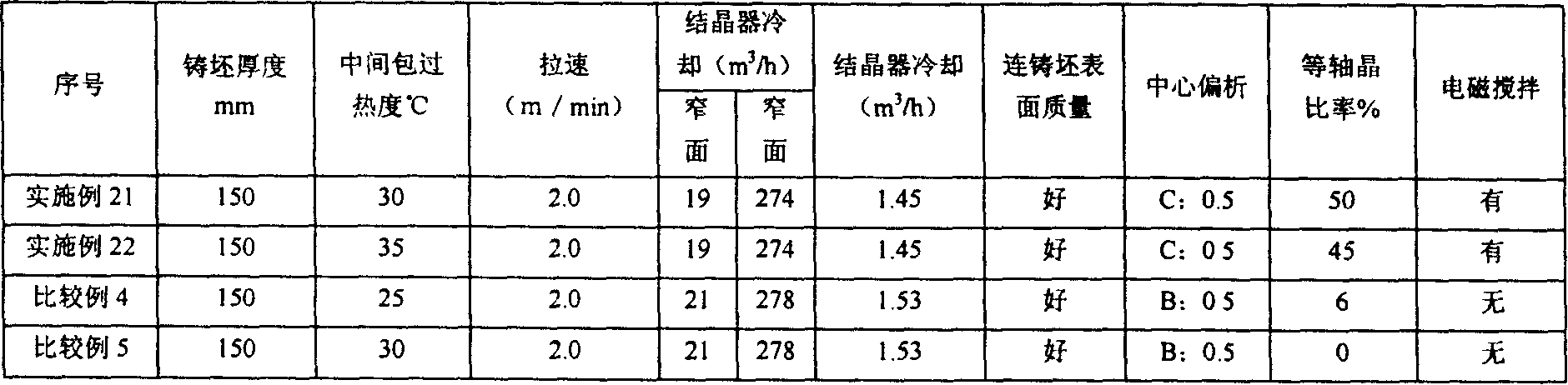

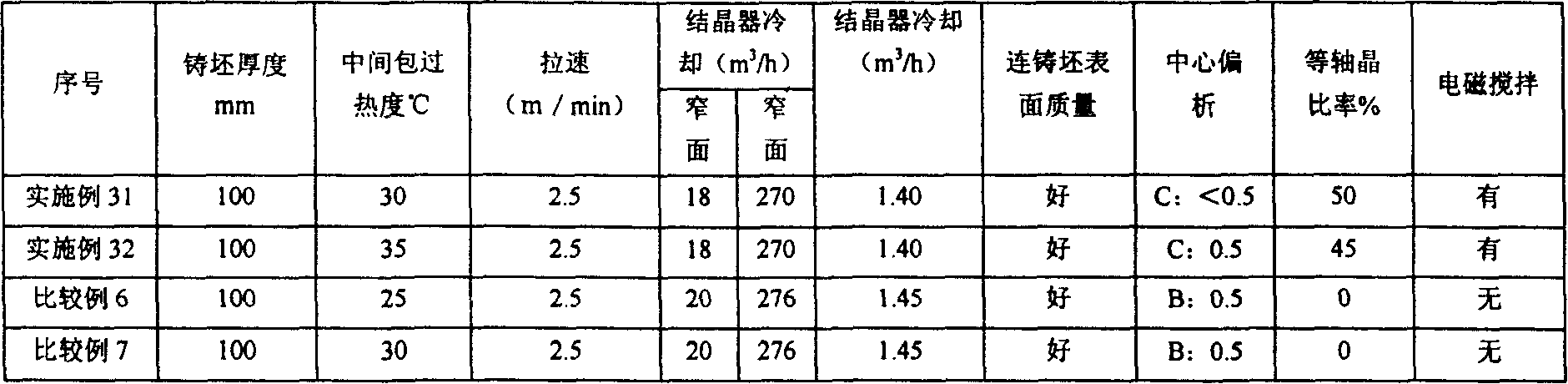

Continuous casting method for increasing equal thickness continuous casting plate billet equal axial crystal rate in non-oriented silicon steel

InactiveCN101164720AImprove mechanical propertiesImprove dynamic conditionsSiliconElectromagnetic stirring

The present invention provides a continuous casting method capable of increasing non-oriented silicon steel medium-thickness continuous cast slab equiaxial crystal rate. It is characterized by that it adopts a medium-thickness slab continuous casting machine, in the continuous casting second cooling zone it adopts a roller electromagnetic stirring equipment. The casting billet size of continuous casting machine is 100-150mmX850-1550mm, pouring speed is 1.5-3.5m / min, the cooling pattern: the narrow edge of crystallizer is 14-25m3 / h, the wide edge of crystallizer is 250-290m3 / h and second cooling intensity is 1.3-1.8L / kg. The described electromagnetic stirring equipment includes 2-4 pairs of introroller built-in traveling wave magnetic field type electromagnetic stirring devices which are assembled into two groups and mounted.

Owner:ANGANG STEEL CO LTD

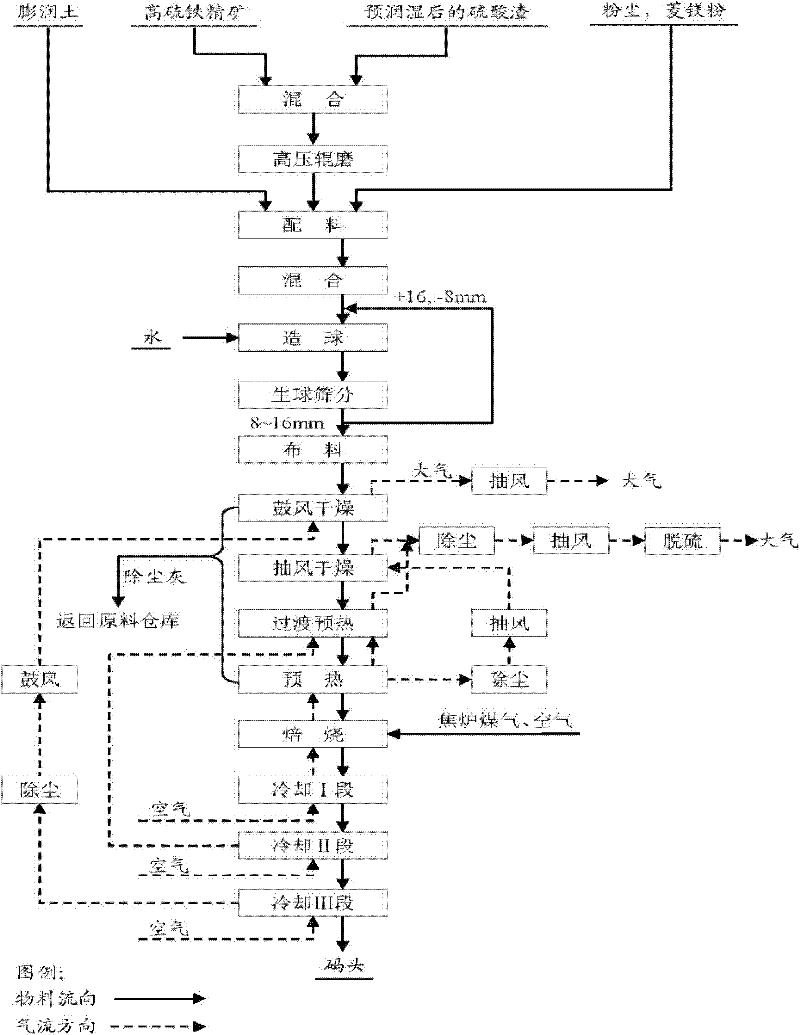

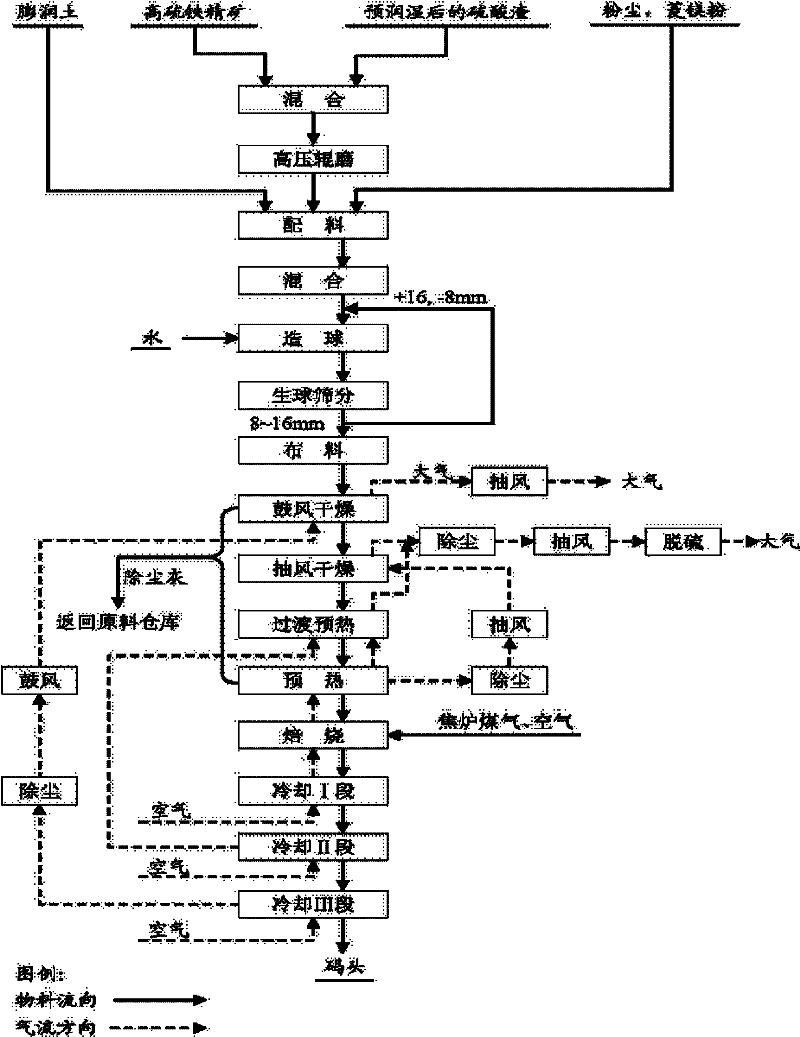

High sulfide pyrite pellet reinforced roasting consolidation technology

ActiveCN102242254ASolve roasting problemsImprove dynamic conditionsBlast furnace detailsDecompositionSlag

The invention discloses a high sulfide pyrite pellet reinforced roasting consolidation technology. Pellets are produced by adopting the technology of drying grate--rotary kiln--ring type refrigeration machine--flue gas desulphurization. The basic flow is as follows: prebatching--mixing--high press roll grinding--batching--mixing--pelletizing--drying--preheating--roasting--cooling--finished product output--flue gas desulphurization. From the perspectives of the occurrence state of sulfur in raw materials, the decomposition behavior of sulfur during the heating process, the iron ore pellet forming theory and the iron ore pellet consolidation mechanism, the system integration reinforced high sulfide pyrite pellet forming and pellet consolidating technology, which includes the improvement of pyritic slag pellet forming dynamics condition, the reinforcement of high sulfur pellet desulphurization and consolidation during the preheating and roasting processes and the control of high SO2 concentration flue gas features and migration rules, is adopted to solve the roasting problem of high sulfide pyrite, make the sulfur content of the finished pellets and the pellet ore strength reach related technical requirements and basically prevent flue gas from corroding equipment. The invention provides a new approach for effective utilization of high sulphur-containing iron concentrate and sulfuric acid slag resource.

Owner:CENT SOUTH UNIV +1

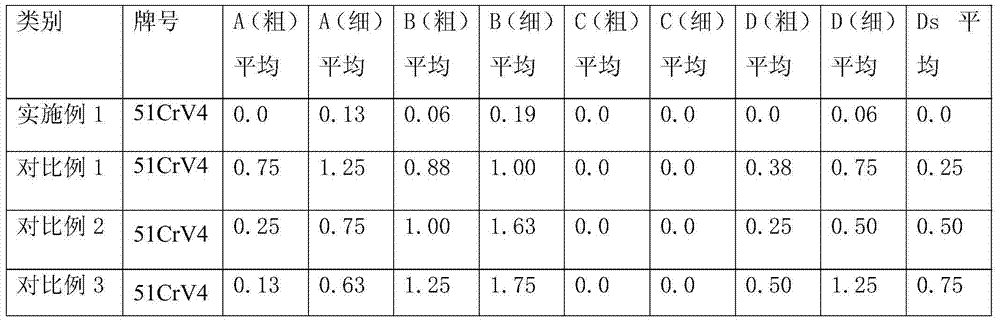

Smelting process of Cr-Mn series spring steel

ActiveCN104745765AImprove liquiditySolve the problem of high alkalinity slag and difficult adsorption and inclusionElectric furnaceProcess efficiency improvementNon-metallic inclusionsSmelting process

The invention belongs to the field of metallurgy and discloses a smelting process of Cr-Mn series spring steel. The smelting process of Cr-Mn series spring steel comprises the following steps: (1) by taking a low-sulfur molten iron and a high-quality steel scrap as the electric furnace smelting iron and steel materials, controlling the electric furnace end point carbon content to greater than 0.15%; (2) adding active lime and composite refining slag in the electric furnace tapping process, and adding calcium carbide to perform pre-deoxidation in the tapping process; (3) feeding an Al line in an argon station before LF refining; (4) producing high basicity white slag in the refining earlier stage and controlling the basicity of slag in the refining middle and later stages to 1.5-2.5; (5) controlling the ultimate vacuum front argon flow to 15-25 L / min and controlling the ultimate vacuum late argon flow to 30-45 L / min; (6) adding a granular alkaline covering agent and a carbonized rice hull to perform double protection by VD emptying; and (7) stabilizing the speed of continuous casting to 0.8-0.9 m / min, and controlling the degree of superheat to 20-30 DEG C. By adopting the process, the non-metallic inclusion content in the molten steel is reduced.

Owner:ZENITH STEEL GROUP CORP +1

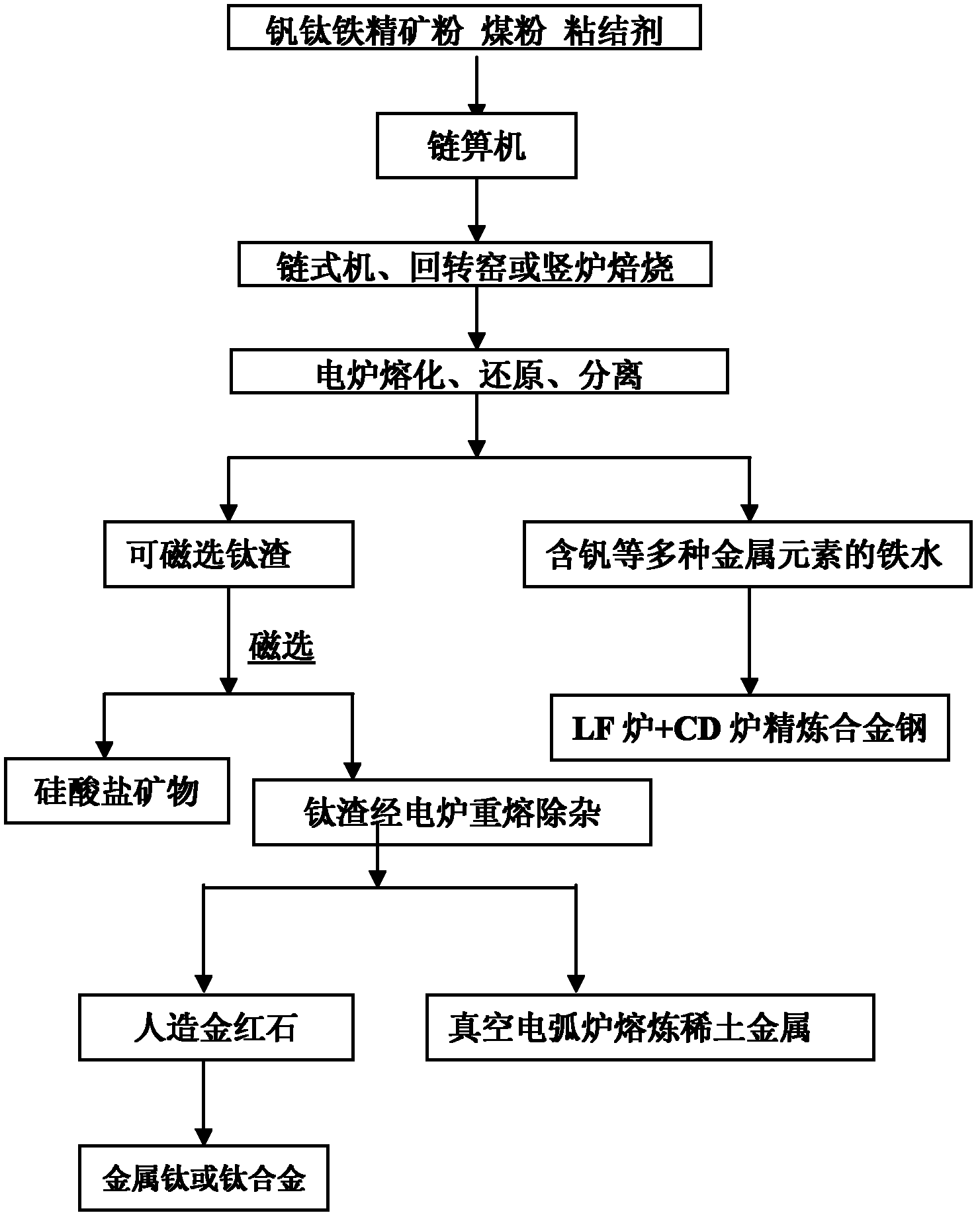

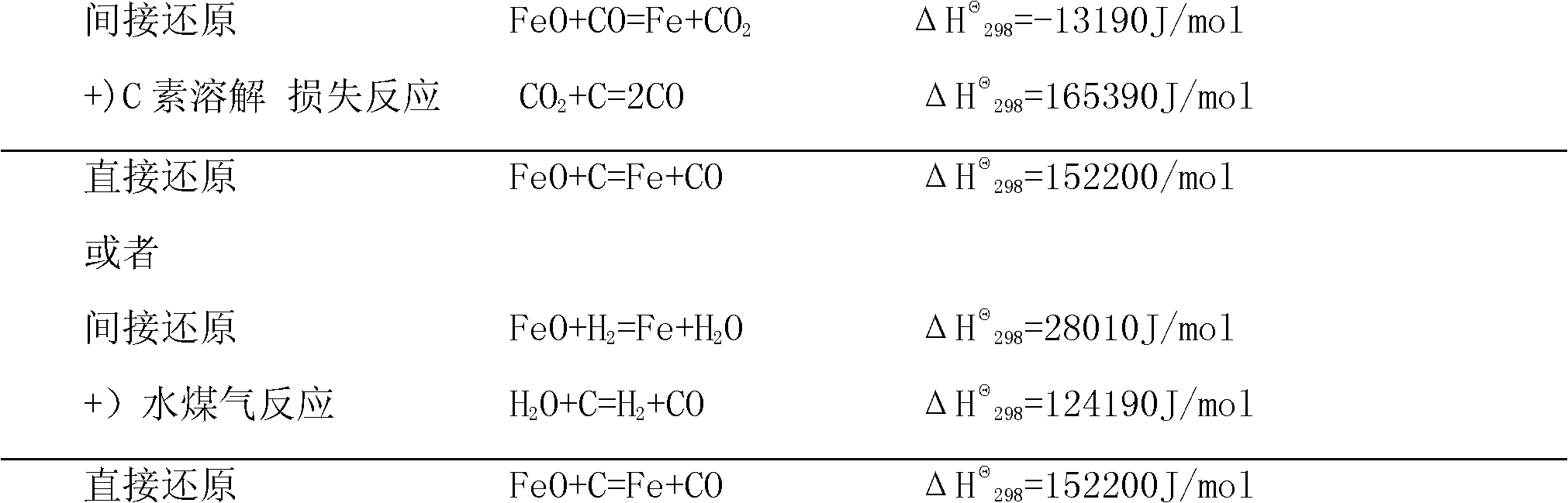

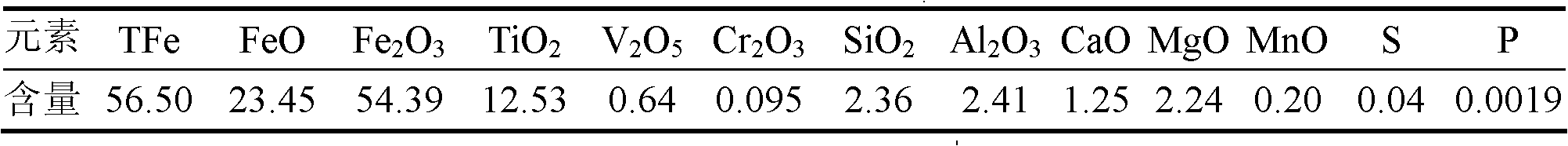

Method for selecting and smelting titanium from vanadium titanomagnetite at low temperature

InactiveCN102352423AQuick restoreIncrease magnetic susceptibilityProcess efficiency improvementElectric furnaceDc arc furnaceTitanium metal

The invention relates to a method for selecting and smelting titanium from vanadium titanomagnetite at low temperature, belonging to the technical field of metallurgy. The method comprises the following steps: 1) roasting at the low temperature of 500-1100 DEG C; 2) adding a solid reductant to the roasted product, carrying out reduction smelting at 1100-1300 DEG C, and separating slag and iron torespectively obtain molten iron and titanium slag; carrying out magnetic separation on the titanium slag to remove impurities, thereby obtaining the titanium-rich material; and 4) adding required metal oxide concentrate into a direct-current arc furnace, and directly alloying the molten iron to obtain alloy steel. The smelting method provided by the invention is a brand new smelting method, and changes the existing iron ore selection into titanium ore selection; the pellet is molten and reduced by roasting at low temperature, and the separated molten iron facilitates the addition of ores withdeficient metal elements so as to directly smelt the alloy steel; the titanium slag is subjected to magnetic separation to obtain the titanium-rich material, and the titanium-rich material is furthersmelted to obtain the titanium alloy or titanium metal; and the smelting slag can be used as the raw material for smelting rare earth metals so as to sufficiently and respectively utilize the elements in the ores in one step.

Owner:攀枝花慧泰金属新材料有限公司

Smelting process for control of spring steel inclusions

ActiveCN105907919AEasy to controlReduce sources of refractory and refractory inclusionsProcess efficiency improvementElectric furnaceSmelting processIntermediate stage

The invention discloses a smelting process for control of spring steel inclusions, wherein the smelting process includes the steps: 1) electric furnace primary smelting; 2) argon blowing; 3) LF refining; 4) VD furnace refining; and 5) continuous casting. In the electric furnace primary smelting steel-tapping process, an Si / Mn Al-free deoxidation process is adopted for pre-deoxidation, and at the same time, active lime, a compound agent and refining slag are adopted; in the earlier stage of the LF refining, an Si / Mn Al-free deoxidation process and active lime are adopted, and the furnace slag basicity is controlled at 1.5-2.5; in the middle stage of the LF refining, refined slag is added, followed by, the Si / Mn Al-free deoxidation process continues to be adopted, deoxidation and desulfuration continues to be carried out, and the furnace slag basicity is guaranteed to be controlled at 0.7-1.4; argon bottom blowing is carried out in the whole process of the LF refining. The Al-free deoxidation process and the low-basicity furnace slag desulfuration process are adopted and are combined with a specific deoxidizing agent, the inclusions in spring steel can be well controlled, and thus the anti-fatigue property of the spring steel is improved.

Owner:HANGZHOU IRON & STEEL GRP

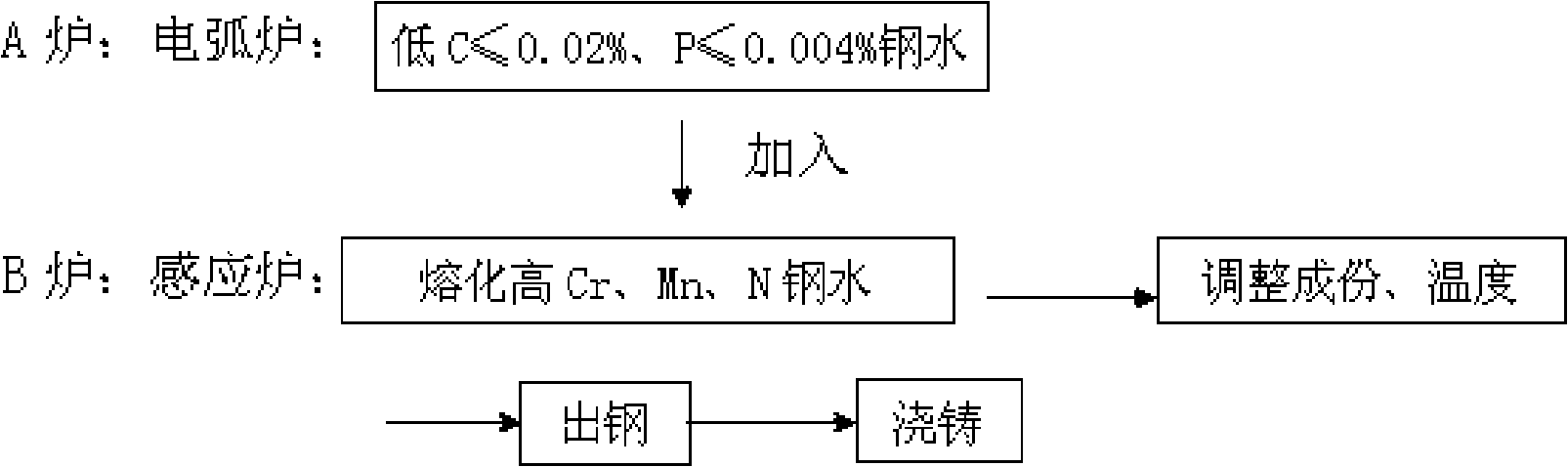

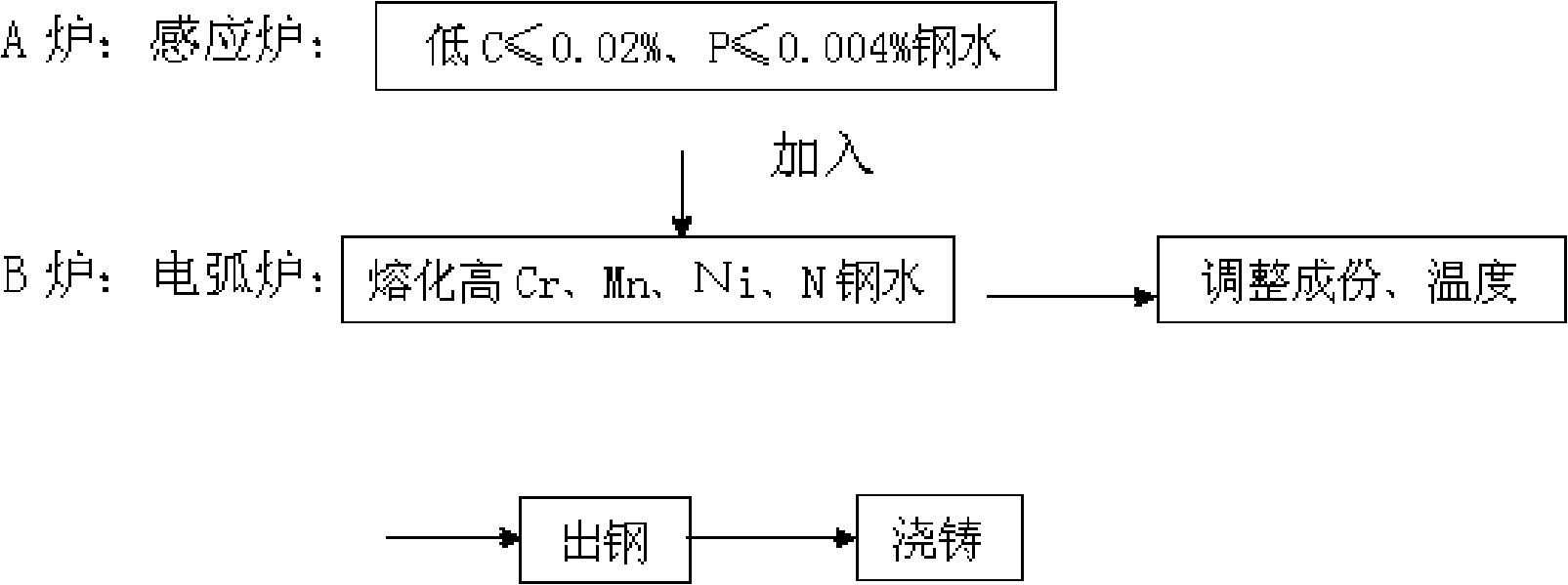

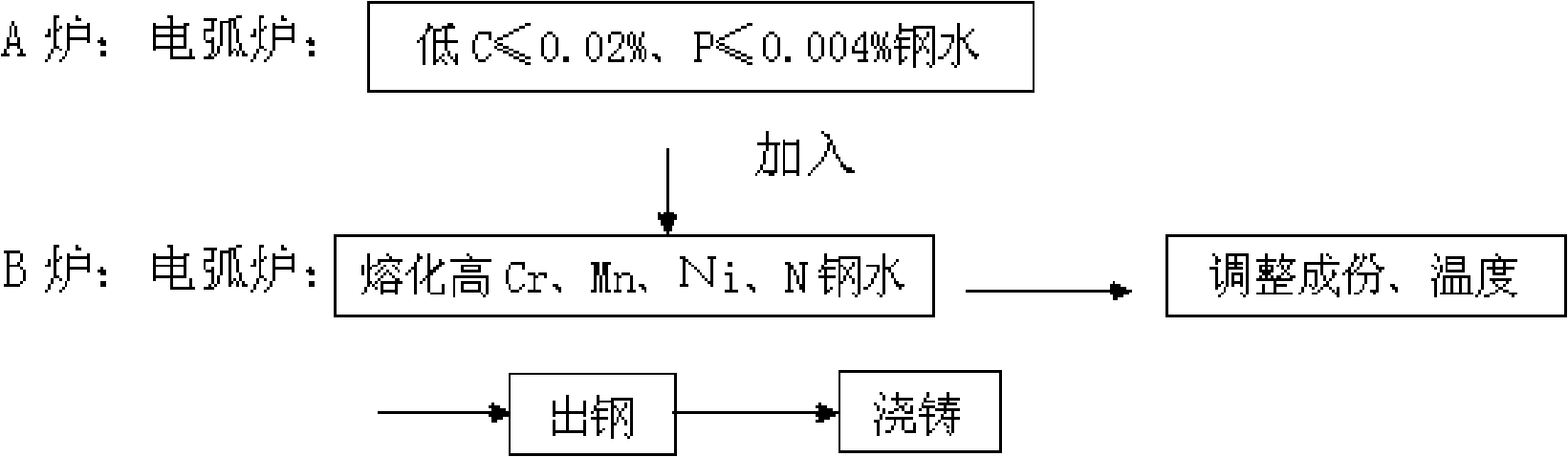

Method for smelting high-nitrogen steel

The invention discloses a method for smelting high nitrogen steel, which comprises a smelting method of a high nitrogen steel which can effectively improve and guarantee the content of N in alloy, the technical proposal which is adopted comprises the following steps: firstly, smelting molten steel with an electric arc furnace or an induction furnace, secondly, simultaneously adopting another electric arc furnace or an induction furnace to smelt nitrogen containing alloy, adapting the sum of molten steel components in the step one and the step two with steel grade, thirdly, adding molten steel which is smelted in nitrogen containing alloy solution, and refining under the protection of nitrogen, and getting high nitrogen steel. The technical proposal of the invention which is adopted by the invention to smelt high nitrogen steel without needing complex pressurization and remelting equipment, the total smelting time is greatly shortened, which is only one half of the time for smelting high nitrogen steel in the prior art, the operation is simple, and chemical components in steel are stable, fluctuation of steel components among furnaces is small, which is beneficial for processing follow-up process. And meanwhile, the number of deoxidation reducing agent is greatly reduced, and smelting cost is lowered.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

Hot briquetted iron coke for iron-making and preparation method thereof

The invention belongs to the technical field of iron-making and specifically relates to hot briquetted iron coke for iron-making and a preparation method thereof. The hot briquetted iron coke is composed of the following raw materials in percentage by mass: 10%-30% of iron ore powder, 60%-80% of pulverized soft coal and 10%-20% of pulverized blind coal. The preparation method comprises the following steps: thoroughly and evenly mixing the raw materials to obtain a mixture, heating the mixture in a heating furnace to 200-350 DEG C, performing instant hot briquetting on the mixture to obtain a hot briquetted iron coke green ball, putting the hot briquetted iron coke green ball in a tunnel kiln and performing high-temperature destructive distillation and carbonization at a certain temperature increased previously at a certain rate, and then taking out the braised material for cooling, thereby obtaining the hot briquetted iron coke. The prepared hot briquetted iron coke has excellent compressive strength, abrasive resistance, reactivity and post-reaction strength; the hot briquetted iron coke is used for blast furnace iron-making instead of partial coke, and therefore, the adaptability of blast furnace iron-making to fuels is improved. The preparation method of the hot briquetted iron coke is wide in raw material source, low in production cost, simple in process flow and free from the use of a binder, and has wide industrial application prospect.

Owner:NORTHEASTERN UNIV

Method for recovering rare earth in neodymium-iron-boron waste by high-temperature and high-pressure leaching

The invention relates to a method for recovering rare earth in neodymium-iron-boron waste by high-temperature and high-pressure leaching. The neodymium-iron-boron waste is subjected to oxidation roasting, hydrochloric acid high-temperature and high-pressure leaching, and oxidation and impurity removal purification on Fe2+ in a leachate so as to obtain a rare-earth chloride leachate; and the rare-earth chloride leachate can be used as a subsequent process and a product raw material, rare earth is obtained through extraction and separation, rare earth carbonate is prepared through precipitation,or rare earth oxide is prepared through precipitation-roasting. According to the method, a closed high-pressure reaction kettle is adopted as leaching equipment, so that the dynamic condition of theleaching process is excellent, the requirement for the particle size of the leached raw materials is low, a large amount of dust generated by the fine grinding process of the raw materials is avoided,the leaching rate of rare earth in the leaching process is high, the utilization rate of hydrochloric acid is high, no acid gas is discharged, energy is saved, and the environment is protected; and in addition, the method has the advantages of being short in process flow, simple in process conditions and low in recovery cost, and the method has considerable economic, social and environmental protection benefits for large-scale recovery of the neodymium-iron-boron waste.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Preparation method of nano LiFel-xMxPO4/C lithium phosphate composite positive pole material

ActiveCN101789504AImprove dynamic conditionsComposition is stableCell electrodesChemical reactionHigh energy

The invention relates to a preparation method of nano LiFel-xMxPO4 / C lithium phosphate composite positive pole material. Lithium dihydrogen phosphate, iron powder, an M element source and an organic carbon source are uniformly mixed in a solvent medium, are treated for 2 to 7h through a high-energy ball mill, have chemical reaction under mechanical activation, and a uniformly dispersed precursor is prepared. The precursor is thermally treated for 2 to 10h at 600 to 800 DEG C under atmosphere protection and cooled to be room temperature, and the nano LiFel-xMxPO4 / C lithium phosphate composite positive pole material is prepared. The preparation method has simple and high-efficiency process and the whole process does not produce ammonia, wastewater and other polluting substances, and is applicable to industrial production. The primary particles of the prepared material are nano particles which are uniformly distributed, and the material is characterized by high specific capacity and good rate cycle performance.

Owner:四川浩普瑞新能源材料股份有限公司

Dilution treatment method for copper smelting slag

InactiveCN105671325AImprove dynamic conditionsReduce copper contentProcess efficiency improvementSlagAfter treatment

The invention provides a dilution treatment method for copper smelting slag. The dilution treatment method includes the technological steps that firstly, a mechanical stirring device is introduced into a dilution furnace, the high-temperature molten state copper smelting slag at the temperature ranging from 1150 DEG C to 1350 DEG C is guided into the dilution furnace, a stirring paddle is adjusted to stretch to the part from the 1 / 3 position of the liquid level of the copper smelting slag to the 1 / 2 position of the liquid level of the copper smelting slag, heating and stirring are started, the temperature of the copper smelting slag is controlled to range from 1200 DEG C to 1350 DEG C, the stirring speed ranges from 50 r / min to 200 r / min, and a vortex with the diameter height ratio ranging from 0.5 to 3 is formed; secondly, a vulcanizing agent is carried through carrier gas and injected to the position, close to the center of the vortex, of the surface of a copper smelting slag pool through a nozzle above the liquid level of the high-temperature molten state copper smelting slag, the adding amount of the vulcanizing agent is 0.3-8% of the mass of the copper smelting slag, and heat-preservation stirring is conducted for 10-60 min; and thirdly, standing layering is conducted, and copper matte on the lower layer and diluted slag on the upper layer are collected. The copper content of the diluted slag obtained after treatment is below 0.3%.

Owner:NORTHEASTERN UNIV

Method for directly producing metallic iron powder with high-alumina iron ore

ActiveCN101293281AImprove dynamic conditionsQuality improvementMagnetic separationAluminiumLower intensity

The invention provides a method for directly preparing a metal iron powder by high alumina ironstone. In the method, ironstones are smashed and ground, then mixed with an additive evenly for balling, coal-based direct reduction is carried out on the dry balling, after being smashed and ground, the reduction product is sorted by adopting low intensity magnetic separation, thus obtaining the metal iron powder in which the general iron level is more than 90%, the iron recovery rate is more than 90%, the content of Al2O3 is about 1.0%, and the content of SiO2 is less than 1%, the iron powder can be taken as the raw material of electric furnace steelmaking. The method of the invention can be applicable to the separation of aluminum and iron of ironstone in which the content of aluminum is higher and separation can be carried out difficultly by a physics method; by adopting the method, the metal iron powder which can satisfy the requirement of electric furnace steelmaking can be prepared directly by high alumina ironstone, the process flow is short, the production cost is low, and the environmental pollution is little, thus having wide application prospect.

Owner:CENT SOUTH UNIV

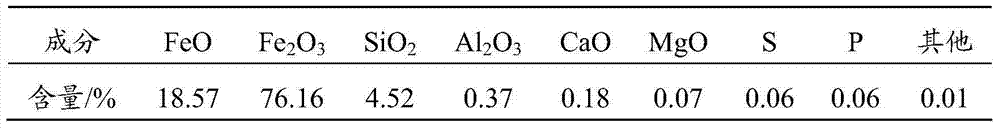

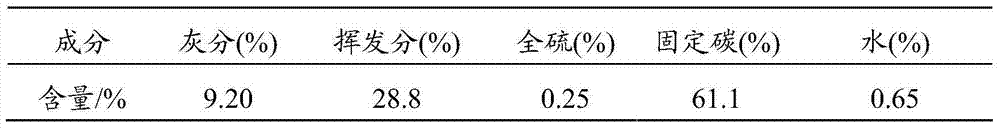

Method for using stainless steel dust to produce chrome, nickel and iron alloy

InactiveCN104498711AAdaptableReduce manufacturing costProcess efficiency improvementSlagSS - Stainless steel

The invention provides a method for using stainless steel dust to produce chrome, nickel and iron alloy, and belongs to the technical field of metallurgical waste comprehensive utilization. The method for using the stainless steel dust to produce the chrome, nickel and iron alloy mainly includes: compounding the stainless steel dust and coal powder according to a certain proportion, mixing the stainless steel dust and the coal powder evenly so as to obtain a mixture, heating the mixture, hot pressing the mixture into a hot pressing block, and then obtaining the chrome, nickel and iron alloy and slag by using water to quench the hot pressing block and screening the hot pressing block after the hot pressing block is reduced by a rotary hearth furnace. The method for using the stainless steel dust to produce the chrome, nickel and iron alloy is simple in technology, does not need to use an adhesion agent during the whole process, is high in reducibility speed, strong in raw material adaptability, low in energy consumption, small in slag quantity, and high in iron, chrome and nickel yield, has important application value for valuable metal in the stainless steel dust which is recycled, and has a wide industrial application prospect.

Owner:NORTHEASTERN UNIV

Method for recycling copper and preparing qualified molten iron by carrying out smelting, oxidation and chlorination-reduction on copper slag

InactiveCN102417991AComplete desulfurization reactionImprove dynamic conditionsProcess efficiency improvementSulfurCoal

The invention provides a method for recycling copper and preparing qualified molten iron by carrying out smelting, oxidation and chlorination-reduction on copper slag. The method comprises the following steps of: warming the copper slag discharged at high temperature, adding a chlorinating agent and additive, after the copper slag is fully molten, introducing oxide gas into the copper slag, and carrying out oxidation chlorination desulphurization decoppering to obtain molten liquid; carrying out stepped cooling on high-temperature smoke formed during oxidation chlorination desulphurization decoppering and then recycling copper in the smoke; under the inert gas atmosphere, introducing powdered coal to cause the powdered coal to be mixed with the slag under the stirring action of inert gas and be subjected to melting reduction reaction, and standing until the slag and molten iron are separated, thereby obtaining high-temperature qualified molten iron. By applying the method provided by the invention, the defect that sulphur content and copper content in the molten iron in the traditional copper slag direct melting reduction ironmaking process are high can be effectively overcome, and high-efficiency recycling of copper resource in the copper slag is realized, thus the method provided by the invention has better industrialization prospect.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method for producing low-grade ferroniobium by using ferroniobium concentrate

The invention relates to the technical field of smelting ferroalloy, in particular to a production method of low-grade ferrocolumbium by using ferrocolumbium ore concentrate. The method is that ferrocolumbium ore concentrate is taken as primary raw material, which is characterized in that the power of ferrocolumbium ore concentrate, the coal power and a little of bond are blended, heated and pressed into block; after being preheated and selective solid-state deoxidated in high-temperature furnace, the block is loaded into an electric furnace and mixed with the molten iron to get rich niobium-bearing slag and phosphorous semi-steel, the rich niobium-bearing slag, mild-phosphor molten iron, reducer and agent of fusion are put into the electric furnace, and the rich niobium-bearing slag is deeply deoxidated to produce the low-grade ferrocolumbium alloy with high ration of Nb to phosphor. The invention has the advantages of saving energy, shortening the time of process flow and improving the recovery rate of Nb.

Owner:NORTHEASTERN UNIV

Method for improving dephosphorization efficiency in duplex converter by using CO2

ActiveCN104928439ARealize resource utilizationPromote sustainable developmentManufacturing convertersProcess efficiency improvementResource utilizationEngineering

The invention provides a method for improving the dephosphorization efficiency in a duplex converter by using CO2 and belongs to the field of metallurgy technologies and energy conservation and emission reduction. According to the method for improving the dephosphorization efficiency in the duplex converter by using the CO2, top-blowing of the mixed gas of the CO2 and oxygen is conducted in a dephosphorization furnace, bottom-blowing of the CO2 and nitrogen in are conducted in a time-dividing-section switching mode, the CO2 is adopted in blowing, and the nitrogen is adopted for keeping the smoothness of a bottom blow gun when converter reversing and gun lifting are conducted until smelting blowing is started (the non-blowing period). When the phosphorus content is reduced to be lower than 0.030%, molten iron after dephosphorization is added into a decarburization furnace, the top-blowing of the mixed gas of the CO2 and oxygen is conducted for deep dephosphorization in the smelting earlier stage of the decarburization furnace, the gas is switched into pure oxygen for decarburization warming in the middle and later period, the bottom-blowing of the nitrogen or the CO2 or argon is conducted, and the end point phosphorus can be reduced to be lower than 0.010%. According to the method for improving the dephosphorization efficiency in the duplex converter by using the CO2, through the adjustment of the blown gas types and the proportion, the concentration of the oxidizing agent is reasonably controlled to reach the effects of improving converter dephosphorization reaction thermodynamics and dynamic conditions, the dephosphorization efficiency and the molten steel quality are improved, the resource utilization of the CO2 in steel-making processes is achieved, and the sustainable development of the iron and steel industry is promoted.

Owner:UNIV OF SCI & TECH BEIJING

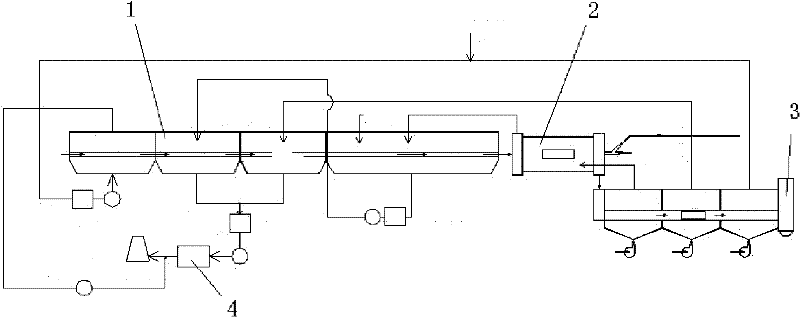

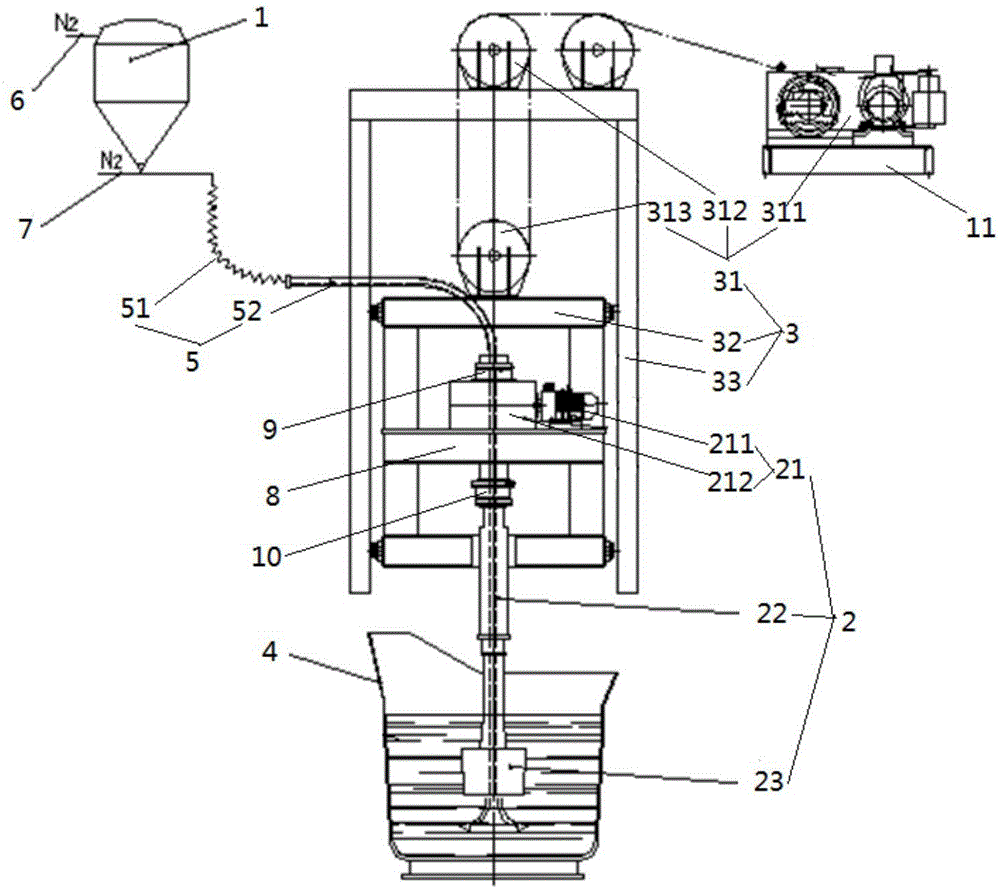

Molten iron desulphurization device and method

InactiveCN106086312AImprove desulfurization efficiencyShortened desulfurization treatment timeMetallurgyMaterials science

The invention provides a molten iron desulphurization device which comprises a blowing tank (1), a stirring unit (2), a lifting unit (3) and a molten iron tank (4). A discharge outlet in the bottom of the blowing tank (1) is connected with the stirring unit (2) through a conveying pipe (5). The molten iron tank (4) is arranged under the stirring unit (2). The lifting unit (3) is connected with the stirring unit (2) to control the stirring unit (2) to go up and down. Furthermore, the invention provides a molten iron desulphurization method adopting the molten iron desulphurization device. By means of the molten iron desulphurization device and method, good dynamic conditions and stable and efficient desulfurization capacity are achieved, and the purpose of efficient desulfurization with low consumption can be achieved.

Owner:WISDRI ENG & RES INC LTD

Dephosphorization method for electric-arc furnace steelmaking

ActiveCN105803155AImprove product qualityFully functional abilityProcess efficiency improvementElectric furnaceSteelmakingElectric arc furnace

The invention provides a dephosphorization method for electric-arc furnace steelmaking, and belongs to the field of electric-arc furnace steelmaking. The dephosphorization method is characterized in that the same spray gun is utilized for delivering oxygen gas, protective gas and carrier gas-dephosphorization powder into an electric-arc furnace molten pool directly, wherein the carrier gas-dephosphorization powder is dephosphorization powder carried in the carrier gas; gas flow violently impacts and stirs a steelmaking molten pool, so that the dephosphorization powder is in sufficient contact with molten steel directly, and good thermodynamic and dynamic conditions are provided for molten pool dephosphorization reaction, and dephosphorization efficiency of an electric-arc furnace steelmaking process is improved, consumption of slag charge such as a dephosphorization agent is reduced, a dephosphorization rate of a smelting process is increased, the quality of end-point molten steel is improved, and the production cost is reduced.

Owner:UNIV OF SCI & TECH BEIJING

Method of synthesizing metal -based composite material by melt reaction in coupling magnetic field and ultrasonic field

InactiveUS20110247778A1Improve dynamic conditionsImprove the situationHigh energyReaction temperature

A method of synthesizing metal matrix composite material by melt reaction in coupling magnetic field and ultrasonic field comprises: adjusting metal-base melt to the onset reaction temperature after refining, then adding reactants which generate reinforced particles by in-situ synthesis reaction with melt, keeping the reacted melt stand until it is cooled to casting temperature after the reaction, and then casting. Magnetic field and high-energy ultrasonic field are exerted simultaneously during the reaction. The magnetic field can be high-power pulse magnetic filed, high-frequency oscillating magnetic field or low-frequency alternating magnetic field. The metal matrix composite material produced by the above-mentioned method exhibits that reinforced particles are much finer, more uniformly distributed, and fit with metal matrix better.

Owner:JIANGSU UNIV

Method of ultra-low-carbon steel dephosphorization outside furnace

The invention provides a method of ultra-low-carbon steel dephosphorization outside a furnace. According to the invention, a converter tapping target temperature is reduced, and small-particle lime is added to a ladle according to a proportion that 2.3-3.1kg of the small-particle lime is added to every ton of steel; during an LF refining process, appropriate amounts of lime and refining slag are respectively added, increased-temperature slagging is carried out, and temperature compensation is controlled; when the temperature increasing process is finished, and the slag is completely melted, an argon stirring dephosphorization process is carried out. According to the invention, temperature controlling is carried out, appropriate amounts of lime and refining slag are respectively added to the ladle and the LF furnace, and dephosphorization is carried out with the argon stirring measure, such that thermo-dynamical and dynamical conditions of dephosphorization are improved, and the controlling level of phosphorus in ultra-low-carbon steel is improved. With the method, an average dephosphorization rate after tapping is above 35%, steel judgment accidents and economic loss caused by standard-exceeding phosphorus content are reduced, and qualification rate of ultra-low-carbon steel quality is improved.

Owner:ANGANG STEEL CO LTD

Coherent jet oxygen blowing method for electric furnace steel making

InactiveCN101684512AAvoid damageImprove adaptabilityProcess efficiency improvementElectric furnaceSteelmakingOxygen

The invention discloses a coherent jet oxygen blowing method for electric furnace steel making, effectively solving the problem of burner damage in the oxygen blowing process of electric furnace steelmaking and enhancing the stirring to a weld pool through the combination of equipment and process improvement. The coherent jet oxygen blowing method for electric furnace steel making comprises the following step: selecting a coherent jet oxygen blowing device and process conditions, wherein the device consists of a primary oxygen spraying and blowing system, a secondary oxygen spraying and blowing system and a fuel gas spraying and blowing system. A primary oxygen spraying hole has a pressure regulation range of 0.8-1.2MPa and an oxygen flow range of 10,000-60,000Nm<3> / h; a secondary oxygenspraying hole has a pressure regulation range of 0.12-0.8MPa and an oxygen flow range of 2,000-10,000Nm<3> / h; and a fuel gas spraying hole has a pressure regulation range of 0.12-0.2MPa, an outlet Mach number of 0.5-1.0 and a fuel gas flow range of 100-2000Nm<3> / h. The invention not only solves the problem of burner damage, but also has important meaning for improving the adaptability of waste steel quality and the internal quality of steel products.

Owner:UNIV OF SCI & TECH LIAONING

Method for producing high carbon steel through double-slag high drawing carbon tapping

ActiveCN102559984AGood dephosphorization effectLess slagManufacturing convertersSteelmakingHigh carbon

A method for producing high carbon steel through double-slag high drawing carbon tapping belongs to the technical field of smelting high carbon steel through a converter. The method comprises processing steps as follows: molten iron and steel scraps are loaded in the converter according to a certain molten iron ratio; in a first stage of converter steelmaking, the converting is performed at the oxygen supplying intensity of 2.8 Nm<3> / min / t, active lime and ore fluxing mediums are added in the converter, and a larger bottom blown flow rate is adopted to stir; the converting is performed at a standard lance height in the prior period for the converting of the converter, and then the lance height rises gradually; part of furnace slag is dumped through a rocking furnace; in the second stage for the converting of the converter, the converting is performed at the oxygen supplying intensity of 3.3 Nm<3> / min / t, and active lime and the ore fluxing mediums are added in the converter; the lance height rule that the converting is performed at a higher lance height in the later period and the lance height descends stage by stage is adopted; a small quantity of ores and fluorites are added frequently within 80 to 90 percent of total converting oxygen consumption; after the converting of the converter is finished, deslagging is performed through the rocking furnace of the converter, and temperature measurement and sampling are carried out; and converter tapping is carried out. The method has the advantage of overcoming the shortages of serious rephosphoration caused during the tapping process, low production efficiency, and so on.

Owner:SHOUGANG CORPORATION

Converter dephosphorization method for high-phosphorus low-silicon molten iron

InactiveCN104878153AImprove slag fluidityImprove dynamic conditionsManufacturing convertersProcess efficiency improvementFerrosiliconSmelting process

The invention discloses a converter dephosphorization method for high-phosphorus low-silicon molten iron, and belongs to the technical field of steel-making process control. According to the converter dephosphorization method, a smelting process combining partial remained final slag and refined white slag added in the earlier stage is adopted, the final slag remaining amount is that 20-60 kg of final slag is remained in per ton of steel, and the refined white slag adding amount is that 10-30 kg of refined white slag is added into per ton of steel; in addition, the adding amount and the adding time of slagging materials are controlled, and the oxygen supply intensity and the gun position during the smelting process are adjusted, so that the dephosphorization rate of high-phosphorus molten iron smelting reaches 90% or above, and the converter end phosphorus content can be controlled within 0.015% stably; through the full utilization of the pre-melting feature of the refined white slag and the characteristic that the refined white slag contains more Al2O3 and certain CaF2, the slag melting point is reduced, the slag fluidity is improved, and the dynamic conditions for dephosphorization are improved; through the full utilization of the characteristic that the refined white slag has higher alkalinity, high-alkalinity slag can be formed earlier, and the thermodynamic conditions for dephosphorization are improved; as the refined white slag can be recycled, the converter steel-making cost can be effectively reduced.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Smelting manufacturing method for high temperature ferric alloy

A technology for smelting the refractory Fe-base alloy includes such steps as primary smelting in ordinary electric arc furnace by return oxygen blowing method and smelting the qualified refractory Fe-base alloy in AOD furnace. Said second step includes blowing the mixture of argon gas and O2 in ratio of 4:1 for decarbonizing, heating, blowing the mixture of argon gas and O2 in ratio of 1:1 when C content is 0.1%, sampling and analyzing, regulating contents of its components, blowing argon gas when C content is 0.03%, adding prereducing slags, prereducing, sampling and analyzing, adding reducing slags, blowing argon for dissolving slags, blowing argon for 3 min, adding Ti in ladle, tapping, and casting rod electrodes.

Owner:宝钢特钢有限公司

MgO-based desulfurizer based on self-propagating and preparation thereof

The invention relates to a MgO base desulfurizer based on self-propagation and a method for preparing the same. The invention is characterized in that: the MgO base desulfurizer is a particle in a spherical shape or other shapes and consists of MgO, carbonaceous reducing agent, self-propagating exothermic agent, reaction promoter, PH value modifying agent and caking agent; the MgO, the carbonaceous reducing agent, the self-propagating exothermic agent, the reaction promoter and the PH value modifying agent are respectively dried for 4 to 20 hours at a temperature of between 120 and 200 DEG C in a drying box, then grinded by a ball mill into powder with a granularity of less than 200 meshes; the material powder is mixed according to the proportion, added with the caking agent, then pressed into particles in a spherical shape or other shapes by a pressure of 20 MPa; and the particles are dried and prepared into the MgO base desulfurizer. The MgO base desulfurizer is used for desulphurization and has the advantages of less slagging amount, low desulphurization cost, high utilization rate of desulfurizer, high desulphurization rate, no obvious temperature reduction in the desulphurization process, no need of specialized desulphurization equipment, simple convenient, etc.

Owner:NORTHEASTERN UNIV

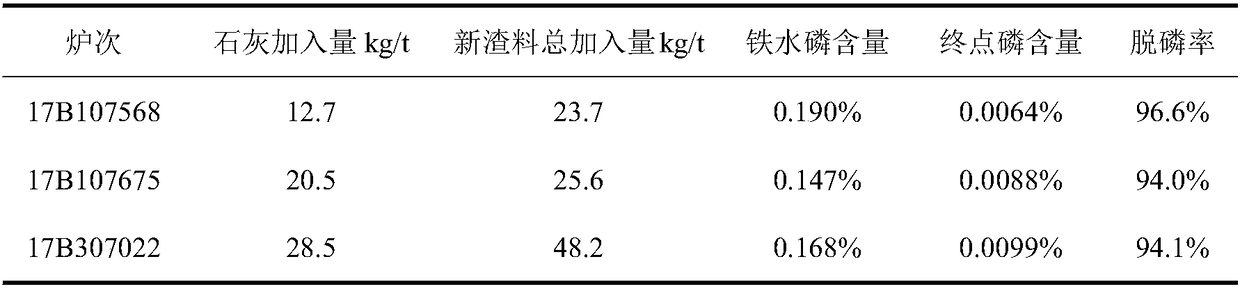

Method for smelting high-phosphorus molten iron to produce steel with converter end point P less than or equal to 0.01% by adopting slagless material

ActiveCN109280731AAvoid going backReduce the temperatureManufacturing convertersProcess efficiency improvementSteelmakingNitrogen

The invention belongs to the technical field of converter steelmaking processes, and particularly relates to a method for smelting high-phosphorus molten iron to produce steel with converter end pointP less than or equal to 0.01% by adopting slagless material. The method comprises the following steps that loading low-silicon high-phosphorus molten iron and steel scrap which are not subjected to triple-removal pretreatment into a converter, a single-slag method is adopted to carry out blowing, a slagging material is added twice in a blowing process and a gun position control mode of high, low, high and low is adopted in the blowing process, and oxygen supply and nitrogen supply are carried out in the blowing process; after the blowing is completed, the steel is discharged, slag splashingis carried out after the steel is discharged, slag is reserved after the slag splashing, and is used for smelting in the next furnace. According to the method, on the premise that lime consumption ofa steel liquid is less than or equal to 30 kg / t, and the consumption of the new slag material is less than or equal to 50 kg / t, dephosphorizing of the molten iron with the following components, by weight, 0.14-0.26% and Si, 0.15-0.20% of P is carried out until P is less than or equal to 0.01%, and a dephosphorization rate is larger than or equal to 94%, so that the problem that low-phosphorus steel is smelted by a low-silicon high-phosphorus molten iron with the few slag material in the single-slag method is solved.

Owner:UNIV OF SCI & TECH BEIJING

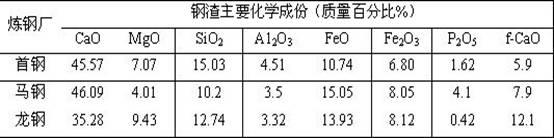

Method for modifying high-temperature steel slag by using compound materials of tailings

ActiveCN102605113AChange compositionChange physical stateIncreasing energy efficiencyCalcium in biologySteelmaking

The invention relates to method for modifying steel slag, in particular to a method for modifying high-temperature steel slag discharged in the final steelmaking stage by using a large amount of mining tailings with low cost, comprising the following steps: mixing 15-30 parts by weight of high alumina silicate tailings, 60-80 parts by weight of high calcium silicate tailings and 5-15 parts by weight of calcium carbonate tailings to obtain compound materials of the tailings; granulating to prepare agglomerated blocks of 3-5cm; adding the compound materials of the tailings into steel slag pot or disc by batches according to the proportion of (70-80%):(20-30%) of the discharged steel slag and the compound materials of the tailings; carrying out steel slag splashing for furnace maintenance, wherein the left steel slag is not poured into the steel slag pot or disc for modifying the steel slag; preserving the temperature of the steel slag at 1,200-1,400 DEG C for 30-60min; quenching by using water, applying heat or covering by heat when the temperature is below 1,200-1,400 DEG C; breaking; and carrying out magnetic separation. Due to the adoption of the method, the separation effect of the steel slag can be improved significantly, the grindability of the separated steel slag can be improved, the total recovery rate of the scrap steel can be up to 95-100%, the components of the separated steel slag are controllable and have high activity, and the separated steel slag contain less than 1.5% by weight of the free calcium oxide, has the grinding work index of 14-17kw.h / t and can replace the portland cement clinker.

Owner:迁安金隅首钢环保科技有限公司

Microwave irradiation pressurized sintering equipment and use method thereof

InactiveCN101786161AIncreased diffusion rateLower sintering temperatureHydraulic cylinderMicrowave oven

The invention relates to microwave irradiation pressurized sintering equipment and a use method thereof, which have the technical scheme that an upper pressing head (21) is fixedly arranged in the center of the inner wall of an upper oven cover (22) of a microwave oven, the upper part and the lower part of the inner wall of a side plate (3) of the microwave oven are respectively and fixedly provided with an upper microwave reflecting plate (20) and a lower microwave reflecting plate (7), a first waveguide tube (5) is embedded in the right side of the side plate (3) of the microwave oven, a second waveguide tube (18) is embedded in the left side of the side plate (3) of the microwave oven, the first waveguide tube (5) and the second waveguide tube (18) are respectively and fixedly connected with a first permatron (6) and a second permatron (19), a hydraulic cylinder (12) is vertically fixed in the center of a base (13), a slide block (11) passes through a chute hole of a lower oven cover (10), and a lower pressing head (8) is arranged on the upper part of the slide block (11). The invention has the characteristics that the sintering temperature can be effectively reduced, the sintering time can be shortened, microstructures of materials are convenient to control, crystal grains are thinned, the investment is saved, and the cost is low.

Owner:WUHAN UNIV OF SCI & TECH

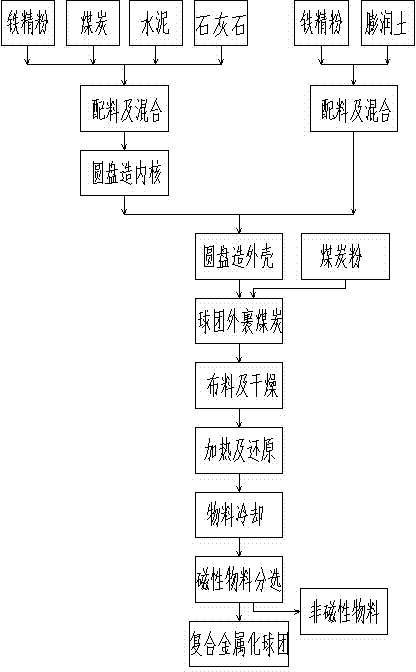

Self-fluxing composite metallized pellet and production process thereof

InactiveCN104745809AIncrease the atmosphere concentration and reduction reaction speedIncrease the speed of the reduction reactionProcess efficiency improvementCoalEnergy consumption

The invention relates to the technical field of metallurgy and mineral engineering, and discloses a self-refluxing composite metallized pellet and a production process thereof. The self-refluxing composite metallized pellet comprises an inner core and an outer shell, wherein the inner core is formed by mixing iron ore concentrate, limestone, coal powder and cement in a proportion of 330:(300-350):(80-120):(6-9); the outer shell is formed by mixing iron core concentrate and bentonite in a mass ratio of 1320:(22-25), the grain size of the inner core is 20-25mm, and the thickness of the outer shell is 5-10mm. The production process for the self-refluxing composite metallized pellet comprises the following steps: preparing the inner core and packaging the outer shell to form a composite metallized pellet; packaging the composite metallized pellet with a reducing layer, distributing and drying the composite metallized pellet, reducing and roasting the composite metallized pellet, cooling and sorting the high-temperature reduced composite metallized pellet. According to the self-refluxing composite metallized pellet and the production process thereof disclosed by the invention, limestone is mixed into the inner core, and CO2 generated by heating and decomposing the limestone in a reducing process of the composite metallized pellet is used as an oxygen producer to participate in gasification reaction of the coal, so that CO concentration inside the pellet is increased, the reducing speed of the pellet is increased, and the energy consumption is reduced.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com